Punching machine suitable for cloth, hide and leather

A punching machine and leather material technology, applied in the field of punching machines, can solve problems such as low punching accuracy, low efficiency, and insufficient punching accuracy, so as to avoid incomplete cutting, improve punching accuracy, and improve punching effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

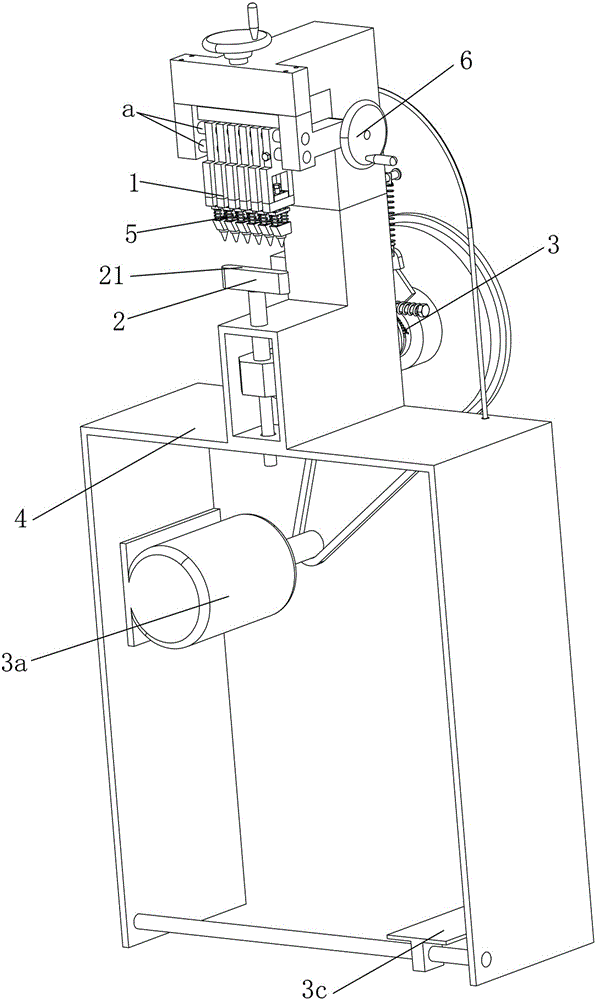

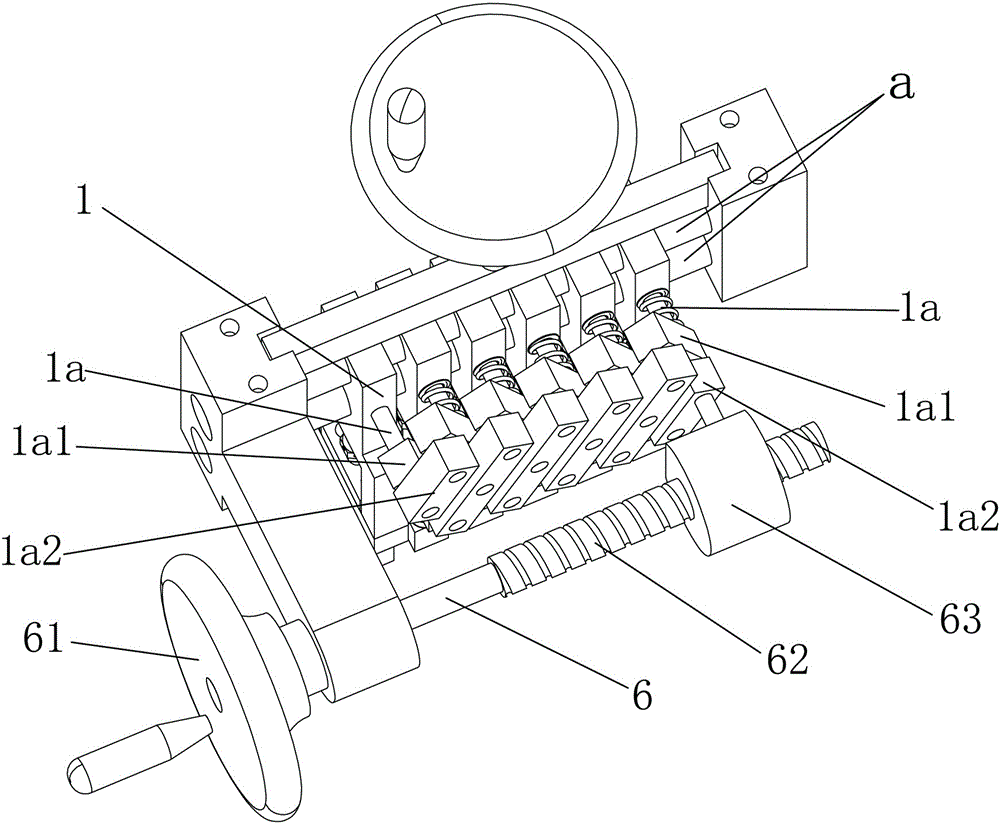

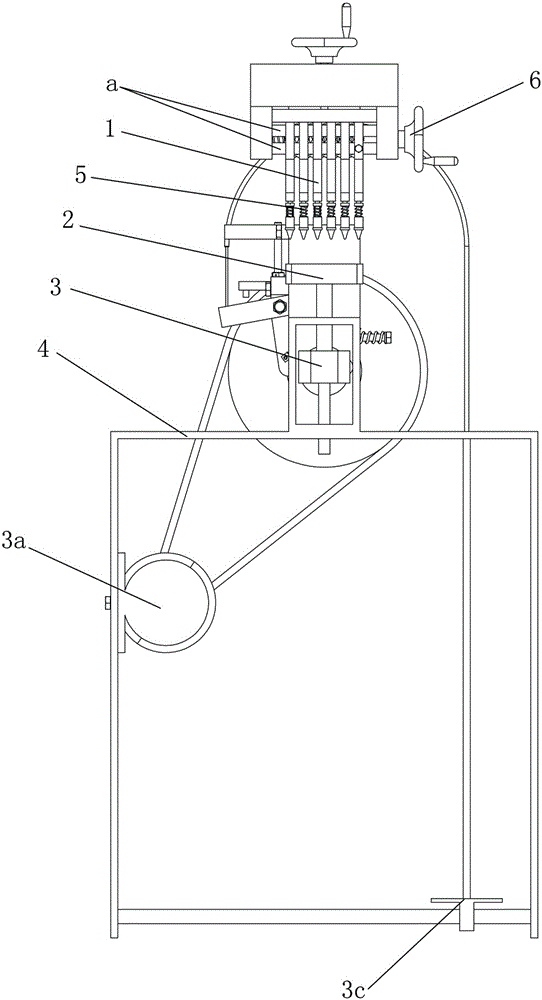

[0021] Such as figure 1 , figure 2 , image 3 The shown embodiment of the punching machine applicable to cloth, leather and leather of the present invention includes a frame 4 in which a punching knife 1, a punching plate 2 and a driving mechanism 3 are arranged, and the punching plate 2 can move up and down It is installed in the frame 4 and impacts on the punching knife 1. The driving mechanism 3 drives the punching plate 2 to move up and down. The end of the punching knife 1 is a plane equal to the pre-processed punching area, and the punching plate 2 has a flat surface. 21. The punching plate surface 21 is parallel to the plane at the end of the punching knife 1. The area of the punching plate surface 21 is larger than the plane area formed at the end of the punching knife 1. The frame 4 has an elastic member 5 acting on the punching knife 1. The punching knife 1 has only The stationary station under the action of the elastic component 5 and the up and down micro-move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com