Control method and system for natural gas engine EGR knocking correction

A control method and engine technology, applied in the direction of engine control, engine cooling, electrical control, etc., can solve the problems of engine exhaust temperature rise, emission deterioration, etc., to ensure safety, improve knock control speed, and prevent recurrence There is a knock effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

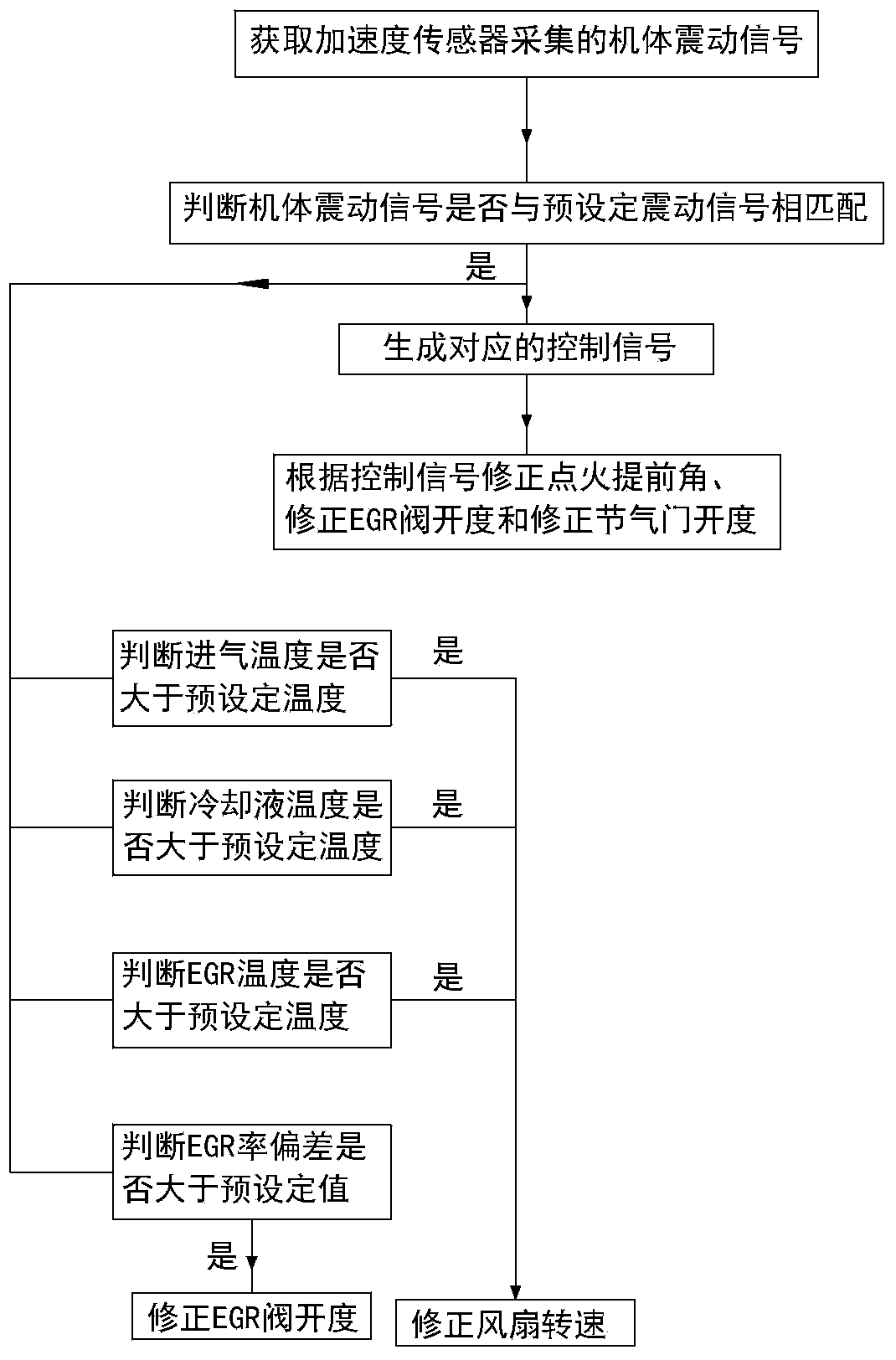

Method used

Image

Examples

Embodiment 2

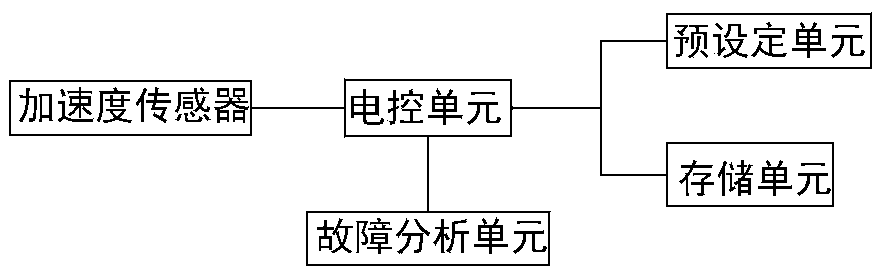

[0081] Such as figure 2 As shown, a natural gas engine EGR knock correction system includes an acceleration sensor arranged on the body, the acceleration sensor is electrically connected to the electronic control unit; the acceleration sensor transmits an electrical signal corresponding to the vibration of the body to the electronic control unit, and the electronic control unit The vibration signal is set to determine whether knocking occurs, and the ignition advance angle, EGR valve opening and / or throttle opening are corrected according to the comparison result.

[0082] The system of the present invention also includes a preset unit and a storage unit electrically connected to the electronic control unit, wherein the preset unit stores the preset vibration signal, the preset intake air temperature and the preset coolant temperature to the electronic control unit; The storage unit is used to store the EGR valve correction amount and the fan speed correction amount when knoc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com