Vertical top pull down hydraulic pumping unit

A pumping unit, hydraulic technology, applied in the direction of liquid variable volume machinery, mechanical equipment, machine/engine, etc., can solve the problems of short service life, high maintenance cost, inconvenient use, etc., and achieve long service life and low maintenance cost. , easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

[0026] Embodiment 3: as attached Figures 7 to 8 As shown, the difference from the above-mentioned vertical top-down hydraulic pumping unit is: as attached Figure 7 As shown, the base of the frame 15 of Embodiment 3 is located on the ground, which is convenient for installation.

Embodiment 4

[0027] Embodiment 4: as attached Figures 7 to 8 As shown, the difference with embodiment 3 is: as attached Figure 8 As shown, the hydraulic device of embodiment 4 and its corresponding frame 15 part have heat preservation chamber 20, and hydraulic device is positioned at heat preservation chamber 20, and the base of the frame 15 of embodiment 4 can be positioned on the ground, preferably embodiment 4 The hydraulic device and the heat preservation chamber 20 of the corresponding rack 15 part are placed in a relatively constant temperature layer below the ground, which becomes a basement type when in use, because too high or too low ambient temperature is not conducive to the hydraulic device for a long time. Normal work, so that the working environment of the hydraulic device is in a relatively stable state, which is conducive to reducing the failure of the hydraulic device, thereby prolonging the service life of the hydraulic device, reducing maintenance costs, and utilizing...

Embodiment 1

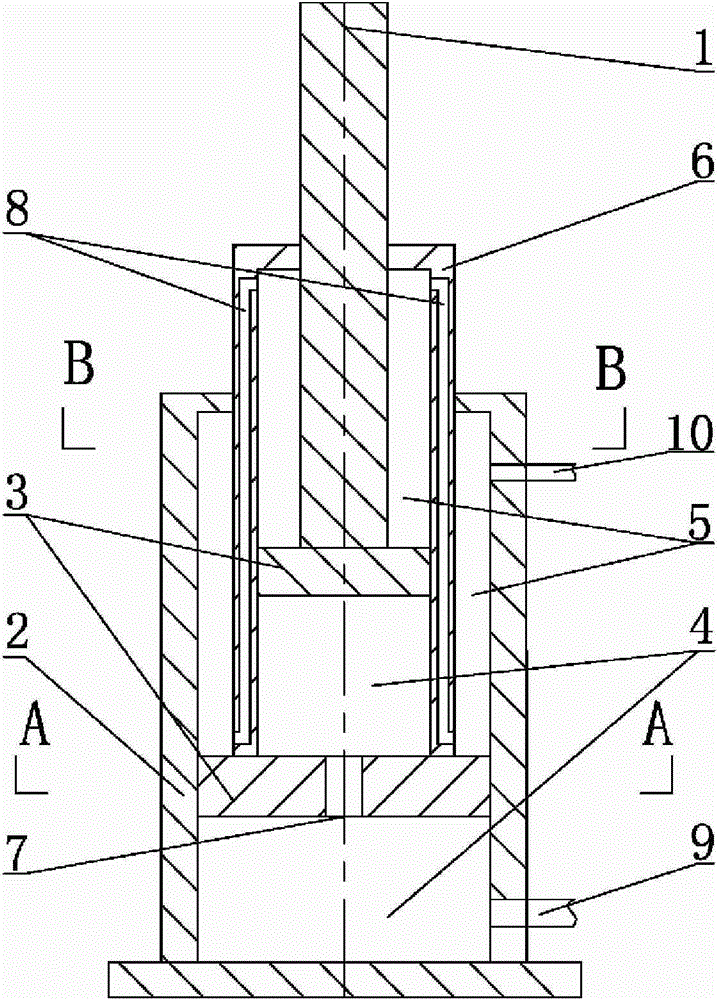

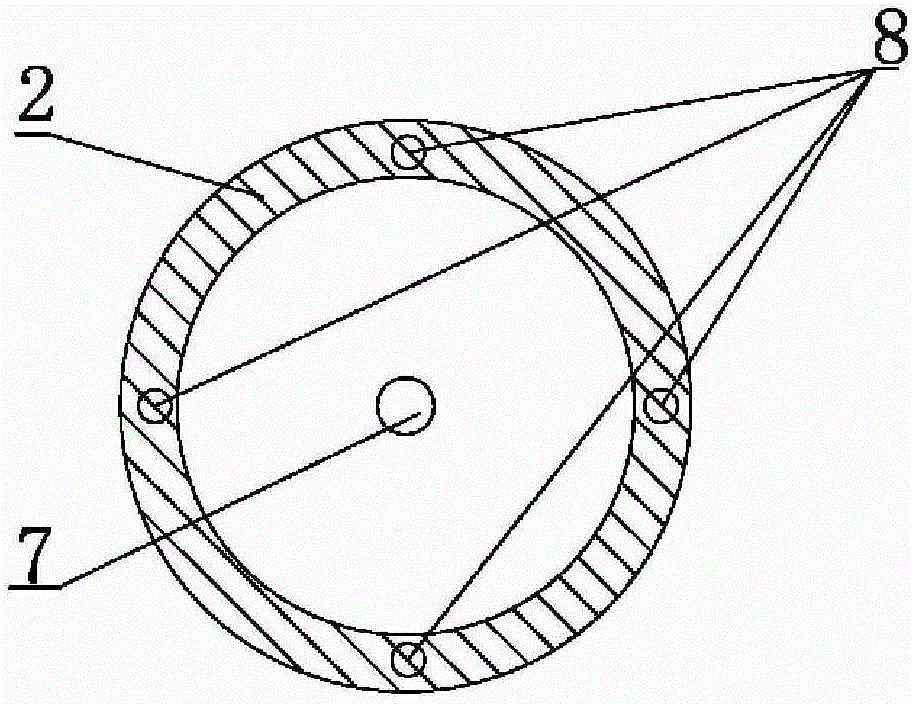

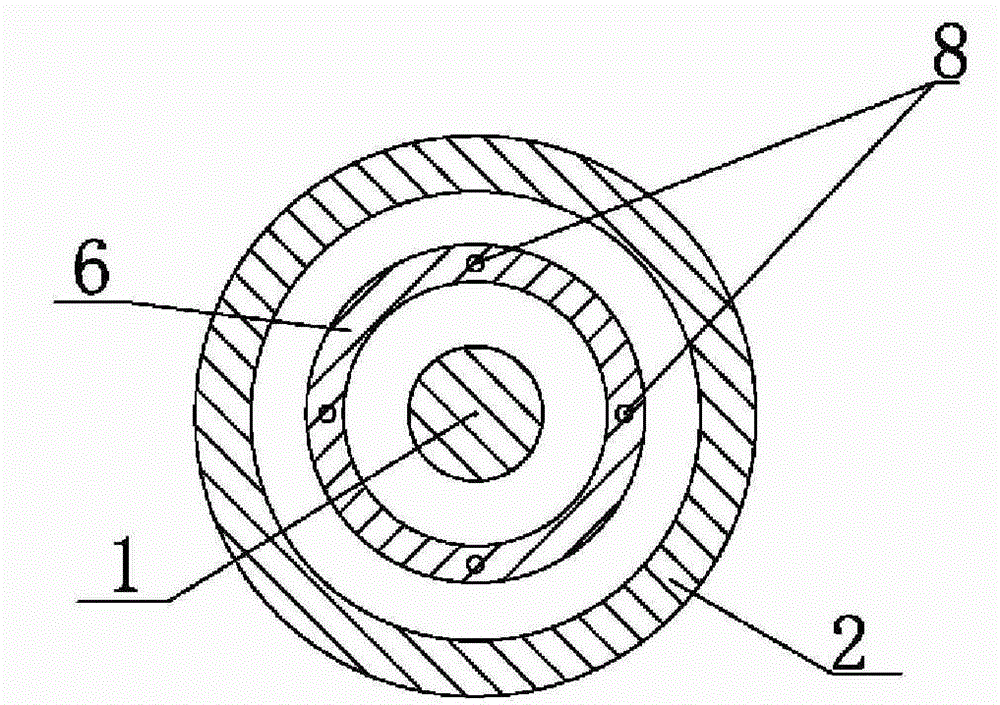

[0033] Embodiment 1: as attached Figures 1 to 3As shown, the difference from the above-mentioned multi-stage piston two-way hydraulic cylinder is that the cylinder body of embodiment 1 includes a fixed cylinder body 2 and a movable cylinder body, and only one level of movable cylinder body is the final movable cylinder body 6, while the final stage movable cylinder body The lower end of the cylinder body 6 is fixed together or integrated with the piston 3 in the fixed cylinder body 2 with its next-level movable cylinder body, and an upward oil passage hole 7 is arranged on the piston 3 to communicate with the upward chamber 4 of the upper and lower cylinder bodies. Its working process is as follows: when the piston rod 1 needs to move upward, high-pressure fluid is injected into the upward cavity 4 through the upward lubricating oil line 9, while the reverse oil line 10 is in the state of discharging high-pressure fluid outward, so that the fixed cylinder 2 Both the piston 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com