110Ksi grade CO2 H2S corrosion-proof oil well pipe and manufacturing method

A manufacturing method and technology for oil well pipes, which are applied in manufacturing tools, temperature control, heat treatment process control, etc., can solve problems such as poor resistance to hydrogen sulfide stress corrosion cracking, low steel strength, and inability to manufacture 758MPa.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

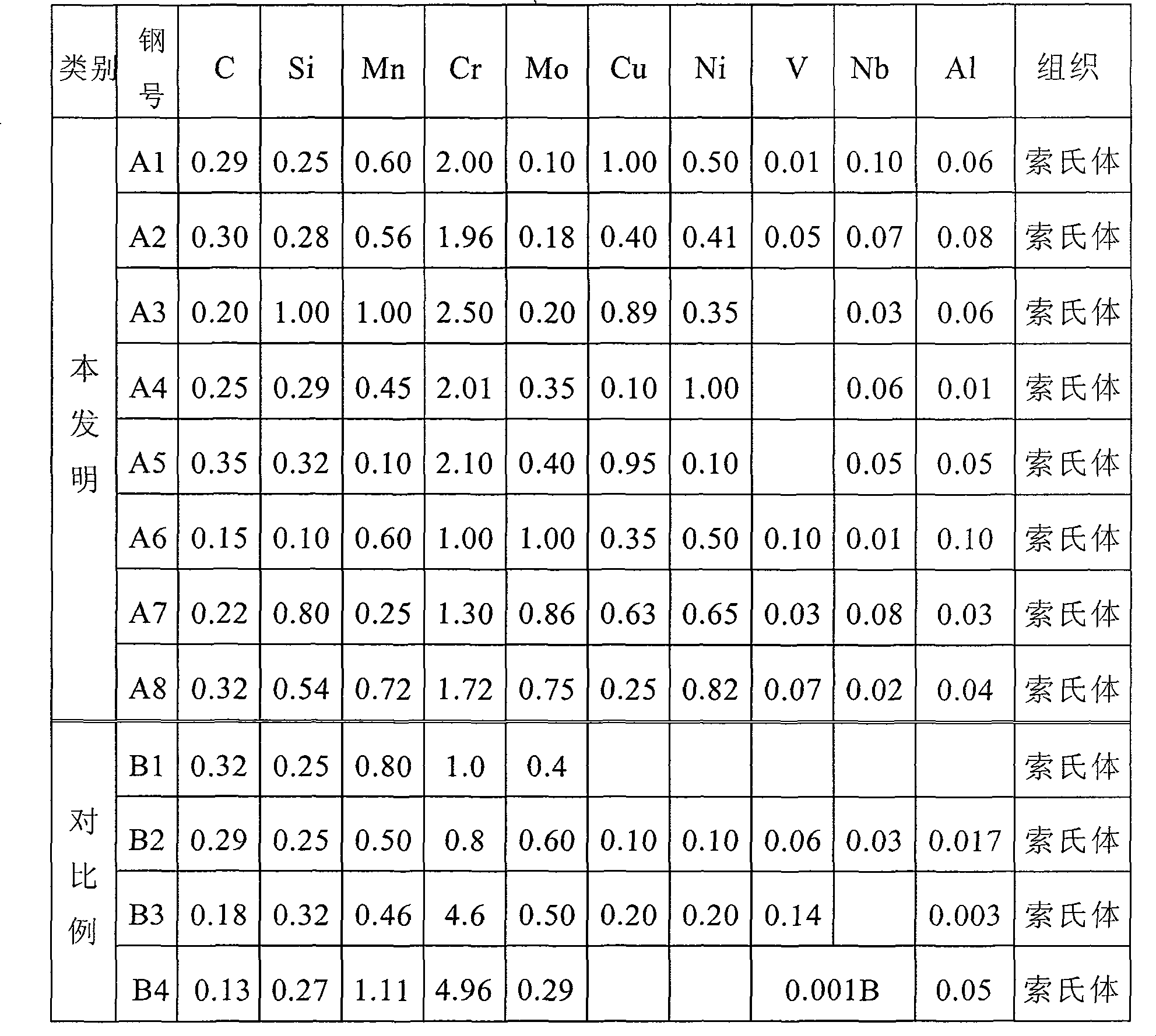

[0033] Refer to Table 1 for the examples of the present invention, and Table 2 shows the performance comparison of the present invention and comparative examples.

[0034] Table 1

[0035]

[0036] Table 2 shows the chemical composition of test steel, A1-A8 is the alloy steel of the present invention, B1-B4 is comparative example, wherein B1, B2 are the P110 common and C110 sulfur-resistant steel pipes commonly used in oil fields at present respectively, and B3, B4 are respectively Comparing the composition of patent alloy steel.

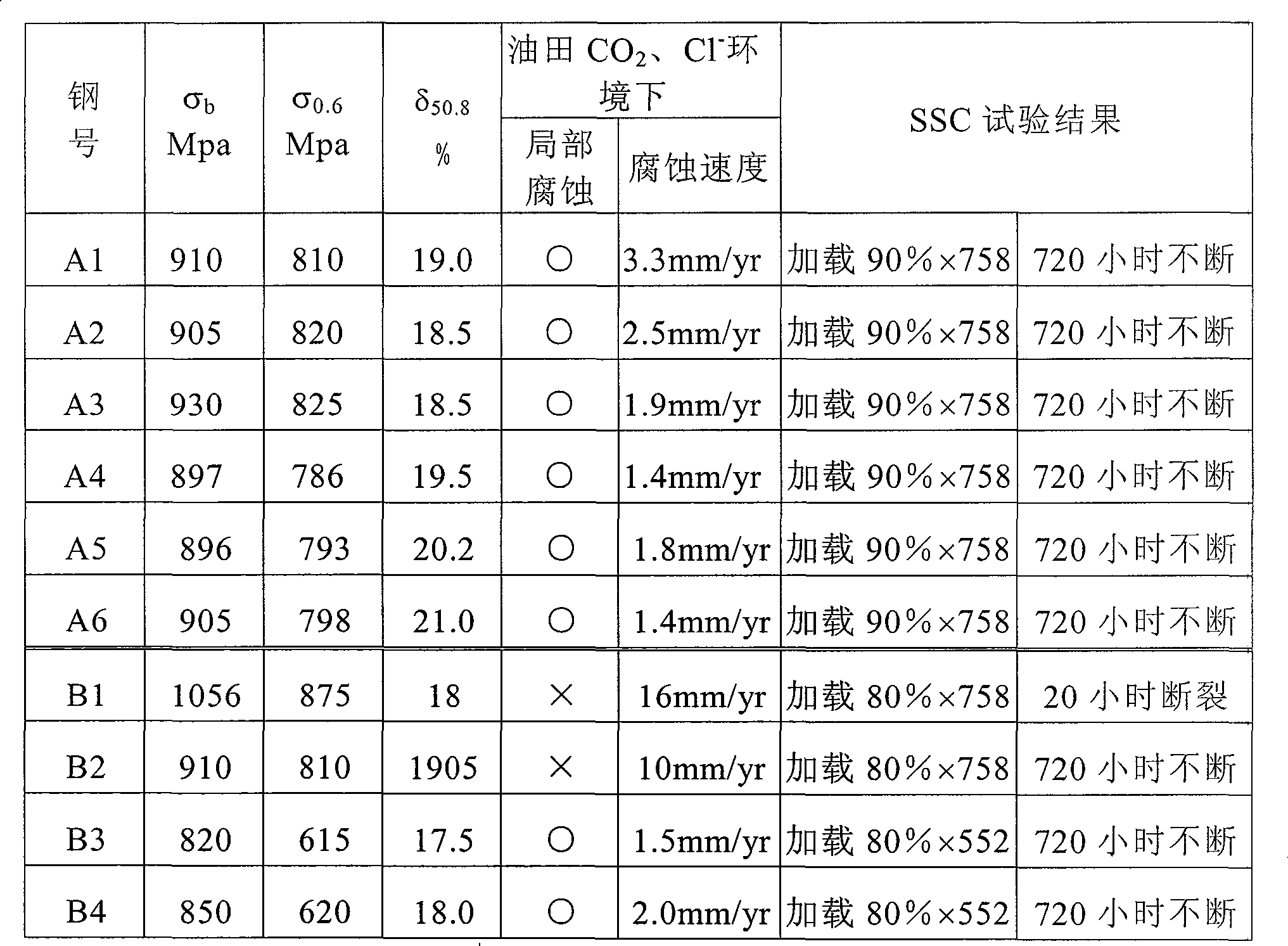

[0037] Table 2

[0038]

[0039] Note: The test condition is Na + +K + : 17183.69mg / L, HCO 3 - : 122.04mg / L, Cl - : 33687mg / L, SO 4 2- : 1440.9mg / L, Fe 2+ : 100mg / L, Fe 3+ : 30mg / L, Ca 2+ : 1603.2mg / L, Mg 2+ : 641.5mg / L, PH=6.0, test temperature: 110°C, CO 2 Partial pressure: 2.0Mpa, flow velocity: 1.5m / s.

[0040] ○: Indicates no localized corrosion; ×: Indicates localized corrosion.

[0041]After the alloy steel of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com