Adjustable breathable roof and wall assembling system

An assembly system and adjustable technology, applied in the direction of roof, wall, roof, etc., can solve the problem of lack of ventilation, and achieve the effect of meeting the needs of use, the operation time is short, and the operation difficulty is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

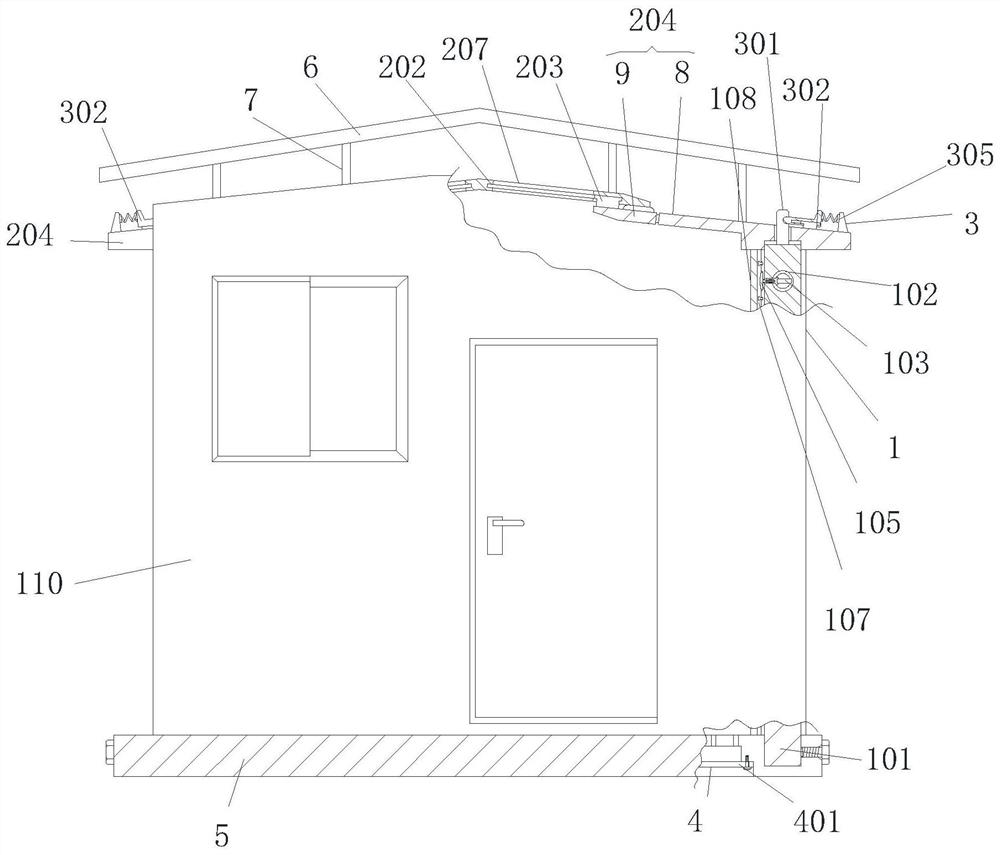

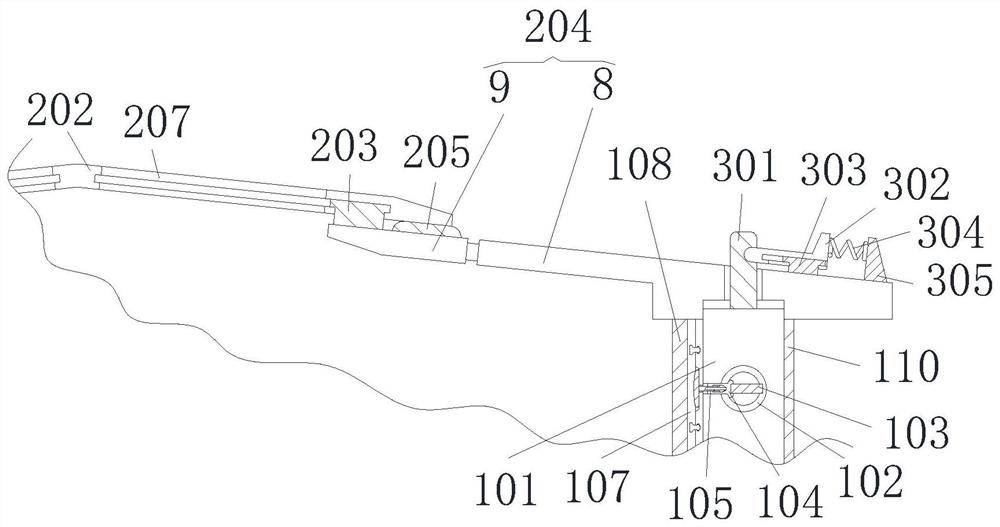

[0036] An assembly system for an adjustable breathable roof and wall, see Figure 1-3 , comprising a base plate 5, a wall 1 is provided above the base plate 5; a cover 2 is provided above the wall 1;

[0037] The cover body 2 includes a first slant plate 202, a first slider 203, a second slant plate 204, a rubber plate 205 and a rubber pad 206;

[0038] The inner surface of the bottom of the first slant plate 202 is slidably engaged with a first slider 203, and the first slant plate 202 is provided with a plurality of windows 207, the windows and the sliders are arranged at intervals, and the first slider 203 The bottom is fixedly connected with a second slant plate 204, the second slant plate 204 is a telescopic plate composed of a fixed plate 8 and an extension plate 9, the top of the extension plate of the second slant plate 204 is fixedly connected with a rubber plate 205, and the rubber plate The top of 205 is pressed against the bottom of the first slant plate 202, the ...

Embodiment 3

[0043] As an option, see figure 1 and 5 The bottom of the bottom plate 5 is provided with a floor drain device 4, the floor drain device 4 includes a steel mesh 401 and a vertical hole 402, the outer wall of the steel mesh 401 is matched with the bottom inner surface of the bottom plate 5, the steel mesh 401 prevents the top of the bottom plate 5 from accumulating water, and the steel mesh 401 The net 401 is fixed together with the bottom plate 5 by screws, vertical holes 402 are equidistant above the steel mesh 401 , the vertical holes 402 are opened on the top of the bottom plate 5 , and the vertical holes 402 run through the bottom plate 5 .

[0044] The solution in this embodiment can be selectively used in combination with the solutions in other embodiments.

Embodiment 4

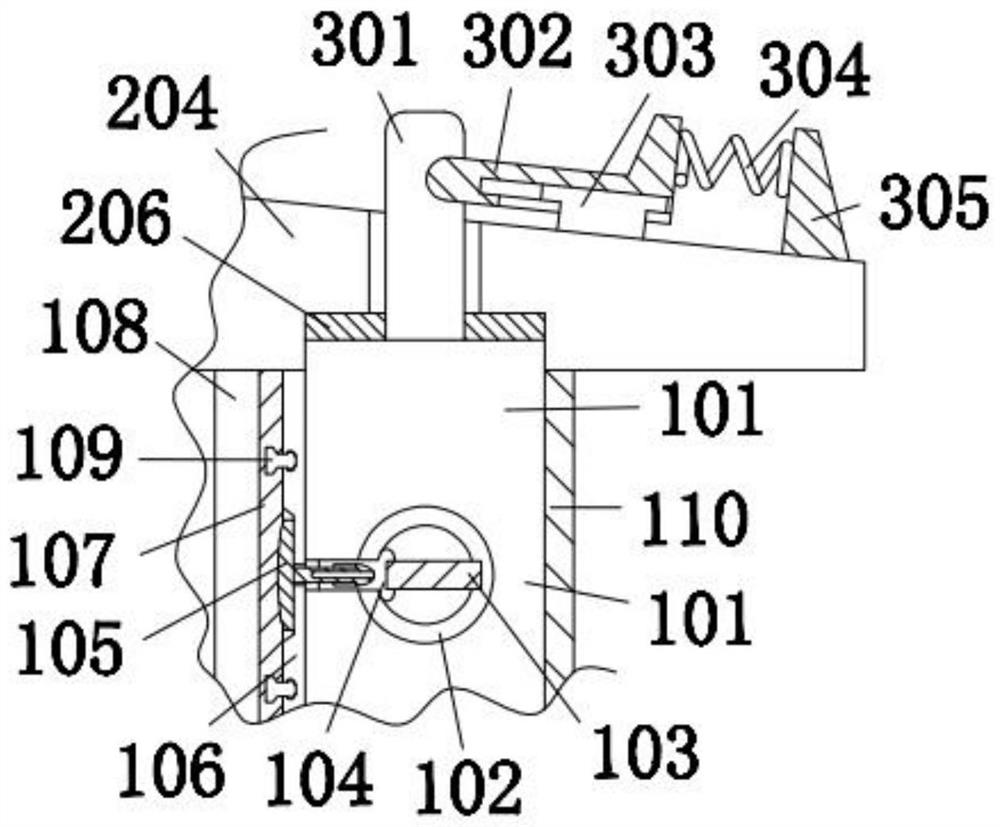

[0046] Fitting system to make it soundproof, see image 3 , including the base plate 5, the top of the base plate 5 is provided with a wall 1, four walls 1 are respectively installed on the four sides of the base plate 5, windows and door facilities are installed on the designated wall 1, and the wall 1 includes a base plate 101, a steel pipe 102 , rubber column 103, clamping rod 104, latch 105, wooden board 106, sound insulation board 107, first decorative board 108, rubber strip 109, second decorative board 110 and rubber tube 111, the inside of base plate 101 is equidistantly embedded with steel pipe 102 , the steel pipe 102 improves the strength of the base plate 101, the base plate 101 is formed by pouring reinforced concrete, the inside of the steel pipe 102 is provided with a rubber column 103, and the rubber column 103 plays a role of limiting the clamping rod 104, the right end of the rubber column 103 and the steel pipe 102 The inner walls are tight against each othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com