A constant tension cloth belt guiding device on a square tooth rice discharge machine

A technology of constant tension and rice discharge machine, which is applied in the direction of clothing, sliding fastener components, winding strips, etc., can solve the problem of uneven tension of cloth tapes, achieve the effect of increasing motor speed, simple structure, and accelerated transmission rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

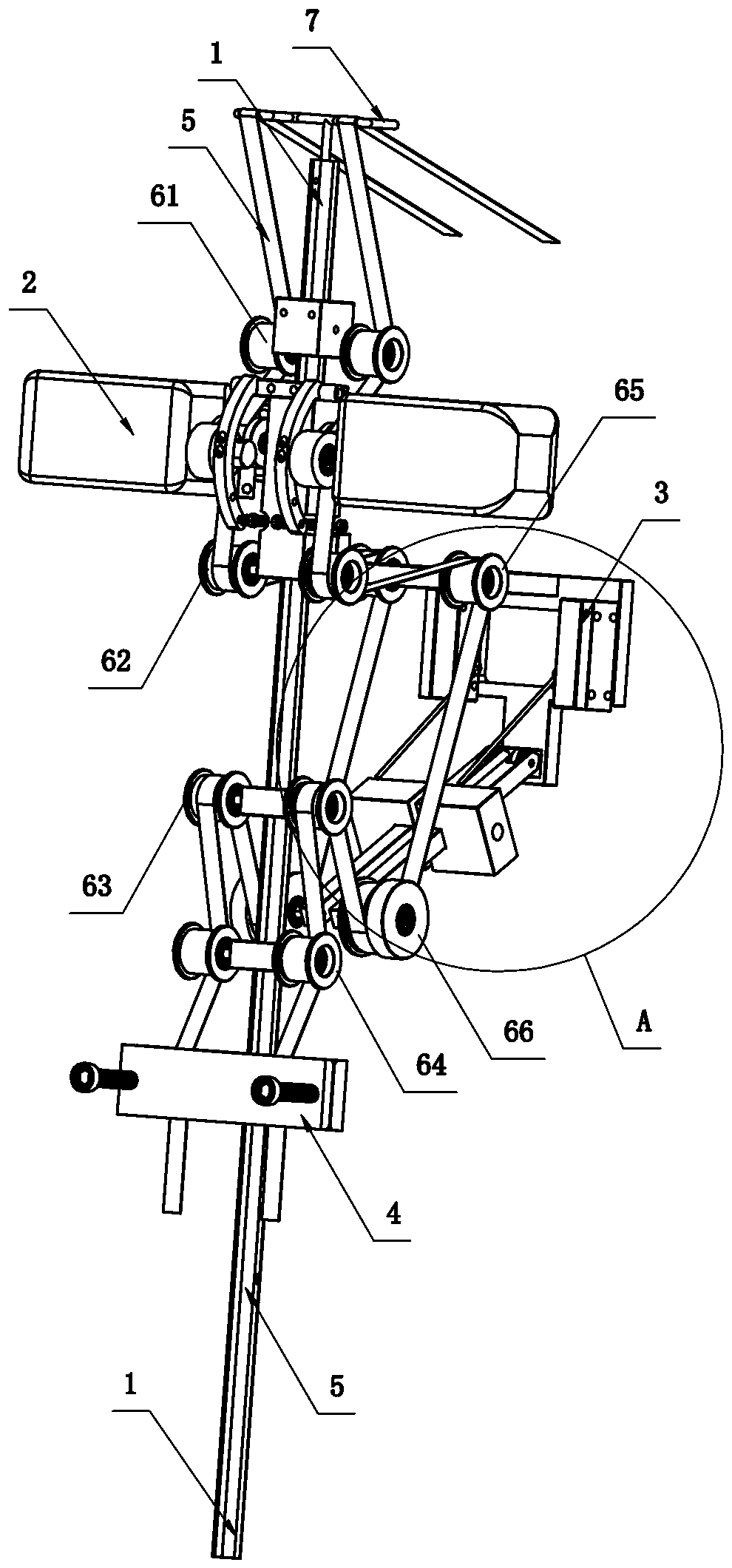

[0035] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 with Figure 7 . A constant tension cloth belt guiding device on a square tooth rice discharge machine, comprising a vertically arranged guide post 1, on which a cloth belt conveying device 2 and a swing rod feeding device are fixedly installed in sequence from top to bottom 3. Tape clamping device 4; among the above three devices,

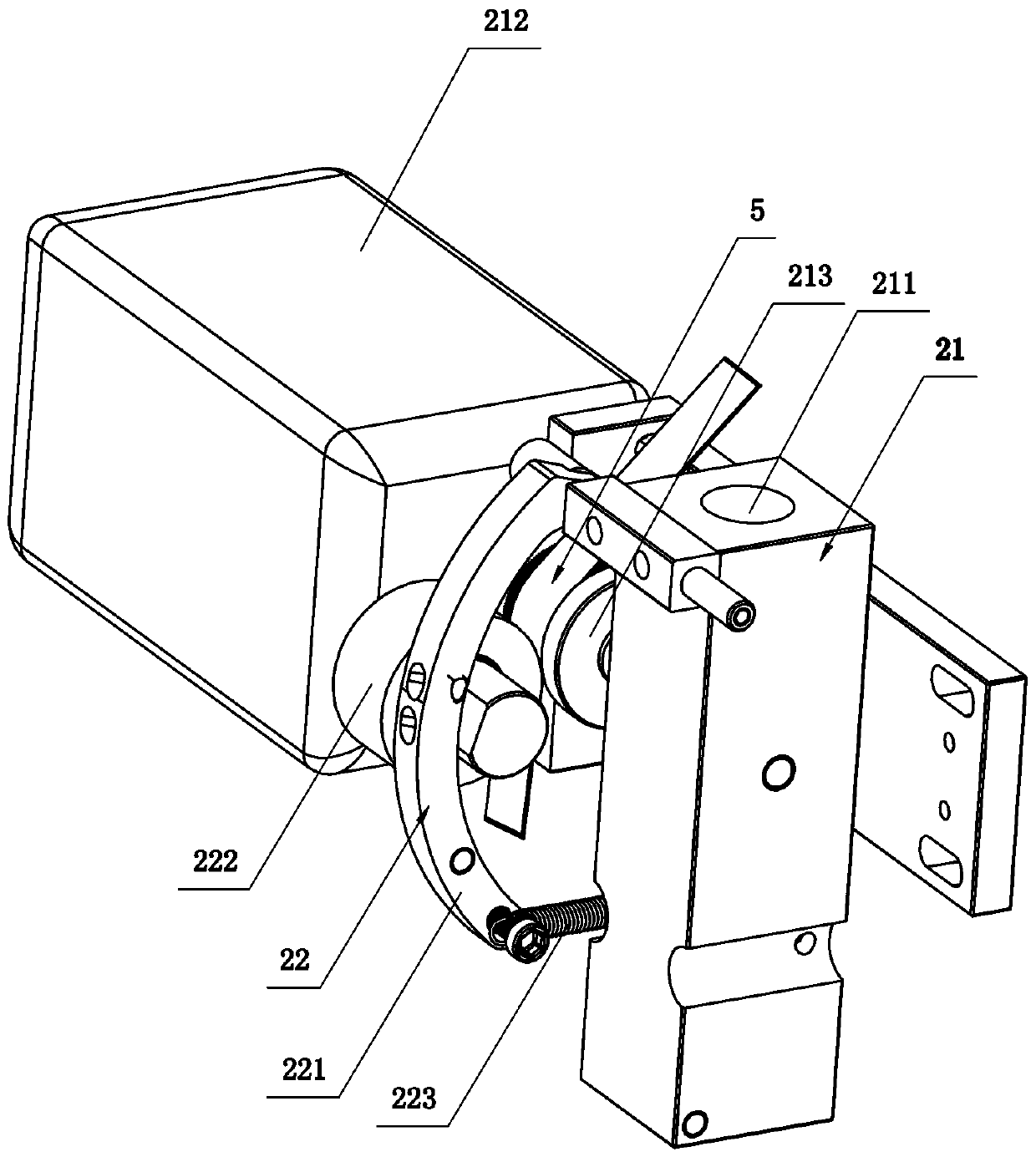

[0036] The cloth belt conveying device 2 includes a transmission mechanism 21 and a first constant tension mechanism 22 connected with the transmission mechanism 21, and the cloth belt 5 is sandwiched between the transmission mechanism 21 and the first constant tension mechanism 22 for transmission;

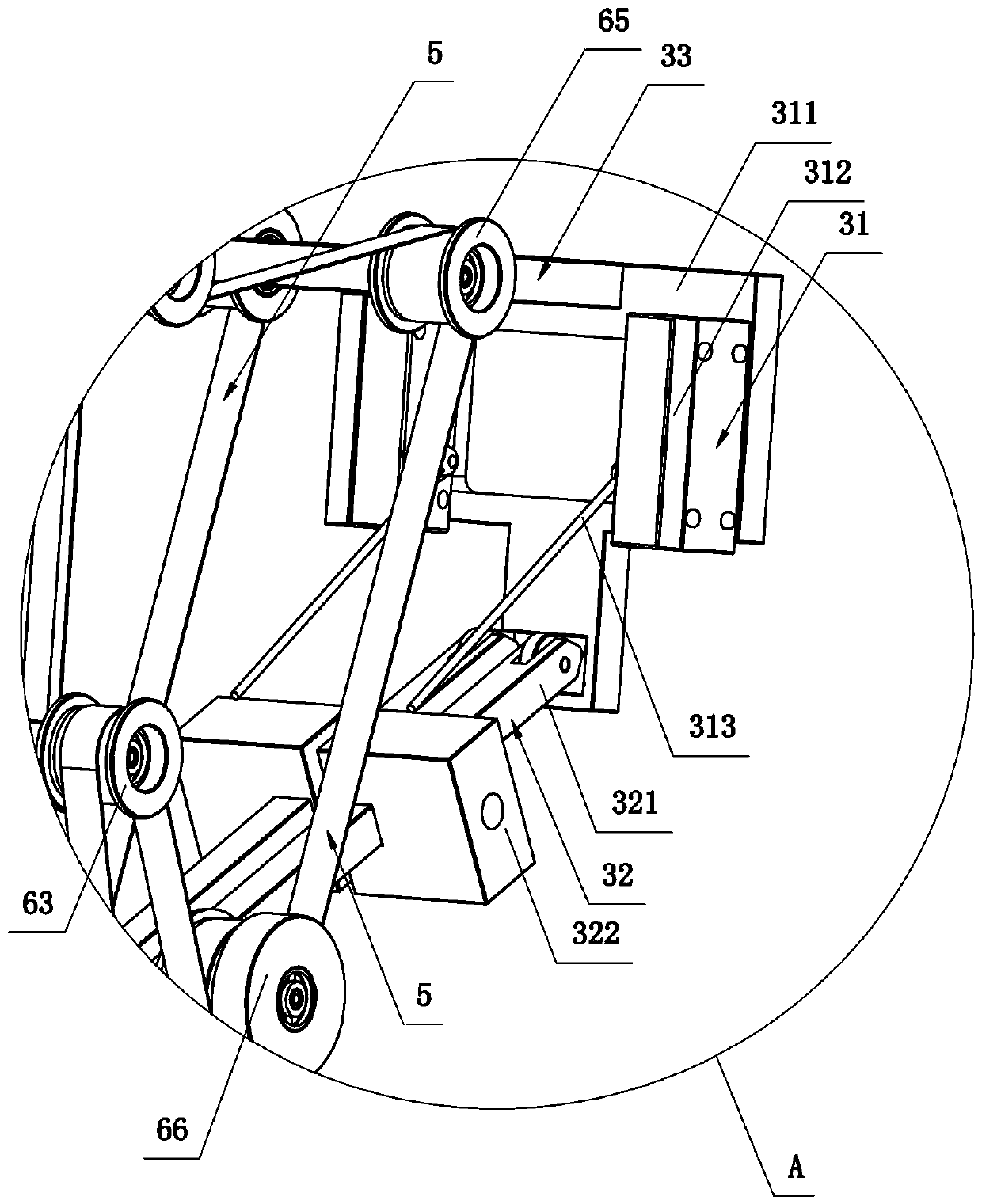

[0037] The swing rod feeding device 3 includes a speed regulating mechanism 31 connected with the transmission mechanism 21 and a swing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com