Patents

Literature

33results about How to "Affect heat transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

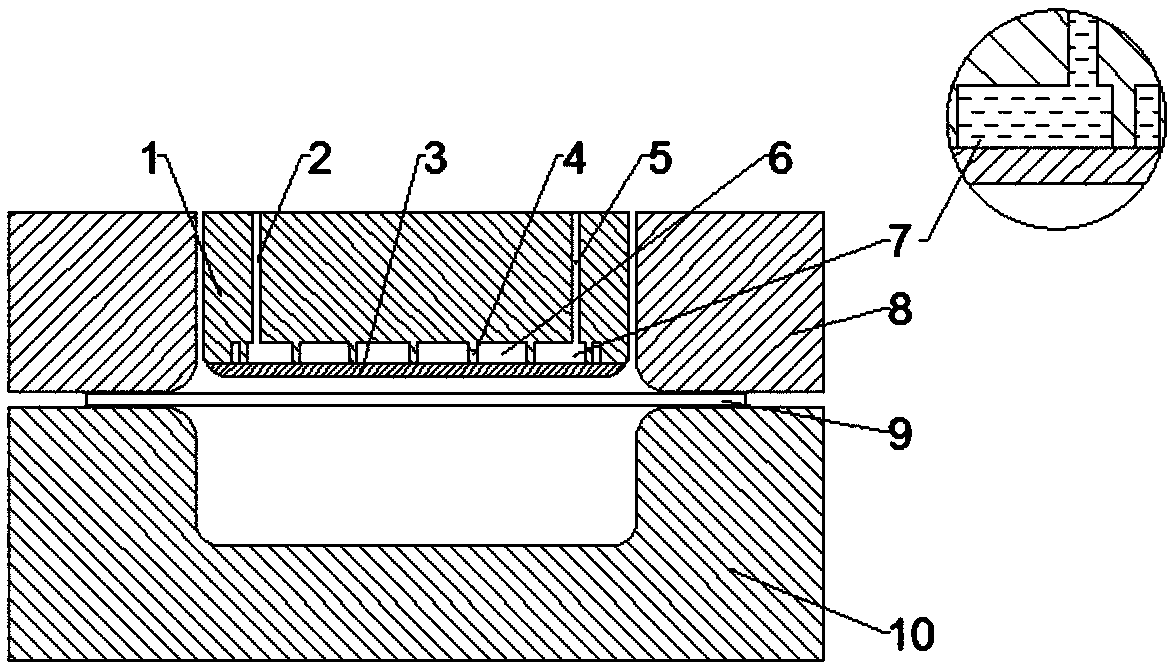

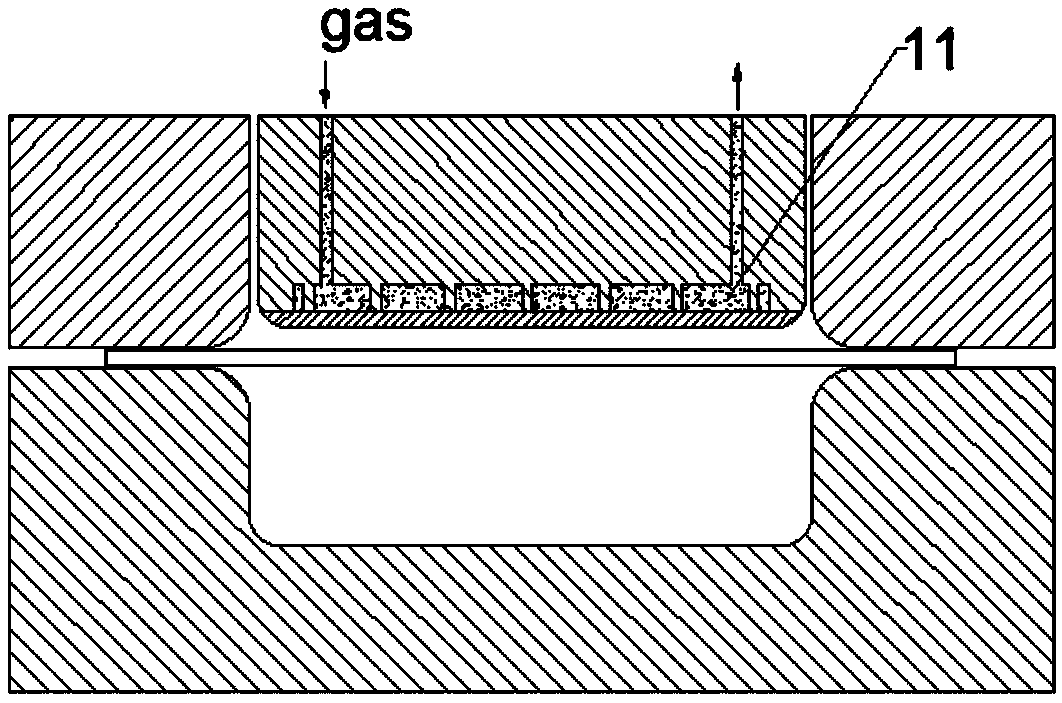

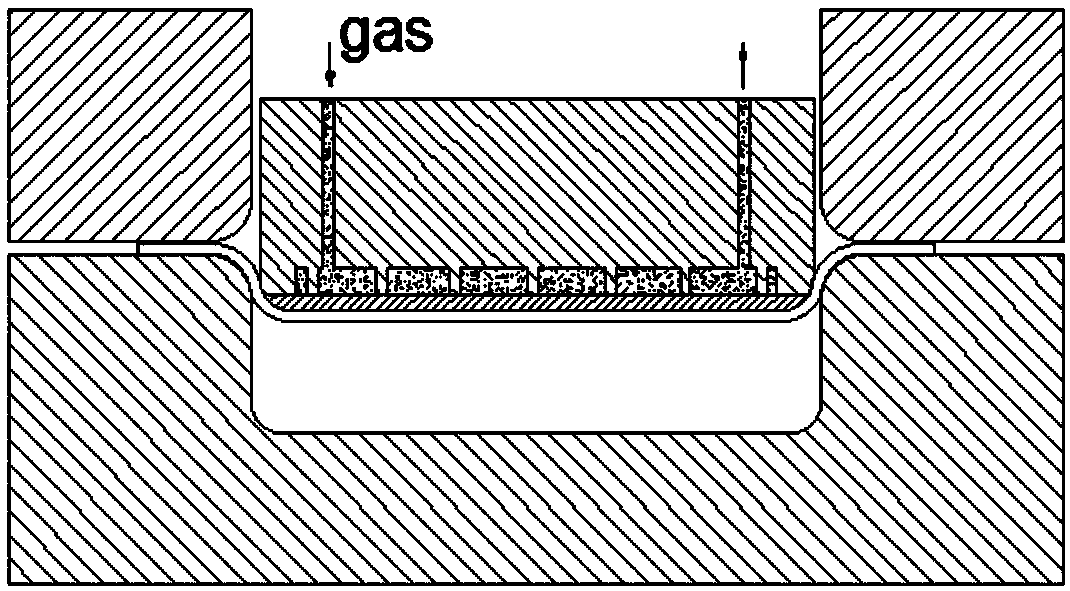

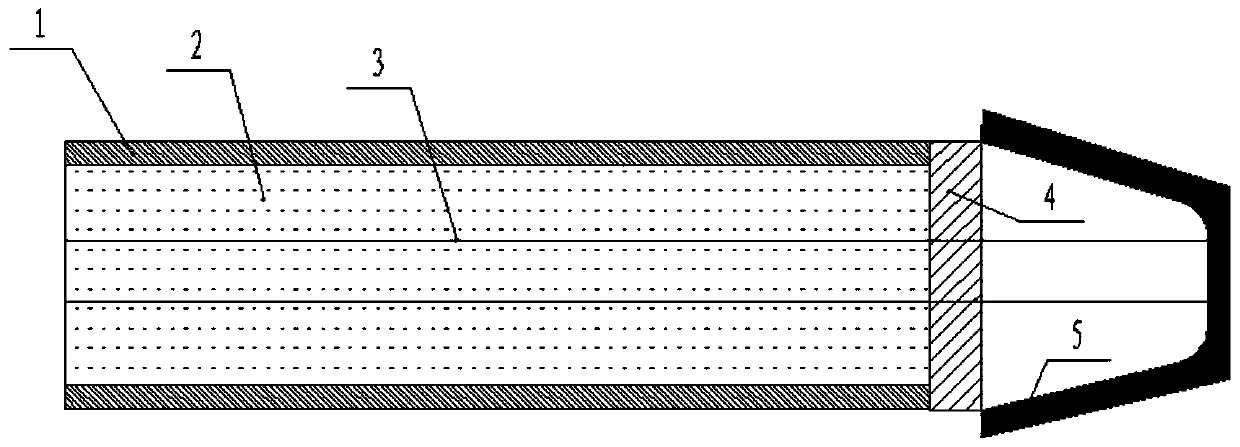

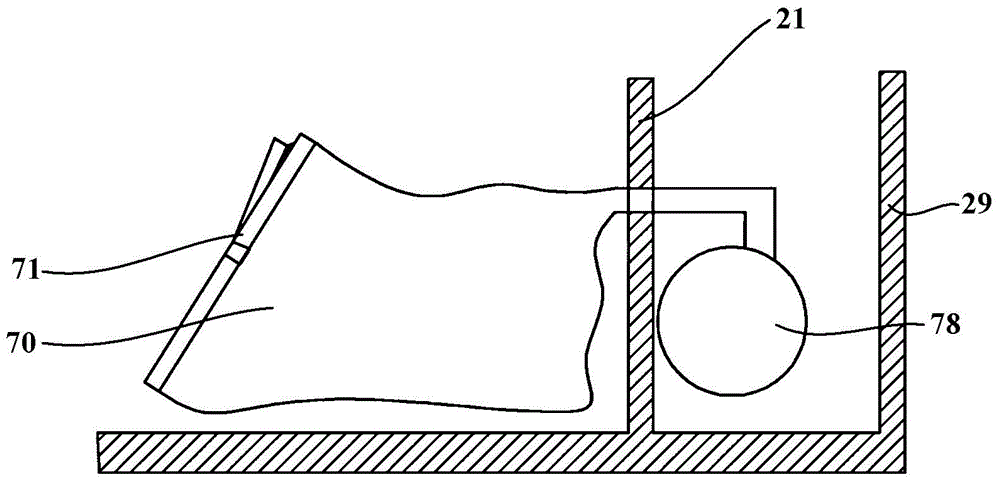

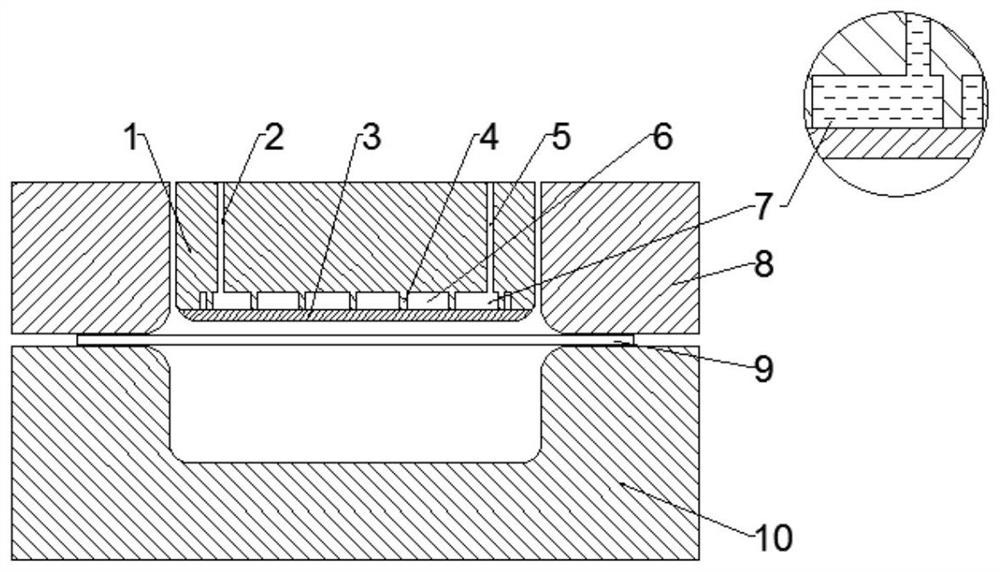

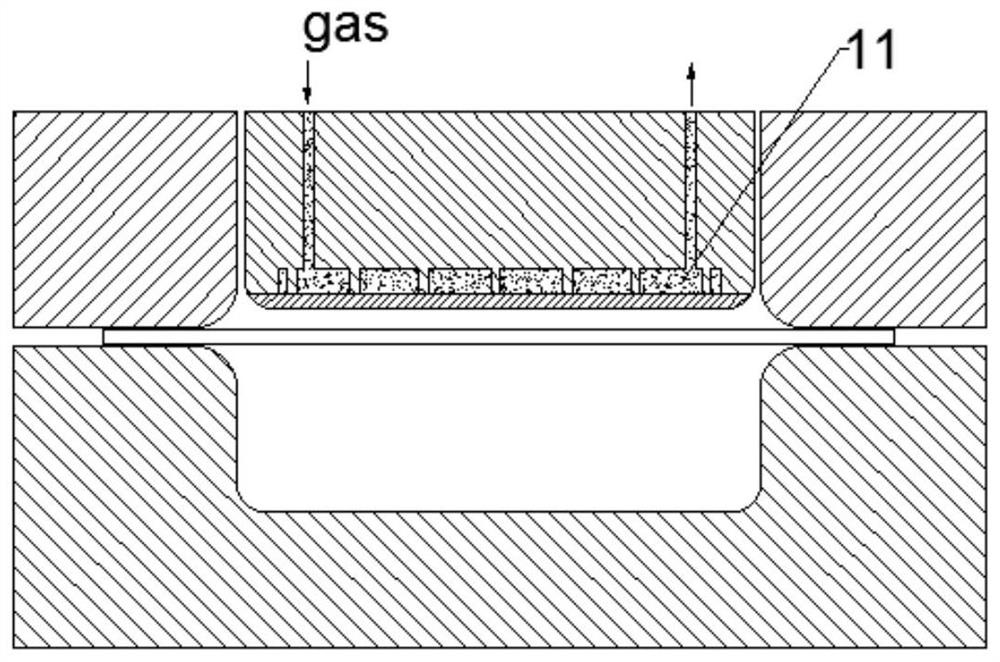

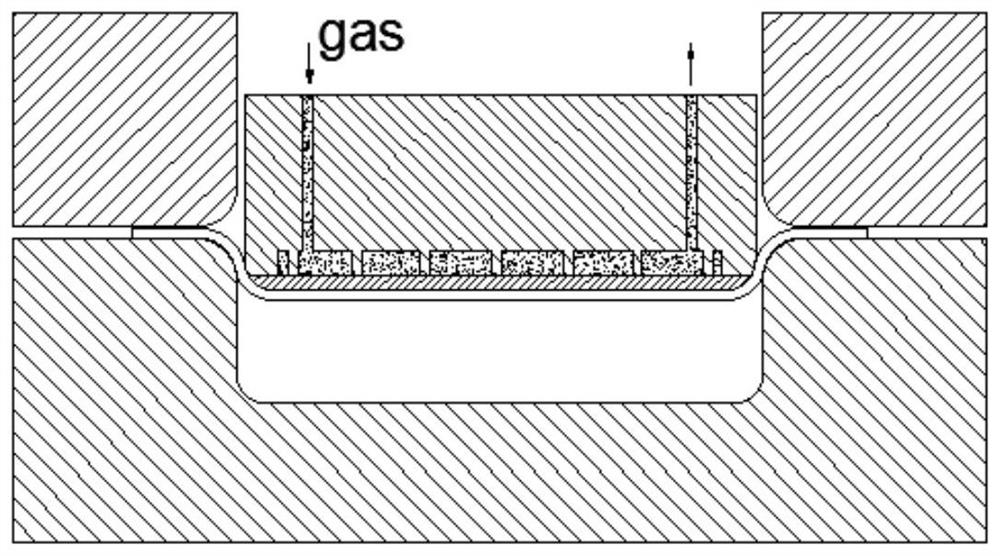

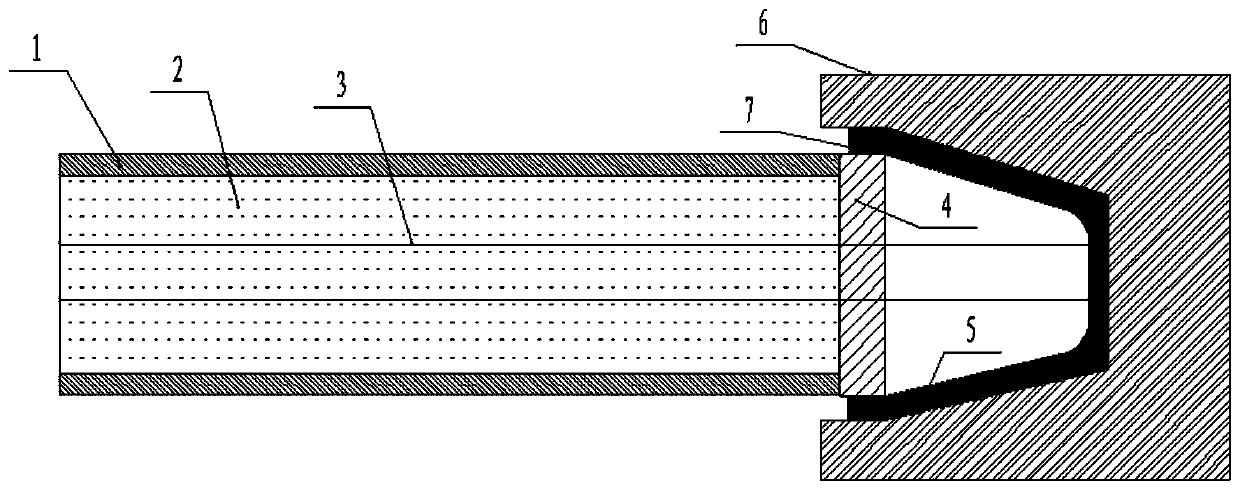

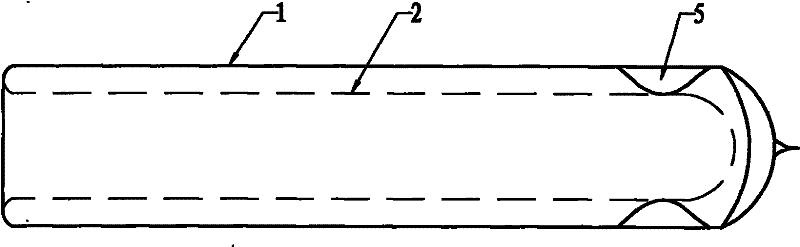

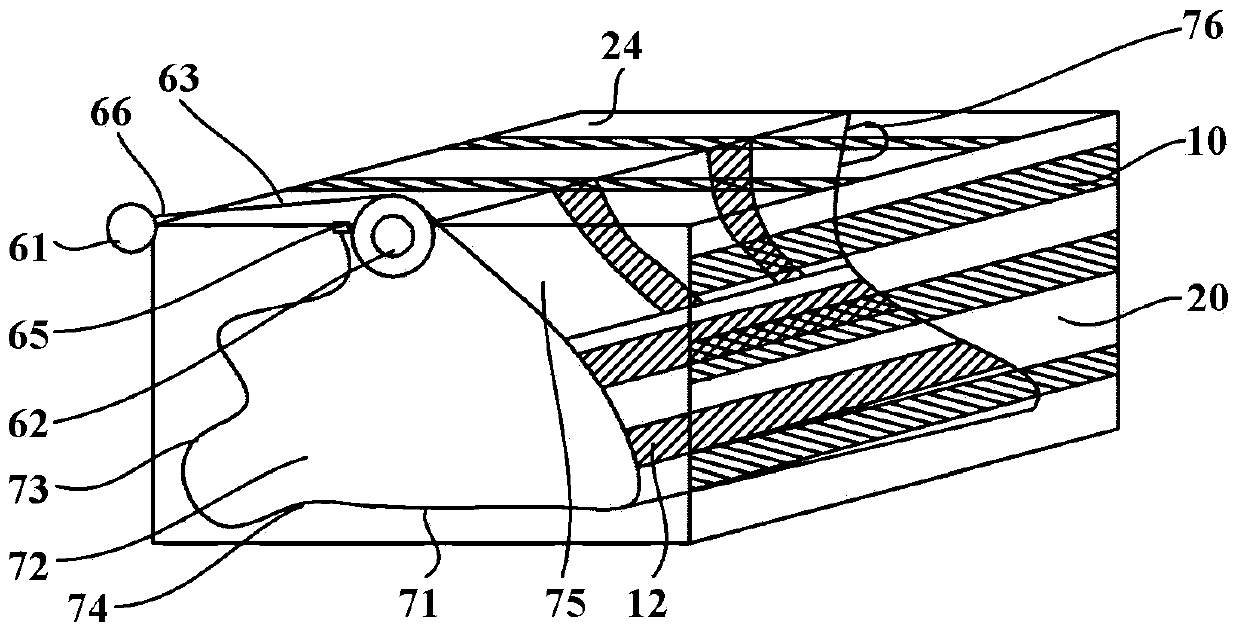

Mold for achieving in-mold rapid forming and quenching

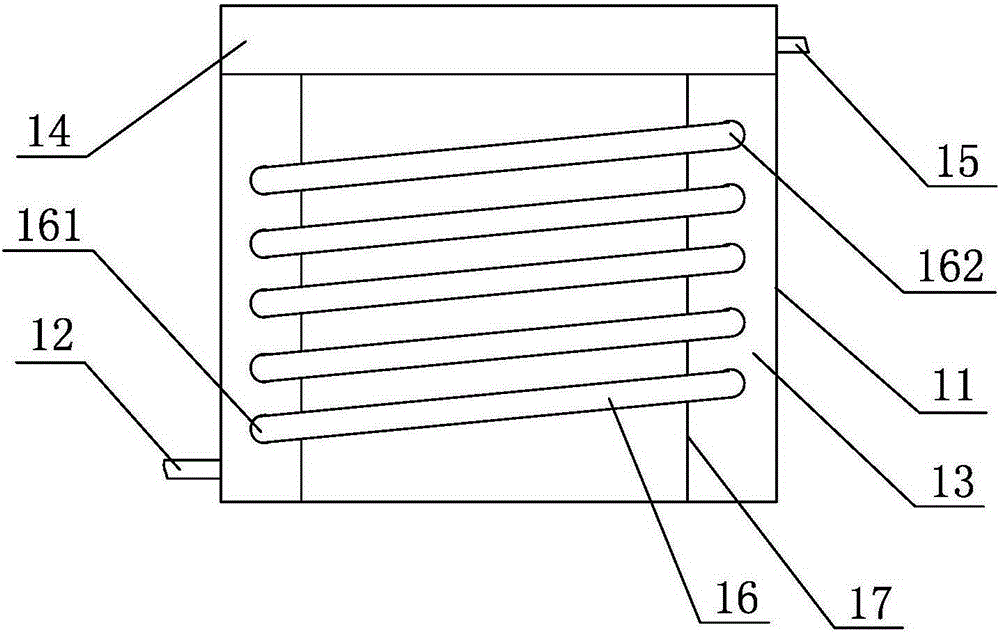

The invention provides a mold for achieving in-mold rapid forming and quenching. The mold comprises an upper mold, a binder ring and a lower mold, the upper mold is composed of an inner solid mold core and a thin-walled skin, and interconnected grooves are formed between the inner solid mold core and the thin-walled skin. In the forming stage, no heat insulation material such as filler or fillinggas exists in the grooves, and a low-temperature medium is introduced into the grooves in the quenching stage. The mold has the advantages that the forming and quenching processes are relatively independent and have little influence on each other, the skin is small in wall thickness and small in heat capacity, the grooves are filled with the heat insulation materials, the problem that a hot plateblank and a cold mold are rapidly cooled after making contact during forming can be avoided, and rapid cooling and quenching of the formed hot plate blank can be achieved. The mold core is prepared from common mold materials through common machining equipment, the mold manufacturing period is short, and the cost is low. The mold can be used for achieving rapid forming and quenching of metal materials of different types and thicknesses.

Owner:DALIAN UNIV OF TECH +1

CPE (chlorinated polyethylene) thin film and production method thereof

The invention belongs to the technical field of packaging materials, and particularly discloses a CPE (chlorinated polyethylene) thin film and a production method thereof. The CPE thin film is prepared from the following raw materials in parts by mass: 60 parts of CPE, 4 to 7 parts of aluminum foil, 12 to 18 parts of plasticizer, 1 to 5 parts of heat stabilizer, 2 to 3 parts of composite flame-retardant agent, 1 to 3 parts of antioxidant, and 4 to 10 parts of aramid fiber. The production method of the CPE thin film comprises the following steps of (1) preparing of materials; (2) mixing and charging of the materials; (3) extruding and plasticizing; (4) flow-casting; (5) cooling: adopting a cooling device, and utilizing compressed air to blow and attach the flow-casting material onto a cooling roll to cool; (6) thickness measuring and controlling; (7) corona treating; (8) slicing; (9) drawing and coiling. The CPE thin film produced by the method has the advantages that the cooling effect of the CPE thin film is good, and the low quality of the thin film due to nonuniform cooling and overhigh cooling temperature can be avoided.

Owner:CHONGQING RUITING PLASTIC

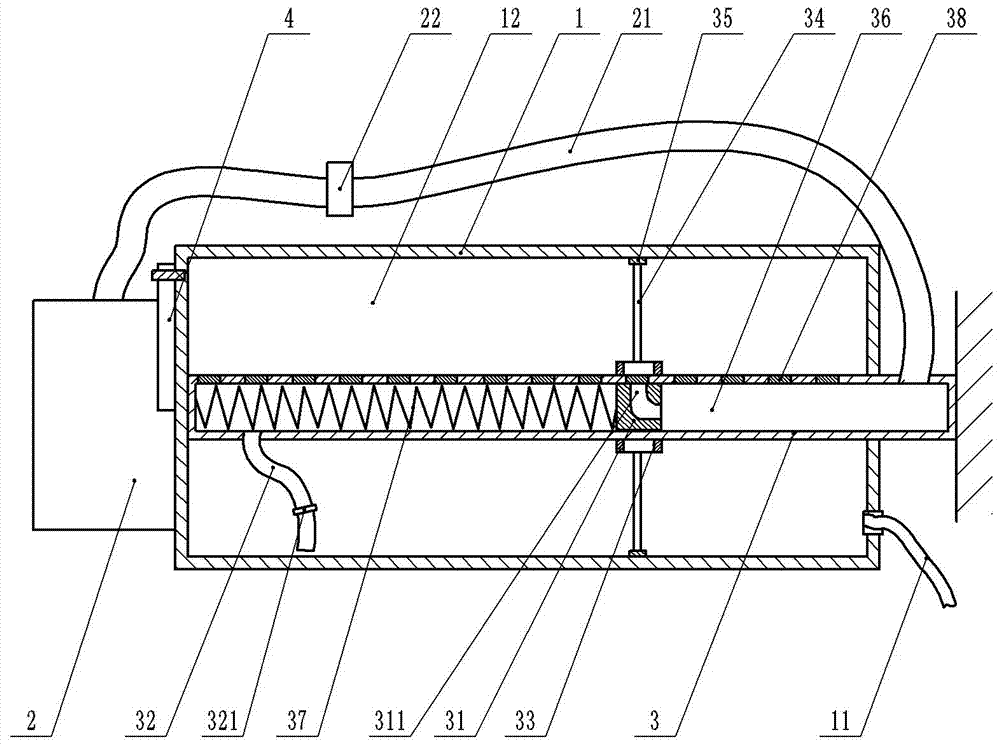

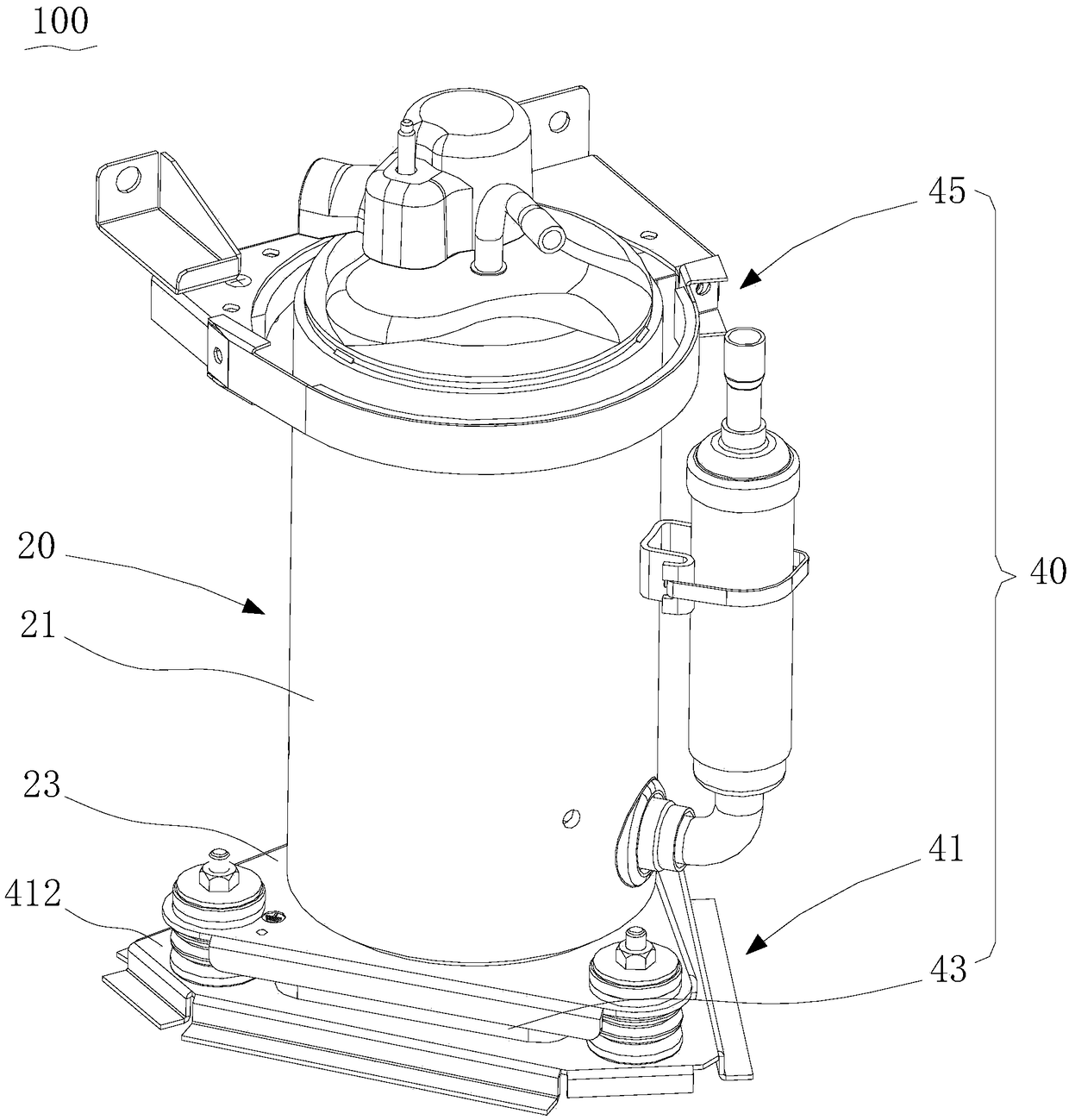

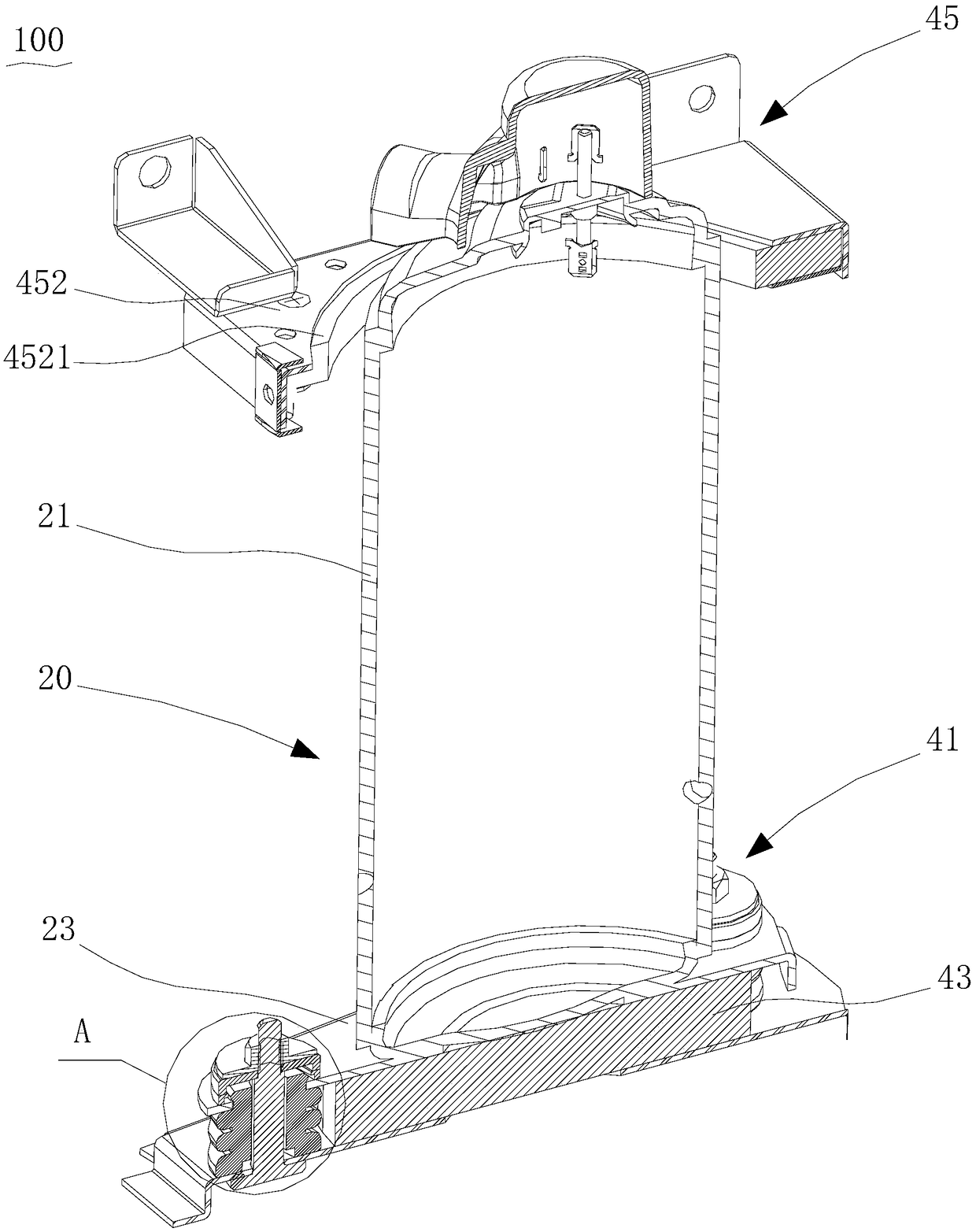

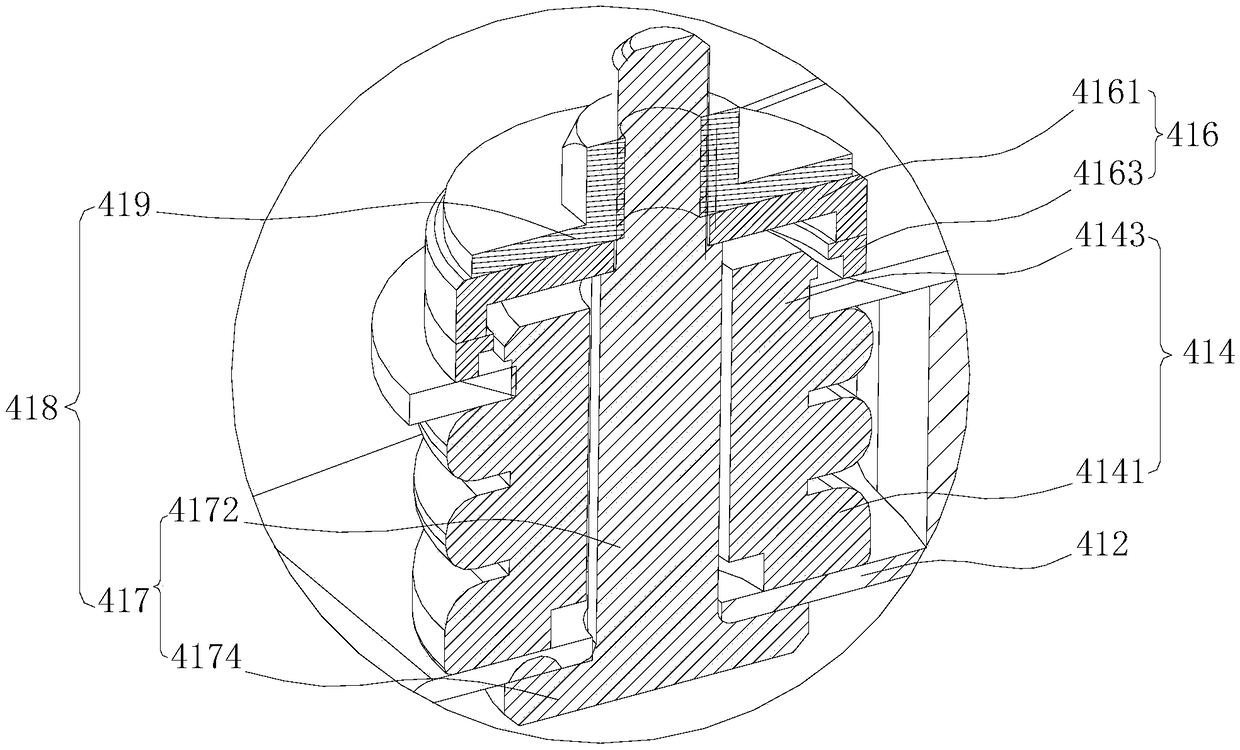

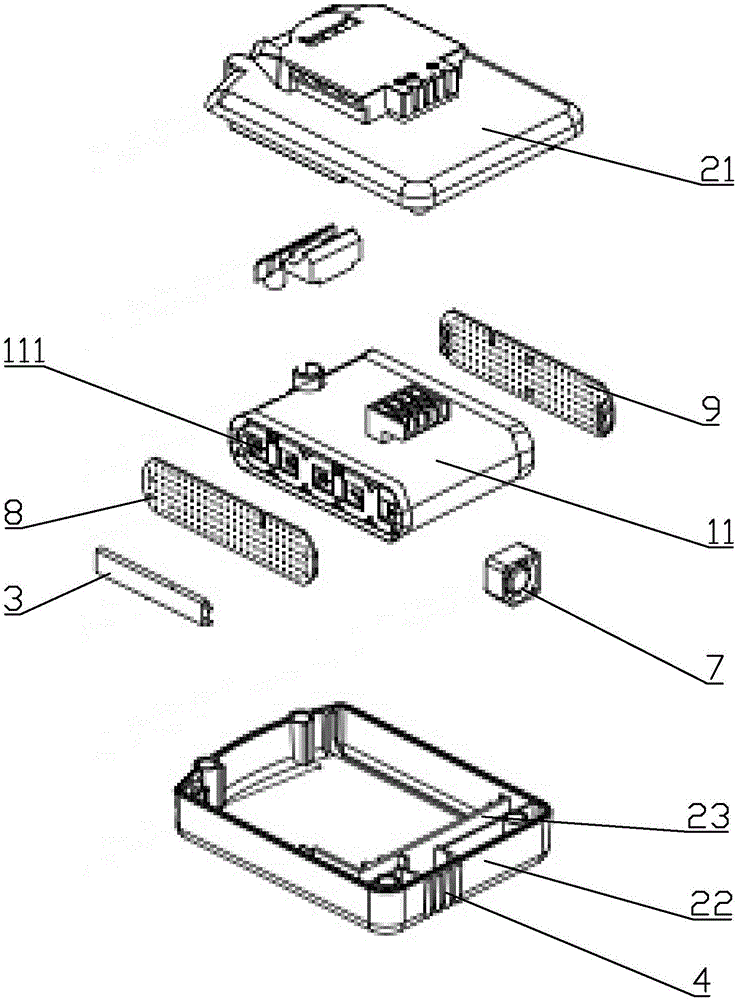

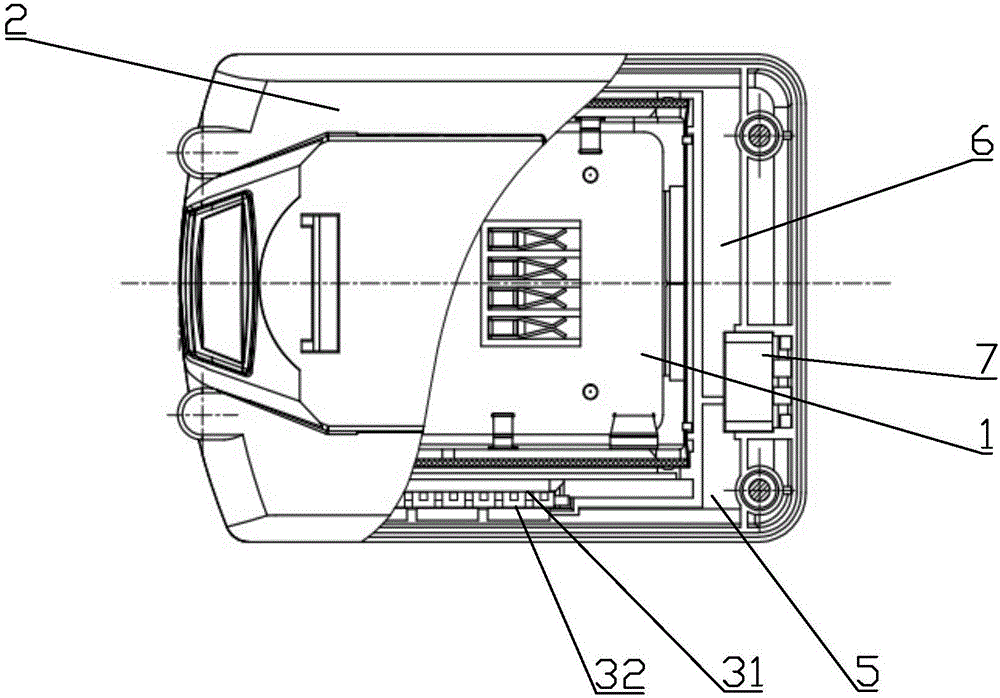

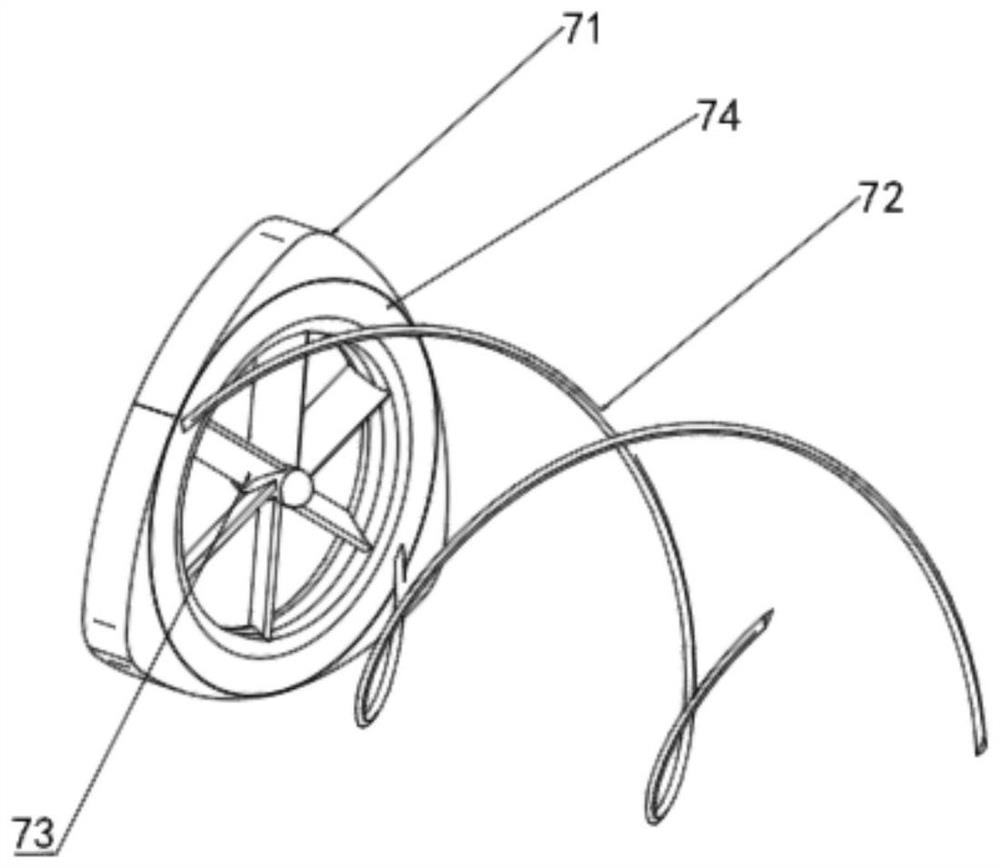

Vibration reduction device, compressor with vibration reduction device and air conditioner

PendingCN109026609ALimit shakingReduce shakingPositive displacement pump componentsPositive-displacement liquid enginesElastic vibrationMechanical engineering

The invention relates to a vibration reduction device, a compressor with the vibration reduction device and an air conditioner. The vibration reduction device is used for fixing the compressor, the compressor comprises a compressor main body and a fixed plate arranged at one end of the compressor main body, the vibration reduction device comprises a mounting base, an elastic vibration reduction part on one side of the mounting base, a limiting assembly arranged on the side, away from the mounting base, of the elastic vibration reduction part in a spaced manner and an axial fixing assembly sequentially penetrating through the mounting base, the elastic vibration reduction part and the limiting assembly so as to axially and fixedly connect the elastic vibration part and the limiting assemblyto the mounting base; the limiting assembly and the elastic vibration reduction part jointly form a fixed gap used for limiting the fixed plate of the compressor, and the limiting assembly can exertpressure facing the mounting base to the fixed plate. According to the vibration reduction device, due to the fact that the fixed plate of the compressor is limited in the fixed gap jointly formed bythe limiting assembly and the elastic vibration reduction part, shaking of the compressor can be effectively limited and relieved, and severe vibration of the compressor can be avoided.

Owner:GREE ELECTRIC APPLIANCES INC

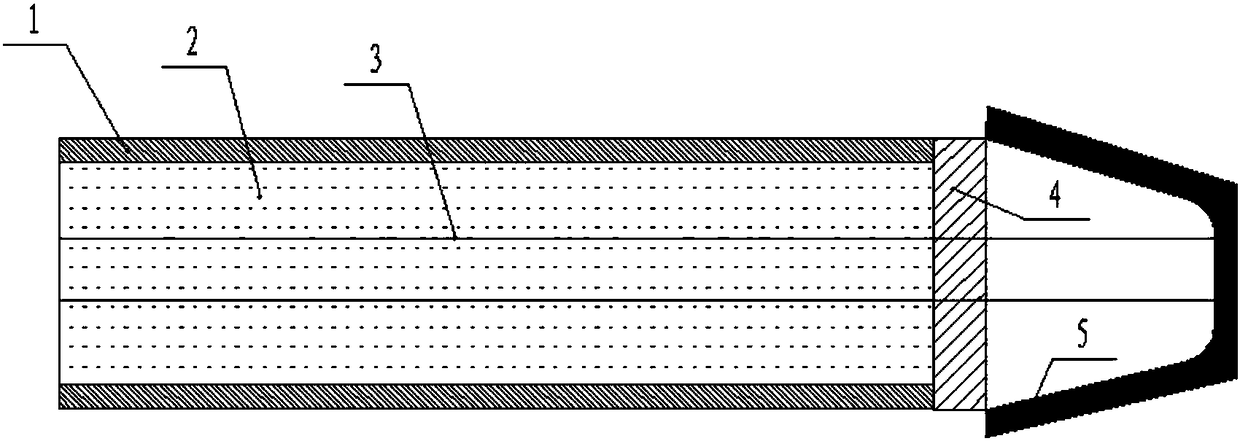

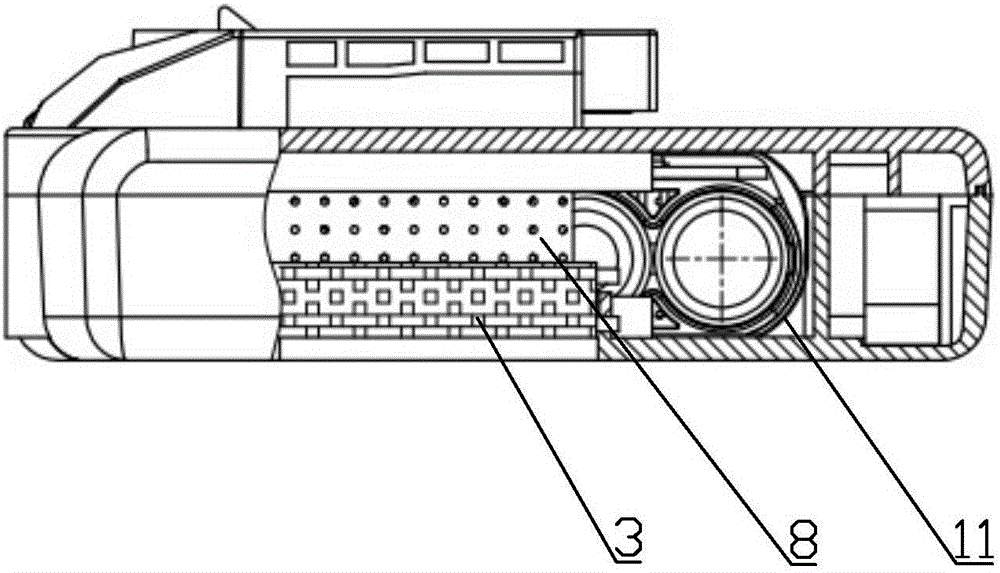

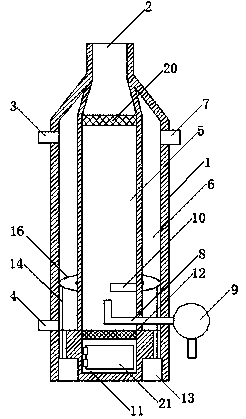

Quick response temperature measuring thermocouple for casting mold

ActiveCN108414106AIncrease contact areaAffect heat transferThermometer detailsThermometers using electric/magnetic elementsThermocouple WireCasting mold

The invention discloses a quick response temperature measuring thermocouple for casting a mold. The device comprises two thermocouple wires which are arranged in a protective sleeve and are connectedby a metal joint at a hot end. The metal joint is a truncated cone structure, the longitudinal section of the metal joint is trapezoidal, and a trapezoidal center is a hollow structure. The contact part of the metal joint and a mold temperature measuring hole is a smooth plane, at the same time, the corresponding contact plane of the metal joint in the mold temperature measuring hole is also processed into a smooth plane. The thermocouple is externally provided with a covering sleeve, a cross section of a contact part of the front end of the covering sleeve and the mold is a shape adapted to the contour of the outer surface of the mold, and a sealing material is arranged on a contact surface between the front end of the covering sleeve and the mold. The thermocouple and the rear end of thecovering sleeve are connected to a driving mechanism to realize forward and backward movement. According to the quick response temperature measuring thermocouple, the heat after the temperature riseof the mold is rapidly transferred to the thermocouple, and the rapid response of the thermocouple to a temperature is realized. The smooth contact surface of the thermocouple metal joint is protectedfrom being affected by an environment. The metal joint is insulated from thermocouple parts other than the thermocouple wires, and interference is avoided.

Owner:BEIHANG UNIV

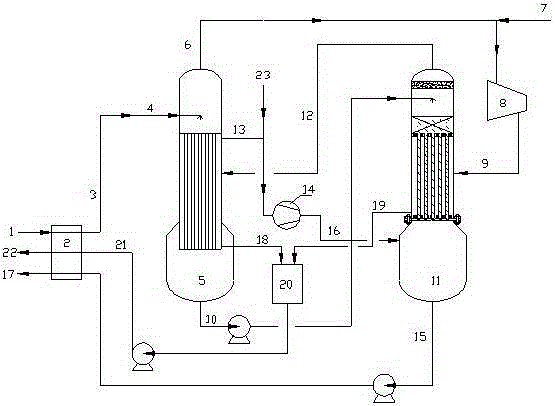

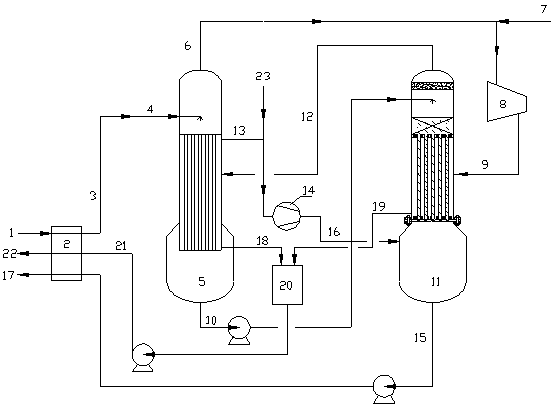

Technology and system used for processing waste water

ActiveCN106629936AAchieve recyclingReduce the effective heat transfer areaWater contaminantsWater/sewage treatment by heatingWater useGas compressor

The invention provides a technology and a system used for processing waste water. The system comprise a waste water preheater, a first effect evaporator, a second effect evaporator, a vapour compressor, a condensed water collector, and a noncondensable gas compressor. The invention also provides the technology used for processing waste water using the system. The waste water processing technology and the system are safe and reliable; equipment is simple; operation cost is low; energy saving effect is obvious; and 50 to 95% of water resource can be recycled.

Owner:CHINA PETROLEUM & CHEM CORP +1

Battery pack temperature adjusting device

InactiveCN106229432AReduce the temperatureSpeed up the charging processCells structural combinationCell component detailsElectrical batteryEngineering

The invention discloses a battery pack temperature adjusting device, and aims at solving the problems that a battery pack is poor in charge and discharge performance under the conditions of a high temperature and a low temperature. According to the technical scheme for solving the problem, the battery pack temperature adjusting device mainly comprises the battery pack and a battery box sleeving the outer side of the battery pack, wherein the battery pack is provided with a control circuit and a temperature sensing element; the control circuit is electrically connected with the temperature sensing element; a diversion outlet is arranged in the battery box; a refrigeration piece electrically connected with the control circuit is arranged between the battery pack and the battery box and comprises a positive temperature control surface and a reverse temperature control surface; the positive temperature control surface faces the battery pack; and airflow formed on the positive temperature control surface passes through the battery pack and then flows outside from the diversion outlet. By the battery pack temperature adjusting device, the continuous charge and discharge time of the battery pack is prolonged.

Owner:ZHEJIANG YAT ELECTRICAL APPLIANCE CO LTD

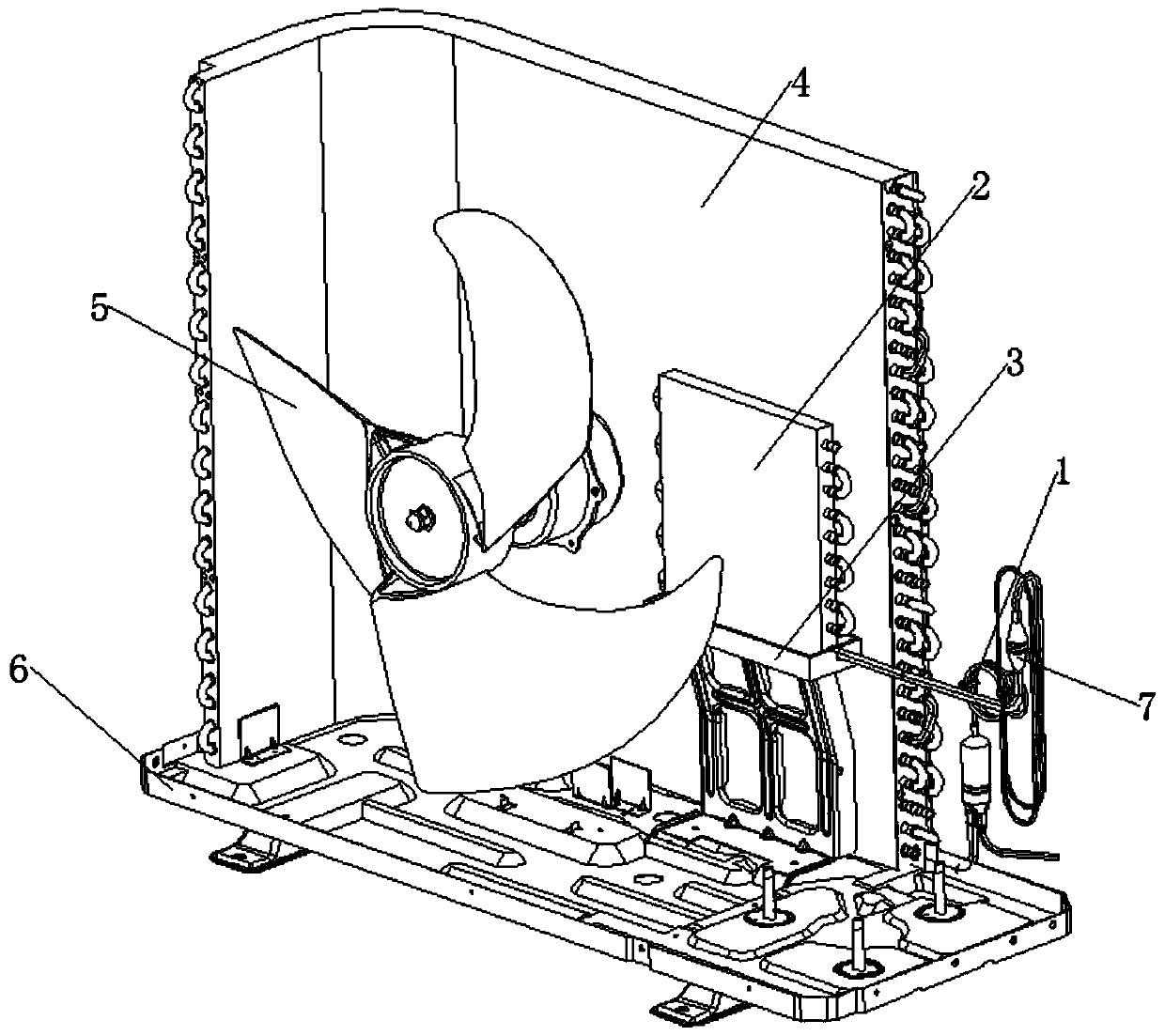

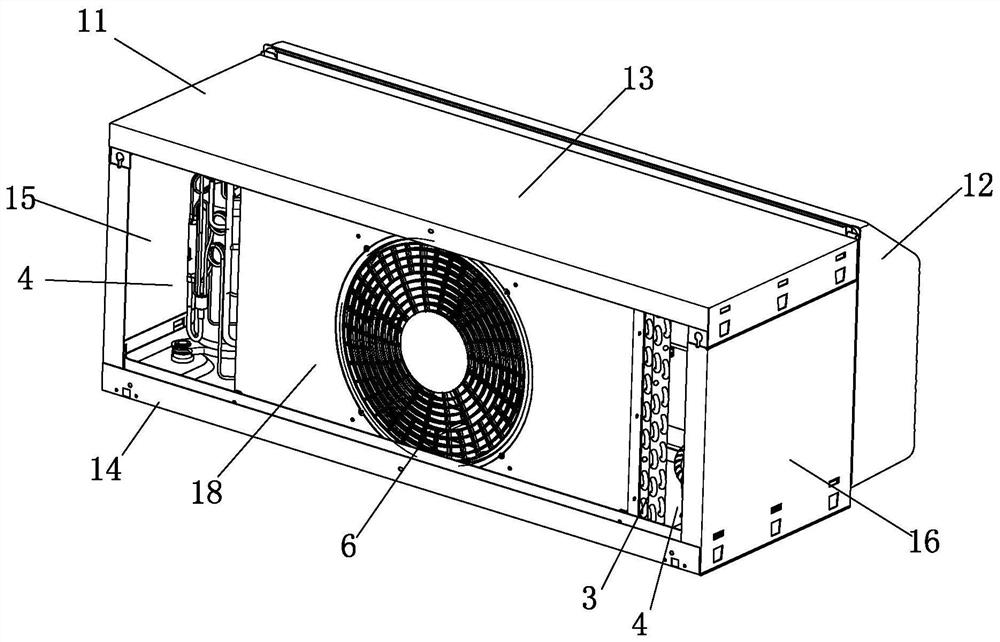

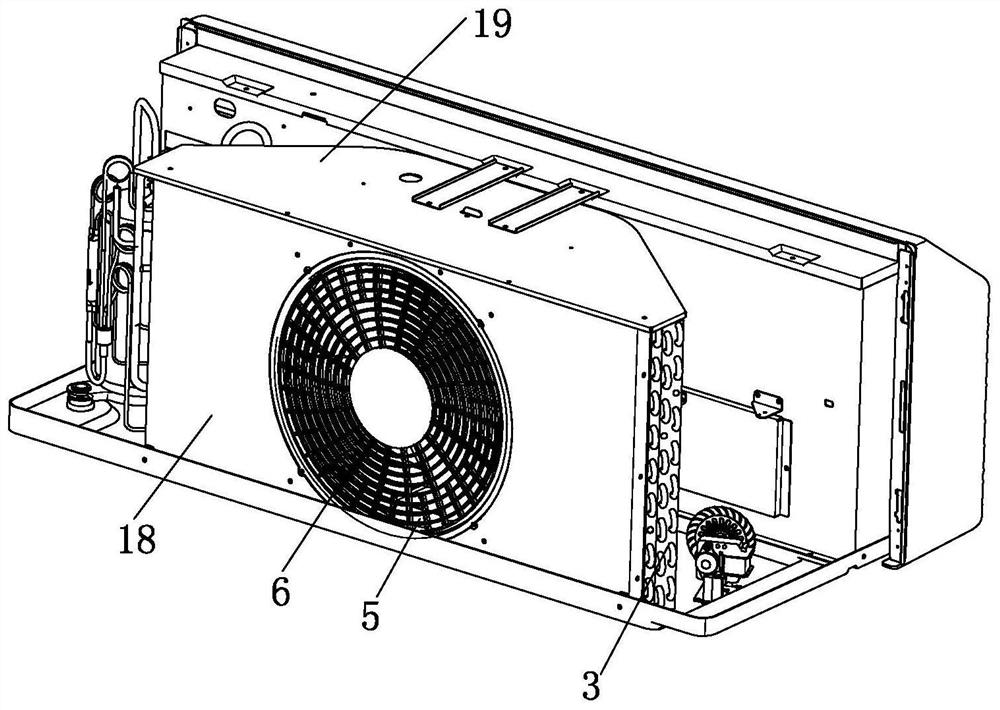

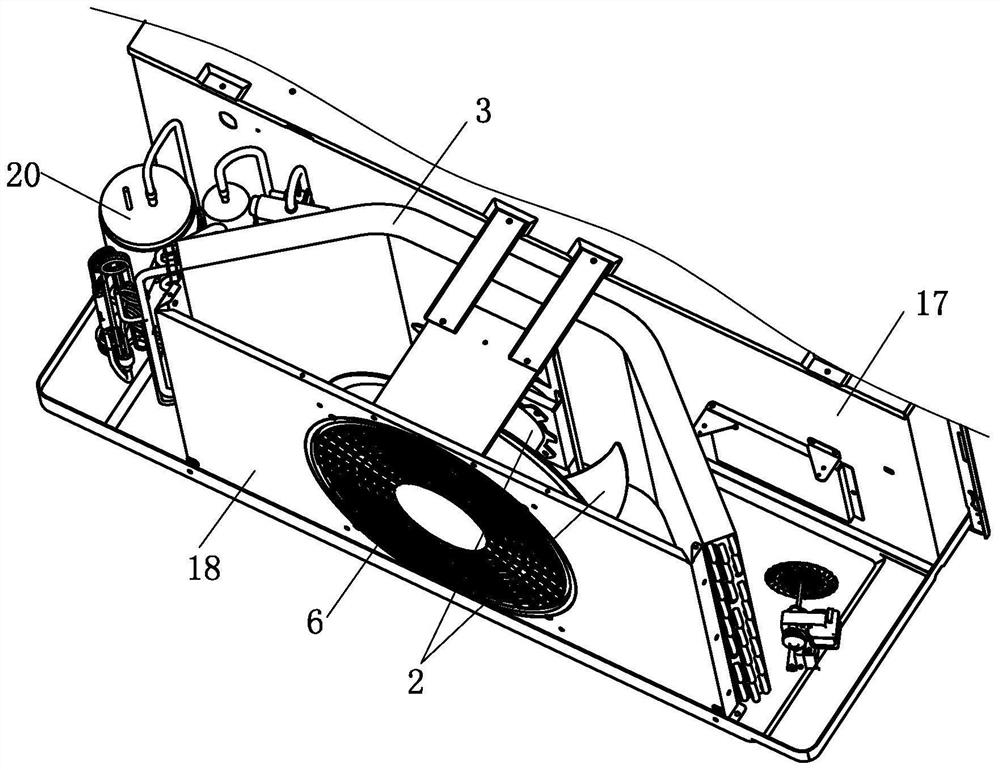

Outdoor unit of air conditioner, and air conditioner

PendingCN111059643ASimple structureHigh trafficMechanical apparatusCondensate preventionWater storageThermodynamics

The invention relates to the technical field of air conditioners, in particular to an outdoor unit of an air conditioner, and the air conditioner. The outdoor unit of the air conditioner comprises: athrottling device; an auxiliary evaporator, which is connected with the throttling device; and a water storage device, which is suitable for storing condensate water generated by the auxiliary evaporator and comprises a water outlet that is suitable for being communicated with the indoor unit of the air conditioner. A refrigerant throttled by the throttling device in the air conditioner can exchange heat with outdoor air in the auxiliary evaporator; the refrigerant evaporates and absorbs heat in the auxiliary evaporator, so condensate water is formed on the auxiliary evaporator when outdoor air flows through the auxiliary evaporator; the water storage device is arranged to store condensate water generated by the auxiliary evaporator and guides the condensate water into the indoor unit of the air conditioner to provide a water source for the indoor unit of the air conditioner, so the air conditioner does not occupy indoor space when providing a humidifying function; and the overall structure of the air conditioner is simpler as only one auxiliary evaporator is additionally arranged on the outdoor unit.

Owner:GREE ELECTRIC APPLIANCES INC

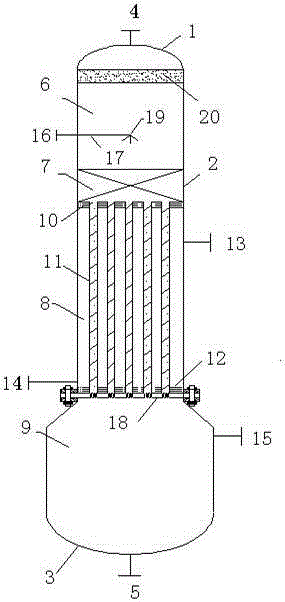

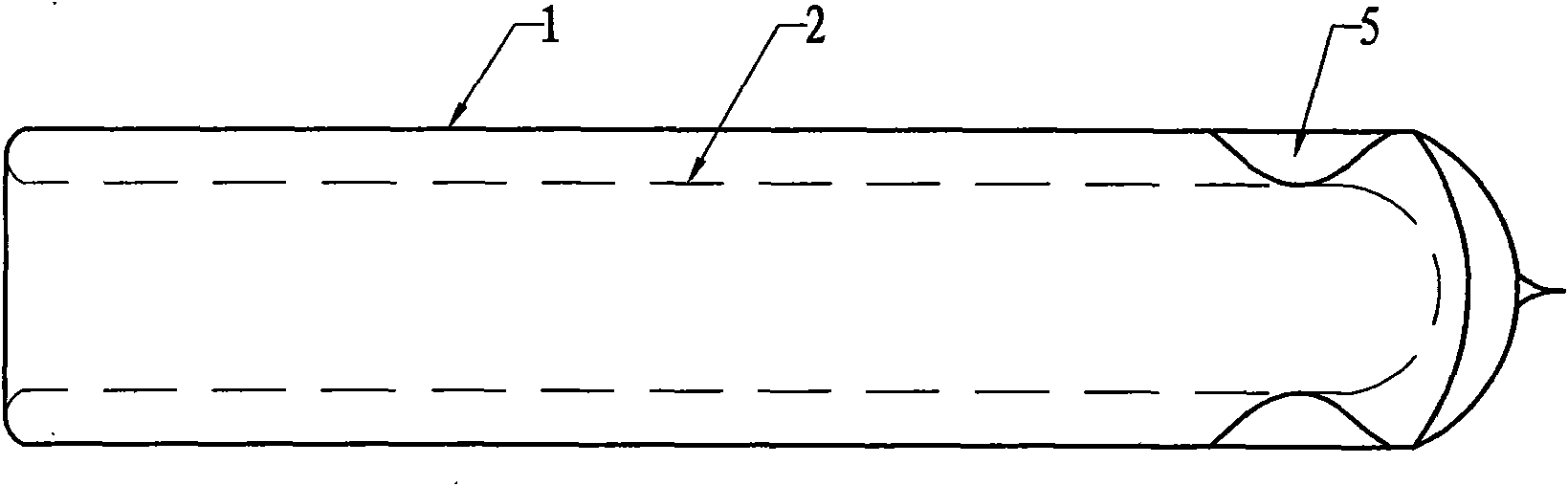

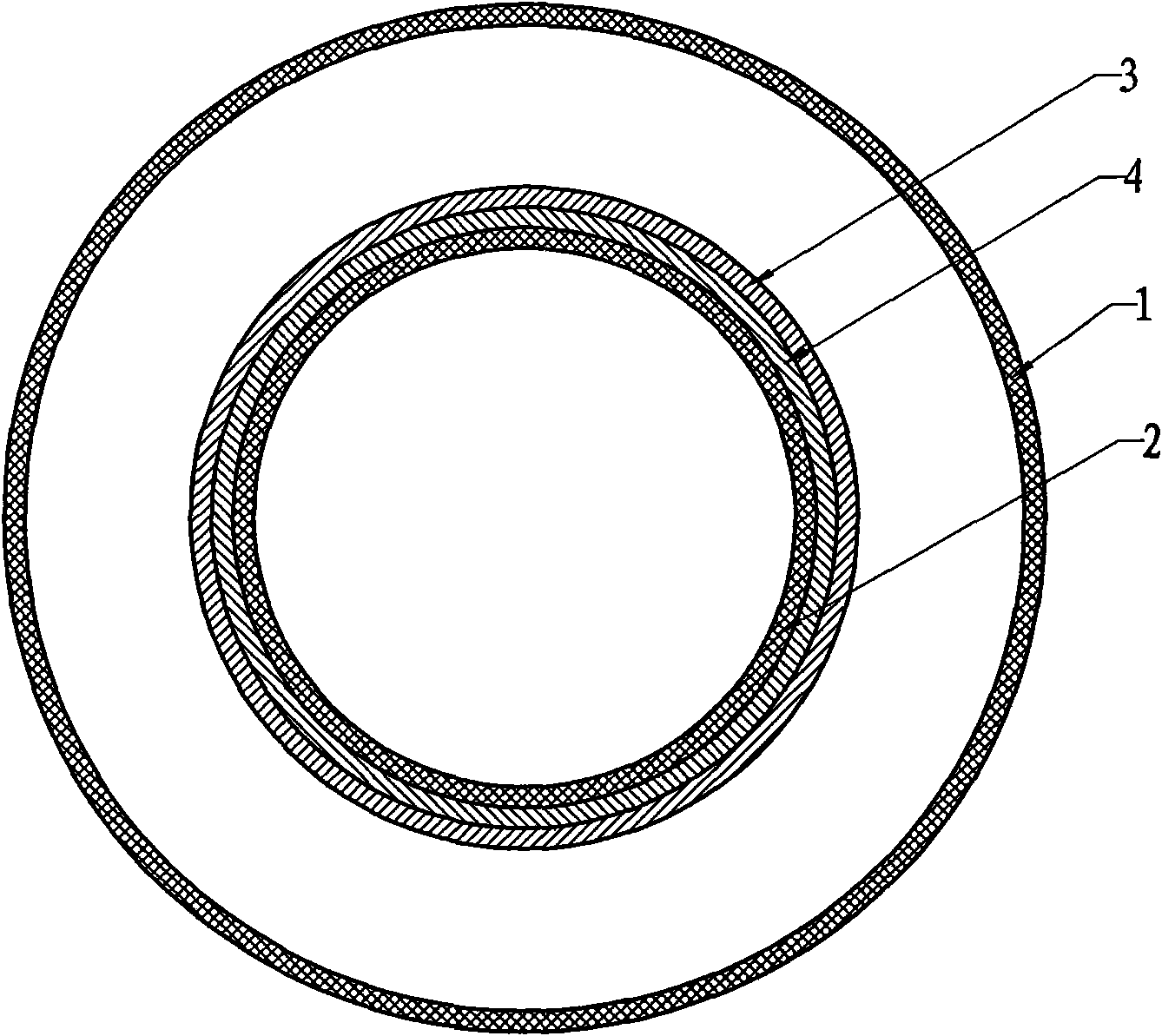

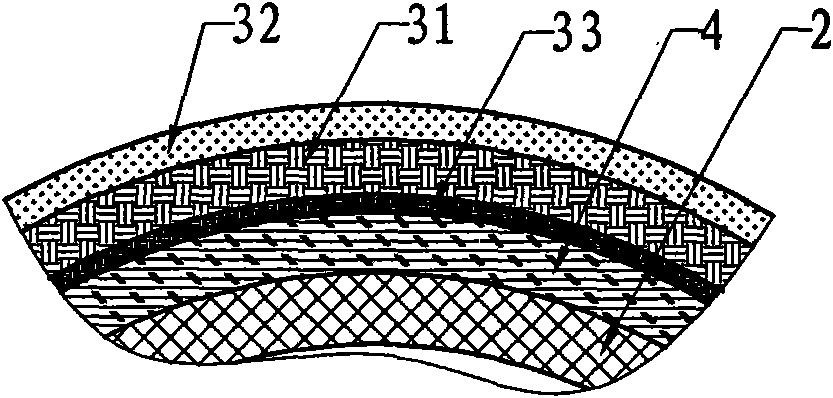

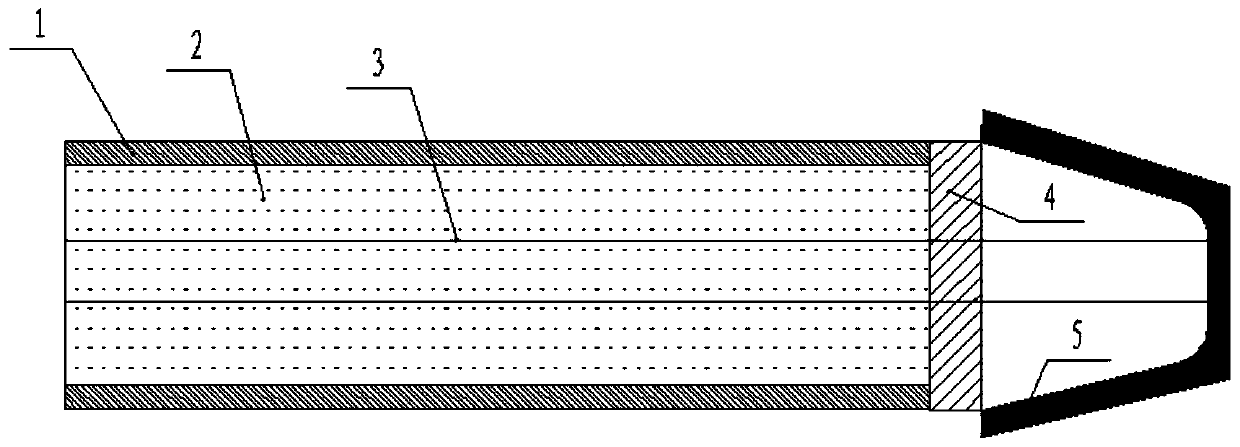

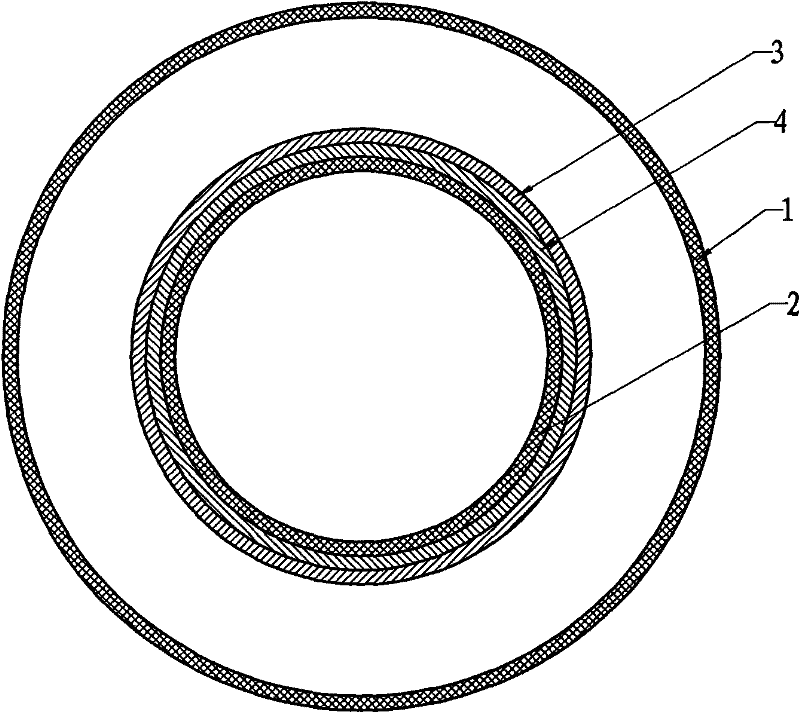

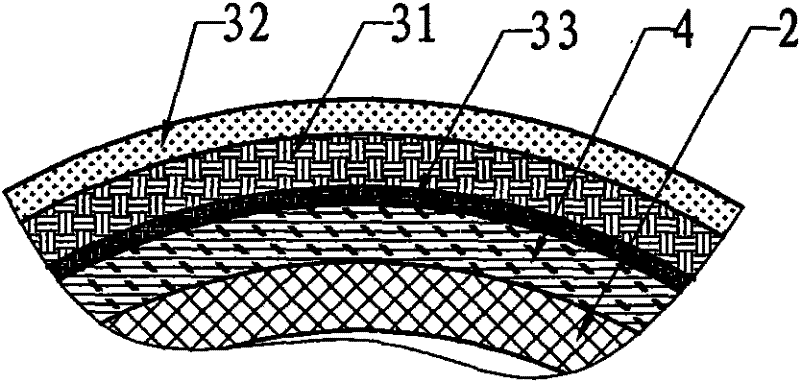

Vacuum collector tube and manufacturing method thereof

InactiveCN101650091ANot easy to fall offImprove light-to-heat conversion performanceSolar heating energySolar heat devicesAluminium foilCopper foil

The invention provides a vacuum collector tube and a manufacturing method thereof, and the method comprises the following steps: after the manufacturing of a glass inner tube is completed, when preparing a film on the outer surface of the glass inner tube, firstly selecting the aluminium foil or the copper foil as a metal substrate; utilizing the sputtering process to form an aluminium nitrogen compound absorbing layer or utilizing the electroplating process to form a chromium plating absorbing layer on one side of the metal substrate; utilizing the polishing process to polish the surface of the metal substrate to form a reflecting layer on the other side of the metal substrate; clipping the film, and then coating the prepared film on the outer surface of the glass inner tube and utilizingthe heat-conducting transparent organic adhesive to adhere the prepared film on the outer surface of the glass inner tube seamlessly; carrying out tight closeness and butt joint on the edge; and finally forming the interval space between the glass inner tube and the glass outer tube into vacuum and sealing the connector. The heat absorption capacity of the vacuum collector tube is higher, and canreach 96% to 98%; the film is not easy to fall off; the service life is long; the color consistency is good; and the operation is simple and the manufacturing cost is low by adopting the method.

Owner:SHANDONG SANGLE SOLAR ENERGY

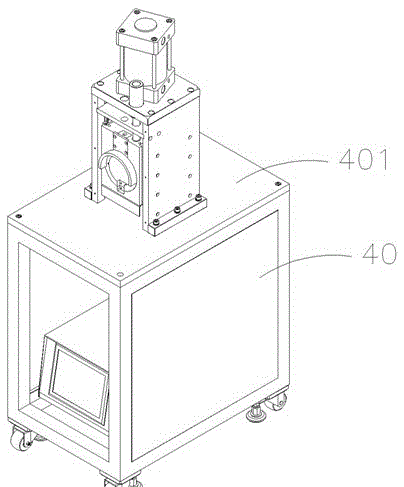

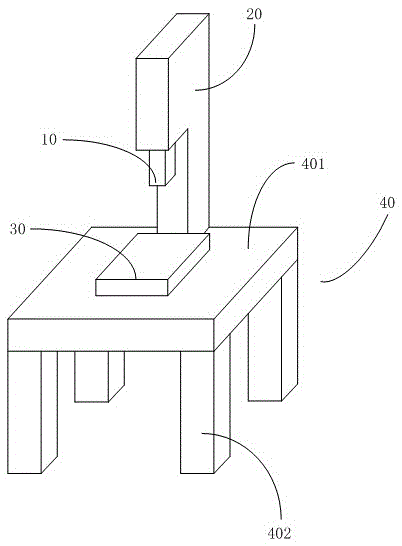

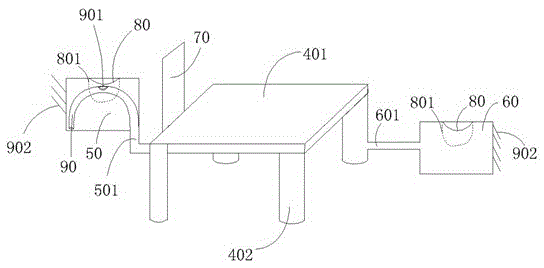

Ultrasonic welding machine with temperature shock resistance function

InactiveCN105643087AImprove cooling effectImprove mechanical propertiesNon-electric welding apparatusMotor driveUltrasonic welding

The invention discloses an ultrasonic welding machine with a temperature shock resistance function. The ultrasonic welding machine comprises a welding head, a servo motor driving mechanism, a support, a base and a rack. The support is made of carbon steel; the base is used for bearing a product and is provided with a containing cavity for containing the product to be welded; the rack is used for bearing the support and the base; the rack comprises a working table in contact with the base and four supporting legs which are used for supporting the working table and located on the lower portion of the working table; and the rack is of a hollow structure, the hollow supporting legs and the hollow working table are connected into a cavity, one supporting leg is connected with a first water storage tank through a water inlet pipe, and the other supporting leg is connected with a second water storage tank through a water outlet pipe. The mounting height of the first water storage tank is larger than that of the second water storage tank, and one side wall of the first water storage tank and one side wall of the second water storage tank are transparent and provided with scales; and the top face of the first water storage tank and the top face of the second water storage tank are each provided with a hand hole. The ultrasonic welding machine is simple in whole structure, high in practicability, long in service life and easy to use and popularize.

Owner:JIANGSU XINSIWEI PHOTOELECTRIC CO LTD

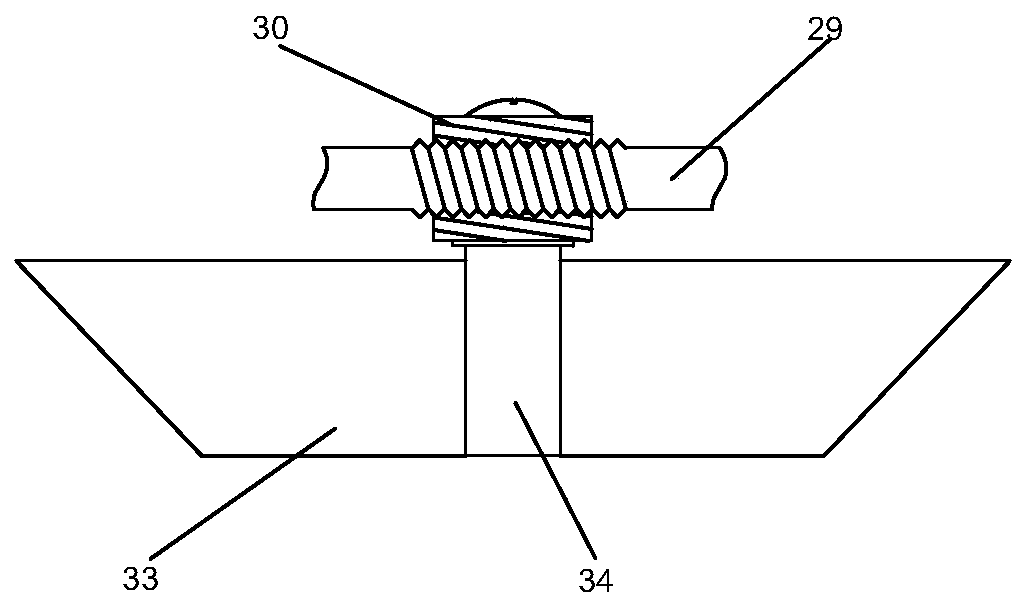

Rapid response temperature measuring thermocouple for metal mold casting

ActiveCN108387320AIncrease contact areaQuick responseThermometer detailsThermometers using electric/magnetic elementsThermocouple WireEnvironment effect

The invention discloses a rapid response temperature measuring thermocouple for metal mold casting, comprising two thermocouple wires, which are arranged in a protective sleeve and connected by a metal joint at a hot end. The metal joint is a truncated cone structure, the longitudinal section is trapezoidal, and the center of the trapezoid is a hollow structure. A part, contacted with a mold temperature measuring hole, of the metal joint is a smooth plane, and the contact surface of the mold temperature measuring hole corresponding to the metal joint is also processed into a smooth plane; andbehind the metal joint, a high temperature sealant is arranged between the inner wall of the temperature measuring hole and the protective sleeve. The rapid response temperature measuring thermocouplerapidly transfers heat of the mold after the temperature rise to the thermocouple, and realizes the rapid response of the thermocouple to the temperature. The smooth contact surface of the metal joint of the thermocouple is protected from environmental influences. The metal joint is insulated from thermocouple parts other than the thermocouple wires so as to avoid interference.

Owner:BEIHANG UNIV

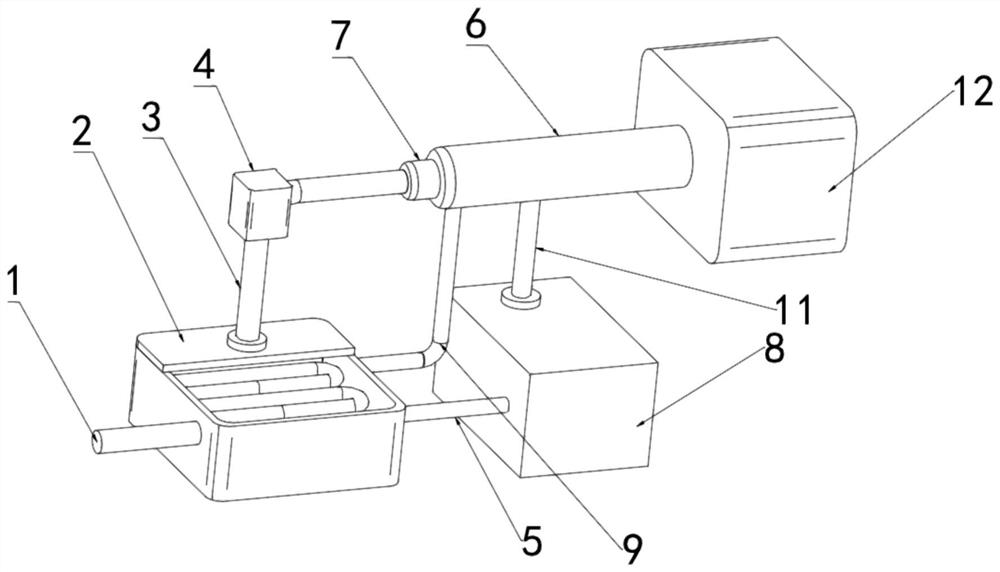

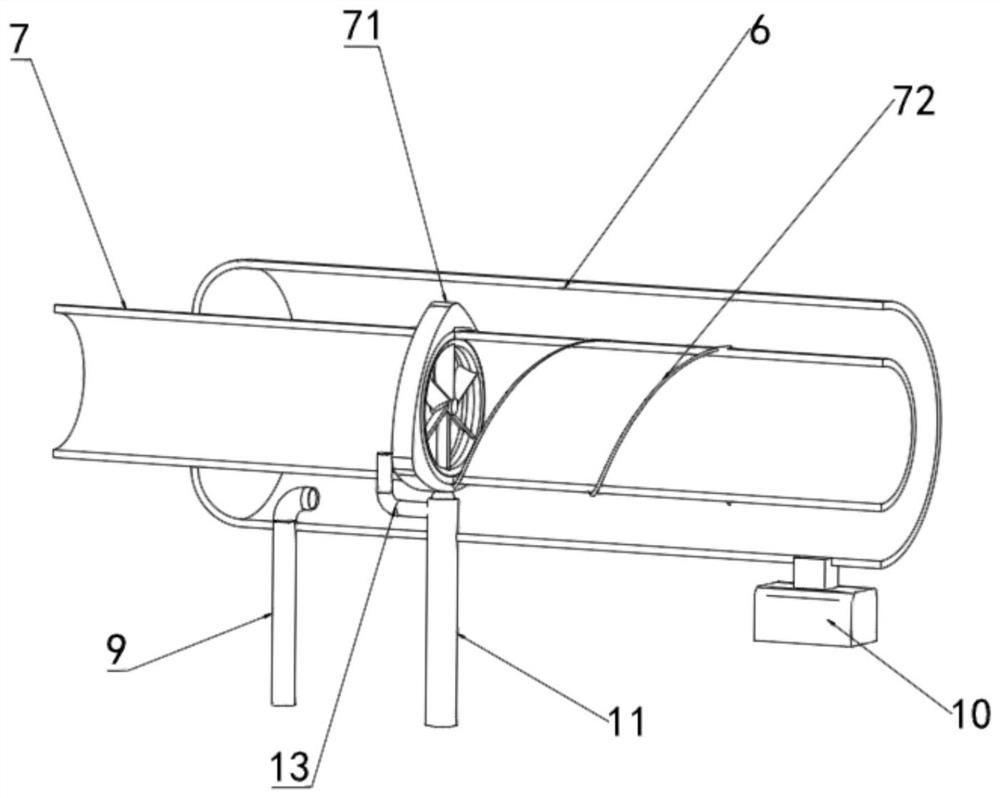

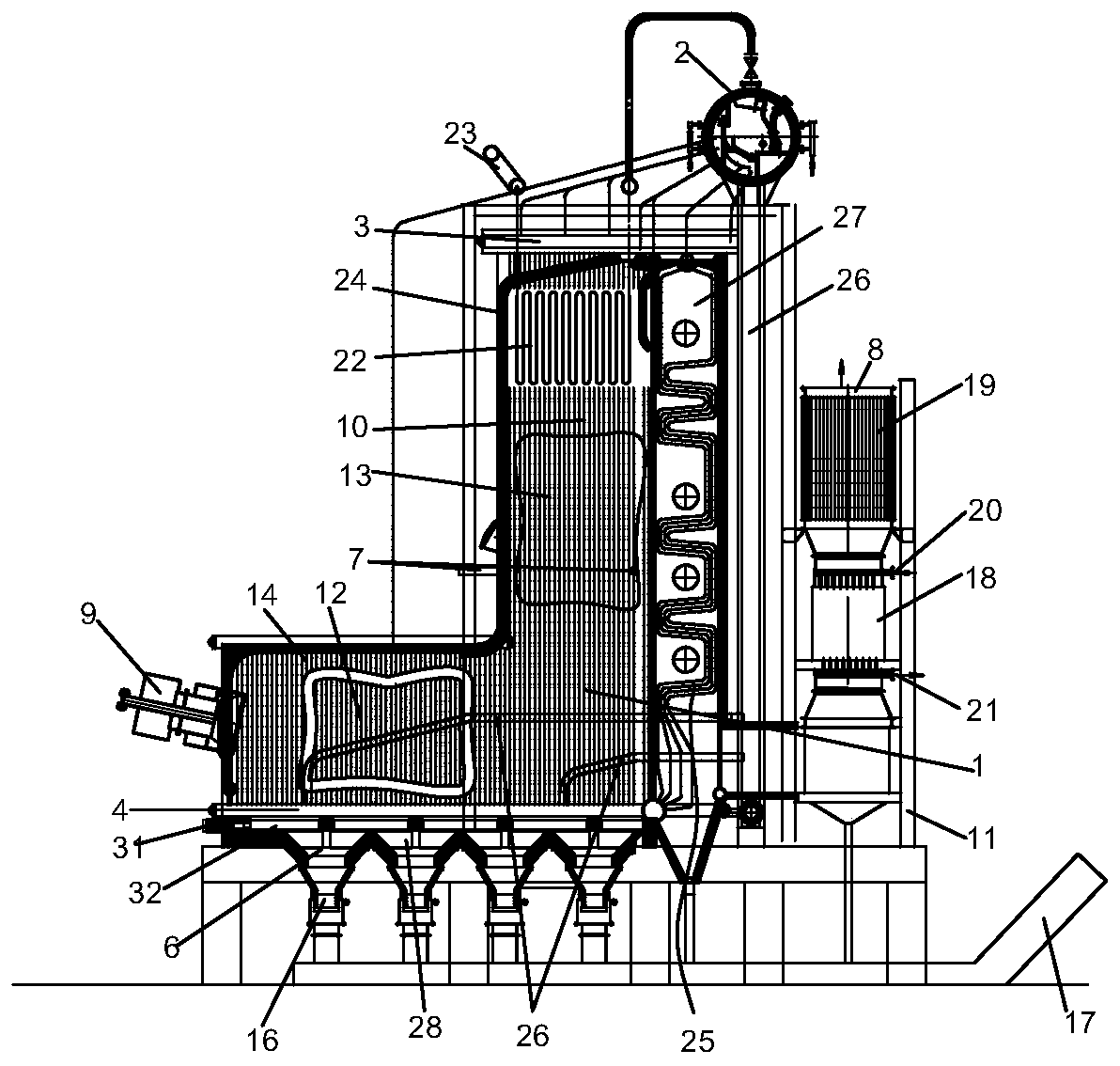

Energy-saving environmental-friendly boiler for thermal power generation

InactiveCN108826264AAffect heat transferIncrease profitBoiler cleaning apparatusSteam boilersCombustion chamberEngineering

The invention discloses an energy-saving environmental-friendly boiler for thermal power generation. The energy-saving environmental-friendly boiler for thermal power generation comprises a boiler shell, wherein a combustion chamber is ranged at the center of the boiler shell; a heating water cavity is formed between the combustion chamber and the boiler shell; a dust collection cavity is formed in the bottom of the boiler shell; a supporting net is arranged between the dust collection cavity and the combustion chamber; two hydraulic air cylinders are arranged at the two sides of the bottom end of the boiler shell; the output ends of the hydraulic air cylinders are connected to hydraulic rods; one ends of the hydraulic rods pass through the bottom end of the heating water cavity and are connected to fixing parts; the fixing parts are welded at the inner side of an outer cleaning ring; the inner side of the outer cleaning ring is fixedly connected to an inner cleaning ring through a supporting rod; scraping sheets are fixedly arranged at the bottom ends of the outer cleaning ring and the inner cleaning ring; and a filtering net is arranged on the top end of the combustion chamber. The energy-saving environmental-friendly boiler for thermal power generation scrapes scale bulges generated on side walls by using the scraping sheets on the cleaning rings, prevents scale from affecting the heat transfer of the boiler, improves the utilization rate of fuel and saves resources.

Owner:陈仕铮

Flue gas denitration utilization device for waste heat boiler of gas turbine

PendingCN114653198ASave laying costsSave on running costsDrying solid materials without heatDispersed particle separationFlue gasProcess engineering

The invention discloses a gas turbine waste heat boiler flue gas denitration utilization device, and relates to the field of flue gas denitration, the gas turbine waste heat boiler flue gas denitration utilization device comprises a heat exchanger, a urea hydrolysis device and a denitration reactor, a gas inlet of the heat exchanger is connected with a flue gas inlet pipe, and an output port of the heat exchanger is connected with a pressure reduction and temperature reduction flue gas pipe; a pneumatic control valve is arranged at the other end of the pressure and temperature reduction flue gas pipe, the output end of the pneumatic control valve is connected with a dilution air pipeline, the other end of the dilution air pipeline is connected with the ammonia gas input end of the denitration reactor, and a heat tracing pipeline is fixedly installed on the side face of the denitration reactor; the heat tracing pipeline is located on the outer side of the dilution air pipeline. The flue gas of the unit is directly extracted, so that the laying and operation cost of a high-temperature fan and a steam heat exchanger can be saved, the transportation condition of an ammonia gas mixture after hydrolysis is met, the operation cost is effectively reduced, and efficient and stable denitration work is ensured.

Owner:HUANENG NANTONG GAS TURBINE POWER GENERATION CO LTD

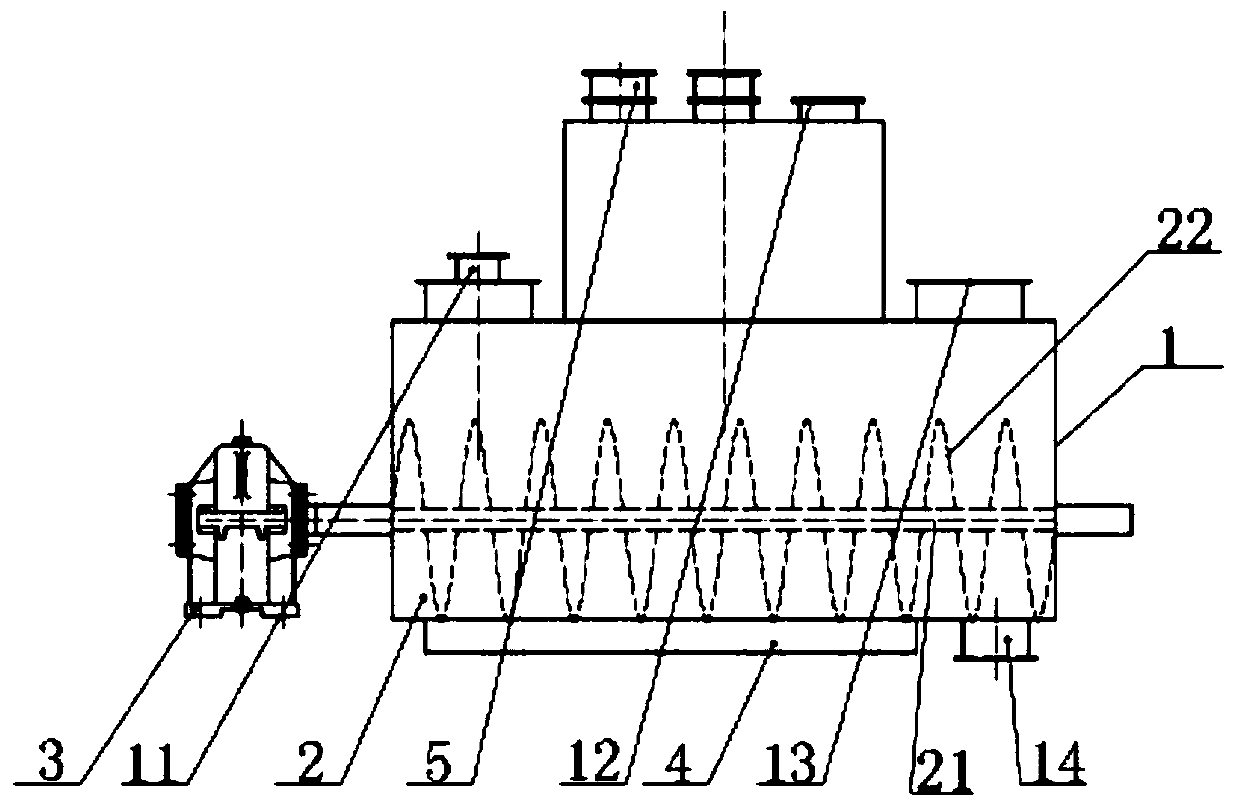

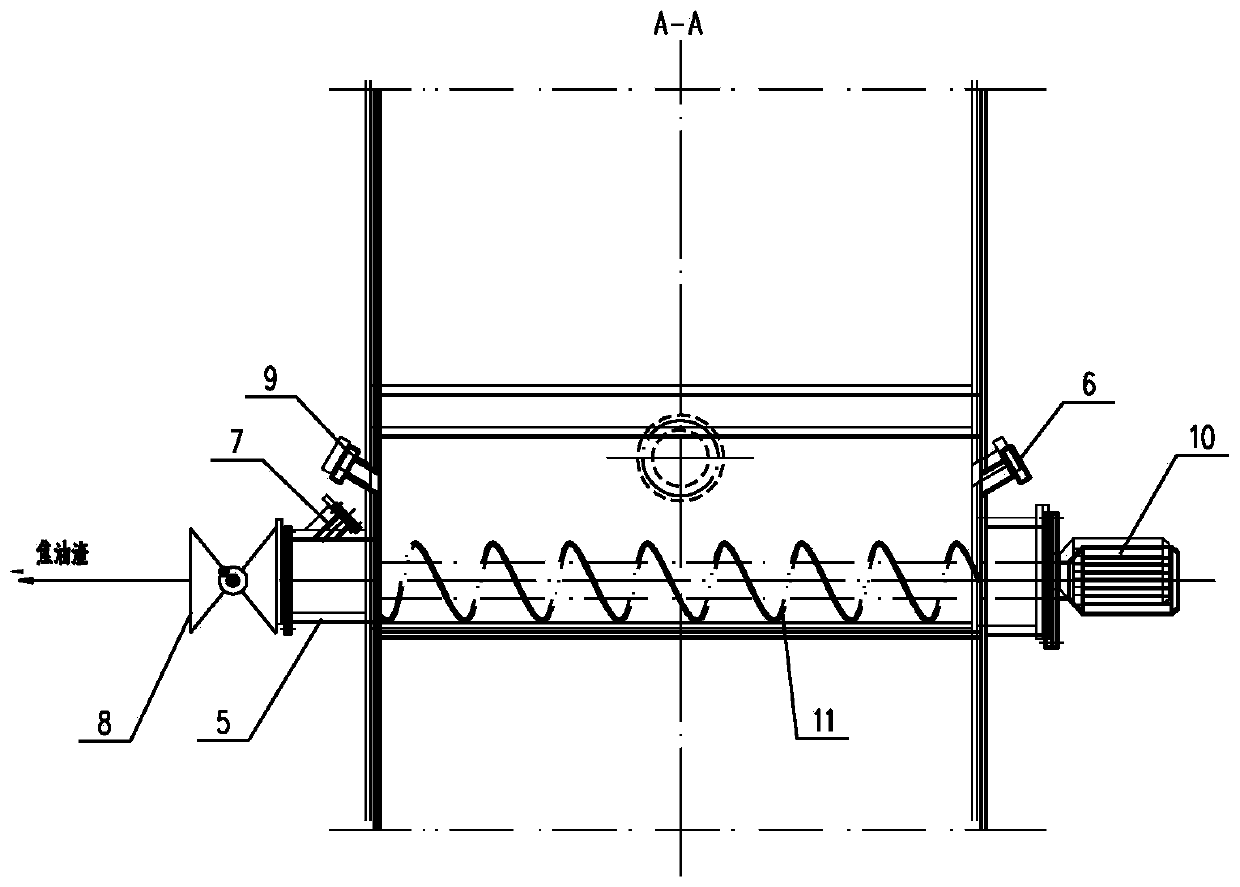

Oil-containing waste pyrolysis equipment and reduction treatment method

PendingCN111500300AFully pyrolyzedAffect heat transferLiquid hydrocarbon mixture productionIndirect heating destructive distillationReduction treatmentCondenser (heat transfer)

The present invention discloses oil-containing waste pyrolysis equipment and a reduction treatment method. The oil-containing waste pyrolysis equipment comprises a sealed tank body, a stirring and scraping device, a power supply driving device, a heating device, a condenser and an oil-water separation device, the top of the sealed tank body is provided with a feeding opening, an air outlet and anobservation window, and the bottom of the sealed tank body is provided with a slag outlet; the stirring and scraping device is mounted in the sealed tank body; the power supply driving device is fixedoutside the sealed tank body and is in transmission connection with the stirring and scraping device; the heating device is arranged at the periphery of the sealed tank body; the condenser is communicated with the air outlet; and the oil-water separation device is connected and communicated with the condenser. In the whole process, the tank body is fixed and static, oil-containing waste is stirred through the stirring and scraping device inside the tank body, slag on the inner wall of the tank body is scraped off to prevent coking, leakage is not likely to happen, the safety performance is high, materials cannot coke on the tank wall to influence heat transfer, and pyrolysis is sufficient.

Owner:东营兴盛环保科技股份有限公司

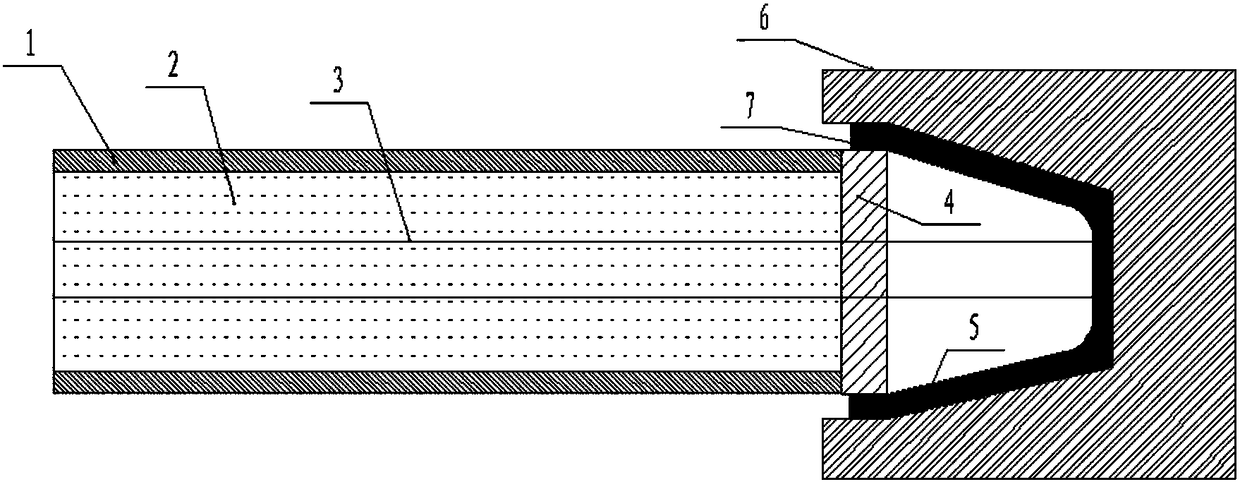

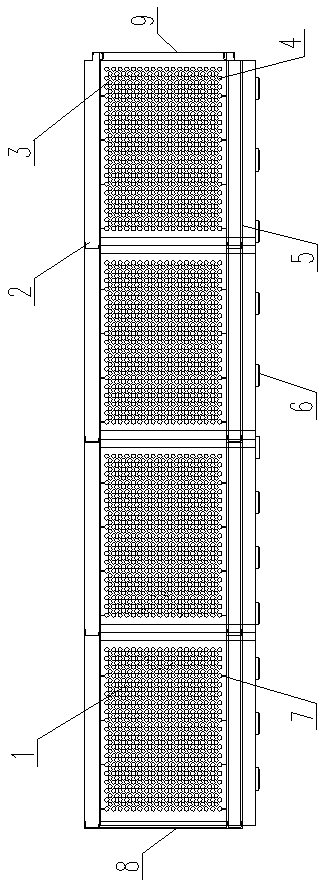

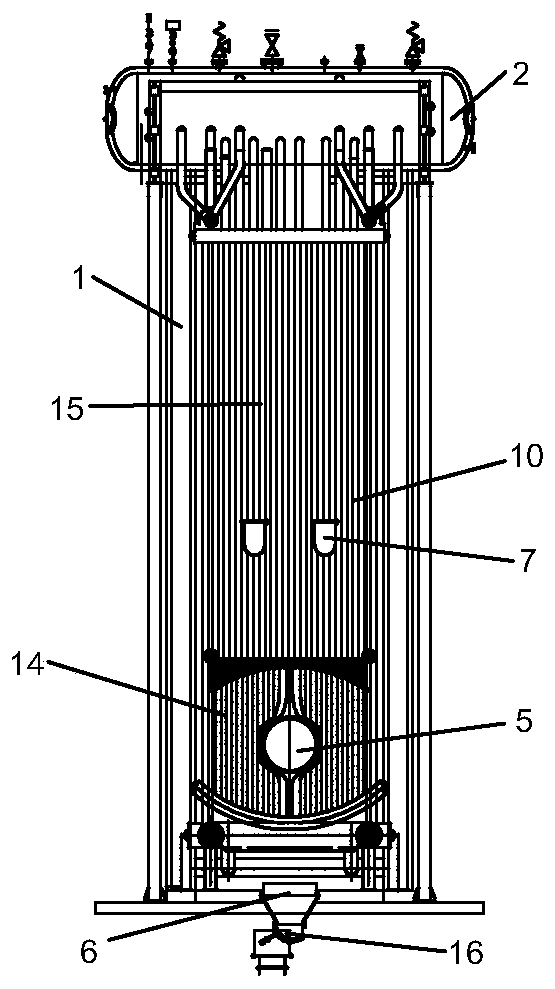

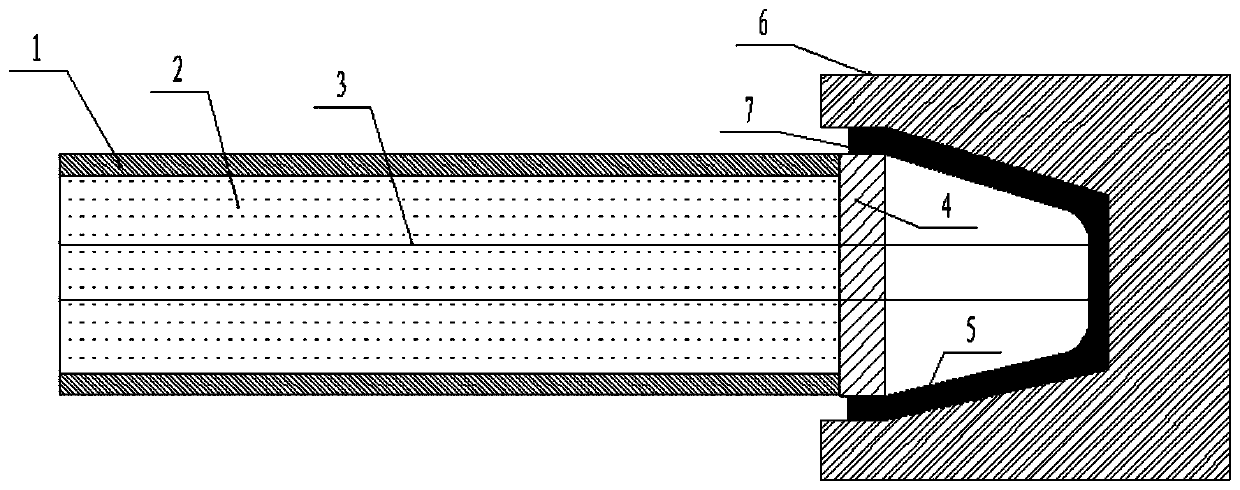

Novel tubular preheater for carbon dioxide testbed and preheating method

InactiveCN110081458AOptimize layoutSimple structureIndirect carbon-dioxide mitigationAir/fuel supply for combustionFlue gasEngineering

The invention relates to a novel tubular preheater for a carbon dioxide testbed and a preheating method. As a result of increasingly competitive market competition and increasingly improvement of arrangement forms of boilers, original channel equipment cannot achieve horizontal flowing heat exchange of flue gas and air. The preheater comprises a middle tube bundle (1) which comprises front and back tube plates (3). Each tube plate is provided with a horizontal round hole and is vertically mounted on a sliding base plate (6), a tube (4) is threaded in the horizontal round holes between the front and back tube plates, steel flat (7) is separately fixed above and below the middle tube bundle, the upper and lower sides of the tube plate are separately fixed to an upper protecting plate (2) anda lower protecting plate (5), an air duct communicating box A (10) is mounted on one side of the middle tube bundle and an air duct communicating box B (13) is mounted on the other side of the middletube bundle. The invention provides the novel tubular preheater for the carbon dioxide testbed.

Owner:HARBIN BOILER

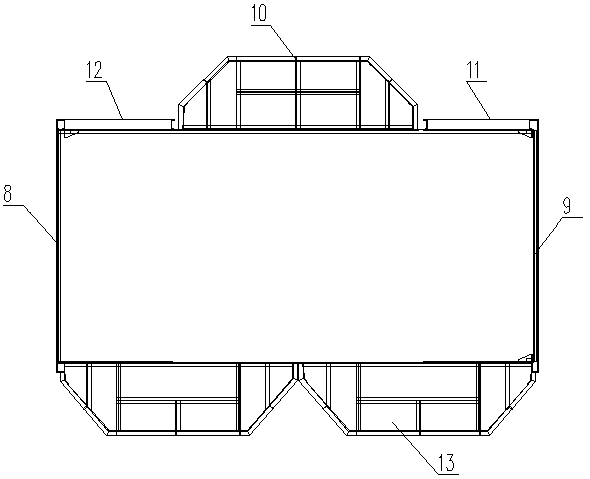

Gas and powder fuel dual-purpose boiler provided with front O type horizontal hearth and rear vertical hearth

PendingCN111351018ABurn fullyIncrease profitBoiler water tubesSteam superheatersCombustorProcess engineering

The invention provides a gas and powder fuel dual-purpose boiler which is provided with a front O type horizontal hearth and a rear vertical hearth and capable of reducing fouling of heating surface,solving the coking problem in the hearth and increasing burn-off rate of fuel. The gas and powder fuel dual-purpose boiler comprises a boiler body, wherein the boiler body comprises a boiler drum, a steam-water system, a burner, a hearth and a flue, a feed port, a dust falling port, a burnout tuyere and an exhaust gas outlet are formed in the boiler body, the front horizontal hearth with a burningzone and the rear vertical hearth with a burnout zone are arranged in the hearth, the right end of the front horizontal hearth communicates with the lower end of the rear vertical hearth, the burnouttuyere is formed in the furnace wall of the rear vertical hearth and communicates with the hearth, the boiler drum is arranged above the rear vertical hearth, the feed port is located on the left side of the front horizontal hearth, the burner is obliquely arranged in the feed port, the dust falling port is formed at the lower end part of the boiler body, the boiler body is provided with a gas locking device, the flue is vertically arranged on the right side of the boiler body, the gas inlet end of the flue communicates with the rear vertical hearth, and the exhaust gas outlet is formed at the gas outlet end of the flue.

Owner:FUJIAN ETERNAL ENERGY MANAGEMENT

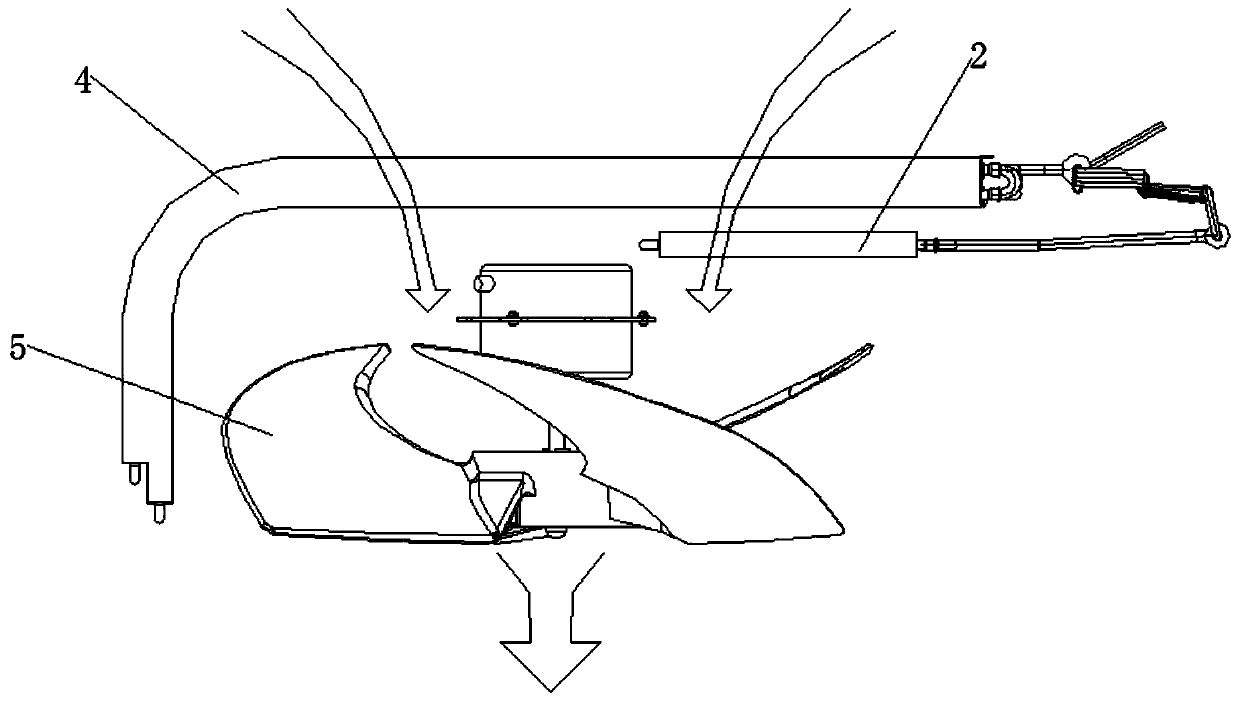

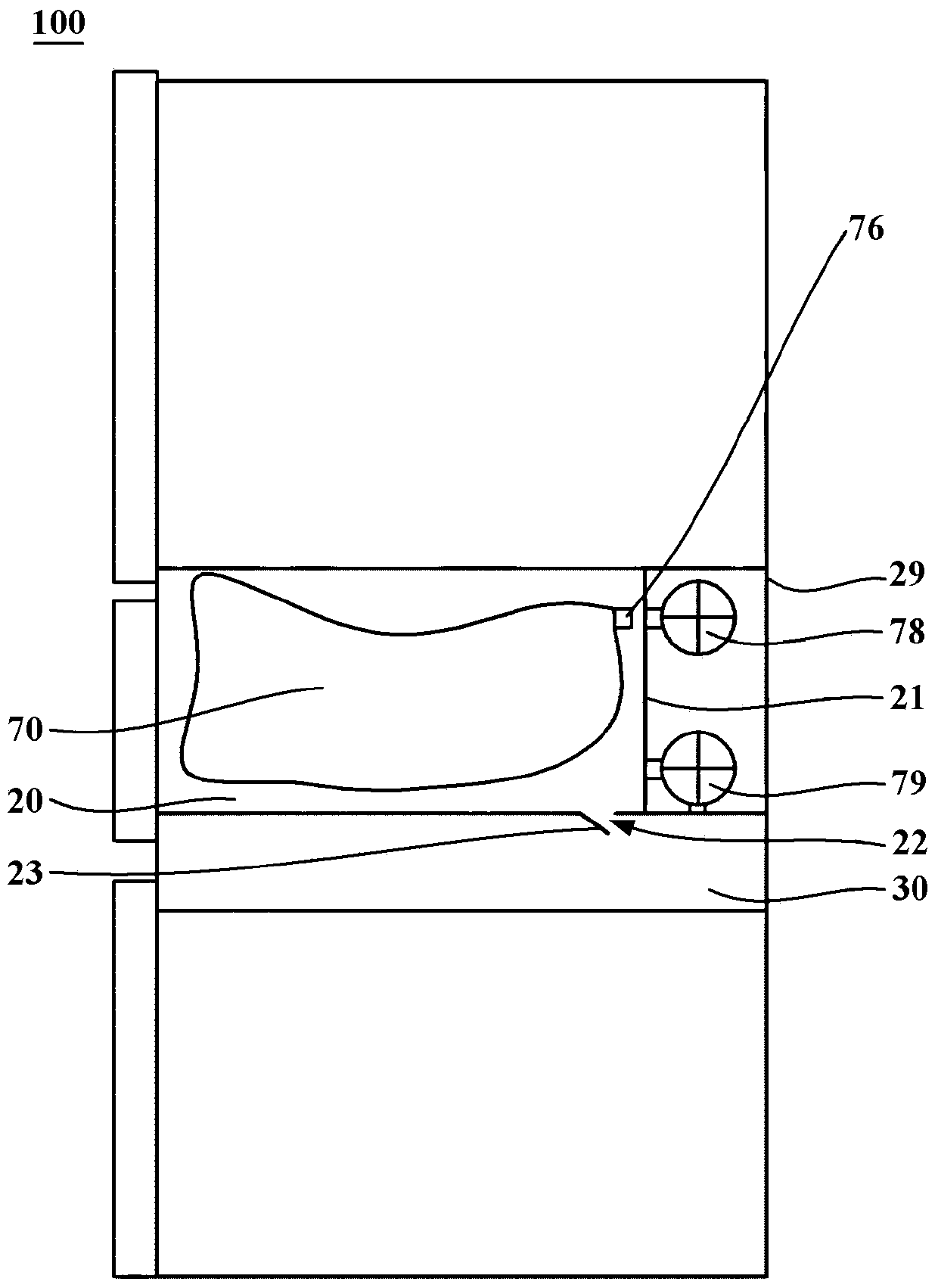

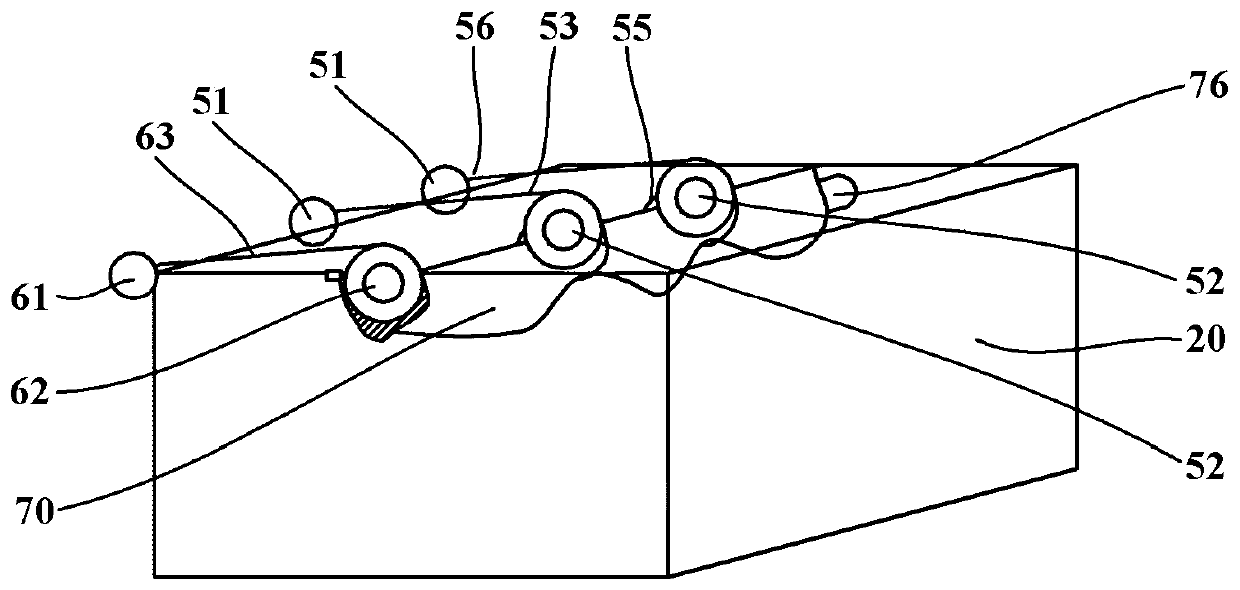

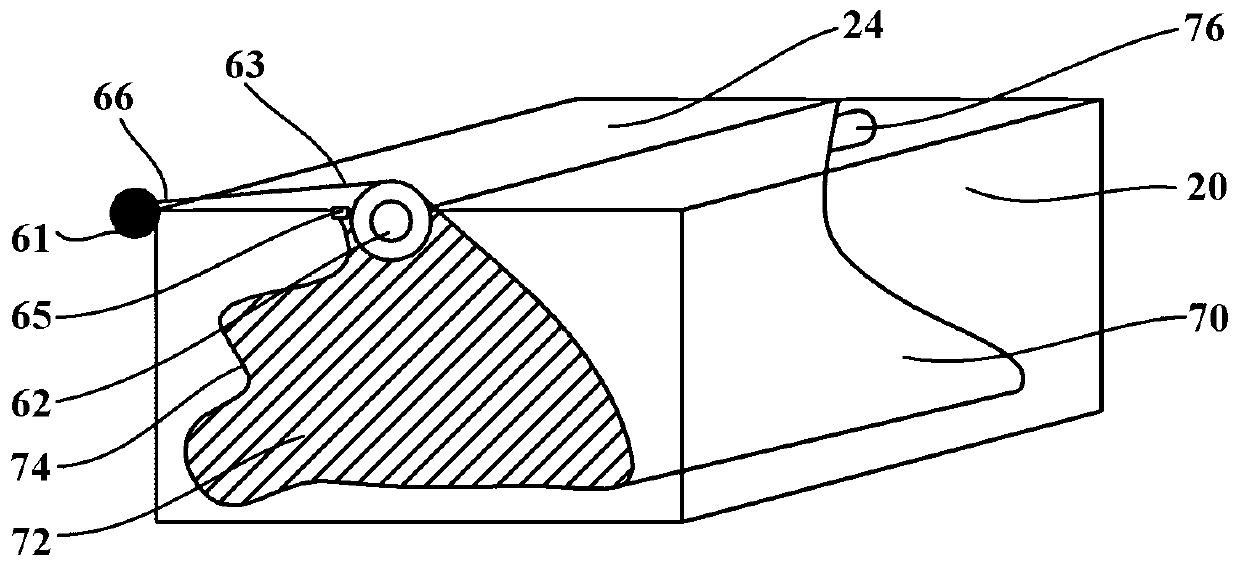

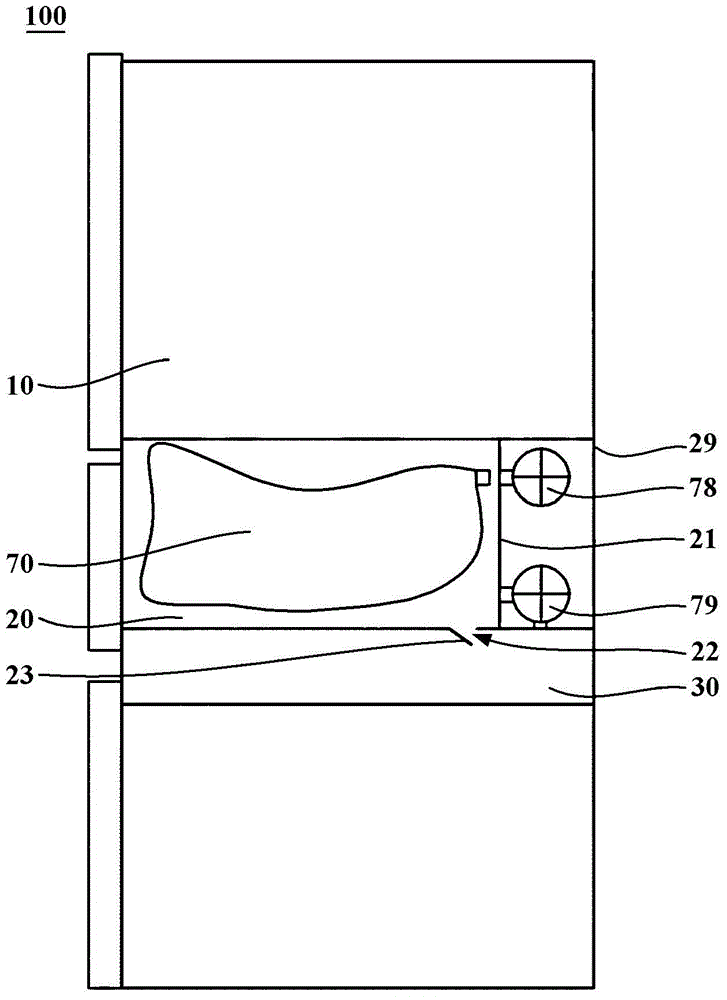

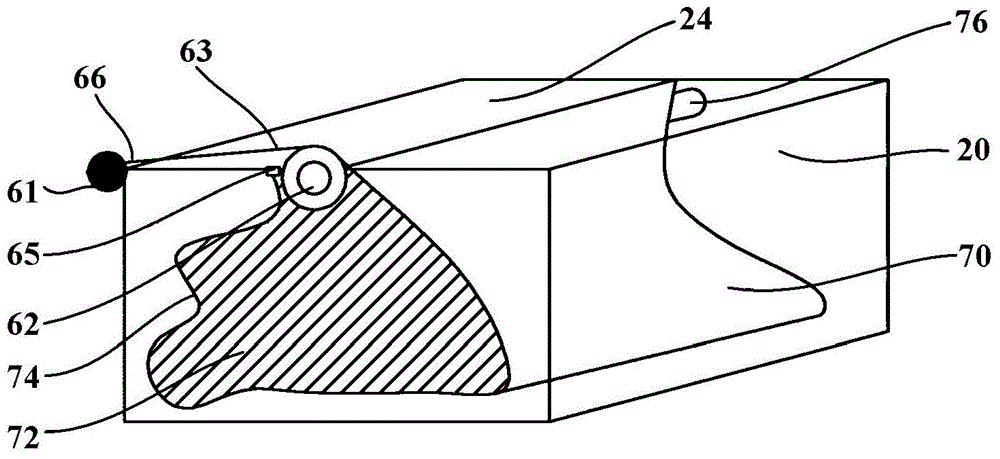

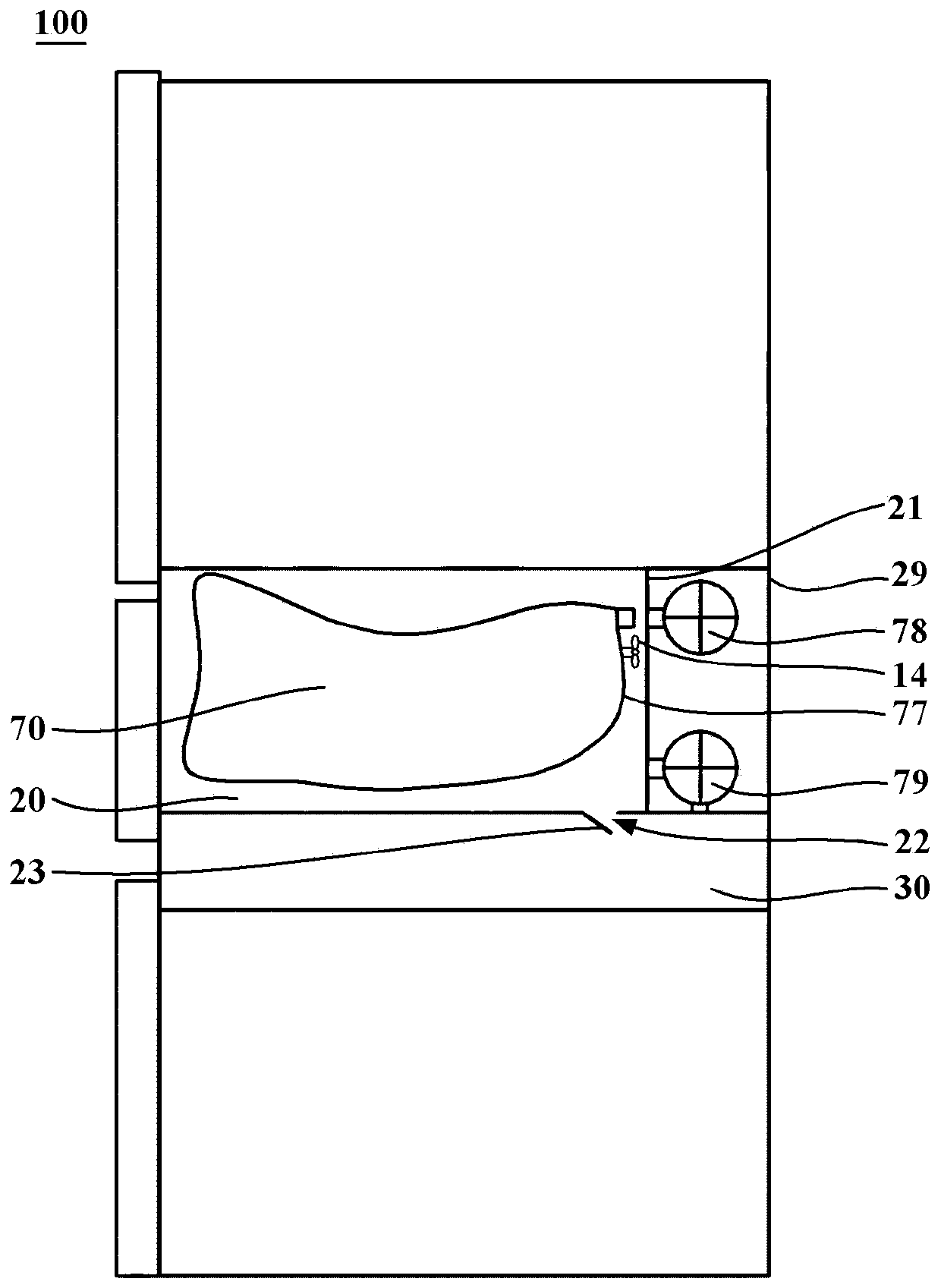

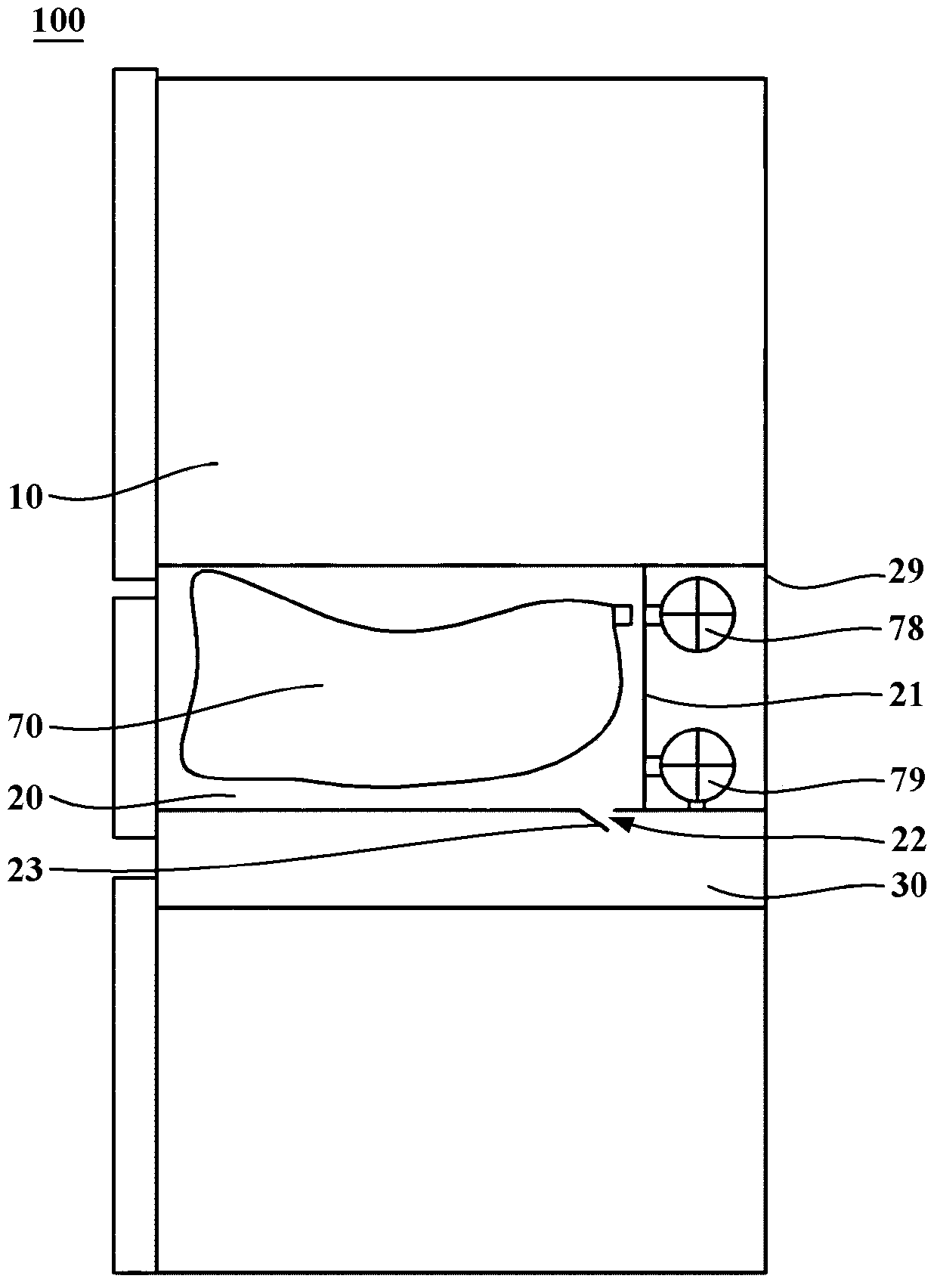

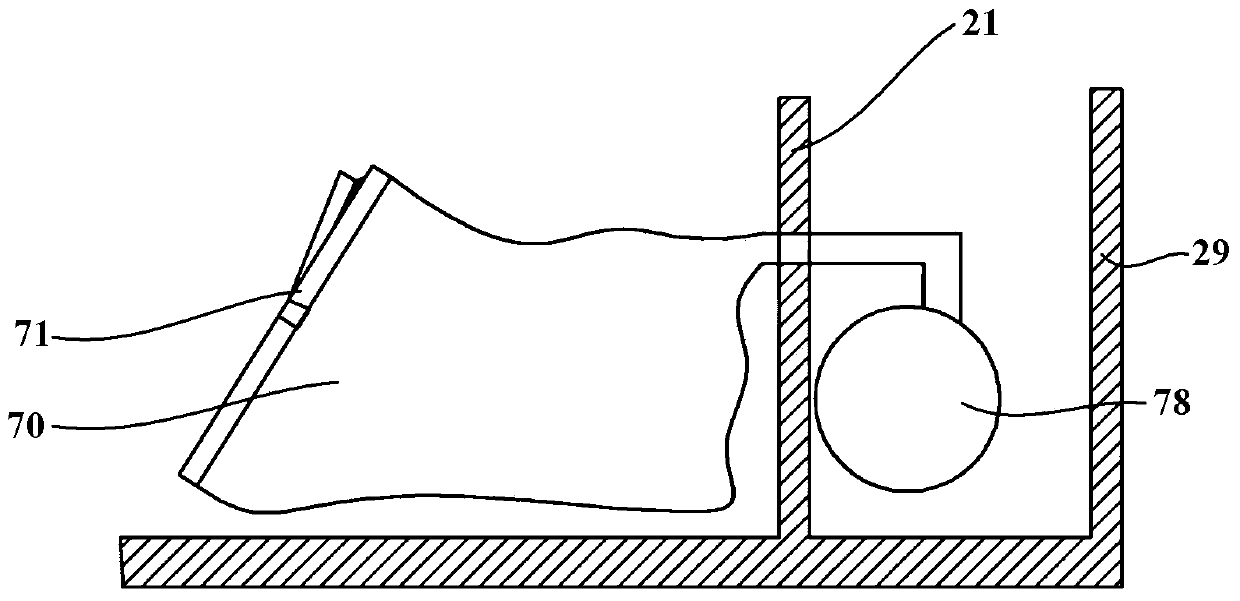

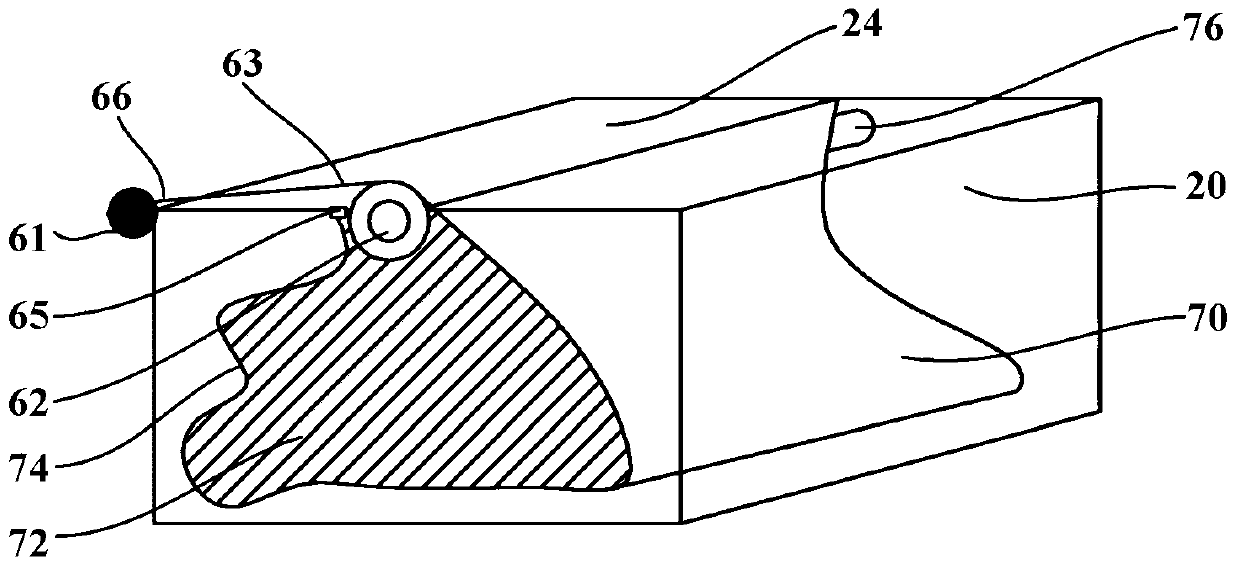

Refrigerator and quick-freezing method therefor

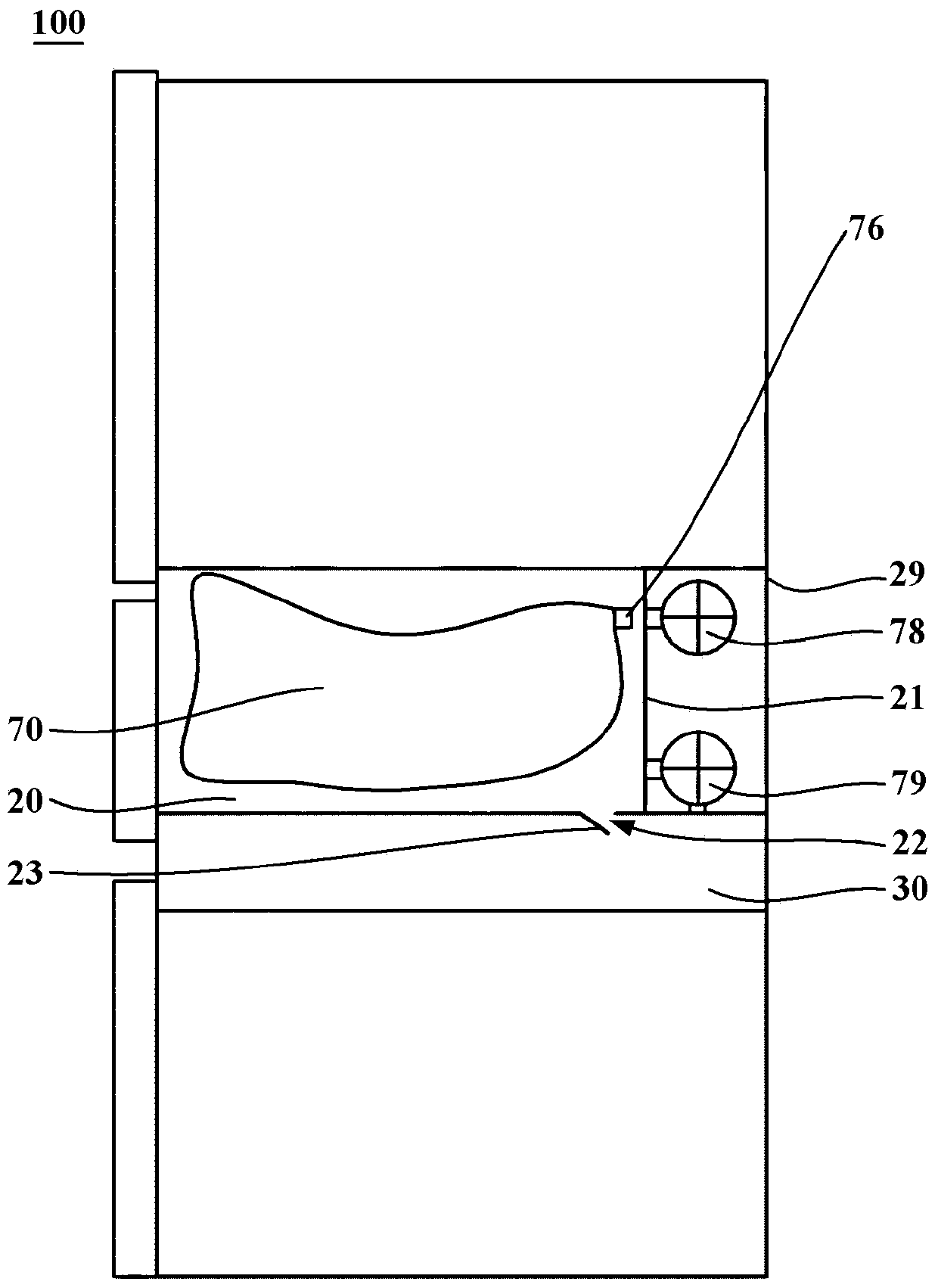

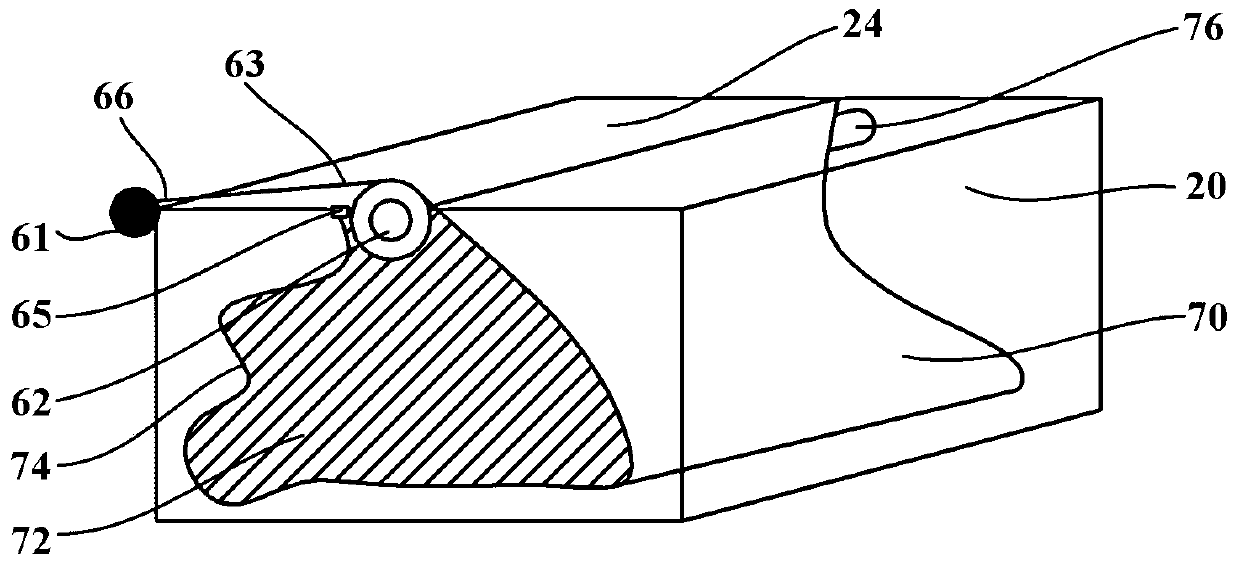

ActiveCN106152669BEasy to operateDoes not take up storage spaceLighting and heating apparatusDomestic refrigeratorsEngineeringConductor Coil

The invention provides a refrigerator and a quick-freezing method for the refrigerator. The refrigerator comprises an isolation bag, a first cord and a first motor, wherein the isolation bag is arranged in a storage compartment of the refrigerator and provided with a bag opening used for storing and taking objects; the first cord movably surrounds the periphery of the bag opening, and the bag opening can be fastened when the first cord is strained towards the winding end of the first cord; and the first motor is rotated towards a first direction in a controlled mode so that the first cord can be driven to be strained in the winding end of the first cord so as to fasten the bag opening. The invention further provides the quick-freezing method for the refrigerator. When the objects are quickly frozen through the quick-freezing method, on one hand, the objects can be protected against contamination or air-drying, and on the other hand, the bag opening of the isolation bag can be fastened automatically.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD

A fast response temperature measuring thermocouple for casting mold

ActiveCN108414106BIncrease contact areaAffect heat transferThermometer detailsThermometers using electric/magnetic elementsEngineeringThermocouple Wire

Owner:BEIHANG UNIV

Refrigerator and quick-freezing method for refrigerator

ActiveCN106152668BDoes not take up storage spaceAffect heat transferLighting and heating apparatusDomestic refrigeratorsQuick FreezeEngineering

Owner:QINGDAO HAIER SMART TECH R & D CO LTD

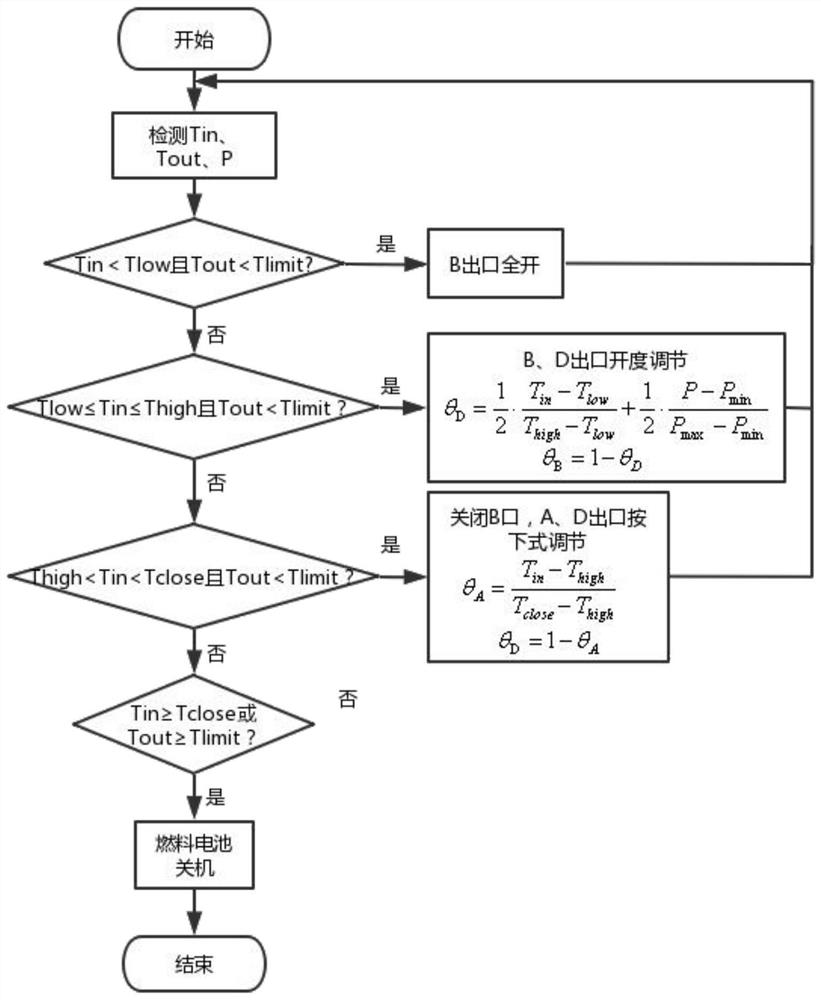

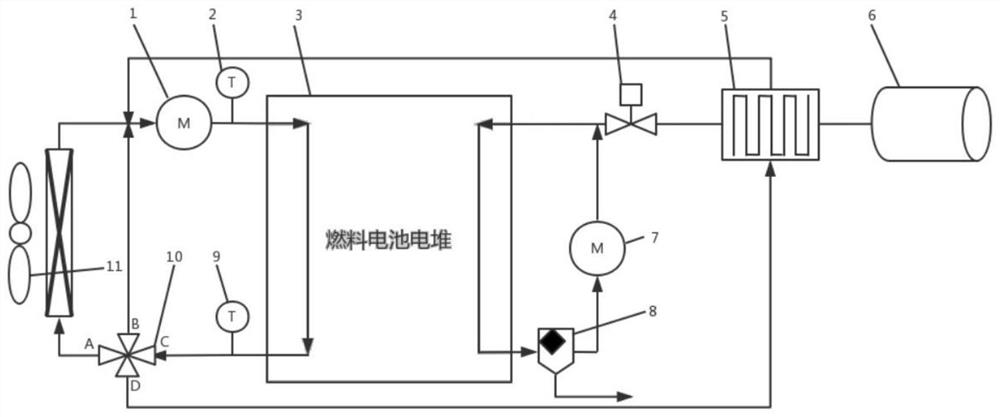

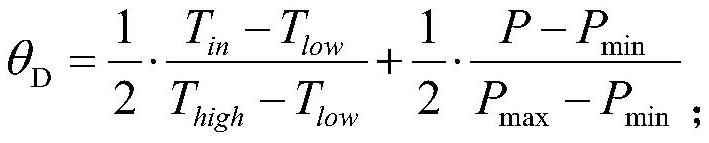

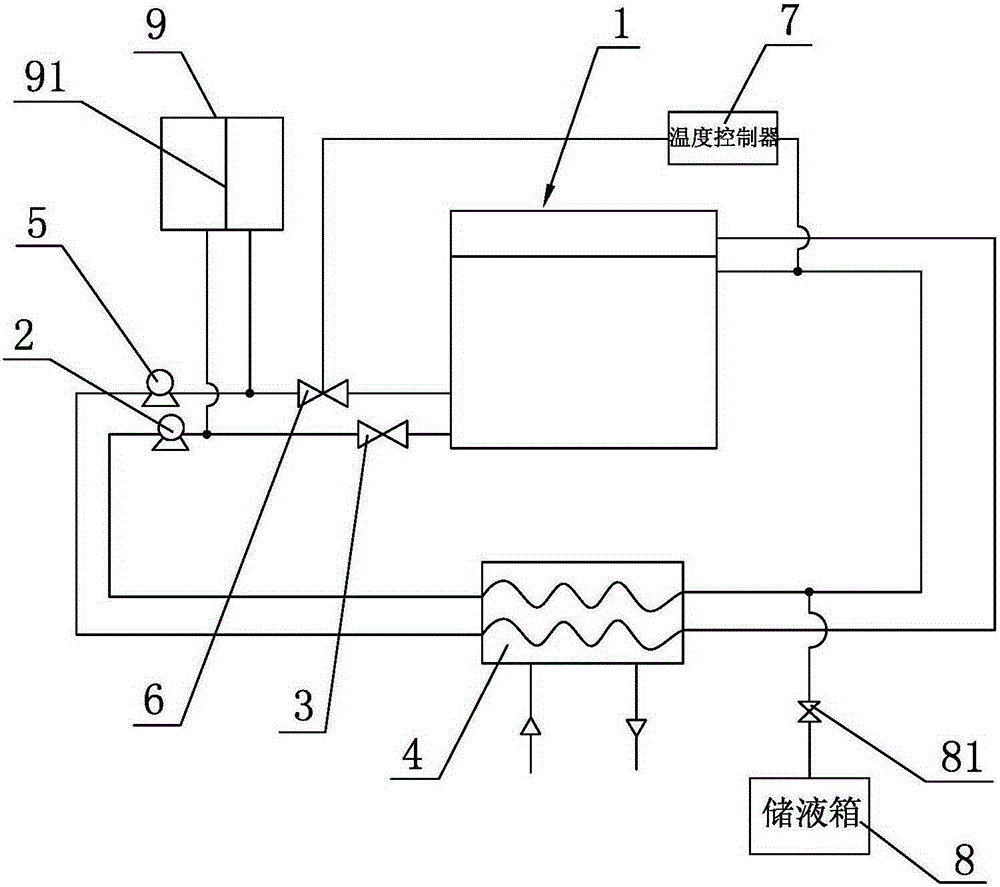

A kind of control method of liquid hydrogen fuel cell waste heat recovery system

ActiveCN113258105BEfficient use ofReduce performance requirementsFuel cell heat exchangeHydrogen fuel cellLiquid hydrogen

Owner:四川荣创新能动力系统有限公司

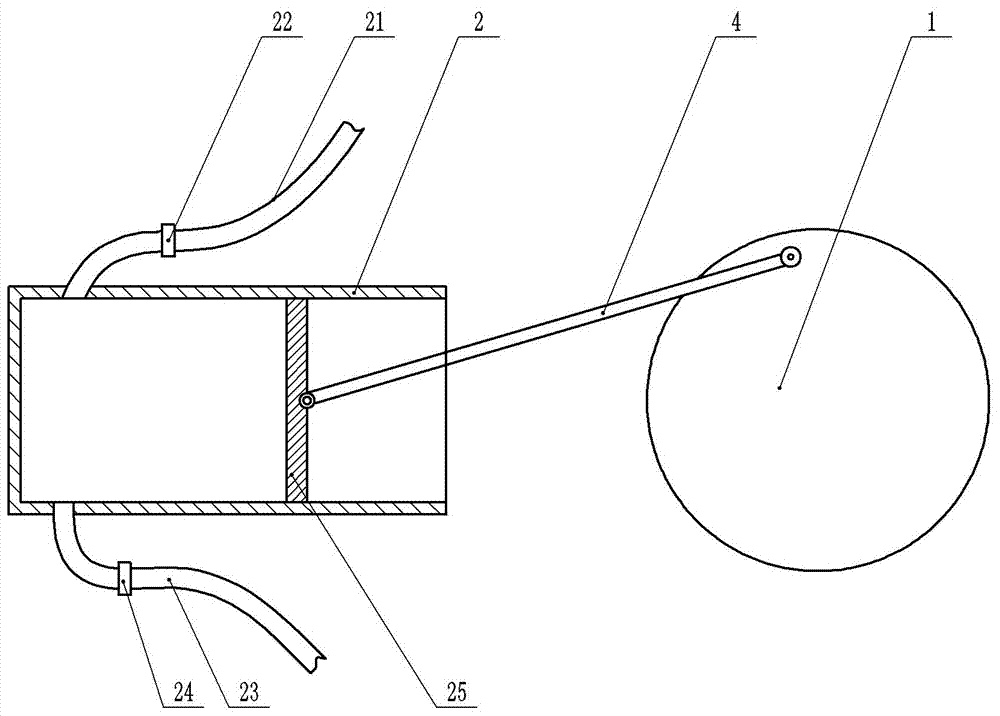

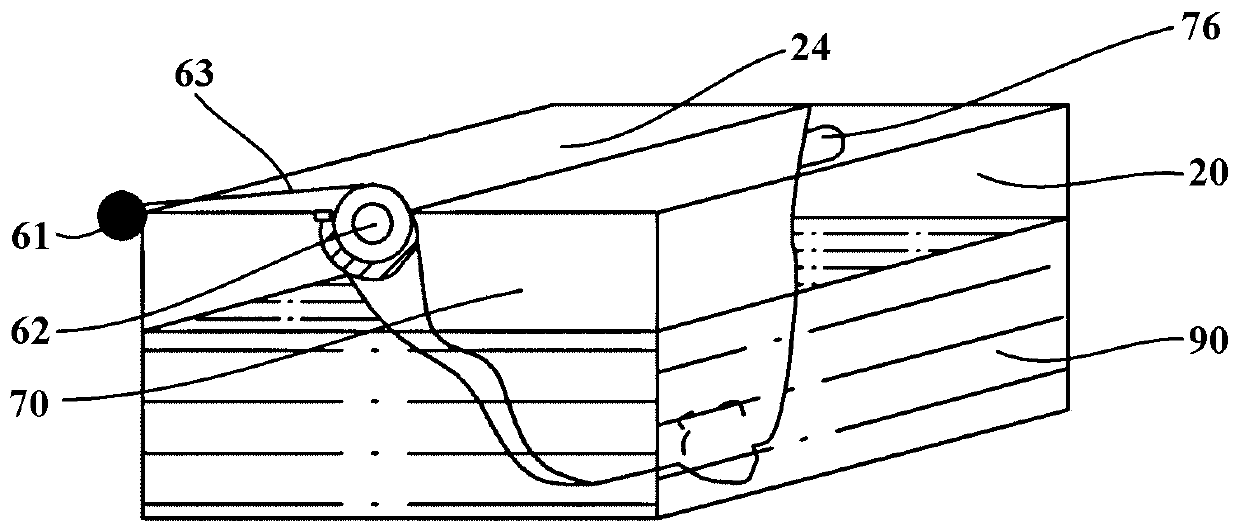

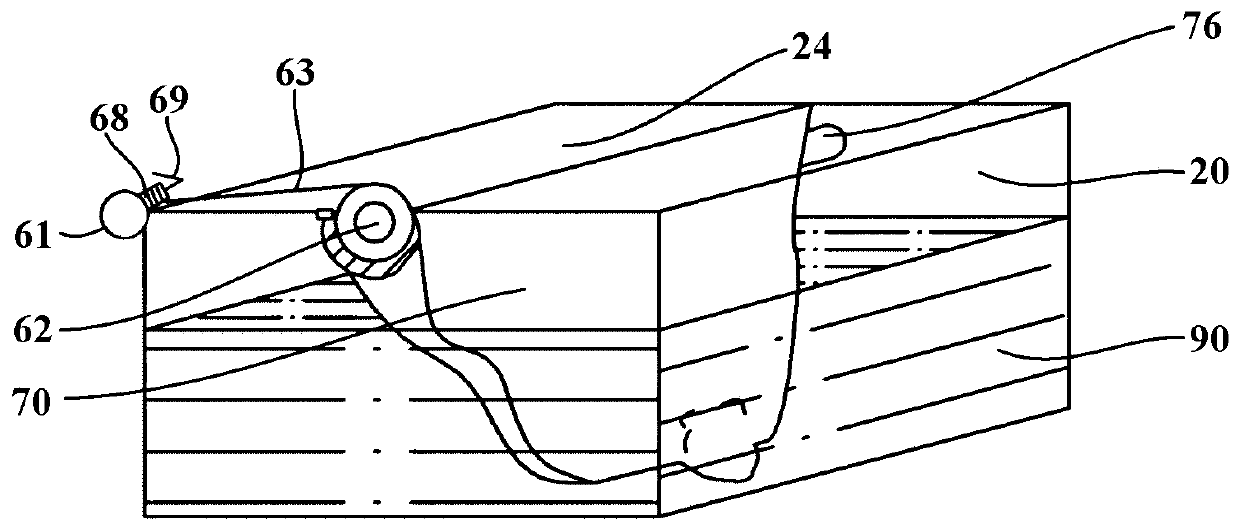

Refrigerator and quick freezing method used for refrigerator

ActiveCN106152666AAffect heat transferIncrease contact areaLighting and heating apparatusDomestic refrigeratorsQuick FreezeCollapse mode

The invention provides a refrigerator and a quick freezing method used for the refrigerator. The refrigerator comprises an isolation bag and an air extracting pump, wherein the isolation bag is arranged in a storage room and used for storing a to-be-cooled object, and the air extracting pump is configured to conduct air extracting on the isolation bag in a controlled mode so that the wall of the isolation bag can be attached to the outer surface of the object stored in the isolation bag in a collapsed mode. The storage room is configured to contain quick freezing liquid injected into the storage room in a controlled mode so that the object stored in the isolation bag is at least partially immersed in the quick freezing liquid. The invention further provides the quick freezing method used for the refrigerator. When the object is subjected to quick freezing through the quick freezing method, on the one hand, the object can be protected from being polluted or air-dried, on the other hand, the situation that quick freezing liquid heat transfer is affected by air is avoided, the large contact area of the object and the quick freezing liquid is ensured, and thus quick freezing is conducted on the object at a high freezing speed.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD

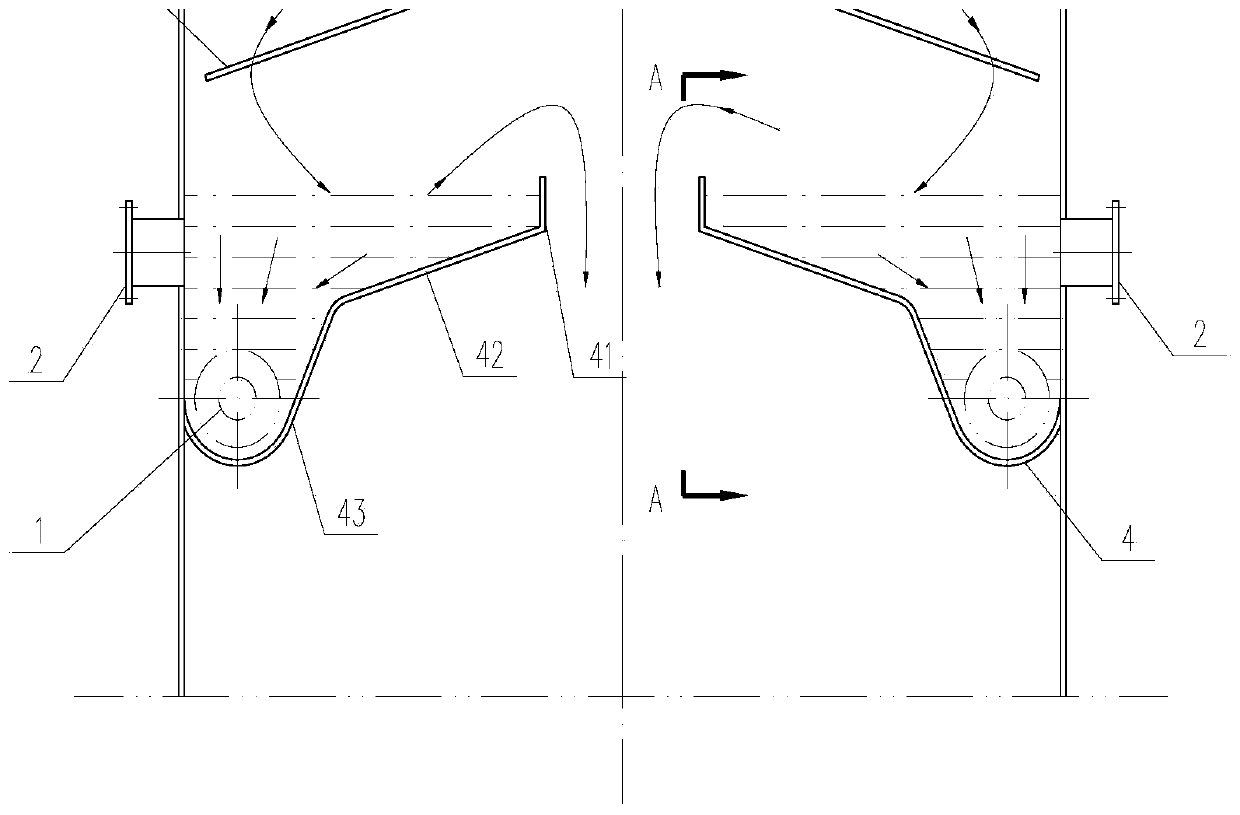

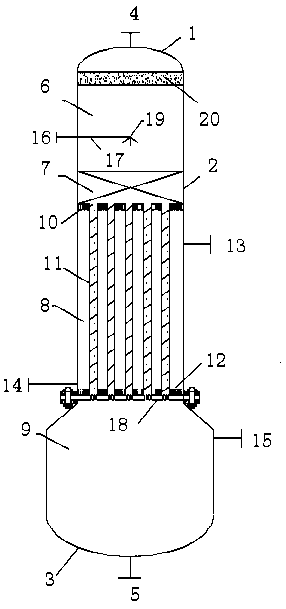

Slag discharge device for primary cooler

PendingCN110903862AAffect stabilityAffect heat transferPackagingGas purification by non-gaseous materials condensationSlagEngineering

The invention relates to a slag discharge device for a primary cooler. The slag discharge device comprises a spiral conveyor, an upper-section condensate outlet, a baffle plate, a liquid cut-off disc,a slag discharge outlet, a field sight glass, a steam cleaning opening, a slag discharge valve and a teletransmission sight glass, wherein the baffle plate is arranged at the upper part of the liquidcut-off disc; the spiral conveyor is arranged in the liquid cut-off disc; an outlet end is connected with the slag discharge outlet which is connected with the slag discharge valve; the steam cleaning opening is arranged on the slag discharge outlet; and the upper-section condensate outlet, the field sight glass and the teletransmission sight glass are arranged on the wall of the primary cooler.The slag discharge device provided by the invention has the following beneficial effects: generated tar residues can be discharged in time under the condition that normal operation of the primary cooler is not affected; blockage is avoided; operation stability of a coal gas system is improved; the effects of heat exchange and naphthalene washing are improved; consumption of water is reduced; and the slag discharge device has the characteristics of simple structure and convenient operation.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

A mold for in-mold rapid forming and quenching

ActiveCN109433924BRealize formingQuenching achievedShaping toolsQuenching devicesMetallic materialsEngineering

The present invention provides a die capable of achieving rapid forming and quenching therein. The die includes an upper die, a blank holder and a lower die, where the upper die is composed of an internal solid die core and a thin-walled skin. Grooves in communication with each other are disposed between the internal solid die core and the thin-walled skin. In a forming stage, the grooves are not filled or filled with a heat insulating material such as a gas; and in a quenching stage, a low-temperature medium is introduced into the grooves. The die can be used to achieve rapid forming and quenching of metal materials of different types and thicknesses.

Owner:DALIAN UNIV OF TECH +1

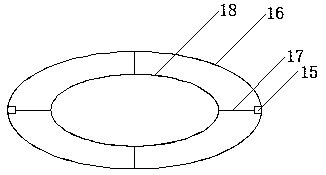

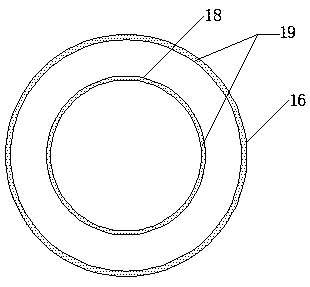

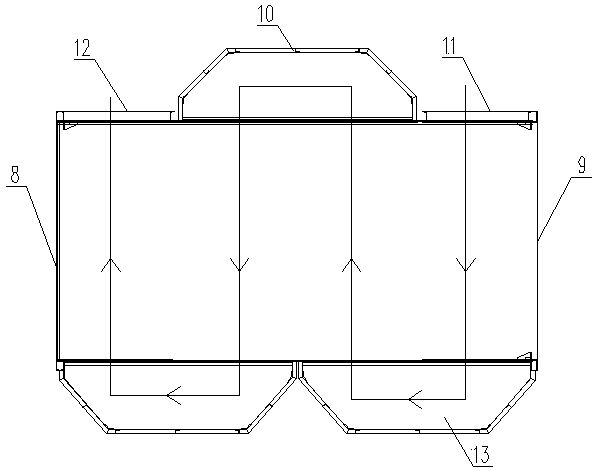

Outdoor side heat exchange structure of air conditioner all-in-one machine

PendingCN113899023AImprove heat transfer effectImprove heat transfer efficiencyLighting and heating apparatusAir conditioning systemsAir volumeAir velocity

The invention relates to an outdoor side heat exchange structure of an air conditioner all-in-one machine. The outdoor side heat exchange structure of the air conditioner all-in-one machine comprises a shell, a condenser and a fan, wherein the condenser and the fan are arranged in the shell; and the shell is provided with an air inlet and an air outlet. The outdoor side heat exchange structure of the air conditioner all-in-one machine is characterized in that the fan is positioned between the condenser and the air outlet; the condenser surrounds the fan; the fan rotates to generate negative pressure to suck air outside the shell into the shell and drive the air to flow through the condenser and then to be discharged out of the shell; the air enters the shell through the air inlet; and after the air exchanges heat with the condenser, the air is discharged out of the shell through the air outlet. According to the outdoor side heat exchange structure of the air conditioner all-in-one machine provided by the invention, when the fan sucks air, the flowing state of air entering the shell is mainly a laminar flow state, the air flows through all the positions of the condenser from multiple directions and then is exhausted from the air outlet, the air volumes and the air speeds of all the positions of the condenser are the same, and air supply is uniform, so that the heat exchange effect of the condenser is good, and the heat exchange efficiency of the condenser is high.

Owner:广西格美乐电器有限责任公司

A metal mold casting rapid response temperature measuring thermocouple

ActiveCN108387320BIncrease contact areaAvoid pollutionThermometer detailsThermometers using electric/magnetic elementsThermocouple WireThermocouple device

The invention discloses a fast-response temperature-measuring thermocouple for metal mold casting, which comprises two thermocouple wires, which are located in a protective sleeve and connected at the hot end by a metal joint. It is a hollow structure, the contact part between the metal joint and the mold temperature measuring hole is a smooth plane, and the corresponding contact surface between the mold temperature measuring hole and the metal joint is also processed into a smooth plane; behind the metal joint, the inner wall of the temperature measuring hole and the protective cover A high temperature sealant is provided between the tubes. The invention enables the heat of the mold to be rapidly transferred to the thermocouple after the mold is heated up, so as to realize the rapid response of the thermocouple to the temperature. Protects the smooth contact surfaces of thermocouple metal junctions from the environment. The metal junction is insulated from the thermocouple parts except the thermocouple wire, avoiding interference.

Owner:BEIHANG UNIV

Vacuum collector tube and manufacturing method thereof

InactiveCN101650091BNo peelingStrong adhesionSolar heating energySolar heat devicesAbsorption capacityHeat conducting

The invention provides a vacuum collector tube and a manufacturing method thereof, and the method comprises the following steps: after the manufacturing of a glass inner tube is completed, when preparing a film on the outer surface of the glass inner tube, firstly selecting the aluminium foil or the copper foil as a metal substrate; utilizing the sputtering process to form an aluminium nitrogen compound absorbing layer or utilizing the electroplating process to form a chromium plating absorbing layer on one side of the metal substrate; utilizing the polishing process to polish the surface of the metal substrate to form a reflecting layer on the other side of the metal substrate; clipping the film, and then coating the prepared film on the outer surface of the glass inner tube and utilizing the heat-conducting transparent organic adhesive to adhere the prepared film on the outer surface of the glass inner tube seamlessly; carrying out tight closeness and butt joint on the edge; and finally forming the interval space between the glass inner tube and the glass outer tube into vacuum and sealing the connector. The heat absorption capacity of the vacuum collector tube is higher, and can reach 96% to 98%; the film is not easy to fall off; the service life is long; the color consistency is good; and the operation is simple and the manufacturing cost is low by adopting the method.

Owner:SHANDONG SANGLE SOLAR ENERGY

A process and system for treating wastewater

ActiveCN106629936BAchieve recyclingReduce the effective heat transfer areaWater contaminantsWater/sewage treatment by heatingWater useGas compressor

The invention provides a technology and a system used for processing waste water. The system comprise a waste water preheater, a first effect evaporator, a second effect evaporator, a vapour compressor, a condensed water collector, and a noncondensable gas compressor. The invention also provides the technology used for processing waste water using the system. The waste water processing technology and the system are safe and reliable; equipment is simple; operation cost is low; energy saving effect is obvious; and 50 to 95% of water resource can be recycled.

Owner:CHINA PETROLEUM & CHEM CORP +1

Refrigerator and quick-freezing method for refrigerator

ActiveCN106152667BDoes not take up storage spaceProtection from pollutionLighting and heating apparatusDomestic refrigeratorsEngineeringRefrigerated temperature

Owner:QINGDAO HAIER SMART TECH R & D CO LTD

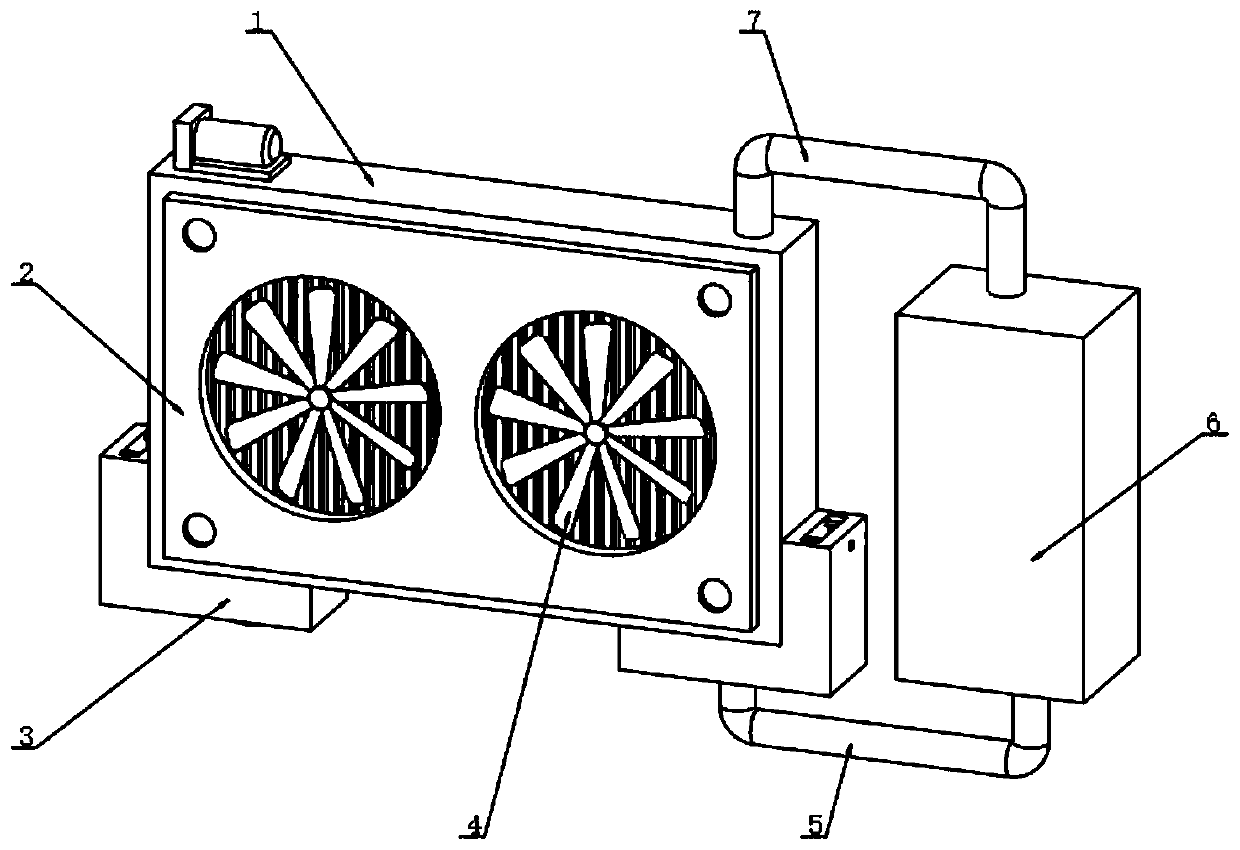

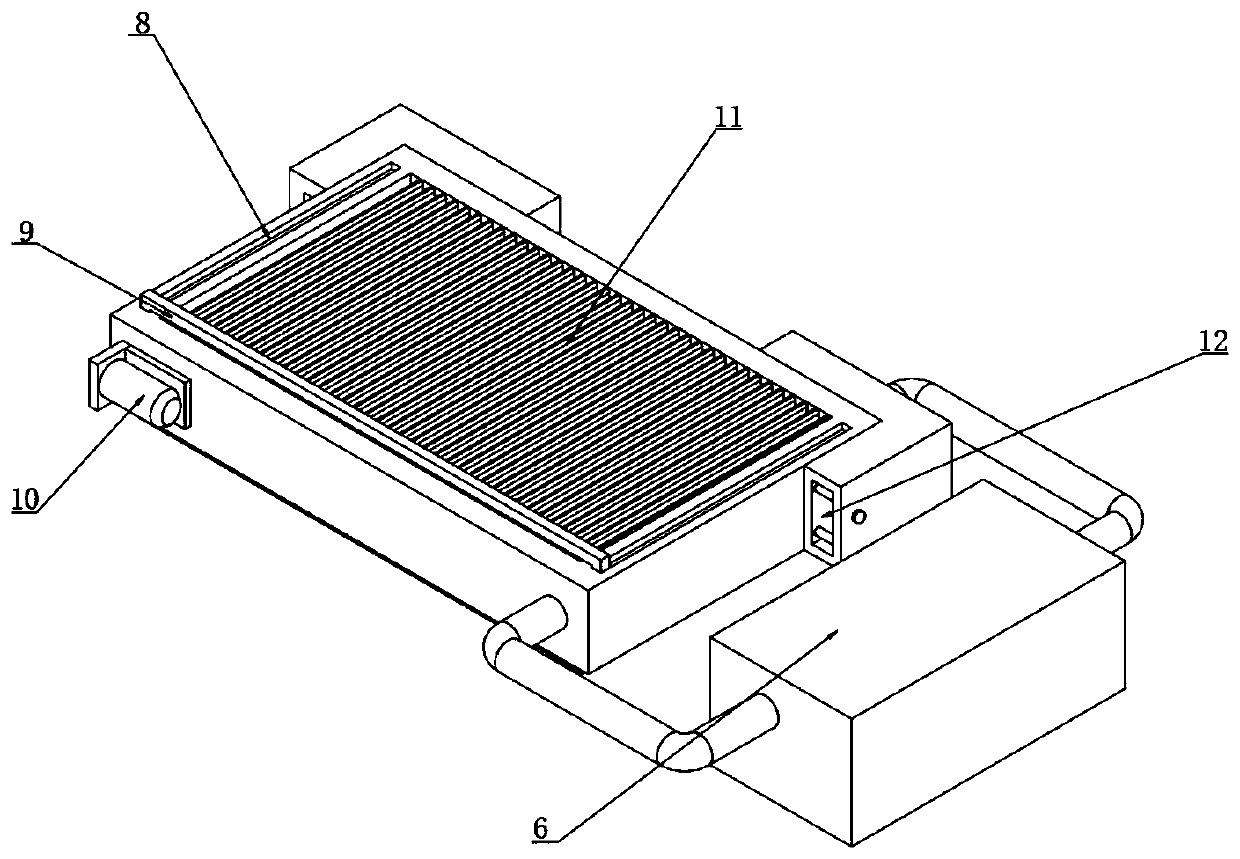

A car radiator with shock absorbing structure

ActiveCN109296442BScientific and reasonable structureEasy to useLiquid coolingMachines/enginesCleansing AgentsHeat spreader

The invention discloses an automobile radiator with a shock absorbing structure. A cooling fin installing base is included; one side of the cooling fin installing base is fixedly connected with a faninstalling plate; cooling fans are symmetrically embedded in and installed in one side of the fan installing plate; and the inner wall of the top of the cooling fin installing base is uniformly connected with cooling fins. The automobile radiator with the shock absorbing structure is scientific and reasonable in structure, and safe and convenient to use; after cooling an automobile, due to runningof a water sucking pump, a cooling fin cleaning agent in a second storing bin can be conveyed into the cooling fins, and therefore the interiors of the cooling fins installed in the cooling bin installing base can be cleaned, and it can be avoided that scale is accumulated in the cooling fins, and consequently the cooling fins are blocked; and due to shock absorbing installing bases symmetricallyinstalled at the bottom of the cooling fin installing base, shock absorbing protection can be performed on the automobile radiator, and it is avoided that waggle generated by the automobile is transmitted to the automobile radiator, and consequently the interior of the automobile radiator is vibrated.

Owner:郴州市中马汽车空调有限公司

Refrigerator and quick-freezing method for refrigerator

ActiveCN106152666BAffect heat transferIncrease contact areaLighting and heating apparatusDomestic refrigeratorsQuick FreezeCollapse mode

The invention provides a refrigerator and a quick freezing method used for the refrigerator. The refrigerator comprises an isolation bag and an air extracting pump, wherein the isolation bag is arranged in a storage room and used for storing a to-be-cooled object, and the air extracting pump is configured to conduct air extracting on the isolation bag in a controlled mode so that the wall of the isolation bag can be attached to the outer surface of the object stored in the isolation bag in a collapsed mode. The storage room is configured to contain quick freezing liquid injected into the storage room in a controlled mode so that the object stored in the isolation bag is at least partially immersed in the quick freezing liquid. The invention further provides the quick freezing method used for the refrigerator. When the object is subjected to quick freezing through the quick freezing method, on the one hand, the object can be protected from being polluted or air-dried, on the other hand, the situation that quick freezing liquid heat transfer is affected by air is avoided, the large contact area of the object and the quick freezing liquid is ensured, and thus quick freezing is conducted on the object at a high freezing speed.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD

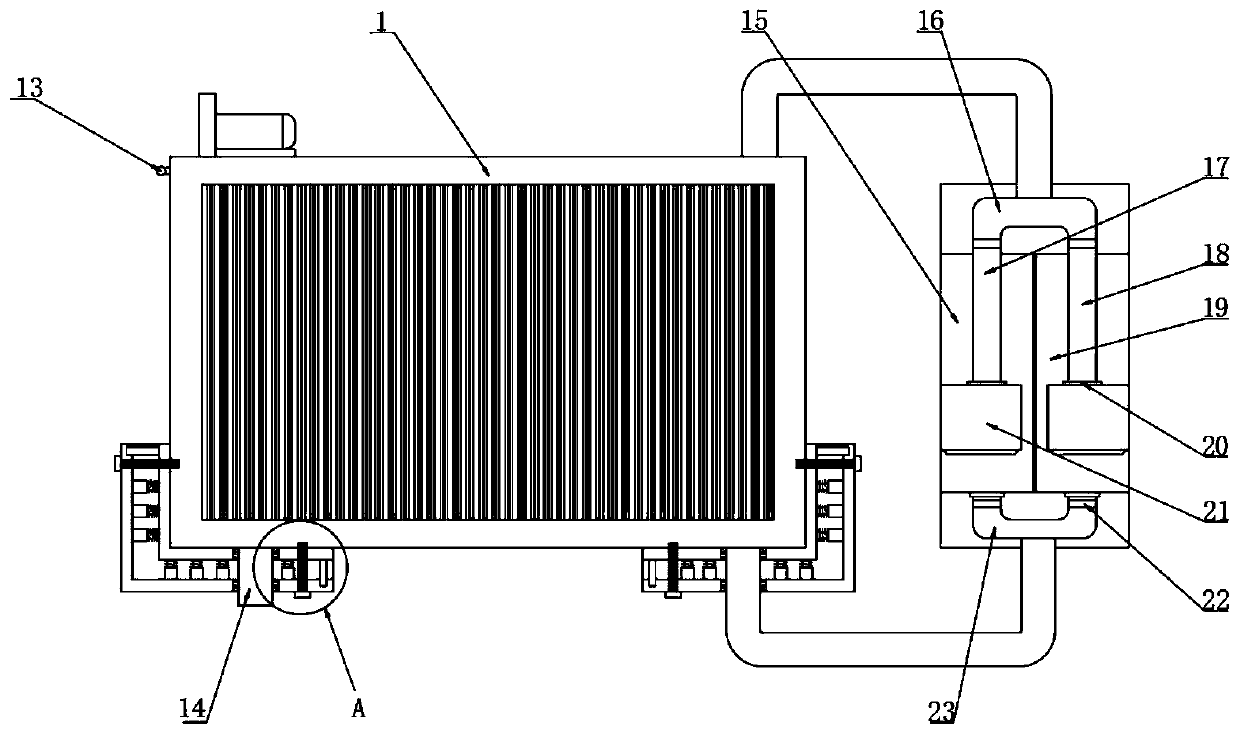

An engine cooling system based on phase change fluid and water

ActiveCN103850775BReduce circulation flowReduce cooling costsLiquid coolingMachines/enginesWater basedPhase change

The invention discloses an engine cooling system based on phase change fluid / water. The engine cooling system comprises an engine and a cooling-water cooling system, wherein the cooling-water cooling system comprises a first pump, a first adjustment valve and a heat exchanger; the first pump is communicated with the first adjustment valve and the heat exchanger respectively; a cooling water inlet is formed in an engine body of the engine; a cooling cavity is formed between the engine body of the engine and a cylinder sleeve; the cooling water inlet is communicated with the cooling cavity; a cooling water outlet is formed in a cylinder cover of the engine; the first adjustment valve is communicated with the cooling water inlet; the cooling water outlet is communicated with the heat exchanger; the engine cooling system based on the phase change fluid / water is characterized by being provided with a phase change fluid cooling system; the phase change fluid cooling system comprises a second pump and a second adjustment valve; a spiral cooling pipe is fixedly arranged in the cooling cavity; the second pump is communicated with the second adjustment valve and the heat exchanger respectively; the second adjustment valve is communicated with an inlet of the cooling pipe; an outlet of the cooling pipe is communicated with the heat exchanger. The engine cooling system has the advantages that the circulating flow of a cooling medium is greatly reduced, pump consumption is reduced, and an energy-saving effect is achieved; meanwhile, the phase change fluid absorbs heat in the engine in a phase change latent heat manner; the temperature of the cylinder body of the engine is more uniform as the temperature region of a phase change material is narrower.

Owner:NINGBO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com