Slag discharge device for primary cooler

A technology of primary cooler and slag outlet, which is applied in the coking field, can solve the problems of large equipment resistance, accelerated equipment scaling and corrosion, and increased water consumption, and achieves the effects of simple structure, timely operation, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

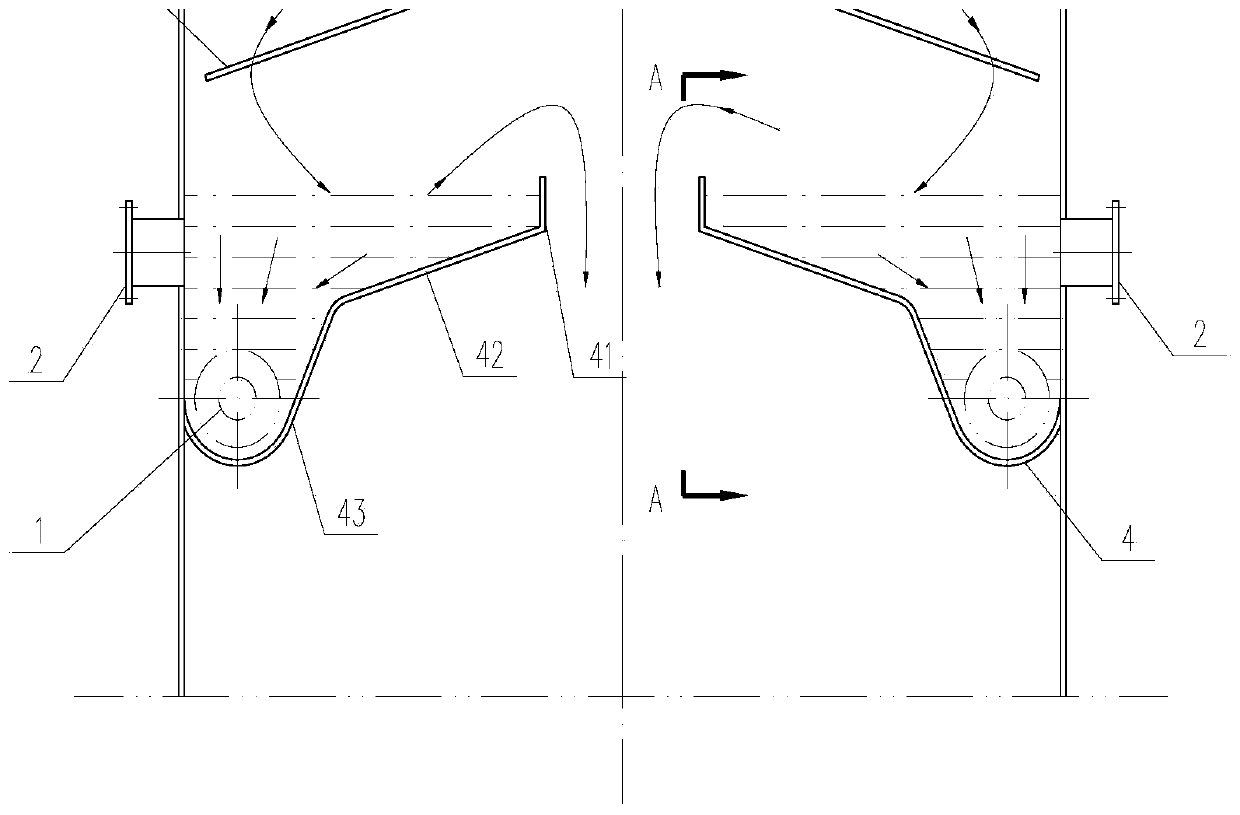

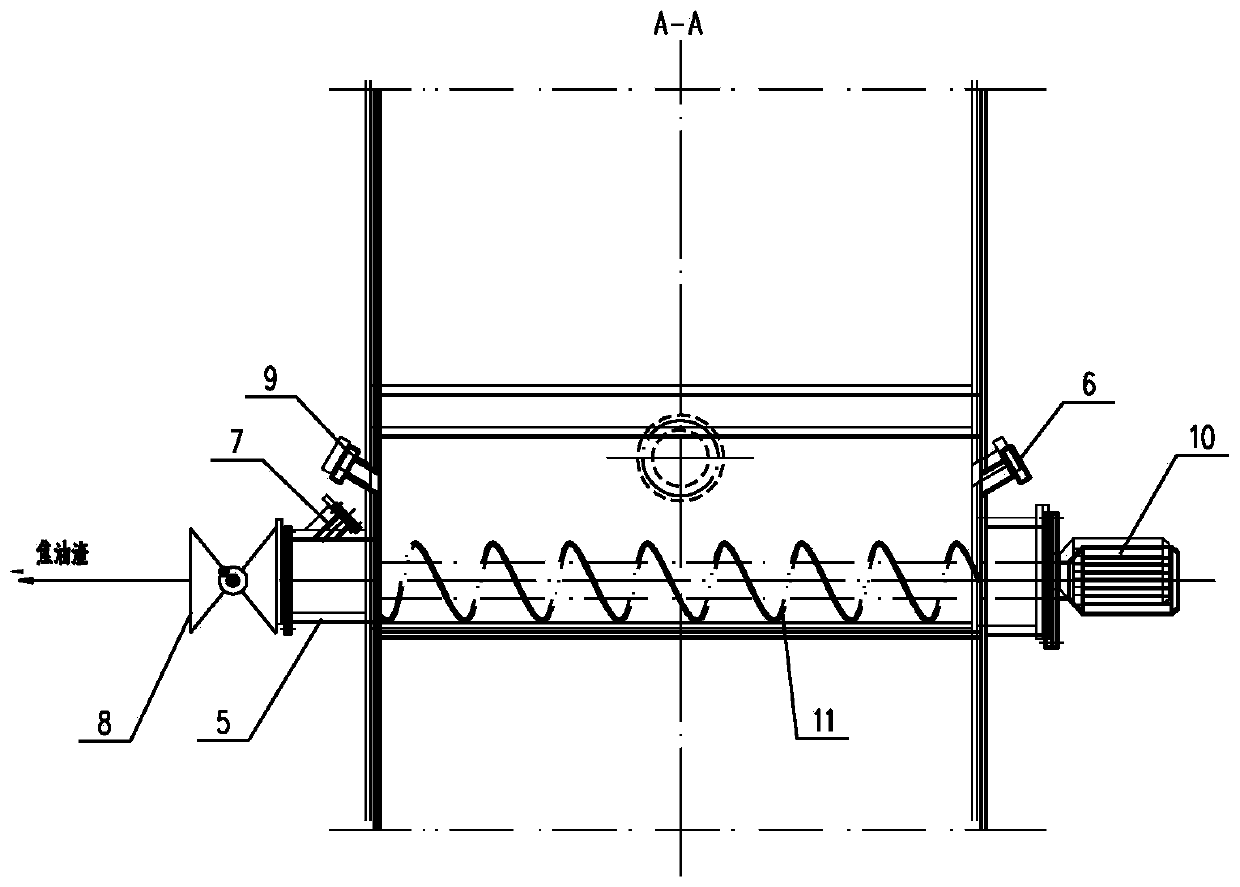

[0021] See Figure 1-Figure 4 As shown, the present invention relates to a slag discharge device for a primary cooler, including a screw conveyor 1, an upper condensate outlet 2, a baffle 3, a liquid breaker 4, a slag discharge port 5, a field sight glass 6, and a steam cleaning port 7. The slag discharge valve 8 and the remote transmission mirror 9. The liquid breaker 4 is composed of a liquid blocking part 41, an inclined part 42 and a groove part 43, wherein the liquid blocking part 41 is vertically arranged, and the inclined part 42 is connected with the liquid blocking part. 41 forms an obtuse angle, the concave part 43 and the inclined part 42 are smoothly transitioned, the bottom of the groove part 43 is a semicircular structure and welded together with the wall of the primary cooler; the liquid breaker 4 is two, along the center line of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com