Gas and powder fuel dual-purpose boiler provided with front O type horizontal hearth and rear vertical hearth

A furnace and vertical technology, which is applied in the field of gas and powder fuel dual-purpose boilers, can solve the problems of insufficient technology, high content of fly ash combustibles, and easy coking of the furnace, so as to save consumables, improve fuel utilization, and use flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

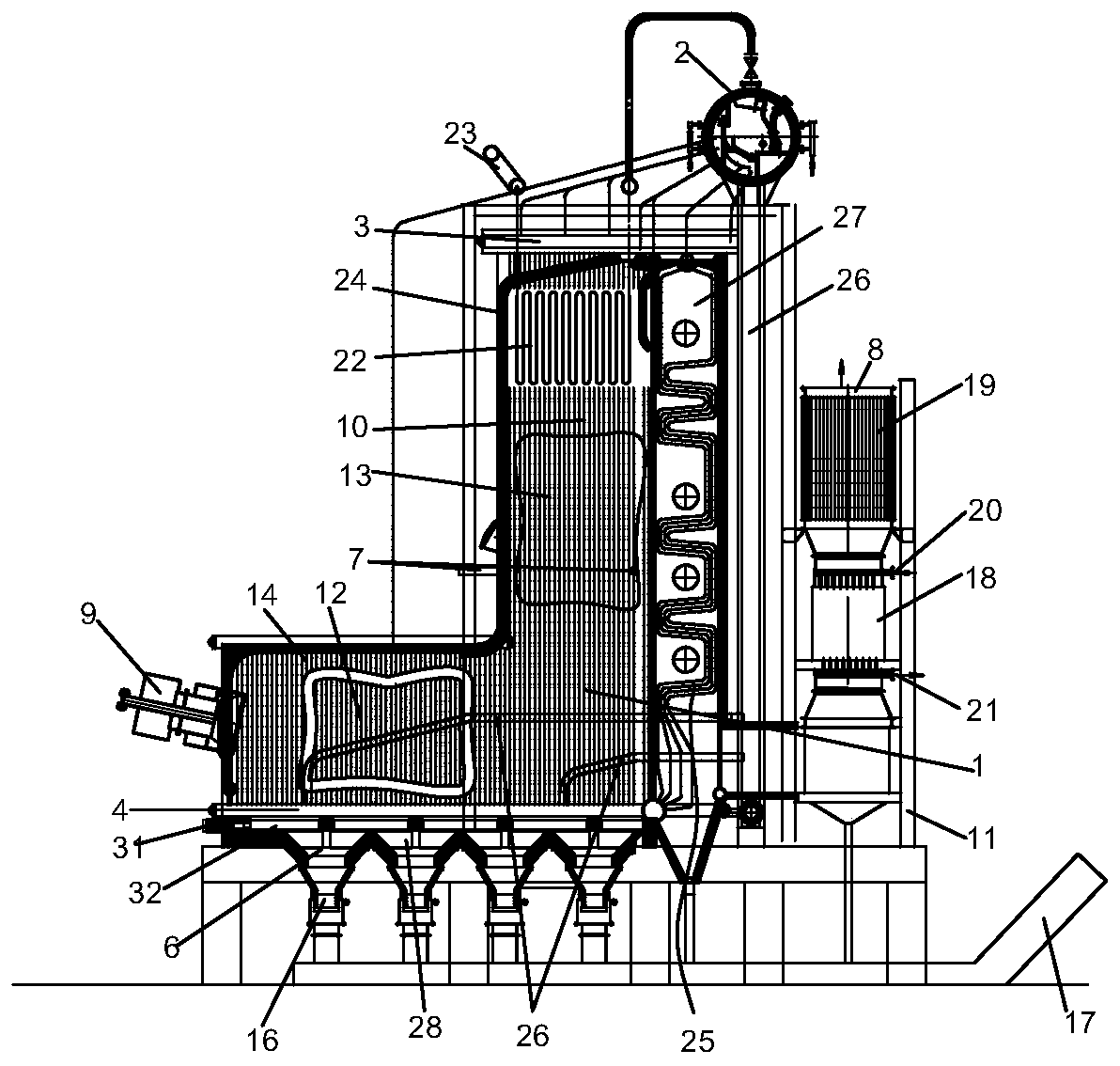

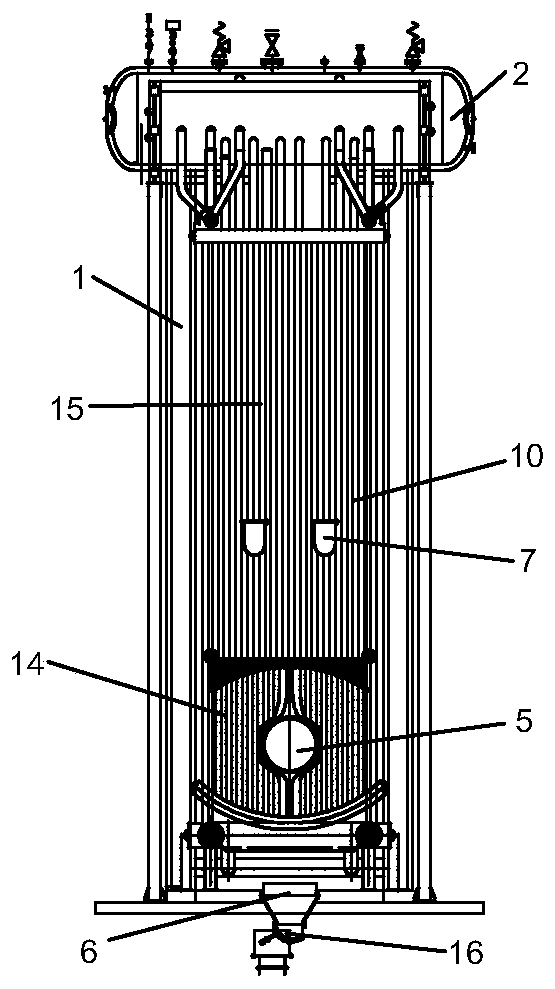

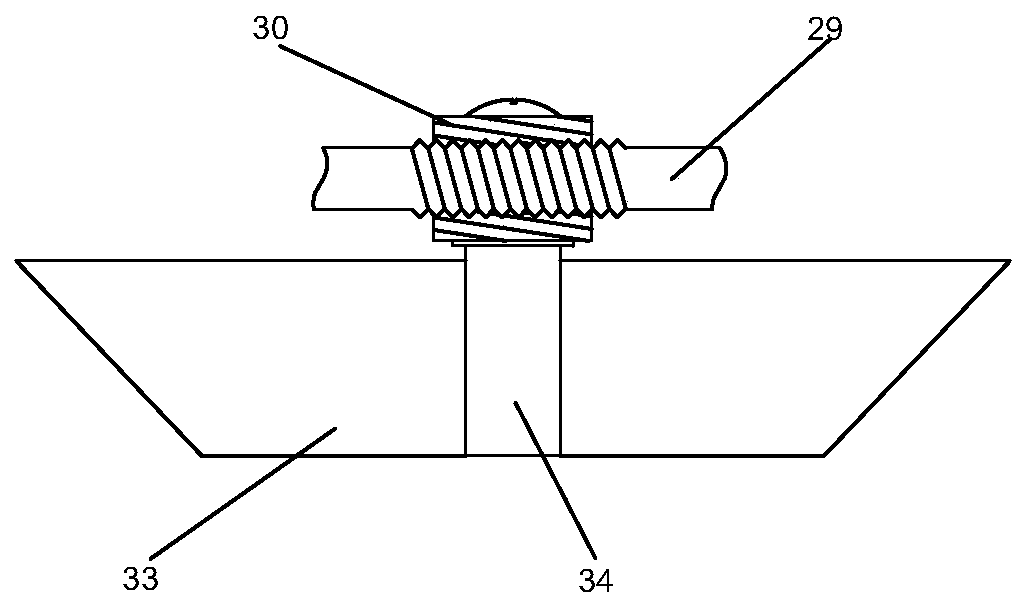

[0026] refer to Figure 1 to Figure 4What the embodiment of the present invention discloses is a gas and powder fuel dual-purpose boiler with an O-type horizontal furnace in the front section and a vertical furnace in the back section, including a boiler body 1, and the boiler body 1 includes a drum 2, a steam-water system, and a low-nitrogen powder two-purpose boiler. With a burner 9 (combustible coal powder, biomass powder and natural gas), a furnace 10 formed by a convection heating surface and a radiation heating surface, and a flue, the boiler body 1 is provided with a feed port 5, four One ash drop port 6, four burn-out tuyere ports 7, flue gas outlet 8, the low-nitrogen powder dual-purpose burner 9 (combustible coal powder, biomass powder and natural gas) is fixedly installed in the feed port 5 , the burner 9 is arranged obliquely with the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com