Physical full tempering method for ultrathin glass

An ultra-thin glass and physical technology, which is applied in glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of poor tempering uniformity, weak tempering strength, poor flatness, etc., and achieve good tempering effect and high tempering strength. High, unbreakable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

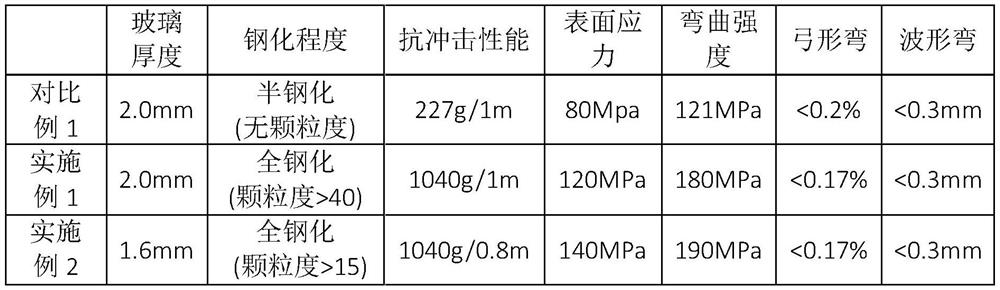

[0032] A method for physical full tempering of ultra-thin glass, the thickness of the ultra-thin glass is 2.0mm, and the size is 2089×1033mm. The tempering method includes the following specific steps:

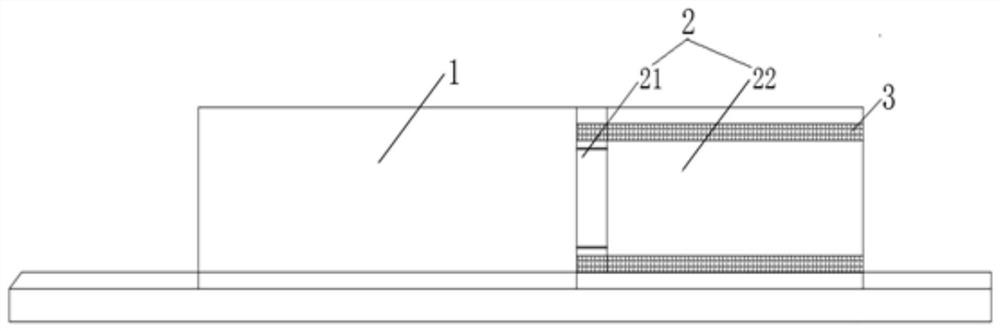

[0033] S1. Transport the above-mentioned ultra-thin glass to the heating section 1 of the tempering equipment through a non-contact transmission method (air flotation transmission method) and heat it to 680°C (deformation point temperature), and keep it warm at this temperature for 100 seconds; in the tempering equipment There is a heating section 1 and a cooling section 2, the initial section of the cooling section 2 is a quenching section 21, and the follow-up of the quenching section is a conventional cooling section 22;

[0034] S2. Transport the above-mentioned heated ultra-thin glass to the quenching section 21 of the tempering equipment by means of non-contact transmission for quenching first, and the cooling time in the quenching section 21 is 5 seconds. The ultra-thin...

Embodiment 2

[0036] A method for physical full tempering of ultra-thin glass, the thickness of the ultra-thin glass is 1.6mm, and the size is 2089×1033mm. The tempering method includes the following specific steps:

[0037] S1. Transport the above-mentioned ultra-thin glass to the heating section 1 of the tempering equipment through a non-contact transmission method (air flotation transmission method), heat it to 710°C (deformation point temperature), and keep it warm at this temperature for 70 seconds;

[0038]S2. Transport the above-mentioned heated ultra-thin glass to the quenching section 21 of the tempering equipment by means of non-contact transmission for quenching first, and the cooling time in the quenching section 21 is 3 seconds. The ultra-thin glass is transported into the conventional cooling section 22 for cooling. The pressure during cooling in the conventional cooling section 22 is 13000 Pa, and the cooling time is 50 seconds; the tempering process of the ultra-thin glass is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com