Control method for erecting main cable based on suspension bridge air spinning method

A control method and main cable technology, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve the problems that the AS method centralized control system has not carried out in-depth research, etc., to improve automation and operability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

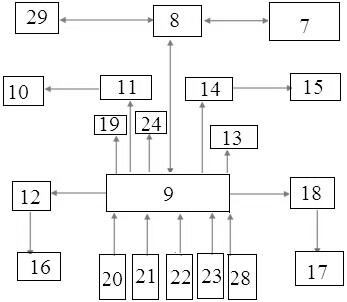

[0030] This embodiment provides a control method for erecting the main cable based on the aerial spinning method of the suspension bridge. During the aerial spinning process, the real-time communication connection between the host computer 7 and the monitoring system is used to monitor the construction site.

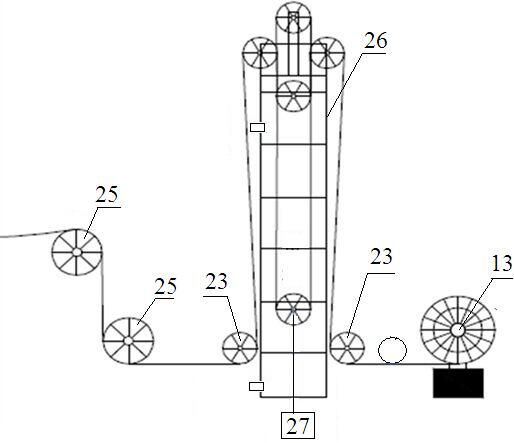

[0031] The lower computer 9 monitors the steel wire tension data measured by the tension measuring devices installed on both sides of the tension tower 26 in real time, and compares the steel wire tension data with the tension set value, and then controls the unwinding mechanism to unwind the wire or the winding mechanism to wind the wire. The tension device adjusts the tension force to realize the constant tension control of the main cable wire;

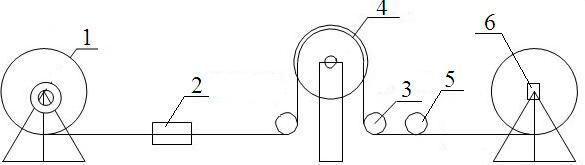

[0032] The lower computer receives the real-time winding diameter of the winding mechanism through the winding diameter measuring device 6, and converts the winding angular velocity of the winding mechanism into a linear speed ...

Embodiment 2

[0035] On the basis of Embodiment 1, this embodiment provides a control method for erecting the main cable based on the aerial spinning method of the suspension bridge. The constant tension control process of the main cable steel wire is as follows: the lower computer 9 measures the unwinding mechanism in real time through the tension measuring device The tension value of the steel wire during the wire winding process of the unwinding or rewinding mechanism outputs a signal to the unwinding proportional valve 12 or rewinding proportional valve 18 in a PID adjustment mode, and continuously adjusts the unwinding tension or rewinding tension to the set value through the tension device , so as to realize the constant tension of the main cable wire.

[0036] Taking the unwinding process as an example, during the unwinding system, the tension sensor measures the actual tension, and the PLC outputs the signal to the pneumatic proportional control valve in the PID adjustment mode, and ...

Embodiment 3

[0038]On the basis of Embodiment 1, this embodiment provides a control method for erecting the main cable based on the aerial spinning method of the suspension bridge. During the unwinding mechanism unwinding or the winding mechanism winding process, the lower computer 9 sends a signal to the The unwinding frequency converter of the winding mechanism or the winding frequency converter 11 of the winding mechanism makes the unwinding motor 13 or the winding motor 10 adopt a constant torque control mode to realize the constant tension of the steel wire during the change of the coil diameter.

[0039] During the unwinding mechanism unwinding or the winding mechanism winding process, the coil diameter changes, and after the coil diameter changes, the tension will also change. Therefore, the real-time coil diameter of the coil mechanism is measured by the coil diameter measuring device 6 and the measured data is real-time. Send it to the lower computer 9, and the lower computer 9 sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com