Full spraying device for environmental-friendly machine

A spraying device and mechanical technology, applied in spraying devices, spraying devices with movable outlets, using liquid separation agents, etc., can solve the problems of small spraying range, insufficient spraying, low work efficiency, etc., and achieve spraying The effect of full, full and long spray distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

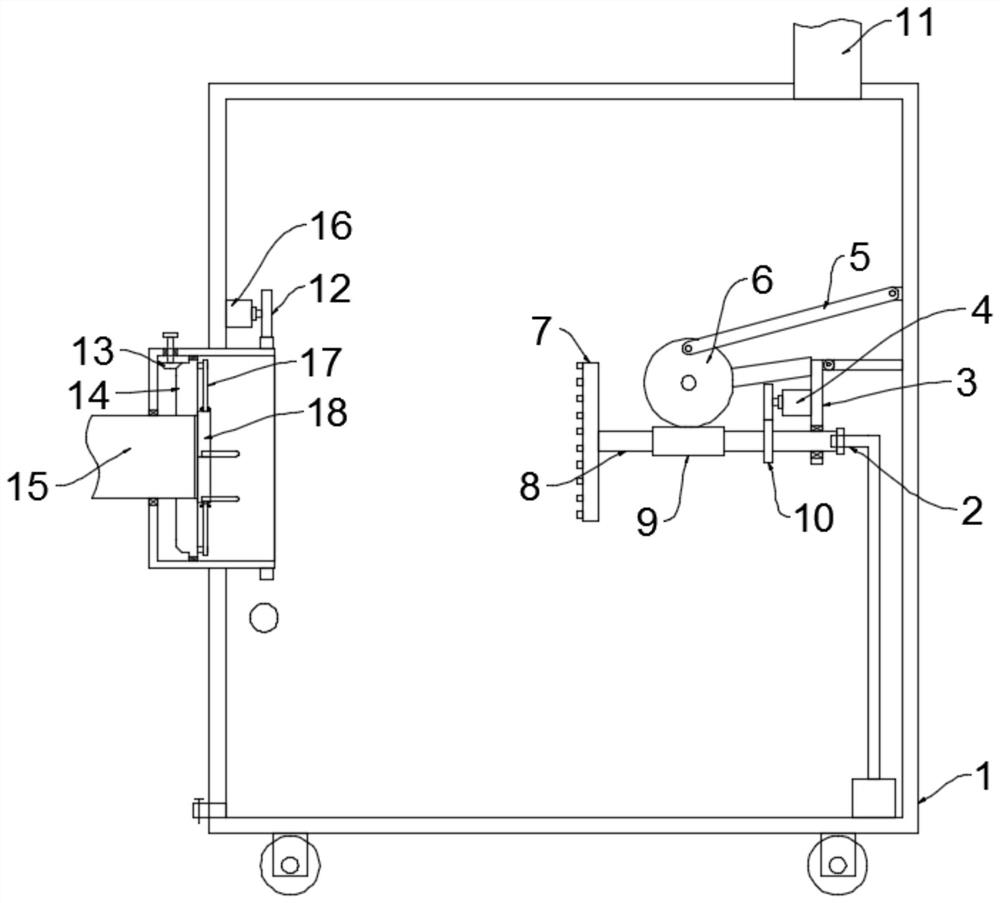

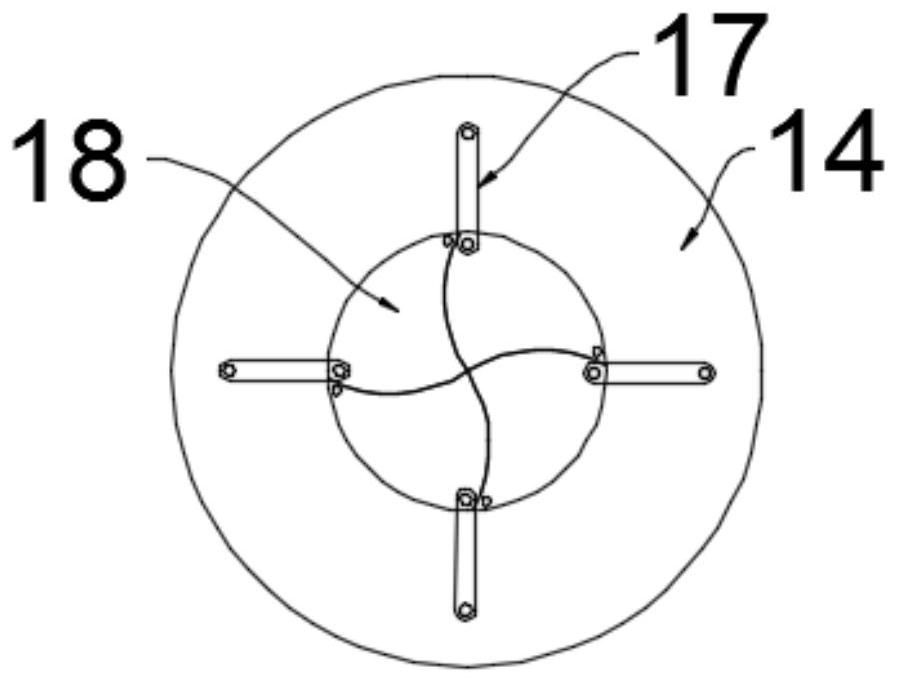

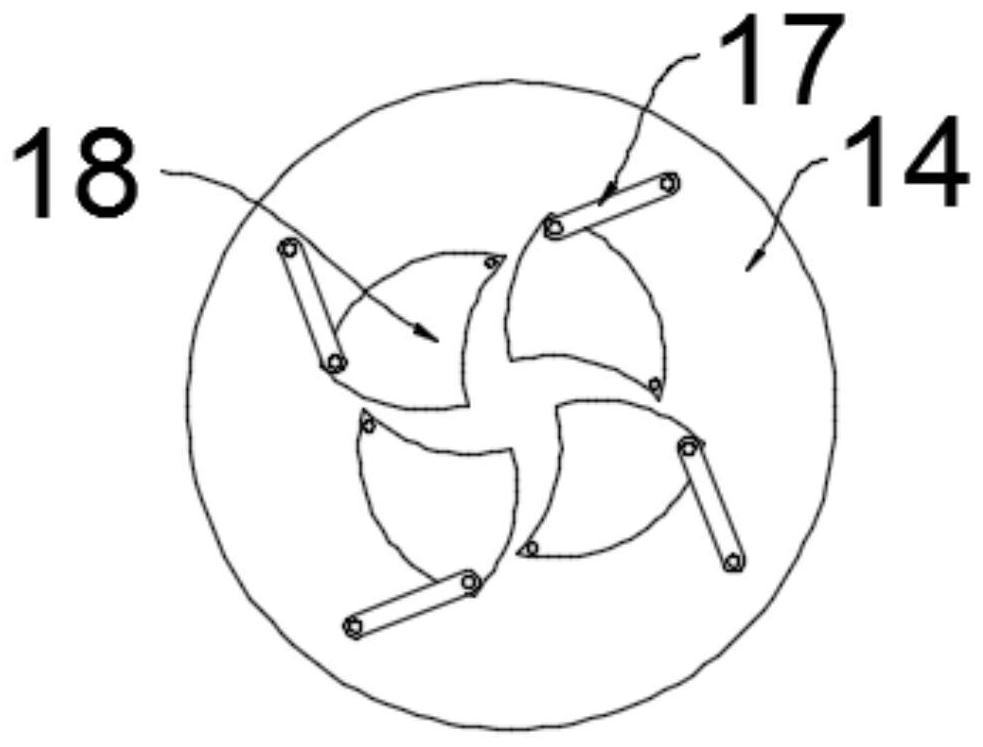

[0025] see Figure 1~4 , in an embodiment of the present invention, a fully spraying device for environmental protection machinery, including a box body 1 and a spray unit installed in the box body 1, the bottom of the box body 1 is evenly and symmetrically fixed with rollers 19 on the top, which is convenient for installation The movement of the box body 1 side wall is connected with the air inlet pipe 15, and the side of the top of the box body 1 away from the air inlet pipe 15 is connected with the air outlet pipe 11. position, the spray unit includes a spray disc 7, a hollow shaft 8, a first drive mechanism for driving the hollow shaft 8 to rotate, a worm 9, a worm wheel 6 and a first connecting rod 5, and the hollow shaft 8 is rotatably mounted on the mounting frame 3, the end of the hollow rotating shaft 8 close to the intake pipe 15 is fixedly installed with a spray disc 7 communicating with the inner cavity, and the side wall of the spray disc 7 close to the intake pip...

Embodiment 2

[0028] see Figure 5 The difference between the embodiment of the present invention and embodiment 1 is that in order to further improve the spraying efficiency, a metal mesh 21 is installed obliquely and fixedly under the outlet pipe 11 in the box body 1, and a metal mesh 21 is installed on the top of the inner cavity of the box body 1 evenly. A plurality of nozzles 20, the nozzles 20 are connected to the second liquid supply pipe 22, when the nozzles 20 spray the exhaust gas from top to bottom, the spray liquid falls on the metal mesh 21, part of it will flow along the metal mesh 21, due to the molecular Due to the attractive force between them, the spray liquid repeatedly fills the entire mesh of the metal mesh 21, thereby forming a spray curtain, which is more fully in contact with the spray liquid, and the spray effect is better.

[0029] The working principle of the present invention is: when working, the first liquid supply pipe 2 feeds spray liquid into the hollow rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com