CPE (chlorinated polyethylene) thin film and production method thereof

A production method and film technology, applied in the field of packaging materials, can solve the problems of easy formation of scale, affecting heat transfer of cooling rolls, poor cooling effect of cooling rolls, etc., and achieve the effects of simple production process, avoiding heat transfer, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A CPE film, the CPE film is composed of the following raw materials in parts by mass: 60 parts of chlorinated polyethylene, 5 parts of aluminum foil, 15 parts of plasticizer, 3 parts of heat stabilizer, 6 parts of chlorinated paraffin, 6.4 parts of antimony trioxide 5.7 parts of magnesium hydroxide, 3.2 parts of tricresyl phosphate, 1.8 parts of antioxidant, 6 parts of aramid fiber.

[0033] A kind of production method of CPE film, comprises the following steps:

[0034] (1) Preparation of materials for the production of CPE film:

[0035] (2) Mixing and feeding: Mix the materials in step (1) evenly, and then transport the materials to the extruder;

[0036] (3) Extrusion plasticization: heating, heating up to 156°C at a heating rate of 30°C / h, and keeping it for 15 minutes; plasticizing; pressurizing;

[0037] (4) Casting: using T-type head for casting;

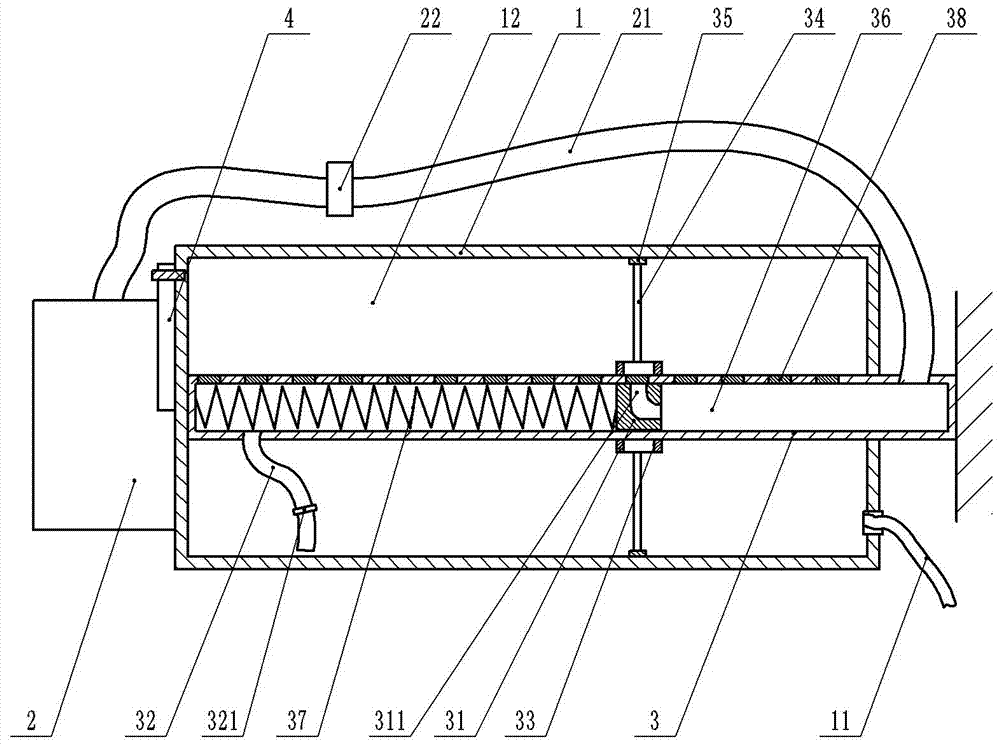

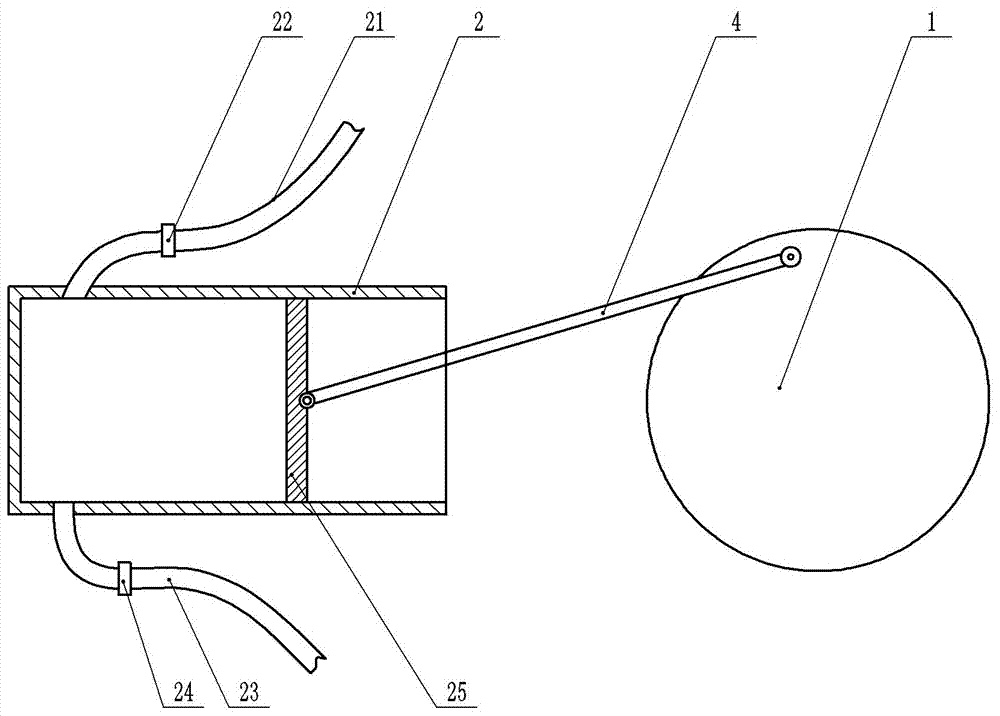

[0038] (5) Cooling: Cooling adopts a cooling device, such as figure 1 , figure 2As shown, the cooling device ...

Embodiment 2

[0044] The difference between this example and Example 1 is that the CPE film is composed of the following raw materials in parts by mass: 60 parts of chlorinated polyethylene, 5.9 parts of aluminum foil, 16 parts of plasticizer, 2.5 parts of heat stabilizer, and 6.2 parts of chlorinated paraffin , 6 parts of antimony trioxide, 5 parts of magnesium hydroxide, 3.5 parts of tricresyl phosphate, 2 parts of antioxidant, 4 parts of aramid fiber.

Embodiment 3

[0046] The difference between this example and Example 1 is that the CPE film is composed of the following raw materials in parts by mass: 60 parts of chlorinated polyethylene, 5 parts of aluminum foil, 16 parts of plasticizer, 3 parts of heat stabilizer, and 6.3 parts of chlorinated paraffin , 7 parts of antimony trioxide, 5.3 parts of magnesium hydroxide, 3 parts of tricresyl phosphate, 1.4 parts of antioxidant, and 8 parts of aramid fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com