Device for reducing residual stress of welded seam of tube and tube plate of heat exchanger

A technology of residual stress and heat exchanger, applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., to achieve the effect of flexible operation, expanding the scope of application, and reducing residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

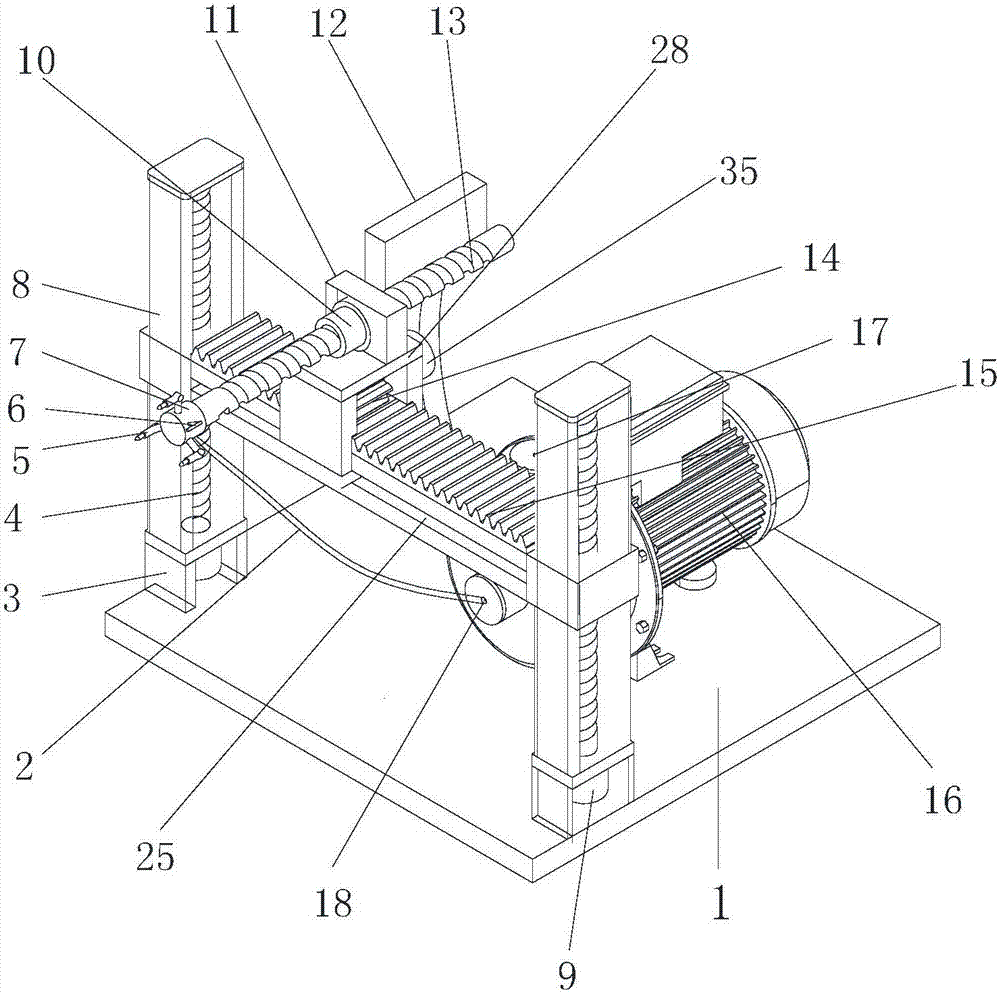

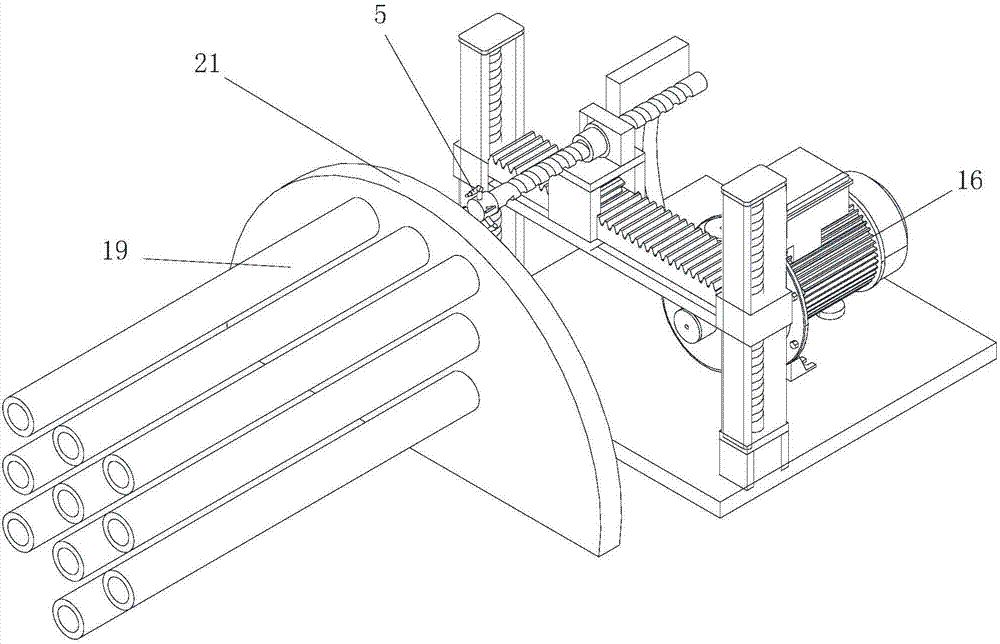

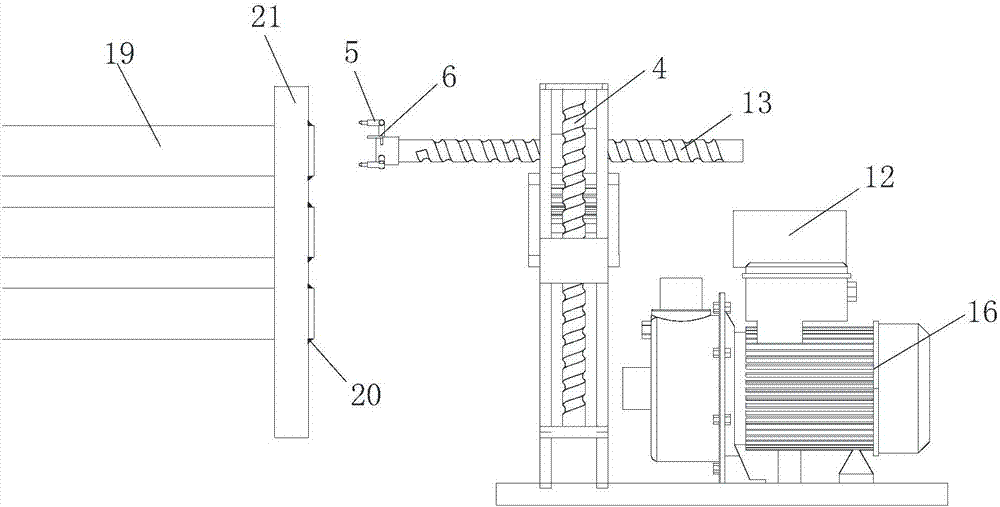

[0029] Such as Figure 1 to Figure 4 As shown, a device for reducing the residual stress of heat exchanger tubes and tube sheet welds includes a controller 12, a nozzle system, and a high-pressure water pump 16 for supplying high-pressure water jets to the nozzle system. The function of the controller 12 is to control the operation of the following motors to achieve the purpose of controlling the entire equipment. The following motors are connected to the controller 12 through lines, and the controller 12 issues instructions to realize the overall reduction of weld residual stress. process.

[0030] The nozzle system includes a nozzle regulator 7 and three nozzles 5. The nozzle regulator 7 includes a connected housing 24 and an end cover 31. The three nozzles 5 are unifor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com