Suckling pig feed tempering equipment and working method thereof

A technology of conditioning equipment and working methods, which is applied in feed, food preservation, food science, etc., can solve the problems of short conditioning time, low conditioning temperature, and low maturity of materials, and achieve high nutritional value and sufficient conditioning , the effect of high maturity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

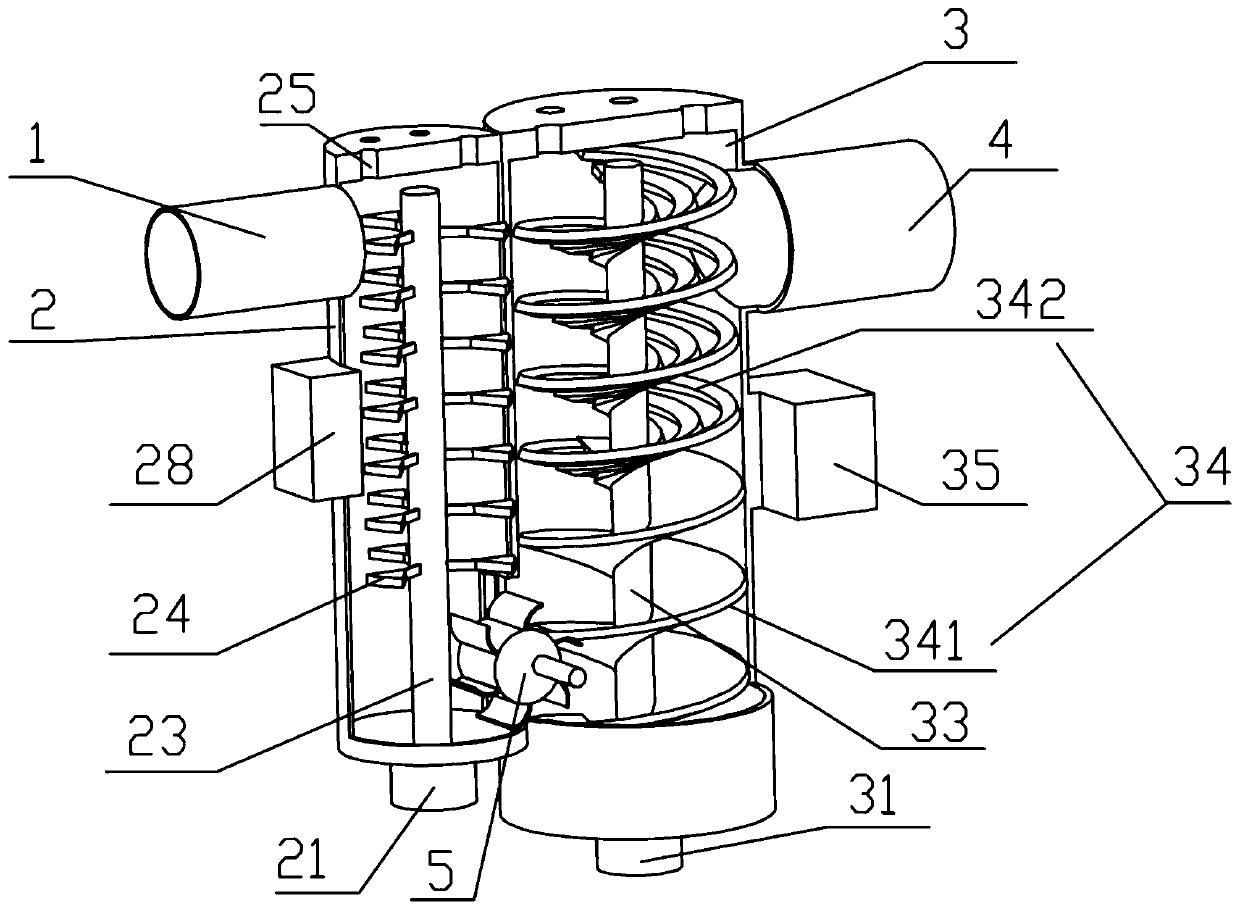

[0031] Such as Figure 1-5 , a suckling pig feed conditioning equipment comprising a feed port 1, a first cavity 2, a second cavity 3, and a discharge port 4;

[0032] The feed port 1 is located on the upper part of the first cavity 2, and the feed port 1 communicates with the first cavity 2; the bottom of the first cavity 2 is fixedly installed with a first motor 21, A first rotating shaft 23 is fixedly installed on the output shaft of the first motor 21, and the first rotating shaft 23 is connected with a first blade 24;

[0033] A steam inlet 25 is installed on the top of the first cavity 2, and the moving direction of the steam in the steam inlet 25 is consistent with the forward direction of the material in the first cavity 2;

[0034] A microwave device 28 is installed on the side of the first cavity 2;

[0035] The bottom of the first cavity 2 communicates with the bottom of the second cavity 3;

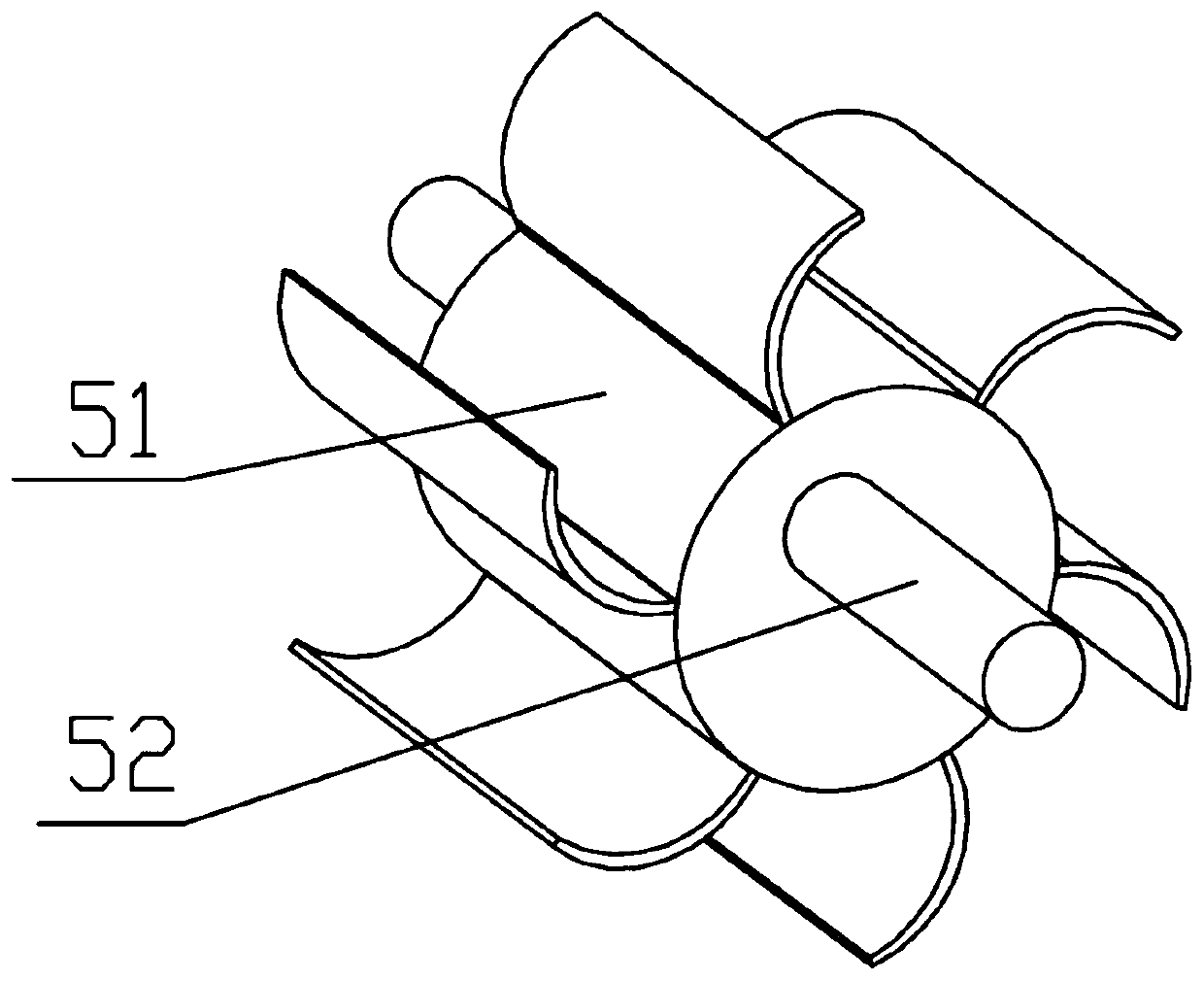

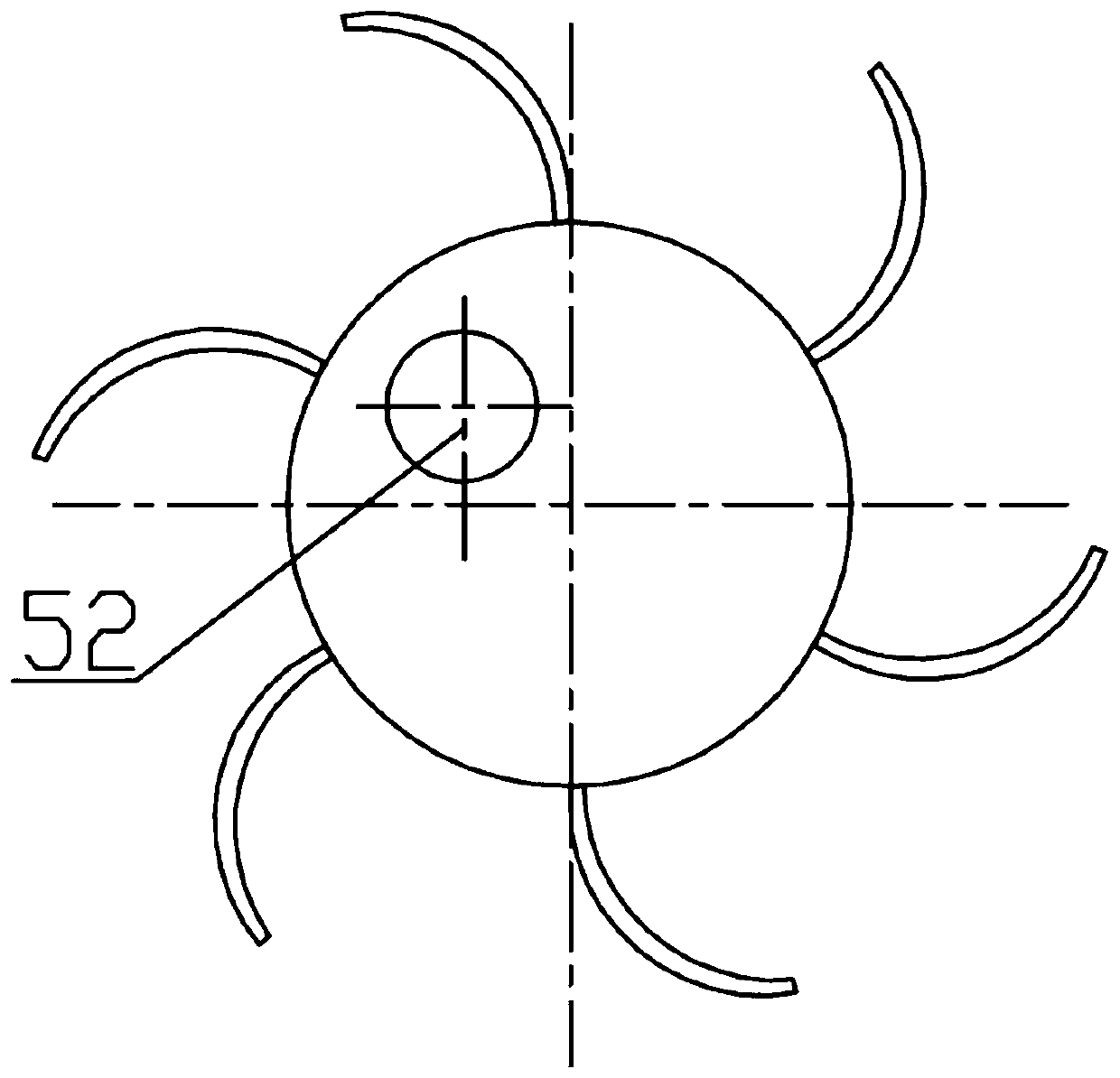

[0036] A guide wheel 5 is installed at the place where the bottom of t...

Embodiment 2

[0048] Such as Figure 1-5 , the working method of the first suckling pig feed conditioning equipment realized on the basis of embodiment 1,

[0049] When the conditioning equipment for suckling pig feed is working, the material passes through the feed inlet, the first cavity, and the second cavity in sequence, and is discharged through the discharge port; without applying microwave and ultrasonic waves, the ripening degree of the suckling pig feed after conditioning is measured as 21.3%, and the pulverization rate after molding is 12.5%.

Embodiment 3

[0051] On the basis of Example 1, when the conditioning equipment for suckling pig feed is working, the first stage of conditioning is carried out in the first cavity 2, the microwave power is 23kW, and the vacuum degree is 0.06MPa; the conditioning time is 8s; then enter the second stage. The cavity 3 is subjected to the second stage of conditioning: the ultrasonic power is 3250W, the frequency is 13kHz, and the conditioning time is 27s. It is measured that the ripening degree of the suckling pig feed after conditioning is 36.8%, and the pulverization rate after molding is 3.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com