Intelligent control system and method of multi-specification tubular continuous annealing furnace

An intelligent control system, technology of continuous annealing furnace, applied in heat treatment process control, furnace, heat treatment furnace, etc., can solve the problems of inability to realize remote monitoring and intelligent control, low automation level, etc., to reduce equipment investment costs and not waste energy , the effect of eliminating residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

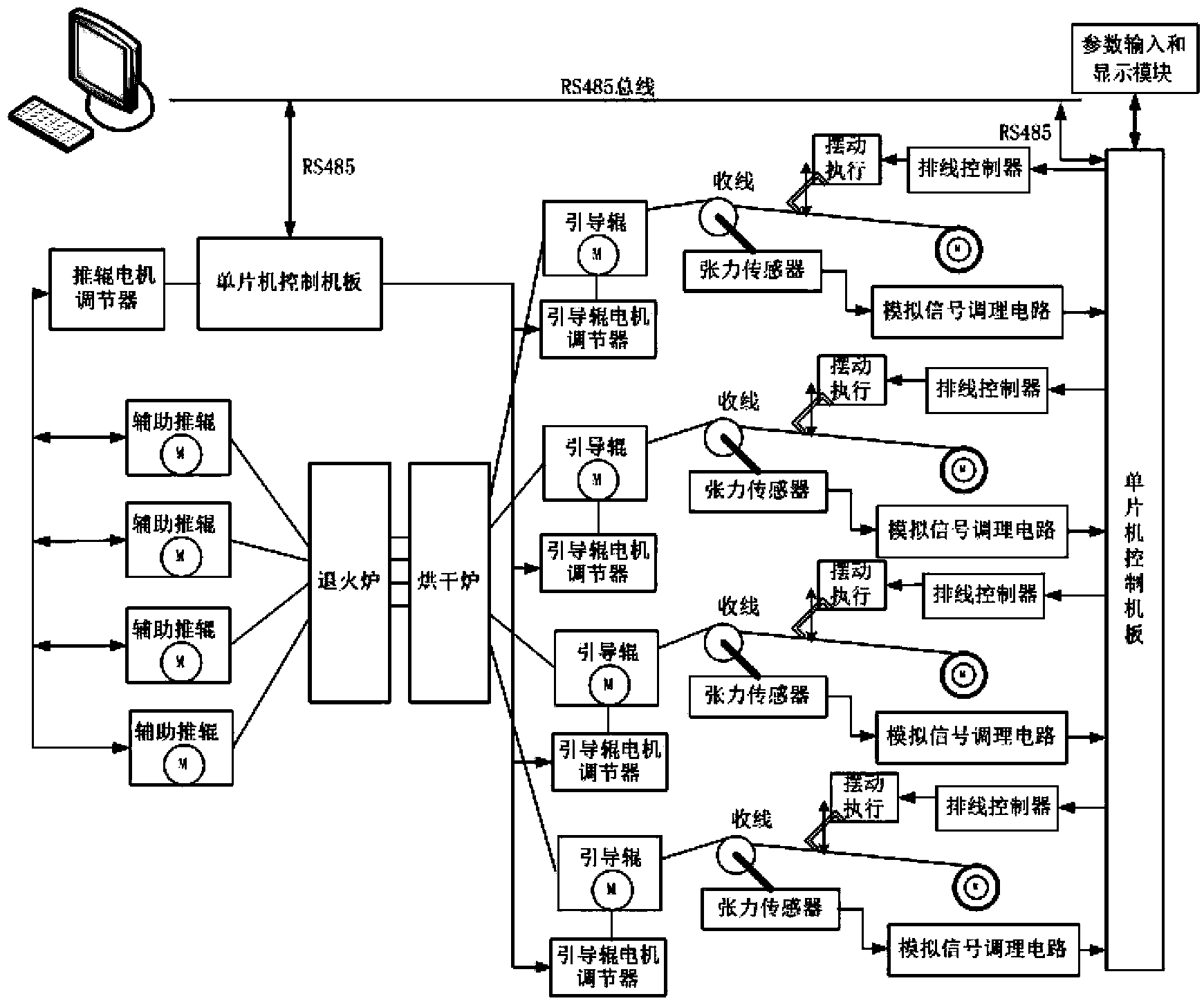

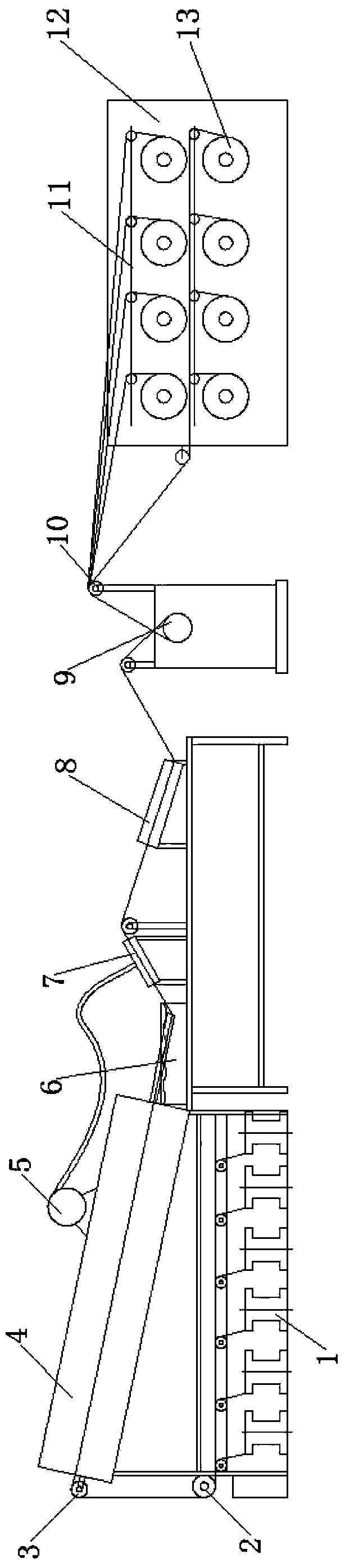

[0046] An intelligent control system for a multi-standard tubular continuous annealing furnace in this embodiment includes a pay-off unit, a temperature control unit, a guide unit, a tension monitoring unit, a take-up unit, a single-chip microcomputer control board, and a parameter input and display module, wherein :

[0047] The pay-off unit includes multiple sets of auxiliary push rollers 2, auxiliary push roller drive motors and auxiliary push roller motor regulators corresponding to each group of auxiliary push rollers 2, specifically in this embodiment, the auxiliary push rollers 2 are provided with 4 groups, Each group of auxiliary push rollers 2 is connected to the auxiliary push roller driving motor through a pulley and a V-belt. The auxiliary push roller driving motor is connected to the auxiliary push roller motor regulator through a control line, and the auxiliary push roller motor regulator is connected to the single-chip microcomputer control board through a contro...

Embodiment 2

[0062] The basic structure of the intelligent control system of a kind of multi-standard tubular continuous annealing furnace of the present embodiment is the same as that of the embodiment 1, the difference is that the single-chip microcomputer control board and the intelligent temperature control module in the present embodiment communicate with the computer through the RS485 bus According to the material and wire diameter of the wire, the rotation speed of the auxiliary push roller 2, the guide roller 9, the take-up tension, the temperature values of the annealing furnace 4 and the drying furnace 8 are preset by the computer, and are displayed on the computer. All data information is processed in the computer, and instructions are sent to each unit to adjust the data error, so as to realize the remote monitoring and control of the whole system. The intelligent control method of a multi-standard tubular continuous annealing furnace in this embodiment is basically the same a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com