A paper splicer control system and control method

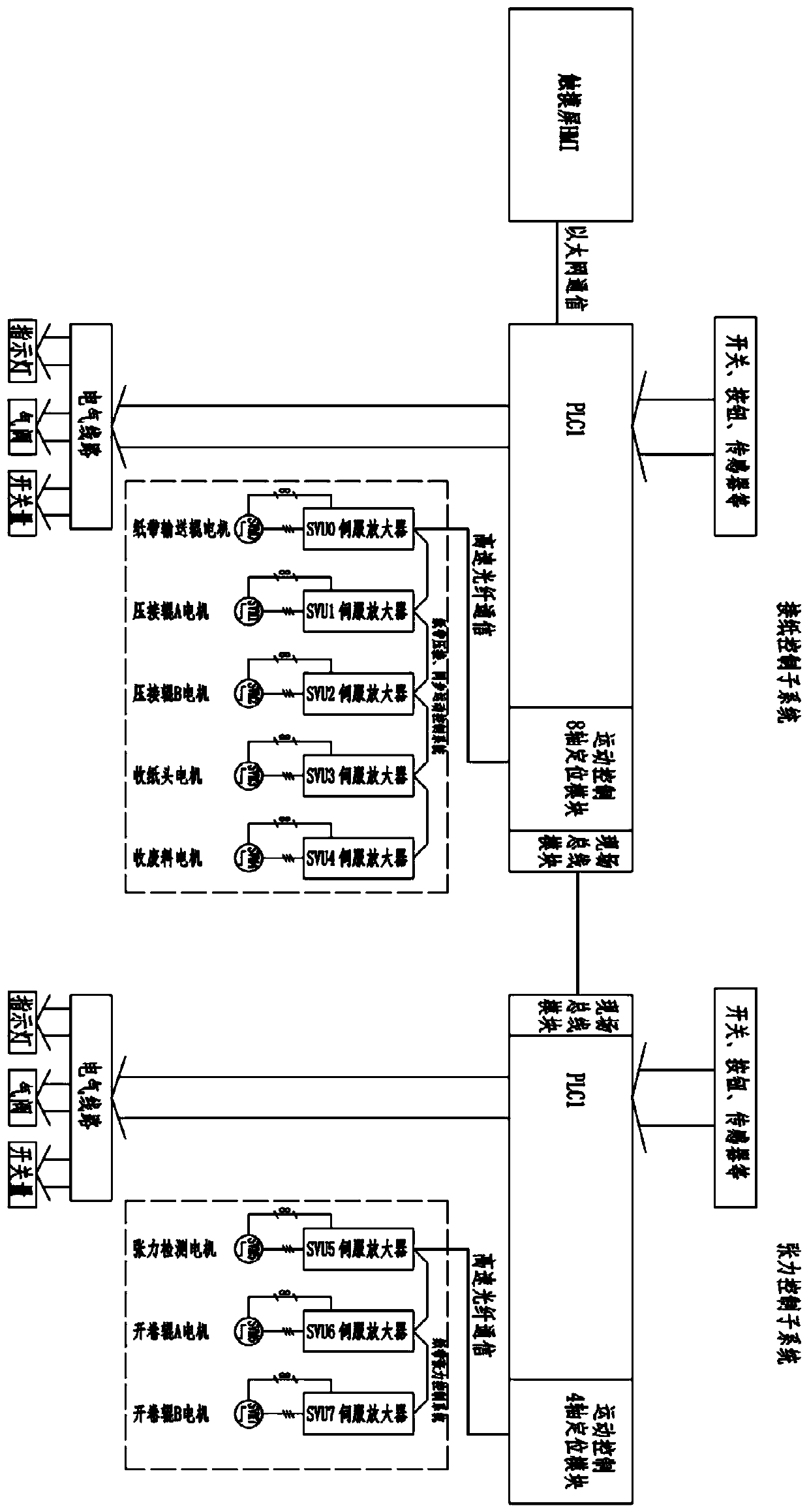

A control system and control method technology, applied in thin material handling, transportation and packaging, winding strips, etc., can solve the problems of difficult to achieve precise control, low measurement accuracy, poor reliability, etc., to reduce machine failure rates, simplify System structure, constant tension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

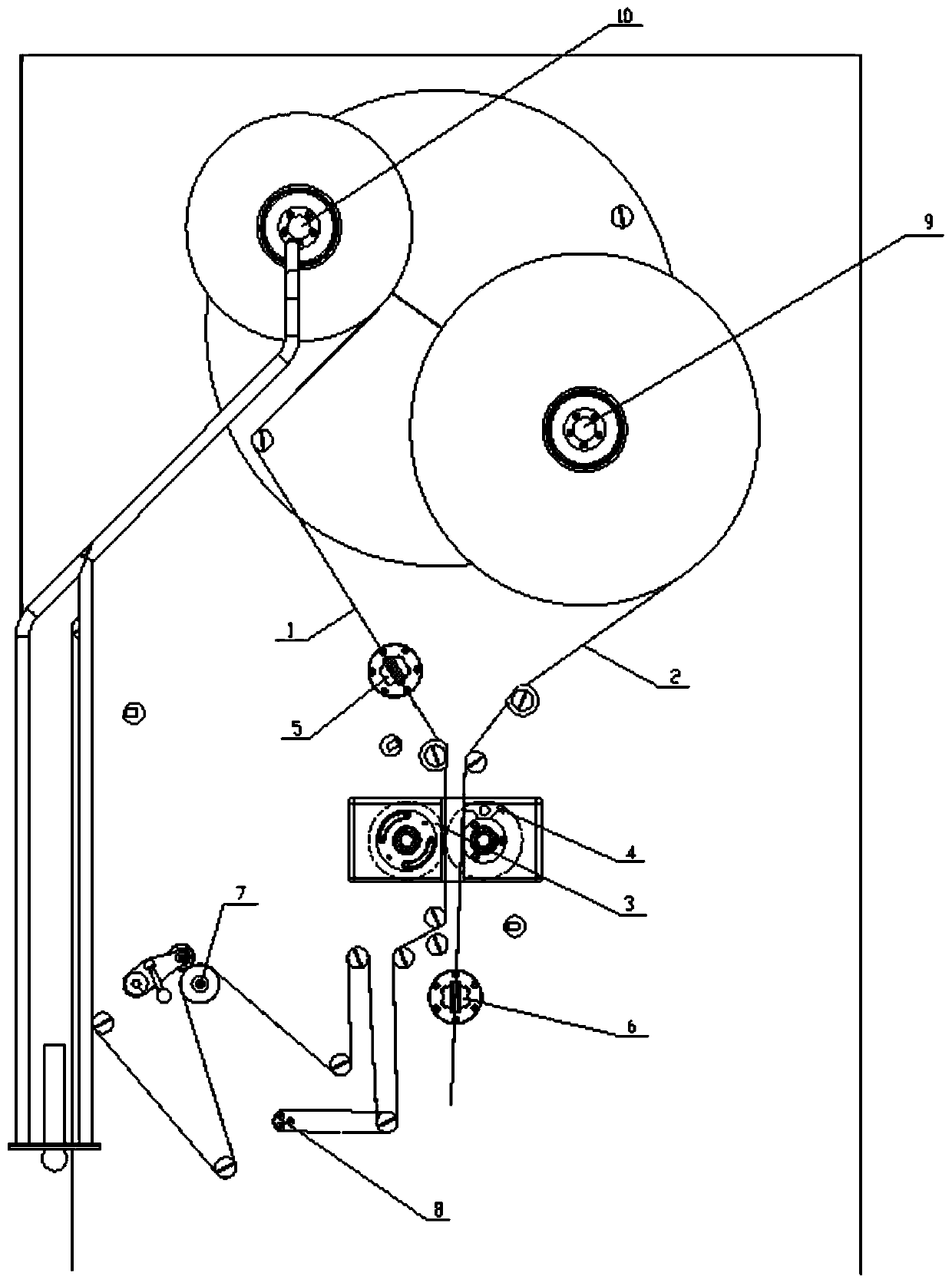

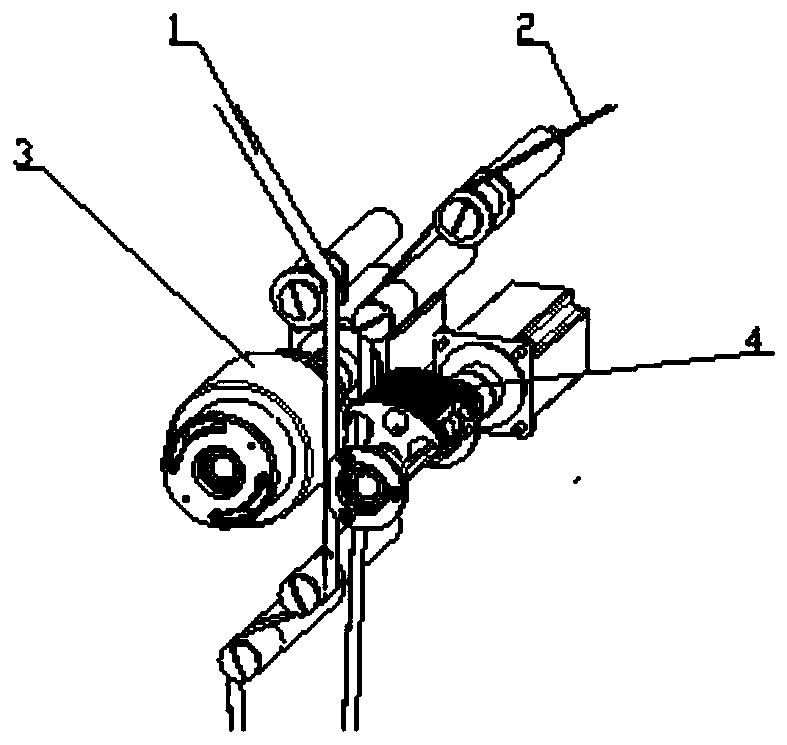

[0030] Such as figure 1 and figure 2 The paper splicing and tension control structure of a splicing machine is shown. Including new paper tape 1, old paper tape 2, full-circumference crimping smooth roller 3, 1 / 4 circle swing crimping roller 4, waste collection roller 5, paper delivery head roller 6, paper tape output roller 7, tension detection shaft 8 , unwinding spindle A9 (old paper tray) and unwinding spindle B 10 (new paper tray). Among them, the position between the full-circumference crimping smooth roller 3 and the 1 / 4-circumference swinging crimping roller 4 is the crimping position of the new and old paper tapes, the waste is controlled by the waste collection roller 5, and the paper end collection is controlled by the paper delivery head roller 6 , the paper tape output is controlled by the paper tape output roller 7, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com