Decompressor of coke-oven gas fuel gas vehicle

A technology of coke oven gas and pressure reducer, which is applied in the direction of combustion engine, machine/engine, internal combustion piston engine, etc., to achieve the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

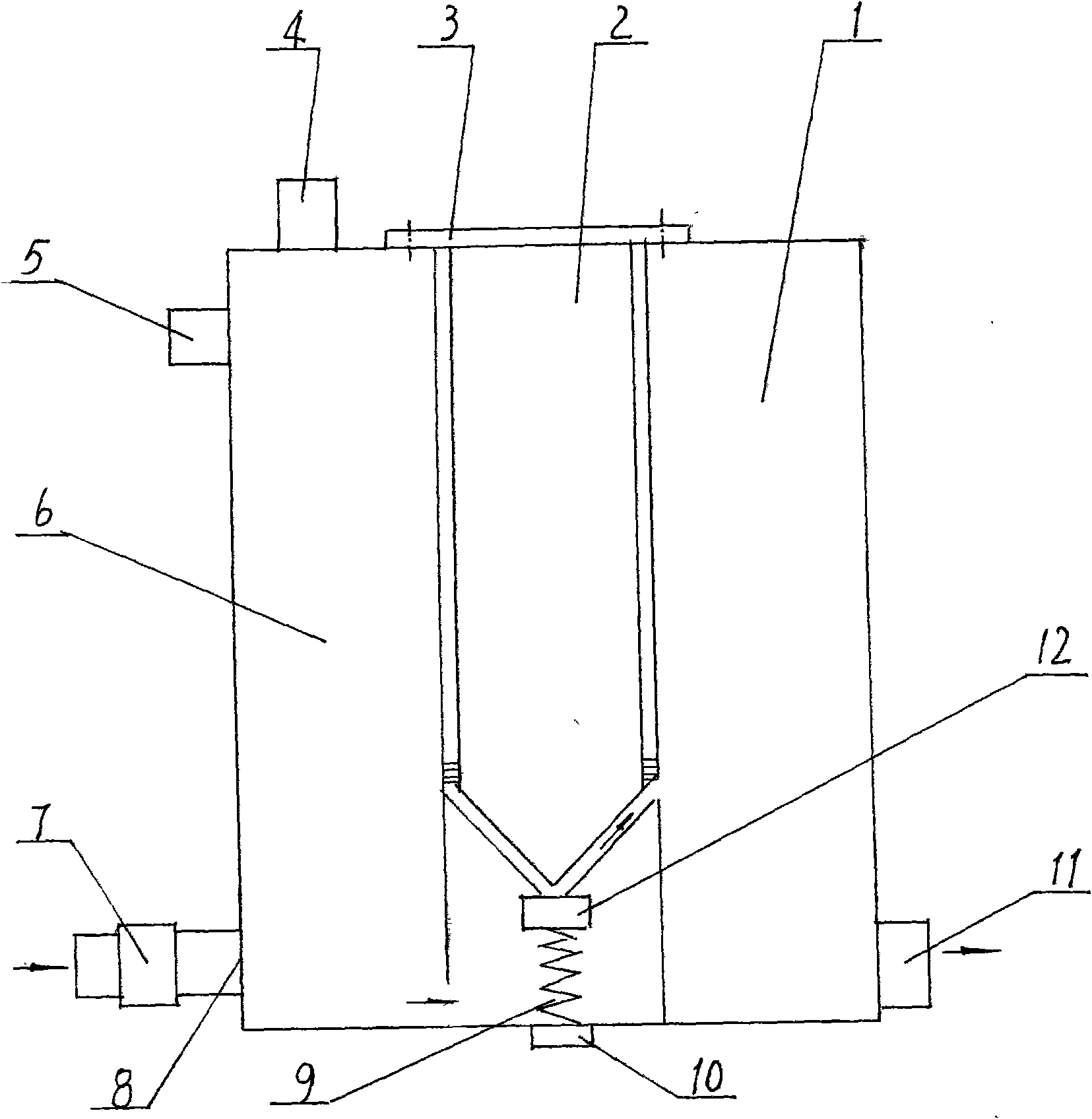

[0009] As shown in the figure, it consists of low-pressure chamber, high-pressure chamber, adjusting bolt, limit bolt, high-pressure digital sensor, locking plate, safety valve, high-pressure solenoid valve, high-pressure air inlet, air outlet valve, and low-pressure air outlet. In the low-pressure chamber 1 Between the high-pressure chamber 6 and the upper part, there is an adjusting bolt 2 fixed on the upper end by a locking plate 3, and an outlet valve 12 and a limit bolt 10 opposite to the adjusting bolt 2 are located below, and the outlet valve is supported by a spring 9. In the high-pressure chamber 6 A high-pressure digital sensor 4 and a safety valve 5 are installed on the top, a high-pressure solenoid valve 7 is installed on the high-pressure gas inlet 8, and a low-pressure gas outlet 11 is arranged on the low-pressure chamber 1. The lower end of the adjusting bolt 2 is conical, which is relatively matched with the conical recess at the upper end of the limit bolt 10 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com