Smokeless cast iron wok and manufacturing method thereof

A manufacturing method and technology without oil fume, applied in the field of kitchen utensils, can solve the problems of human health effects of oil fume, complex components, environmental pollution, etc., and achieve the effects of shortening cooking time, increasing heating area, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Manganese 2.4%, Chromium 22.6%, Nickel 11.0%, Molybdenum 1.2%, Nitrogen 0.30%, Copper 0.5%, Cobalt 1.8%, Boron 0.01%, Carbon 0.03%, Silicon 0.6%, Niobium 0.8%, Calcium 0.01%, Phosphorus 0.04 %, sulfur 0.05%, iron 58.66%.

Embodiment 2

[0056] Manganese 0.8%, Chromium 18.0%, Nickel 5.5%, Molybdenum 0.4%, Nitrogen 0.15%, Copper 0.3%, Cobalt 1.2%, Boron 0.005%, Carbon 0.01%, Silicon 0.1%, Niobium 0.2%, Calcium 0.005%, Phosphorus 0.01 %, sulfur 0.01%, iron 73.31%.

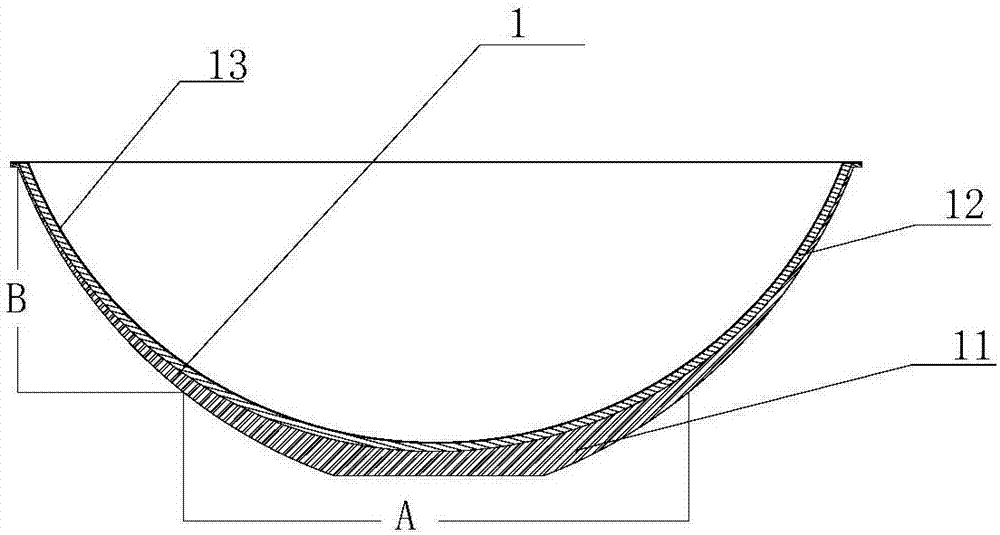

[0057] The present invention uses copper with high thermal conductivity to cast the outer pot body 11 to wrap the inner pot body 12 made of pig iron, which has the advantages of being evenly heated and not easy to break; the inner surface is sprayed with stainless steel coating, which can make the inner surface more evenly heated, and It can prevent the erosion of rust and has the advantage of long service life.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com