Patents

Literature

33results about How to "Raise tempering temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-performance hydrogen sulfide corrosion resistant oil drill rocker and its heat treatment process

InactiveCN101117683AGuaranteed hardenabilityGuaranteed sulfur resistanceDrilling rodsFurnace typesMechanical propertyPetroleum

The present invention relates to a high-performance hydrogen sulfide corrosion resistant petroleum drill pipe with a weight percentage of components as follows: C 0.20-0.32 percent, Si 0.1-0.5 percent, Mn 1.0-1.5 percent, Cr 0.5-1.5 percent, Mo 0.8-1.2 percent, P less than or equal to 0.015 percent, S less than or equal to 0.01 percent and the remainders are Fe and unavoidable impurities. The drill pipe of the present invention has a higher content of Mn, which can guarantee an upset end with a thickness of over 30mms to be fully hardened, thereby guaranteeing the sulfur-resistant performance of the upset end. The drill pipe of the present invention has a higher content of Mo, which can improve the backfire-preventive stability of the material, thereby raising the backfire temperature, reducing the residual stress and guaranteeing the sulfur-resistant performance. Simultaneously, the invention can make the pipe body with a different wall thickness and the upset end have the same cooling speed by controlling the outer water injection of the upset end and pipe body of the steel pipe, reducing the water injection outside the pipe body or increasing the water injection outside the upset end of the drill pipe, to ensure that the pipe body and the upset end have the same quenching structure, and the same mechanical property can be achieved after the backfire.

Owner:BAOSHAN IRON & STEEL CO LTD

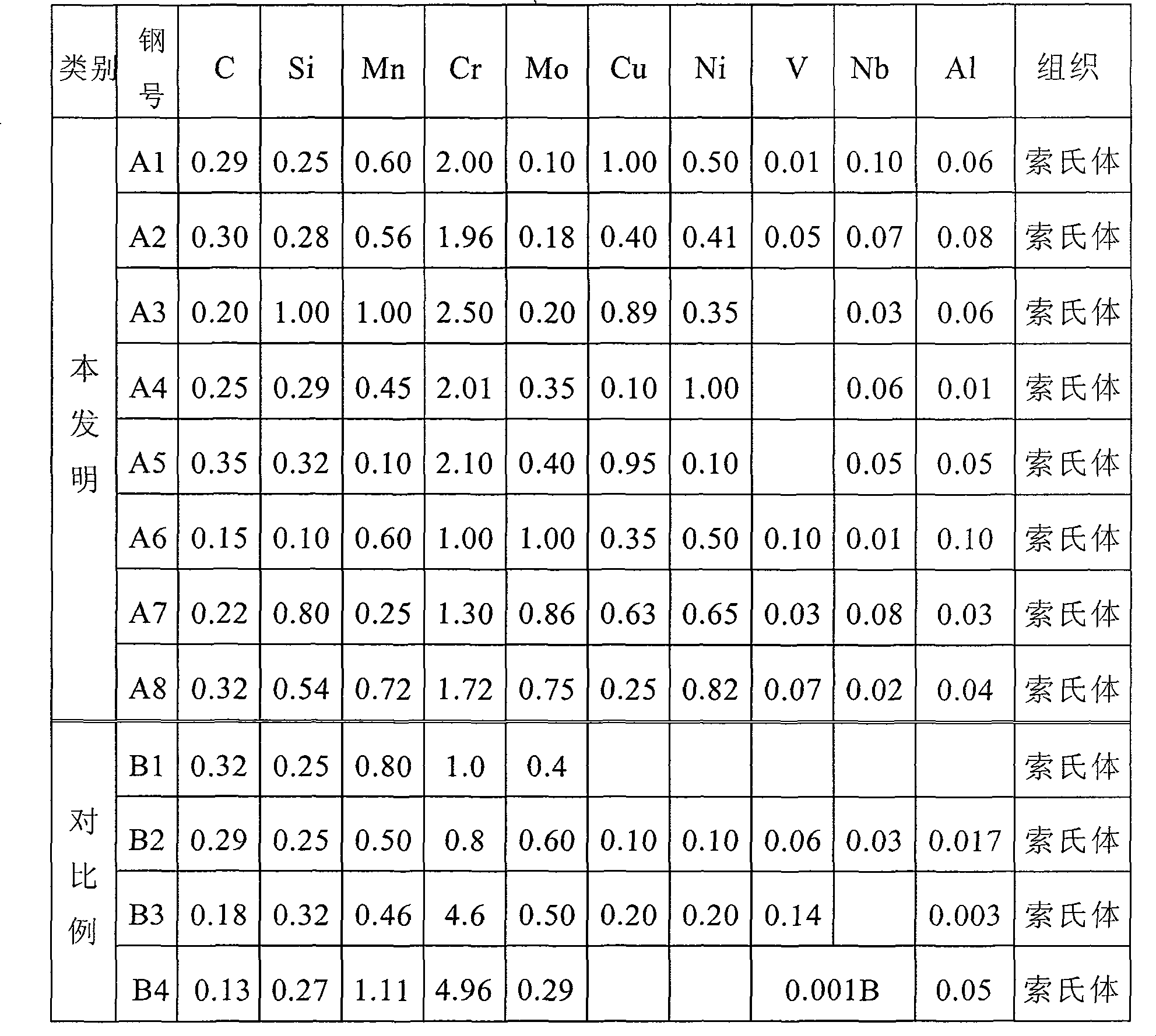

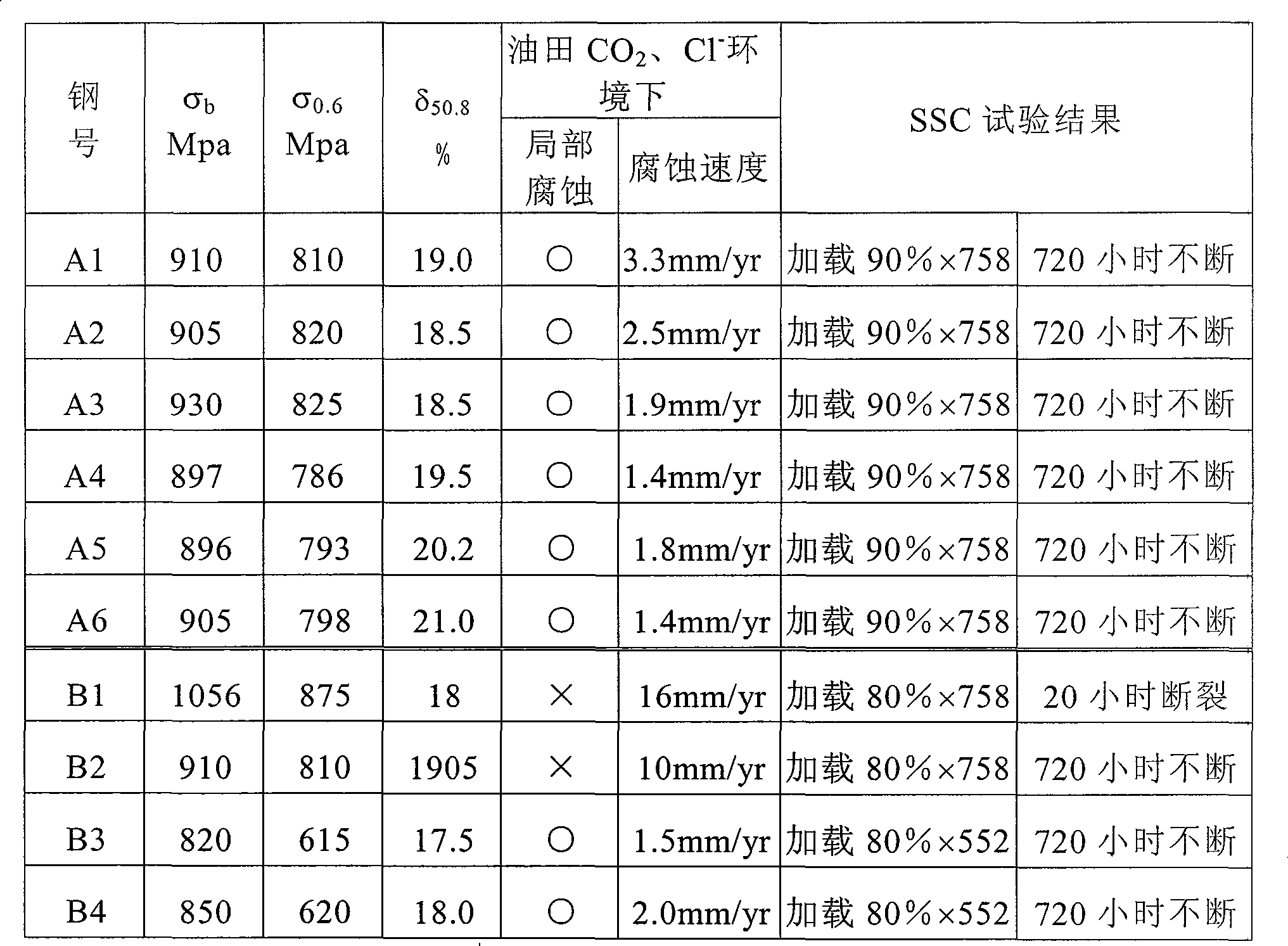

110Ksi grade CO2 H2S rust-proof oil well-pipe and manufacturing method

ActiveCN101082112AAccelerated corrosionHigh strengthTemperature control deviceHeat treatment process controlTemperingPipe

The 110ksi grade steel resisting CO2 and H2S corrosion for oil well pipe has the components including C 0.20-0.35 wt%, Si 0.10-1.0 wt%, Mn 0.10-1.0 wt%, Cr 1.0-2.5 wt%, Mo 0.1-1.0 wt%, Ni 0.10-1.0 wt%, Nb 0.01-0.1 wt%, Cu 0.10-1.0 wt%, Al 0.01-0.10 wt%, and Fe and inevitable impurities for the rest. It is produced through smelting, casting, cogging, rolling pipe, water or oil quenching at temperature over 850 deg.c, and high temperature tempering at temperature over 650 deg.c for over 2 hr. It has high CO2 and H2S corrosion resistance.

Owner:BAOSHAN IRON & STEEL CO LTD

High-strength high-toughness petroleum drill pipe and production method thereof

InactiveCN103789685AImprove toughnessHigh strengthDrilling rodsDrilling casingsRoom temperatureHigh intensity

The invention relates to a high-strength high-toughness petroleum drill pipe and a production method thereof. The steel composition of the petroleum drill pipe comprises the following components in percentage by mass: 0.22-0.35% of C, 0.17-0.30% of Si, 0.45-0.65% of Mn, 0.9-1.5% of Cr, 0.9-1.5% of Mo, 0.05-0.15% of V, 0.02-0.04% of Al, 0.05-0.20% of Ni, 0.01-0.06% of Ti, 0.001-0.008% of B, less than 0.005% of S, less than 0.008% of P and the balance of Fe. The manufacturing method of the petroleum drill pipe comprises the following steps: decarbonizing and refining the liquid steel containing the components to form steel billets and hot rolling into seamless steel tubes through a mandrel mill, wherein after being rolled into the seamless steel tubes, the steel tubes are needed to be subjected to the heat treatment processes of two-time quenching and high-temperature tempering so as to guarantee the strength and the toughness of the steel tubes. The petroleum drill pipe manufactured by adopting the method has a remarkable characteristic that a certain amount of austenite tough phases are dispersively distributed on a superfine lath martensite matrix so as to increase the strength and toughness of steel. The high-strength high-toughness drill pipe disclosed by the invention has the advantages that the yield strength can be up to 150-165KSI under the pressure of 1034-1138MPA and the room temperature longitudinal full-size impact toughness is greater than or equal to 100J.

Owner:SHANGHAI HILONG DRILL PIPE MATERIALS INST +1

Corrosion resistant and squeezing resistant casing pipe

InactiveCN101984124ARaise tempering temperatureImprove low temperature impact toughnessDrilling rodsFurnace typesAlloy elementCorrosion resistant

The invention discloses a corrosion resistant and squeezing resistant casing pipe which comprises the following components by weight percent: 0.15-0.25% of carbon, 0.15-0.3% of silicon, 0.50-1.0% of manganese, 2.80-3.20% of chromium, 0.01-0.05% of nickel, 0.15-0.35% of molybdenum, 0.01-0.05% of vanadium, 0.01% of aluminum and the balance ferrum. In the invention, a small amount of nickel, molybdenum and vanadium alloy elements are added on the basis of 2Cr3Mo oil casing pipe alloy, so that an oil well pipe with the strength grade reaching 80KSI / 95KSI steel grade is obtained, furthermore, due to the compound addition of the nickel, molybdenum and vanadium, the temper temperature of the steel is improved, and the lower temperature impact toughness of the steel is obviously improved; in addition, in the invention, content of the carbon is controlled, and the elements such as chromium, nickel, molybdenum and vanadium are added and are subject to suitable heat treatment, so that the casing pipe which can resist the corrosion of CO2 and chloridion at 120-150DEG C and resist H2S and squeezing is obtained. Compared with the series oil casting pipe materials such as low carbon, nickel and molybdenum, the casting pipe has the advantages that nickel can be saved by 2-3%, molybdenum can be saved by 1-2% and a certain amount of copper can be saved, thus the cost of the alloy is greatly reduced. The casing pipe can be widely used for occasions capable of CO2 resistance, H2S resistance and squeezing resistance at the same time, such as oil well pipes and the like.

Owner:WUXI SEAMLESS OIL PIPE

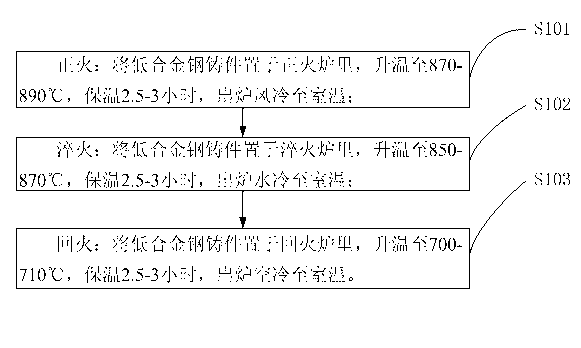

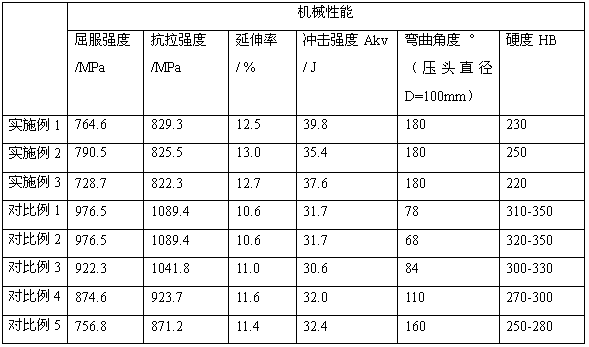

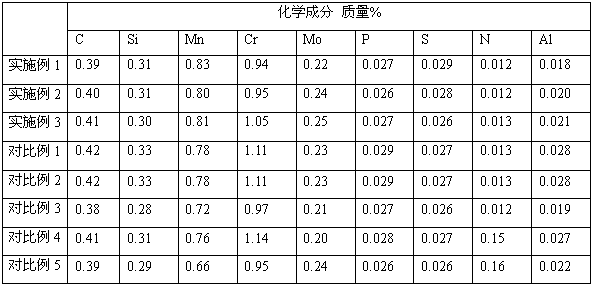

Thermal treatment process of low-alloy steel casting

The invention relates to a thermal treatment process of a casting, and in particular relates to a thermal treatment process of a low-alloy steel casting. The thermal treatment process comprises the following steps of: normalizing, water quenching, and high-temperature tempering air cooling. By adopting the thermal treatment process of the low-alloy steel casting, the tempering temperature of the low-alloy steel casting is improved, a direct furnace tapping air cooling mode is adopted, the treated low-alloy steel casting can meet requirements on strength and hardness, and the toughness of the casting is improved at the same time; and in the thermal treatment process of the low-alloy steel casting, a water cooling mode is used in a quenching step, so that the production cost is reduced, the environmental pollution is reduced, and potential safety hazards are reduced.

Owner:YINGSHAN HUAMAO SHIP OUTFITTING EQUIP

Ultrahigh steel Q960E thick plate and manufacturing method

The invention discloses an ultrahigh steel Q960E thick plate, and relates to the field of ultrahigh-strength steel thick plate producing and manufacturing. The ultrahigh steel Q960E thick plate comprises chemical components including, by mass percent, 0.15%-0.18% of C, 0.20%-0.50% of Si, 0.80%-1.30% of Mn, smaller than or equal to 0.010% of P, smaller than or equal to 0.003% of S, 0.30%-0.50% of Cr, 0.40%-0.60% of Mo, 0.80%-1.0% of Ni, 0.008%-0.030% of Ti, 0.015%-0.050% of Nb, 0.0008%-0.0025% of B and the balance Fe and inevitable impurities. The medium-high carbon and alloying component design is adopted, controlled rolling and offline heat treatment methods are adopted for assistance, and the ultrahigh-strength steel thick plate with the thickness being 90 mm is provided.

Owner:NANJING IRON & STEEL CO LTD

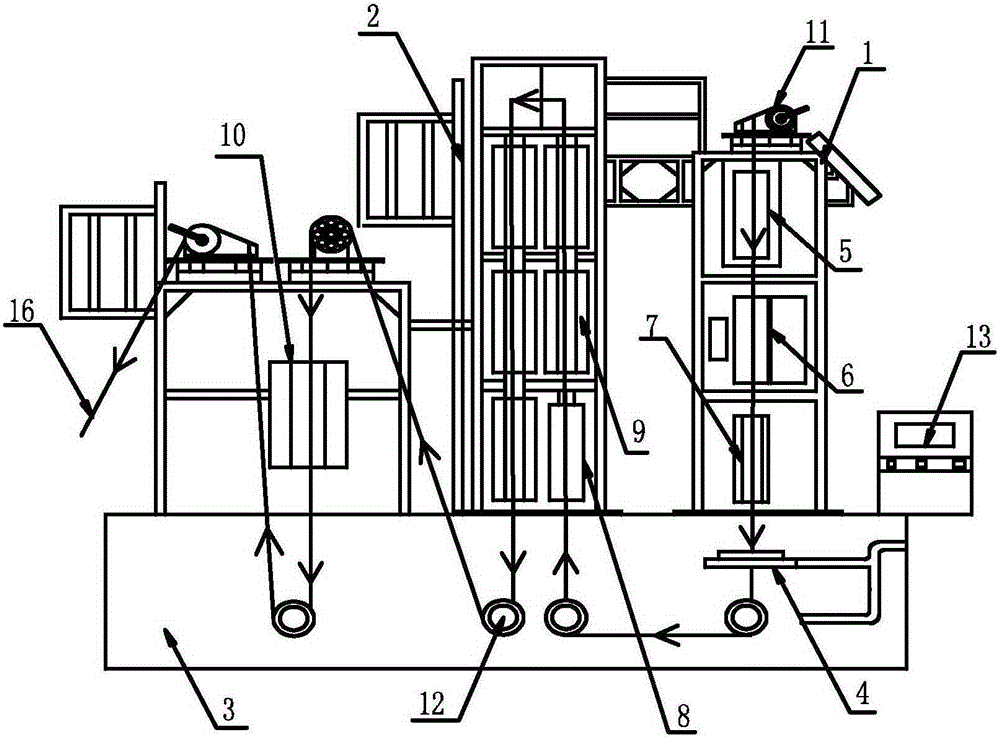

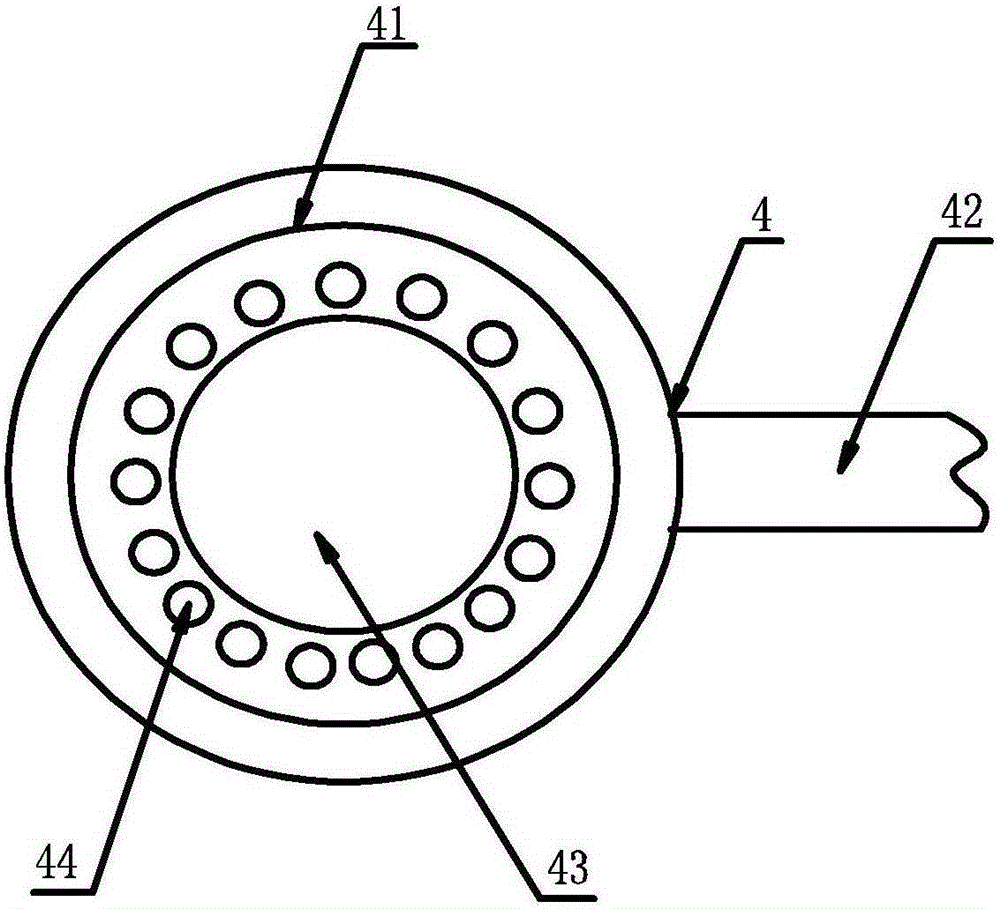

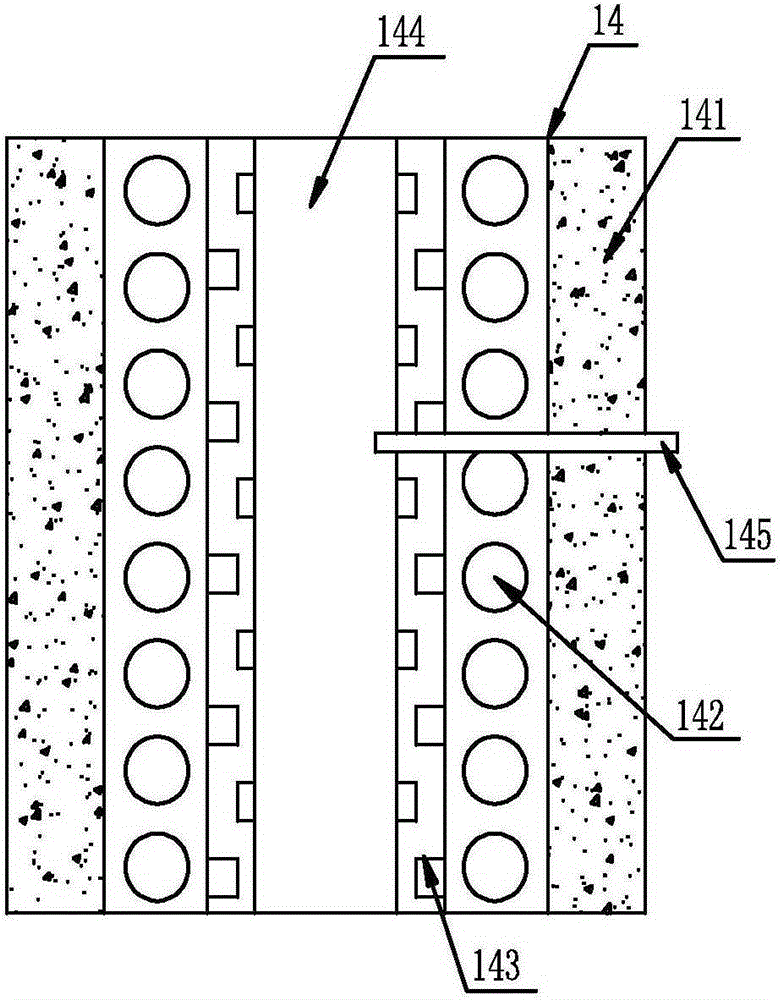

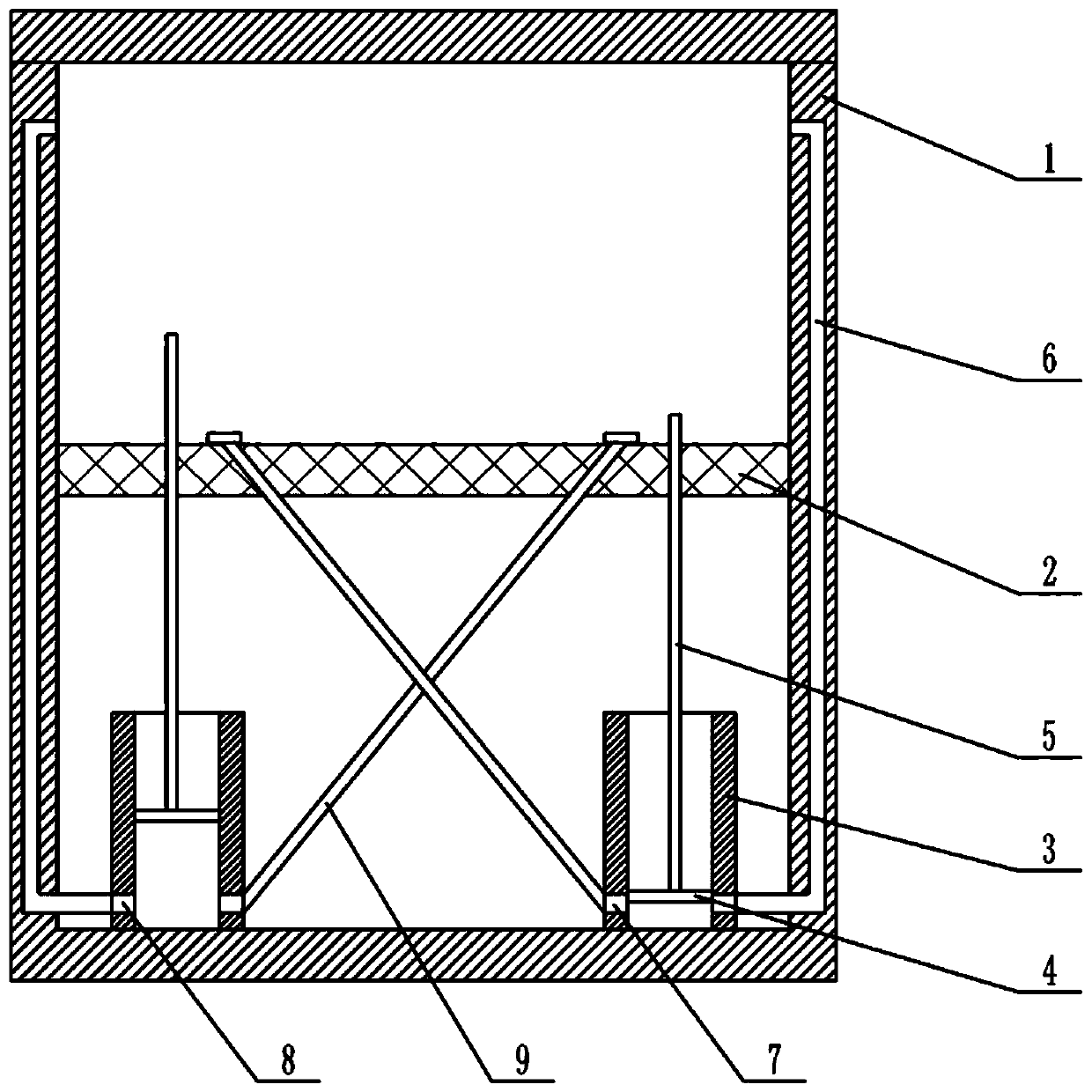

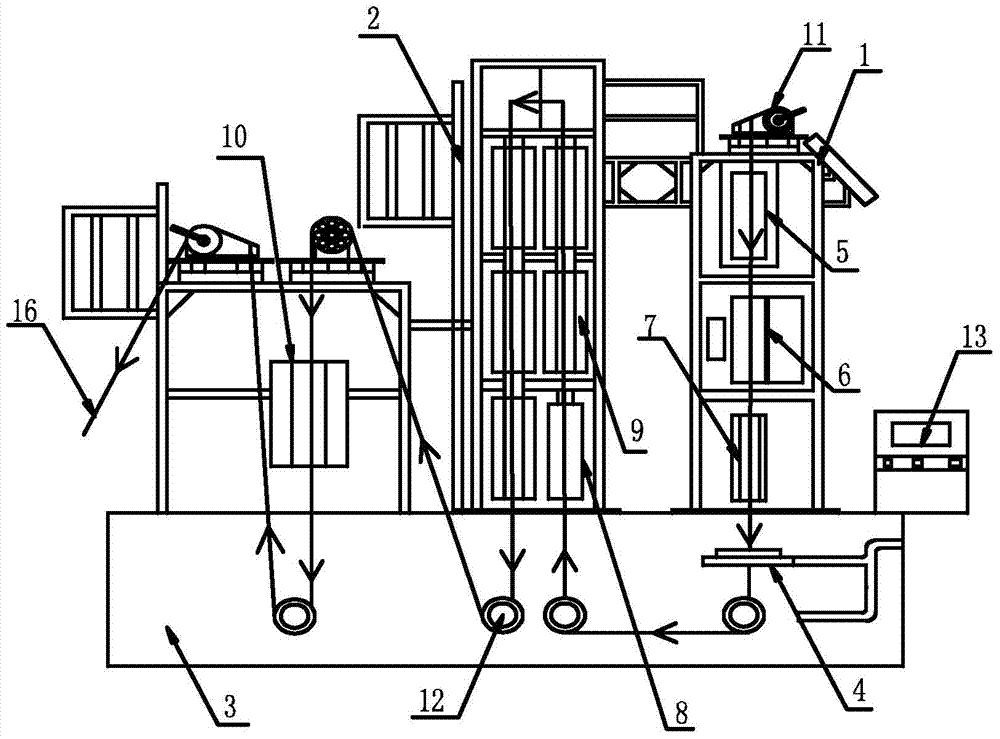

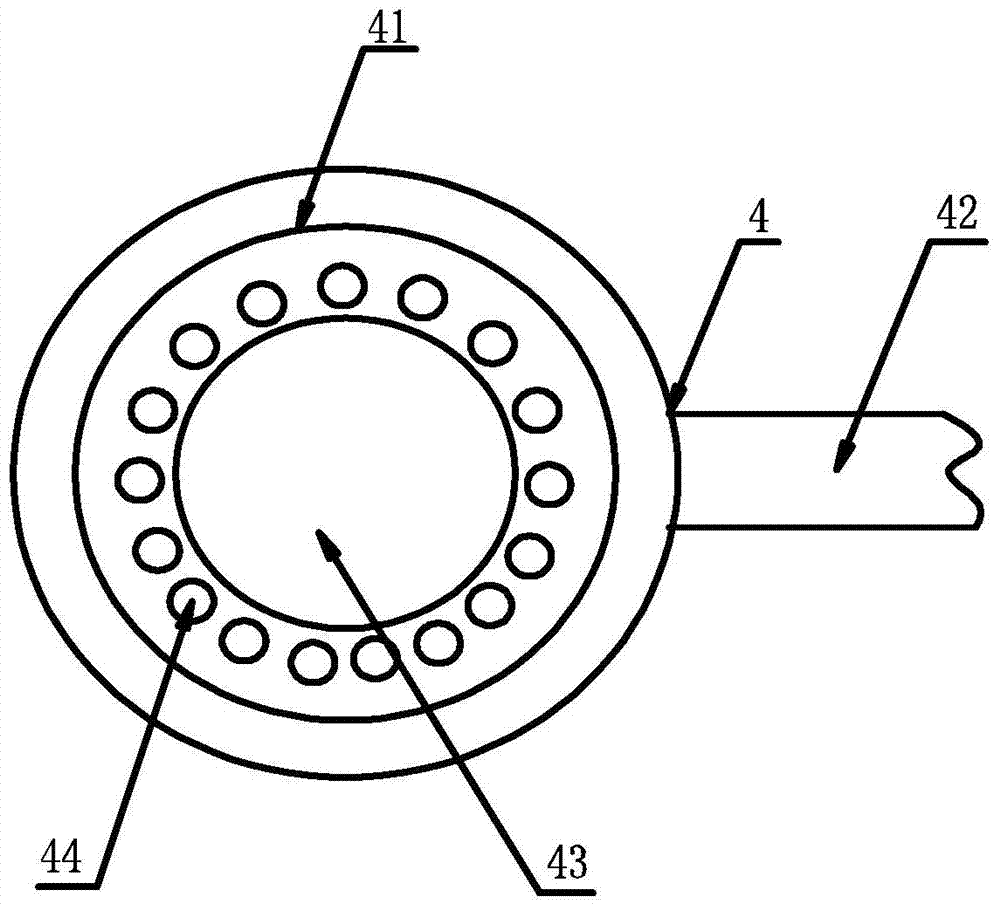

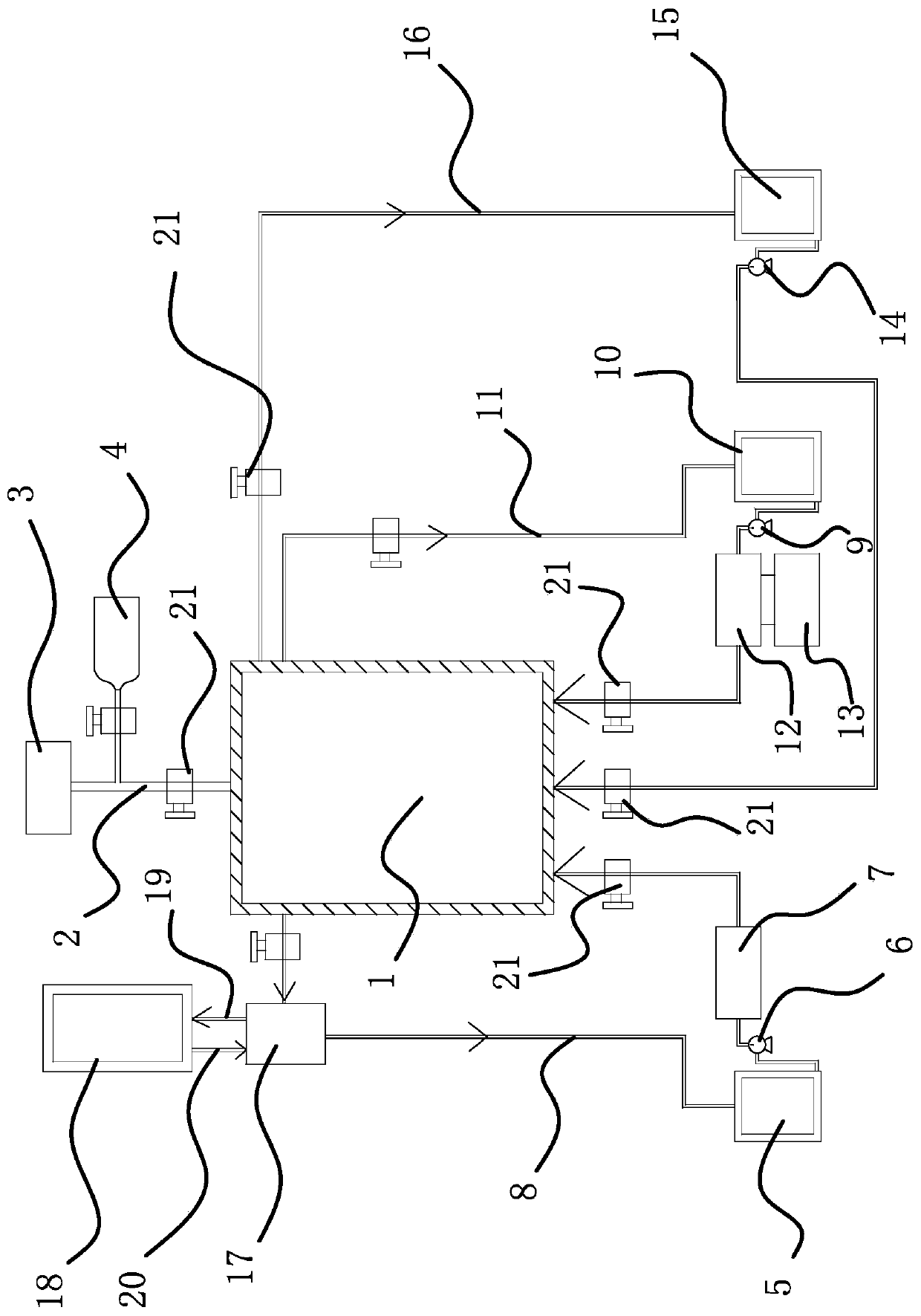

Heat treatment device for round-link chain and application method thereof

ActiveCN105349757AHigh degree of integrationImprove work efficiencyFurnace typesHeat treatment furnacesHardnessLath

The invention discloses a heat treatment device for a round-link chain and an application method thereof. The device comprises a quenching part and a tempering part which are sequentially arranged, wherein first cooling parts are arranged at the quenching part and the tempering part; the quenching part is provided with a quenching temperature regulating box; the tempering part is sequentially provided with an uniform-temperature tempering heating box, at least one tempering temperature regulating box and a differential-temperature tempering heating box; the quenching temperature regulating box is provided with a second cooling part. The device has the characteristics of being high in integration degree and high in working efficiency; after the round-link chain is quenched, an uniform and small low-carbon lath martensite structure can be obtained; the quenching quality is high; the second cooling part and the first cooling parts are correspondingly connected to a cooling source, so that the cooling quality can be improved, and the requirements of each part of the round-link chain on hardness and toughness can be met.

Owner:SHANDONG LUNAN GRP ENERGY EQUIP MFG

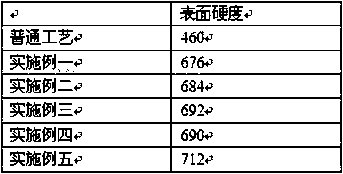

Compound heat treatment technology for wear-resistant gears

ActiveCN106048510ANo pollution in the processHigh hardnessSolid state diffusion coatingFurnace typesWear resistantShielding gas

The invention discloses a compound heat treatment technology for wear-resistant gears. The compound heat treatment technology comprises the following steps: A, washing and drying; B, carburizing; C, carrying out shielding gas air-cooling; D, washing and drying; E, heating and exhausting; F, carrying out intensive carburizing; G, diffusing; H, discharging out of a furnace and air-cooling; and I, carrying out rust prevention. The technology is simple, is environment-friendly and pollution-free in the whole process, can effectively improve the hardness, strength and wear resistance of alloy castings, reduces production cost, saves energy, reduces environmental pollution, is high in tempering temperatures, enables the gears to be resistant to high temperatures, deformation and friction and prolongs the service life.

Owner:东华链条兴化有限公司

Wear-resisting steel plate for extremely cold area and manufacturing method

The invention discloses a wear-resisting steel plate for an extremely cold area. Thechemical components comprise, by mass percent, 0.18 to 0.23% of C, 0.20 to 0.50% of Si, 1.0 to 1.50% of Mn, not larger than 0.010% of P, not larger than 0.002% of S, 0.10 to 0.30% of Cr, 0.10 to 0.30% of Mo, 0.30 to 0.8% of Ni, 0.008 to 0.030% of Ti, 0.012 to 0.040% of Nb, 0.0008 to 0.0025% of B, and the balance Feand inevitable impurities. Medium and high carbon and alloying component design is adopted, an auxiliary rolling and offline heat treatment method is adopted, the obtained steel plate has the Brinellhardness being 450 HBW level, and -60 DEG C low temperature impact toughness is larger than or equal to 34 J.

Owner:NANJING IRON & STEEL CO LTD

Heat treatment technology of low alloy steel casting

The invention relates to heat treatment technology of a casting, specifically to heat treatment technology of a low alloy steel casting. The technology comprises the following steps: normalizing, water quenching, and high temperature tempering and air cooling. According to the heat treatment technology of a low alloy steel casting, the tempering temperature of a low alloy steel casting is increased, and direct air cooling is adopted after the casting is taken out of a furnace, so that the treated low alloy steel casting can meet the strength and hardness requirement, and the toughness of the casting is improved. According to the heat treatment technology, water cooling is adopted in a quenching step, so that the production cost is reduced, the environmental pollution is prevented, and the potential safety hazard is minimized.

Owner:QINGDAO SANTONGDE METAL PROD

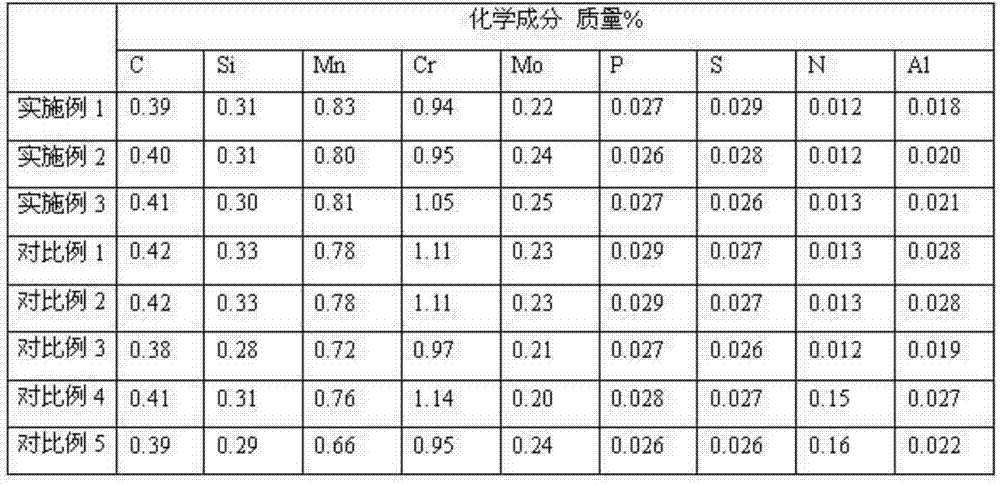

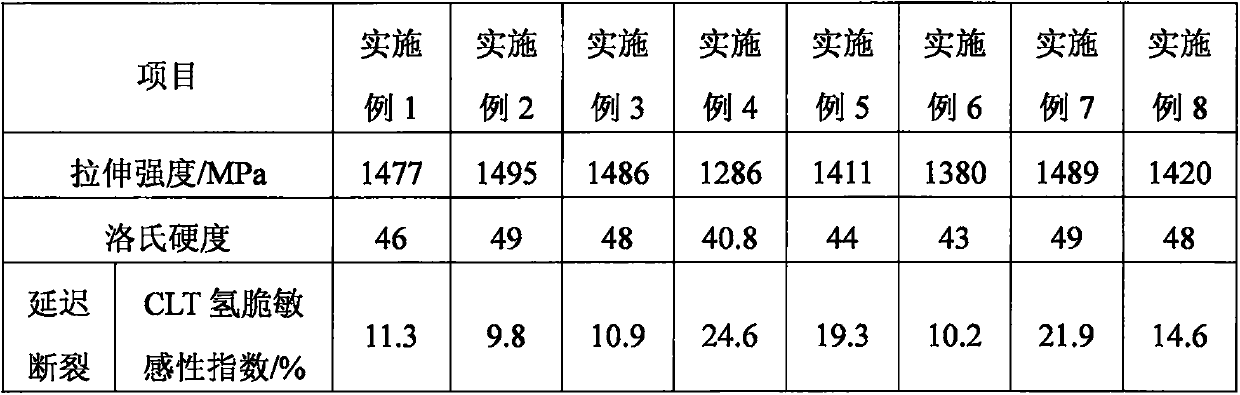

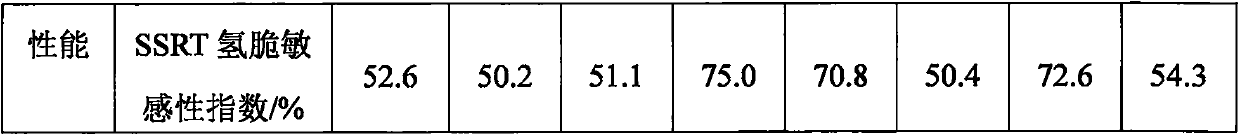

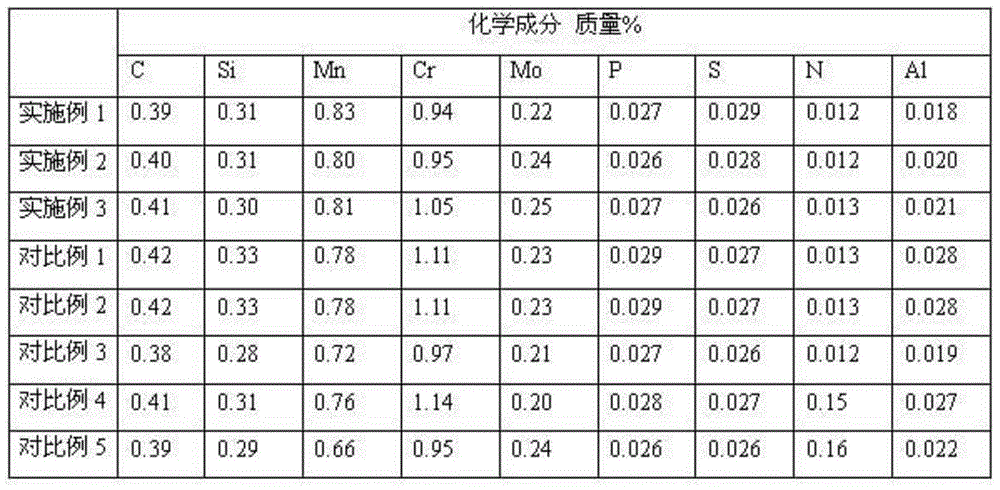

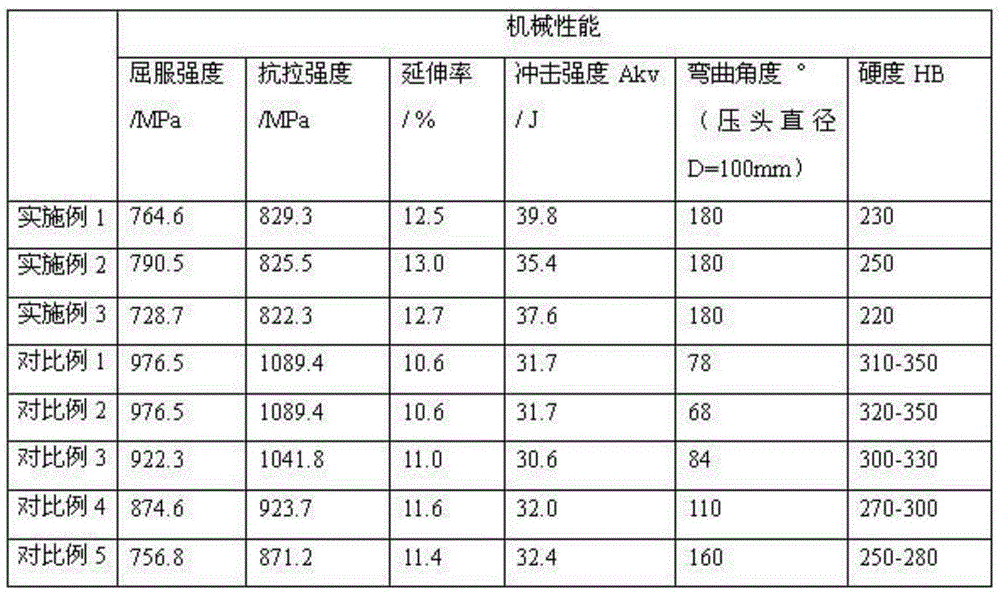

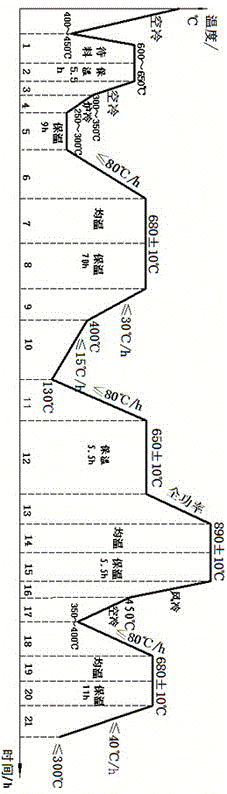

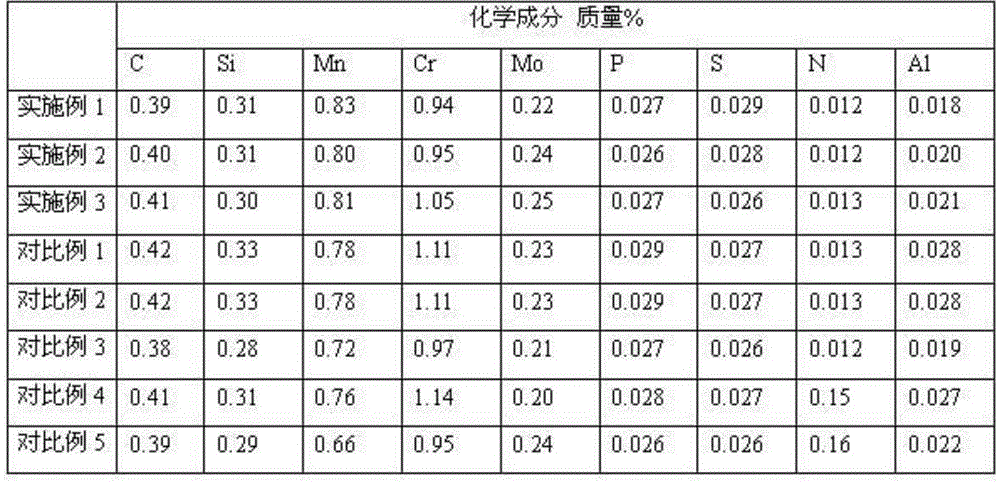

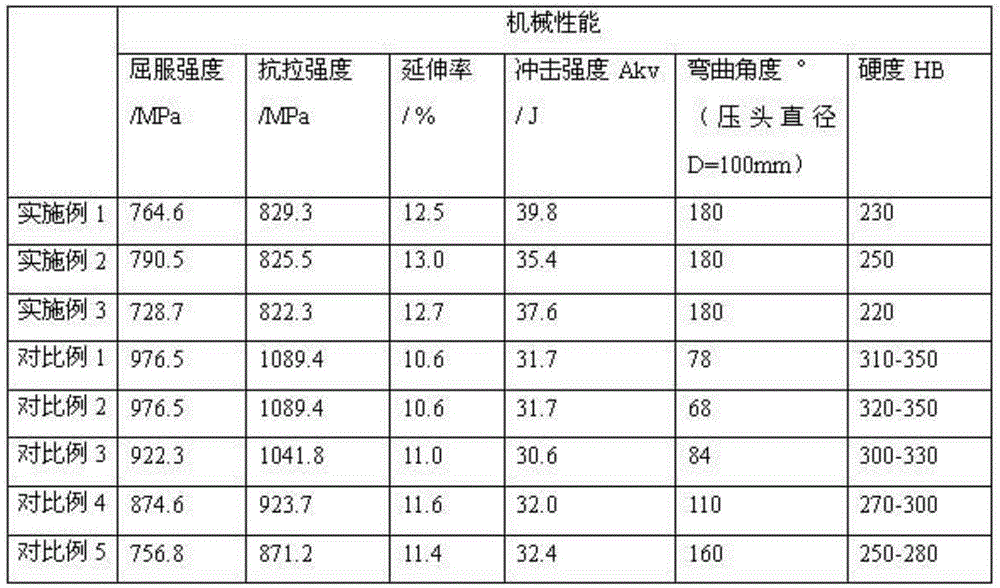

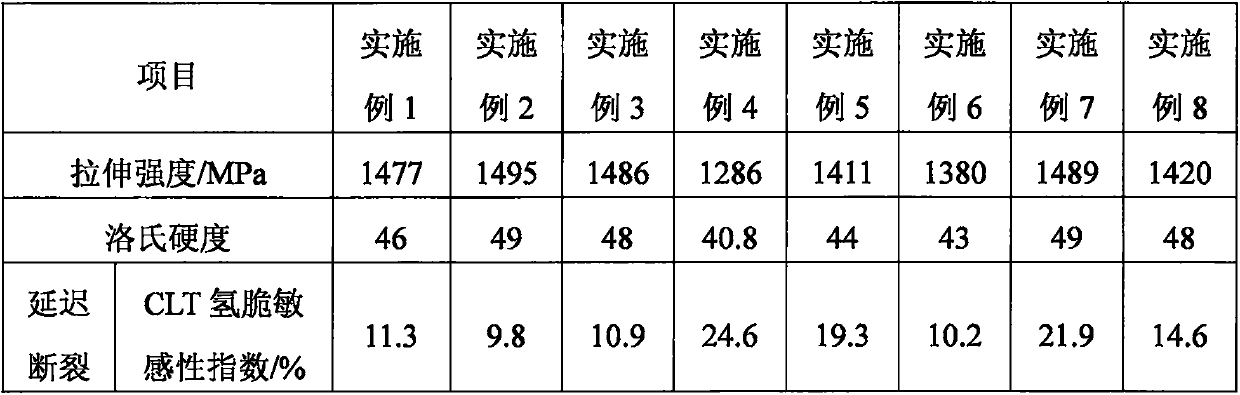

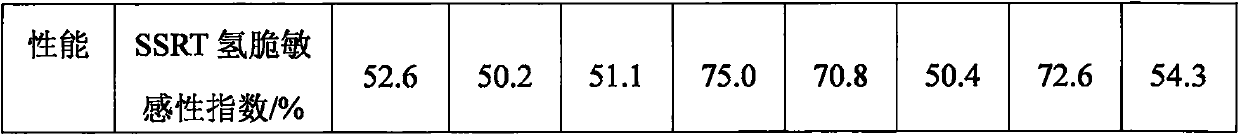

High strength bolt material and preparation method thereof

ActiveCN107604243AImproved resistance to delayed fractureReduced resistance to delayed fractureAustenite grainHydrogen

The invention provides a high strength bolt material and a preparation method thereof. An appropriate amount of microalloy elements of Ti and Nb are added on the basis of 42CrMo steel. The microalloyelements and elements of C and N can form carbon nitride particles to refine austenite grains to form a hydrogen trap, so that material strength and toughness are improved and material resistance to delayed fracture is also improved. The elements of Mo and the like improve the drawing temperature and reduces the content of hydrogen invading from the surface of the material, so that increasing of sensitivity of material delayed fracture is effectively prevented. According to the high strength bolt material, the element of Ni is added. On the one hand, the mechanical property of the material isimproved by the element of Ni cooperating with Ti, Nb and the like. On the other hand, the material resistance to delayed fracture is improved by matching of the element Ni and the element Mo. According to the high strength bolt material, the contents of elements of P, S, Mn and the like are reduced; the amount of non-metallic inclusions in steel is greatly reduced and sensitivity of material delayed fracture is reduced.

Owner:NINGBO ZHENHAI YONGDING FASTENER

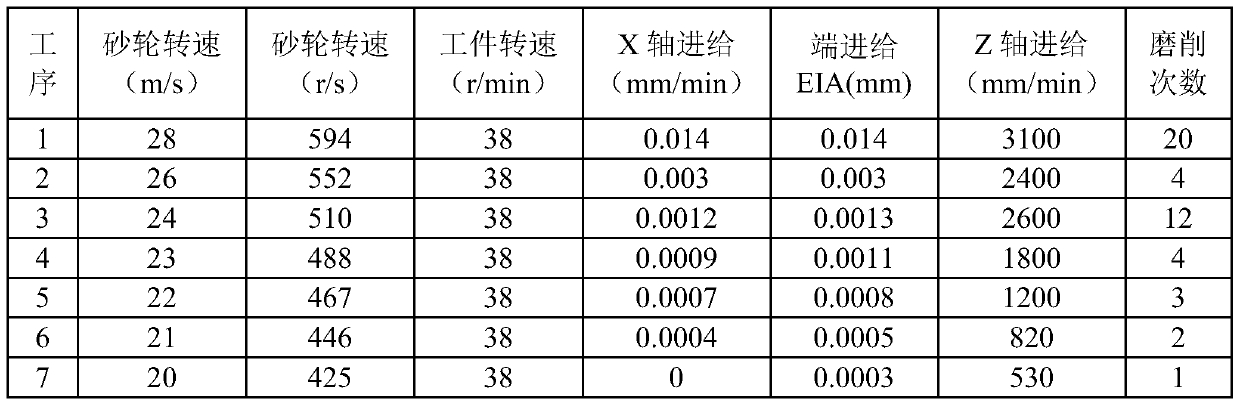

Gear machining and heat treatment process

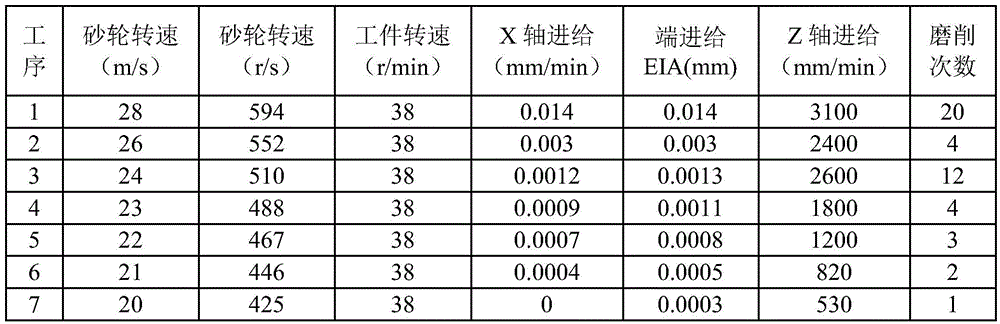

InactiveCN105714040AAdd depthImprove heating uniformitySolid state diffusion coatingMetal working apparatusGear grindingProduct inspection

The present invention discloses a gear machining and heat treatment process, and the gear machining process successively comprises forging, normalizing, quenching and tempering, vertical machining, gear shaping, annealing, vertical machining, gear shaping, vertical milling, stabilizing aging, gear grinding, nitriding and finished product inspection, wherein the step of normalizing is normalizing at (880 + / -10) DEG C for (3-4) h, and then cooling in air; the step of quenching and tempering is quenching and tempering at (850 + / -10) DEG C for (3-4) h, quenching with water, and cooling with oil; the step of the annealing is annealing at (530 + / -10) DEG C for (3-4) h, cooling in a furnace in the heating and cooling rate of less than or equal to 50 DEG C / h; the step of stabilizing aging is stabilizing aging at (510 + / -10) DEG C for (3-4) h, and cooling in the furnace in the heating and cooling rate of less than or equal to 2 5 DEG C / h; and the step of nitriding is nitriding at (510 + / -10) DEG C for (10-12) h, and cooling in the furnace in the heating and cooling rate of less than or equal to 2 5 DEG C / h. The gear machining and heat treatment process is more reasonable, and can reduce distortion after nitriding to improve the overall performance of a gear.

Owner:CHONGQING YUANHUANG MACHINERY MFG CO LTD

Thermal treatment process for low-alloy steel castings

The invention relates to a thermal treatment process for castings, in particular to a thermal treatment process for low-alloy steel castings. The thermal treatment process includes the following steps of normalizing, water quenching and high-temperature tempering and air cooling. By the adoption of the thermal treatment process for the low-alloy steel castings, the tempering temperature of the low-alloy steel castings is increased, the direct tapping air cooling manner is adopted, the treated low-alloy steel castings can meet the requirements for the strength and hardness, and meanwhile the toughness of the castings is improved; and in the thermal treatment process for the low-alloy steel castings, the water cooling manner is used in the quenching step, production cost is reduced, environmental contamination is reduced, and potential safety hazards are reduced.

Owner:QINGDAO QINDE RIGGING HARDWARE

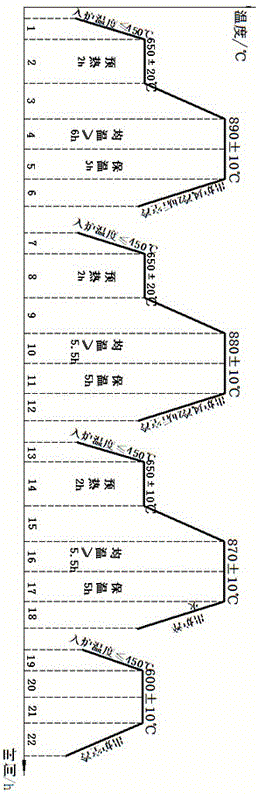

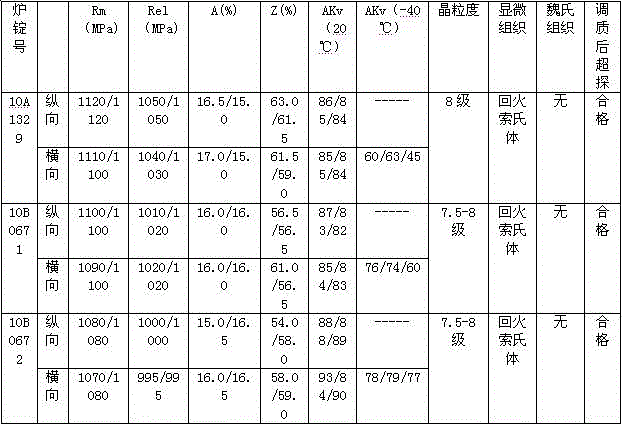

A processing method for grain refinement of crnimov high pressure steel forgings

ActiveCN103981347BHigh low temperature impact toughnessFine grain sizeProcess efficiency improvementTemperature controlChemical composition

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

Heat treatment process for low alloy steel casting

The invention relates to a heat treatment process for a casting, in particular to a heat treatment process for a low alloy steel casting. The process includes the following steps of normalizing, water quenching and high-temperature tempering air cooling. According to the heat treatment process for the low alloy steel casting, the tempering temperature of the low alloy steel casting is increased, a direct tapping air cooling manner is adopted, the treated low alloy steel casting meets the strength and hardness requirements, and meanwhile the toughness of the casting is improved. According to the heat treatment process for the low alloy steel casting, a water cooling manner is used in the quenching step, the production cost is reduced, environmental pollution is reduced, and potential safety hazards are reduced.

Owner:QINGDAO XINHEYI IND & TRADE CO LTD

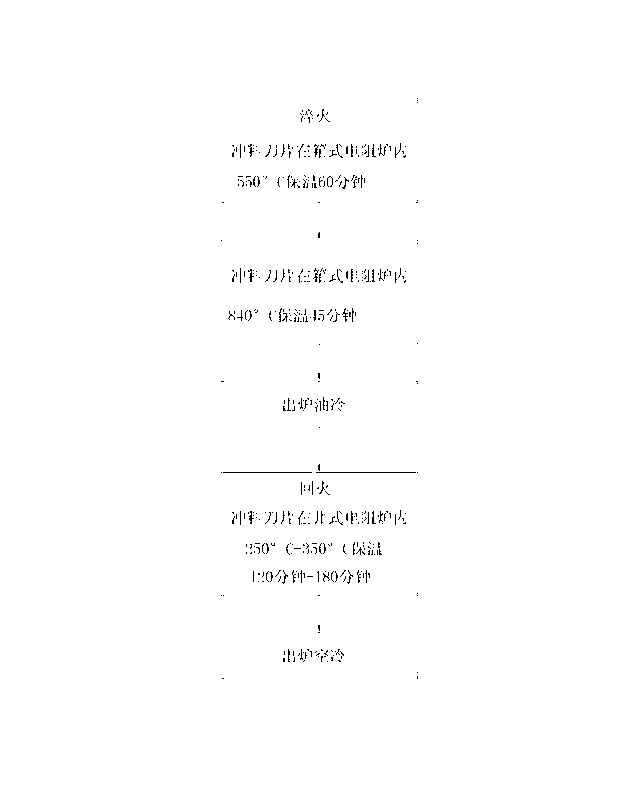

Heat treatment technology of bar shearing die blade

InactiveCN103014294ARaise tempering temperatureImprove mechanical propertiesFurnace typesHeat treatment furnacesFurnace temperatureBrittle fracture

The invention discloses a heat treatment technology of a bar shearing die blade, which comprises the following steps of: 1) quenching: heating a box-type resistance furnace to 550 DEG C, putting the bar shearing die blade into the furnace, and preserving heat at 550 DEG C for 60 minutes; and further increasing the furnace temperature to 840 DEG C, preserving heat for 45 minutes, and discharging the bar shearing die blade from the furnace and performing oil cooling; and 2) annealing: heating a pit-type resistance furnace to 250-350 DEG C, putting the quenched bar shearing die blade into the pit-type resistance furnace, preserving heat at 250-350 DEG C for 120-180 minutes, discharging and performing air cooling. The bar shearing die blade disclosed by the invention does not experience brittle fracture easily, and the cutting edge is not easily disintegrated; one bar shearing die blade can cut 20-30 thousand bars; after long-term use, the shearing die blade is still useful after coping, and the service life is prolonged by over 30 times; and moreover, the utilization rate is high, the needs for production and development are met, and the production cost is greatly saved.

Owner:亚星(镇江)系泊链有限公司

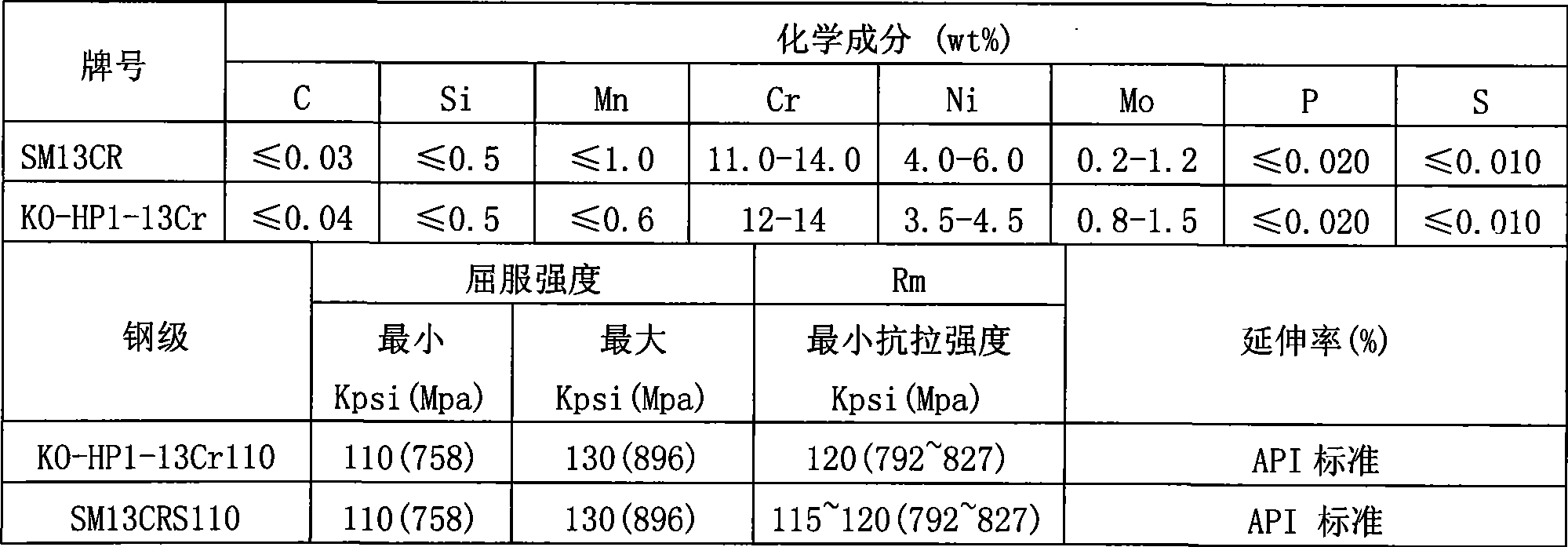

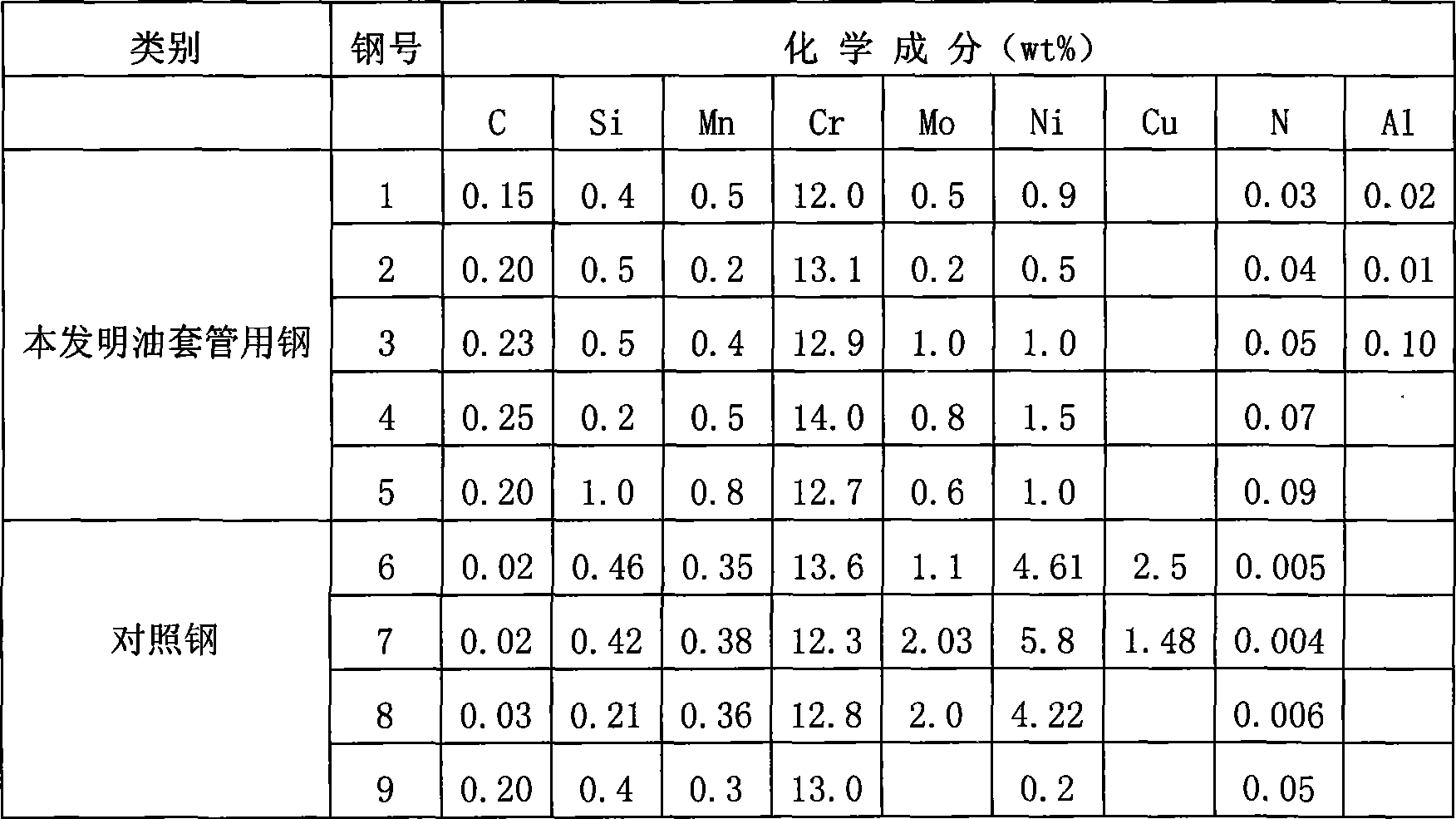

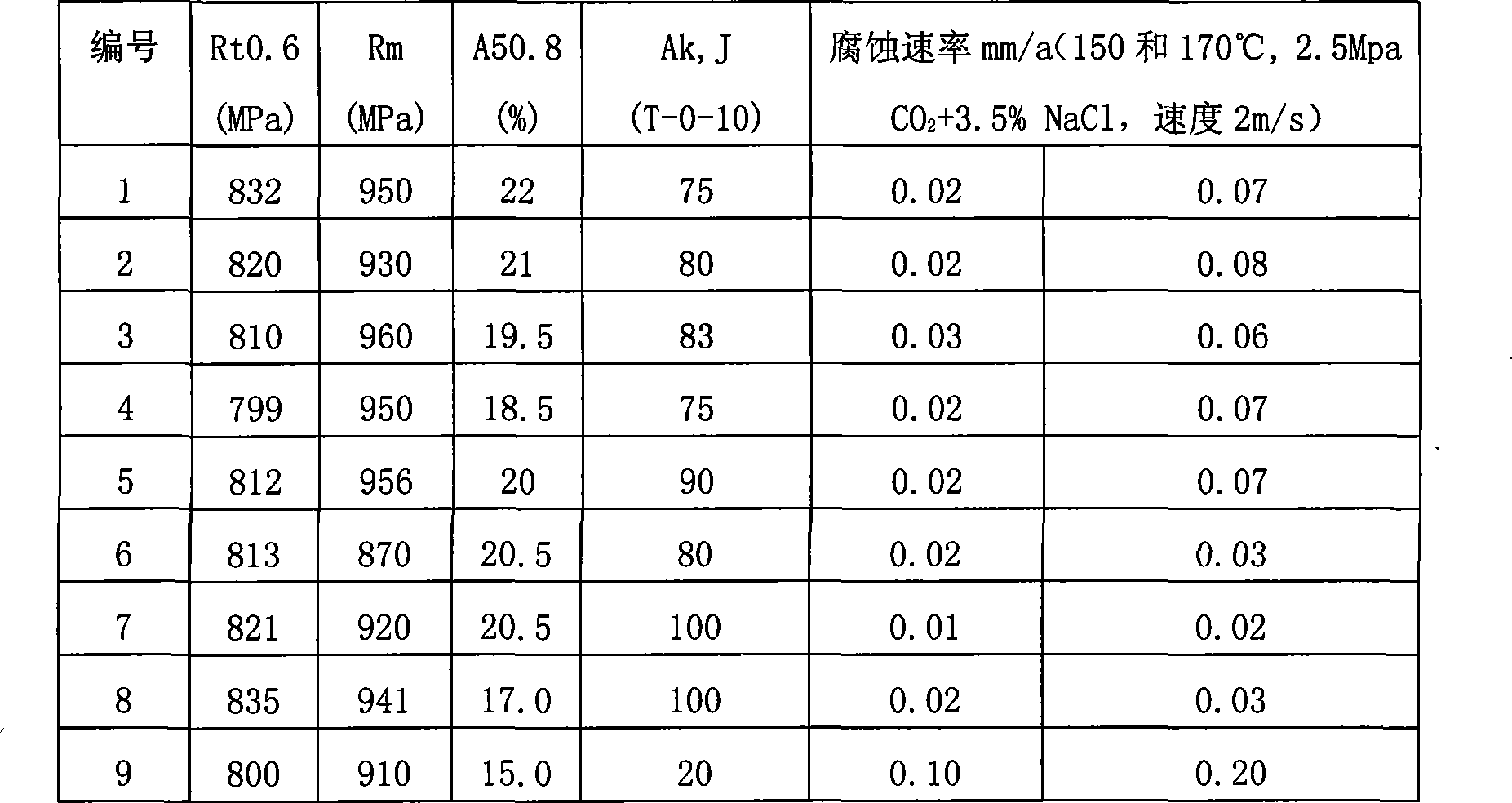

Preparation method for 110ksi high grade steel and high CO2-corrosion resistant tubing and casing and the tubing and casing

ActiveCN101289730BRaise tempering temperatureImprove low temperature impact toughnessTemperature control deviceUltimate tensile strengthCorrosion resistant

The invention provides 110ksi high steel grade and high CO2 corrosion resistance 13Cr steel for an oil casing, the oil casing made of the same and a method for making the oil casing. The component proportion of the steel for the oil casing has the addition of a few nickel, molybdenum and nitrogen alloy elements based on API L80-13Cr oil casing alloy design. The steel for oil casing comprises the following chemical component by weight: 0.15-0.25 percent of C, 0.2-1.0 percent of Si, 0.20-1.0 percent of Mn, 12.0-14.0 percent of Cr, 0.5-1.5 percent of Ni, 0.2-1.0 percent of Mo, 0.03-0.10 percent of N, and the balance being Fe and inevitable impurities. The oil casing with the CO2-chloridion corrosion resistant strength up 110 steel grade at the temperature over 150 DEG C can be obtained after the steel is smelted, rolled and performed with proper heat treatment. Due to low alloy and production cost and good CO2 corrosion resistance, the 110ksi high steel grade and high CO2 corrosion resistance oil casing can be widely used for oil well pipes and other occasions requiring corrosion resistance.

Owner:BAOSHAN IRON & STEEL CO LTD

Steel for steel structure bolts

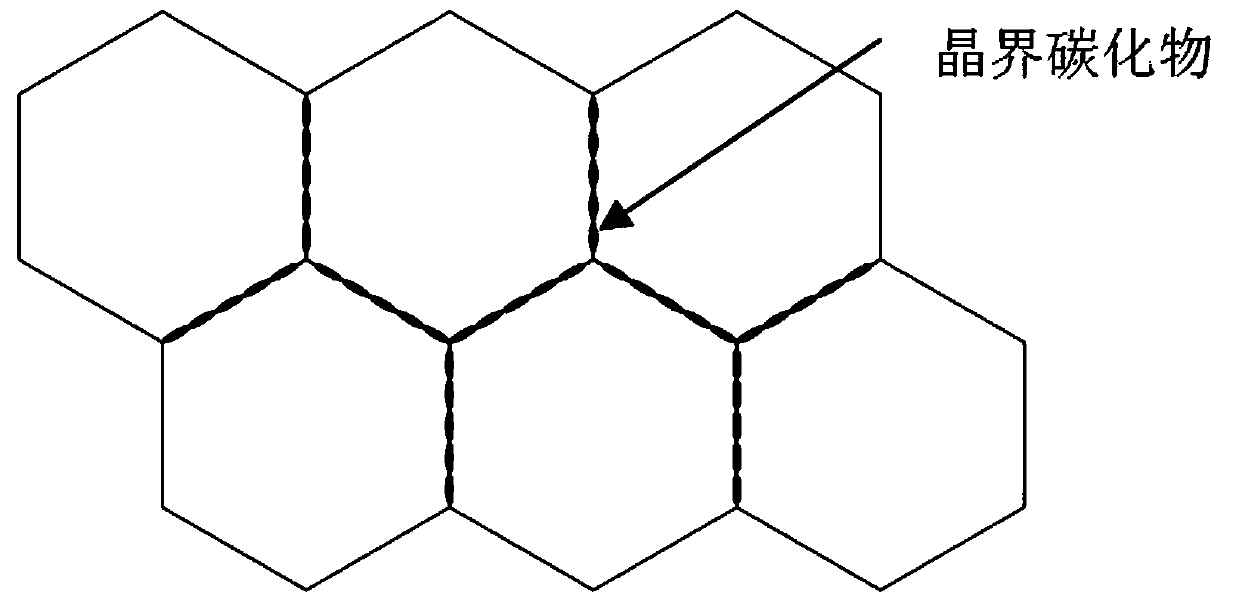

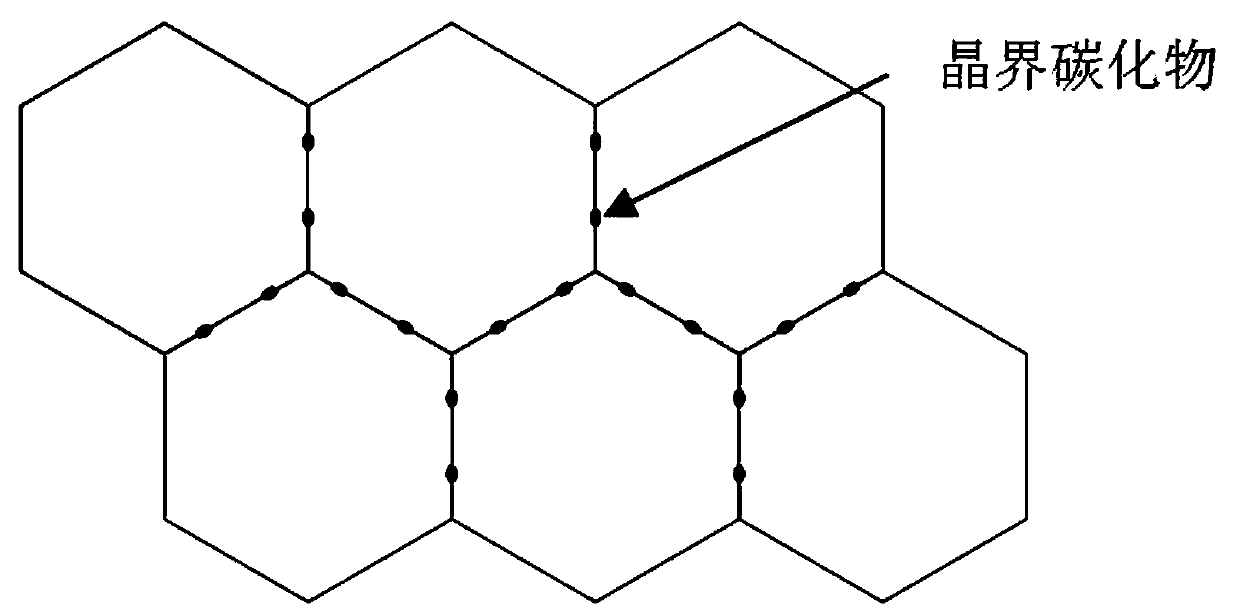

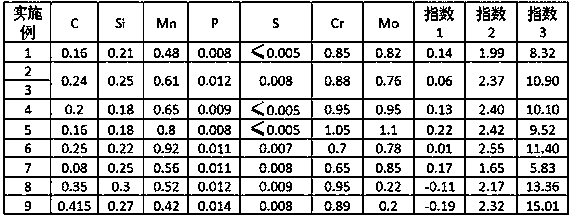

The invention relates to steel for steel structure bolts. The steel material comprises, by mass, 0.1-0.3% of C, 0.10-0.35% of Si, less than or equal to 1.5% of Mn, less than or equal to 0.01% of S, less than or equal to 0.015% of P, 0.5-1.4% of Cr, 0.6-1.2% of Mo, the balance Fe and inevitable impurities, wherein tempering temperature is more than or equal to 600 DEG C during the final heat treatment of the steel material. According to the steel for the steel structure bolts, on the basis of the fracture morphology analysis according to practical steel structure application environment and existing application delayed breakage and fracture, the precipitation quantity and precipitation morphology of intergranular carbide are improved by optimizing alloy components, and the delayed fractureresistance of the material is improved. After the steel for the steel structure bolts is subjected to heat treatment, the tensile strength can reach 1040 MPa or more, and the upper limit can reach 1240 MPa. The fastener performance grade meets the GB / T1231-2006 standard 10.9S grade, and has excellent delayed fracture resistance.

Owner:中船双瑞(洛阳)特种装备股份有限公司

Cold-rolled aluminum working roll with good grinding performance and preparing method thereof

The invention relates to a cold-rolled aluminum working roll with good grinding performance. The working roll comprises chemical components which include, by weight percent, 0.85-0.95% of C, 0.25-0.45% of Si, 0.25-0.35% of Mn, 2.50-3.50% of Cr, 0.20-0.40% of Mo, smaller than or equal to 0.25% of Ni, smaller than or equal to 0.025% of P, smaller than or equal to 0.025% of S and the balance Fe and inevitable impurities. According to the cold-rolled aluminum working roll with the good grinding performance, the cold-rolled aluminum working roll with the good grinding performance is obtained, the requirements for surface hardness and roll face roughness of the working roll are met at the same time, and it is verified that effects are good after a user uses the cold-rolled aluminum working roll.

Owner:邢台轧辊小冷辊有限责任公司

A kind of high-strength bolt material and its preparation method

ActiveCN107604243BImproved resistance to delayed fractureReduced resistance to delayed fractureAustenite grainHydrogen

The invention provides a high strength bolt material and a preparation method thereof. An appropriate amount of microalloy elements of Ti and Nb are added on the basis of 42CrMo steel. The microalloyelements and elements of C and N can form carbon nitride particles to refine austenite grains to form a hydrogen trap, so that material strength and toughness are improved and material resistance to delayed fracture is also improved. The elements of Mo and the like improve the drawing temperature and reduces the content of hydrogen invading from the surface of the material, so that increasing of sensitivity of material delayed fracture is effectively prevented. According to the high strength bolt material, the element of Ni is added. On the one hand, the mechanical property of the material isimproved by the element of Ni cooperating with Ti, Nb and the like. On the other hand, the material resistance to delayed fracture is improved by matching of the element Ni and the element Mo. According to the high strength bolt material, the contents of elements of P, S, Mn and the like are reduced; the amount of non-metallic inclusions in steel is greatly reduced and sensitivity of material delayed fracture is reduced.

Owner:NINGBO ZHENHAI YONGDING FASTENER

Buffer spring production process

InactiveCN110369647AEasy to transformReduce damage rateFurnace typesWire springsMachiningMaterials science

The invention belongs to the technical field of component machining, and particularly discloses a buffer spring production process. A pressed and formed buffer spring is tempered for a plurality of times in a tempering furnace at 350 DEG C to 450 DEG C; and the buffer spring is pressed by using a pressure forming machine between two tempering processes. According to the process disclosed by the invention, the stress of the buffer spring can be eliminated, and the anti-fatigue strength of the buffer spring is improved.

Owner:重庆成俊工贸有限公司

Cold-rolled aluminum work roll with good grinding properties and manufacturing method thereof

ActiveCN105463330BImprove grinding effectGood use verification effectFurnace typesRollsWork rollHardness

The invention relates to a cold-rolled aluminum working roll with good grinding performance. The working roll comprises chemical components which include, by weight percent, 0.85-0.95% of C, 0.25-0.45% of Si, 0.25-0.35% of Mn, 2.50-3.50% of Cr, 0.20-0.40% of Mo, smaller than or equal to 0.25% of Ni, smaller than or equal to 0.025% of P, smaller than or equal to 0.025% of S and the balance Fe and inevitable impurities. According to the cold-rolled aluminum working roll with the good grinding performance, the cold-rolled aluminum working roll with the good grinding performance is obtained, the requirements for surface hardness and roll face roughness of the working roll are met at the same time, and it is verified that effects are good after a user uses the cold-rolled aluminum working roll.

Owner:邢台轧辊小冷辊有限责任公司

110Ksi grade CO2 H2S corrosion-proof oil well pipe and manufacturing method

ActiveCN100494462CAccelerated corrosionHigh strengthTemperature control deviceHeat treatment process controlSulfurImpurity

The 110ksi grade steel resisting CO2 and H2S corrosion for oil well pipe has the components including C 0.20-0.35 wt%, Si 0.10-1.0 wt%, Mn 0.10-1.0 wt%, Cr 1.0-2.5 wt%, Mo 0.1-1.0 wt%, Ni 0.10-1.0 wt%, Nb 0.01-0.1 wt%, Cu 0.10-1.0 wt%, Al 0.01-0.10 wt%, and Fe and inevitable impurities for the rest. It is produced through smelting, casting, cogging, rolling pipe, water or oil quenching at temperature over 850 deg.c, and high temperature tempering at temperature over 650 deg.c for over 2 hr. It has high CO2 and H2S corrosion resistance.

Owner:BAOSHAN IRON & STEEL CO LTD

A circular chain heat treatment device and its application method

ActiveCN105349757BHigh degree of integrationImprove work efficiencyFurnace typesHeat treatment furnacesHardnessLath

The invention discloses a heat treatment device for a round-link chain and an application method thereof. The device comprises a quenching part and a tempering part which are sequentially arranged, wherein first cooling parts are arranged at the quenching part and the tempering part; the quenching part is provided with a quenching temperature regulating box; the tempering part is sequentially provided with an uniform-temperature tempering heating box, at least one tempering temperature regulating box and a differential-temperature tempering heating box; the quenching temperature regulating box is provided with a second cooling part. The device has the characteristics of being high in integration degree and high in working efficiency; after the round-link chain is quenched, an uniform and small low-carbon lath martensite structure can be obtained; the quenching quality is high; the second cooling part and the first cooling parts are correspondingly connected to a cooling source, so that the cooling quality can be improved, and the requirements of each part of the round-link chain on hardness and toughness can be met.

Owner:SHANDONG LUNAN GRP ENERGY EQUIP MFG

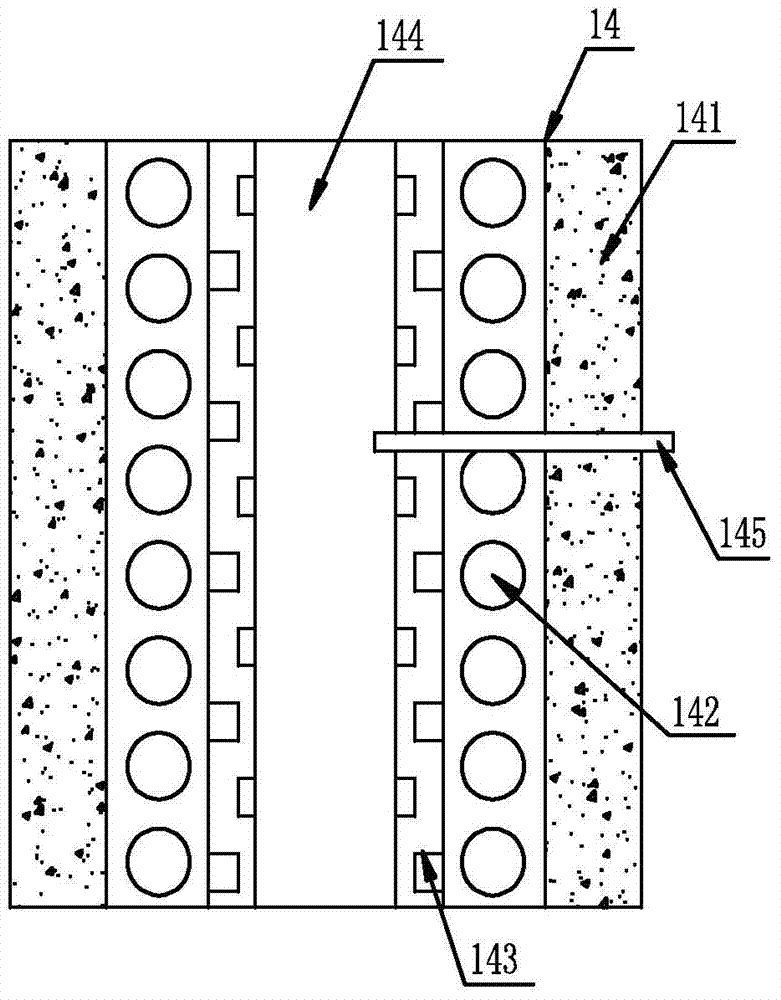

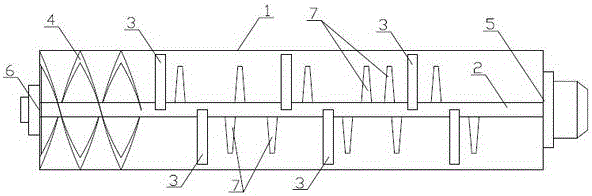

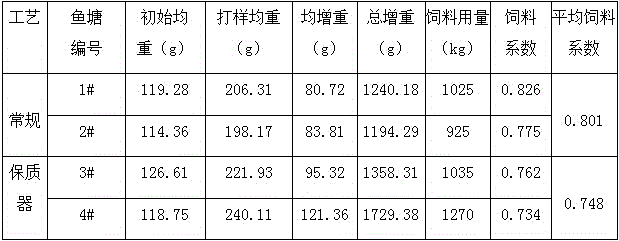

A kind of production technology of tilapia pellet feed

ActiveCN104997144BImprove palatabilityImprove conditioning environmentFeeding-stuffQuenchingOreochromis mossambicus

The present invention relates to production technology of oreochromis mossambicus granulated feed, and belongs to the technical field of fish feed. The production technology includes: conducting an initial quenching and high temperature tempering treatment on raw materials of oreochromis mossambicus feed with a first conditioner, continually conducting a material curing guaranteeing treatment on the raw materials for 130-150 seconds with a material curing guaranteeing device, conducting secondary quenching and high temperature tempering treatment on the raw materials with a second conditioner, and finally placing the raw materials into a granulator, thereby obtaining the oreochromis mossambicus granulated feed. The production technology can not only improve the material quenching and high temperature tempering environment, but also reduce the ring die compression ratio of the granulator in the subsequent granulating process, so that the production technology can not only guarantee product uniformity, water resistance and powder containing ratio requirements, but also improve the production efficiency and the palatability of fish feed.

Owner:JIEYANG TONGWEI FEED

High sulfur resistance petroleum drilling rod heat treatment process

InactiveCN103805860AGuaranteed sulfur resistanceImprove mechanical propertiesThermal insulationSulfur

The present invention discloses a high sulfur resistance petroleum drilling rod heat treatment process. The components of the high sulfur resistance petroleum drilling rod comprise: 0.14-0.18 wt% of C, 0.3-0.5 wt% of Si, 0.7-0.9 wt% of Mn, 1.8-2.2 wt% of Cr, 1.4-1.6 wt% of Mo, 0.2-0.40 wt% of V, 0.07-0.09 wt% of Nb, 0.06-0.08 wt% of Ti, 0.01-0.02 wt% of Ca, 0.05-0.15 wt% of Cu, less than or equal to 0.015 wt% of P, less than or equal to 0.01 wt% of S, and the balance of Fe and unavoidable impurities. The heat treatment process comprises: 1) quenching, wherein the heating temperature is 960-980 DEG C, the thermal insulation time is 0.5-1.5 h, and the obtained material is placed in a water tank with a stirrer, and then is subjected to a cryogenic treatment for 30-40 min at a temperature of -80 DEG C; and 2) tempering, wherein the heating temperature is 510-530 DEG C, and the thermal insulation time is 2-4 h.

Owner:WUXI XINSANZHOU STEEL

A composite heat treatment process for wear-resistant gears

ActiveCN106048510BNo pollution in the processHigh hardnessSolid state diffusion coatingFurnace typesEnvironmental resistanceWear resistant

The invention discloses a compound heat treatment technology for wear-resistant gears. The compound heat treatment technology comprises the following steps: A, washing and drying; B, carburizing; C, carrying out shielding gas air-cooling; D, washing and drying; E, heating and exhausting; F, carrying out intensive carburizing; G, diffusing; H, discharging out of a furnace and air-cooling; and I, carrying out rust prevention. The technology is simple, is environment-friendly and pollution-free in the whole process, can effectively improve the hardness, strength and wear resistance of alloy castings, reduces production cost, saves energy, reduces environmental pollution, is high in tempering temperatures, enables the gears to be resistant to high temperatures, deformation and friction and prolongs the service life.

Owner:东华链条兴化有限公司

Heat treatment process for pick body of cutting pick

PendingCN113755686AIncrease cooling ratePromote fastFurnace typesHeat treatment furnacesCarbon steelMo element

The invention relates to a heat treatment process for a pick body of a cutting pick. The heat treatment process comprises the following steps that S1, after 42CrMo stainless steel is molten into molten carbon steel, 1 part-3 parts of Cr and 0.5 part-2 parts of Mo are added; S2, the molten carbon steel is cast into a stainless steel bar; S3, after the stainless steel bar is forged and pressed, the stainless steel bar is machined and formed into the cutting pick body; S4, quenching is conducted, the cutting pick body is heated to 730 DEG C-950 DEG C at the heating rate of 5 DEG C / min, then heat preservation is conducted for 30 min-90 min, and then the cutting pick body is placed in emulsified liquid or liquid nitrogen to be cooled to the room temperature; and S5, the quenched cutting pick body is heated to 250 DEG C-450 DEG C at the heating rate of 5 DEG C / min and then subjected to heat preservation for 30 min-90 min, and then the quenched cutting pick body is placed in air to be cooled to the room temperature. According to the heat treatment process, 42CrMo is taken as a basis, the hardness of the alloy is adjusted by adjusting the relative contents of C, Cr and Mo elements and quenching and tempering processes through the carbon content, the morphology and distribution of a hard phase are controlled, and the high-temperature strength of the pick body is improved.

Owner:广西斯达奔材料科技有限公司

A medium and low temperature oil bath tempering equipment

Owner:HAINING XINYI MACHINERY & ELECTRICAL

Preparation process of novel mold material for extrusion twist drill

InactiveCN109055851AThe grain size is not coarseImprove toughnessSolid state diffusion coatingFurnace typesChemical compositionWear resistance

The invention relates to a preparation process of a novel mold material for an extrusion twist drill., The main chemical components of the mold material consist of 1.48-1.55 of C, 12-13 of Cr, 0.45-0.50 of Mo, and 0.19-0.22 of V; the preparation process comprises heat treatment and nitriding treatment, wherein the heat treatment process comprises the following steps that (1) firstly, a mold is putinto a furnace to carry out high-frequency heating, and oil cooling or staged cooling is carried out after heating is carried out to 1150-1200 DEG C; and then (2), tempering is carried out at 550-560DEG C for 5-6 times on the obtained mold treated in the step (1). The service life of the mold is prolonged by the process, and the high-temperature resistance and the wear resistance of the mold areimproved.

Owner:HENAN YIGONG DRILLING IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com