Patents

Literature

92results about How to "Even impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

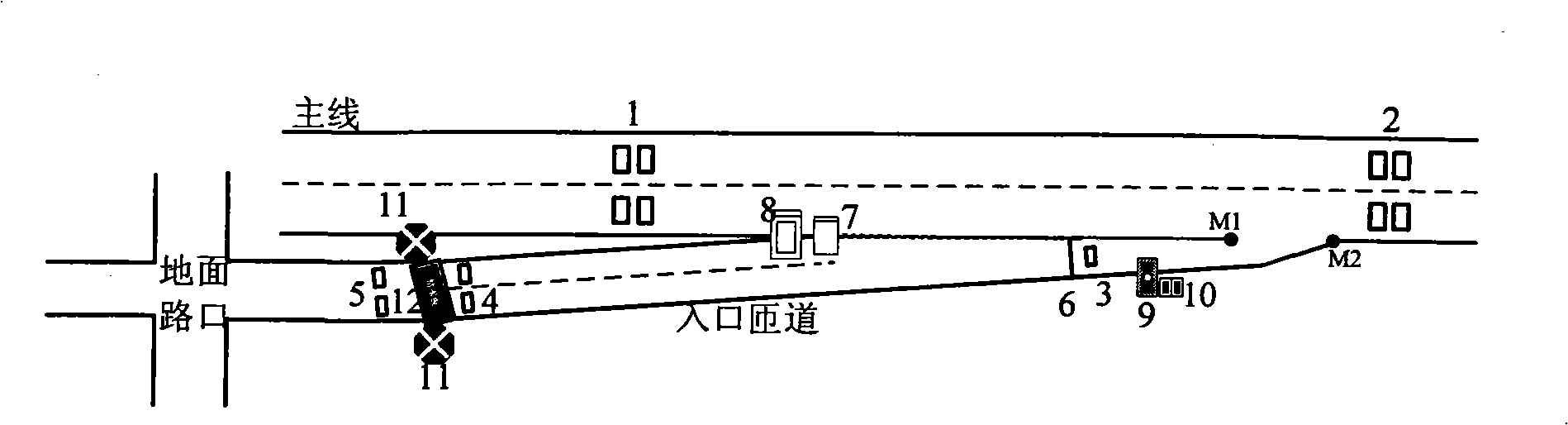

Road self-adapting entrance ramp afflux control equipment and method

InactiveCN101299298APrevent queue overflowEven impactControlling traffic signalsMessage boardTraffic signal

The invention relates to a road self-adapting entry ramp afflux control device and a method thereof, used for adjusting the entry ramp afflux rate of the speedway or the city express way. The core device ramp afflux controller collects the traffic parameters of the flux, the speed, the occupancy and the like detected by the traffic parameter detectors in certain period, through the EXPAlinea arithmetic, the ramp afflux signal lamps change alternately to control the flux, also control the assistant devices of the ramp afflux down counter, the ramp port passing light and the message board and the like, which causes the integral device full of humanness. EXPAlinea arithmetic first adopts the dynamic target occupancy fundamental algorithm to obtain the elemental fundamental algorithm, then performs the smoothness according to the regulation of the last period or adopts the queue preference strategy according to the upstream and downstream of the main line and the ramp. The signal time assignment is the manifestation of the regulation obtained by the EXPAlinea control algorithm, to display by the traffic signal lamp. With the same regulation, the queue length of the ramp is different, and the different signal period and the green ratio are adopted.

Owner:SHANGHAI SEARI INTELLIGENT SYST CO LTD

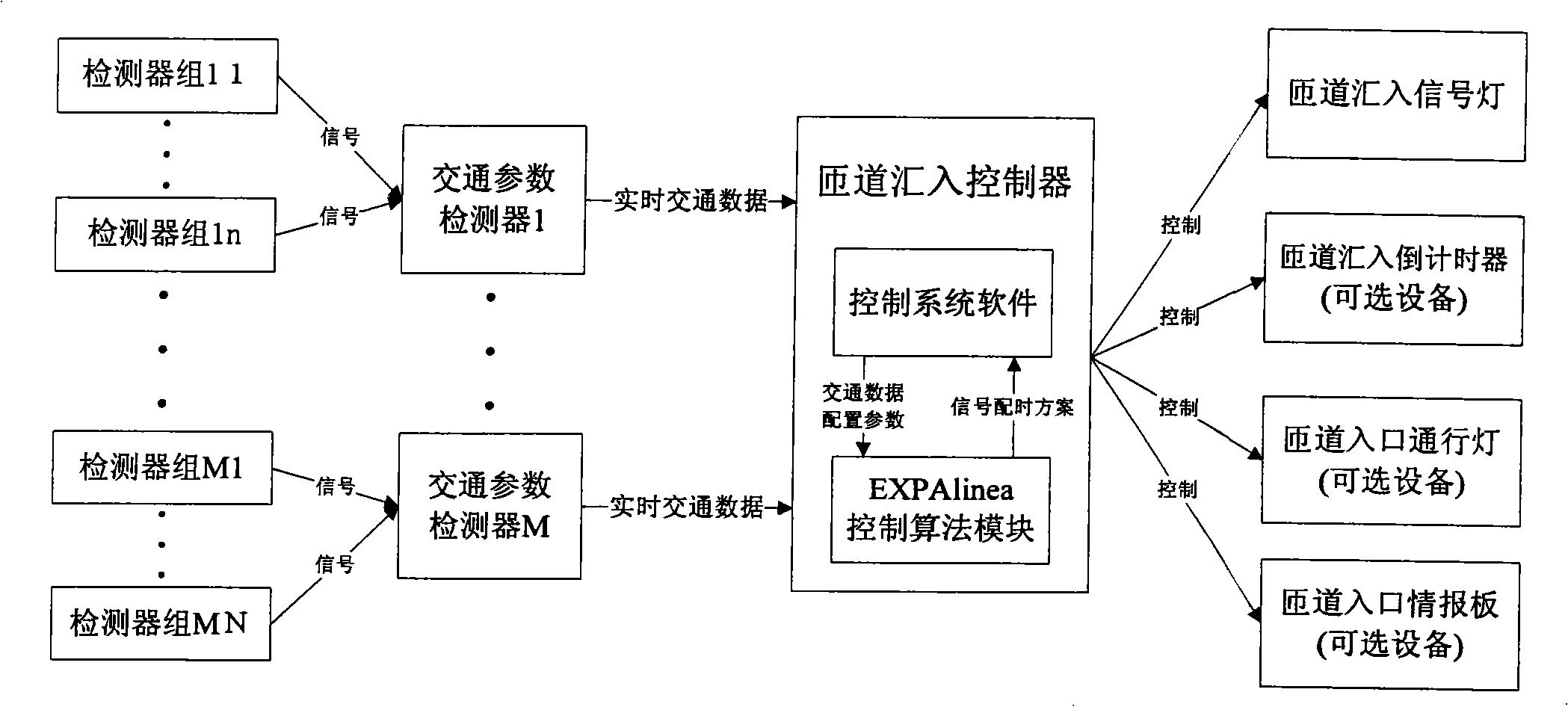

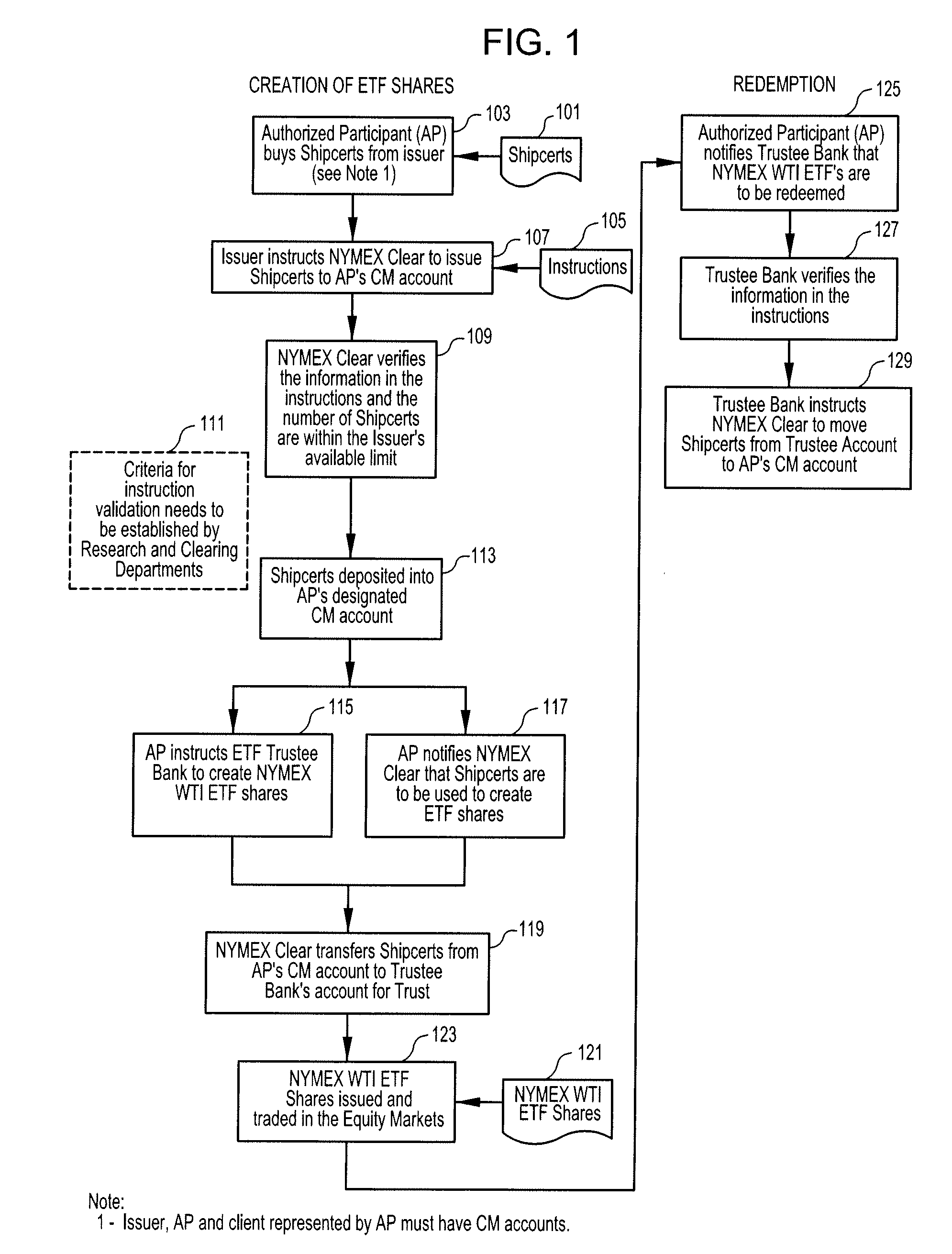

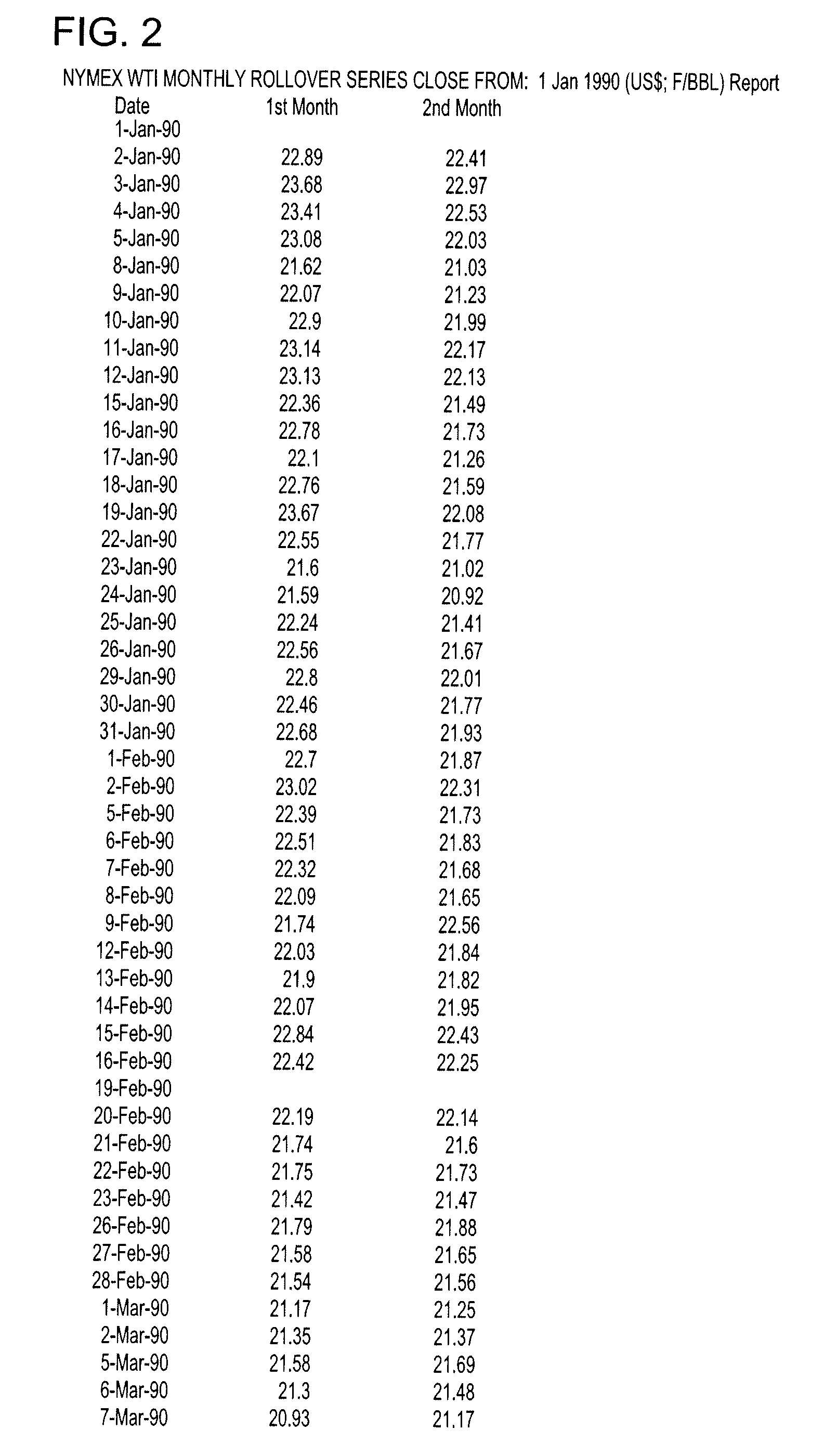

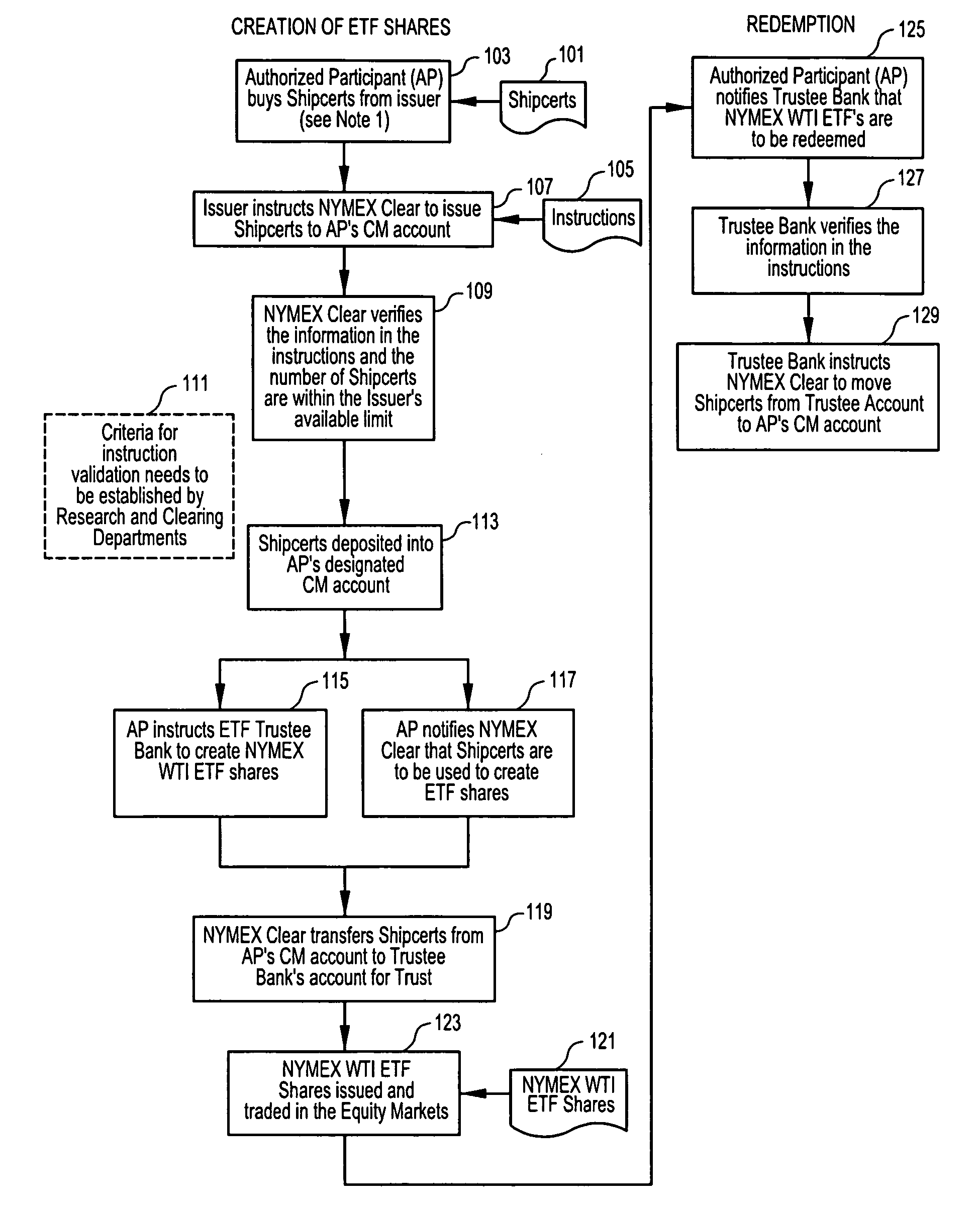

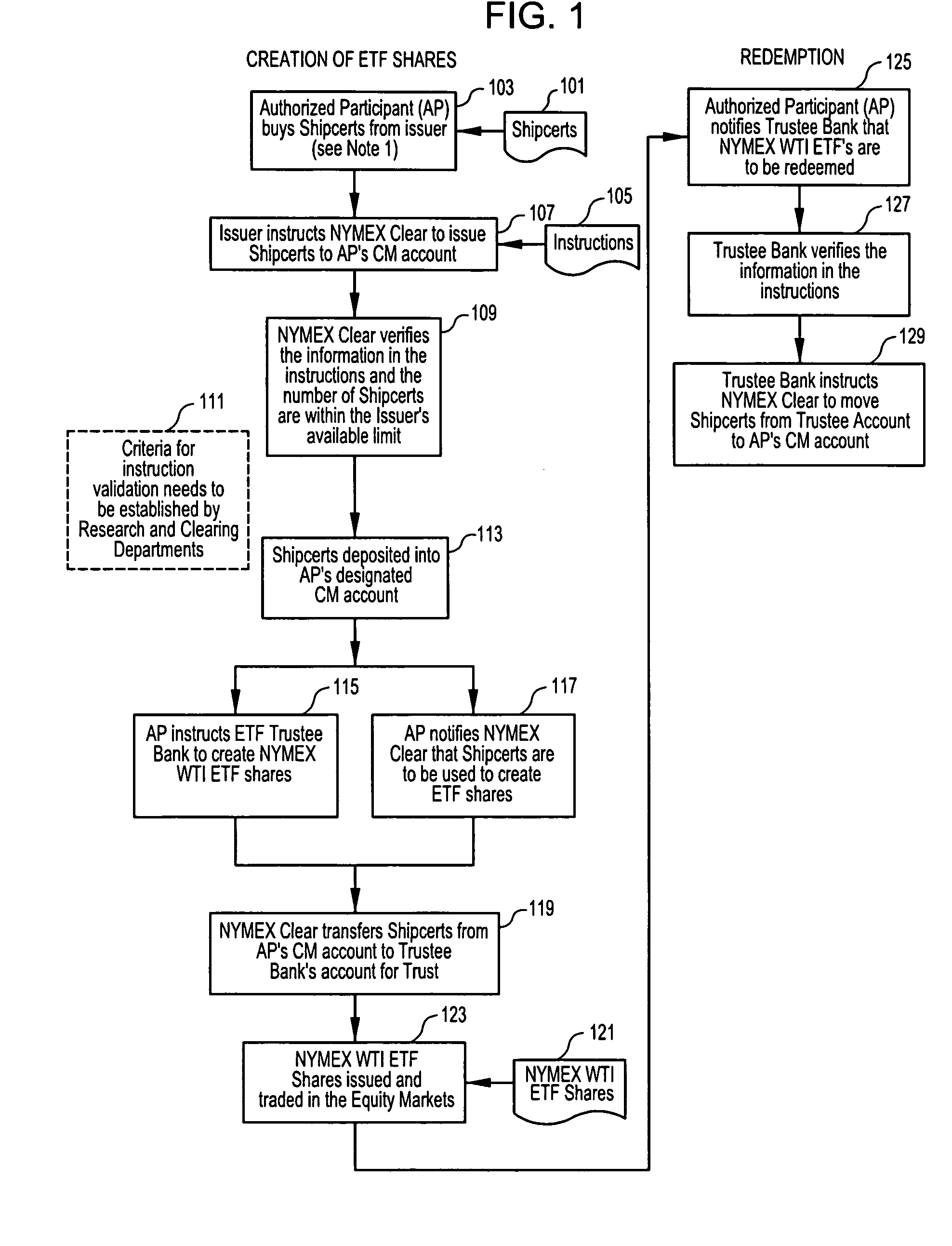

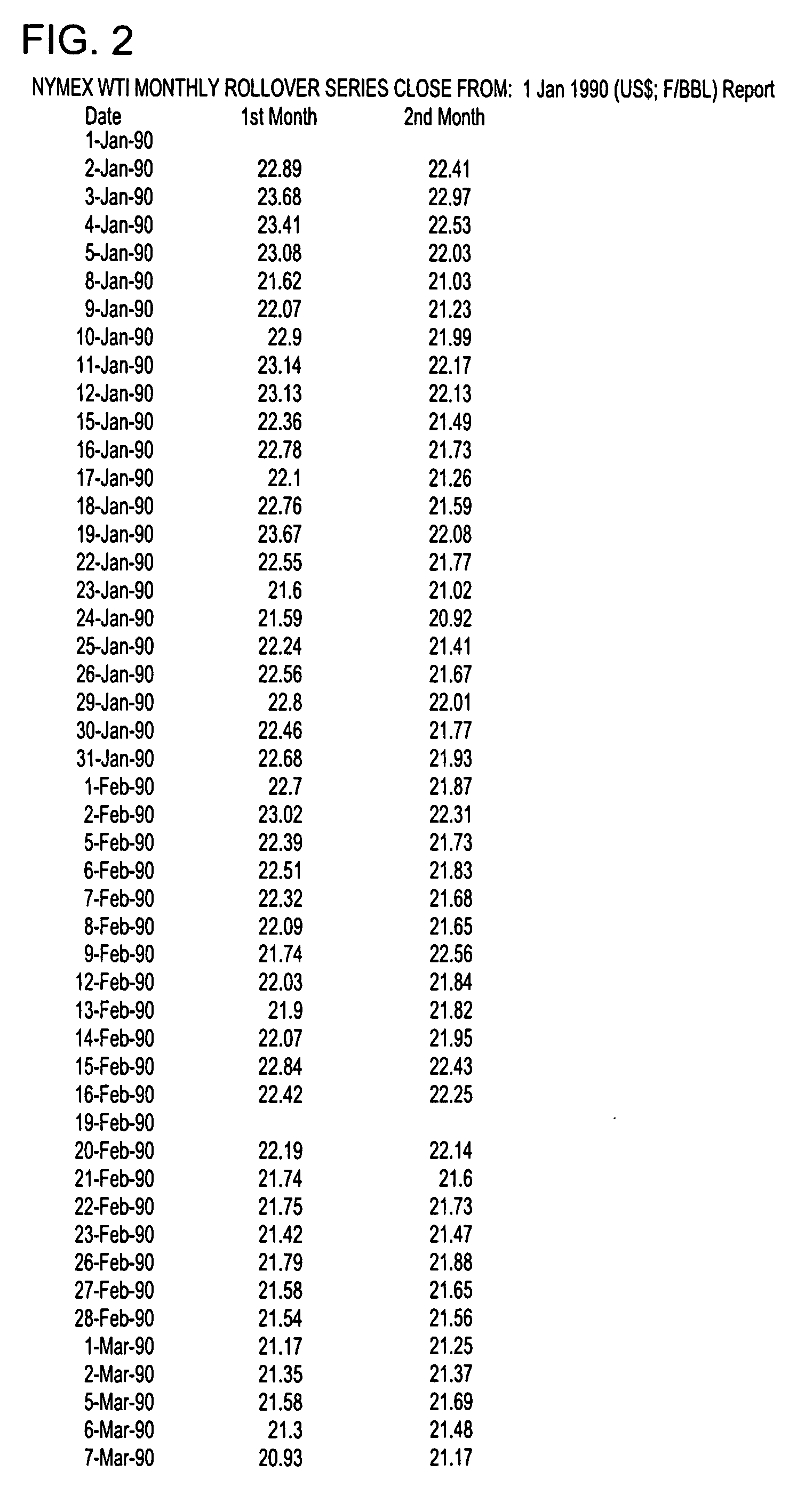

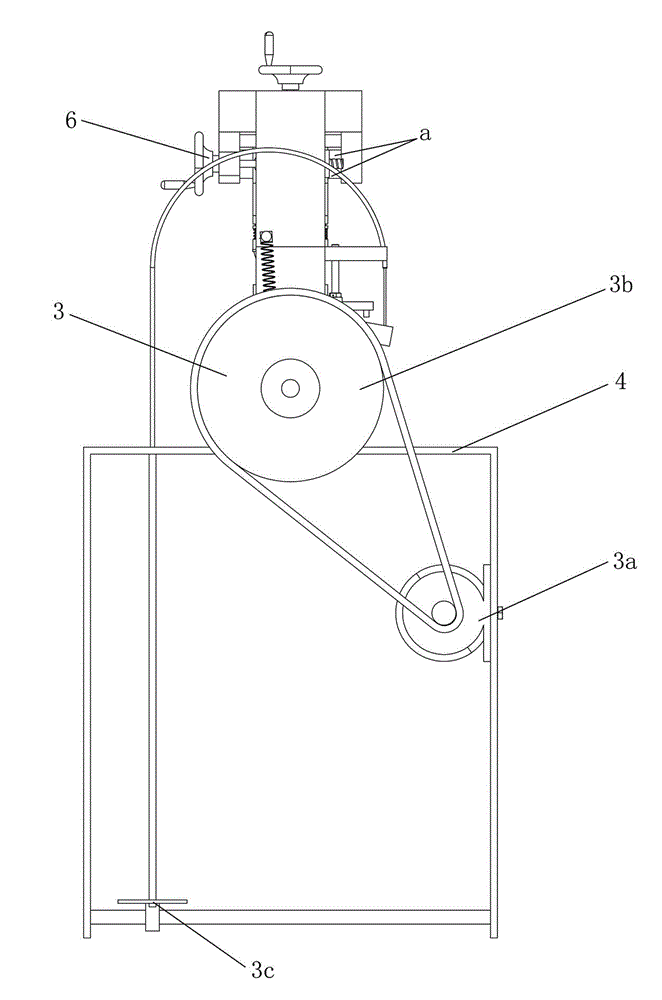

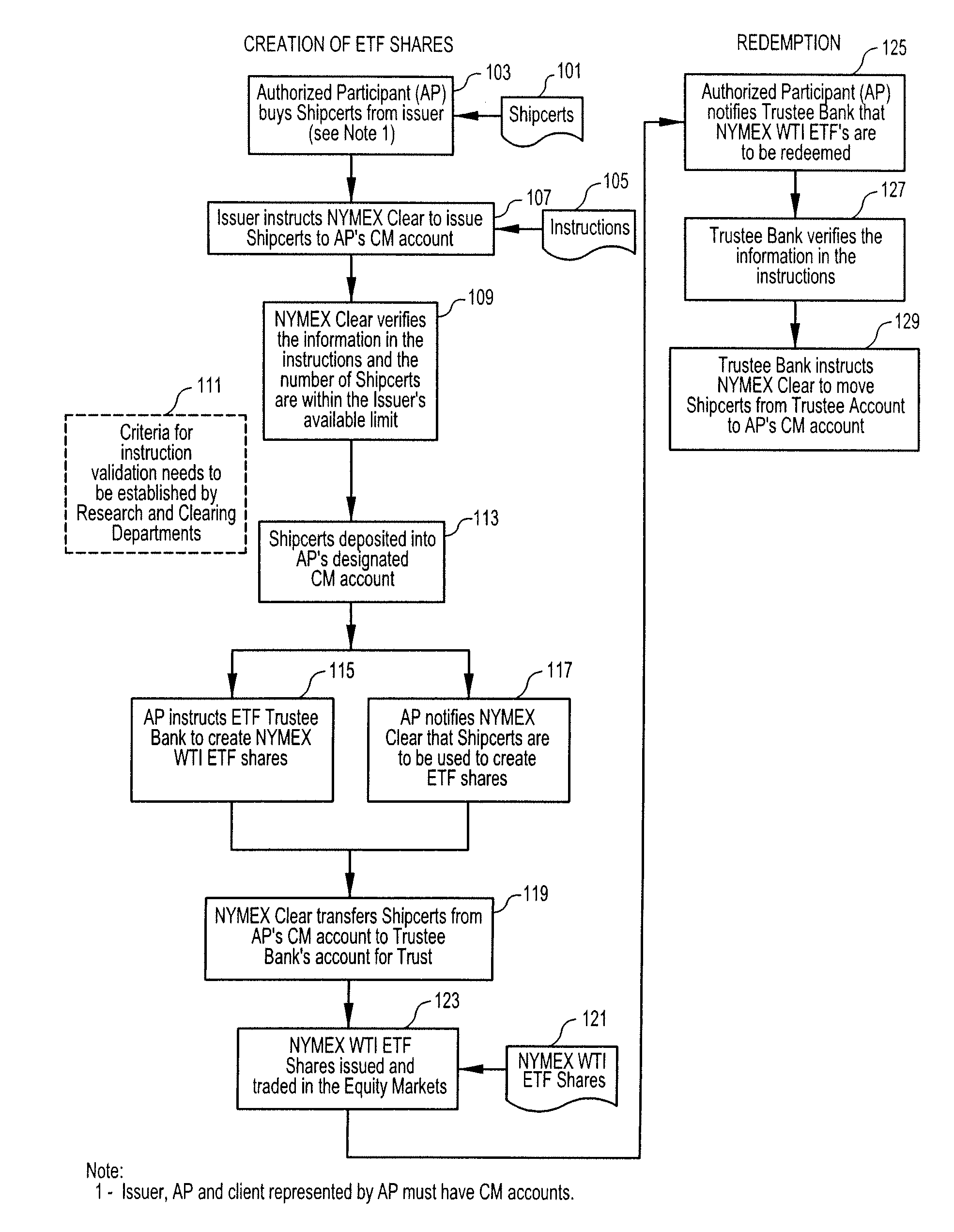

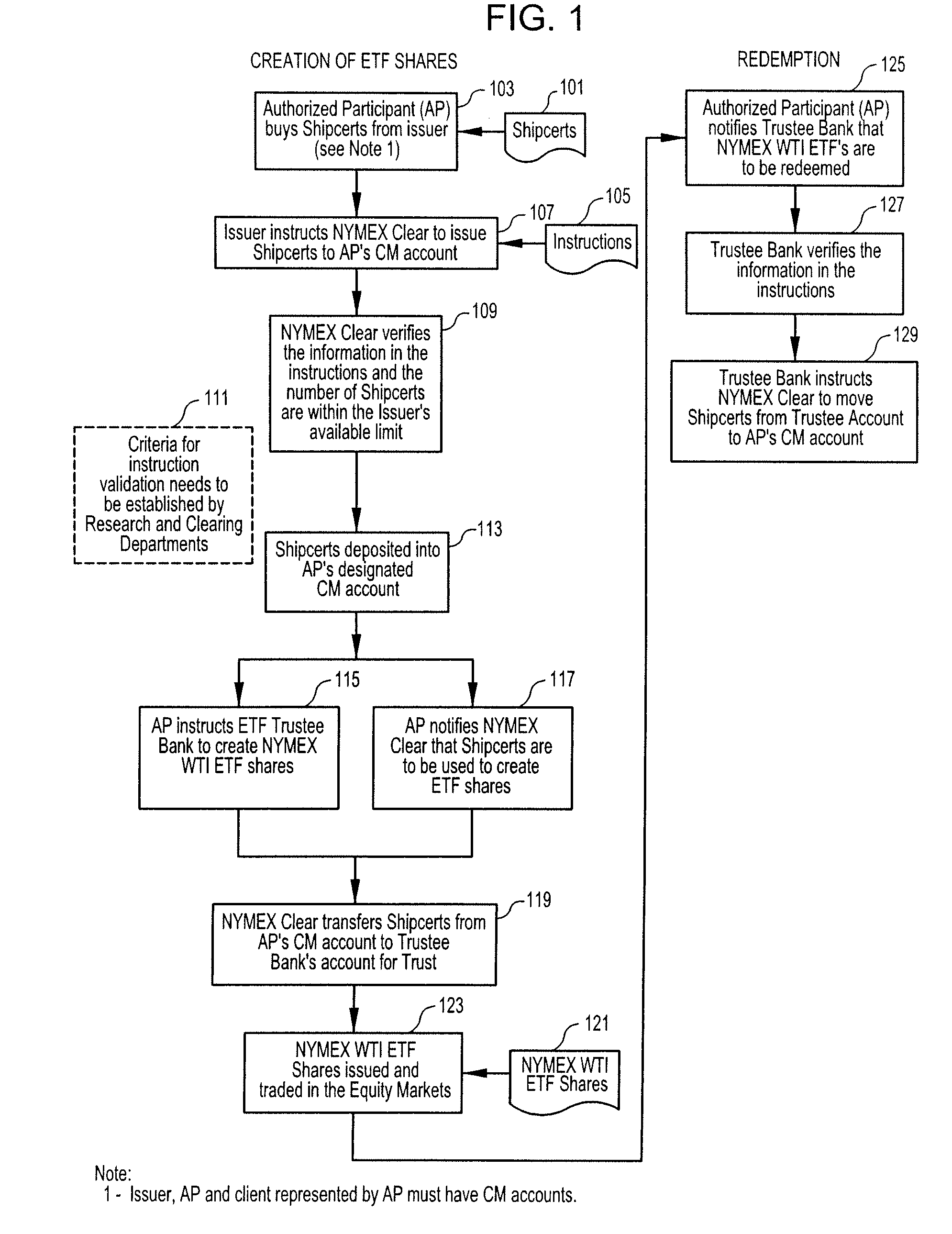

Commodities based securities and shipping certificate therefor

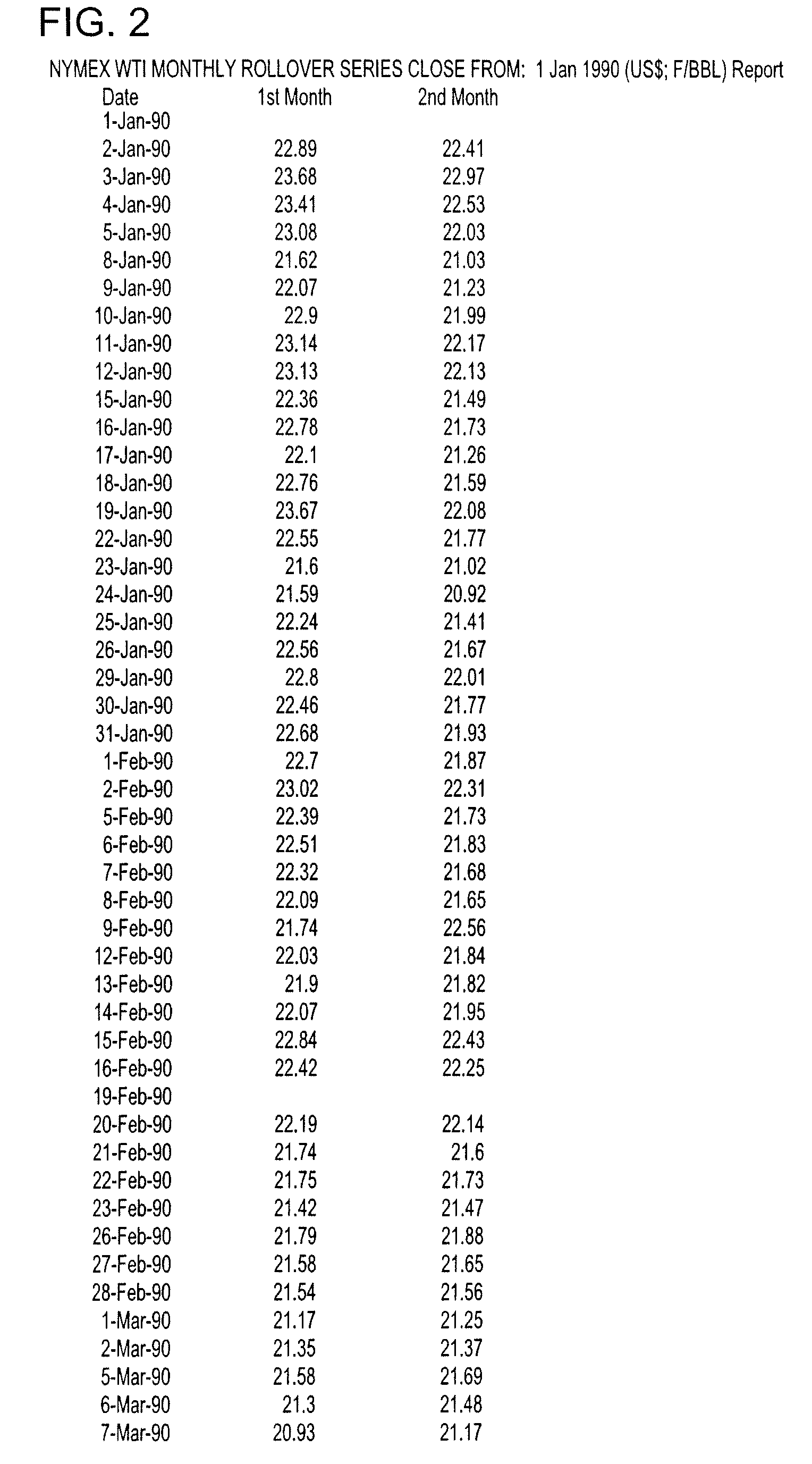

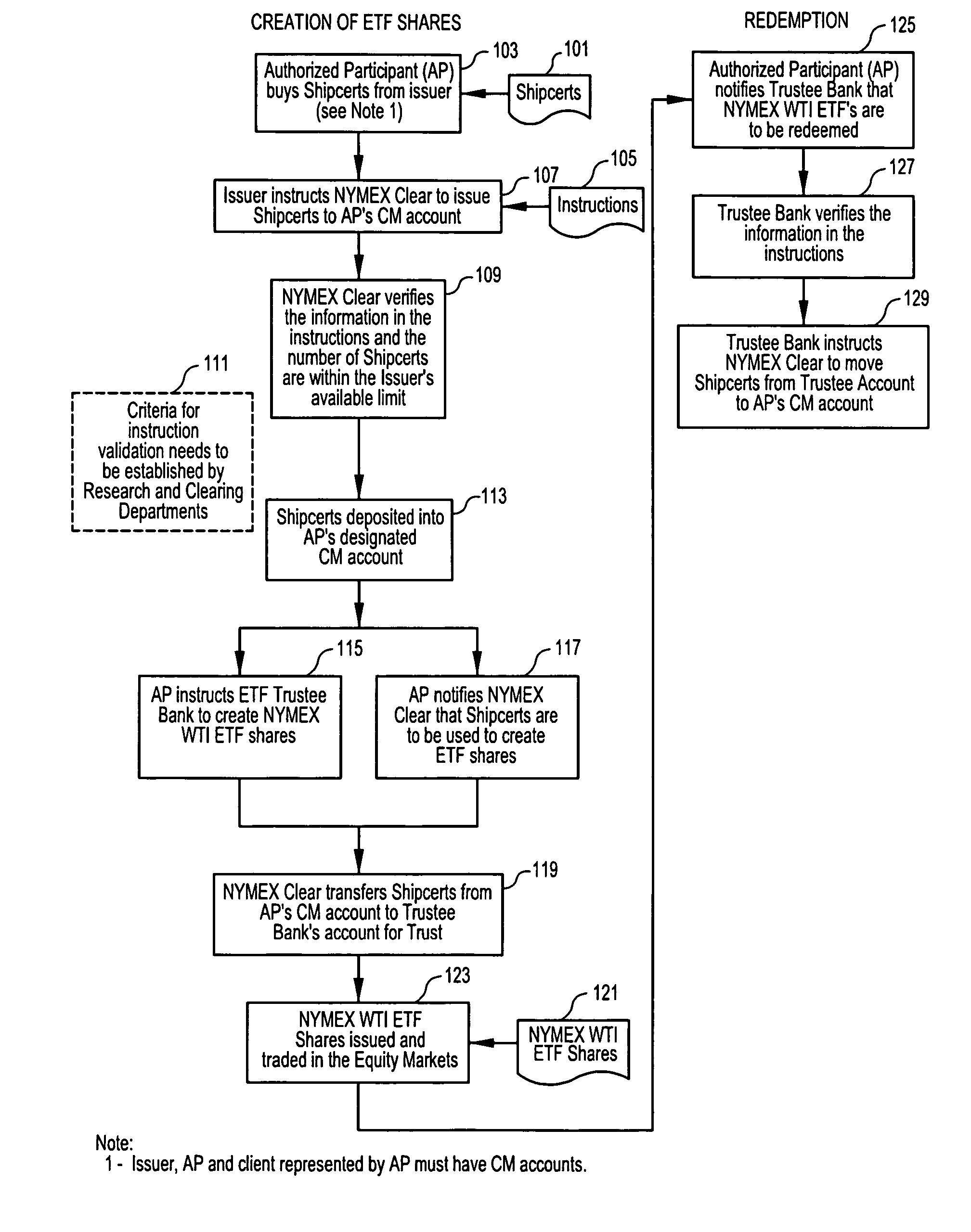

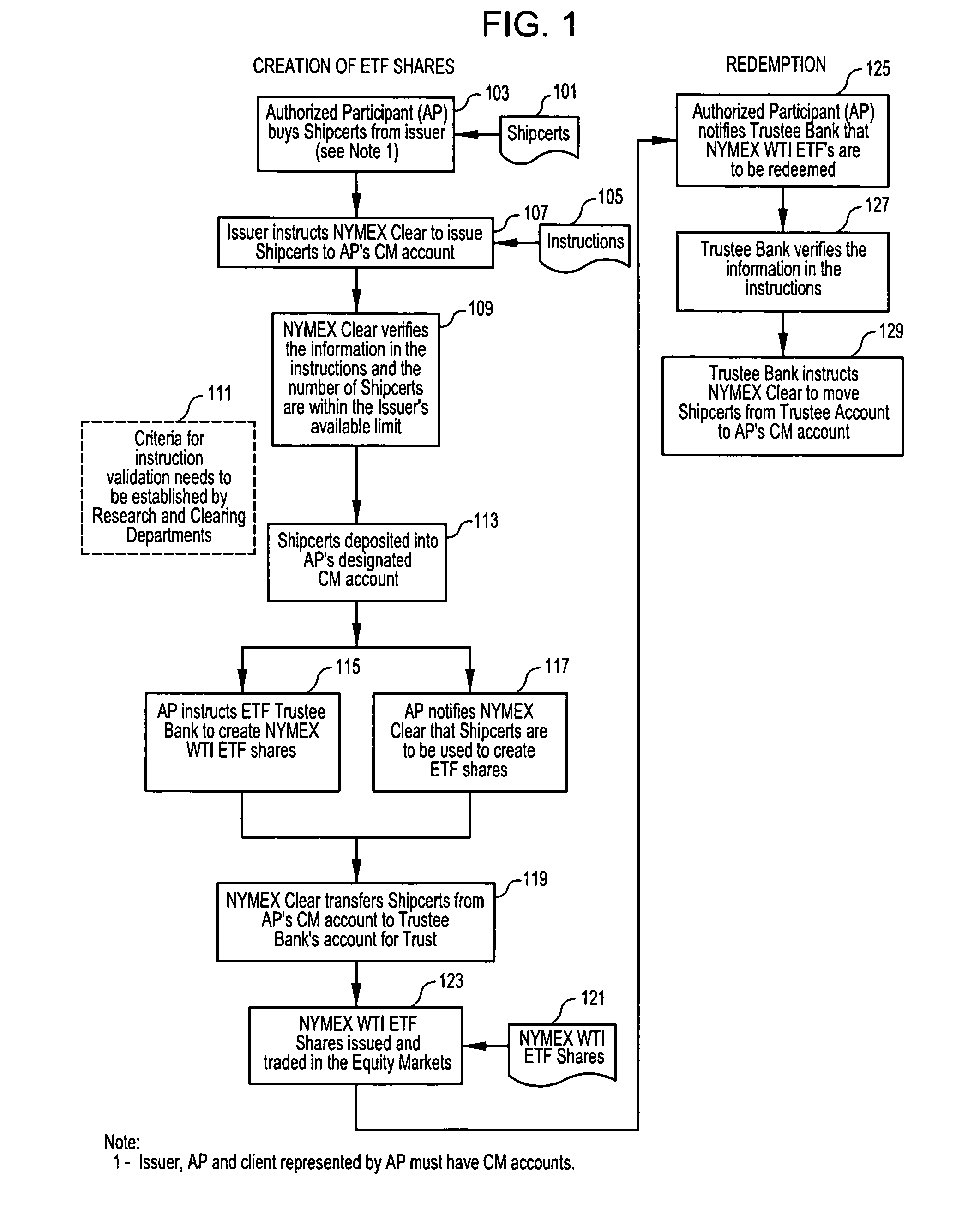

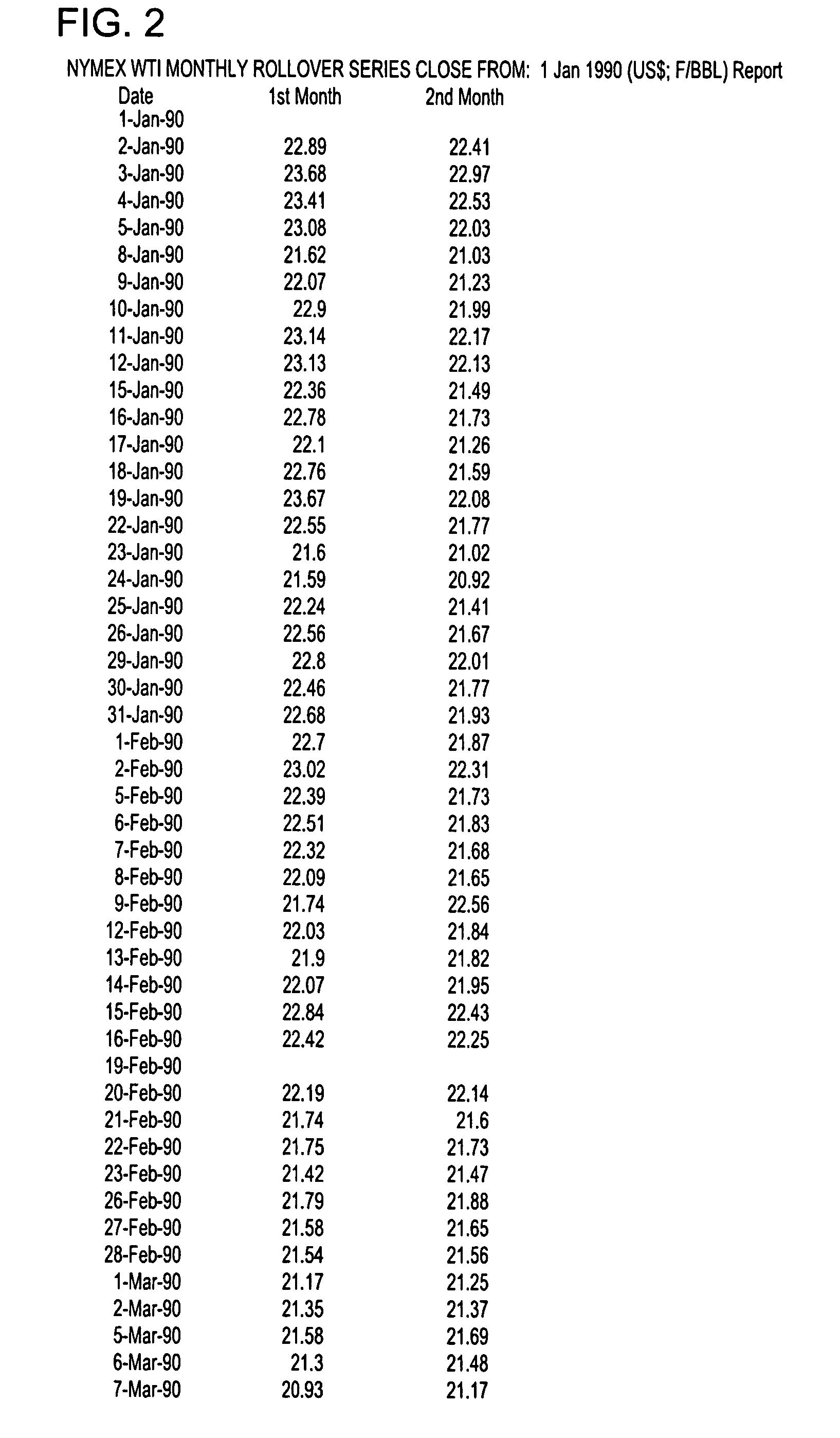

The subject invention pertains to securities, preferably exchange traded funds, or ETFs, relating to commodities subject to futures contracts in a commodities market. More specifically, the invention relates to shipping certificates for commodities that dynamically compensate for commodity “roll neutrality” adjustments by altering the quantity of commodity associated with the shipping certificate, as opposed to a cash adjustment. The subject invention also pertains to the underlying “roll neutrality” adjustment related to a commodities market futures transaction and to the resulting ETF valuation as follows: ΣPiBi, where Pi is the price of the relevant contract month, Bi is the number of commodity units for that month, and i is the time index.

Owner:NEW YORK MERCANTILE EXCHANGE

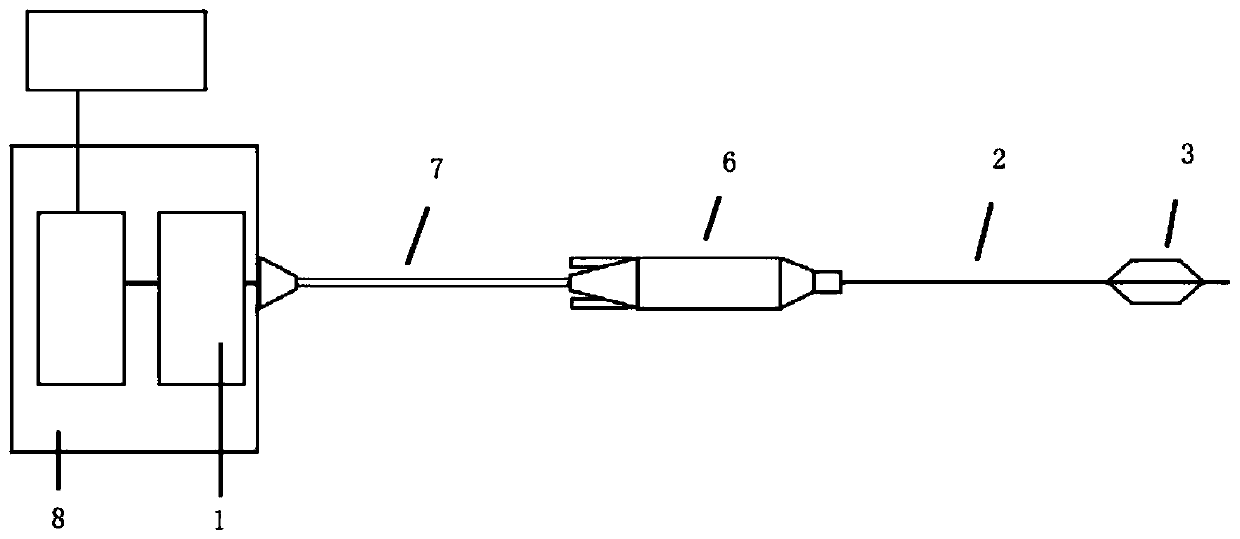

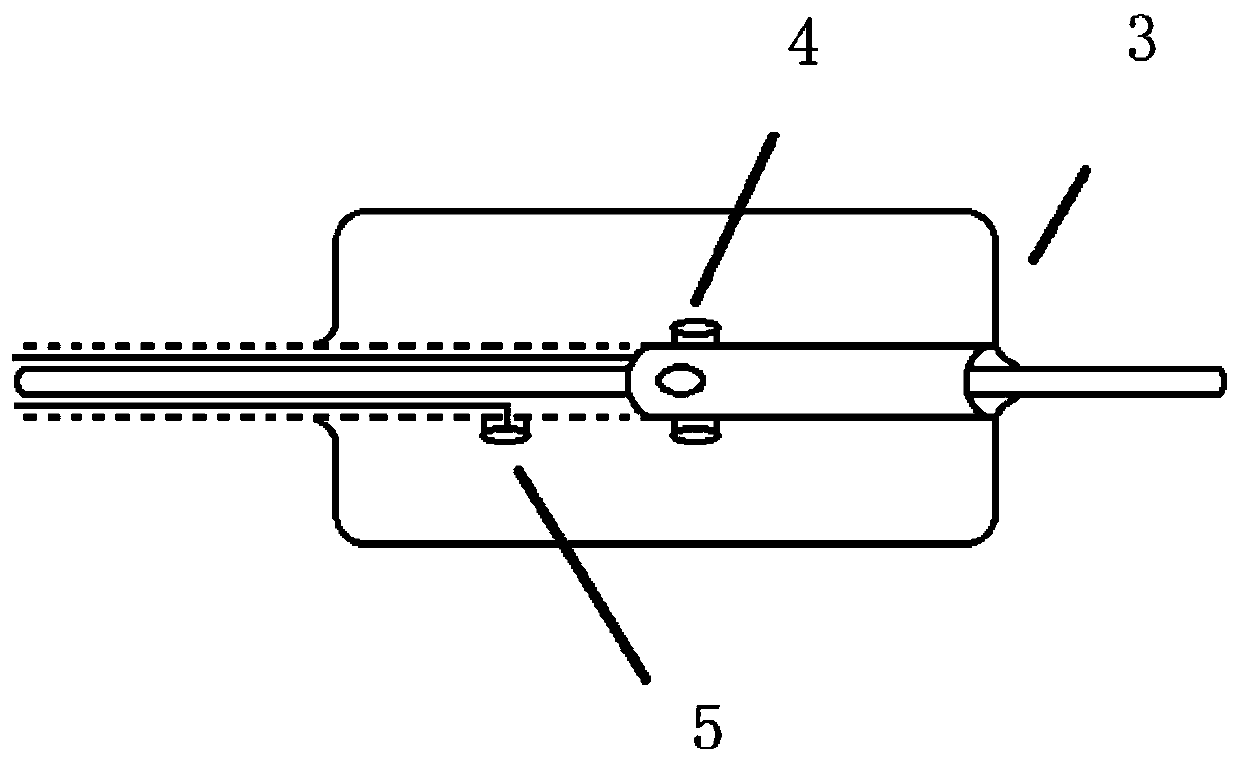

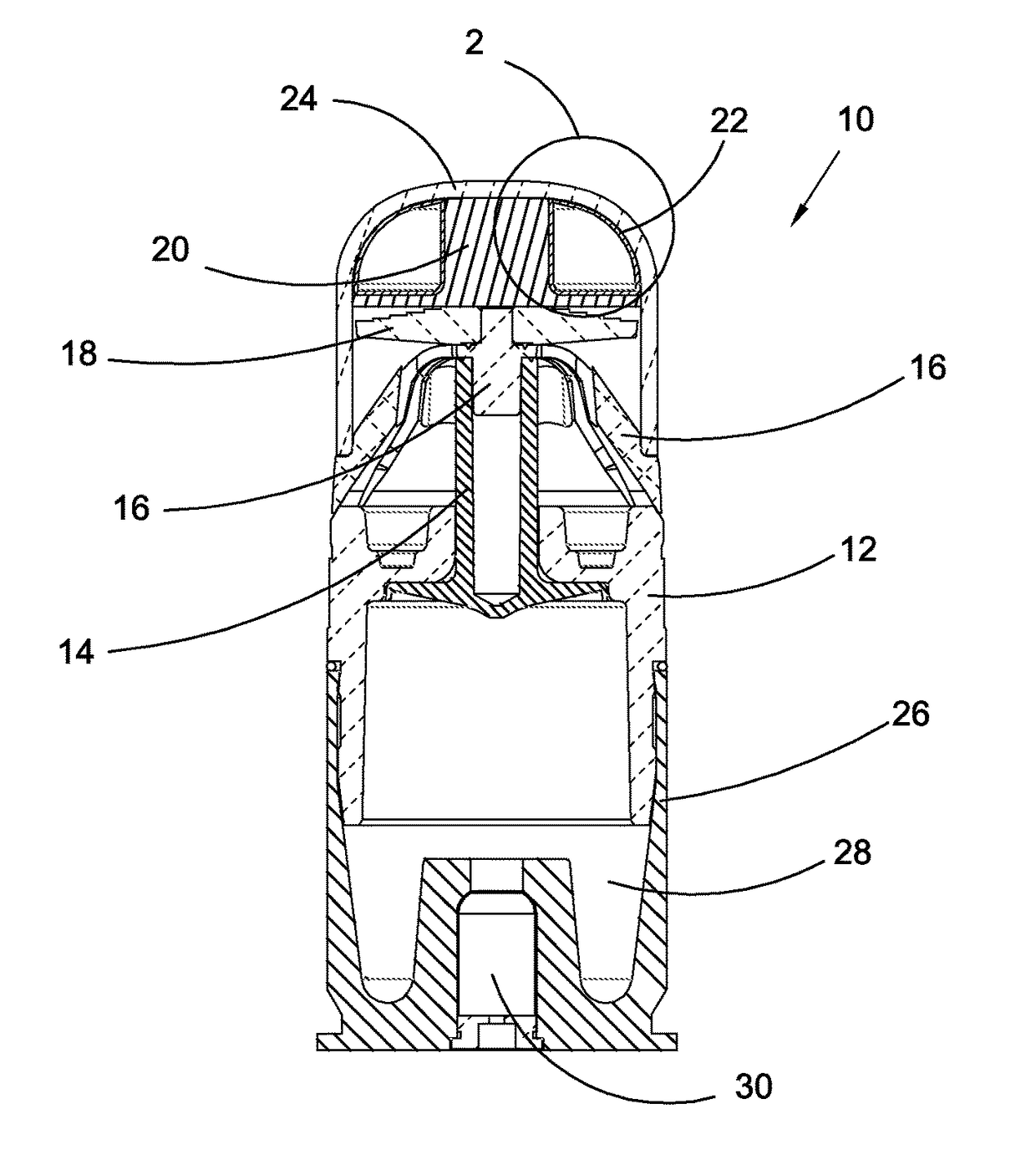

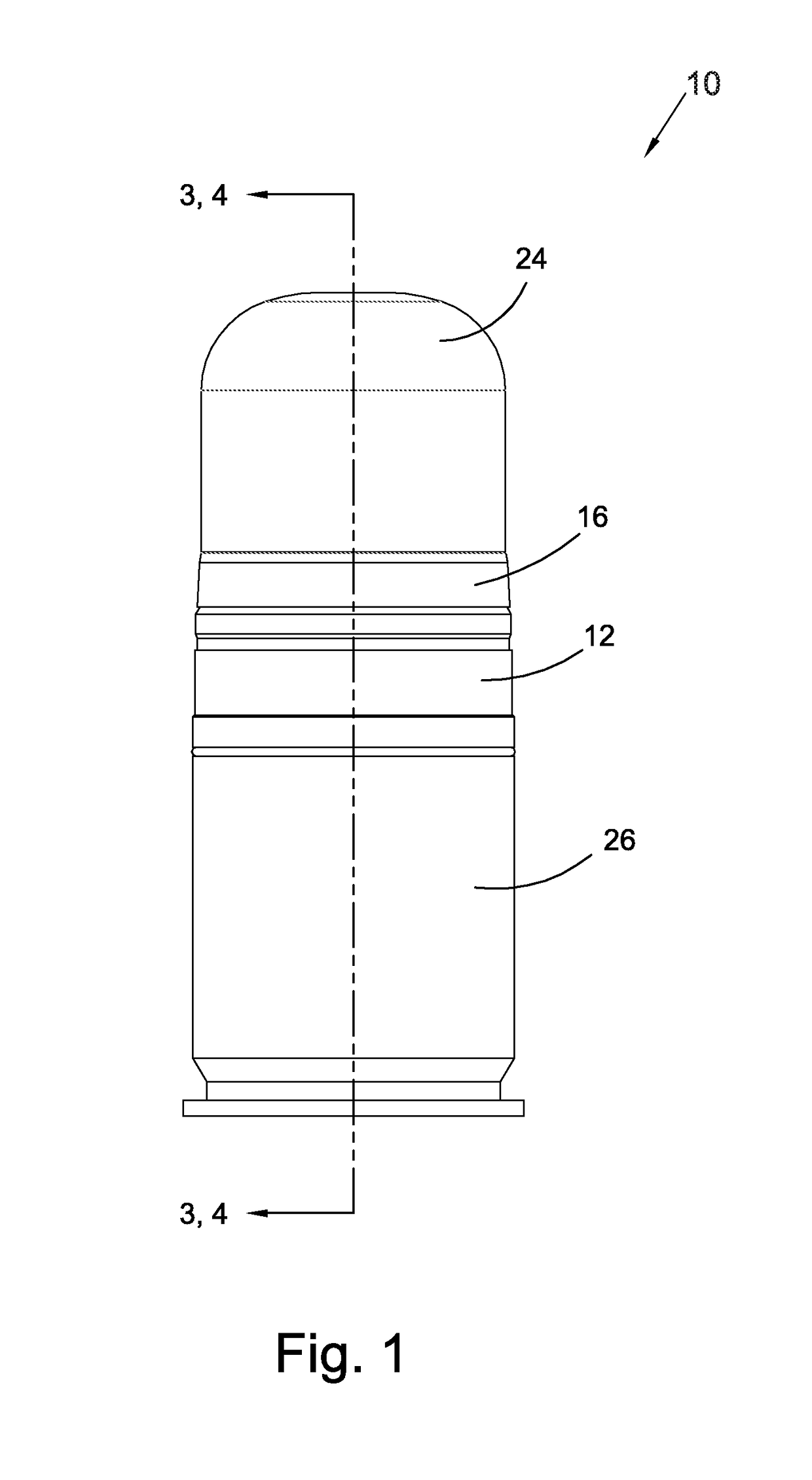

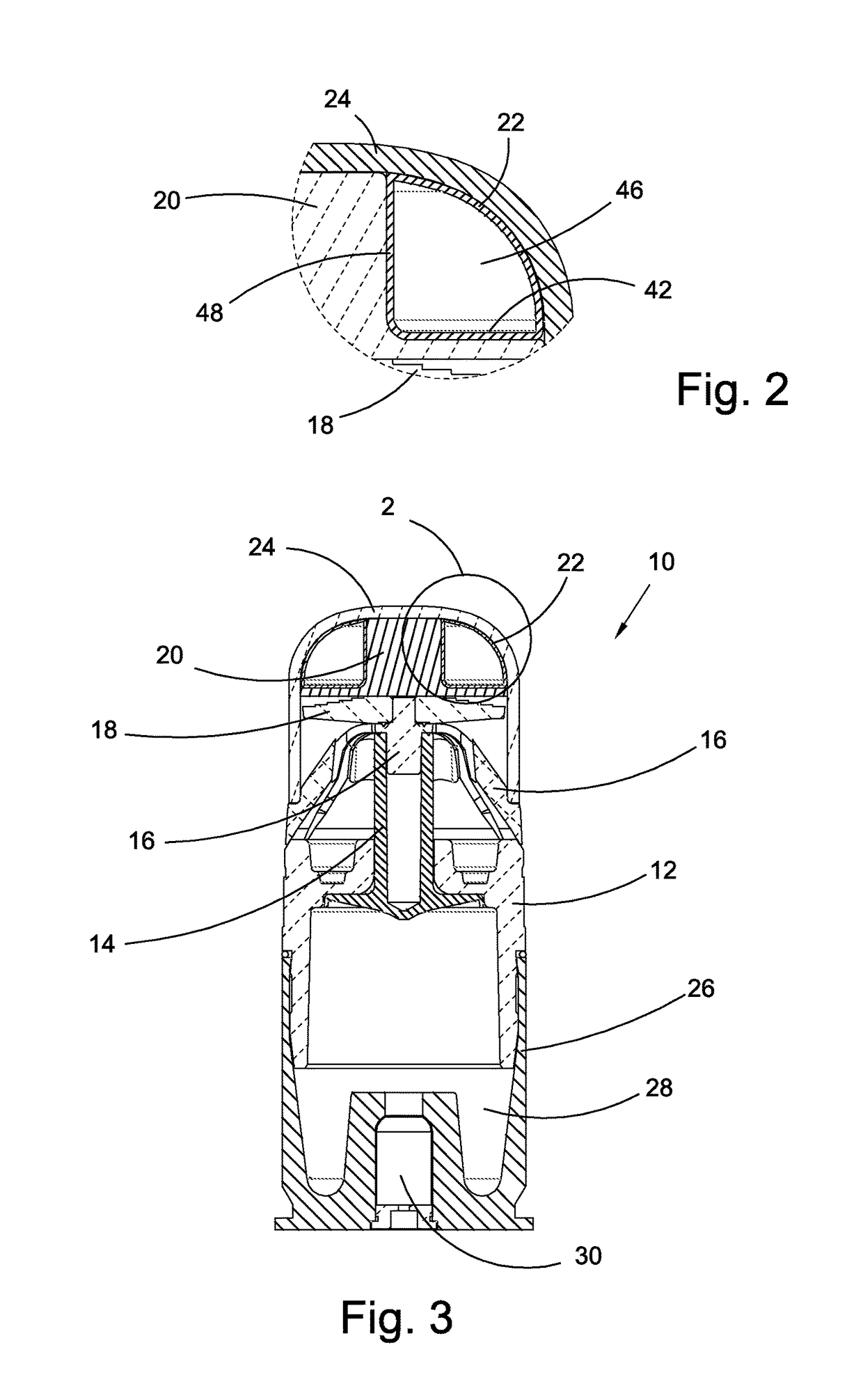

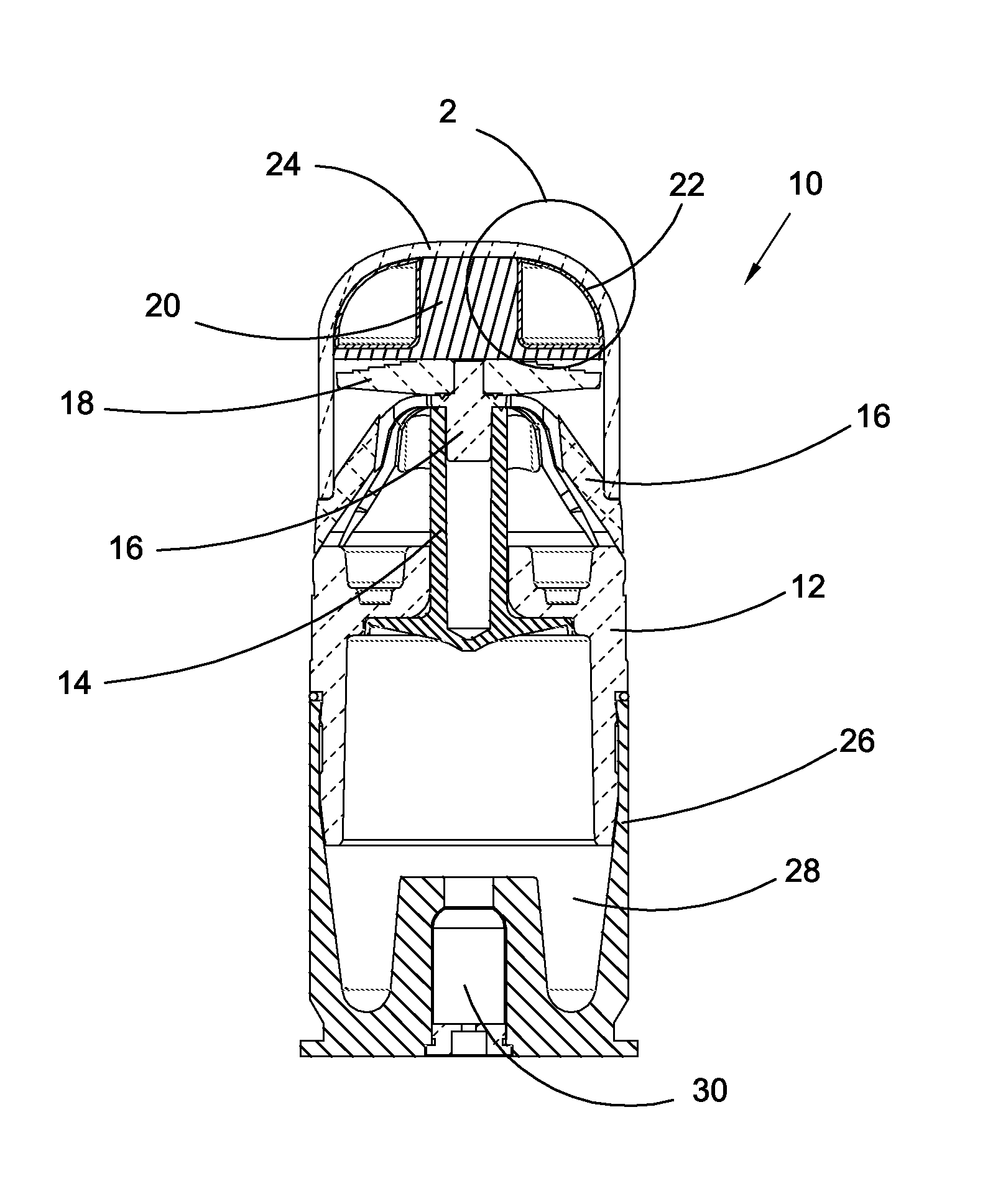

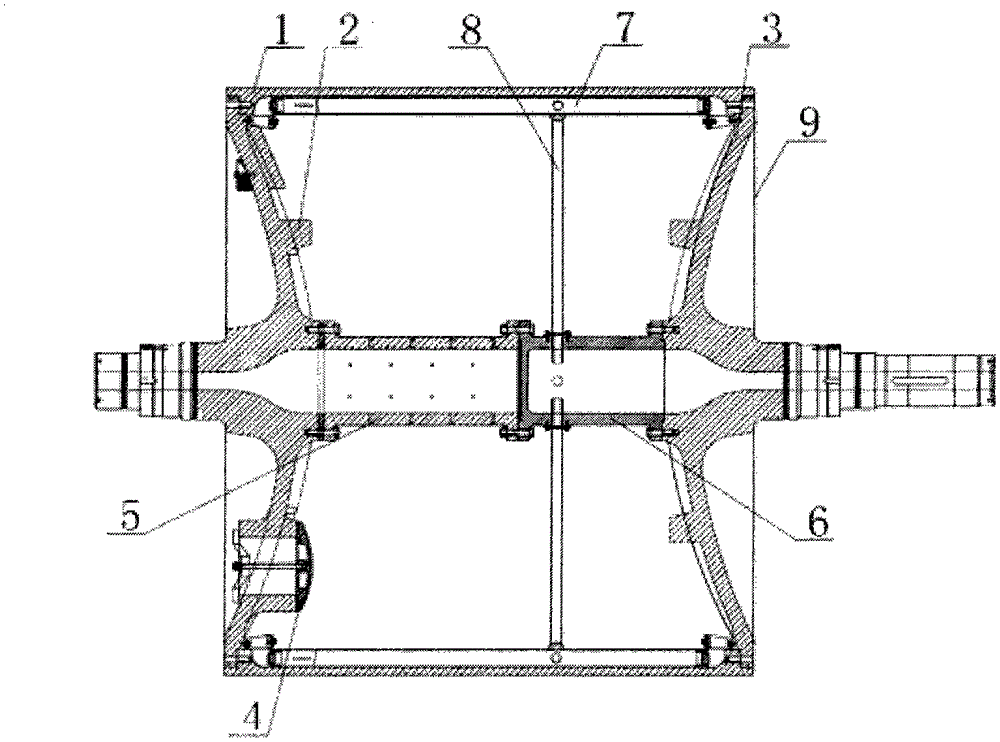

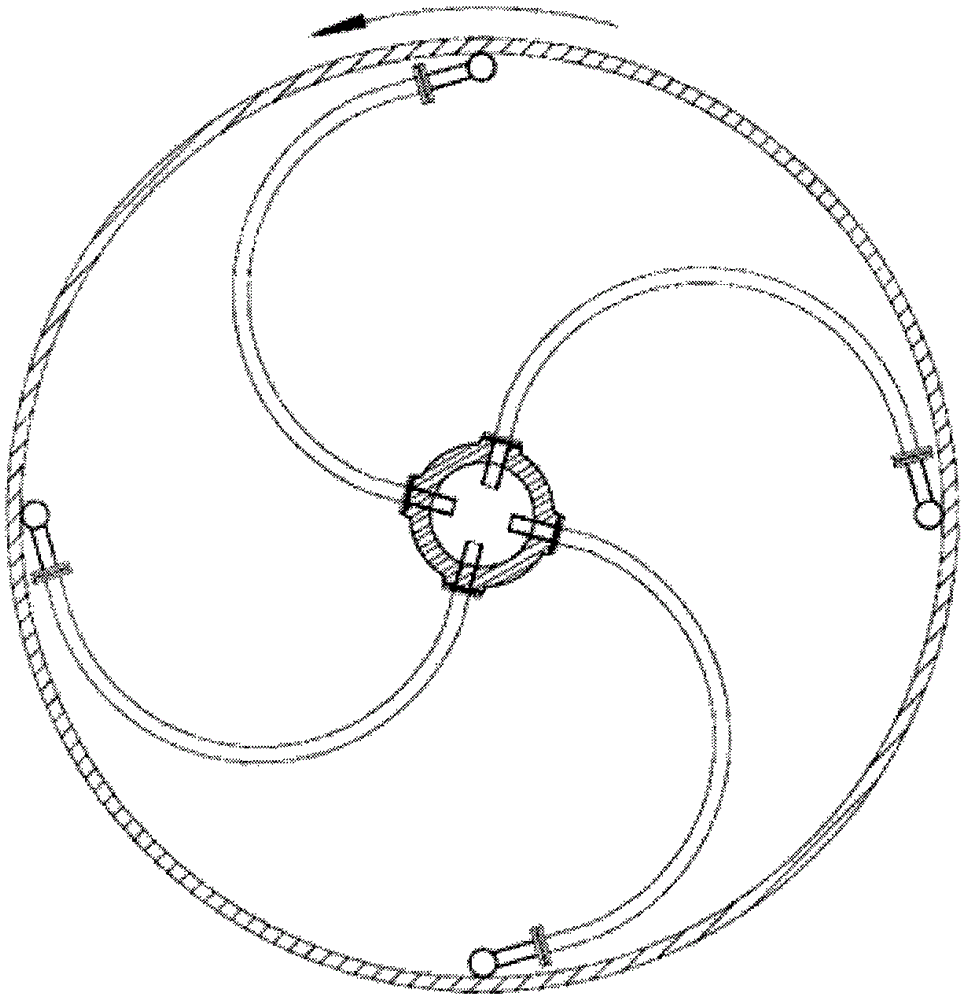

Ultrasonic balloon catheter system for cardiovascular lithotripsy

PendingCN110638501AAvoid unevennessProduce uniformDiagnosticsSurgeryUltrasonic vibrationBalloon catheter

The invention provides an ultrasonic balloon catheter system for cardiovascular lithotripsy. The ultrasonic balloon catheter system comprises an ultrasonic generator, a catheter body and a balloon treatment end, wherein one end of the catheter body is connected with the ultrasonic generator; the balloon treatment end is arranged at the end, away from the ultrasonic generator, of the catheter bodyand internally provided with a plurality of monocrystal ultrasonic transducers and an ultrasonic receiver, and the monocrystal ultrasonic transducers are electrically connected with the ultrasonic generator through the catheter body; and the ultrasonic generator is used for transmitting electric energy to the ultrasonic transducers, the monocrystal ultrasonic transducers are used for converting the electric energy into ultrasonic vibration for lithotripsy, and the ultrasonic wave receiver is used for receiving ultrasonic waves and converting the ultrasonic waves into electric signals. The ultrasonic generator of the ultrasonic balloon catheter system transmits the electric energy to the monocrystal ultrasonic transducers and then emits the ultrasonic waves, and relatively uniform impact force is guaranteed.

Owner:丁奥利弗

Commodities based securities and roll neutrality therefor

The subject invention pertains to securities, preferably exchange traded funds, or ETFs, relating to commodities subject to futures contracts in a commodities market. More specifically, the invention relates to shipping certificates for commodities that dynamically compensate for commodity “roll neutrality” adjustments by altering the quantity of commodity associated with the shipping certificate, as opposed to a cash adjustment. The subject invention also pertains to the underlying “roll neutrality” adjustment related to a commodities market futures transaction and to the resulting ETF valuation as follows: ΣPiBi, where Pi is the price of the relevant contract month, Bi is the number of commodity units for that month, and i is the time index.

Owner:NEW YORK MERCANTILE EXCHANGE

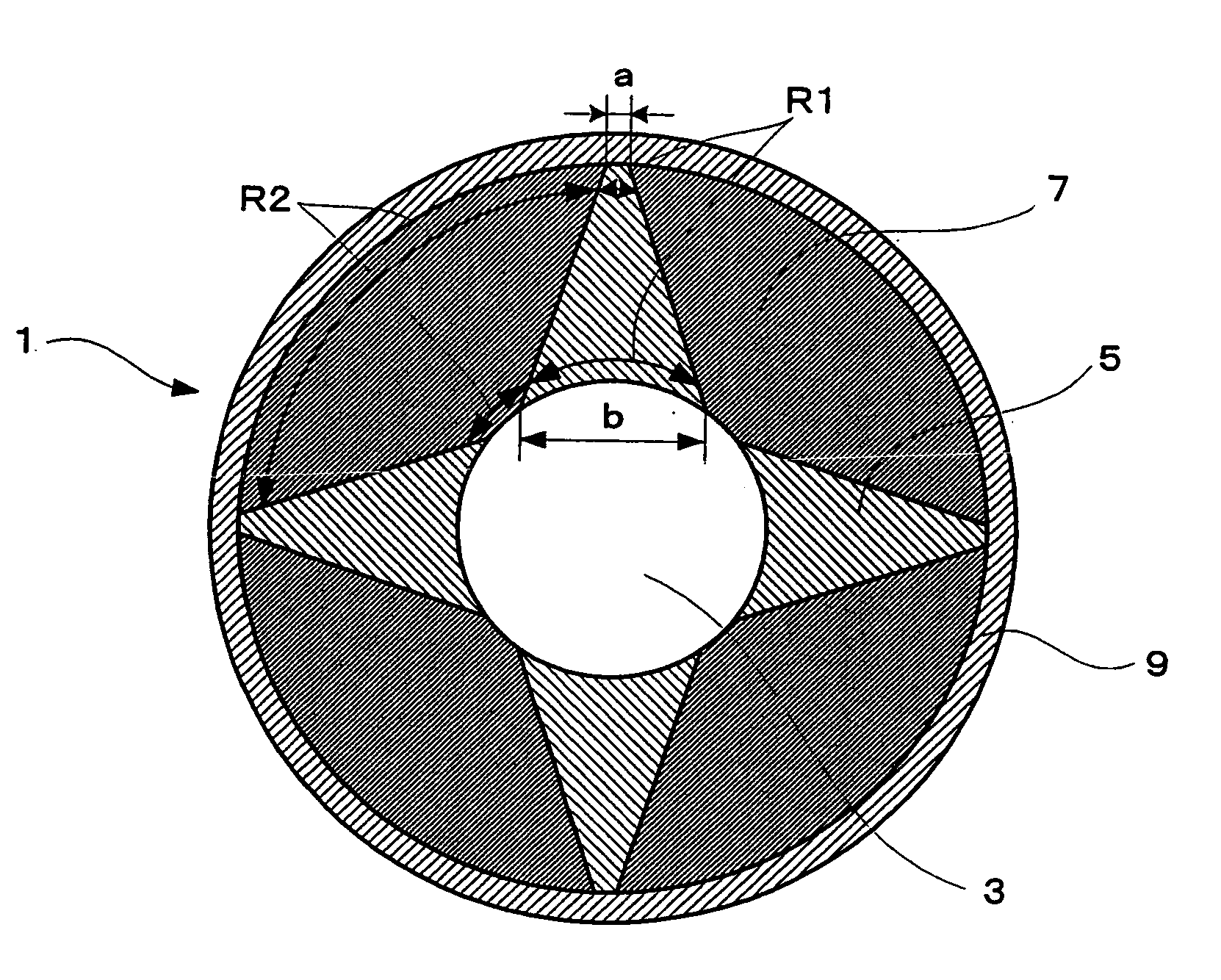

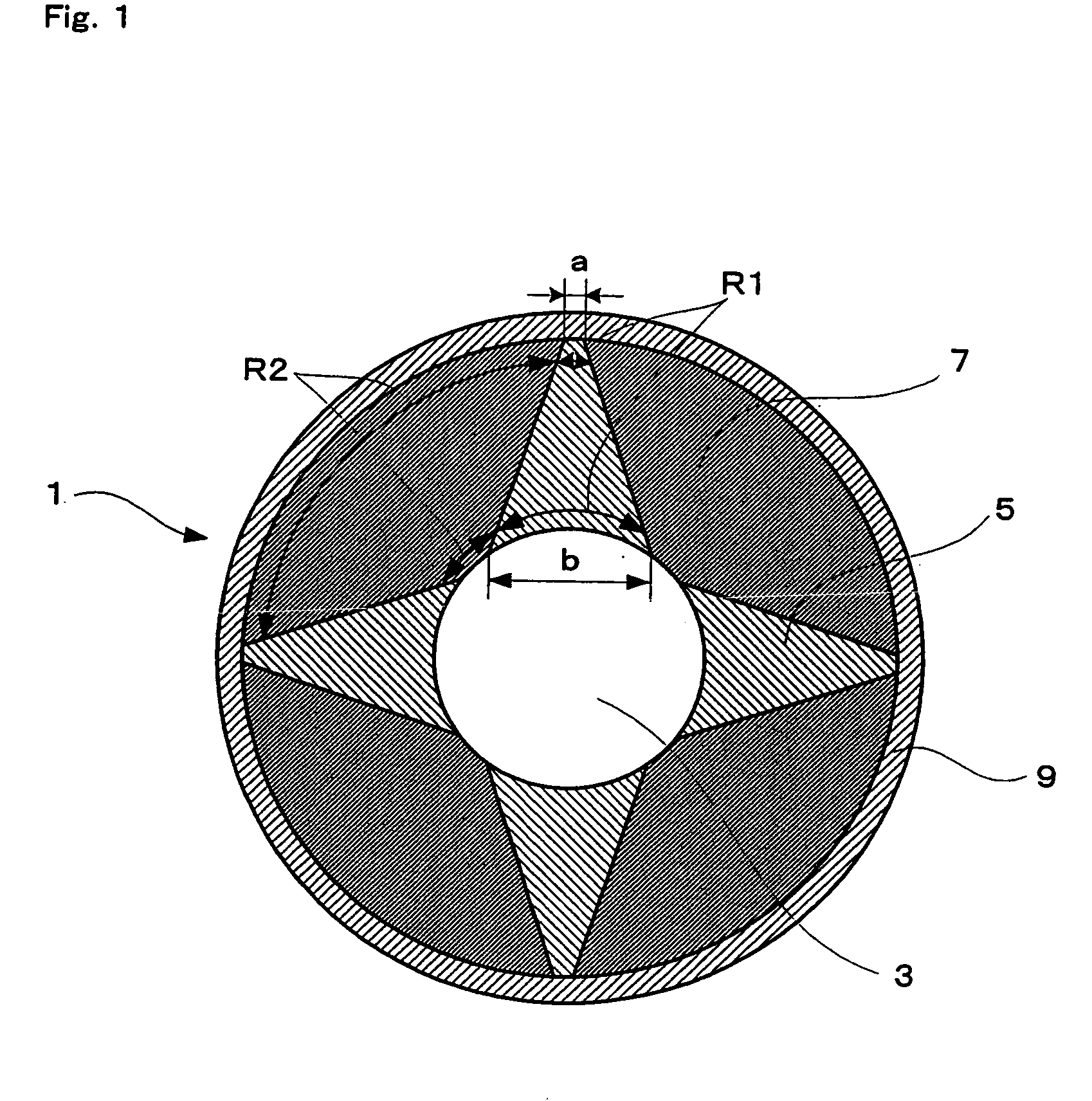

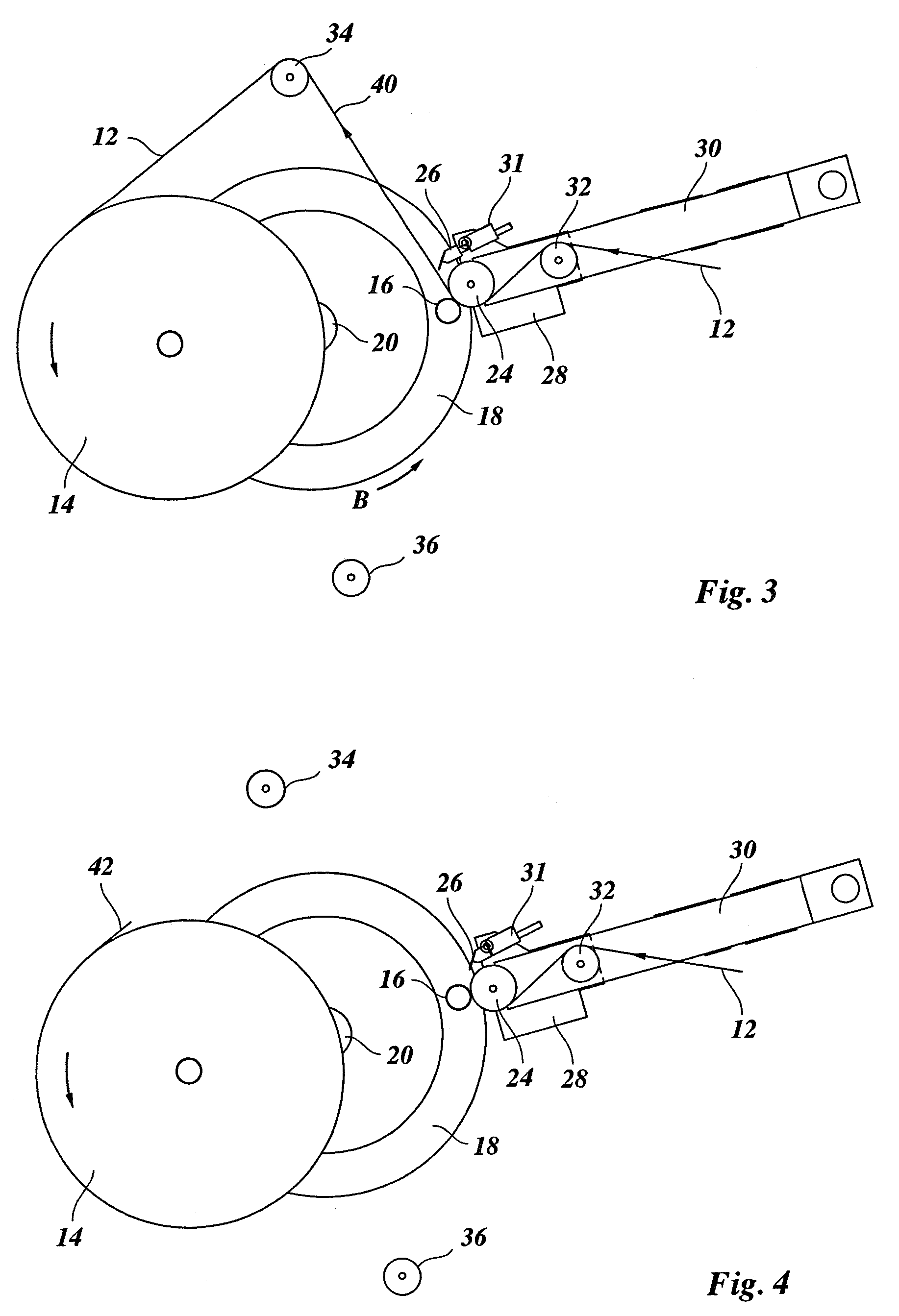

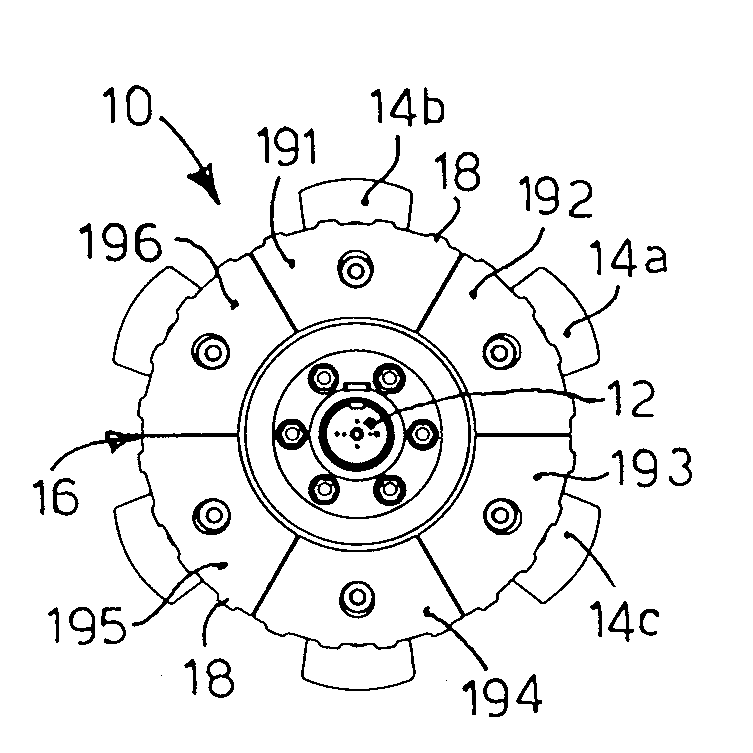

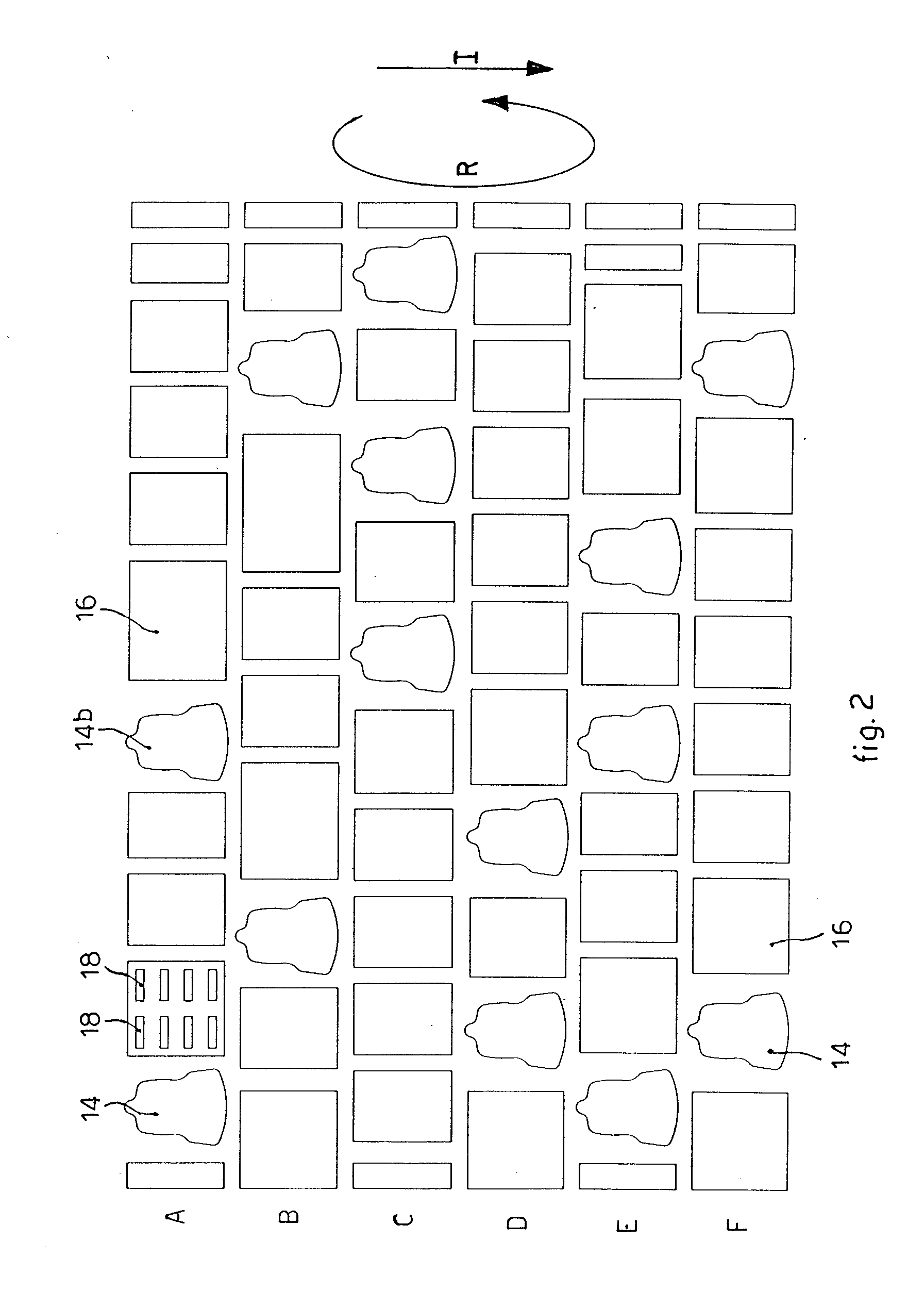

Multi-piece golf ball, manufacturing method thereof and mold for manufacturing the same

The present invention provides a multi-piece golf ball comprising a core 3, a first intermediate layer 5, a second intermediate layer 7, and a cover 9, wherein the first intermediate layer 5 comprises a plurality of ribs 51 formed on the core 3; the second intermediate layer 7 is placed in concave portions surrounded by the ribs 51; and the cover 9 forms an outermost layer; with each of the ribs extending so that its width increases from the cover side to the core side; the concave portions being shaped into a funnel-like form by the side surfaces of the ribs; the hardness of the core 3, the first intermediate layer 5 and the second intermediate layer 7 being different from each other; and the hardness of the first intermediate layer 5 being greater than that of the second intermediate layer 9.

Owner:MIZUNO CORPORATION

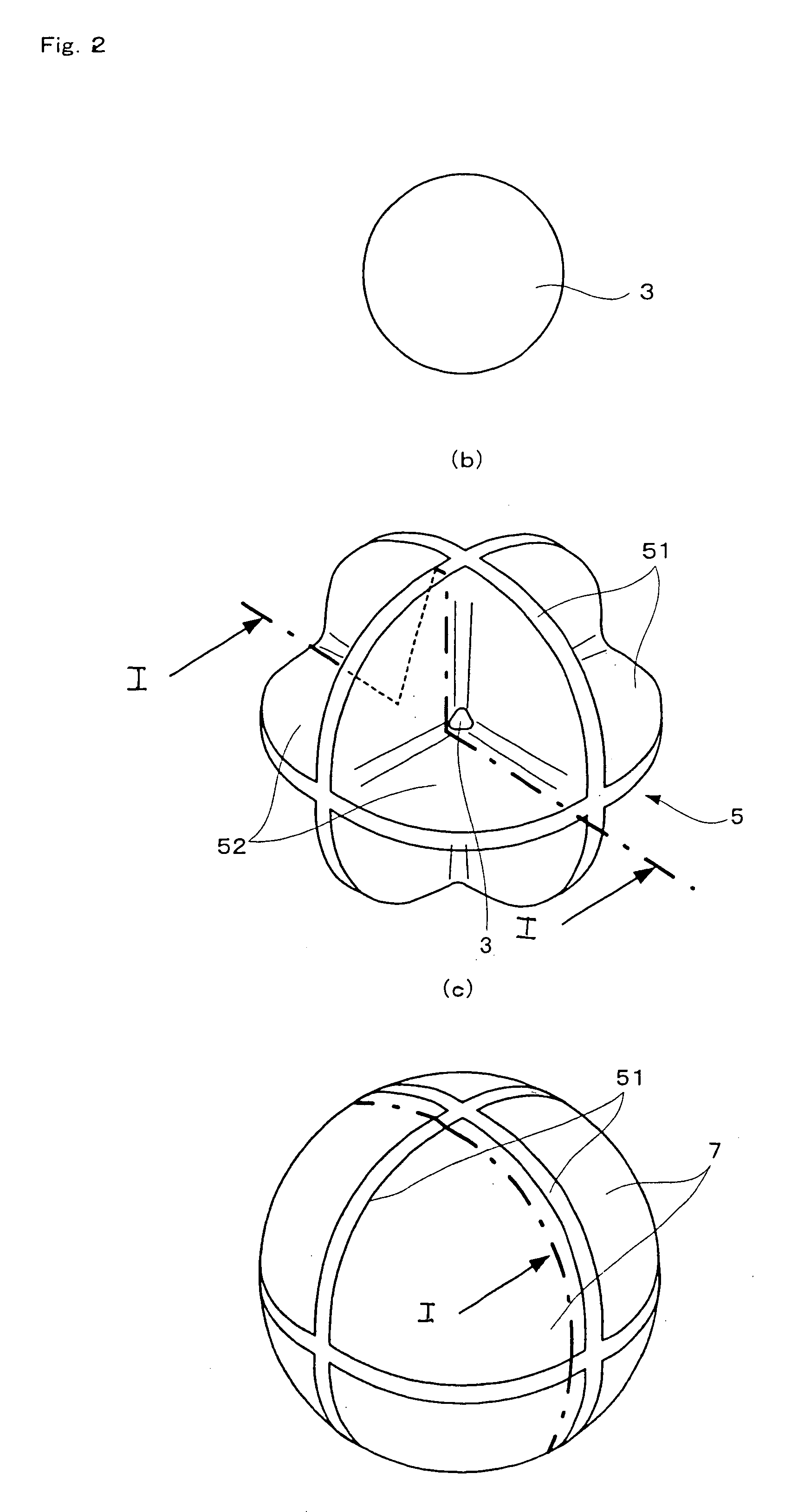

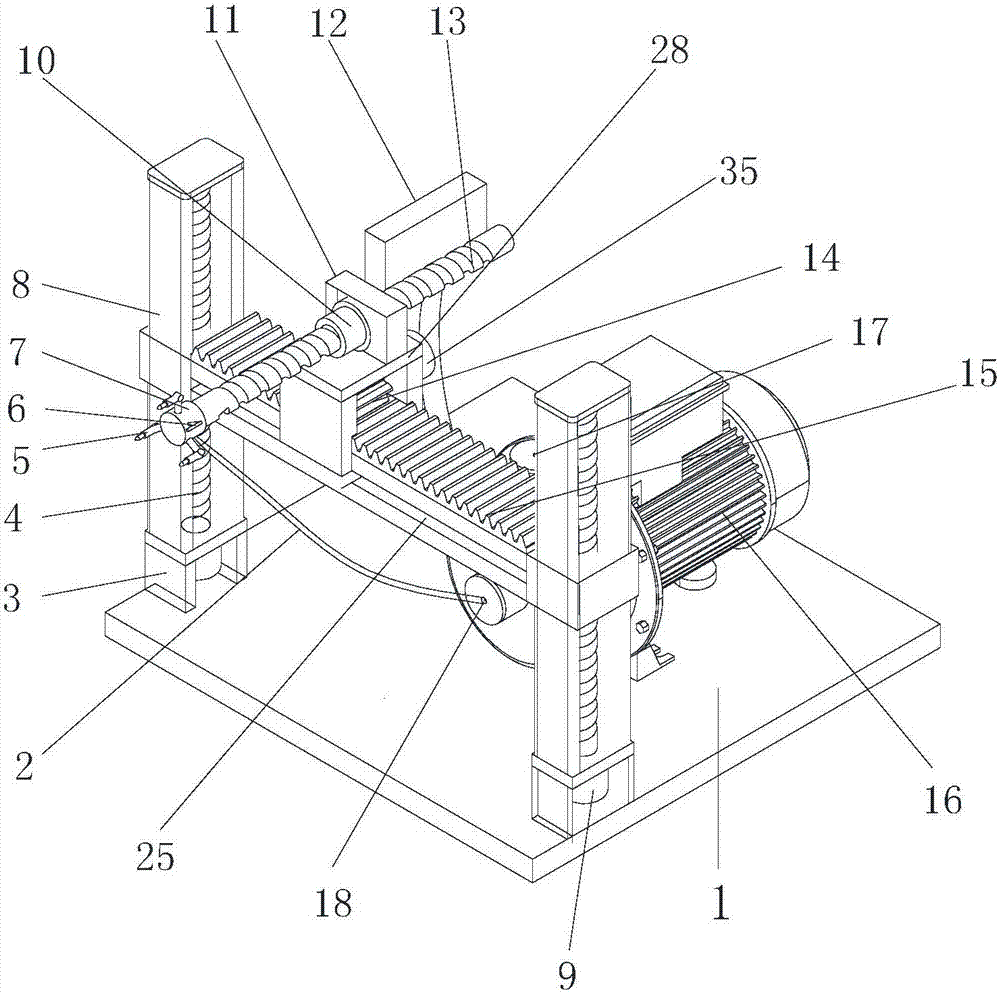

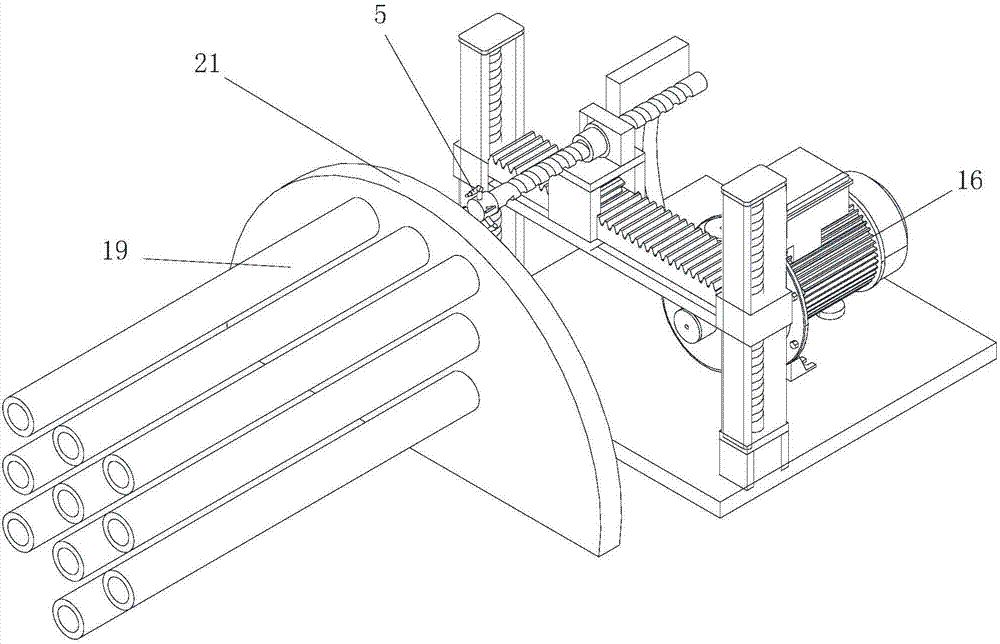

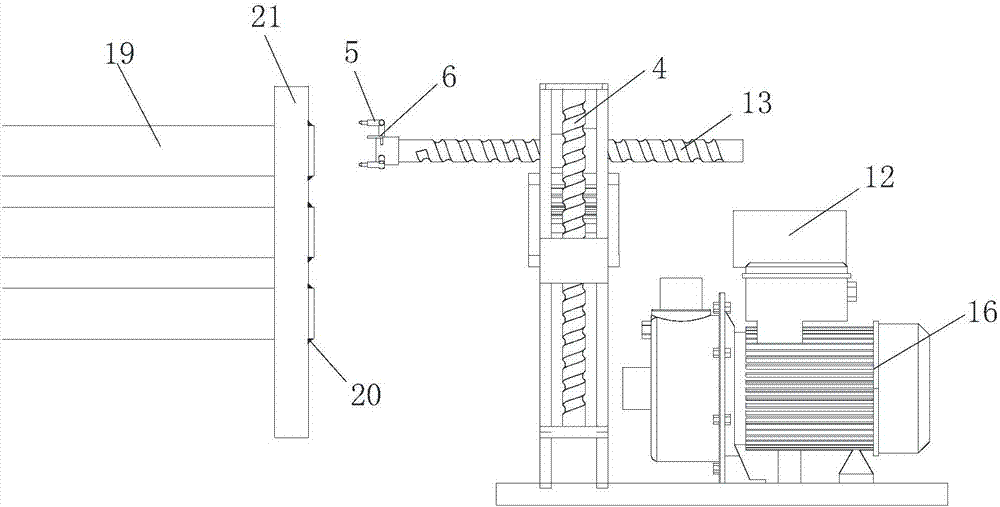

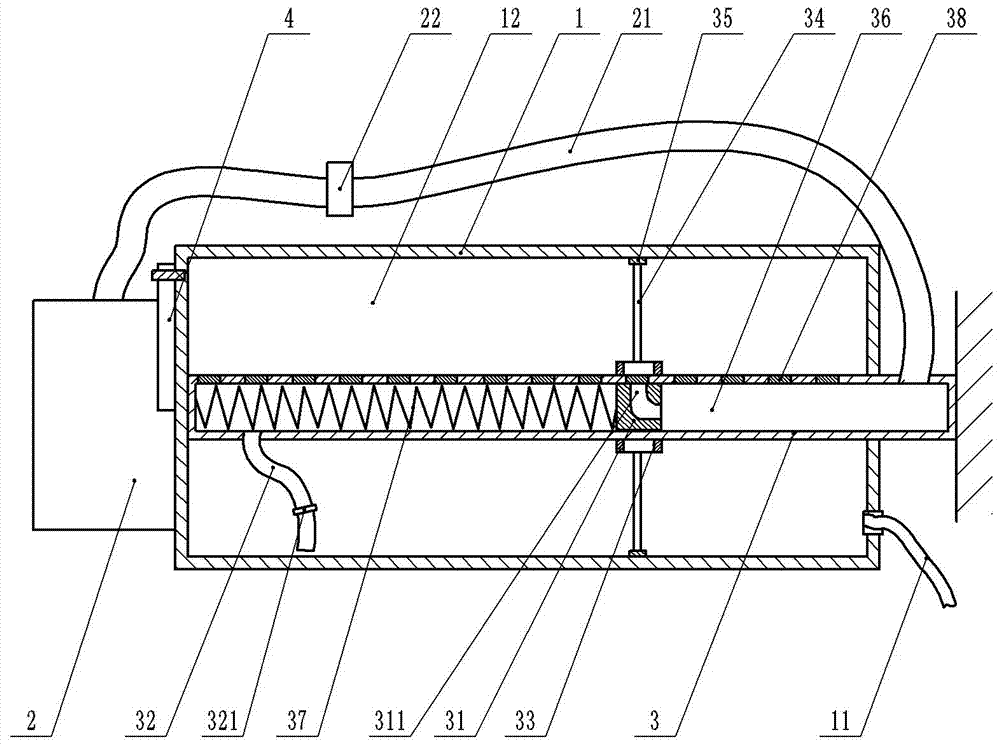

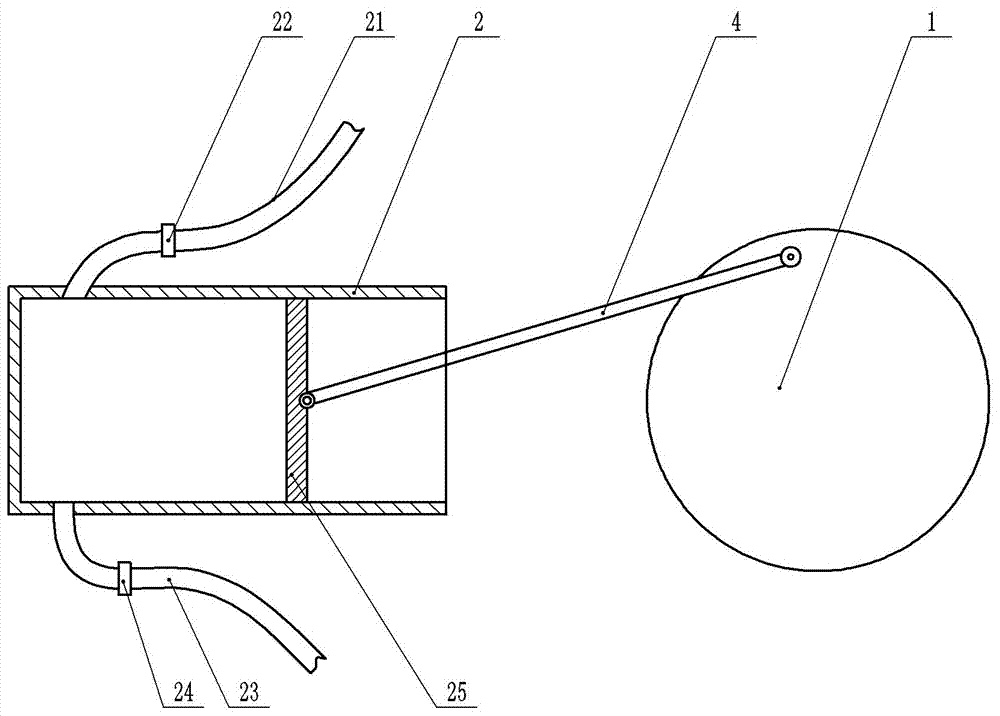

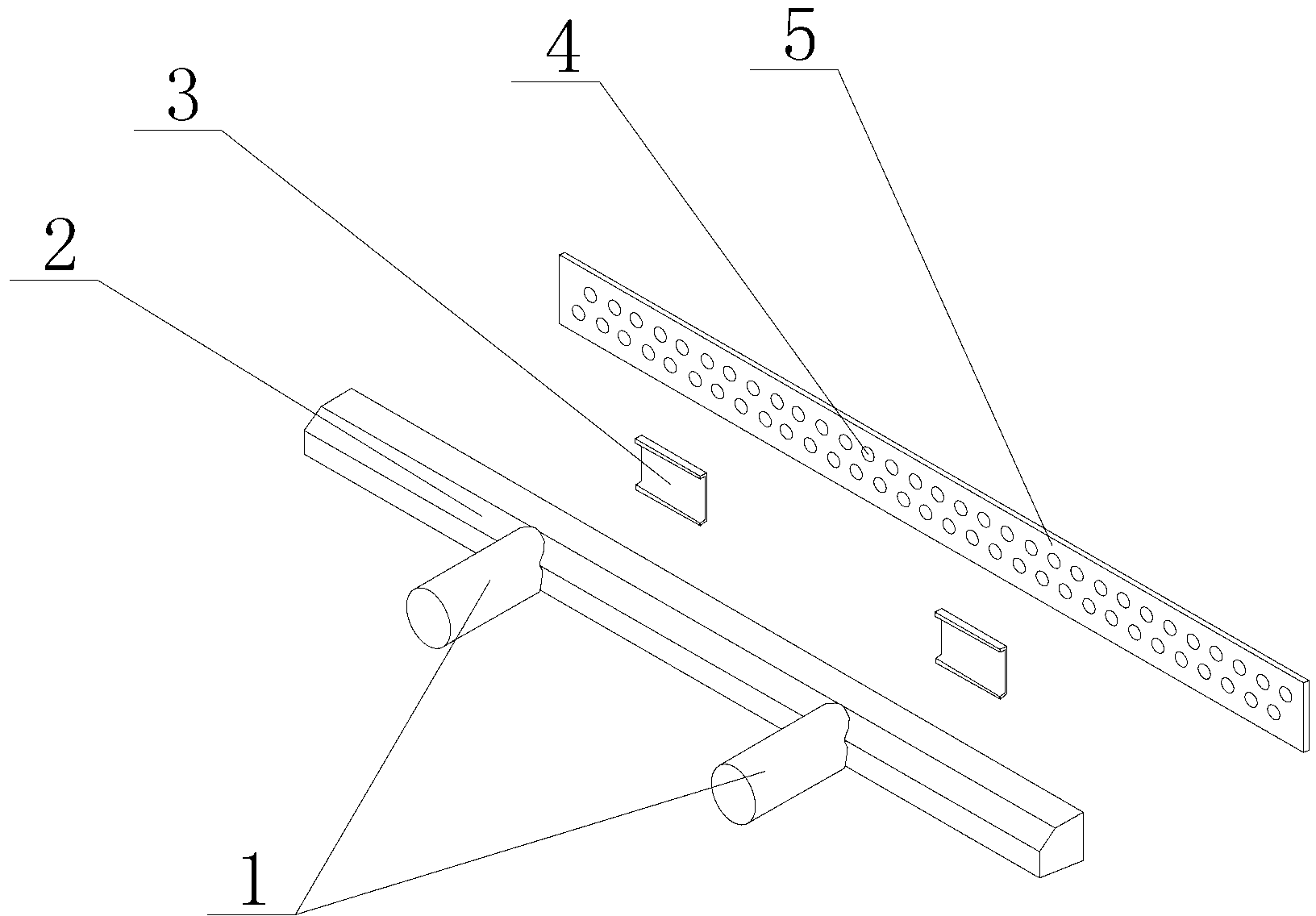

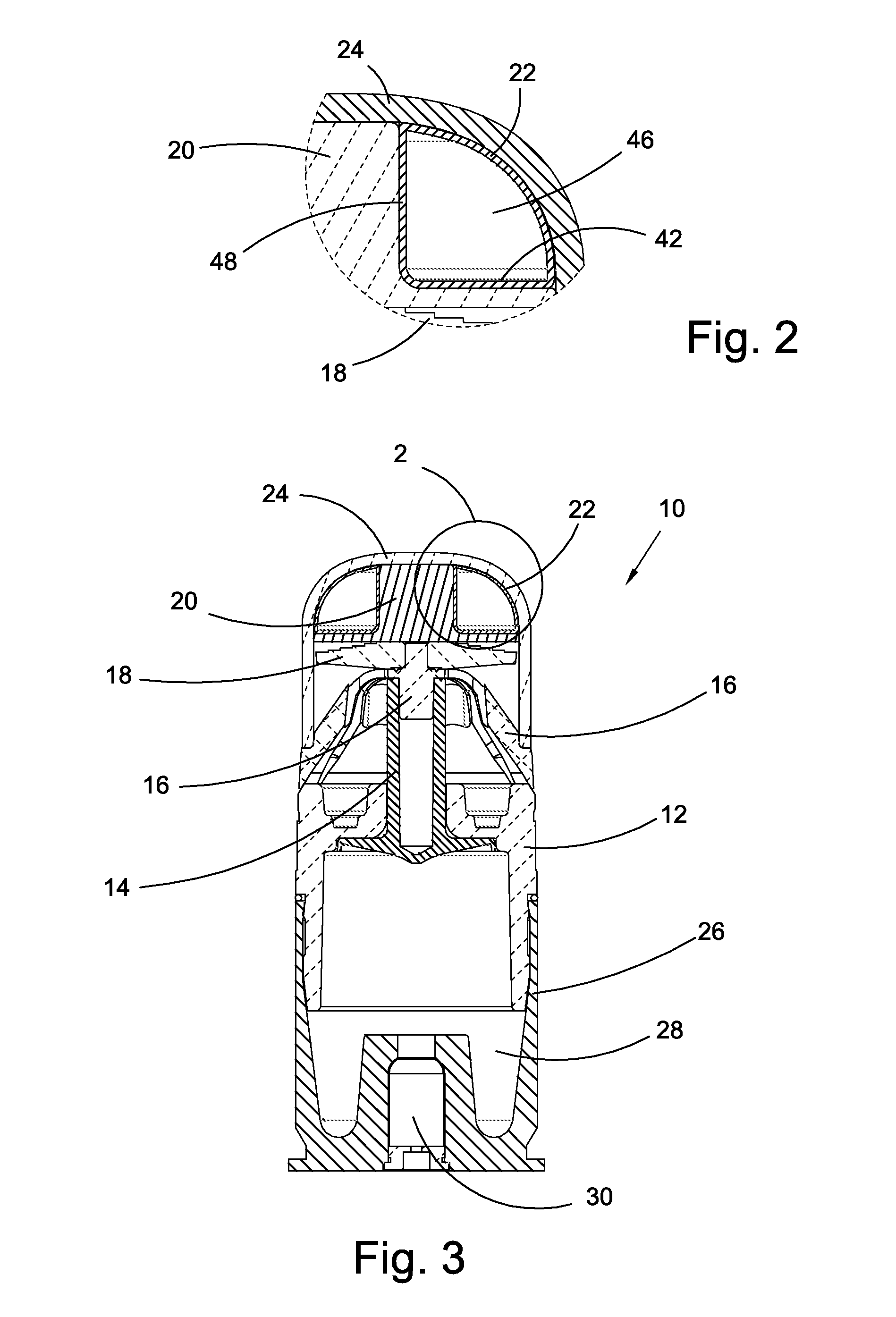

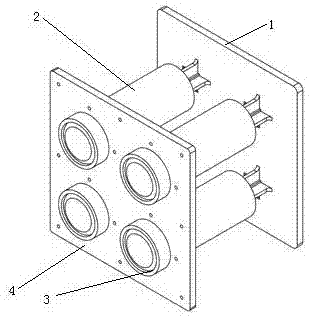

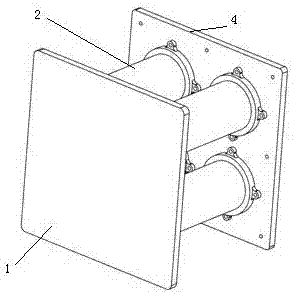

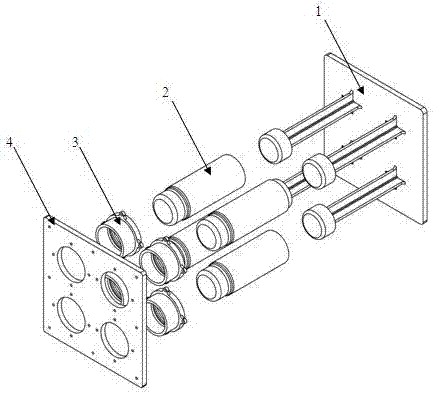

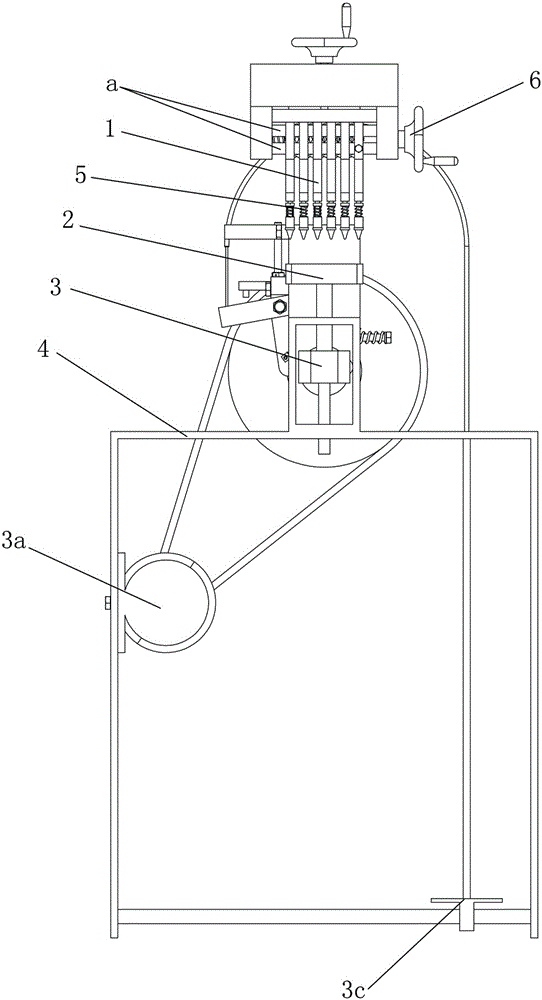

Device for reducing residual stress of welded seam of tube and tube plate of heat exchanger

ActiveCN107511610AFlexible adjustmentAdapt to Residual Stress RequirementsWelding/cutting auxillary devicesAuxillary welding devicesPlate heat exchangerEngineering

The invention discloses a device for reducing residual stress of a welded seam of a tube and a tube plate of a heat exchanger. The device comprises a controller, a nozzle system and a high-pressure water pump for supplying high-pressure water jet to the nozzle system; the nozzle system comprises a nozzle regulator and a plurality of nozzles; the nozzle regulator comprises a casing and an end cover which are connected, and the multiple nozzles are uniformly distributed in the circumferential direction of the casing and are all connected with the high-pressure water pump; and the device further comprises an X-direction driving device, a Y-direction driving device and a Z-direction driving device, wherein the X-direction driving device drives the casing and the nozzles to move horizontally in the X-axis direction, the Y-direction driving device moves horizontally in the Y-axis direction, and the Z-direction driving device lifts in the Z-axis direction. According to the device for reducing the residual stress of the welded seam of the tube and the tube plate of the heat exchanger, a high-pressure water jet technology is used to reduce the residual stress of the annular welded seam with different diameters of different sizes of the heat exchangers, the application range is wide, and the effect of reducing the residual stress is good.

Owner:SHANDONG UNIV OF SCI & TECH

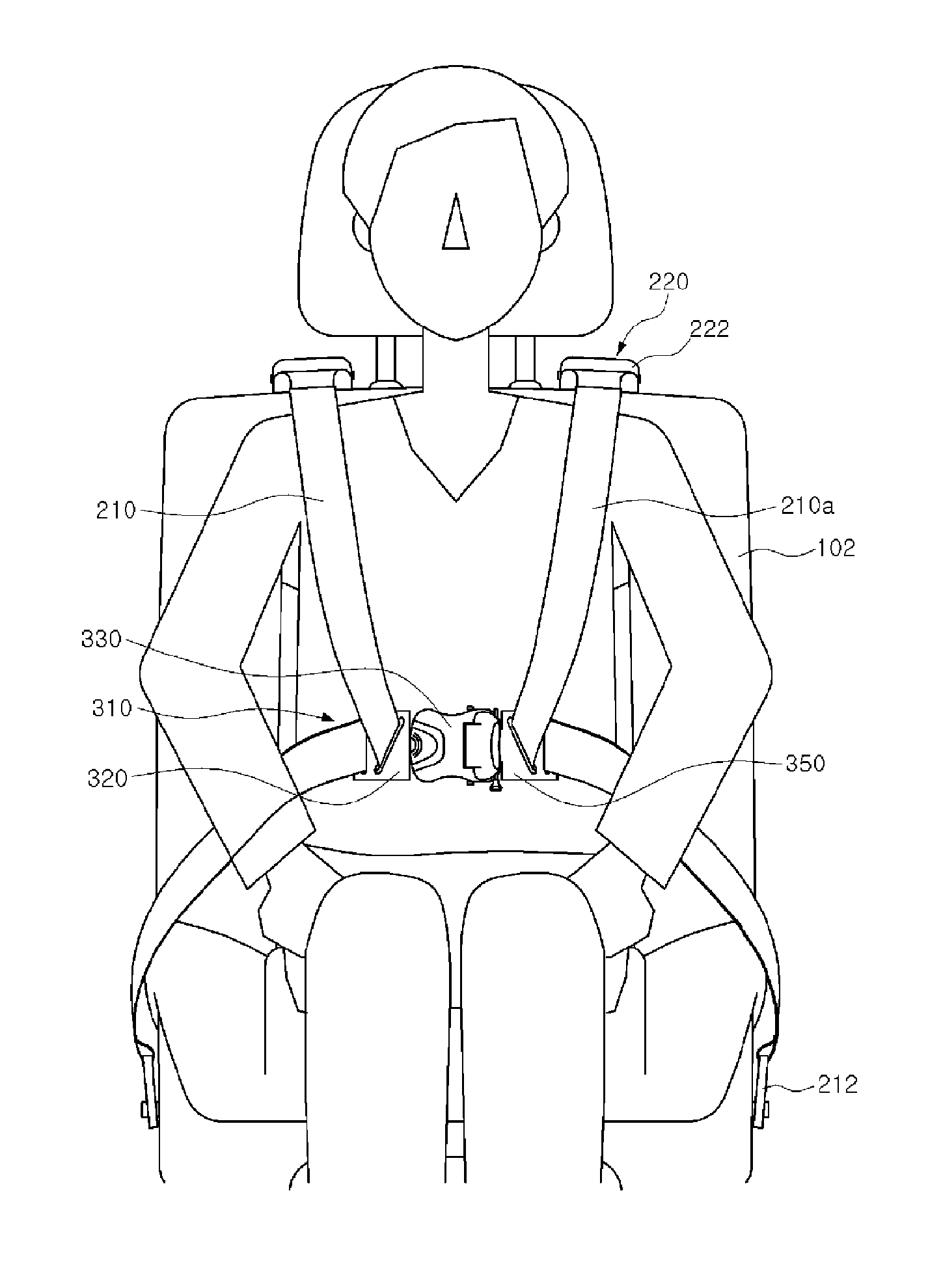

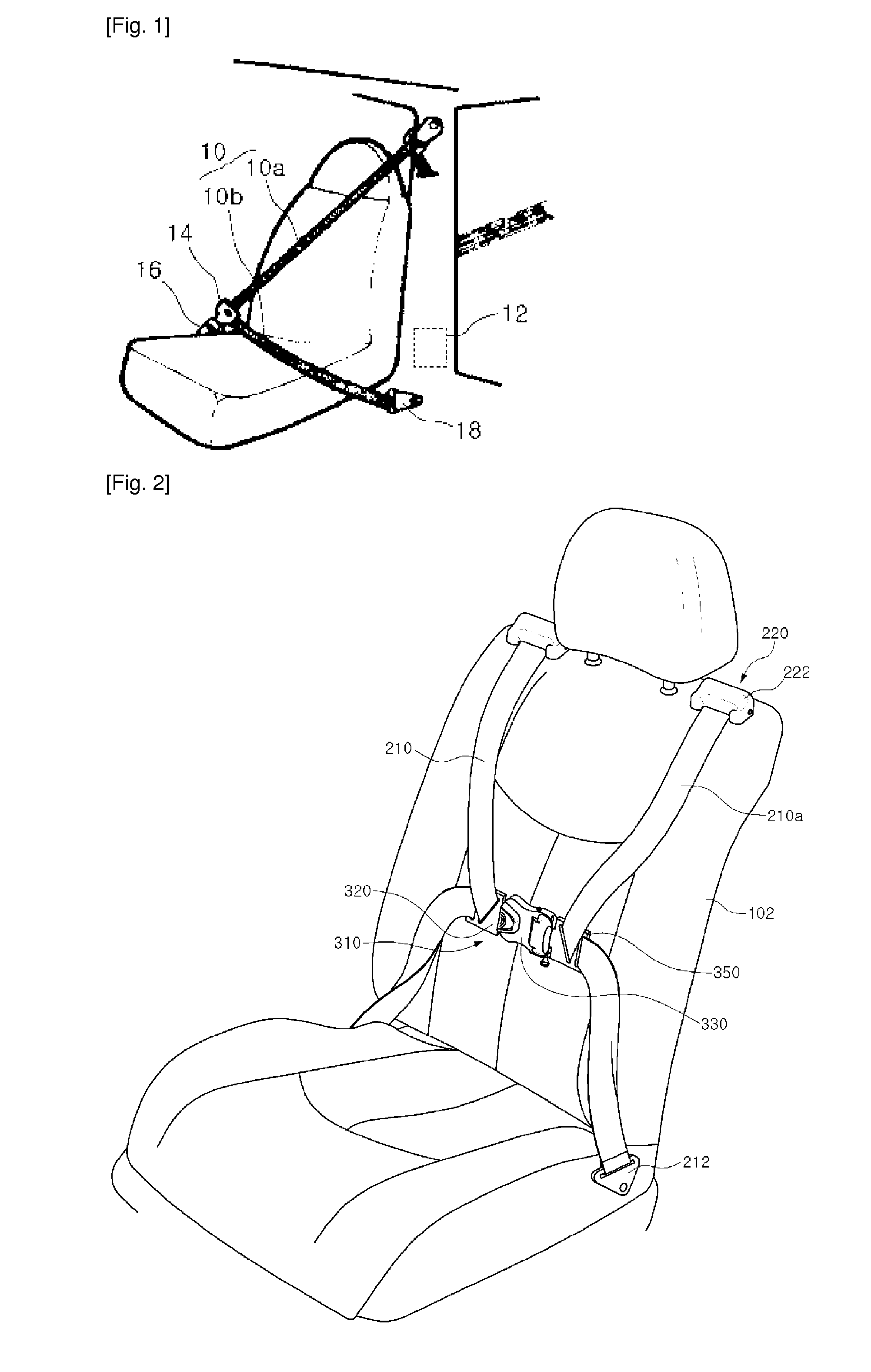

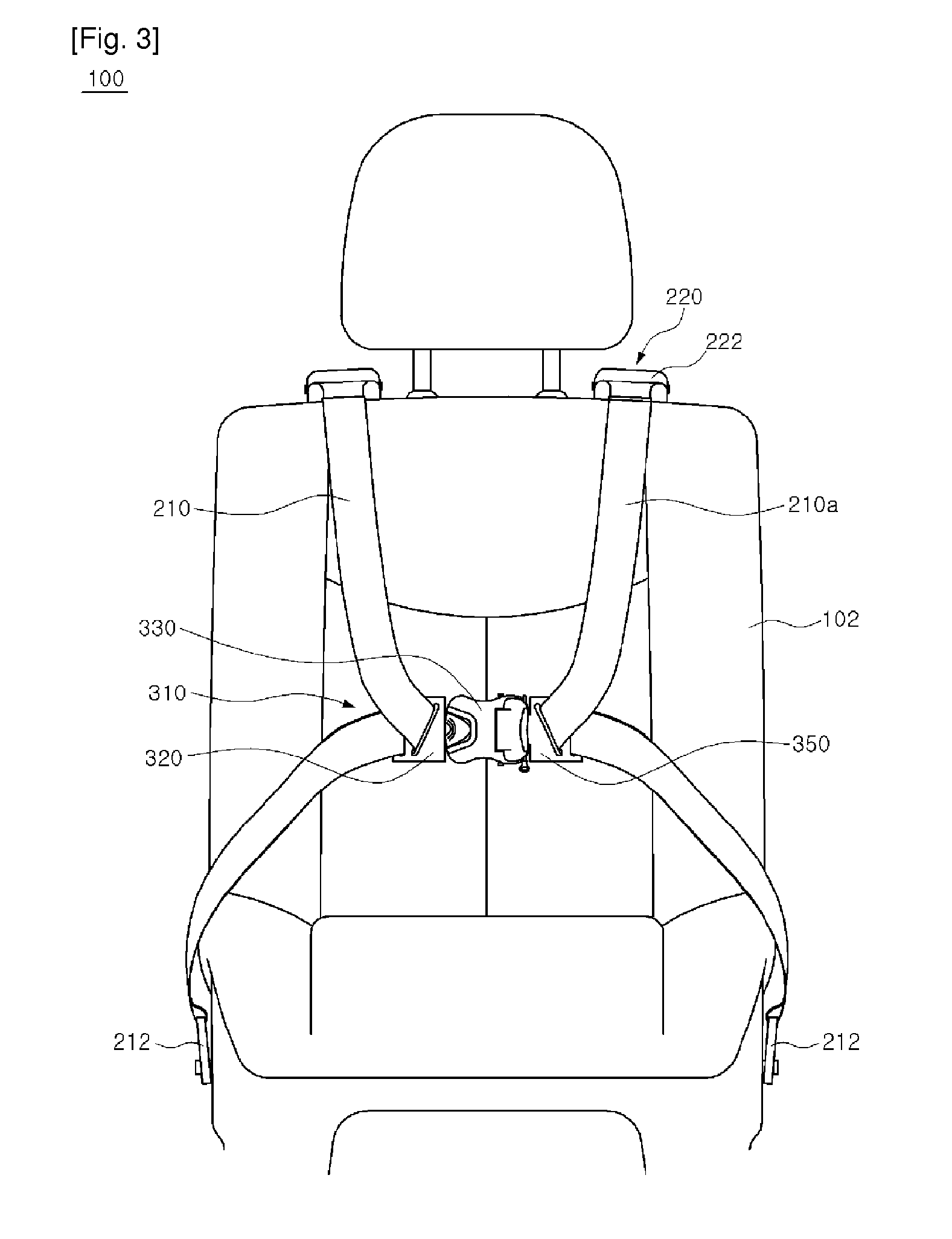

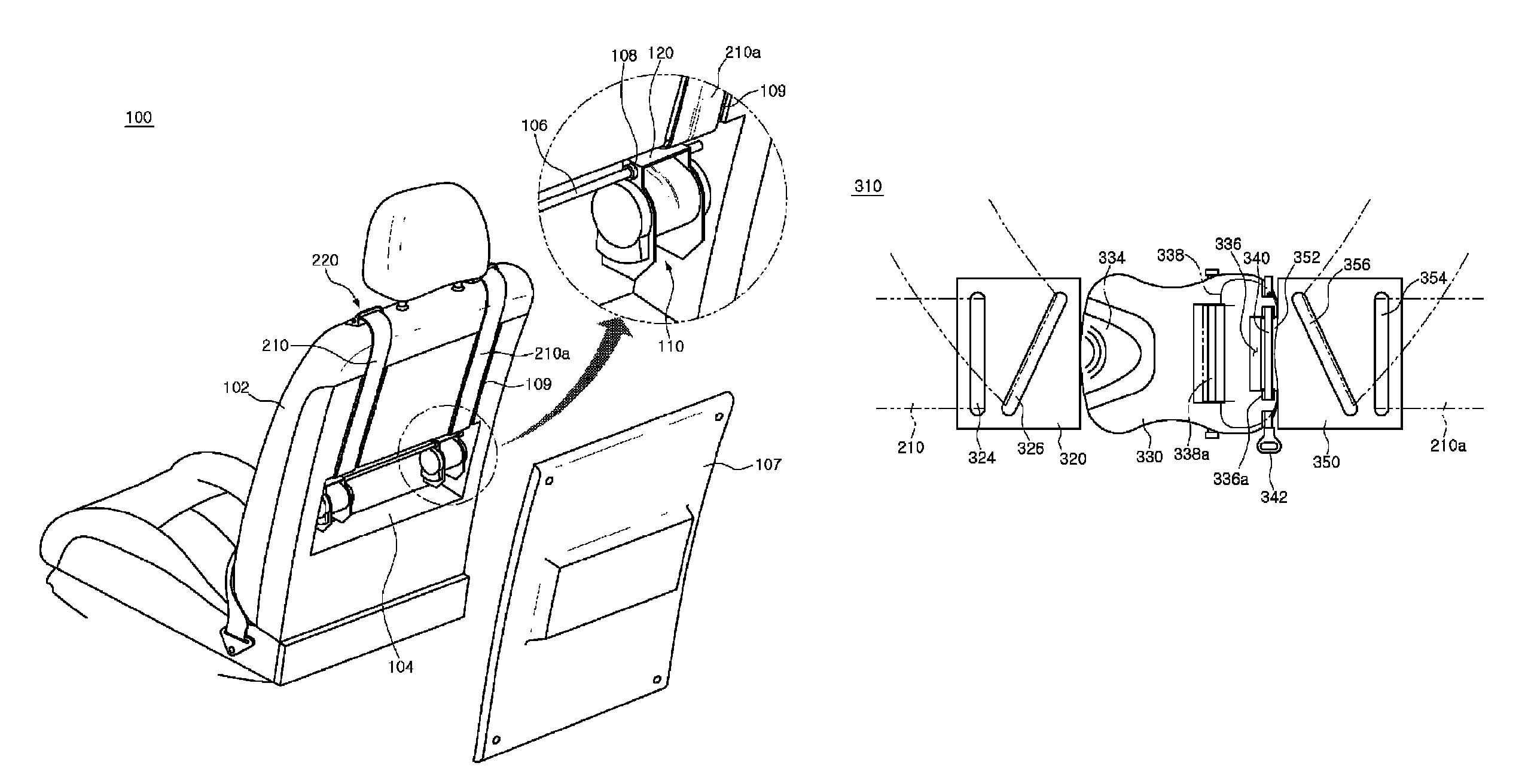

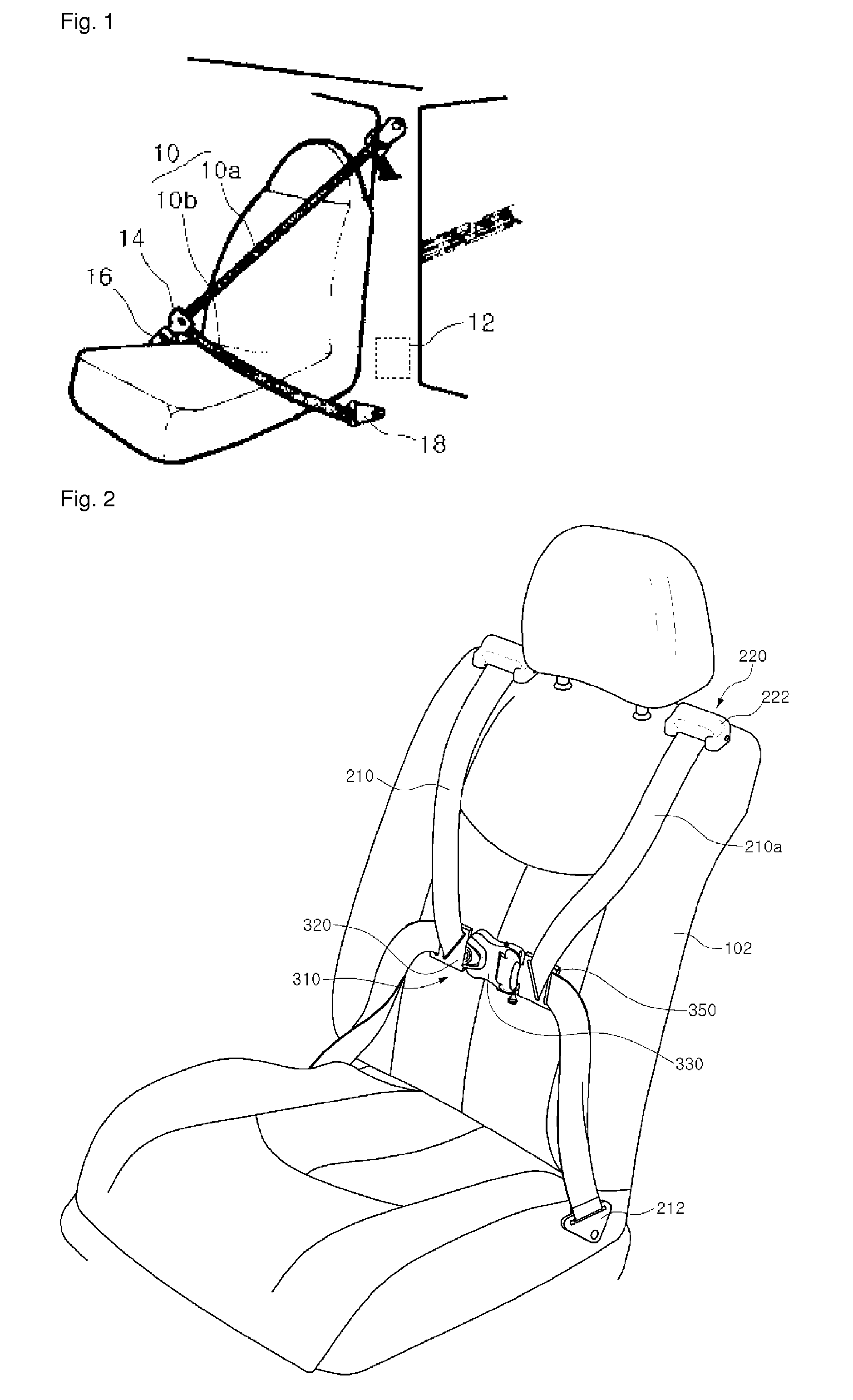

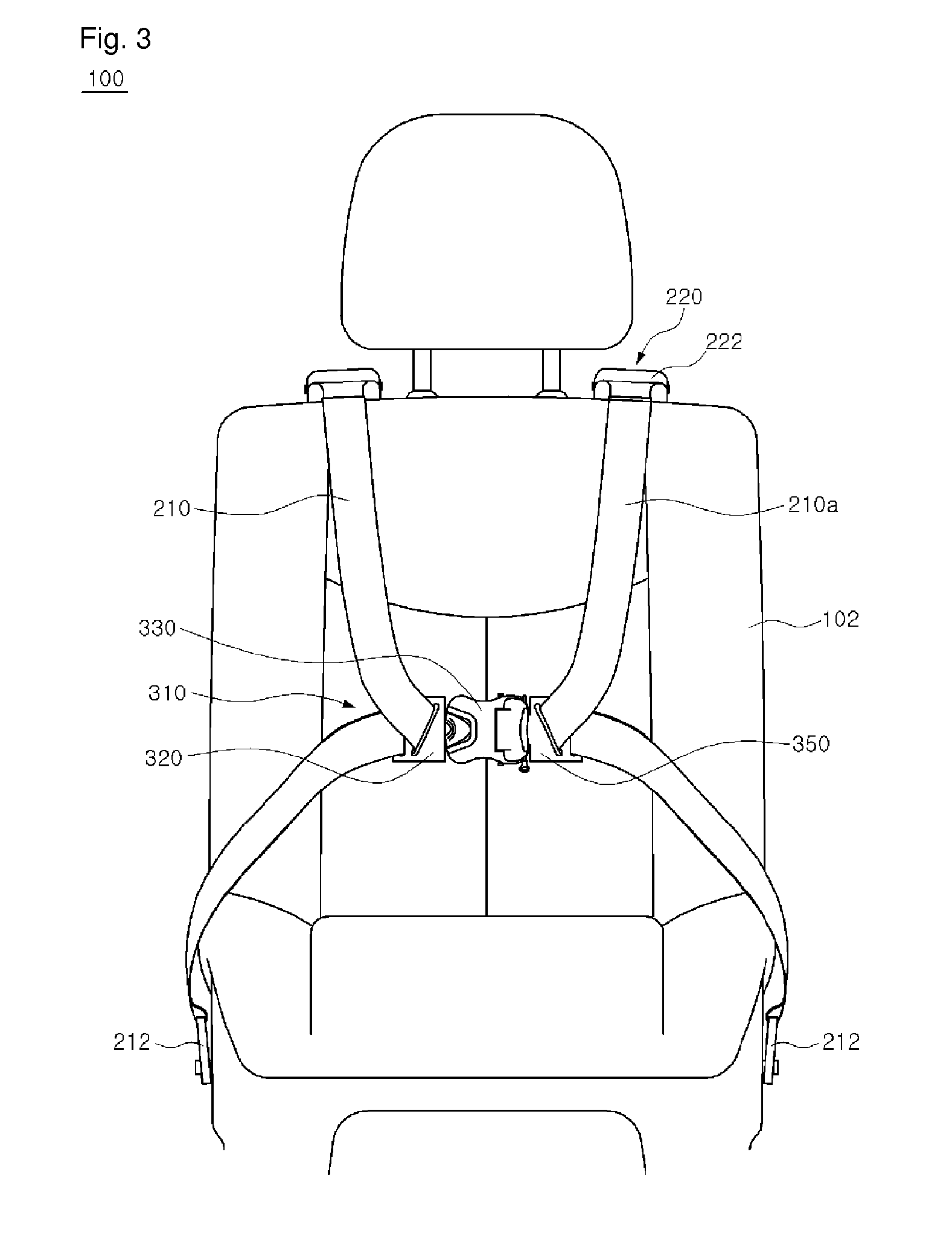

Safety belt for a vehicle

InactiveUS20120019042A1Relieve stressEffective preventionVehicle seatsBelt retractorsSeat beltEngineering

A safety belt for a vehicle which can be worn in a manner of wearing suspenders to prevent a concentration of pressure to a part of the body of a seat occupant, and to uniformly distribute impact to thereby safely protect the seat occupant even upon the occurrence of an emergency during travel. To accomplish the above-described object, the safety belt for a vehicle according to the present invention comprises a pair of belts spaced apart from each other in a vertical direction on the front surface of a seatback and a connection unit for interconnecting the pair of belts.

Owner:PARK NAM YOUNG

Safety belt for a vehicle

InactiveUS8783782B2Relieve stressEffective preventionVehicle seatsBelt retractorsBelt safetyElectrical and Electronics engineering

A safety belt for a vehicle which can be worn in a manner of wearing suspenders to prevent a concentration of pressure to a part of the body of a seat occupant, and to uniformly distribute impact to thereby safely protect the seat occupant even upon the occurrence of an emergency during travel. To accomplish the above-described object, the safety belt for a vehicle according to the present invention comprises a pair of belts spaced apart from each other in a vertical direction on the front surface of a seatback and a connection unit for interconnecting the pair of belts.

Owner:PARK NAM YOUNG

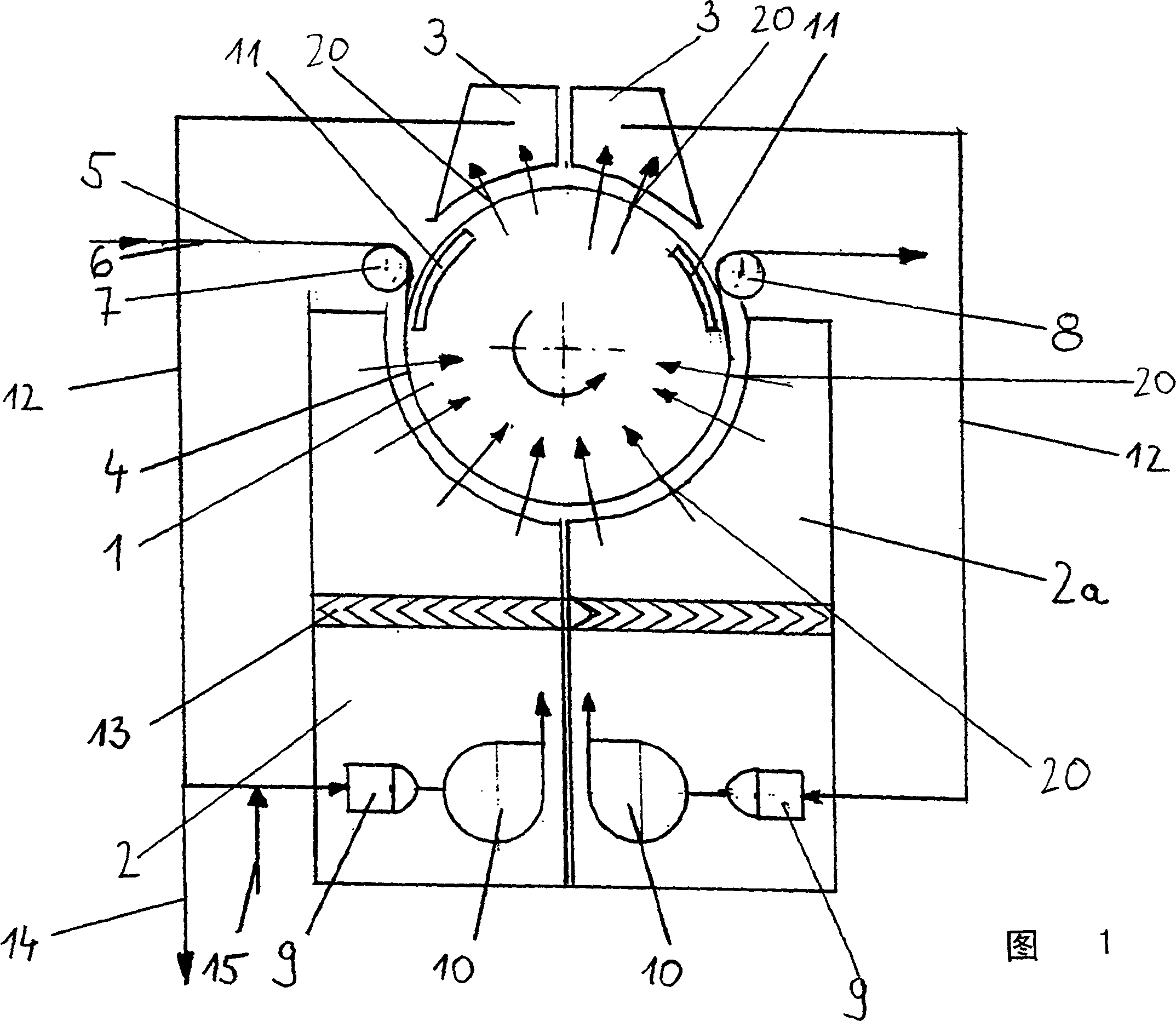

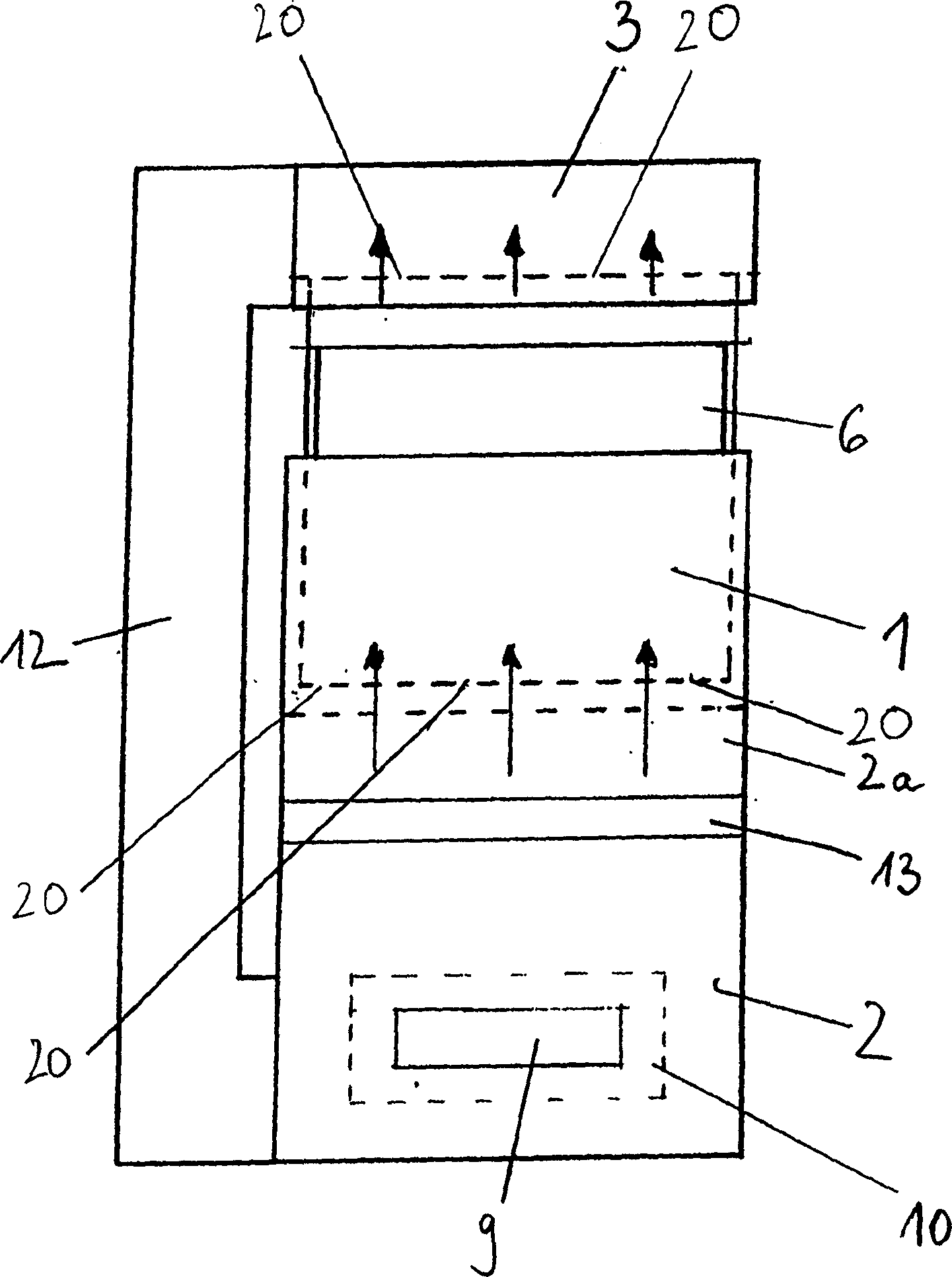

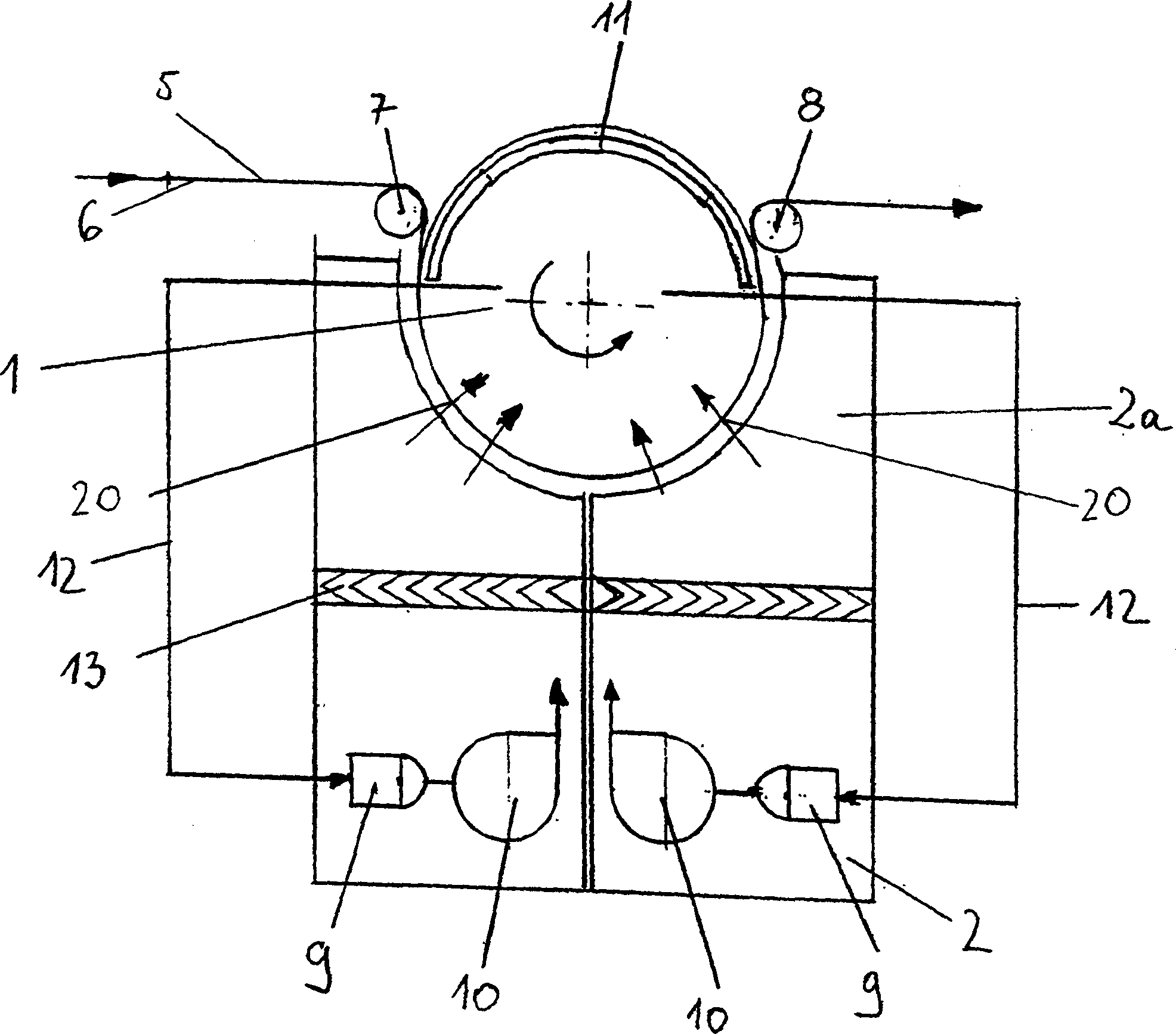

Apparatus for drying a paper web

InactiveCN1542221ASave spaceEvenly distributedDryer sectionAir heatersMoistureMechanical engineering

A device for drying a paper web has a drying drum mounted at least partially inside a housing, whereby the cylinder wall of the drying drum is provided with a large number of apertures or openings so that hot air can flow through the cylinder wall, a heating device to generate hot air, a feed device to apply the hot air to the paper web, and a device to carry off the air containing moisture. In order to permit a compact design, the housing surrounds at least one hood which partly encloses a cylinder wall of the drying drum with the heating device being located inside the hood. Both the feed device and the heating device should be located preferably inside the hood.

Owner:ANDRITZ AG

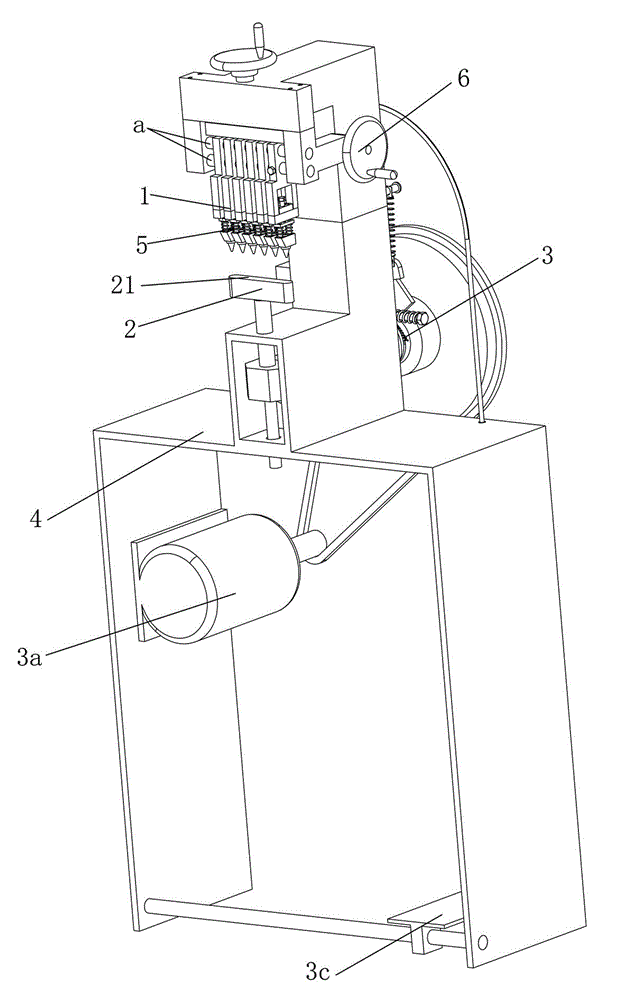

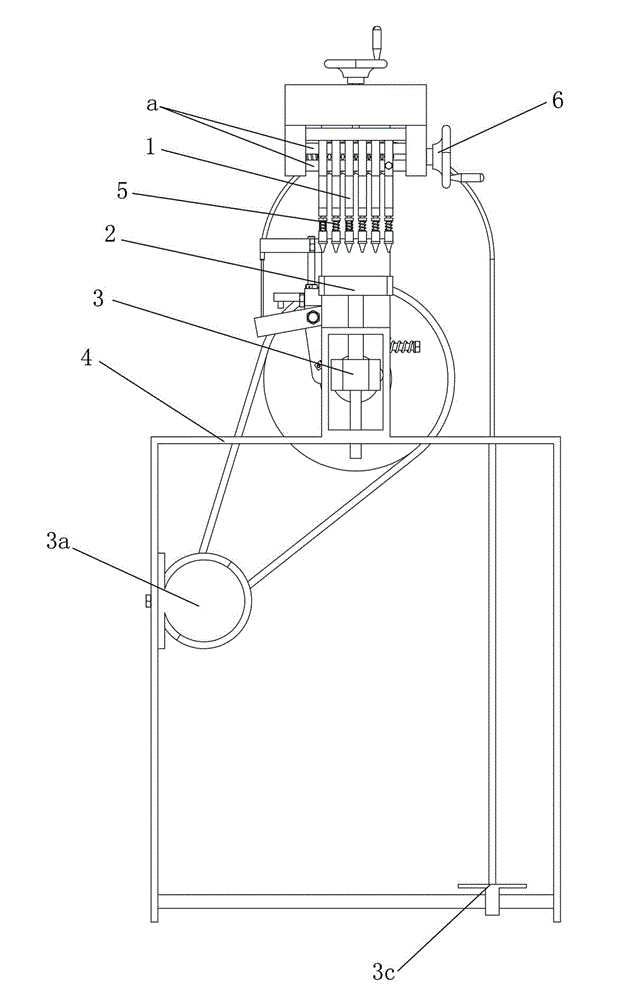

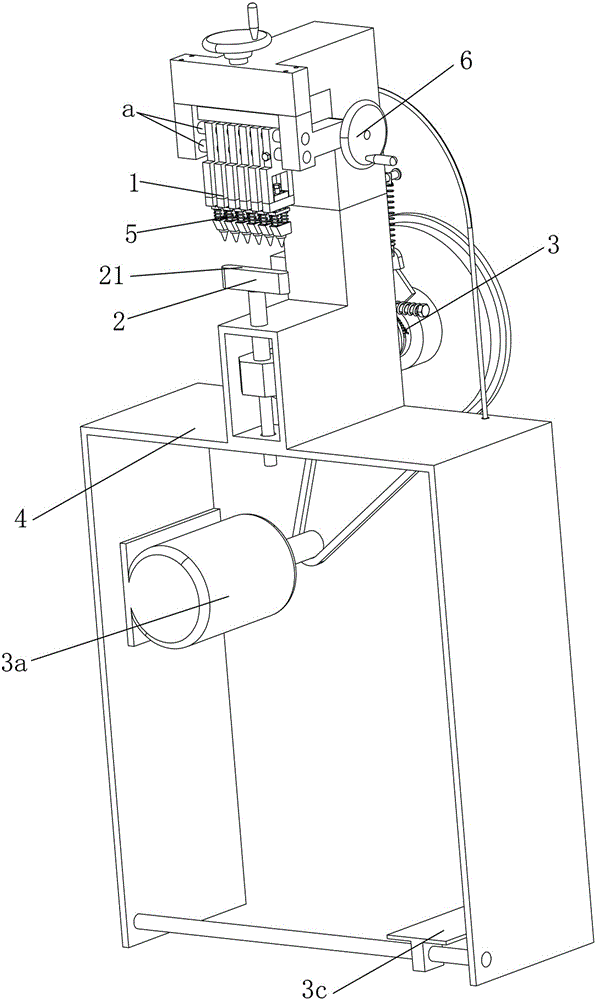

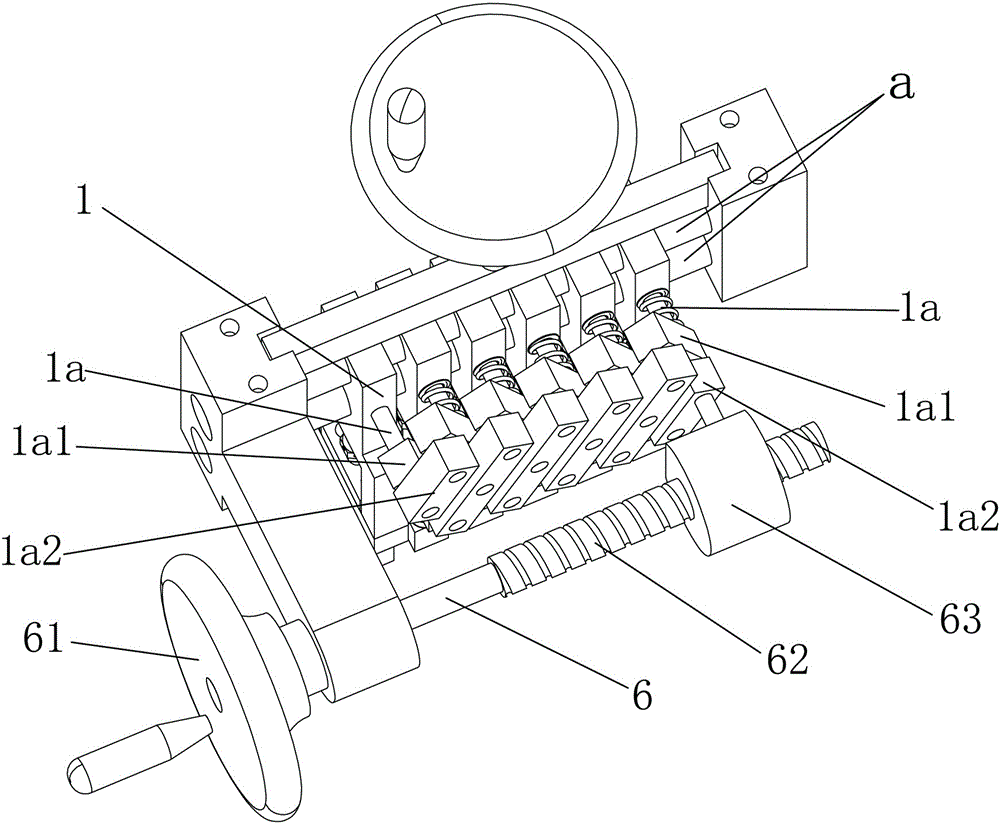

Punching machine suitable for cloth, leather and artificial leather

InactiveCN103144139AMake up for flatness errorAvoid incomplete cuttingLeather clicking/perforating/clickingSevering textilesPunchingElastic component

The invention provides a punching machine which is uniform in impact and excellent in punching precision and punching effect, and suitable for cloth, leather and artificial leather, and is especially capable of improving the punching precision and the punching effect aiming at multiple holes. The punching machine provided by the invention comprises a rack, wherein a punching cutter, a punching plate and a drive mechanism are arranged in the rack; the punching plate is movably arranged in the rack up and down and impacts the punching cutter; the punching plate is driven to move up and down by the drive mechanism; the tail end of the punching cutter is in a plane shape of which the area is equal to the area of a punching hole to be processed; the punching plate comprises a surface in a plane shape; the surface of the punching plate is parallel to the plane of the tail end of the punching cutter; the surface area of the punching plate is larger than the area of the plane formed at the tail end of the punching cutter; the rack comprises an elastic component acting on the punching cutter; and the punching cutter comprises a static station under the action of the elastic component only, and comprises an up and down microstroke under the combined action of the punching plate and the elastic component.

Owner:广州市集盛服饰皮具有限公司

Commodities Based Securities and Roll Neutrality Therefor

The subject invention pertains to securities, preferably exchange traded funds, or ETFs, relating to commodities subject to futures contracts in a commodities market. More specifically, the invention relates to shipping certificates for commodities that dynamically compensate for commodity “roll neutrality” adjustments by altering the quantity of commodity associated with the shipping certificate, as opposed to a cash adjustment. The subject invention also pertains to the underlying “roll neutrality” adjustment related to a commodities market futures transaction and to the resulting ETF valuation as follows: Σ Pi Bi, where Pi is the price of the relevant contract month, Bi is the number of commodity units for that month, and i is the time index.

Owner:NEW YORK MERCANTILE EXCHANGE

Commodities based securities and shipping certificate therefor

The subject invention pertains to securities, preferably exchange traded funds, or ETFs, relating to commodities subject to futures contracts in a commodities market. More specifically, the invention relates to shipping certificates for commodities that dynamically compensate for commodity “roll neutrality” adjustments by altering the quantity of commodity associated with the shipping certificate, as opposed to a cash adjustment. The subject invention also pertains to the underlying “roll neutrality” adjustment related to a commodities market futures transaction and to the resulting ETF valuation as follows: ΣPiBi, where Pi is the price of the relevant contract month, Bi is the number of commodity units for that month, and i is the time index.

Owner:NEW YORK MERCANTILE EXCHANGE

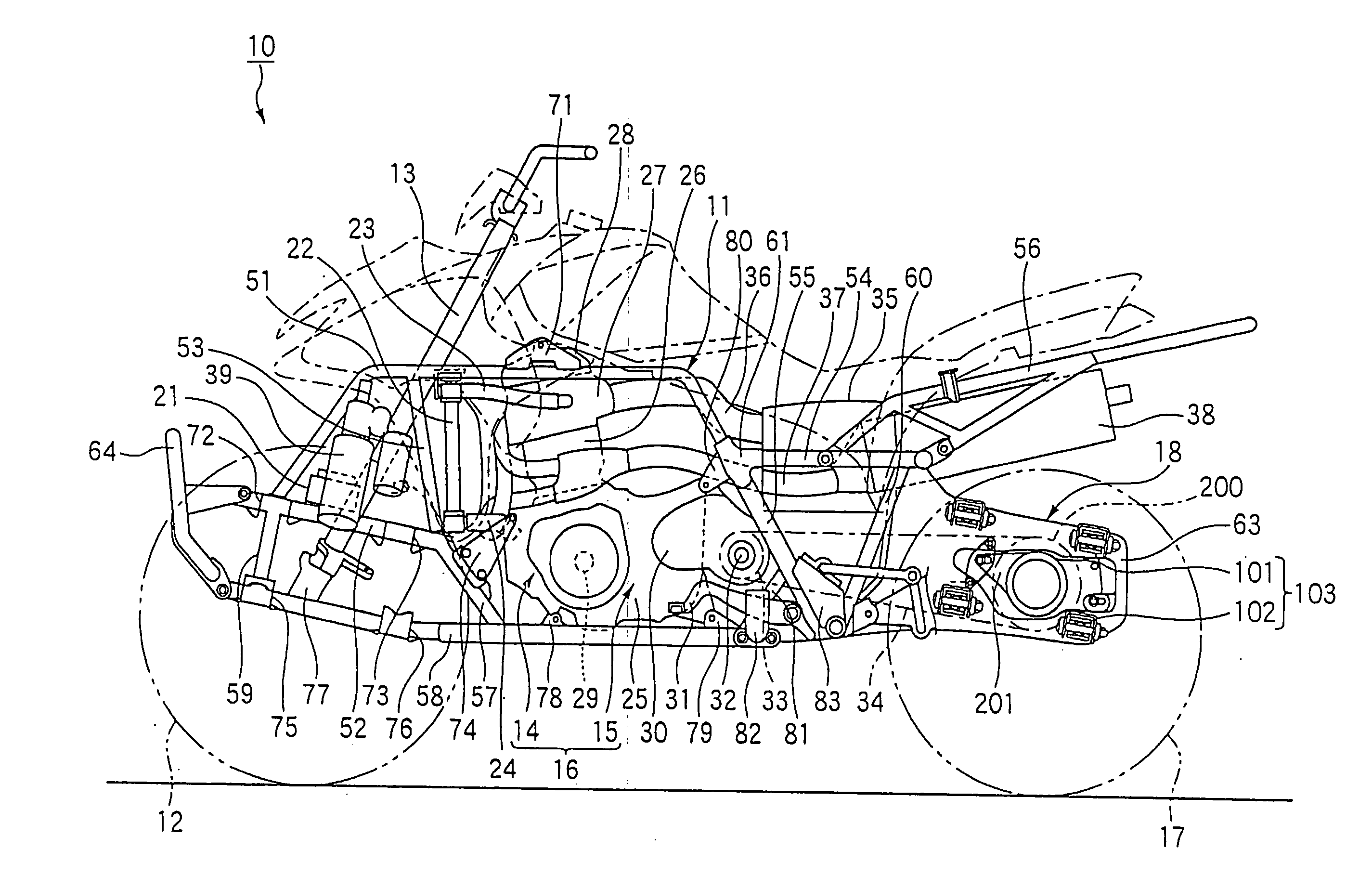

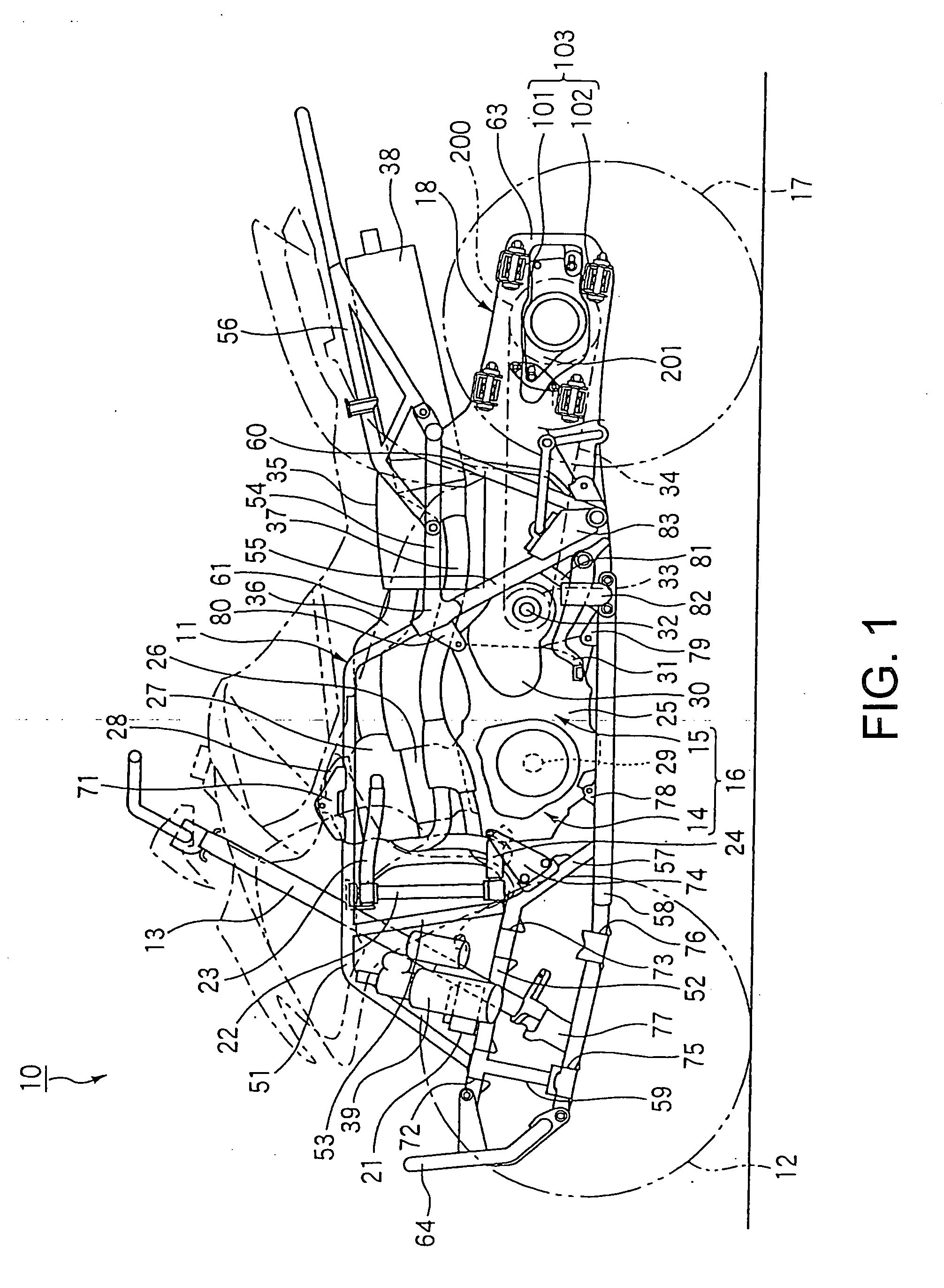

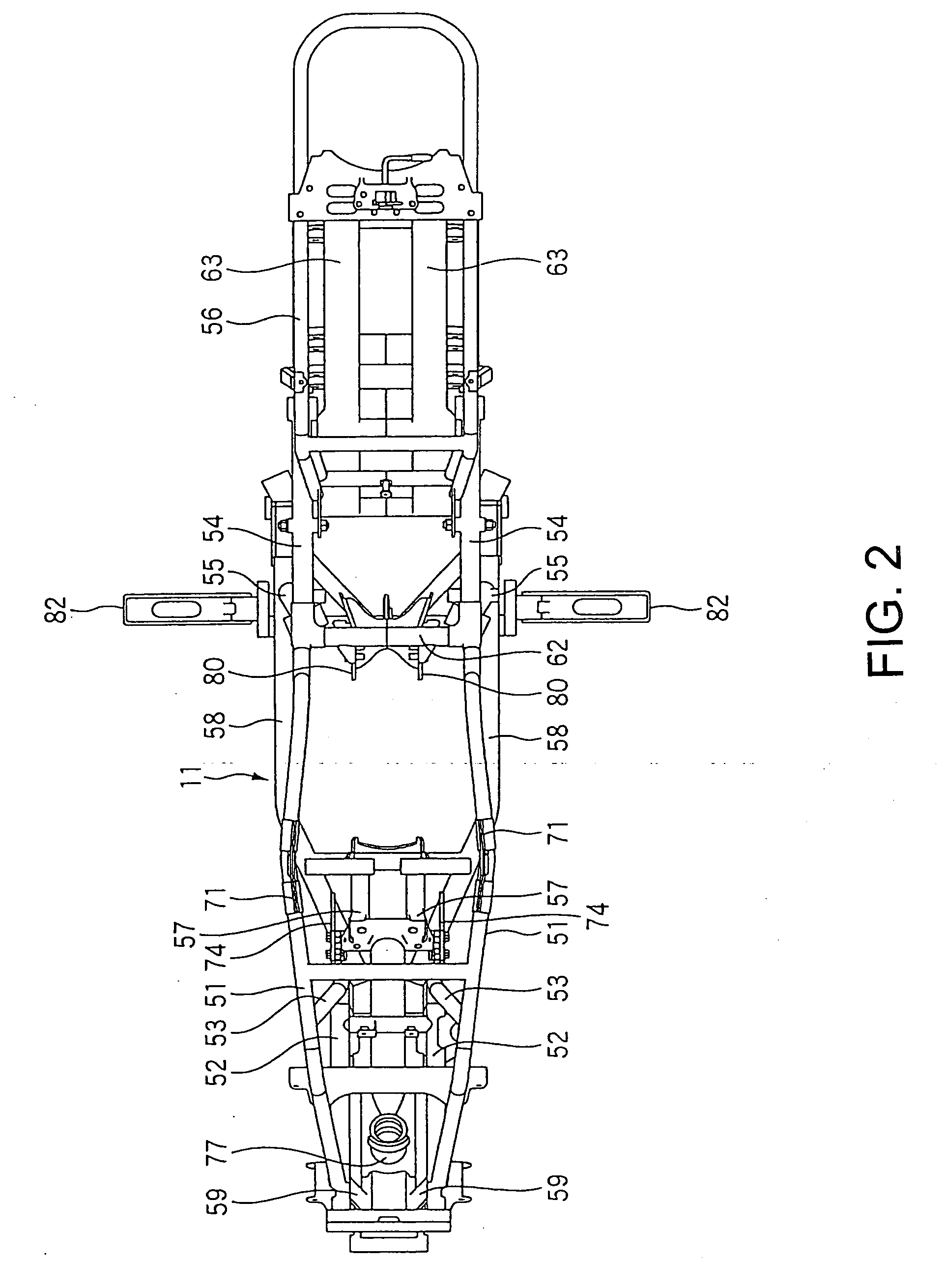

Cushion mounting structure of saddle-ride vehicle

InactiveUS20060220341A1Favorable comfortGood lookingFoot-driven leversWheel based transmissionBraced frameEngineering

A cushion mounting structure of a saddle-ride vehicle with a cushion unit having an elongated stroke length for absorbing an impact from a wheel. The structure includes an upper and a lower arm constituting a suspension arm. The arms are tiltably connected to left and right portions of a support frame, the rear wheels being supported on the suspension arm. One end of a cushion unit is supported on the vehicle body frame, while the other end is supported on an upper arm by a link member and a push rod. The first end of the cushion unit is positioned inside the vehicle body frame in the vehicle body width direction, the second end of the cushion unit is positioned outside the vehicle body frame in a width direction, and an axis of the cushion unit extends in the longitudinal direction of the vehicle while intersecting the vehicle body frame.

Owner:HONDA MOTOR CO LTD

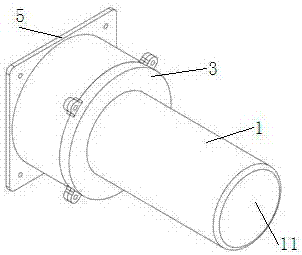

Gas-water separation fire retardant explosion venting device

ActiveCN106051467AEven impactStop the spreadDispersed particle separationPipeline systemsEngineeringFire retardant

The invention belongs to the technical field of safe transportation of a low-concentration gas pipeline, and relates to a gas-water separation fire retardant explosion venting device. The gas-water separation fire retardant explosion venting device comprises a gas inlet pipe (4) and a hollow barrel, wherein both ends of the hollow barrel are closed; a water inlet (9) which is communicated with an external pipeline is formed in one side wall surface of the hollow barrel; water in a cavity between the gas inlet pipe (4) and the hollow barrel is used for water-sealing gas in the gas inlet pipe; the upper end of the gas inlet pipe (4) is bent; a straight section which is eccentric with the hollow barrel is formed on the lower end of the bent section of the gas inlet pipe, and the lower end of the straight section is positioned below the water sealing surface; a perforated plate I (3) is arranged in the combining position of the bent section and the straight section, and the perforated plate I (3) is positioned above the water sealing surface in the plane; a perforated plate II (10) further sleeves the lower end of the straight section of the gas inlet pipe; a baffle (7) is welded on the inner wall surface of a gas outlet pipe. According to the gas-water separation fire retardant explosion venting device, explosion flames are effectively prevented from spreading, and the explosion pressure can be relieved under constant pressure.

Owner:HENAN DIESEL ENGINE IND

CPE (chlorinated polyethylene) thin film and production method thereof

The invention belongs to the technical field of packaging materials, and particularly discloses a CPE (chlorinated polyethylene) thin film and a production method thereof. The CPE thin film is prepared from the following raw materials in parts by mass: 60 parts of CPE, 4 to 7 parts of aluminum foil, 12 to 18 parts of plasticizer, 1 to 5 parts of heat stabilizer, 2 to 3 parts of composite flame-retardant agent, 1 to 3 parts of antioxidant, and 4 to 10 parts of aramid fiber. The production method of the CPE thin film comprises the following steps of (1) preparing of materials; (2) mixing and charging of the materials; (3) extruding and plasticizing; (4) flow-casting; (5) cooling: adopting a cooling device, and utilizing compressed air to blow and attach the flow-casting material onto a cooling roll to cool; (6) thickness measuring and controlling; (7) corona treating; (8) slicing; (9) drawing and coiling. The CPE thin film produced by the method has the advantages that the cooling effect of the CPE thin film is good, and the low quality of the thin film due to nonuniform cooling and overhigh cooling temperature can be avoided.

Owner:CHONGQING RUITING PLASTIC

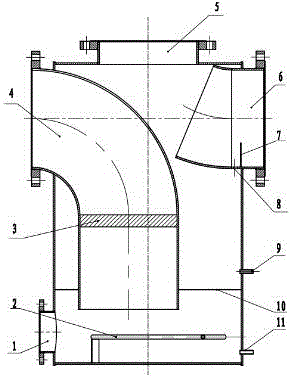

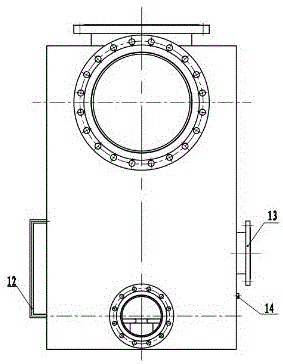

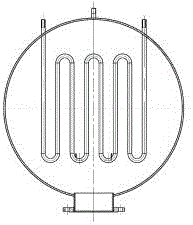

Modified water-separating damper for water inlet of covered pipe of cooler

The invention discloses a modified water-separating damper for a water inlet of a covered pipe of a cooler. The modified water-separating damper comprises a cooling pipe and is characterized in that the cooling pipe is provided with a water-separating damper body mounted on the front lateral part of the cooling pipe. The water-separating damper body comprises a front cover recess plate and a back cover plate, a plurality of water outlets are evenly distributed in the back cover plate, the water inlet pipes are connected to the front end face of the front cover recess plate and communicated with the same, dampers are mounted in the middle positions inside the front cover recess plate and welded on the inner side of the front cover recess plate, and face to the water inlet pipes. According to the arrangement,the inflowing water firstly impacts on the dampers, and then evenly impacts on the whole covered pipe inside; since the water does not impact directly on the cooling pipe, impact force generated is greatly reduced, impact on welding points of the cooling pipe inside is further greatly reduced, and service life of equipment is thus prolonged.

Owner:昆山市润苏物资有限公司

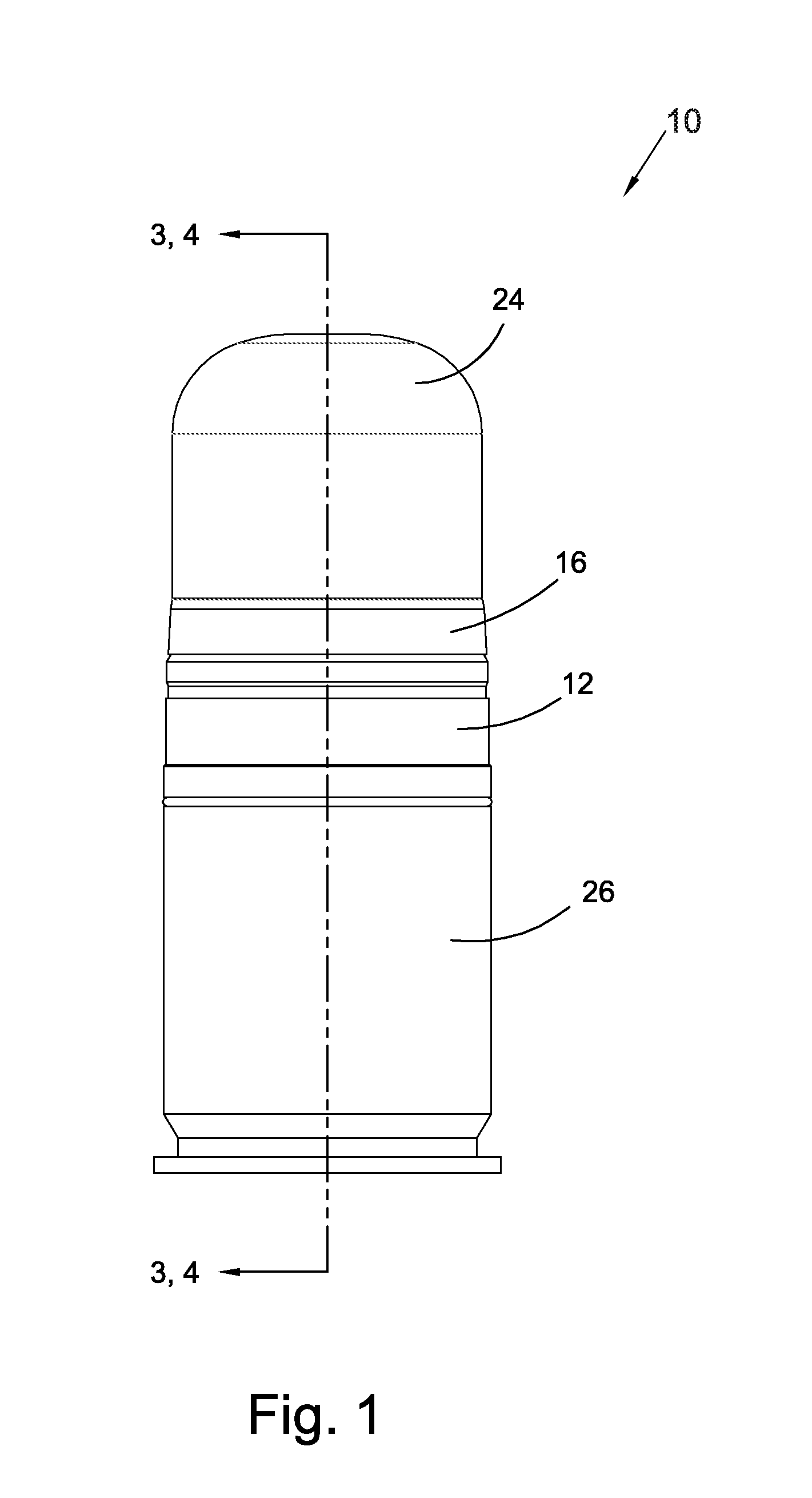

Payload carrying arrangement for a non-lethal projectile

ActiveUS9958242B2Maximize safetyEven impactAmmunition projectilesProjectilesEngineeringMechanical engineering

A payload dispersion system for a non-lethal projectile including a resilient layer and a marker packet having a hollow body including a lower surface, at least a partial opening centrally disposed, an upper surface, a volume formed by the lower surface, the at least a partial opening and the upper surface and a payload contained within the volume. The upper surface of the marker packet includes a wall and at least one weakened portion within the wall. The lower surface of the marker packet contacts an upper surface of the resilient layer.

Owner:FACTA GLOBAL INC

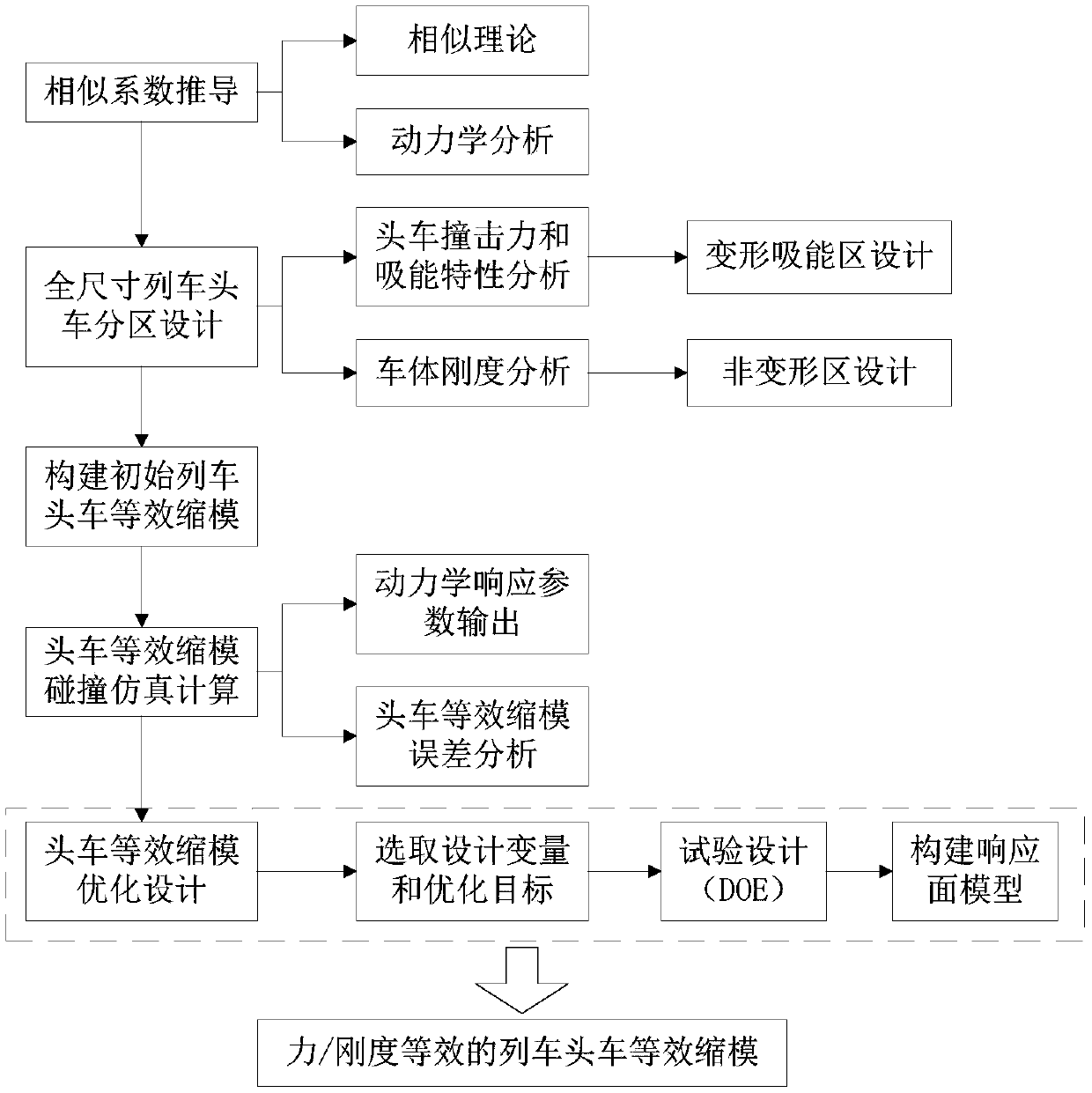

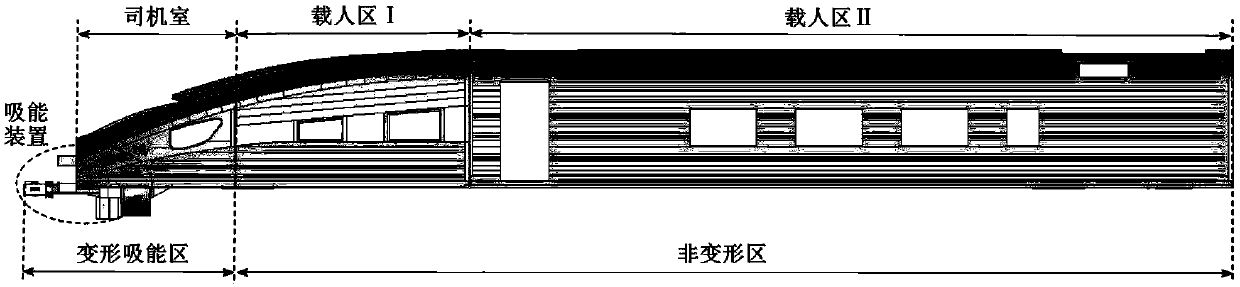

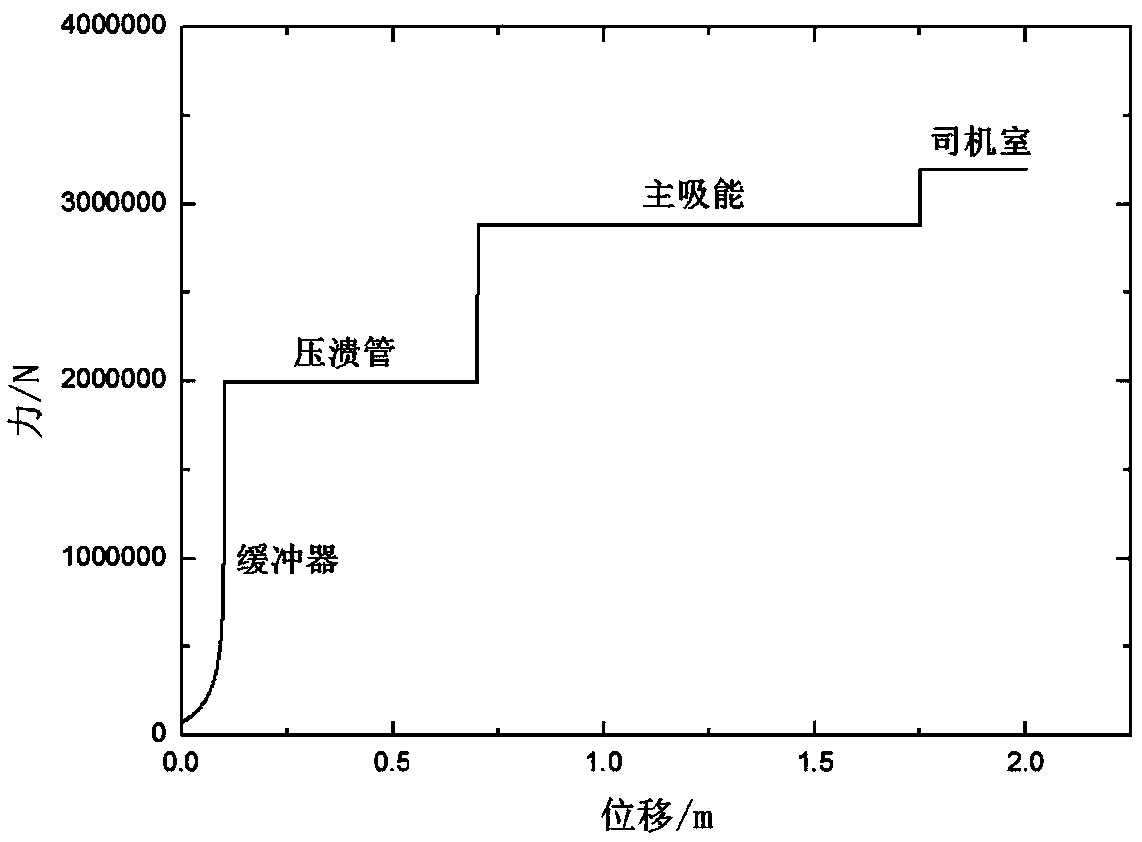

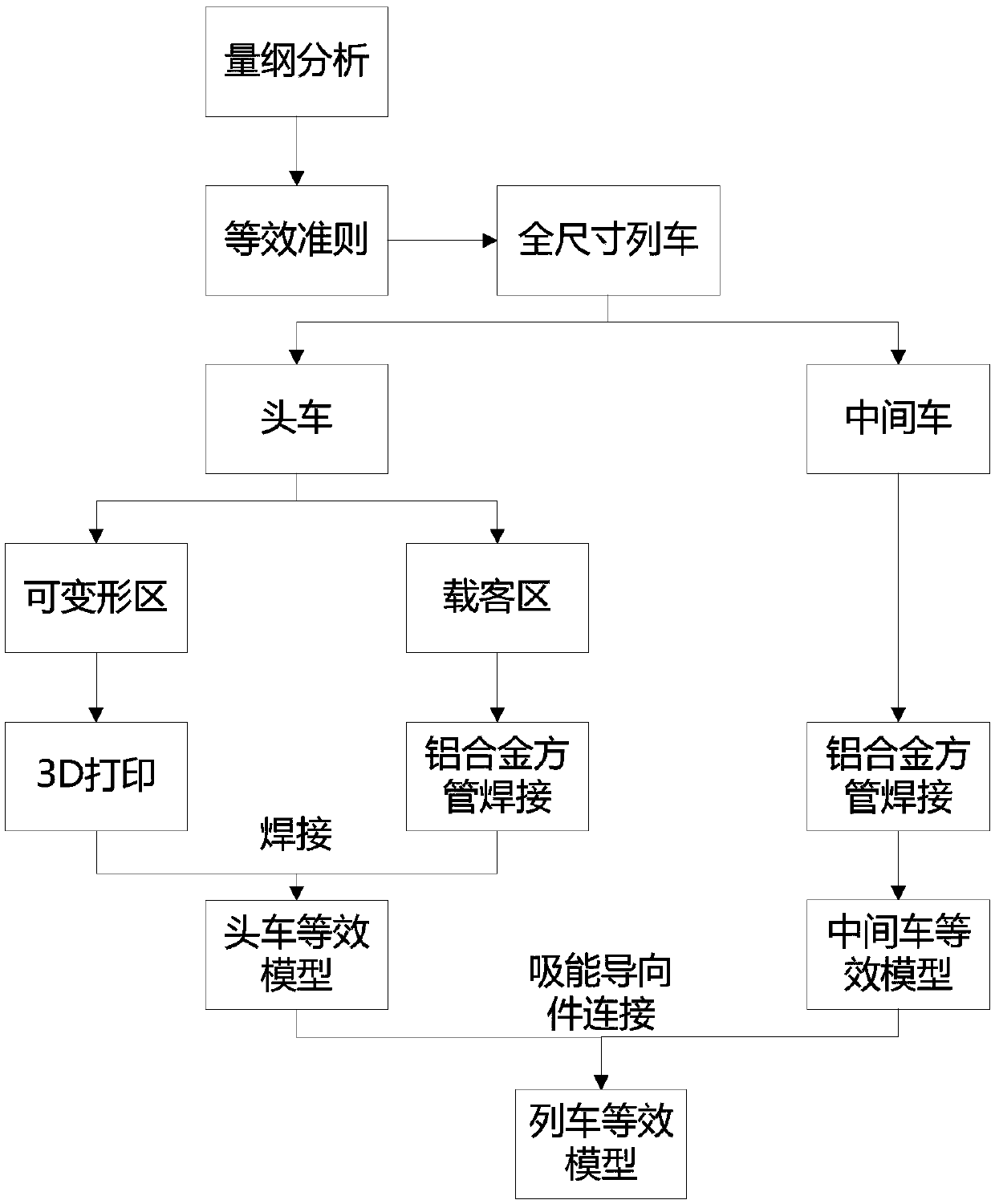

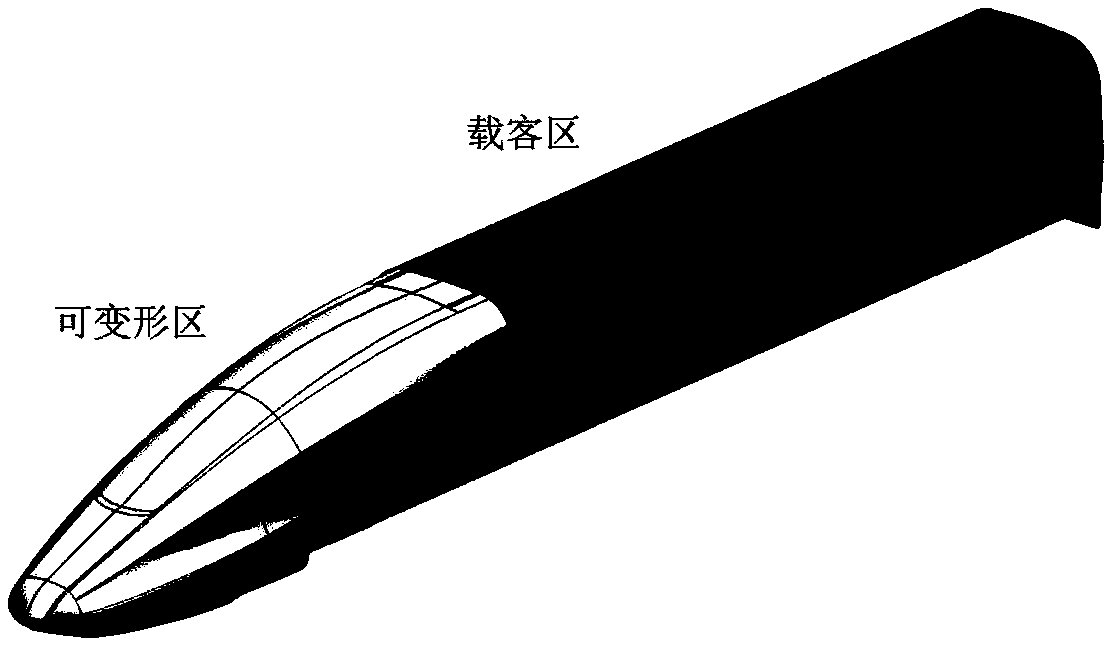

A force and rigidity equivalence-based head car mold shrinkage construction method and a head car mold shrinkage

ActiveCN109670252ASimilar kinetic propertiesEven impactGeometric CADDesign optimisation/simulationEnergy absorptionEngineering

The invention discloses a train head car mold shrinkage construction method based on force and rigidity equivalence and a head car mold shrinkage. The method comprises the following steps of S1, obtaining the similarity factors of the head car mold shrinkage relative to all dynamic parameters of a full-size train; S2, dividing the full-size train head into a deformation energy absorption area anda non-deformation area according to the deformation energy absorption characteristic; S3, respectively constructing a deformation energy absorption area and a non-deformation area of the head car shrinkage mold based on the similarity factors, according to the deformation energy absorption curve of the full-size train head car, a deformation energy absorption characteristic curve of a head car shrinkage mold is obtained through conversion, and the sizes of a buffer, a crushing pipe, a main energy absorption device and a cab in a deformation energy absorption area of the head car shrinkage moldare designed on the basis of the deformation energy absorption characteristic curve of the head car shrinkage mold and size similarity factors; and designing a non-deformation area of the head car shrinkage mold according to the size similarity factor and the rigidity similarity factor. According to the present invention, the built head train shrinkage mold can ensure that the train impact forceand the train body rigidity are similar, the train collision process is accurately restored, and the reliability is higher.

Owner:CENT SOUTH UNIV

Payload carrying arrangement for a non-lethal projectile

ActiveUS20160320167A1Maximize safetyEvenly disperseAmmunition projectilesProjectilesEngineeringProjectile

A payload dispersion system for a non-lethal projectile including a resilient layer and a marker packet having a hollow body including a lower surface, at least a partial opening centrally disposed, an upper surface, a volume formed by the lower surface, the at least a partial opening and the upper surface and a payload contained within the volume. The upper surface of the marker packet includes a wall and at least one weakened portion within the wall. The lower surface of the marker packet contacts an upper surface of the resilient layer.

Owner:FACTA GLOBAL INC

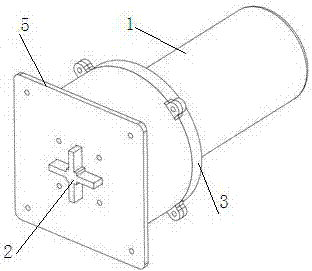

Energy absorption device based on necking plastic deformation

ActiveCN107336721AStable tensile plastic deformationStretch-Plastic Deformation OrderRailway wheel guards/bumpersEnergy absorptionAbsorbed energy

The invention discloses an energy absorption device based on necking plastic deformation. The energy absorption device comprises a mounting plate provided with mounting through holes. A necking concave die is arranged in each mounting through hole of the mounting plate. A necking through hole is formed in the middle of each necking concave die. A necking deformation pipe is embedded in each necking through hole in a cooperation manner. An impact convex die is inserted in the necking deformation pipes. One end of the impact convex die is located outside the large-diameter pipe ends of the necking deformation pipes, the other end of the impact convex die is in contact with a bottom plate arranged at the small-diameter pipe end of each necking deformation pipe, and the small-diameter pipe ends are inserted into the necking through holes of the necking concave dies. Each necking deformation pipe is a thin-wall metal pipe, and the strength of the necking deformation pipes is smaller than that of the impact convex die and that of the necking concave dies. The impact convex die can transmit impact force to the bottom plates of the necking deformation pipes, so that the necking deformation pipes are converted to be pulled from being pressed to generate stable plastic deformation so as to absorb energy. The energy absorption device further has the beneficial effects of being simple in structure, convenient to mount, capable of bearing stronger impact force, capable of avoiding transverse unstability and stable in deformation, saving cost and the like.

Owner:CENT SOUTH UNIV

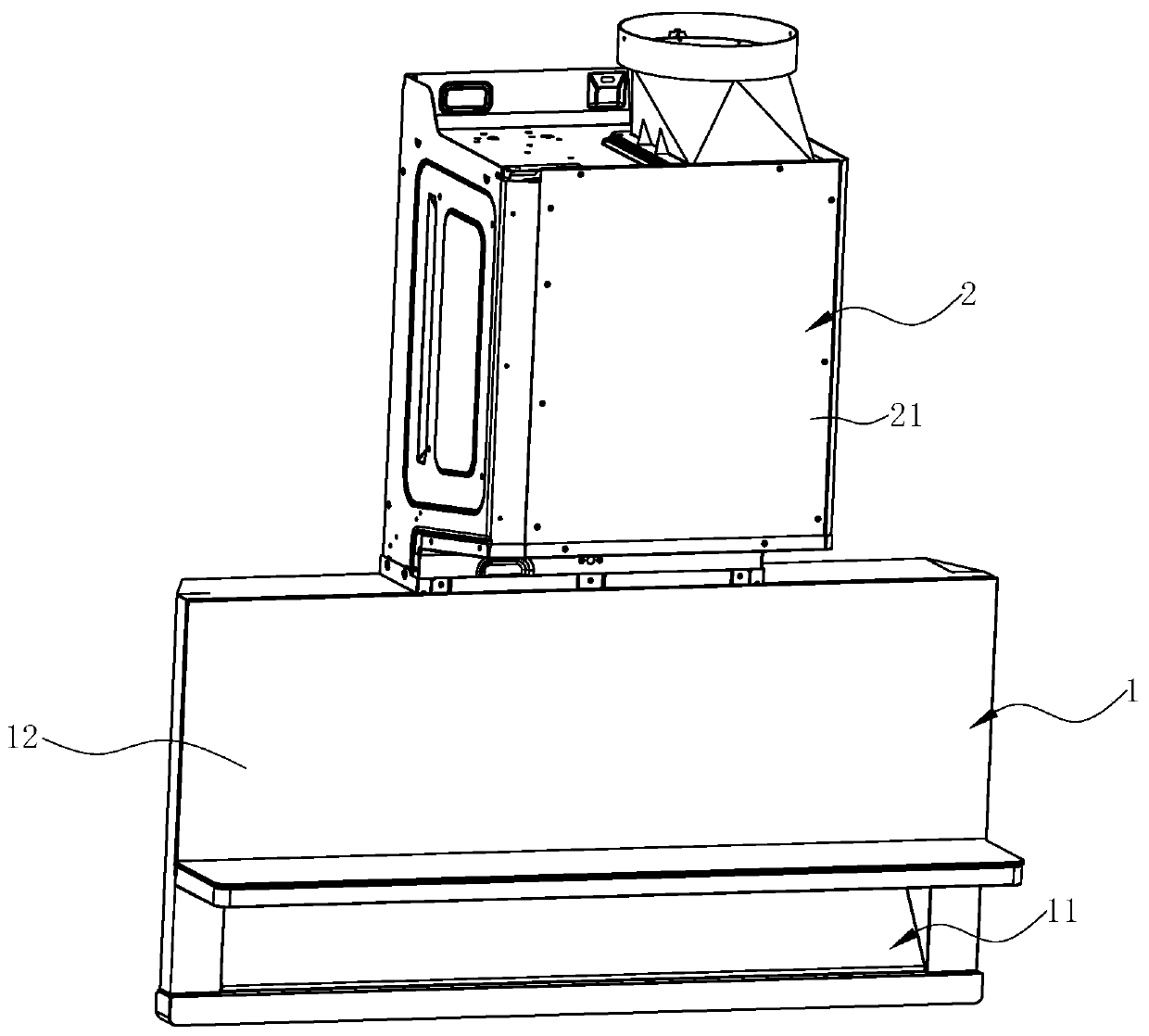

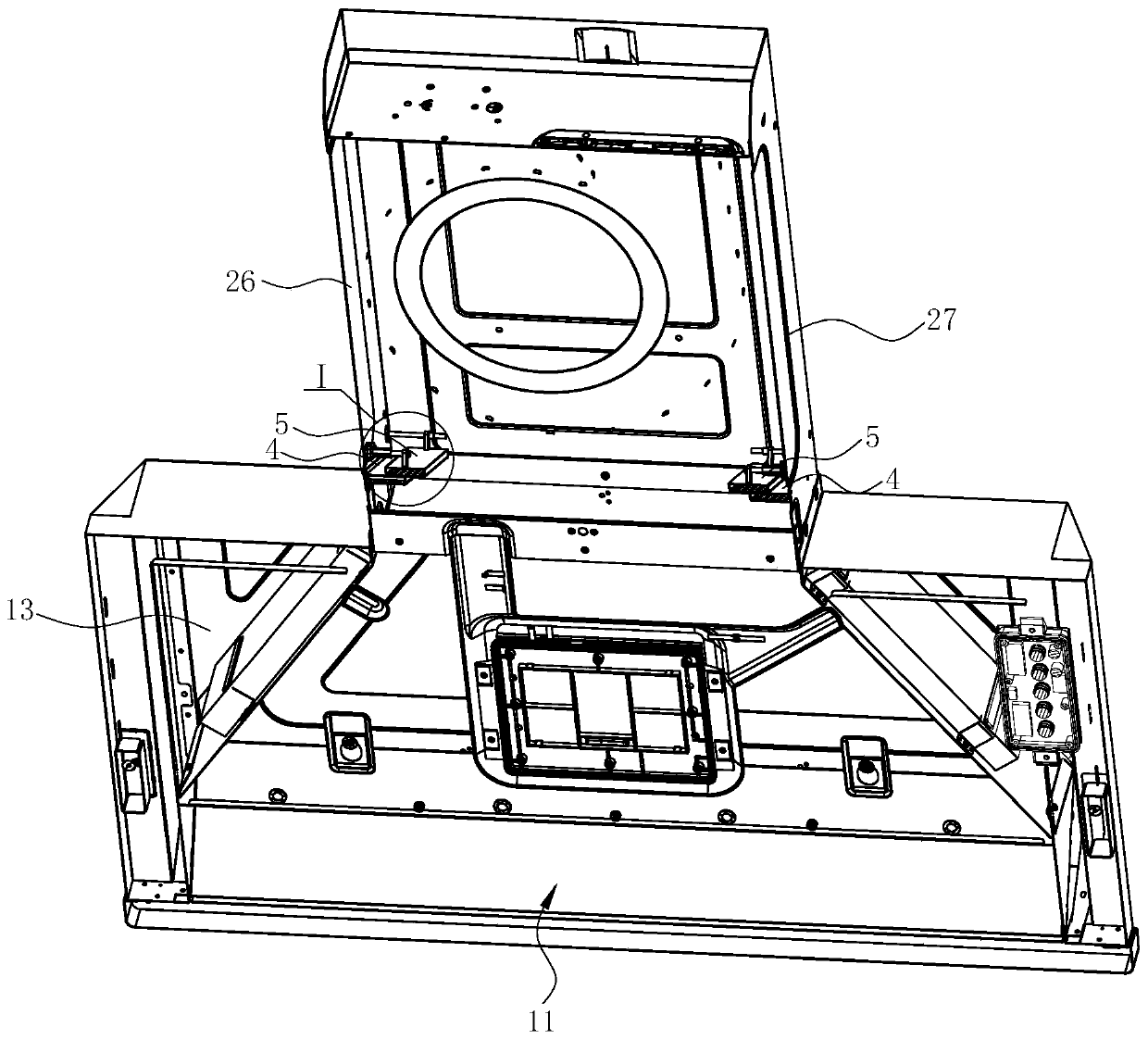

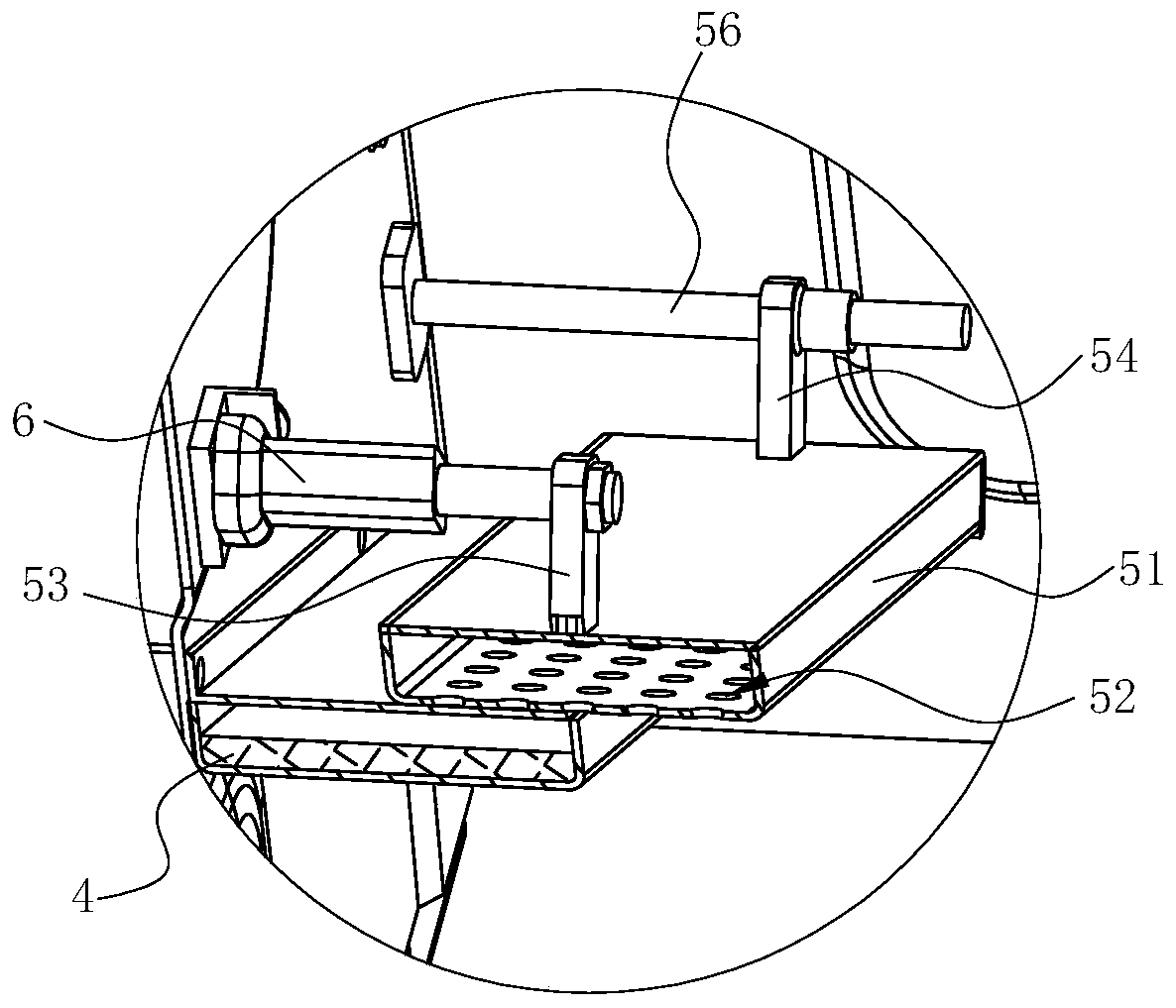

Range hood and control method thereof

ActiveCN111197780AEvenly loadedPrevent skippingDomestic stoves or rangesPump componentsImpellerEngineering

The invention discloses a range hood. The range hood comprises an air inlet assembly, a fan frame arranged above the air inlet assembly and a fan system arranged in the fan frame, wherein the fan system is provided with a main air inlet facing backwards and an auxiliary air inlet facing forwards, the range hood further comprises first flow deflectors and second flow deflectors arranged in the fanframe, the two first flow deflectors extend in the front-back direction and are arranged below the left side and the right side of the fan system correspondingly, each first flow deflector gradually inclines downwards from front to back, the two second flow deflectors extend in the front-back direction and are arranged below the left side and the right side of the fan system in a left-right movingmode correspondingly, and each second flow deflector gradually inclines downwards from front to back. The invention further discloses a control method of the range hood. Compared with the prior art,the range hood and the control method have the advantages that vortexes inside the range hood and separated boundary layers of air flow can be adjusted, so that the air flow impact on an impeller of the fan system is relatively uniform.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

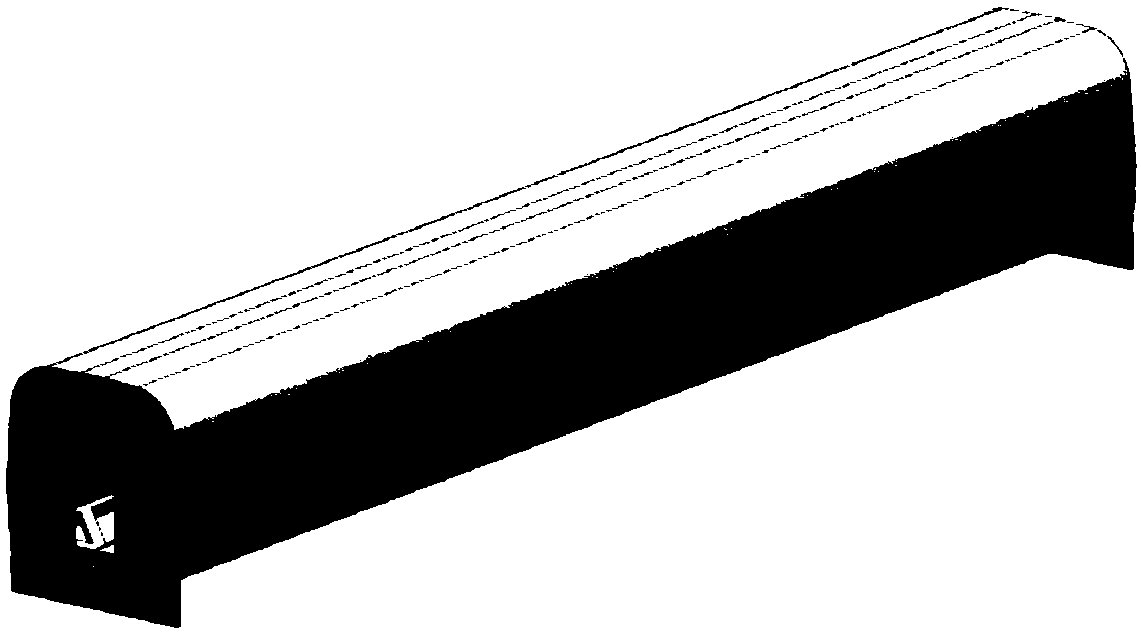

Train equivalent mold shrinkage construction method and a train equivalent mold shrinkage

ActiveCN109657377AImprove reliabilityEven impactGeometric CADSpecial data processing applicationsHoneycombAluminium

The invention discloses a train equivalent mold shrinkage construction method and a train equivalent mold shrinkage. The method comprises the steps of acquiring scale factors of the train equivalent mold shrinkage relative to all dynamic parameters of a full-size train; dividing the train into a head train and a middle train according to the deformation energy absorption characteristics in the train collision process, and dividing the head train into a deformation energy absorption area and a non-deformation area; respectively constructing a head car and an intermediate car of train equivalentmold shrinkage based on the scale factor of the dynamic parameters; According to the deformation energy absorption characteristics of the connecting couplers between the adjacent carriages on the full-size train, constructing energy absorption guide pieces between the adjacent carriages on the train equivalent shrinkage mold, and calculating the length of the honeycomb aluminum cylinder based onthe size scale factor; And calculating the sectional area of the energy absorption guide piece according to the structural size of the connecting coupler and the deformation energy absorption characteristic curve. The built head train shrinkage mold can ensure that the train impact force and the train body rigidity are similar, the train collision process is accurately restored, and the reliability is higher.

Owner:CENT SOUTH UNIV

Punching machine suitable for cloth, hide and leather

InactiveCN105150275AImprove punching effectImprove drilling accuracyLeather clicking/perforating/clickingSevering textilesElastic componentPunching

The invention provides a punching machine suitable for cloth, hide and leather. The punching machine is uniform in impact, high in punching accuracy, excellent in punching effect and particularly capable of improving the punching accuracy and the punching effect of multiple holes. The punching machine suitable for cloth, hide and leather comprises a rack, a punching knife, a punching plate and a driving mechanism are arranged in the rack, the punching plate is installed in the rack in a vertically movable mode and has an impact effect on the punching knife, and the driving mechanism drives the punching plate to move vertically; the tail end of the punching knife is provided with a plane with the area equal to that of pre-machined punching holes, the punching plate is provided with a planar surface, the surface of the punching plate is parallel to the plane at the tail end of the punching knife, and the area of the surface of the punching plate is larger than the area of the plane formed at the tail end of the punching knife. The rack is provided with an elastic component acting on the punching knife, and the punching knife has a static station under the single action of the elastic component and a vertical microstroke under the combined action of the punching plate and the elastic component.

Owner:徐州千百度鞋业有限公司

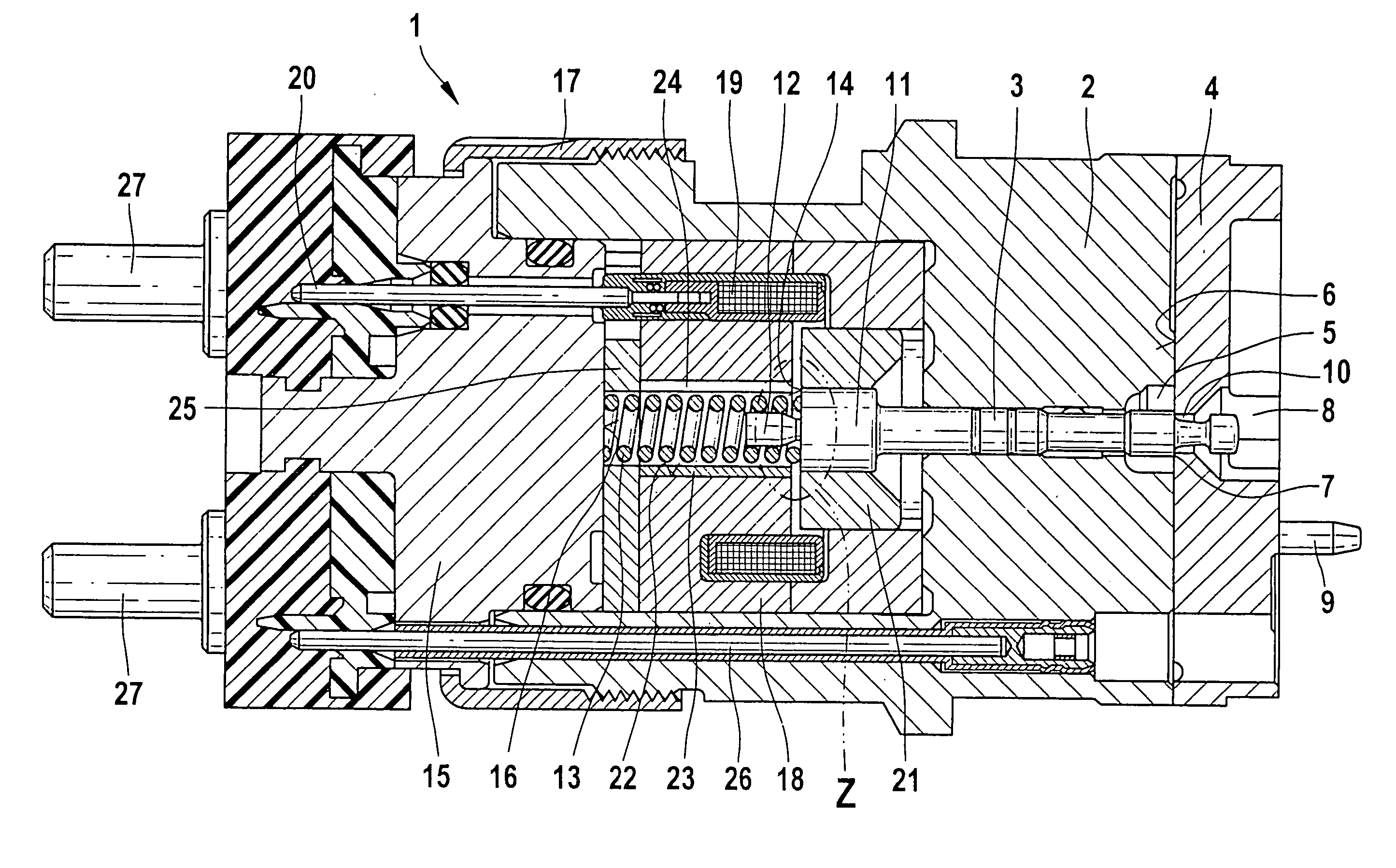

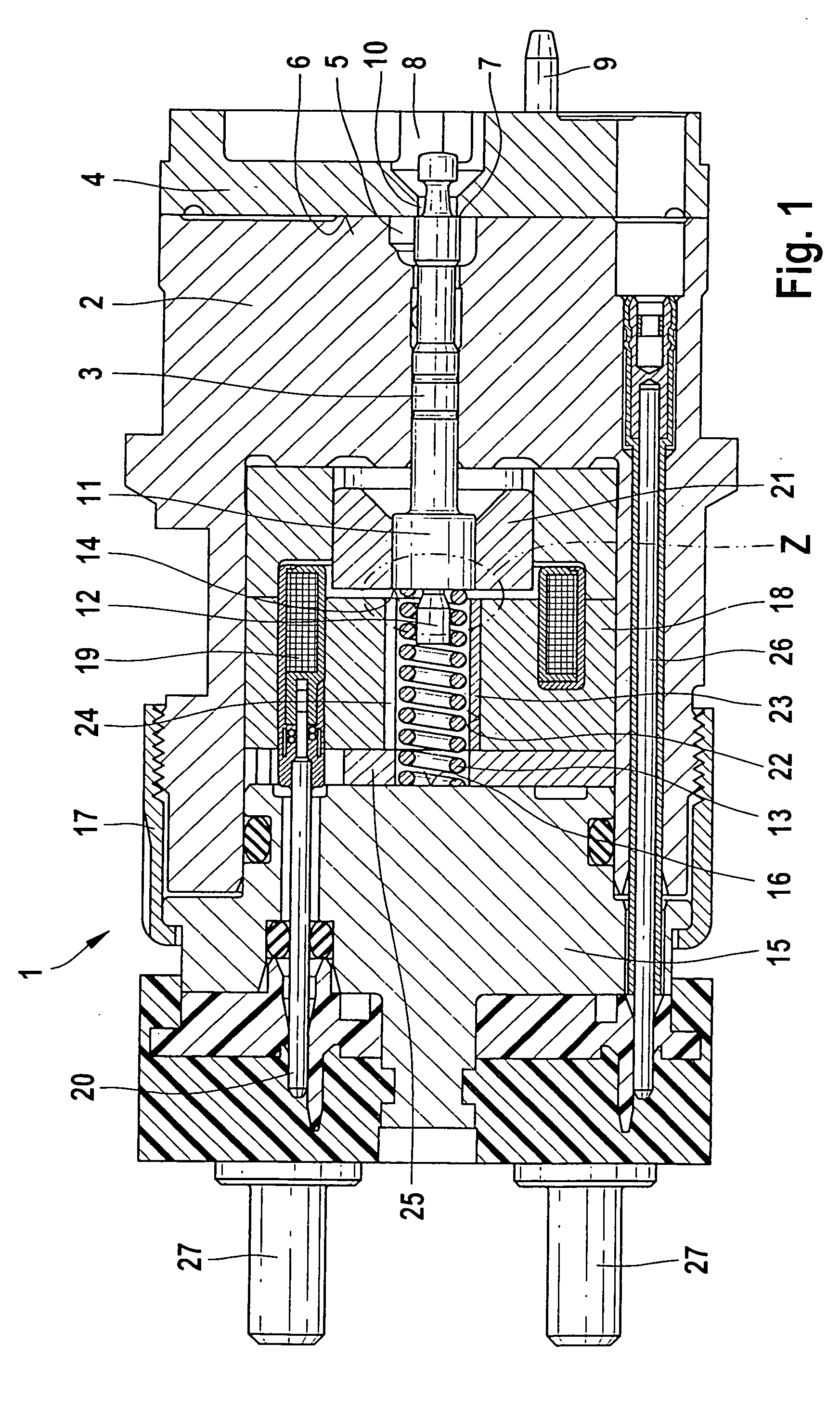

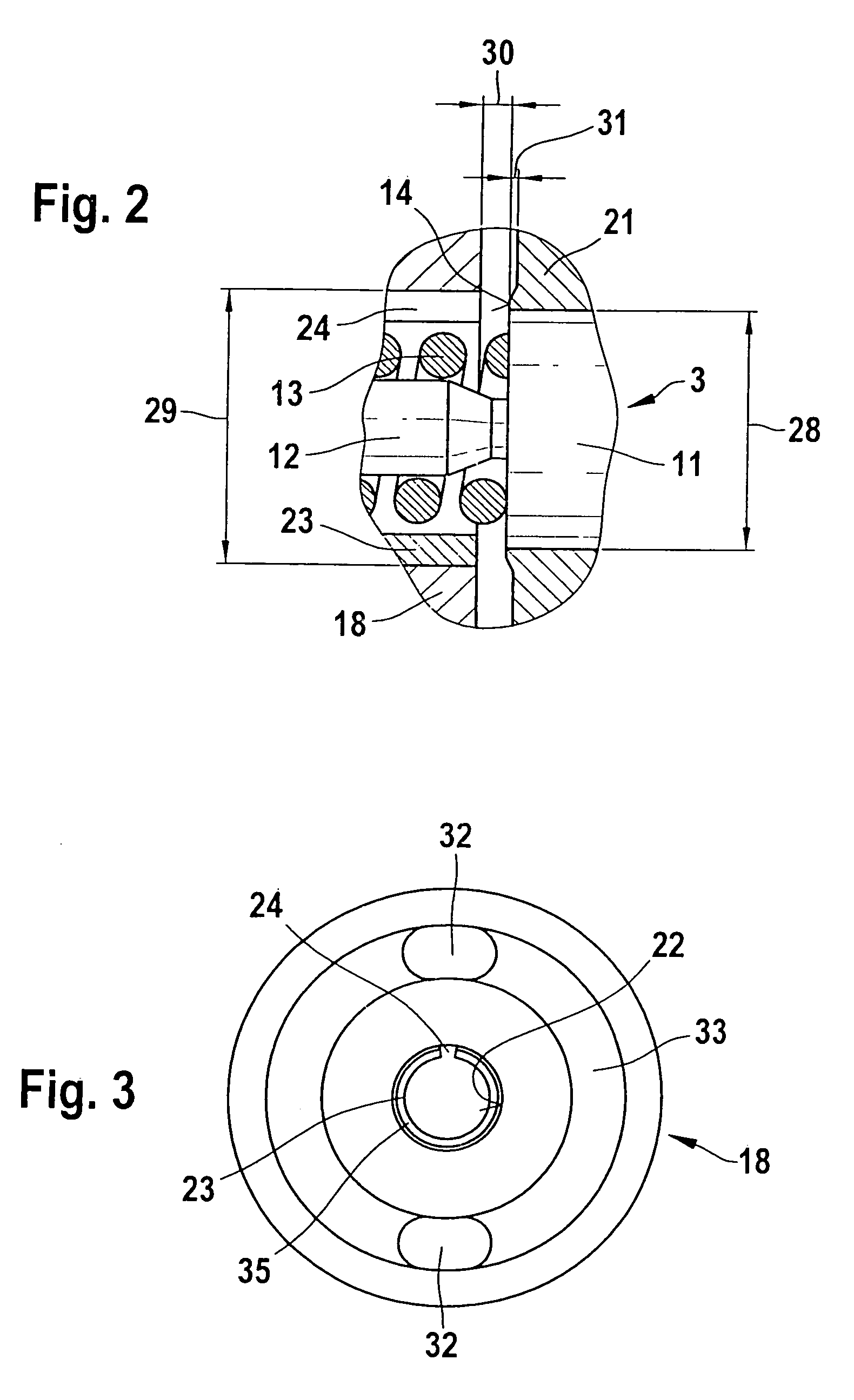

Fuel injector with clamping sleeve as a stop for a valve needle

InactiveUS20050274829A1Even impactAccurate openingOperating means/releasing devices for valvesSpray nozzlesCombustionEngineering

The invention relates to a fuel injector for internal combustion engines, having a control valve with an electromagnetically actuatable valve needle; a coil is received in a magnet cup made of magnetizable material. At least one clamping sleeve, with a gaplike opening extending between the face ends of the clamping sleeve, is received in the magnet cup. The invention also relates to a method for producing the fuel injector.

Owner:ROBERT BOSCH GMBH

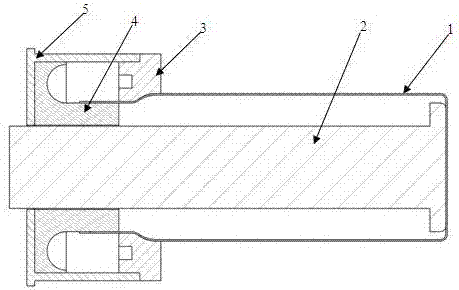

Energy absorbing device of coupling-necking and spalling-deformation

ActiveCN107380192AImprove protectionEnhanced ability to absorb impact kinetic energyRailway wheel guards/bumpersEngineeringFlange

The invention discloses an energy absorbing device of coupling-necking and spalling-deformation. The energy absorbing device of coupling-necking and spalling-deformation comprises an installing base, a guiding rod, a ballooning convex platform, a necking flange and a necking deformation pipe. One end of the guiding rod is arranged in a guiding through hole of the installing base in an inserting mode. The ballooning convex platform is located in an installing cavity of the installing base and arranged on the guiding rod through a guiding hole of the ballooning convex platform in a sleeving mode. The necking deformation pipe is arranged on the guiding rod in the sleeving mode. A plurality of small grooves are formed in a pipe opening of a small diameter pipe of the necking deformation pipe, and the small diameter pipe is arranged at the periphery of the ballooning convex platform in the sleeving mode. A bottom plate is arranged at the end of a large diameter pipe, and the end of the large diameter pipe makes contact with the end part of the other end of the guiding rod to be used as an impacting end. The necking flange is arranged on the outer side of the necking deformation pipe in the sleeving mode and in a matched mode through a necking through hole of the necking flange and fixedly connected with the installing base. A storing cavity which can store coupling-necking and spalling-buckling-deformation caused by moving after the necking deformation pipe is impacted is formed between the periphery of the ballooning convex platform, the end part of the necking flange and the inner wall of the installing base. The energy absorbing device of coupling-necking and spalling-deformation has the advantages of being simple in structure, convenient to install, saving in cost, high in energy absorbing capability, stable and controllable in deformation and the like.

Owner:CENT SOUTH UNIV

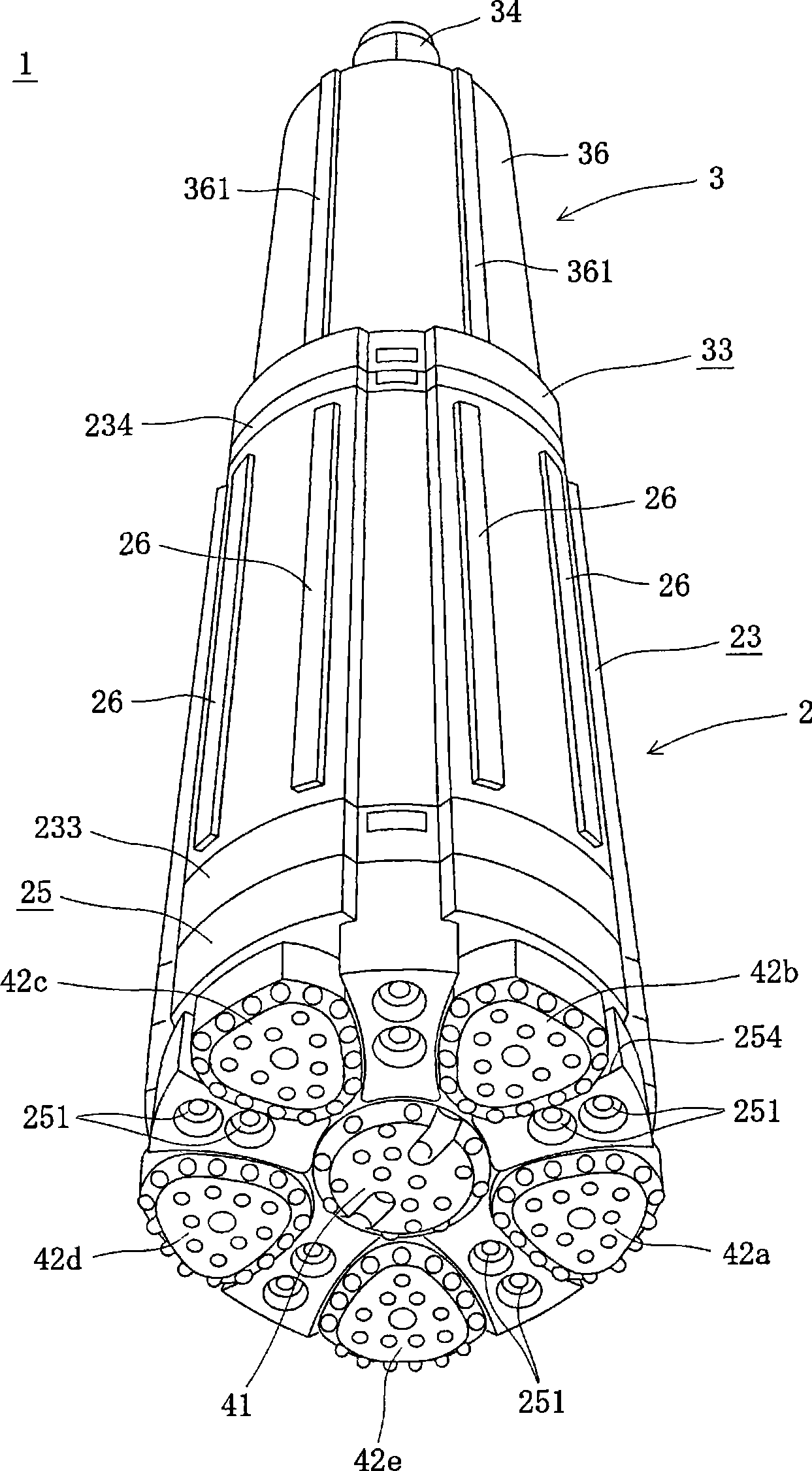

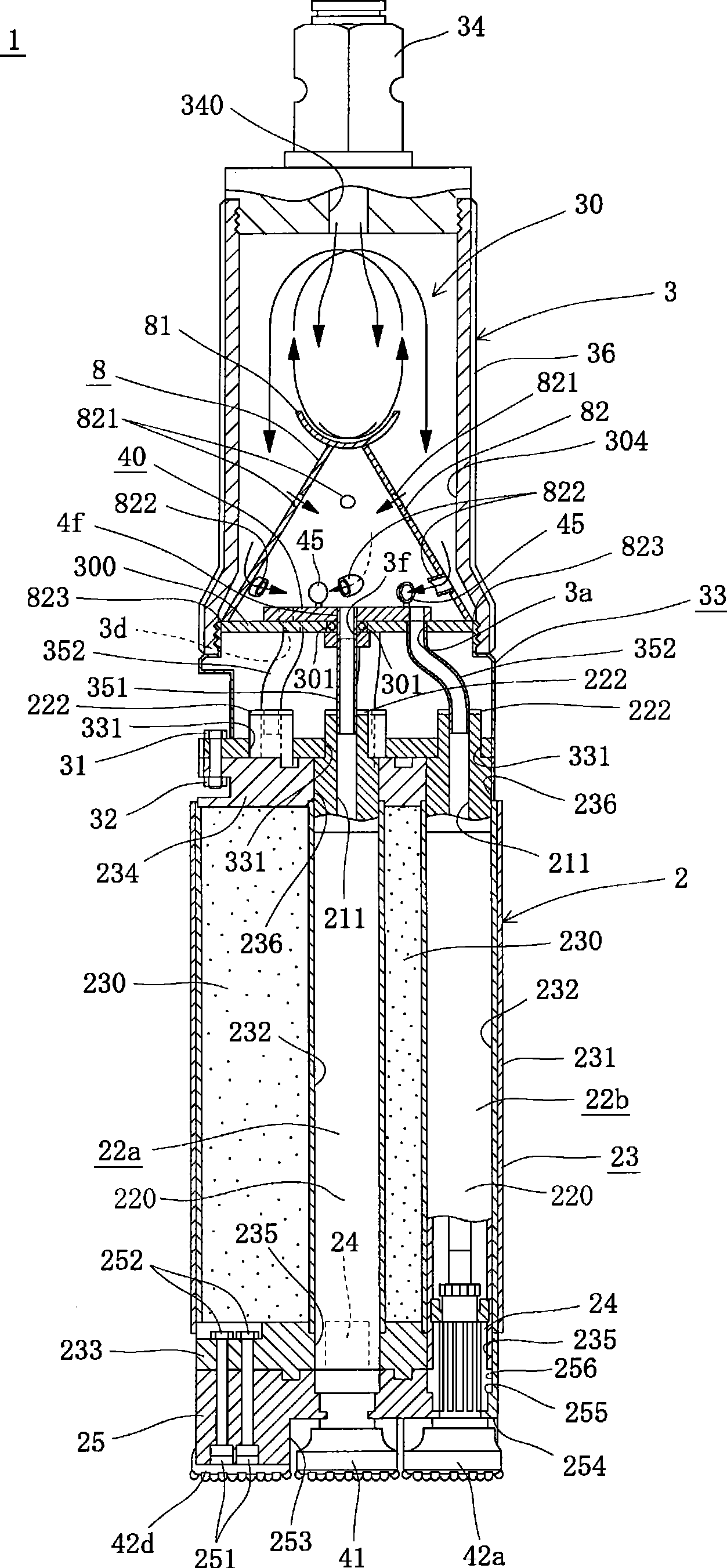

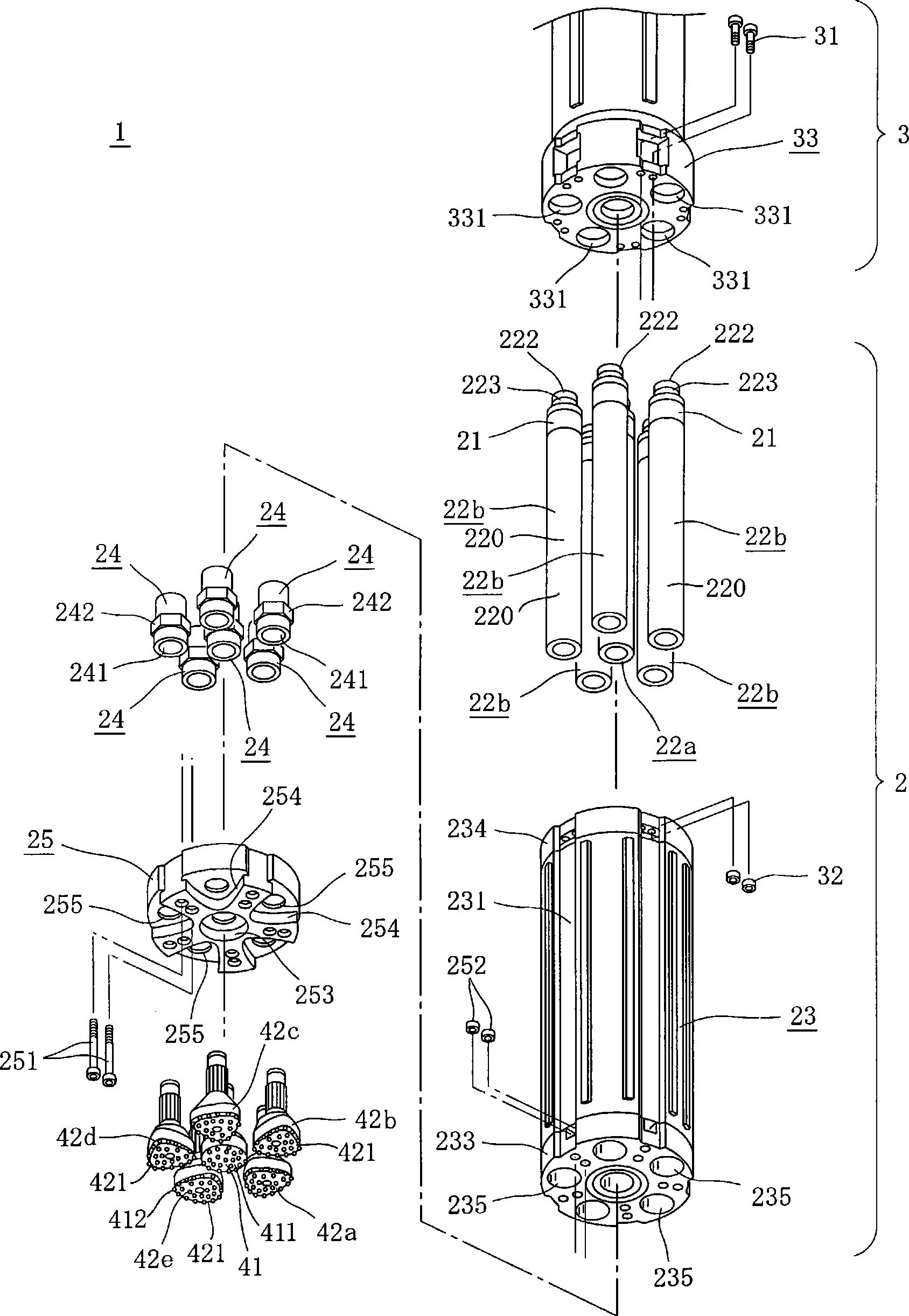

Excavator for underground excavating, rotary excavator and underground excavating method

ActiveCN101484657AReduce shockBig impactBorehole drivesDrilling machines and methodsLow noiseWorking fluid

An excavator for underground excavating arranged to perform excavating work with low vibration and low noise. A rotary excavator and an underground excavating method are also provided. The excavator (1) for underground excavating comprises a plurality of bits (42a, ...) having the outside diameter smaller than that of the excavator body (2) and advancing / retracting to / from the excavating side, piston case members (22b, ...) incorporating pistons (61) for applying a hitting force to respective bits (42a, ...) by the energy of working fluid, a section (30) for storing the working fluid being fed to respective piston case members (22b, ...), working fluid circulation passages (352) for allowing the working fluid being fed to respective piston case members (22b, ...) to pass, and a body of rotation (40) provided with a plurality of holes (4a, ...) for allowing the fluid storage section (30) to communicate with the circulation openings (3a, ...) of each working fluid circulation passage (352) in order to feed the working fluid from the fluid storage section (30) to the circulation openings (3a, ...) of the respective working fluid circulation passages (352).

Owner:古木一功

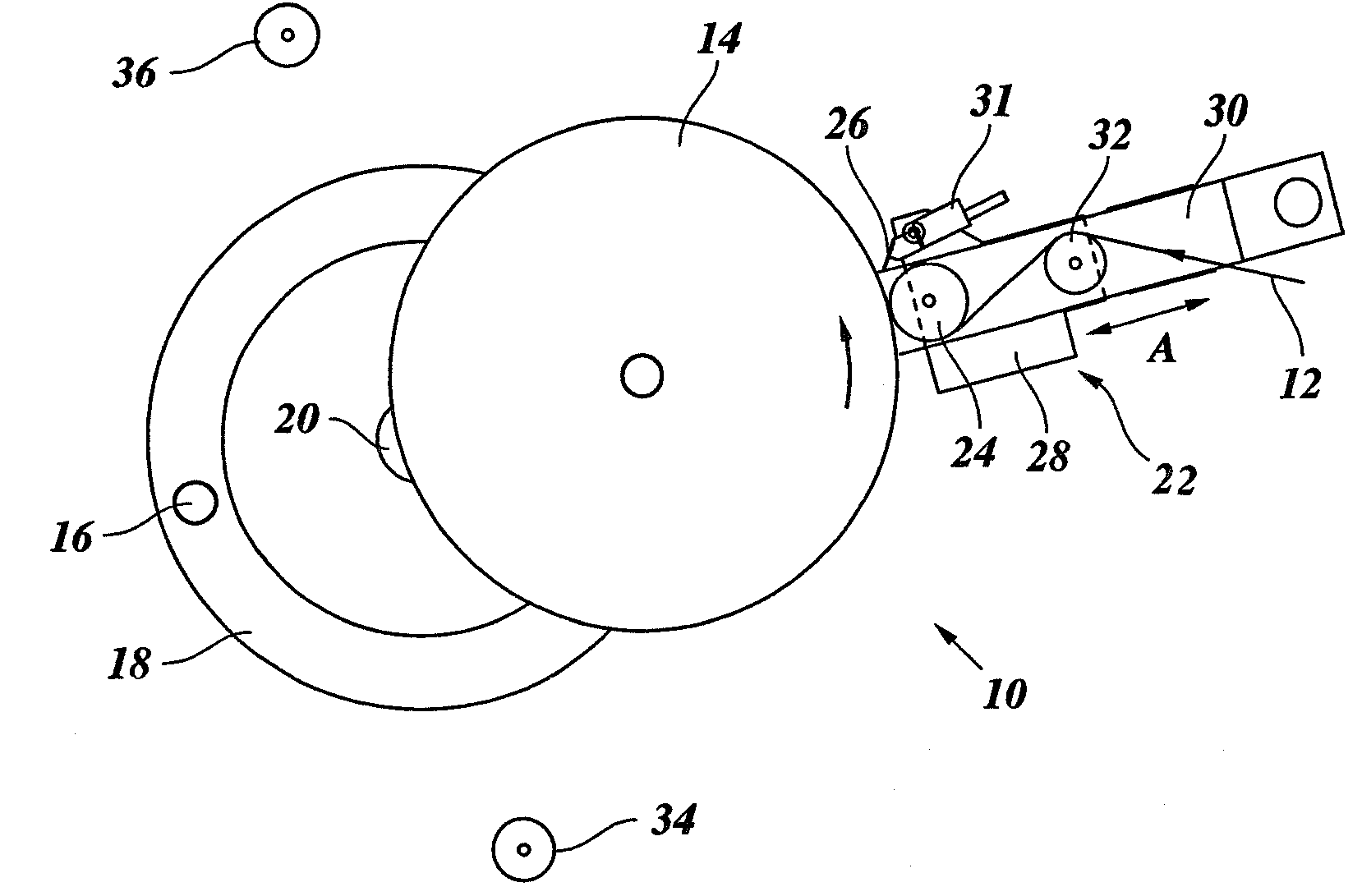

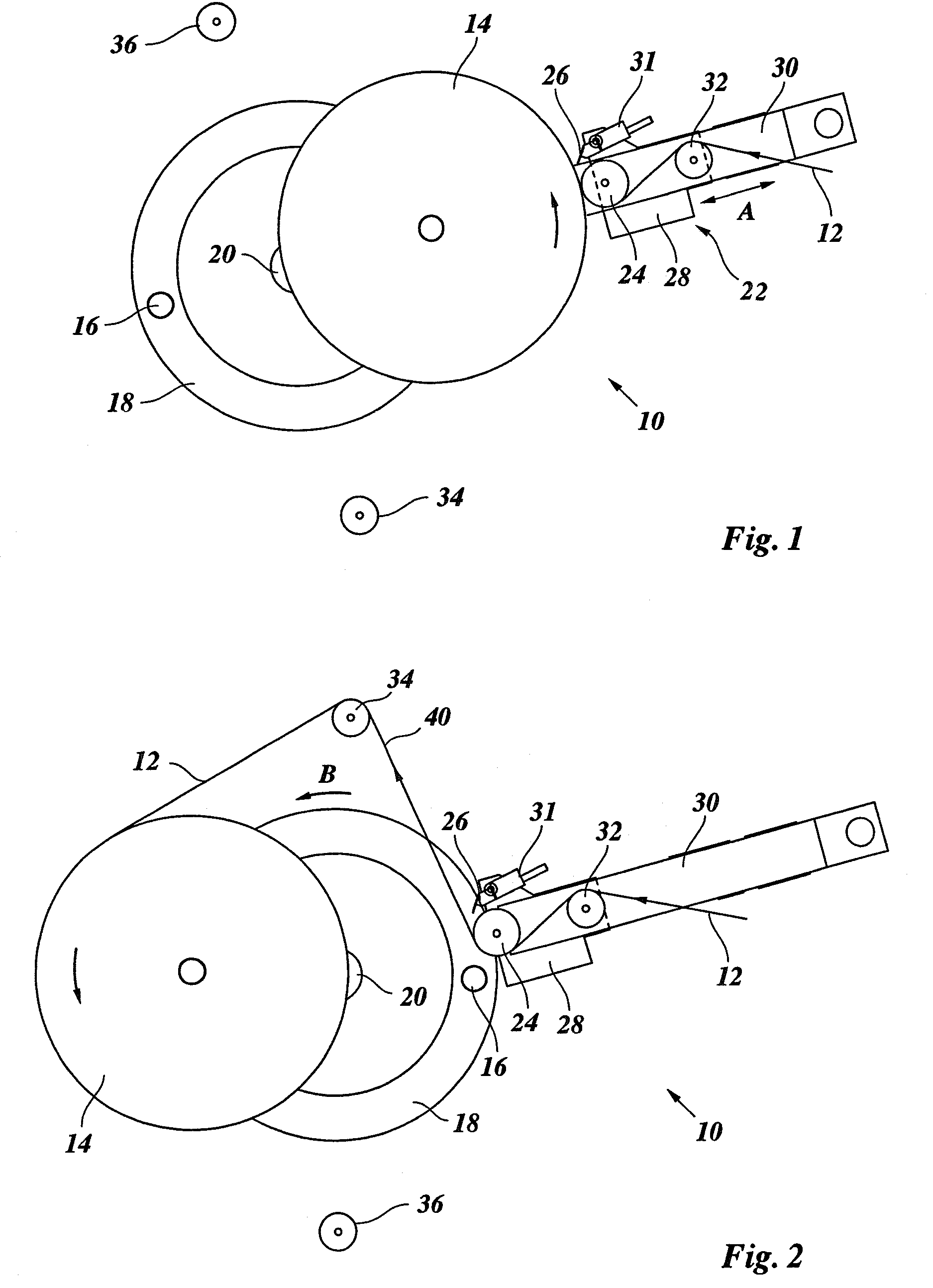

Method for knocking off a web wound on a turret winder

A method for knocking-off a web (12) round on a turret winder (10) by a knocking-off device (22) includes a pressure roller (24), in which the knocking-off device (22) and a coil (16) of the winder (10) are, through an abrupt relative movement, brought into a position in which the pressure roller (24) engages the periphery of the coil (16) and the abrupt movement is a pivotal movement (B) of the coil (16) about a pivotal axis that extends in parallel with the axes of rotation thereof.

Owner:FISCHER & KRECKE

Shredding device for a shredding plant

InactiveUS20110168822A1Effective expansionFor quick ejectionGrain treatmentsEngineeringMechanical engineering

Owner:DANIELI UK HLDG

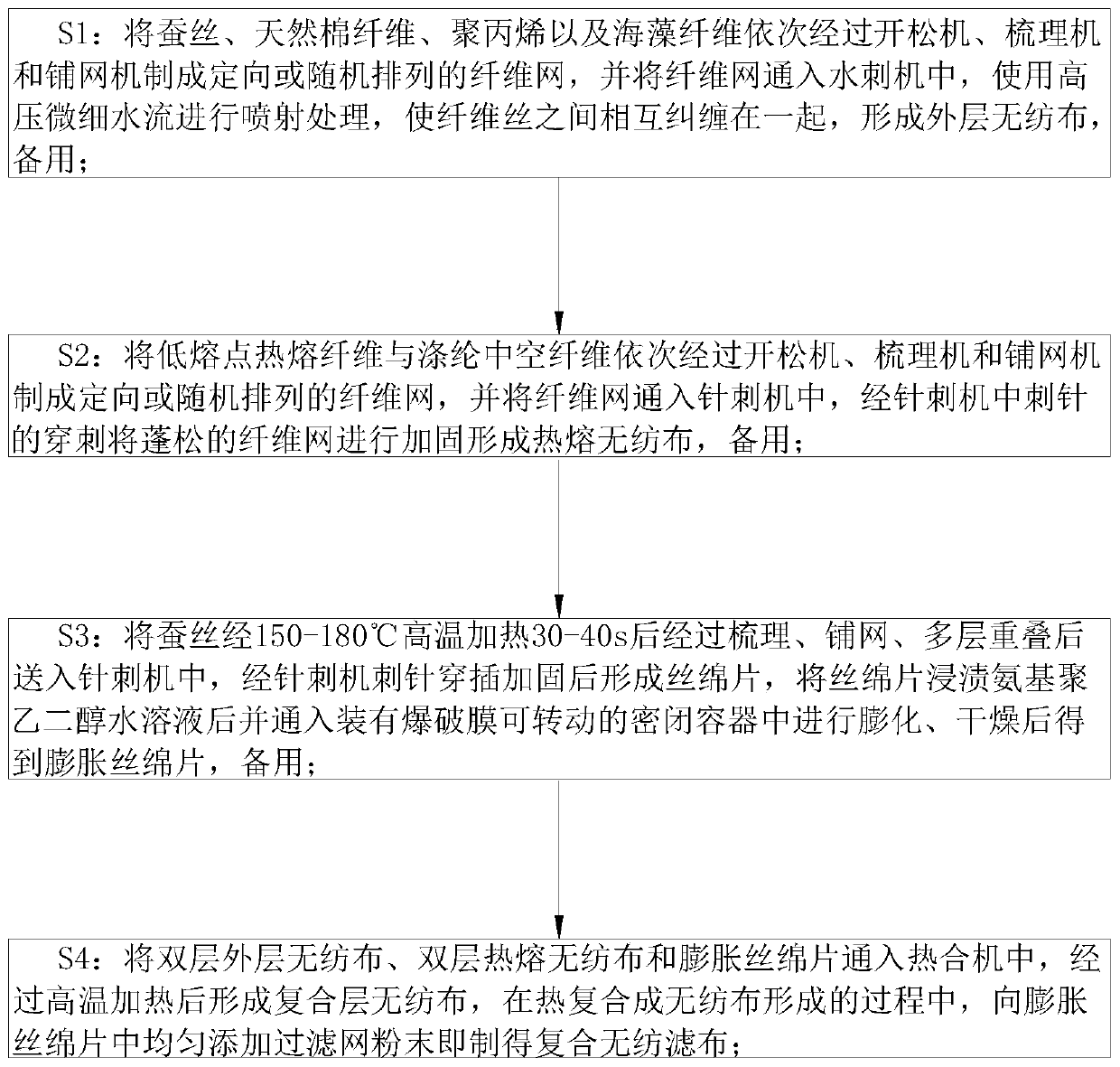

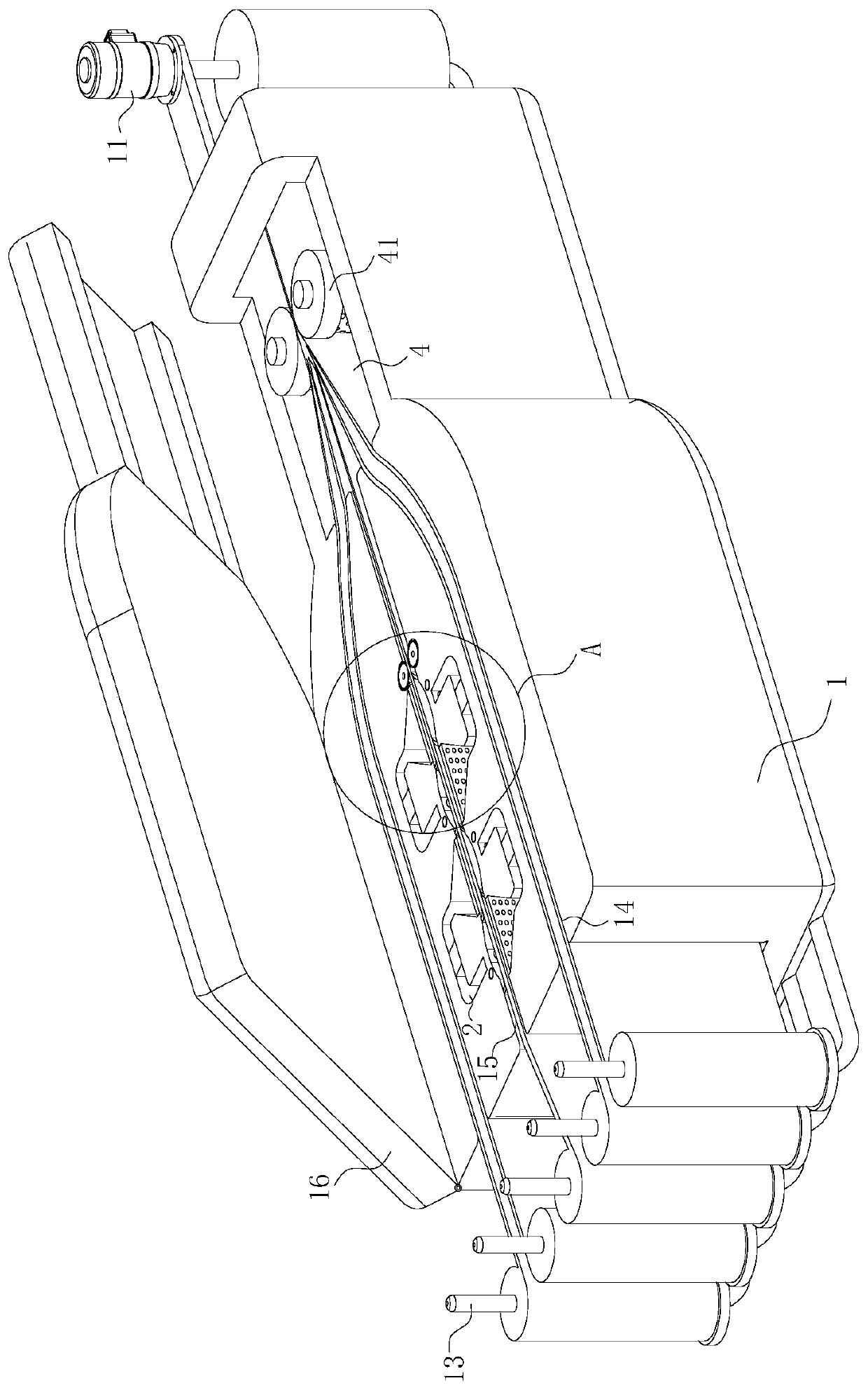

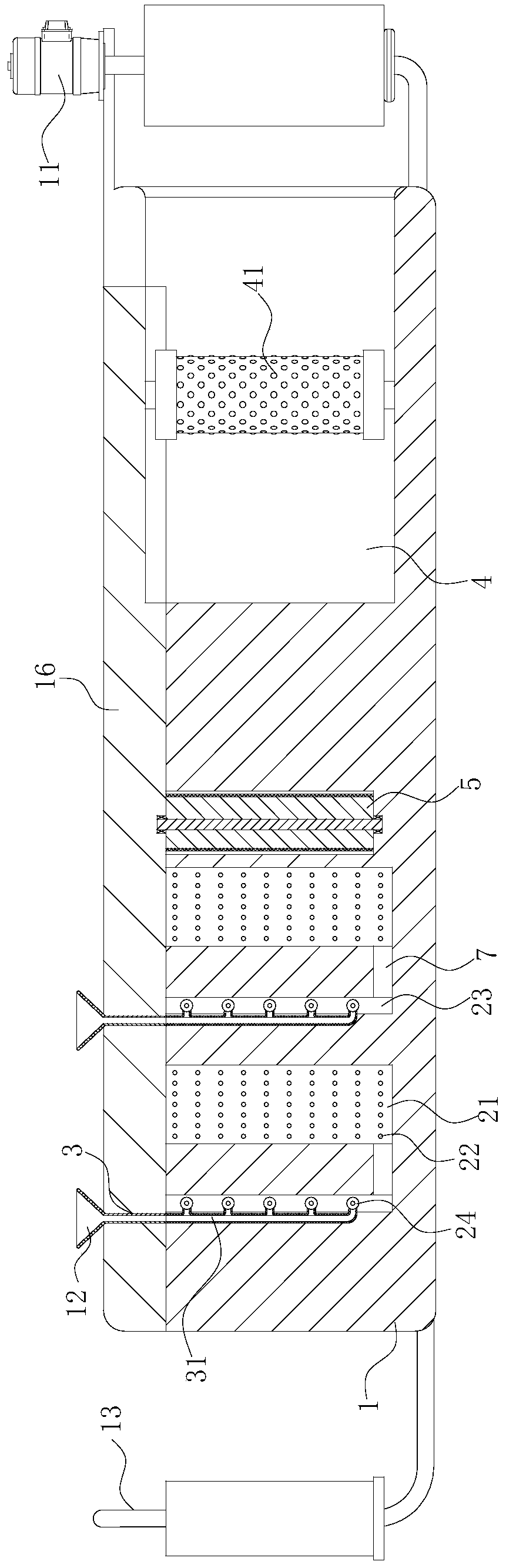

Preparation method of composite layer non-woven fabric

InactiveCN111497371AUniform filtering effectEven impactLamination ancillary operationsSynthetic resin layered productsPolymer scienceNonwoven fabric

The invention belongs to the technical field of polymer composite materials, and particularly relates to a preparation method of a composite layer non-woven fabric, wherein the preparation method comprises a shell, a motor and a hopper; one end of the shell is fixedly connected with a feeding roller through a guide rod; the feeding roller is sleeved with an outer-layer non-woven fabric, a hot-meltnon-woven fabric and an expanded silk floss sheet respectively; symmetrically designed drying grooves are formed in the shell; a fluorescent lamp constant-temperature design is adopted in the dryinggrooves; a modification groove is formed in the shell; the modification groove is used for performing modification treatment on the expanded silk floss sheet; the drying grooves and the modification groove are both positioned at an opening in the upper part of the shell; a sealing cover is hinged to the upper portion of the shell. First cavities are formed in the positions, located on the two sides of the modification groove, of the shell. Adsorptive particles are impacted on the expanded silk floss sheet under the entrainment of airflow, fibers on the surface of the expanded silk floss sheetare impacted and enter the expanded silk floss sheet along gaps among the fibers, and thus the adsorptive particles are evenly distributed in the expanded silk floss sheet.

Owner:冉肖伟

High-alloy cast iron drying cylinder

InactiveCN104631188AImprove the ability to withstand high pressureStrong pressure capacityDryer sectionPulp and paper industryHardness

The invention provides a high-alloy cast iron drying cylinder. The high-alloy cast iron drying cylinder comprises a cylinder body, an operation side cylinder cover and a transmission side cylinder cover. The two ends of the cylinder body are fixedly connected with the operation side cylinder cover and the transmission side cylinder cover respectively. The high-alloy cast iron drying cylinder further comprises a steam chamber and a condensate water chamber. The steam chamber is communicated with the operation side cylinder cover. The condensate water chamber is communicated with the transmission side cylinder cover. The steam chamber is fixedly connected with the condensate water chamber. Steam spray holes are evenly distributed in the steam chamber. A condensate water drainage device is arranged on the inner wall of the cylinder body. A water drainage pipe of the condensate water drainage device is communicated with the condensate water chamber. Heat preservation plates are arranged on the two sides of the cylinder body. One end of the cylinder body of the drying cylinder is connected with the operation side cylinder cover, the other end of the cylinder body of the drying cylinder is connected with the transmission side cylinder cover, and the high pressure bearing capacity of the drying cylinder is improved. The steam spray holes are evenly formed in the steam chamber, steam flowing out of the steam spray holes at a high speed evenly impacts a condensate water annular layer on the whole inner wall of the drying cylinder, and the uniform temperature of the whole outer wall face of the drying cylinder is facilitated; the surface hardness is increased through high-alloy cast iron, and the drying efficiency can be easily improved. The drying cylinder has the advantages of being high in strength and pressure bearing capacity, good in sealing effect and the like, and the service life of the drying cylinder can be prolonged.

Owner:张公文

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com