Quenching and tempering system for oil-containing sludge

A sludge conditioning and conditioning technology, applied in sludge treatment, water/sludge/sewage treatment, mixers, etc., can solve the problems of complex causes and difficult treatment, and achieve sufficient conditioning and good conditioning effect. , effects that are easy to re-refine and exploit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

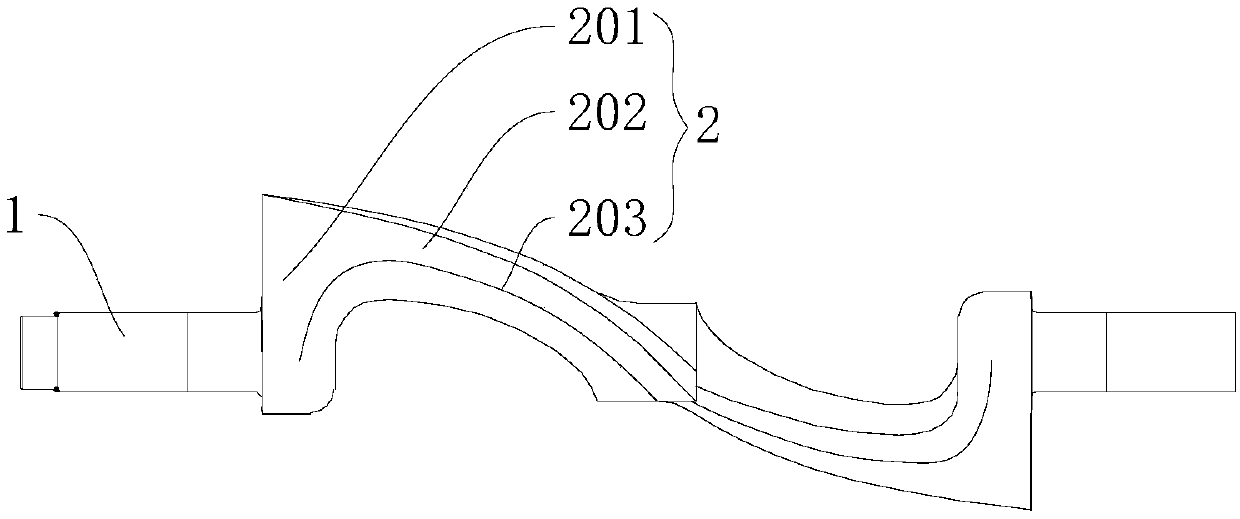

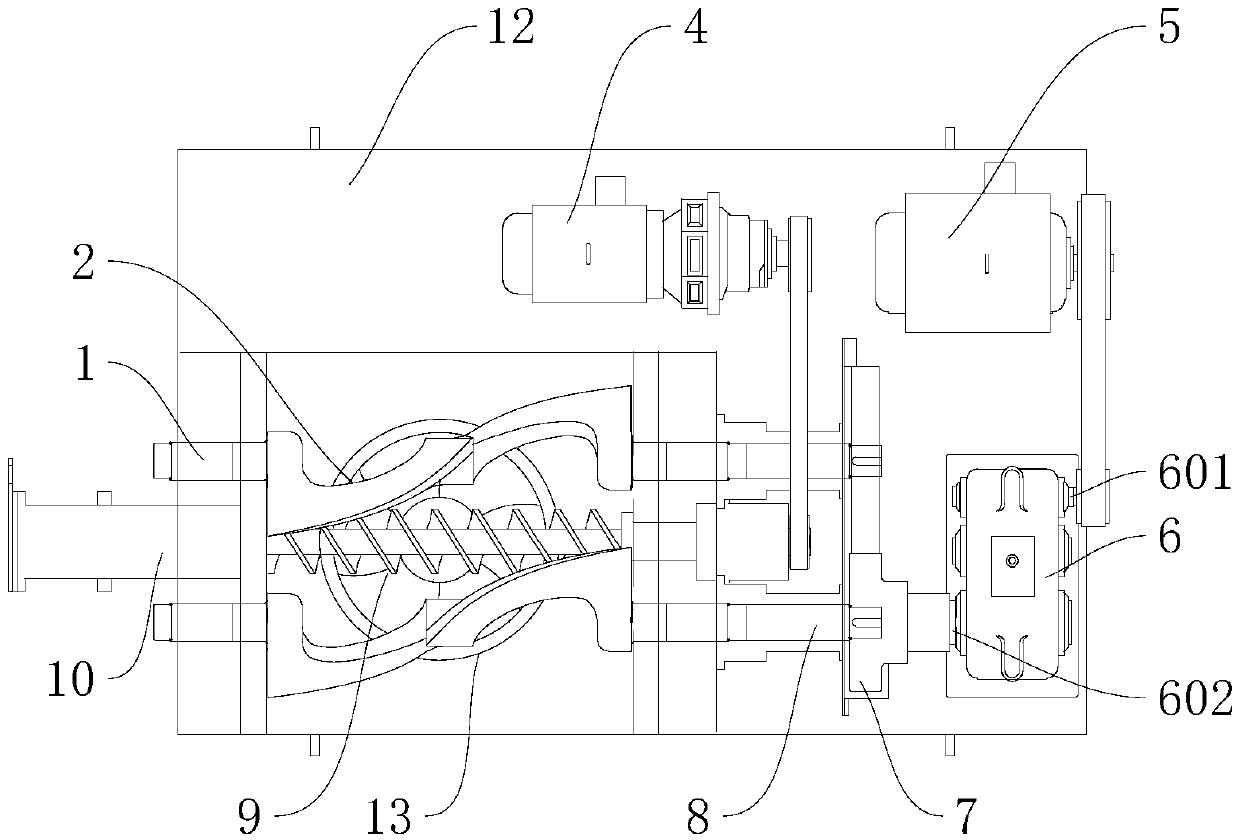

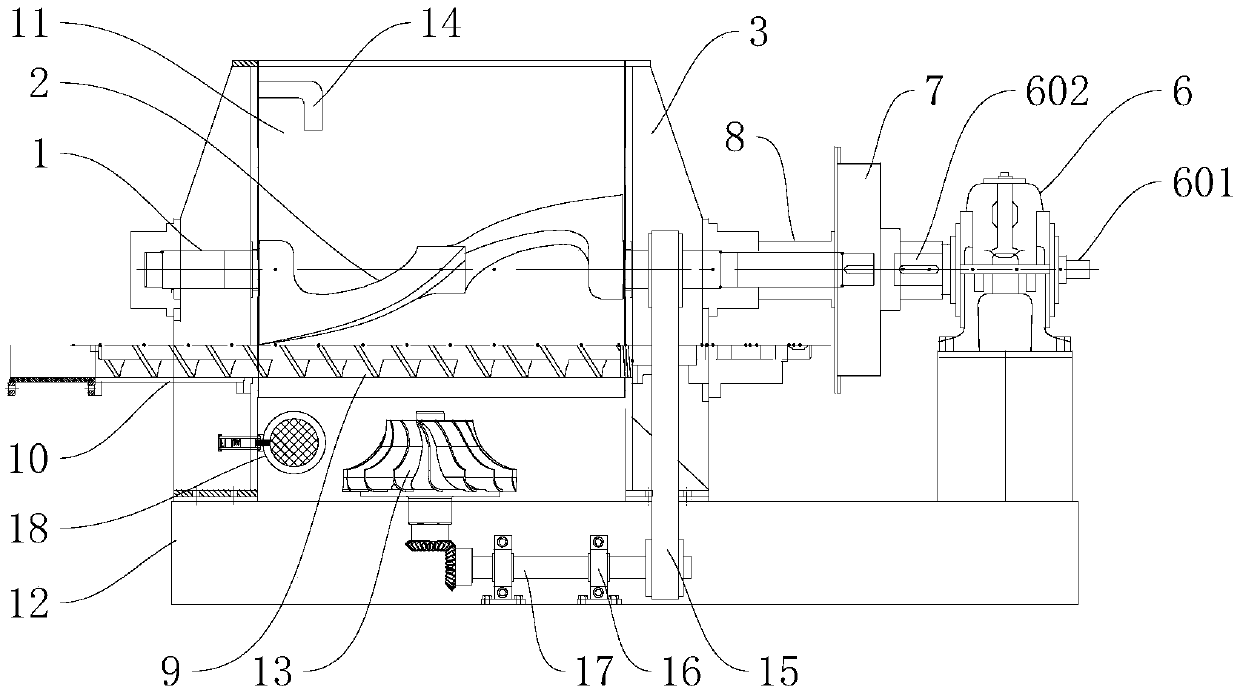

[0038] Such as figure 1 , figure 2 , image 3 As shown, this embodiment discloses a conditioning system for oily sludge, which includes a main body 3 on which a conditioning chamber 11 and a conditioning device are arranged. Specifically, the tempering device includes two tempering blades located in the tempering bin 11 of the main body 3 and turning in opposite directions. The tempering blades include two tempering parts symmetrically arranged in the center. The quality part includes a rotating shaft part 1 and a stirring part 2 connected to each other, and the stirring parts 2 of the two conditioning parts are connected to each other and the rotating shaft part 1 is arranged coaxially.

[0039] A viscosity detection device 18 is arranged in the tempering bin, and the viscosity detection device 18 includes a housing 181 fixed on the main body 3, a detection chamber is arranged in the housing, and a detection assembly is arranged in the detection chamber ; One end of the h...

Embodiment 2

[0043] This embodiment discloses a conditioning system for oily sludge. The same as in Example 1, the conditioning system disclosed in this embodiment includes a main body 3 on which a conditioning chamber 11 and a conditioning device are arranged. Specifically, the tempering device includes two tempering blades located in the tempering bin 11 of the main body 3 and turning in opposite directions. The tempering blades include two tempering parts symmetrically arranged in the center. The quality part includes a rotating shaft part 1 and a stirring part 2 connected to each other, and the stirring parts 2 of the two conditioning parts are connected to each other and the rotating shaft part 1 is arranged coaxially.

[0044] Such as Figure 5 As shown, the viscosity detection device 18 is arranged in the tempering chamber, and the viscosity detection device 18 includes a housing 181 fixed on the main body 3, a detection chamber is arranged in the housing, and a detection chamber is...

Embodiment 3

[0050] This embodiment discloses a conditioning system for oily sludge. The same as in Example 1, the conditioning system disclosed in this embodiment includes a main body 3 on which a conditioning chamber 11 and a conditioning device are arranged. Specifically, the tempering device includes two tempering blades located in the tempering bin 11 of the main body 3 and turning in opposite directions. The tempering blades include two tempering parts symmetrically arranged in the center. The quality part includes a rotating shaft part 1 and a stirring part 2 connected to each other, and the stirring parts 2 of the two conditioning parts are connected to each other and the rotating shaft part 1 is arranged coaxially.

[0051] A viscosity detection device 18 is arranged in the tempering bin, and the viscosity detection device 18 includes a housing 181 fixed on the main body 3, a detection chamber is arranged in the housing, and a detection assembly is arranged in the detection chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com