Heat treatment process for low alloy steel casting

A low-alloy steel and casting technology, applied in the field of heat treatment process of low-alloy steel castings, can solve the problems of easy to produce temper brittleness, poor toughness of low-alloy steel castings, environmental pollution, etc., to reduce environmental pollution and safety hazards, meet the Strength and hardness requirements, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

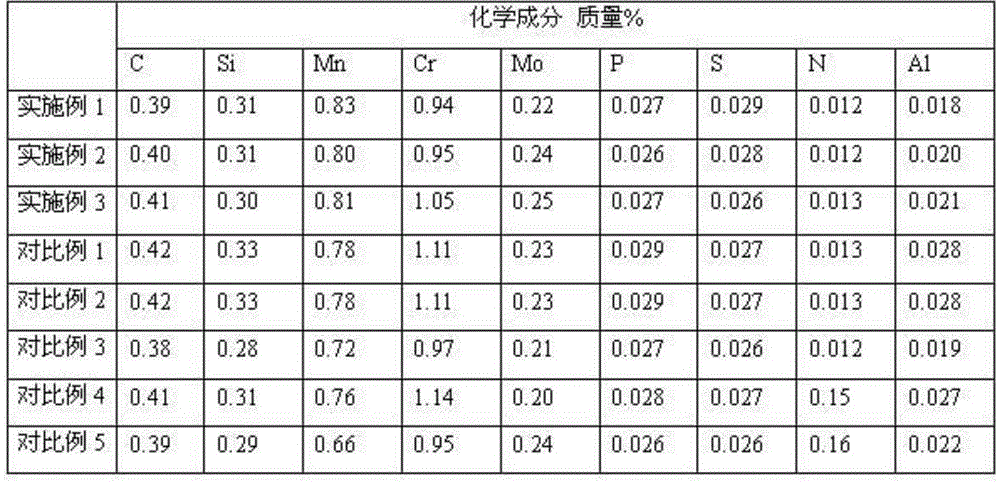

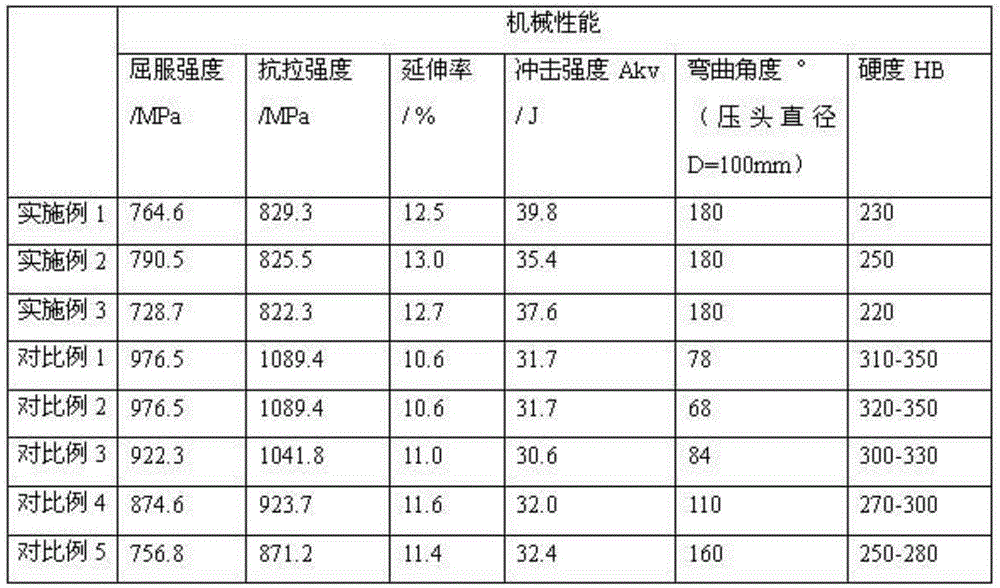

Embodiment 1

[0017] Embodiment 1: The heat treatment process steps of the low-alloy steel casting of the present embodiment are as follows:

[0018] (1) Normalizing: Place the low-alloy steel casting in a normalizing furnace, raise the temperature to 870°C, keep it warm for 3 hours, and cool it to room temperature after taking it out of the furnace;

[0019] (2) Quenching: Place the low-alloy steel casting in a quenching furnace, raise the temperature to 850°C, keep it warm for 2.5 hours, and cool it to room temperature when it comes out of the furnace;

[0020] (3) Tempering: Place the low-alloy steel casting in a tempering furnace, raise the temperature to 700°C, keep it warm for 3 hours, and then take it out of the furnace and air-cool it to room temperature.

Embodiment 2

[0021] Embodiment 2: the heat treatment process steps of the low-alloy steel casting of the present embodiment are as follows:

[0022] (1) Normalizing: Place the low-alloy steel casting in a normalizing furnace, raise the temperature to 880°C, keep it warm for 2.5 hours, and cool it to room temperature after taking it out of the furnace;

[0023] (2) Quenching: Place the low-alloy steel casting in a quenching furnace, raise the temperature to 860°C, keep it warm for 3 hours, and cool it to room temperature when it comes out of the furnace;

[0024] (3) Tempering: Place the low-alloy steel casting in a tempering furnace, raise the temperature to 710°C, keep it warm for 3 hours, and then take it out of the furnace and air-cool it to room temperature.

Embodiment 3

[0025] Embodiment 3: the heat treatment process steps of the low-alloy steel casting of the present embodiment are as follows:

[0026] (1) Normalizing: Place the low-alloy steel casting in a normalizing furnace, raise the temperature to 890°C, keep it warm for 3 hours, and cool it to room temperature after taking it out of the furnace;

[0027] (2) Quenching: Place the low-alloy steel casting in a quenching furnace, raise the temperature to 870°C, keep it warm for 3 hours, and cool it to room temperature after taking it out of the furnace;

[0028] (3) Tempering: Place the low-alloy steel casting in a tempering furnace, raise the temperature to 710°C, keep it warm for 2.5 hours, and then take it out of the furnace and air-cool it to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com