Rollback control of a hybrid electric vehicle

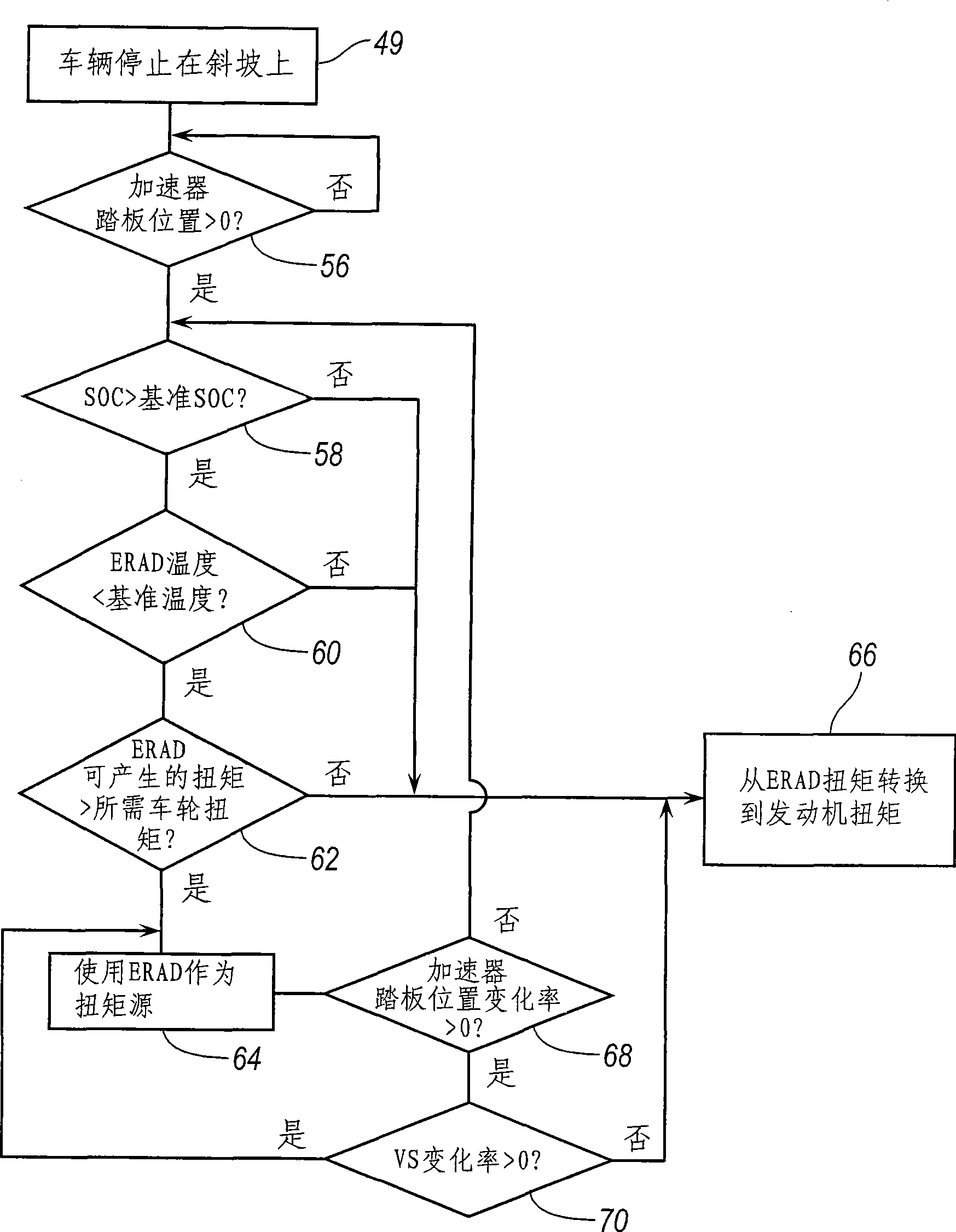

一种车辆、倒溜的技术,应用在动力传动系统领域,能够解决车轮扭矩延迟等问题,达到防止车辆倒溜的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

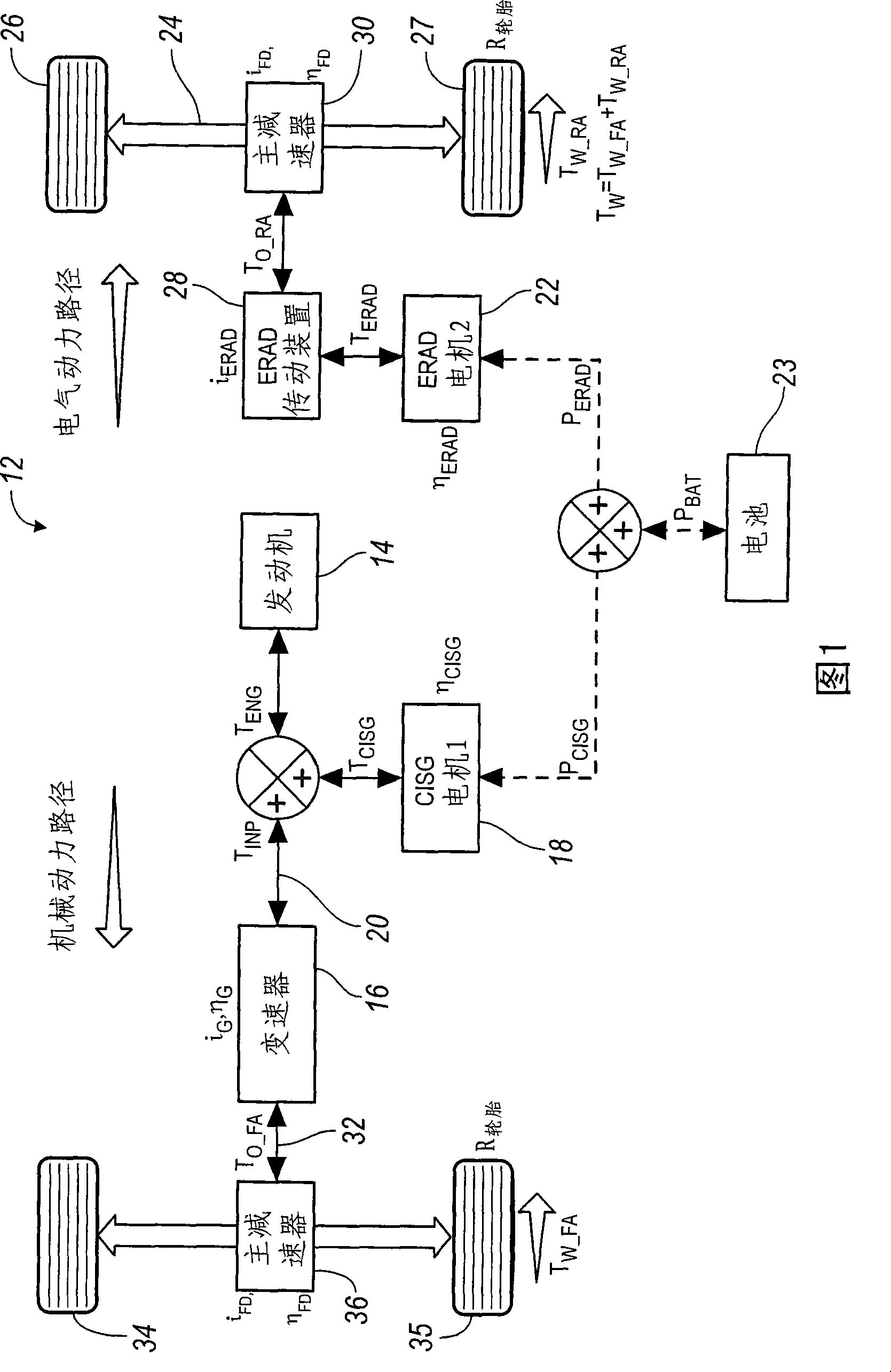

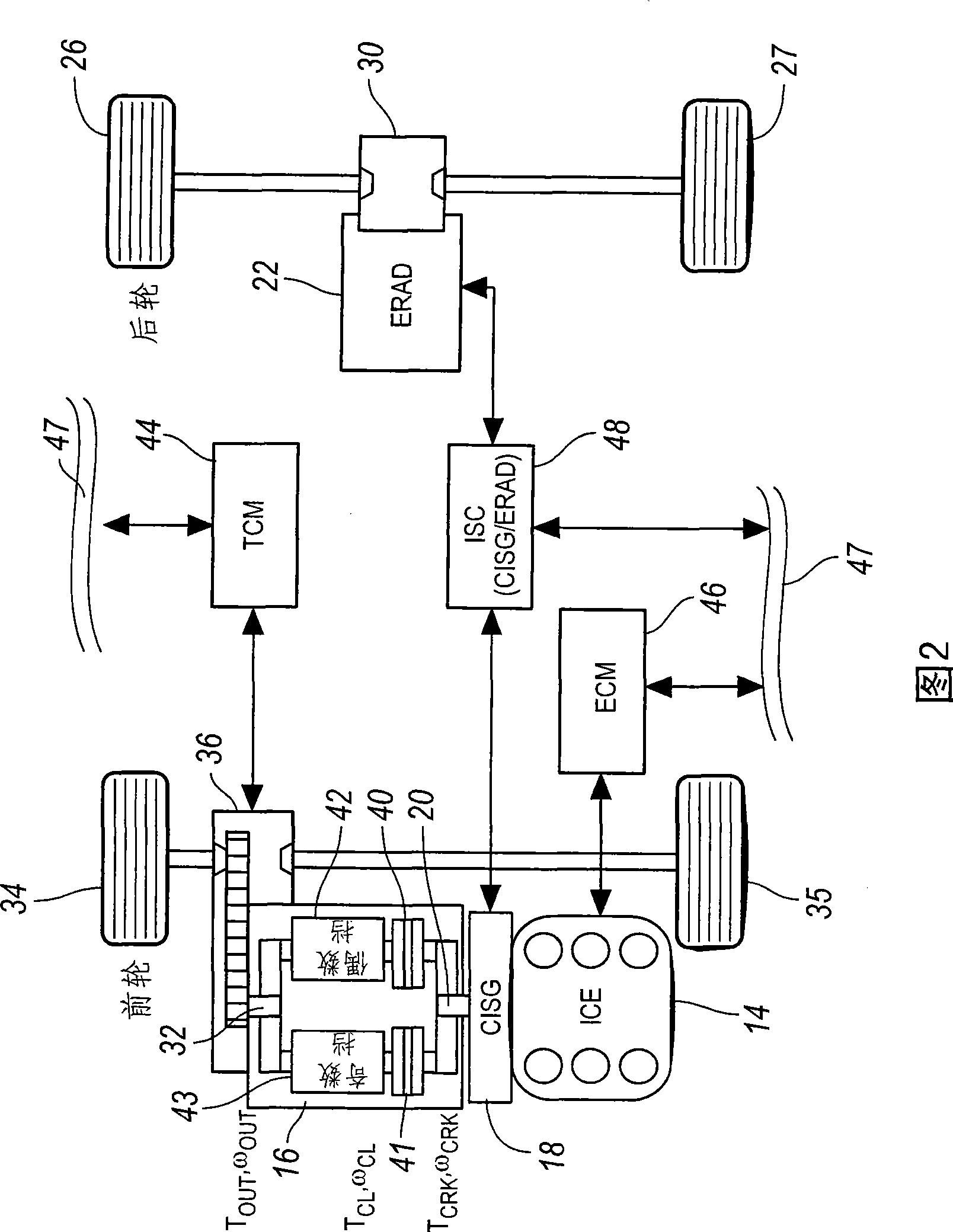

[0021] As shown in Figures 1 and 2, the vehicle power transmission system 12 includes an engine 14, such as a diesel engine or a gasoline engine; a transmission 16, such as a double wet clutch power shift transmission or another multi-speed transmission without a torque converter; An electric motor 18 , such as a CISG (crankshaft-integrated starter-generator, crankshaft-integrated starter / generator) connected to the transmission input 20 ; and an additional electric motor 22 , such as an electric motor. The electric machine 18 provides rotational power to turn the engine 14 when the engine is started and generates electrical power which is provided directly to the electric machine 22 or the battery 23 or both.

[0022] An electric motor 22, sometimes referred to as an electronically controlled rear axle drive or electronically controlled rear axle drive (ERAD), is connected to the final drive of the rear axle or axle 24 and is electrically driven or hybrid (series / parallel) Dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com