A metal mold casting rapid response temperature measuring thermocouple

A temperature measuring thermocouple and metal mold casting technology, applied in the direction of measuring heat, thermometer, measuring device, etc., can solve the problems of unable to meet the requirements of temperature measurement and temperature control, slow response of armored thermocouple, etc., to increase the contact area , fast response, ensure the effect of contact accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

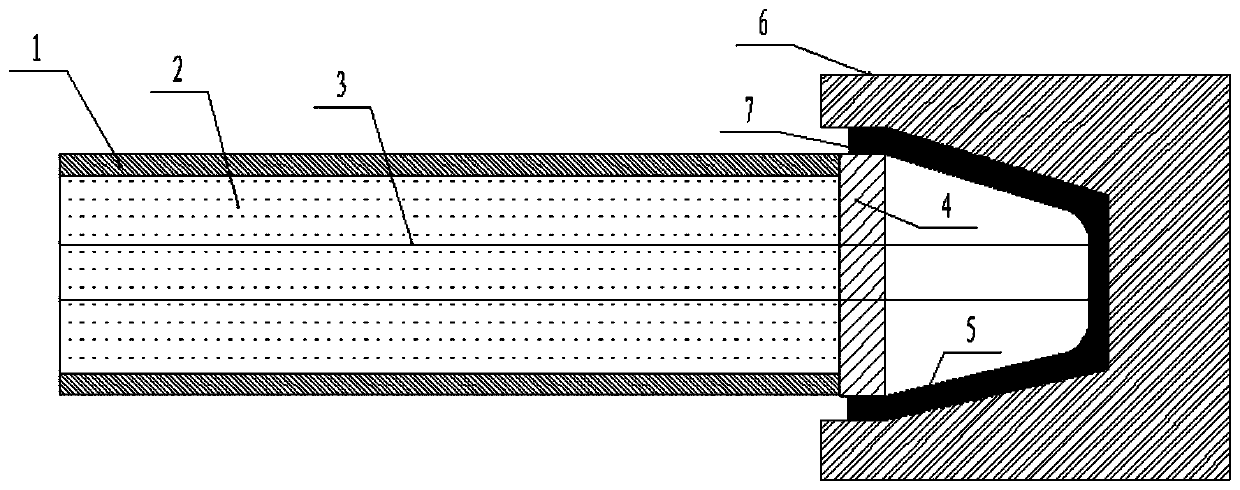

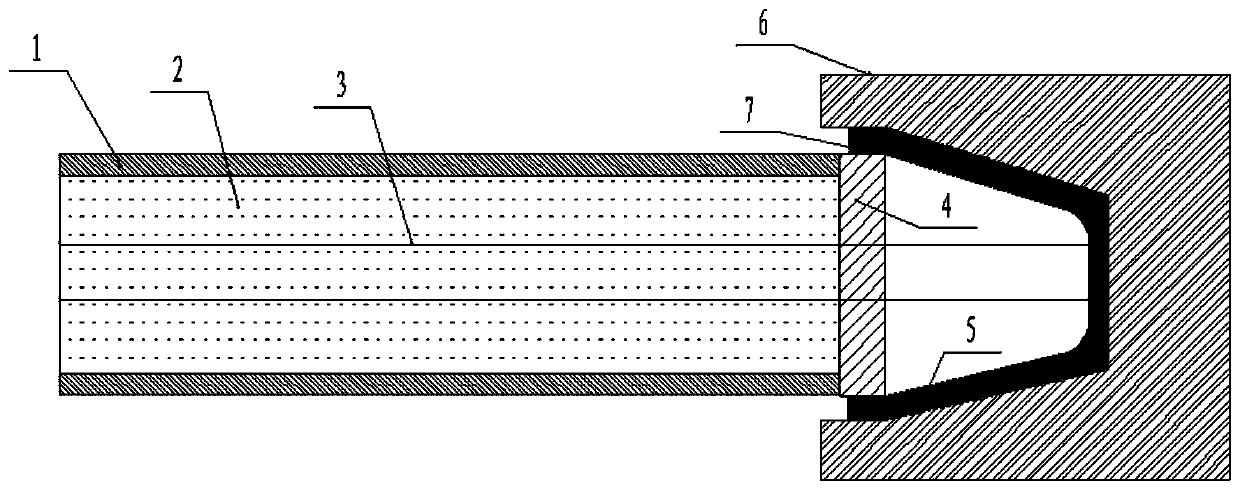

[0018] The fast-response thermocouple disclosed in the present invention includes two thermocouple wires 3, the materials used for the two thermocouple wires are NiCr alloy and NiSi alloy respectively, the thermocouple wires are located in the protective sleeve 1, and the sleeve is filled with insulating material 2, The two thermocouple wires are connected by a metal joint 5 at the hot end, and there is an insulating pad 4 between the metal joint and the casing.

[0019] When measuring temperature, such as measuring the temperature of an aluminum alloy low-pressure casting mold, the metal joint is directly inserted into the temperature measuring hole of the mold 6 to contact the mold wall. During temperature measurement, the heat is directly transmitted to the metal joint through the mold wall. At this time, the metal joint The contact point wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com