A Constant Force Quick Adjustment Device for Weft Feeder

An adjustment device and constant force technology, which is applied in textiles, textiles, papermaking, looms, etc., can solve the problems of short service life, easy wear and high maintenance rate of fast positioning mechanisms, so as to improve service life and operate quickly and conveniently , the effect of simplifying the track structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

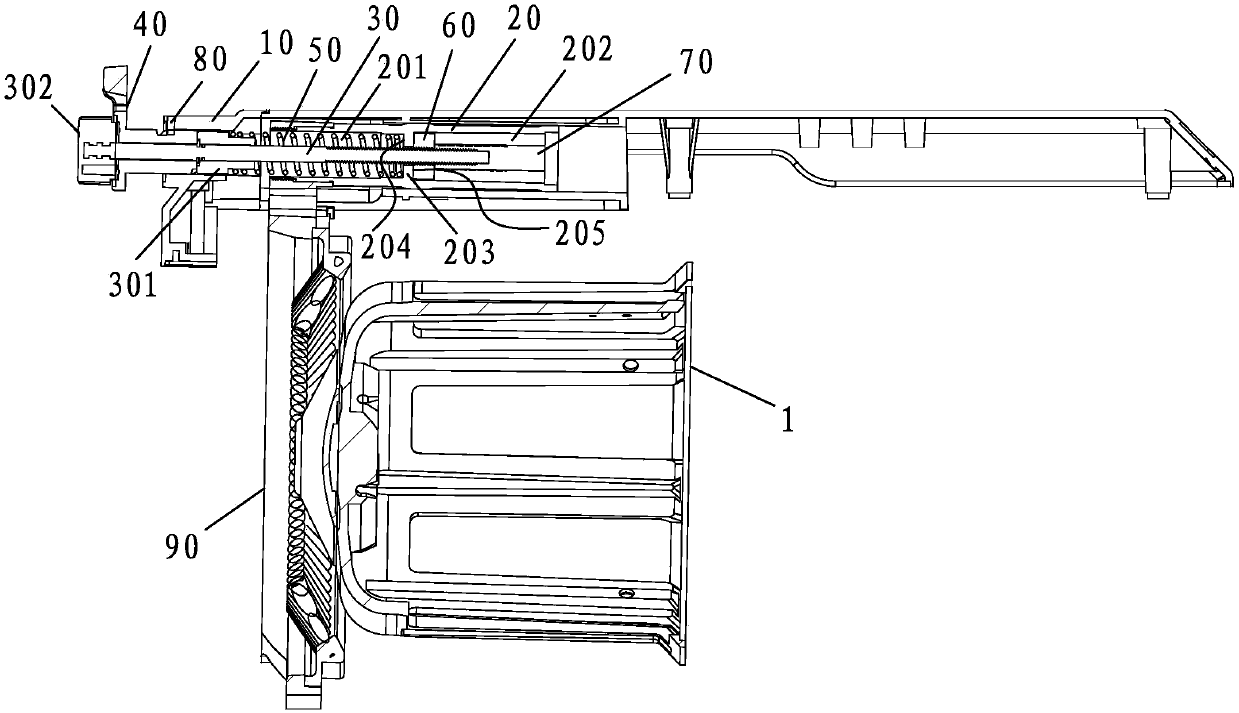

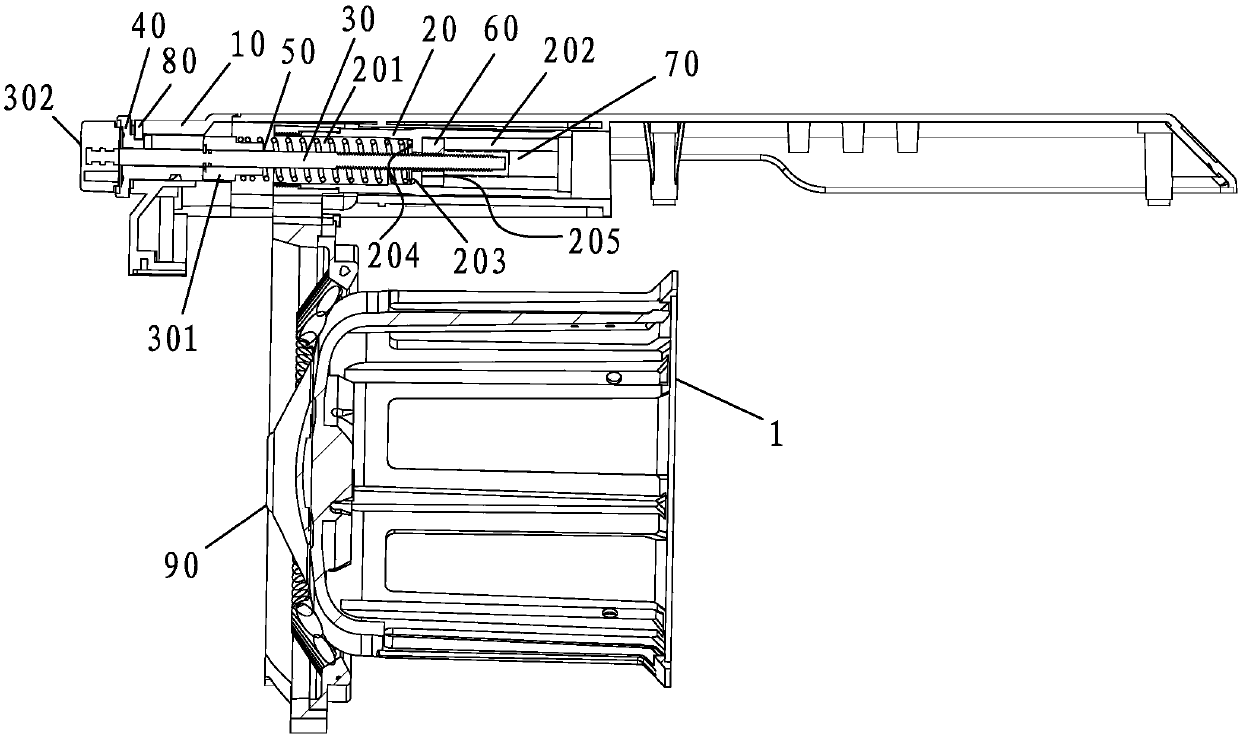

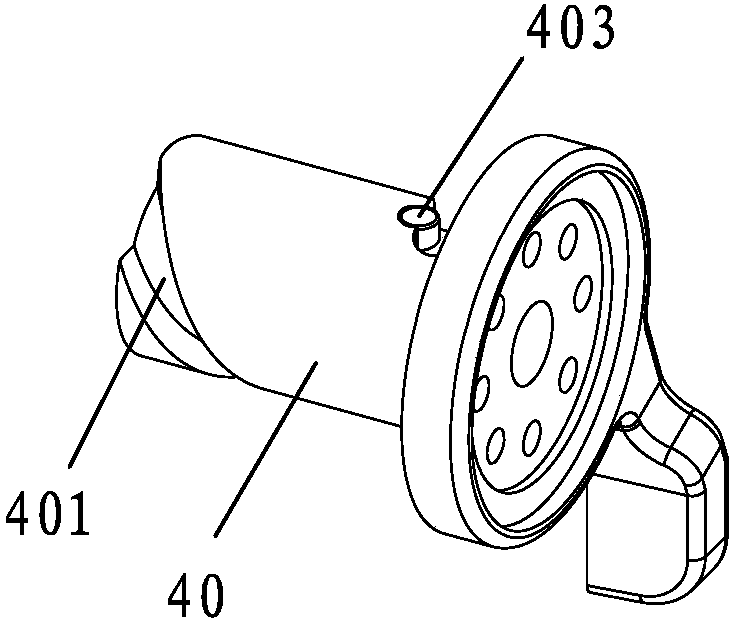

[0037] The utility model relates to a constant-force fast adjusting device of a weft feeder, which is mainly used to adjust the distance between the brush circle 9 and the yarn drum 1, and has two kinds of coarse adjustment and fine adjustment. Coarse adjustment is realized by the wrench assembly 4 to quickly adjust the large spacing, which is convenient for manually pulling out the yarn from the yarn drum 1 and passing through the brush ring 9 . The fine-tuning is to realize the micro-distance change of the brush ring 9 through the cooperation of the screw rod 3 and the pressure block, so that the tension of the yarn passed between the yarn drum 1 and the brush ring 9 can be adjusted. The specific principle structure is as follows:

[0038] The preferred embodiment of the present invention is such as Figure 5 to Figure 7 As shown, it includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com