Yarn carrying spindle for controlling bobbin pay-off tension through magnetic damping for knitting machine

A pay-off tension and magnetic damping technology, applied in woven fabrics, textiles and papermaking, can solve the problems of unstable pay-off tension, uncontrollable tension, insufficient knitting stroke, etc., to ensure product stability, improve quality, The effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

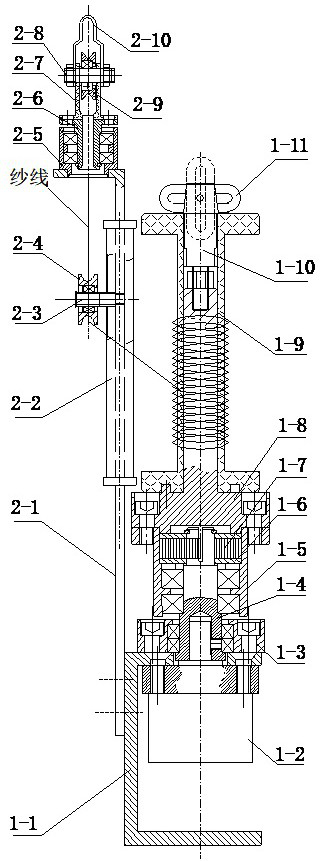

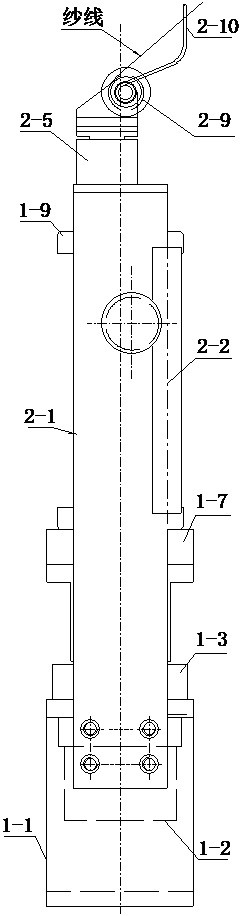

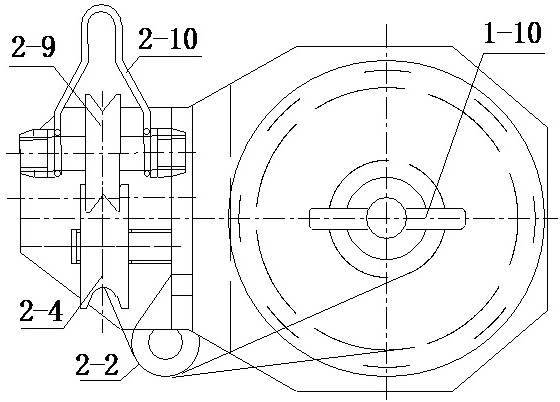

[0030] Embodiment 1: A spinning spindle for controlling the tension of bobbin pay-off by magnetic damping includes: a tension pay-off mechanism 1 and a wire outlet mechanism 2;

[0031] The tension pay-off mechanism 1 includes: a base 1-1, a magnetic damper 1-2, a bearing flange 1-3, a mandrel 1-4, a sheath 1-5, a gasket 1-6, a scroll Spring 1-7, bobbin seat 1-8, bobbin 1-9, bobbin pin 1-10 and bobbin buckle 1-11.

[0032]A magnetic damper 1-2 is installed on the lower part of the upper plane of the base 1-1, and a bearing flange 1-3 is installed on the upper part of the upper plane of the base 1-1; the mandrel 1-4 passes through the center of the bearing flange 1-3 , and installed on the bearing flange 1-3 through the bearing; the output shaft of the magnetic damper 1-2 is inserted into the central hole at the lower end of the mandrel 1-4, and is connected with the mandrel 1-4 as a whole; A sheath 1-5 is installed on the top of the mandrel 1-4 through a bearing, a notch is o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com