Modified water-separating damper for water inlet of covered pipe of cooler

A technology of cooling pipes and nozzles, applied in the direction of water shower coolers, heat exchanger types, direct contact heat exchangers, etc., can solve the problems of affecting the cooling effect of equipment, uneven water flow in branch pipes, and damage to welding points, etc., to achieve impact Force reduction, impact reduction, and the effect of avoiding frost cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

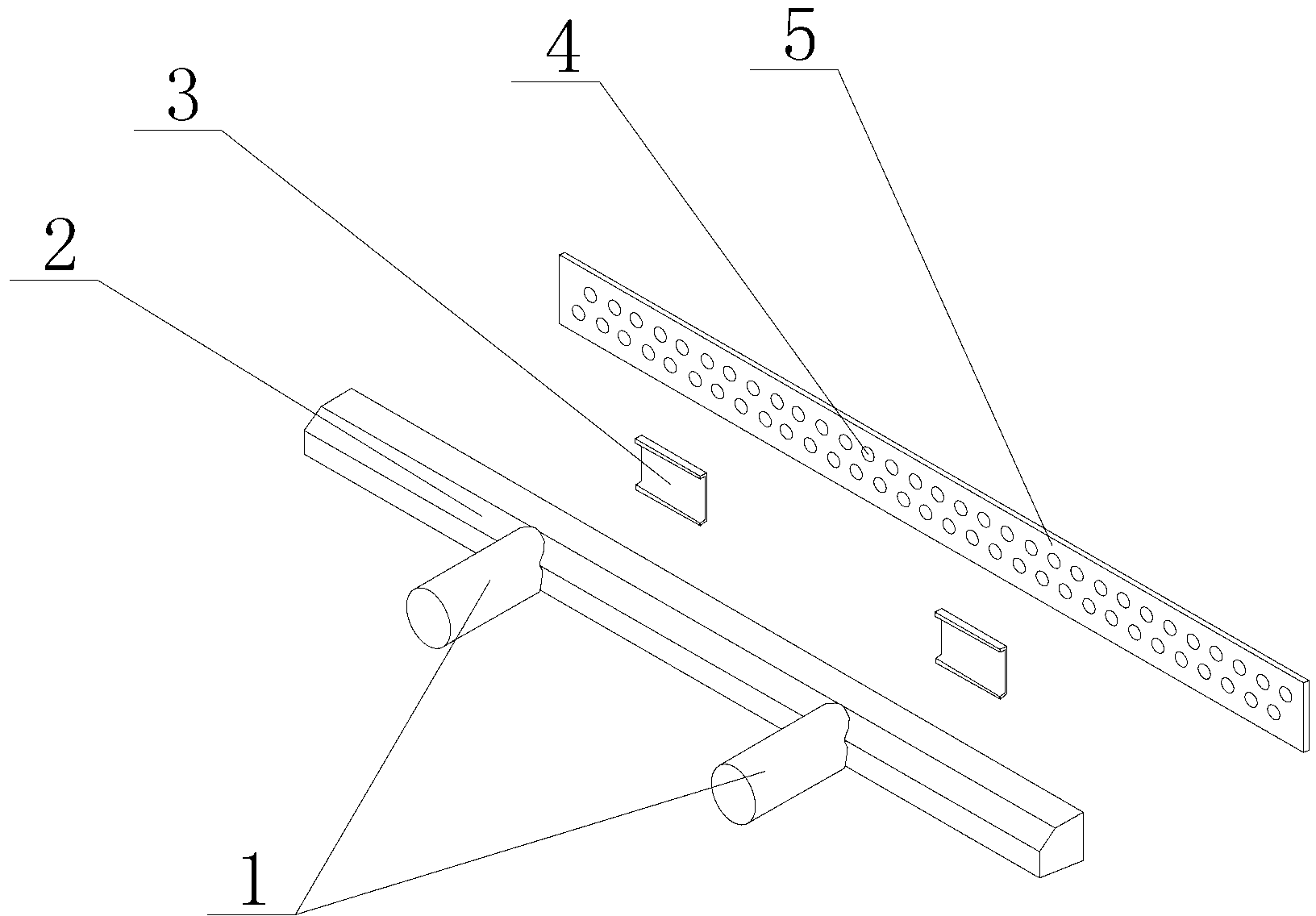

[0020] Such as figure 1 As shown, a water diversion device at the water inlet of a cooling pipe includes a cooling pipe, and a water diversion baffle is arranged in the cooling pipe, and the water diversion baffle is installed on the front side of the cooling pipe.

[0021] In this embodiment, the water-separating baffle includes a front cover concave plate 2 and a rear cover plate 5 . The rear cover 5 is provided with several evenly distributed water outlets 4 . The front end surface of the front cover concave plate 2 is connected and communicated with the water inlet pipe 1, and the middle position in the front cover concave plate 2 is equipped with a baffle plate 3. The baffle plate 3 is welded on the inner side of the front cover concave plate 2, and the baffle plate 3 is facing the water inlet pipe 1. The baffle plate 3 is parallel to the water inlet pipe 1 of the concave plate 2 of the front cover.

[0022] In this embodiment, the cladding tube includes a front cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com