Patents

Literature

119results about How to "Tight winding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

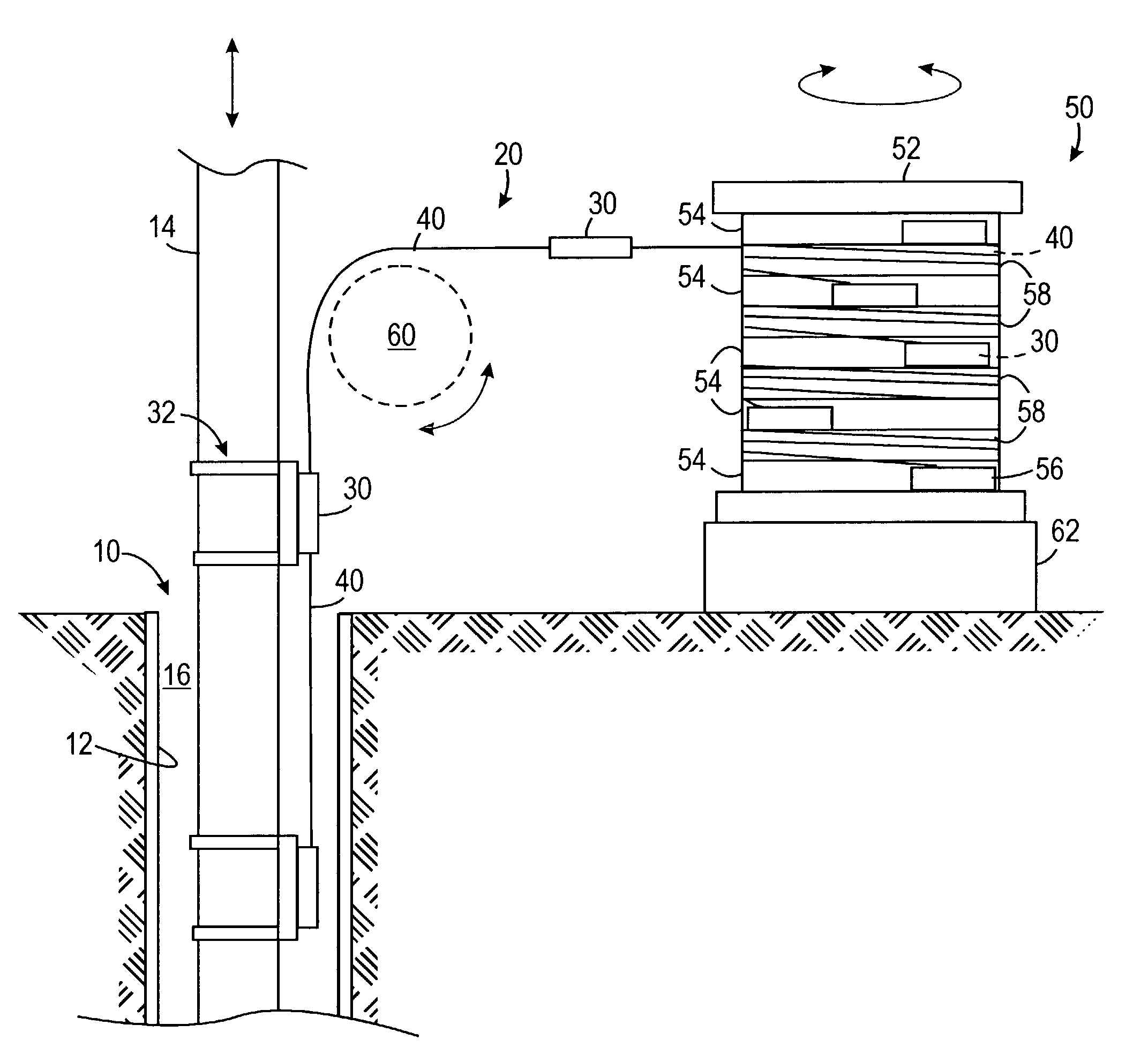

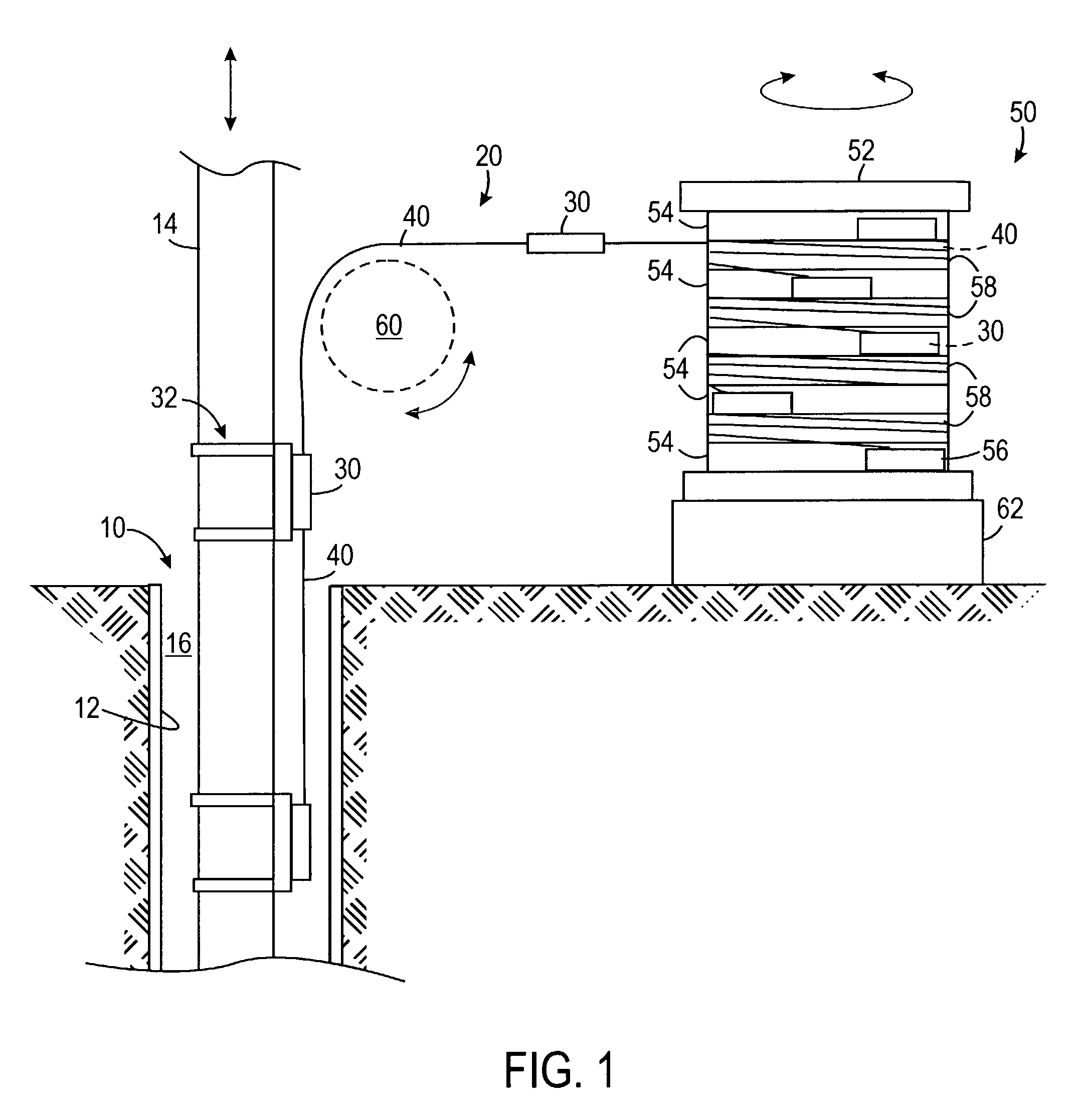

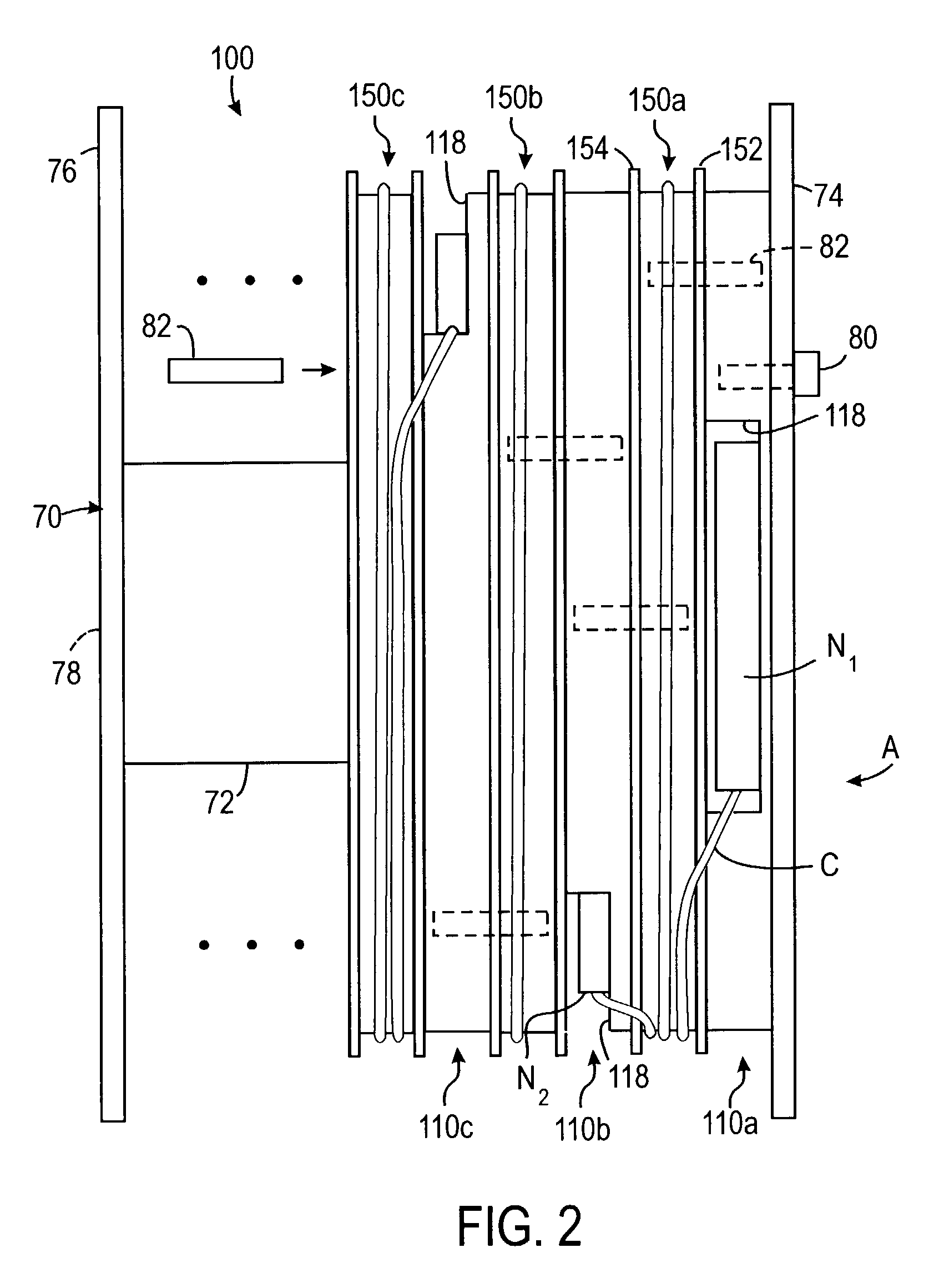

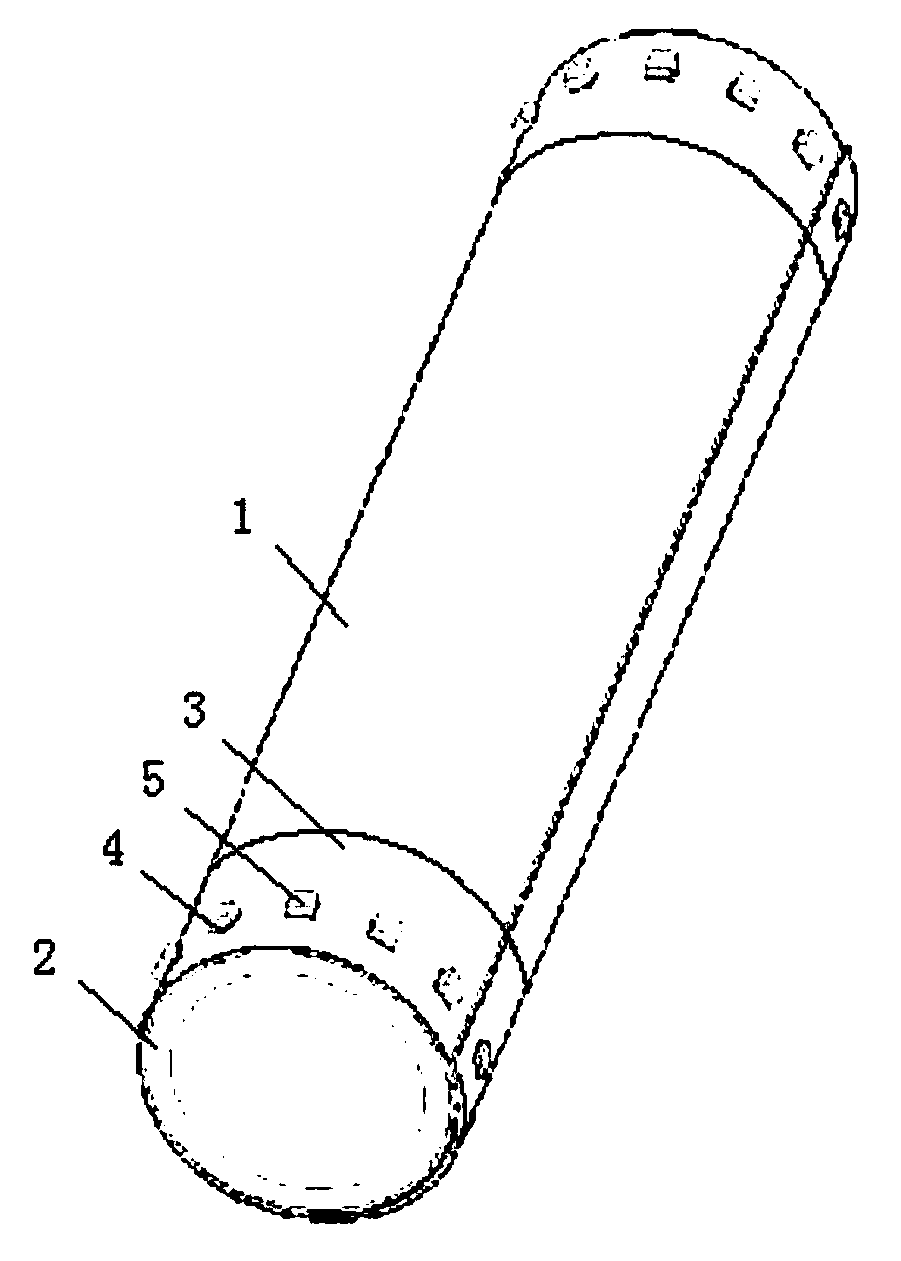

Apparatus and method for transporting, deploying, and retrieving arrays having nodes interconnected by sections of cable

InactiveUS7036601B2Tight windingEasy to unwindSurveyDrilling rodsEngineeringElectrical and Electronics engineering

Owner:WEATHERFORDLAMB

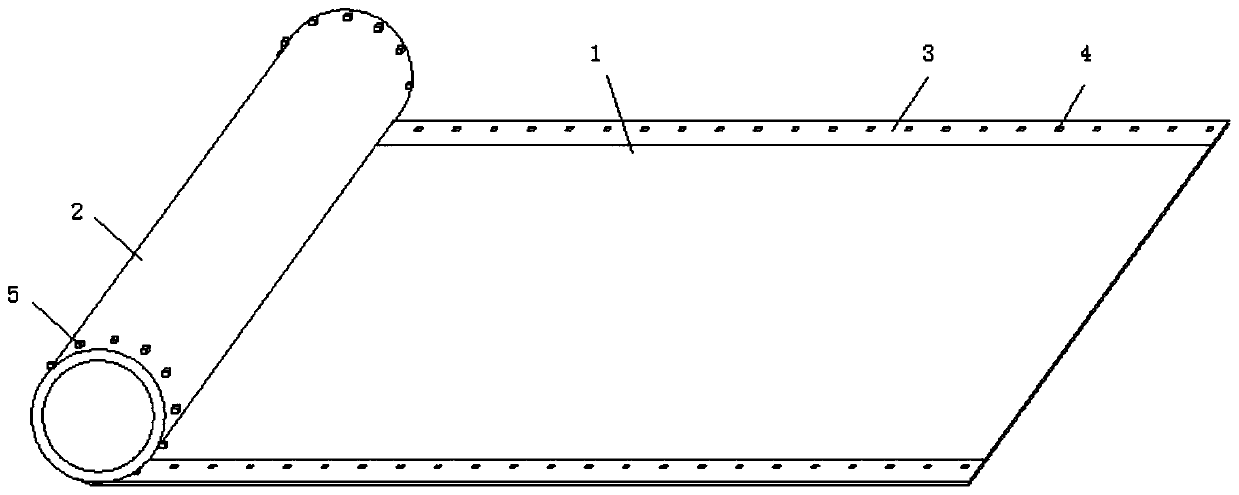

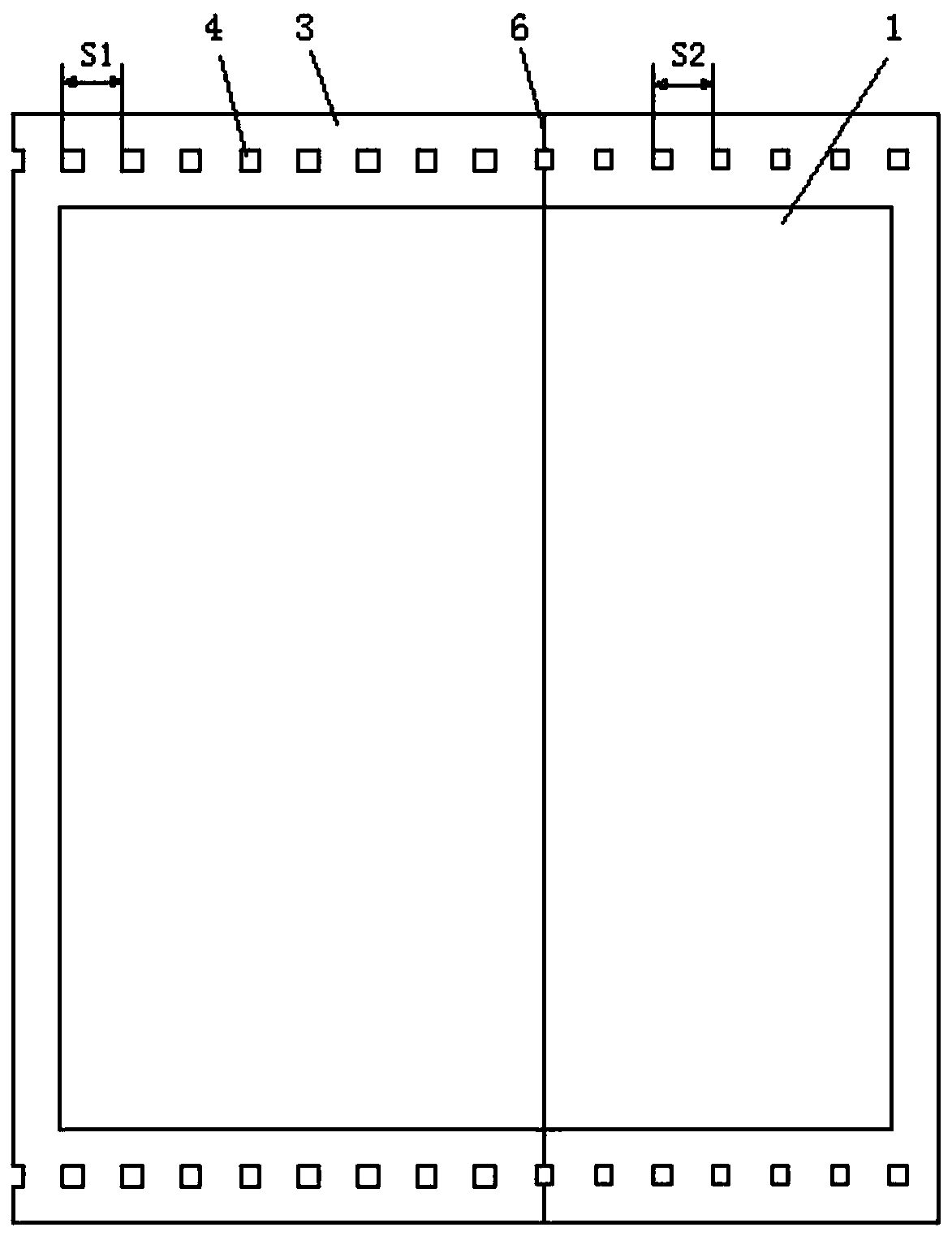

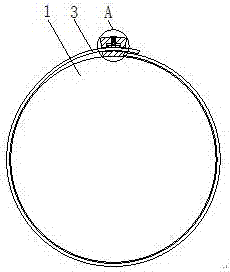

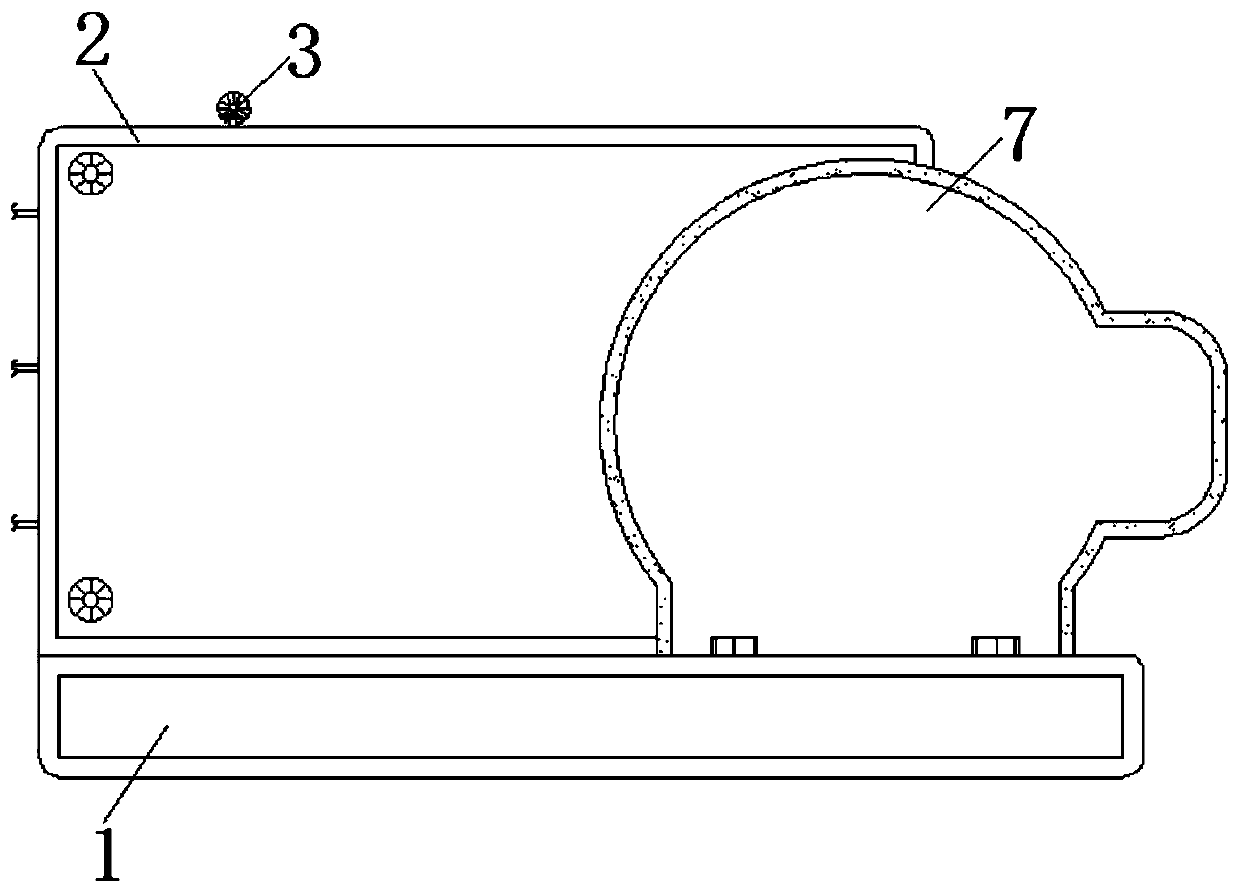

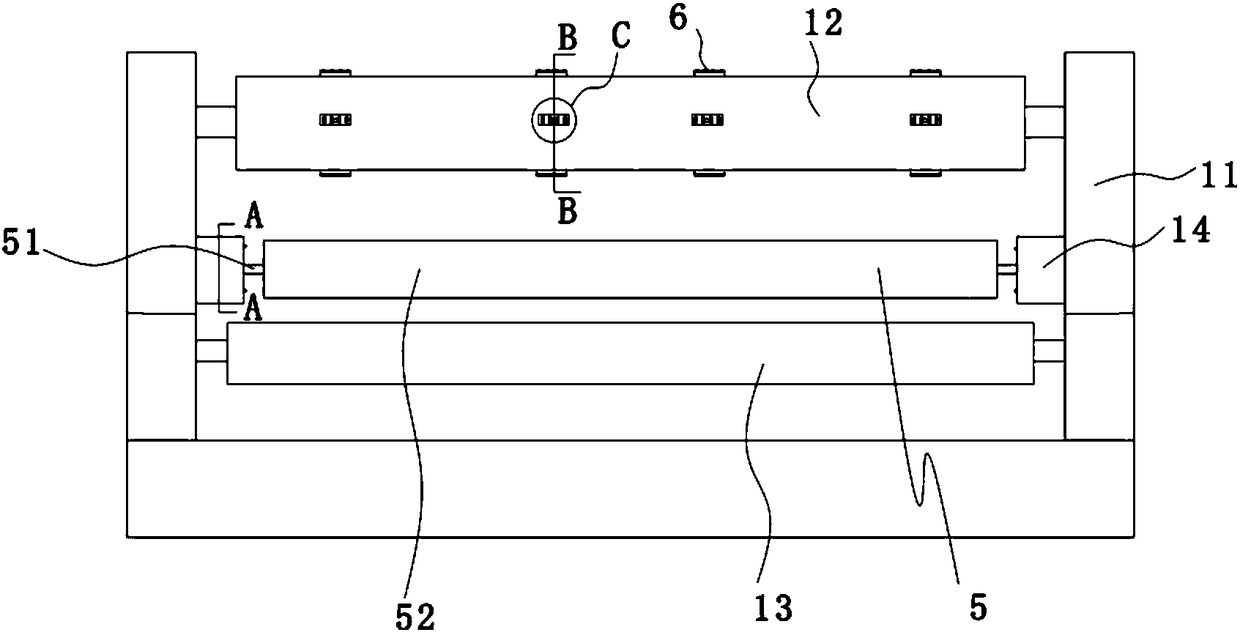

Rollable display device

ActiveCN109872639AEffective protectionTight windingDigital data processing detailsCasings with display/control unitsFlexible displayDislocation

The invention discloses a rollable display device, and relates to the technical field of display. The problems are solved that when a flexible display screen is rolled, the edge of the flexible display screen is prone to dislocation and damage, and loosening easily occurs after rolling. According to the technical scheme, the device includes a flexible display panel, a reel, and support structures,wherein the reel is connected with one end of the flexible display panel, and the flexible display panel can be rolled up around the reel and spread, the support structures are arranged on the edgesof the two sides of the flexible display panel in the rolling direction, and first fixation parts are arranged on the support structures; the reel is provided with second fixation parts matched with the first fixation parts, and the second fixation parts are used for fixing the support structures and the reel when the flexible display panel is rolled up.

Owner:BOE TECH GRP CO LTD

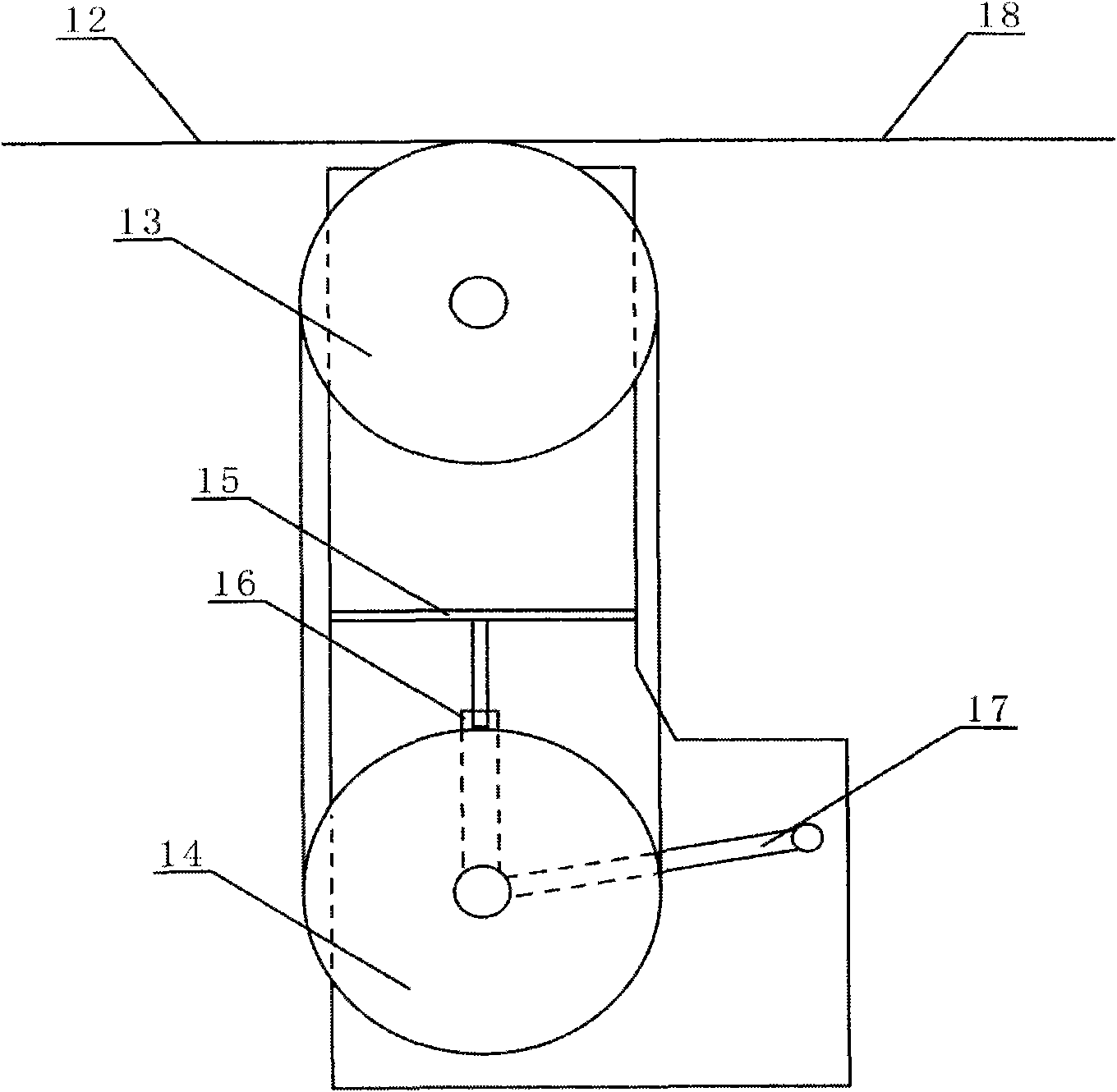

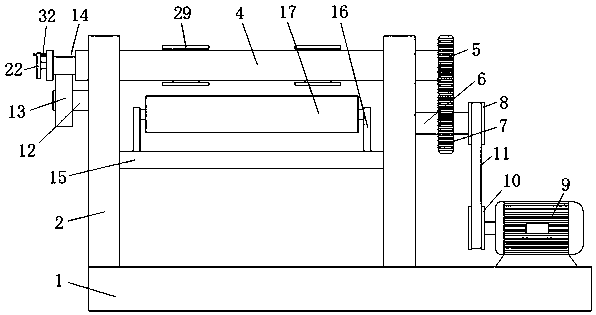

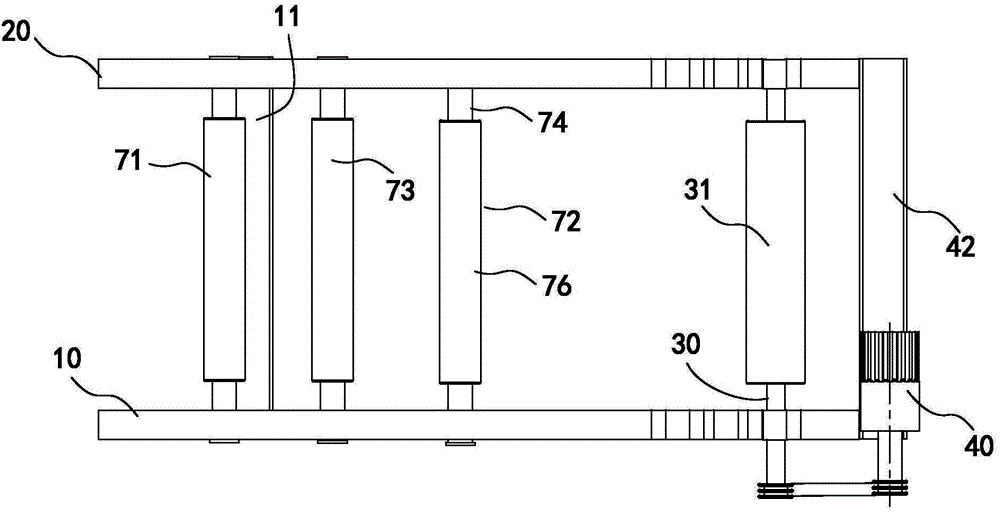

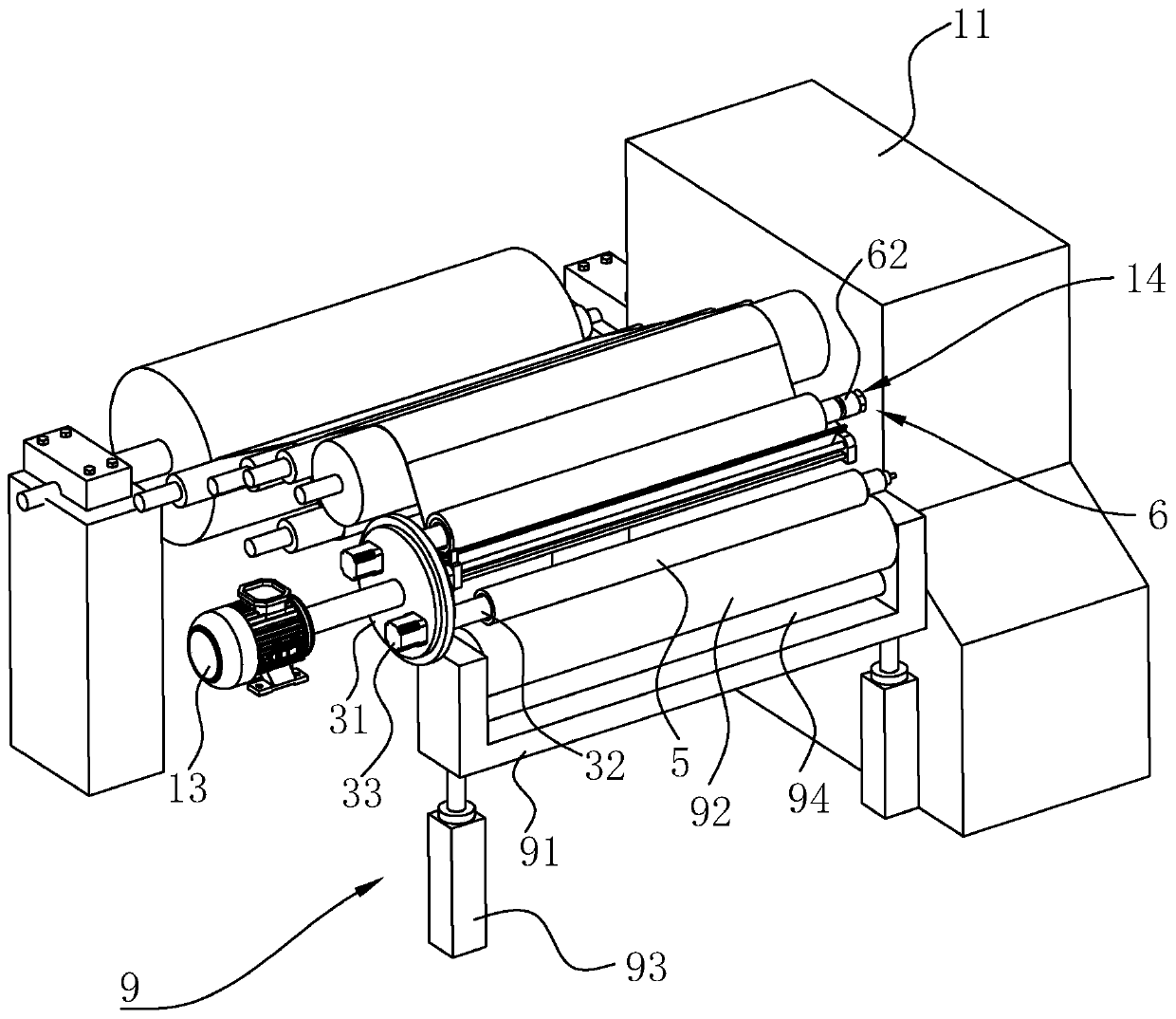

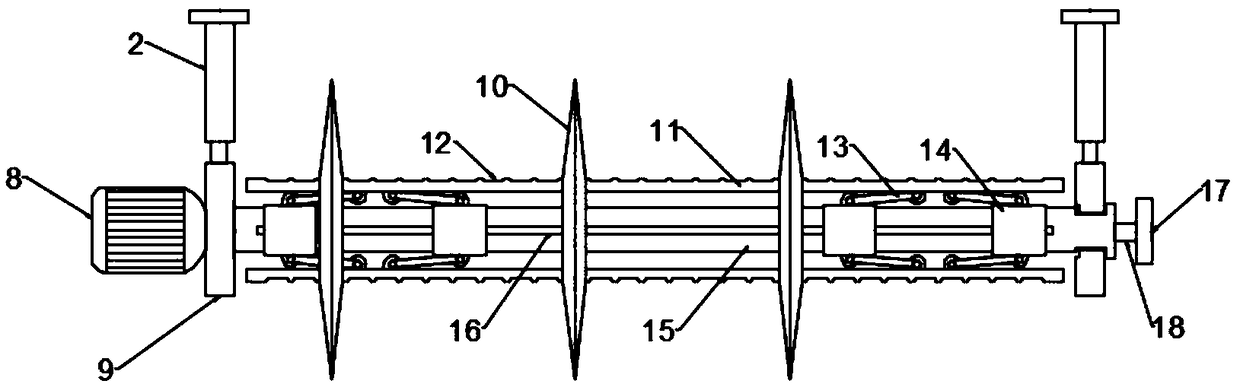

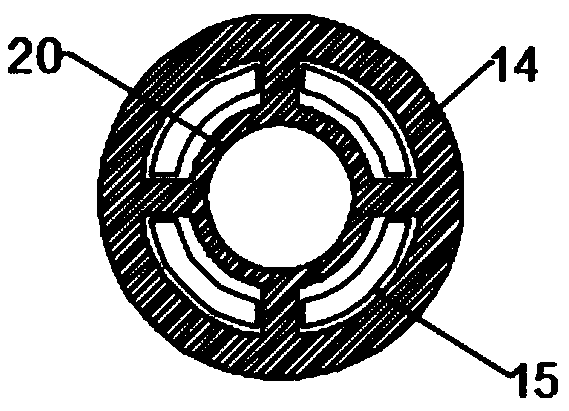

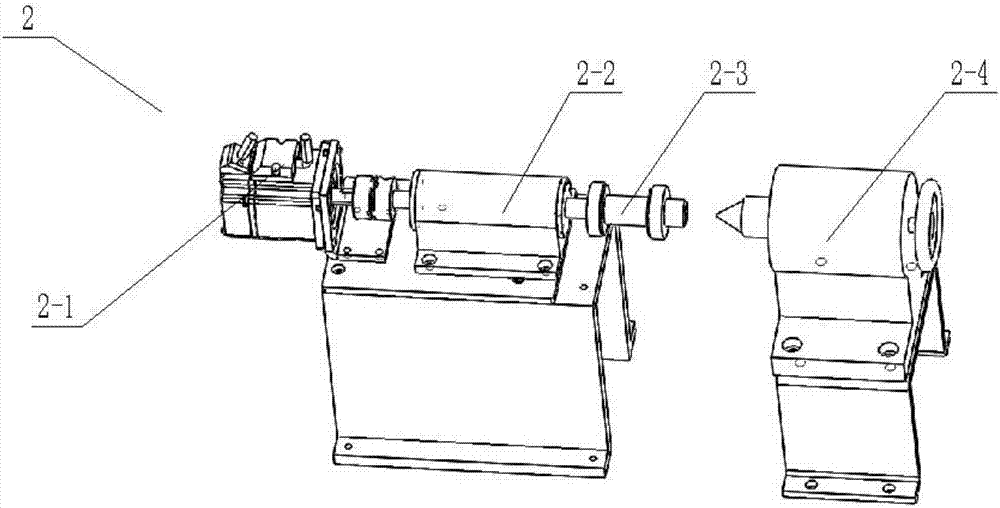

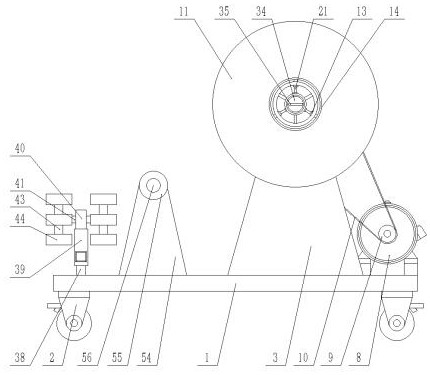

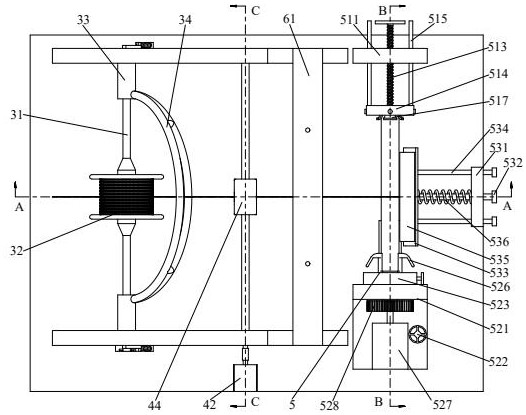

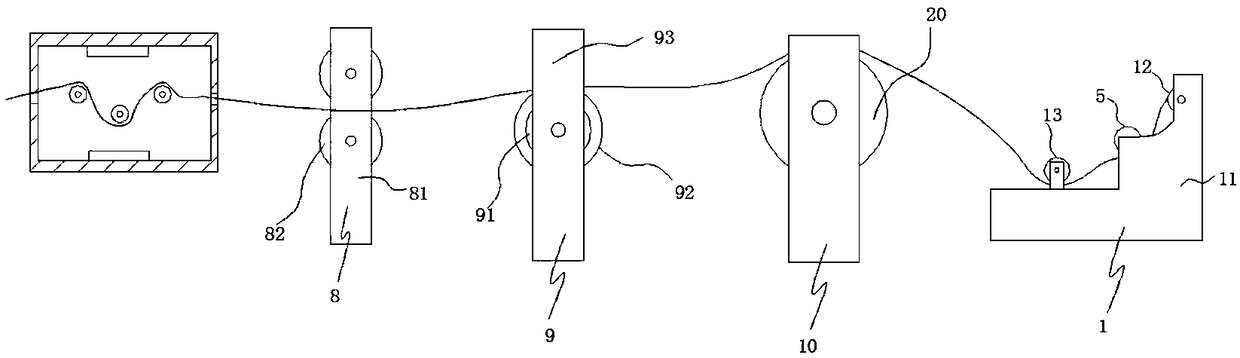

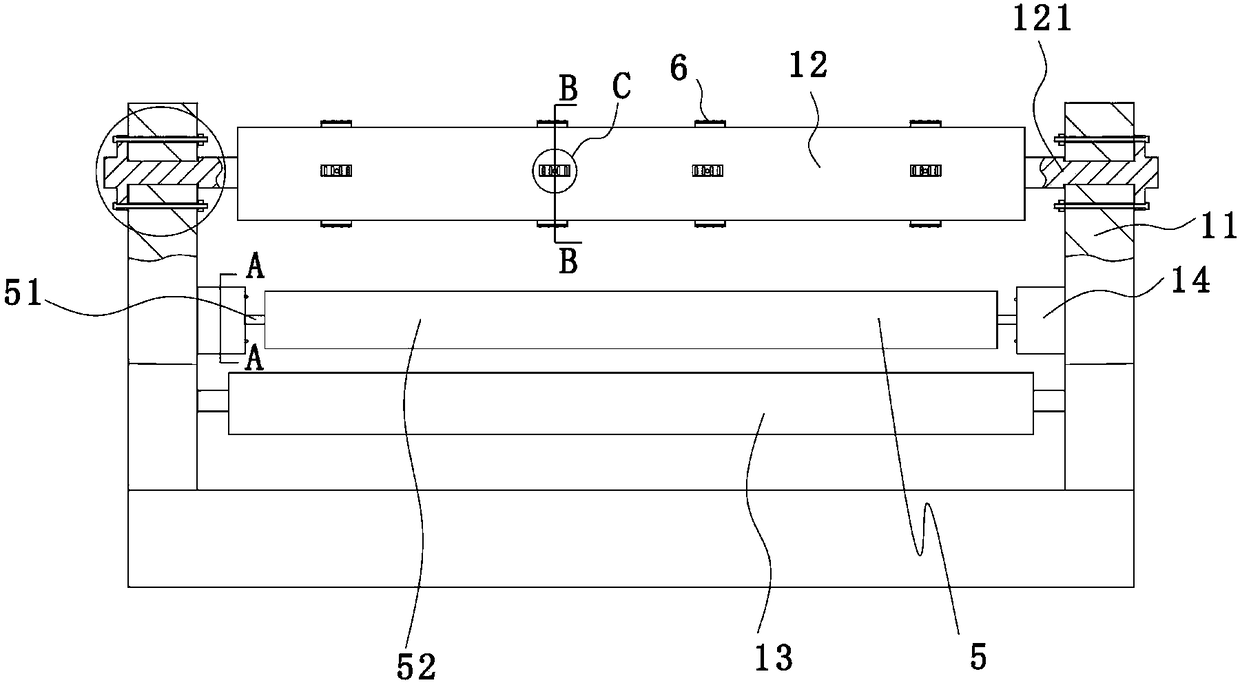

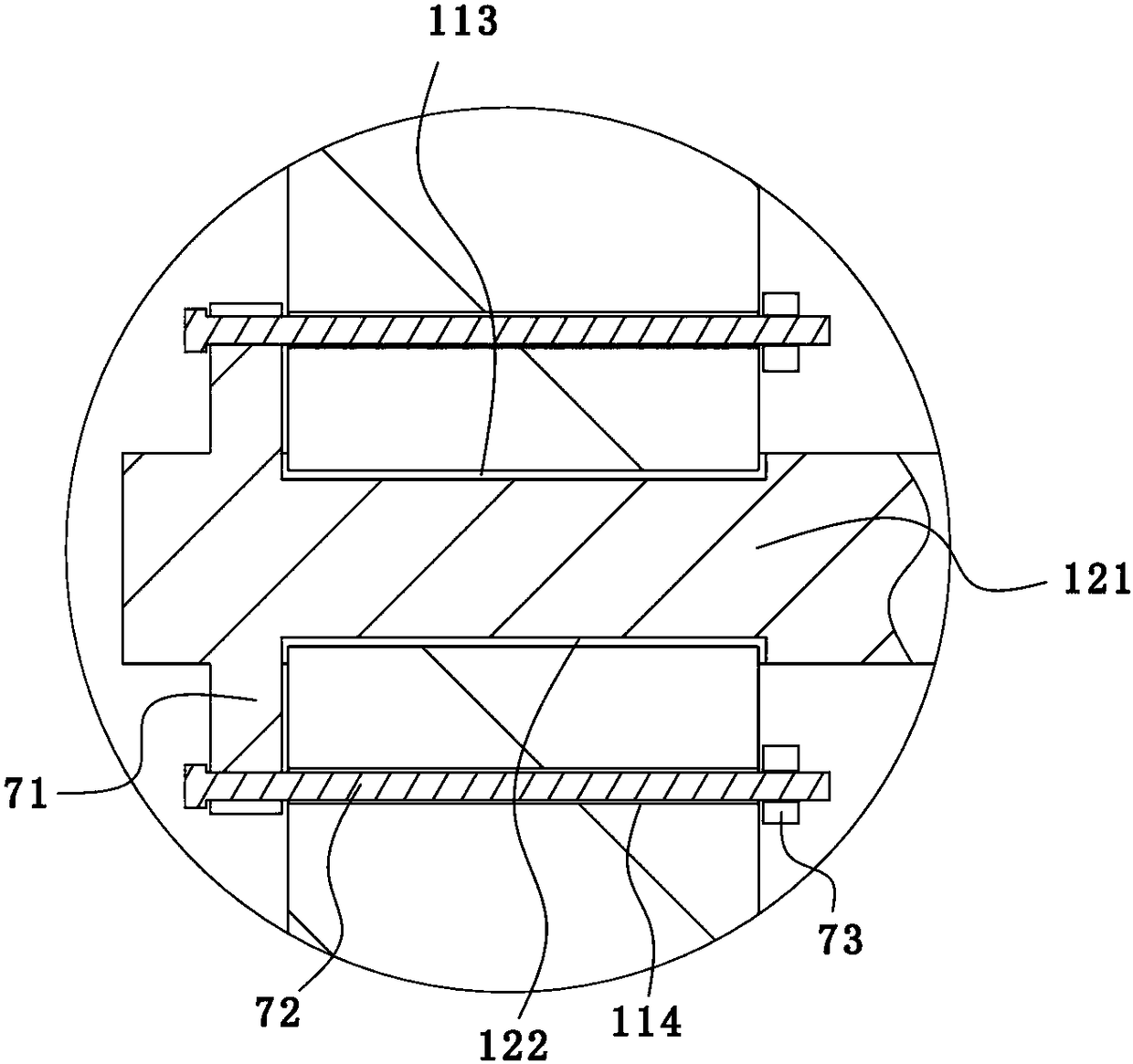

Active wire paying-off rewinder of aluminum clad steel wires

The invention discloses an active paying-off rewinder of aluminum clad steel wires. The rewinder is characterized by comprising an active paying-off mechanism, a tension mechanism and an automatic wire arranging and taking-up mechanism, wherein the aluminum clad steel wire grail tool of the active paying-off mechanism of the rewinder is driven by a motor to realize uniform wire paying-off; an upper tension pulley of the tension mechanism is fixed on a rack, and a lower tension pulley of the tension mechanism is jointly supported by a pneumatic cylinder and a lower tension pulley support; under the action of the pneumatic cylinder and aluminum clad steel wire tension, the tension pulley is used for adjusting the aluminum clad steel wire tension by vertical movement; and the automatic wire arranging and taking-up mechanism is characterized in that a wire arranging seat rotating shaft, a wire arranging seat guide rail, a movable mandril and a fixed mandril are arranged between two fixed supports; the wire arranging seat rotating shaft is provided with a wire arranging seat and a wire arranging seat driving wheel; the wire arranging seat guide rail is provided with two stop pins for playing a limit role; the movable mandril and the fixed mandril are respectively connected with the grail tool in a splicing mode; the fixed mandril is provided with a grail tool driving wheel, a brake pad and a driven wheel; and the driven wheel is connected with the wire arranging driving wheel which is arranged on the wire arranging seat rotating shaft by a driving belt. Therefore, the product quality is ensured, the production efficiency is improved and the labor intensity is reduced.

Owner:HENAN TONG CABLE

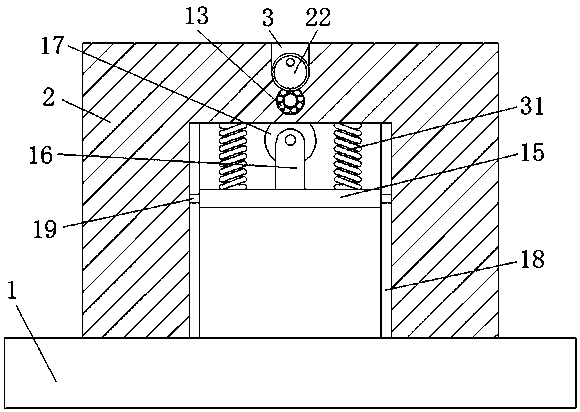

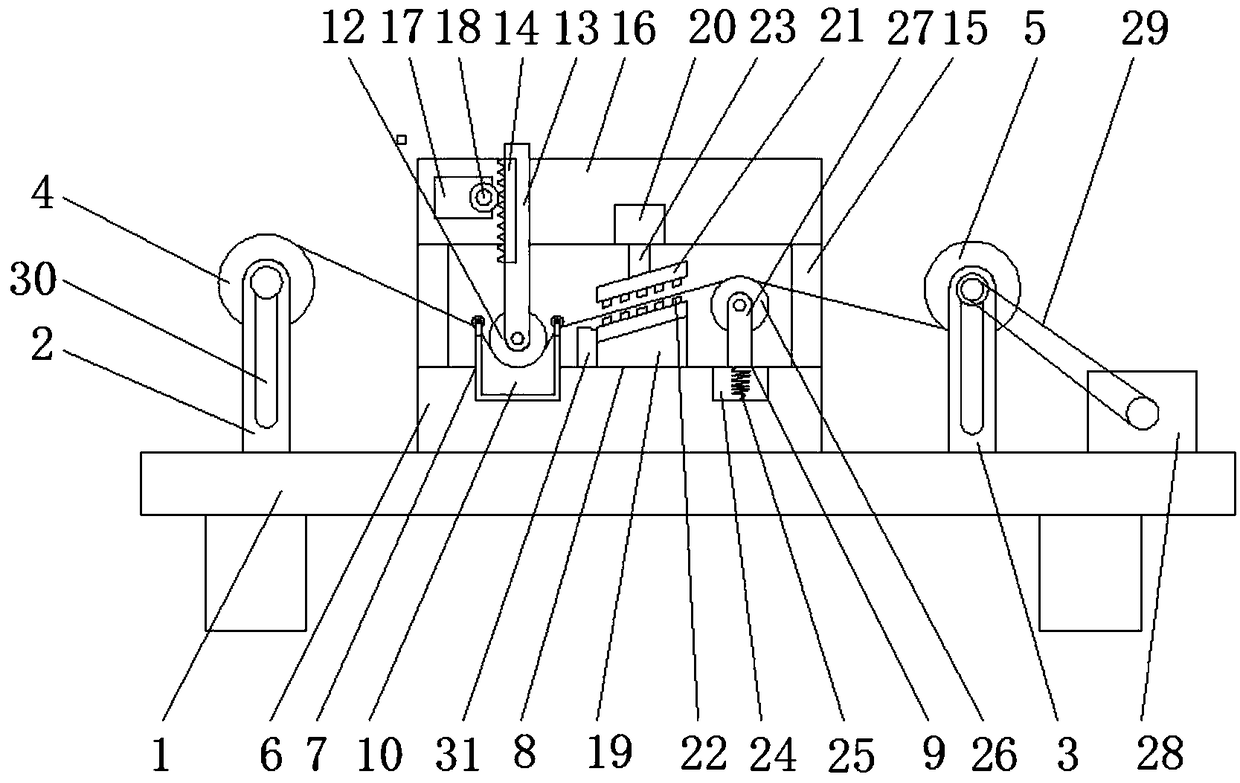

Coiling device applied to textile machinery

The invention discloses a coiling device applied to a textile machinery. The coiling device comprises a pedestal; the upper surface of the pedestal is vertically, symmetrically and fixedly connected with supporting plates; each supporting plate is of a reversed-U-shaped structure; the middle parts of the top ends of the two supporting plates are each provided with an accommodating groove; each accommodating groove is internally provided with a coiling roller; one end of each coiling roller is fixedly connected with a first gear; corresponding to the lower portion of the first gear, one side ofone supporting plate is rotationally connected with a fixing rod; the fixing rod is fixedly connected with a second gear; the second gear is engaged with the first gears; the side, corresponding to the second gear, of the fixing rod is fixedly connected with a first belt disc; the side, corresponding to one side of one supporting plate, of the upper surface of the pedestal is fixedly connected with a motor; and the output end of the motor is fixedly connected with a second belt disc. The coiling device disclosed by the invention prevents the phenomena that fabrics are coiled not closely, areeasily loosened and are not in order, is convenient to use, is also used for conveniently fixing a hard paper coiling cylinder, is simple to mount and dismount and improves the work efficiency.

Owner:安徽双盈纺织有限公司

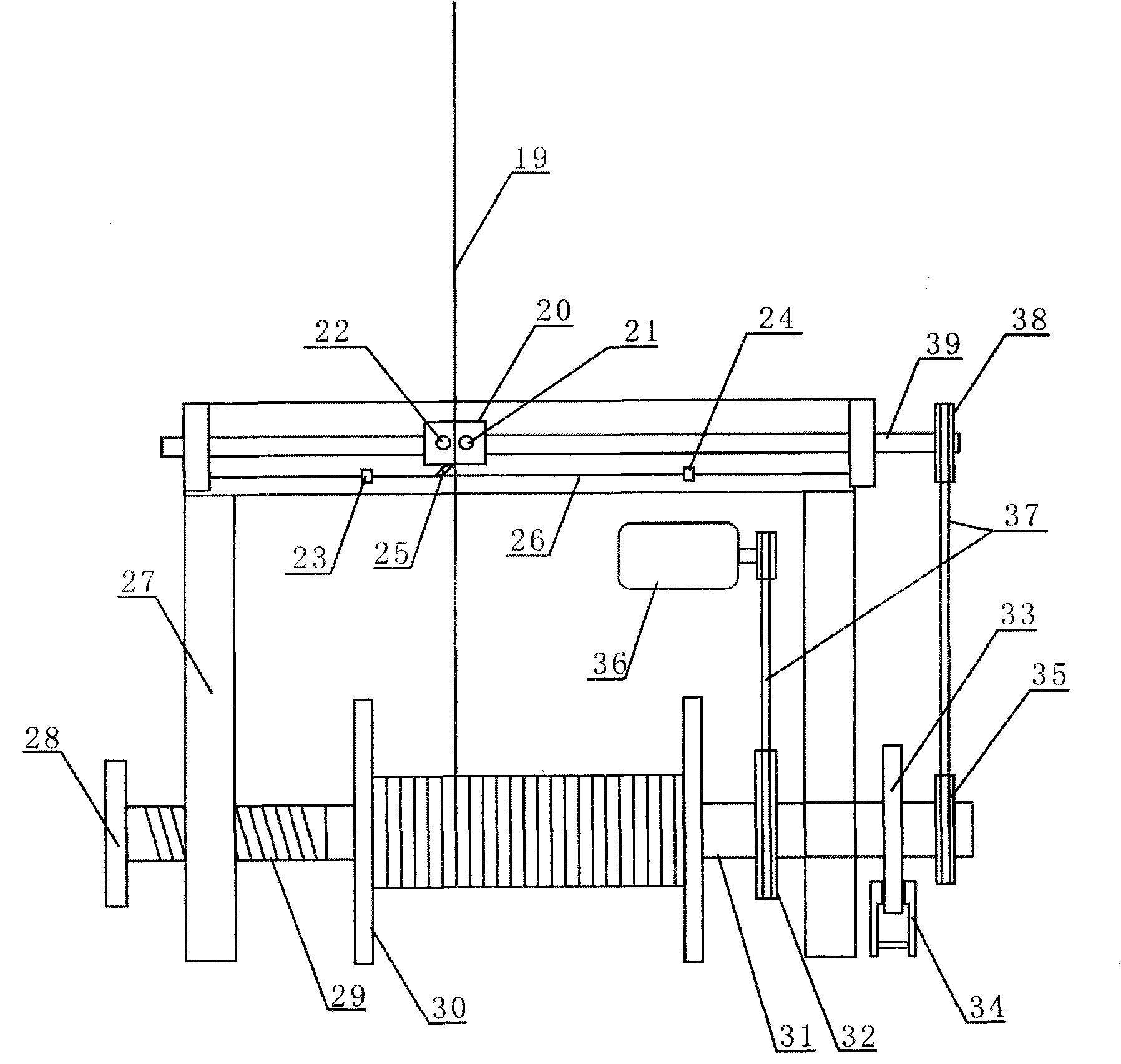

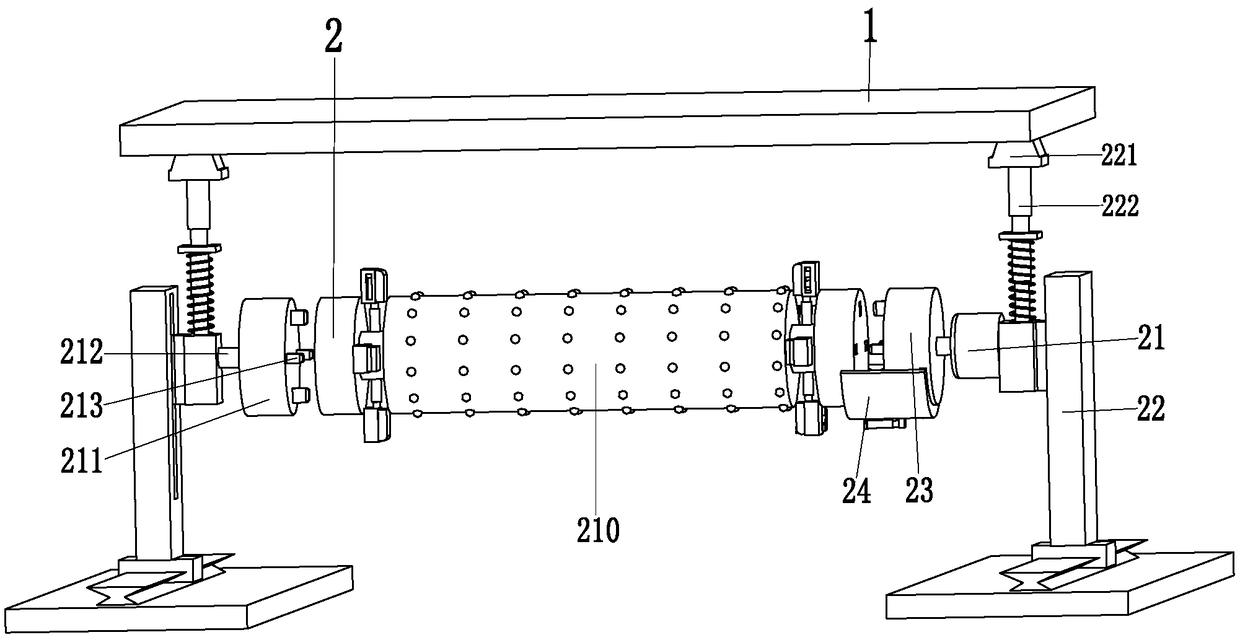

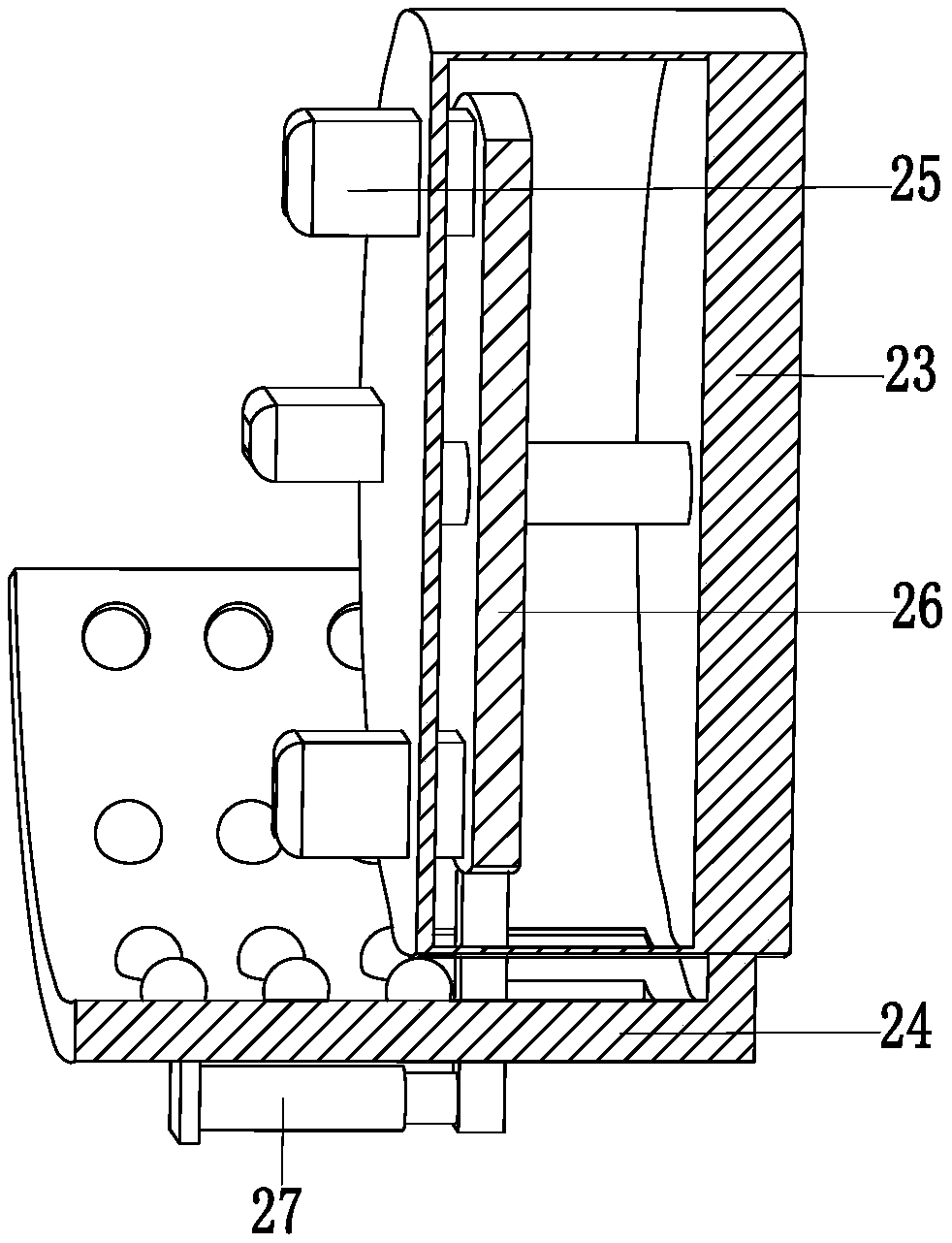

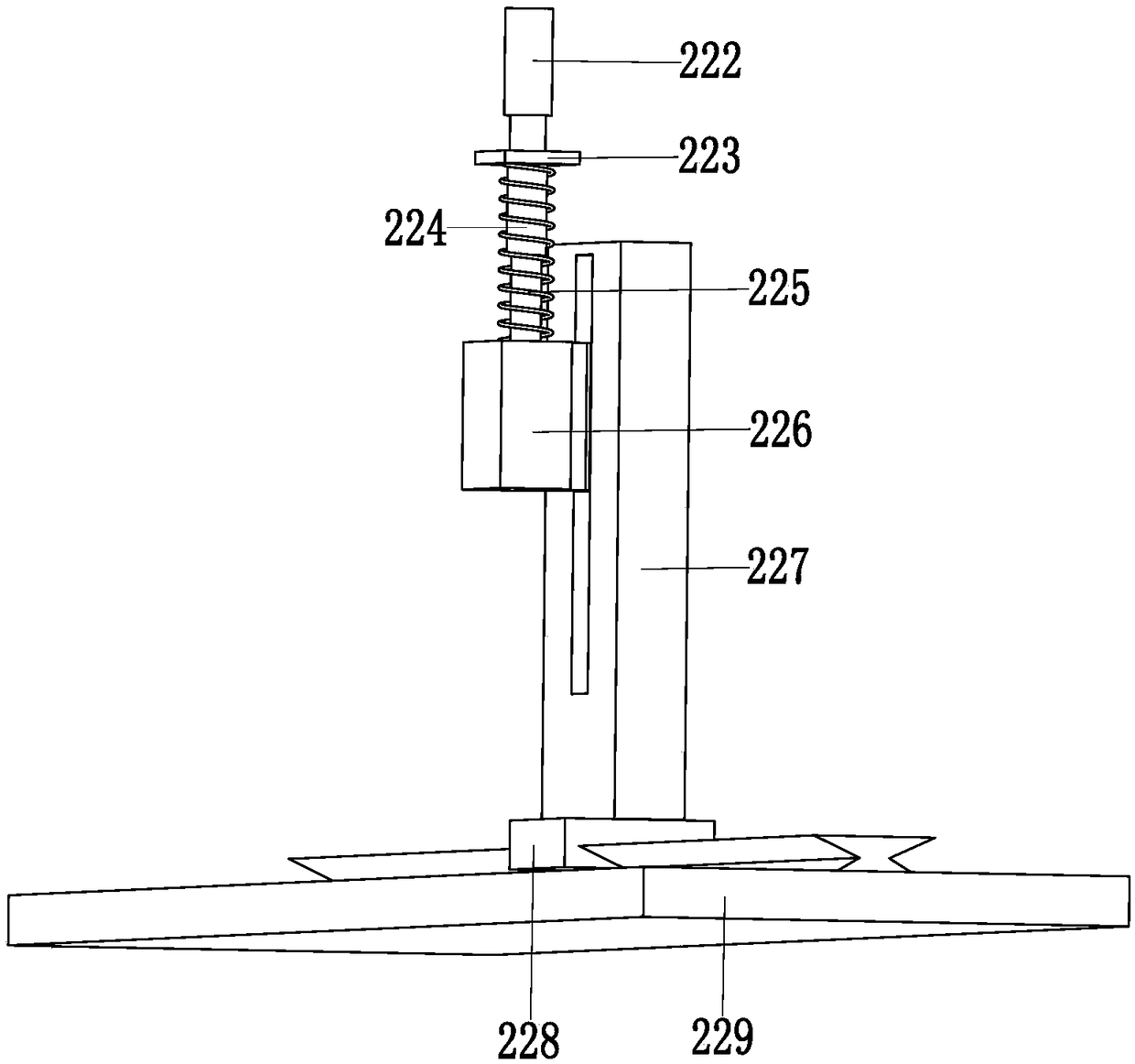

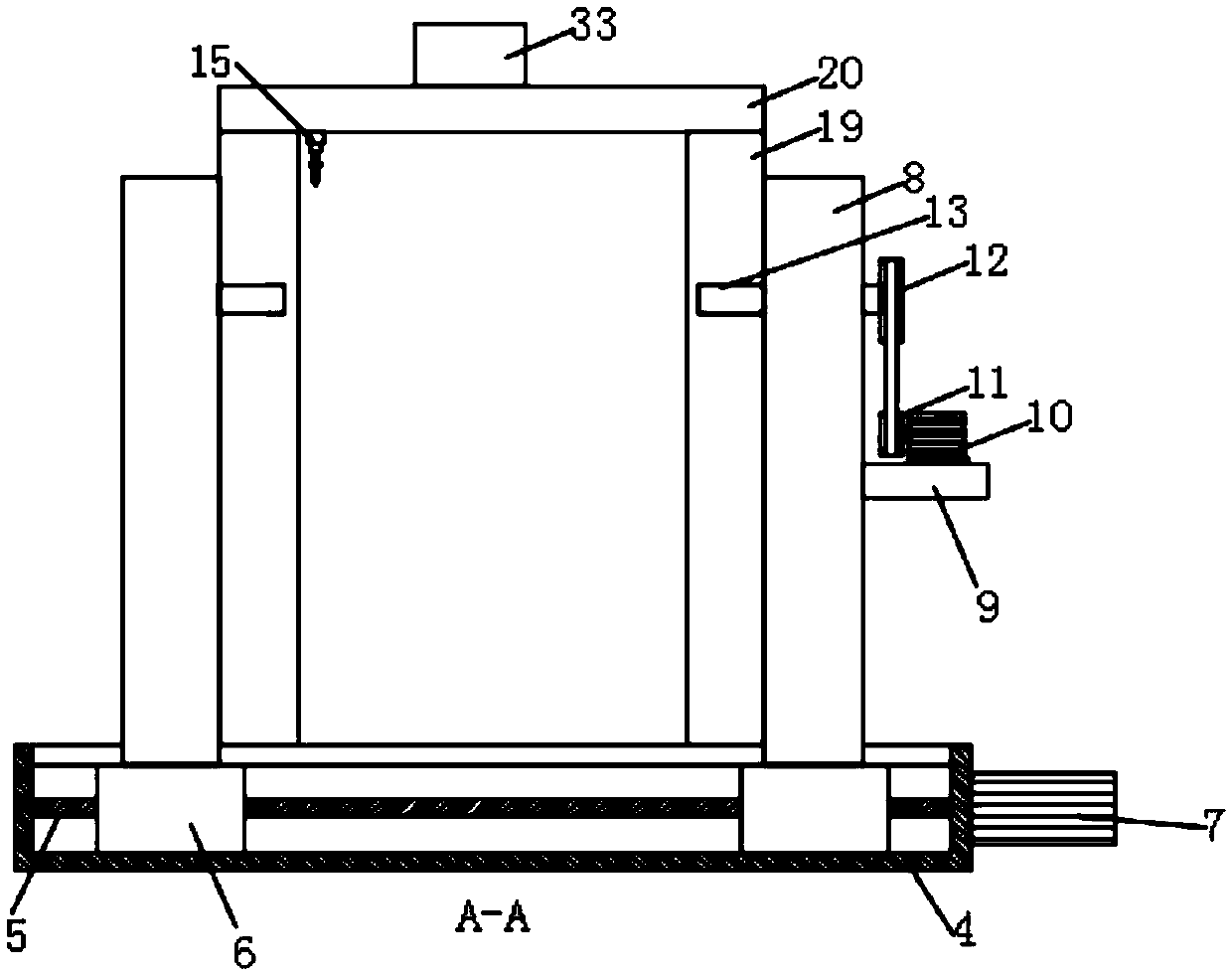

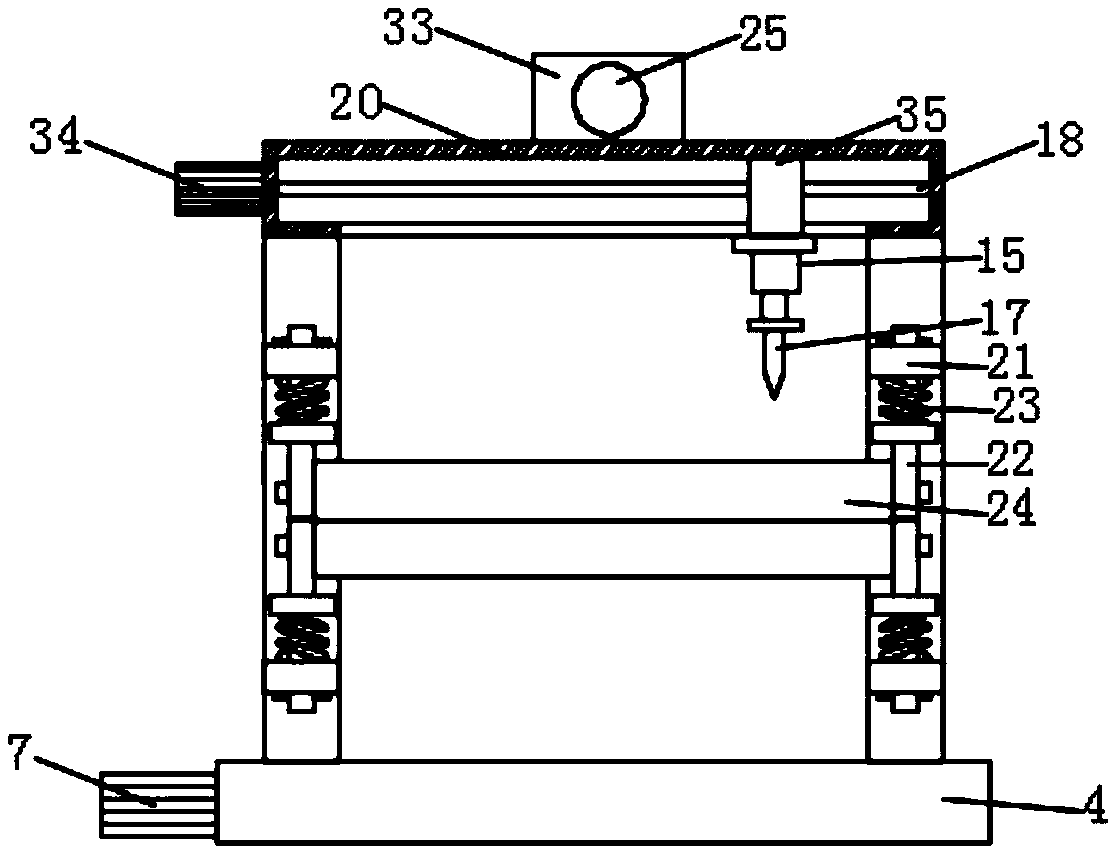

Automatic casting aluminum plate winding robot

The invention relates to an automatic casting aluminum plate winding robot. The automatic casting aluminum plate winding robot comprises a supporting top plate and a winding device, sliding grooves are formed in the left and right ends of the bottom of the supporting top plate, and the winding device is mounted at the lower end of the middle portion of the supporting top plate. The winding devicecomprises a winding motor, moving mechanisms, a rotary roller, a rotary supporting seat, telescopic clamping blocks, a connecting clamping plate, a clamping plate push rod, a buckle mechanism, a winding wheel, a connecting wheel, a connecting rotary shaft, connecting clamping blocks and limiting branched chains. The moving mechanism each comprise moving connecting blocks, moving push rods, a moving connecting plate, a moving telescopic rod, a moving spring, a height slide object, a moving vertical plate, a moving electric sliding block and a moving supporting plate. The automatic casting aluminum plate winding robot can solve the problems that labor intensity is high, the working efficiency is low, aluminum plate winding is relatively cluttered, aluminum plate winding is not tight and an aluminum plate is difficult to take down from a winding rod after winding during existing casting aluminum plate winding.

Owner:江苏铭鹏机械设备有限公司

Multifunctional winder

The invention discloses a multifunctional winder. The multifunctional winder comprises a base, a tripod, a bearing, a rotating rod, a winding frame, a toothed groove, a mounting rod, an upper gear, a lower gear, a rocking handle and a locking device. Compared with the prior art, the winder can be locked, so that the winding tightness and efficiency are both improved, convenience is brought to textile processing, and the multifunctional winder is simple in structure and convenient to operate, apply and popularize.

Owner:HANGZHOU AOKE GARMENT ACCESSORIES

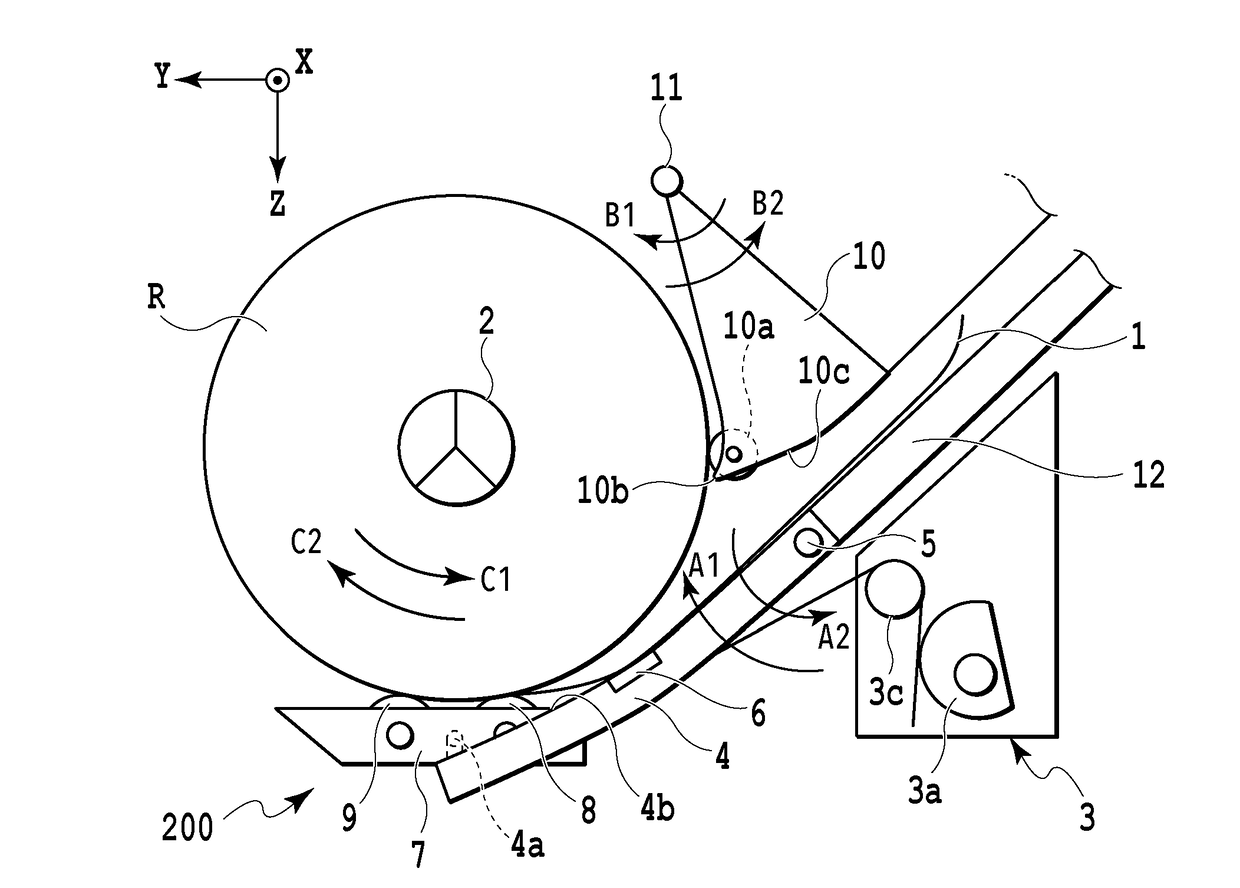

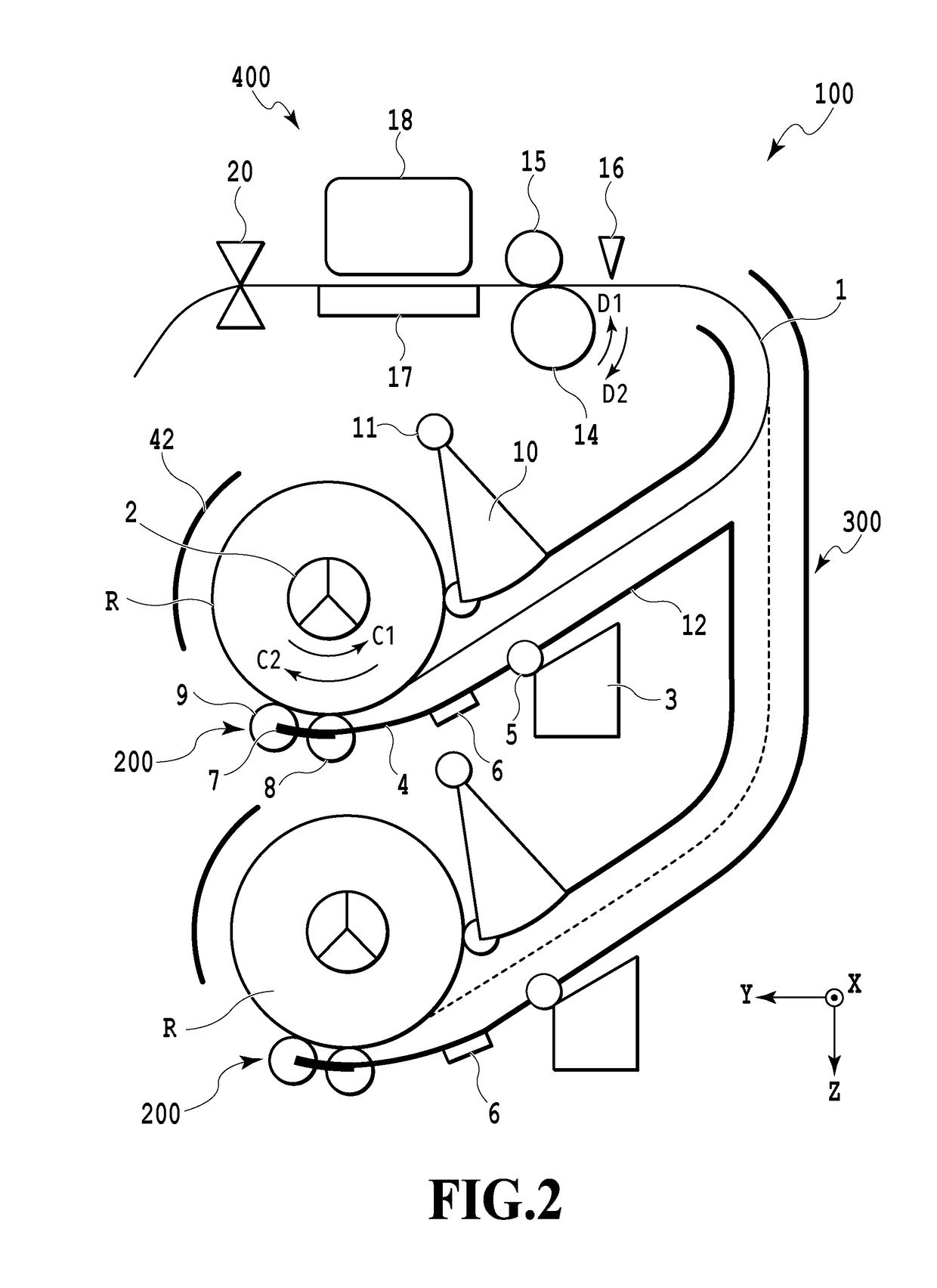

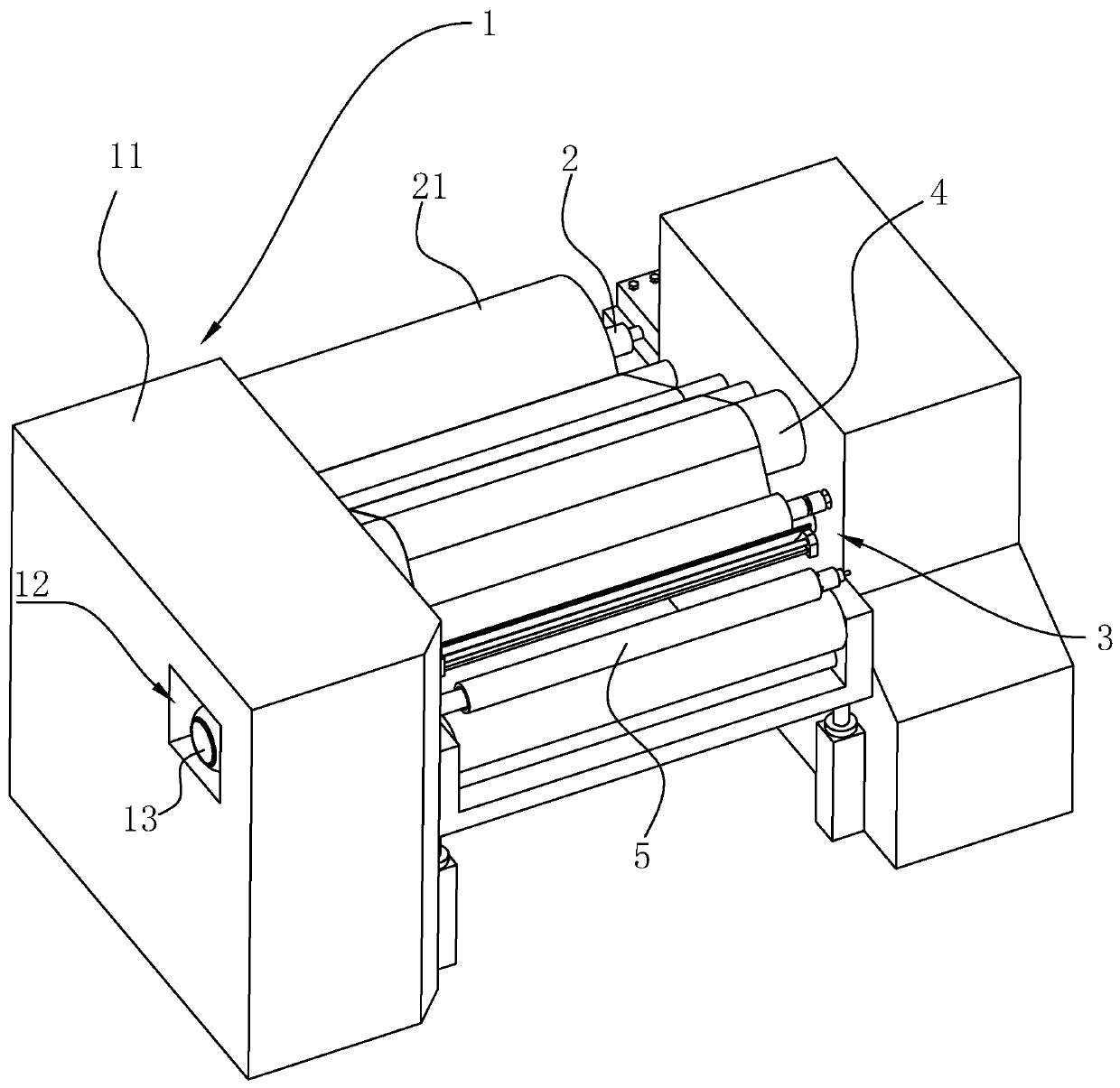

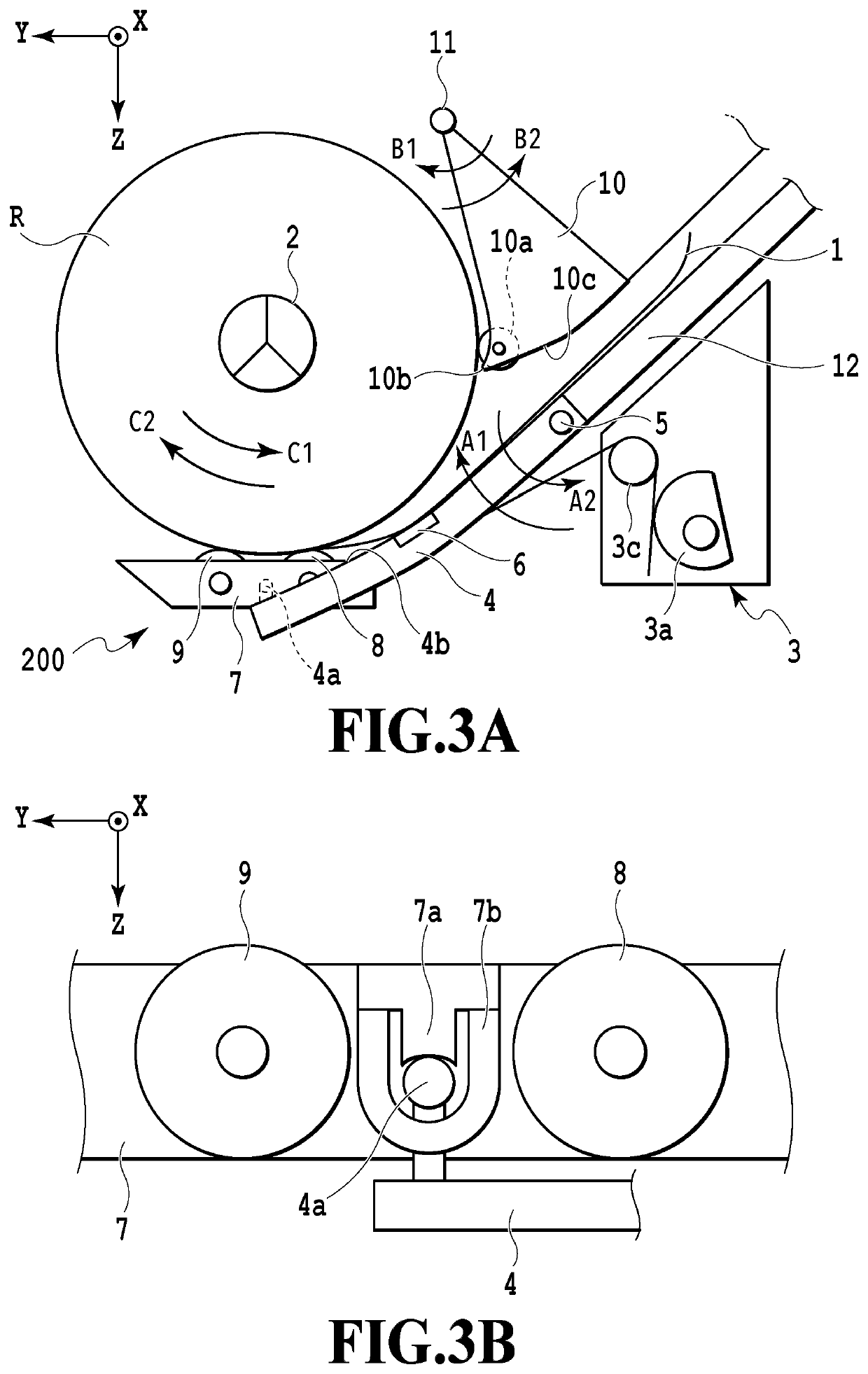

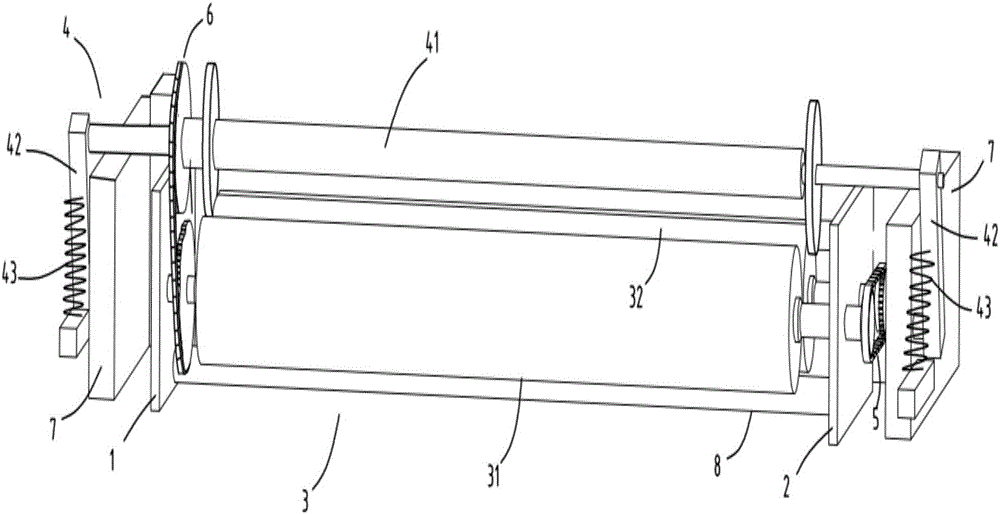

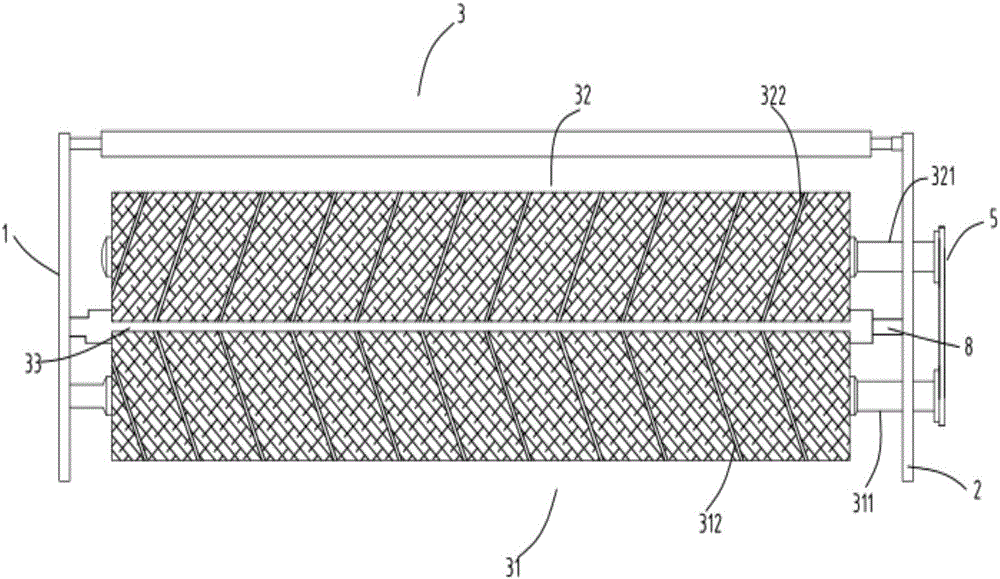

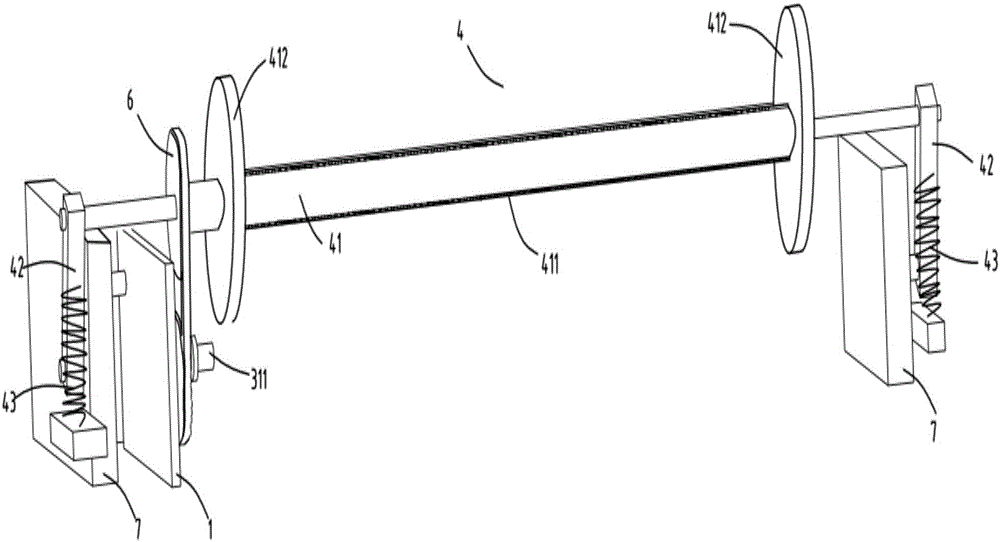

Sheet supplying apparatus and printing apparatus

ActiveUS20180257893A1Tight windingFunction indicatorsOther printing apparatusEngineeringContinuous rotation

Owner:CANON KK

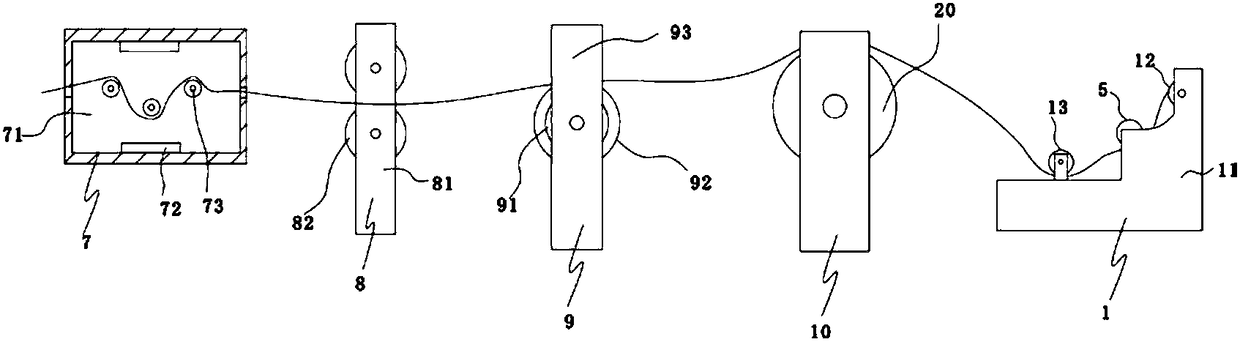

Yarn lubricating conveying device

The invention discloses a yarn lubricating conveying device which comprises a workbench. The workbench is provided with a first support and a second support; the first support is provided with an unwinding roller; the second support is provided with a winding roller; and a base is arranged between the first support and the second support. A lubricating mechanism, a cleaning mechanism and a tensioning mechanism are sequentially arranged on the base in the conveying direction of yarns. The lubricating mechanism comprises a lubricating material groove, two yarn ejecting rollers and lubricating rollers. The cleaning mechanism comprises a benchboard, a second motor and a pressing plate, and cleaning brushes are evenly distributed on the benchboard. The tensioning mechanism comprises a groove, aspring and a transitional roller which are arranged on the base, and a winding motor is arranged on the side, away from the base, of the second support. An output shaft of the winding motor is sleeved with a belt, and the other end of the belt is arranged at one end of the winding roller in a sleeving mode. According to the yarn lubricating conveying device, the yarns can be fully lubricated, redundant lubricants on the yarns can be removed, and the yarns can be more tidy and cleaner in the winding process.

Owner:XIANGSHUI YONGTAI TEXTILE GARMENT CO LTD

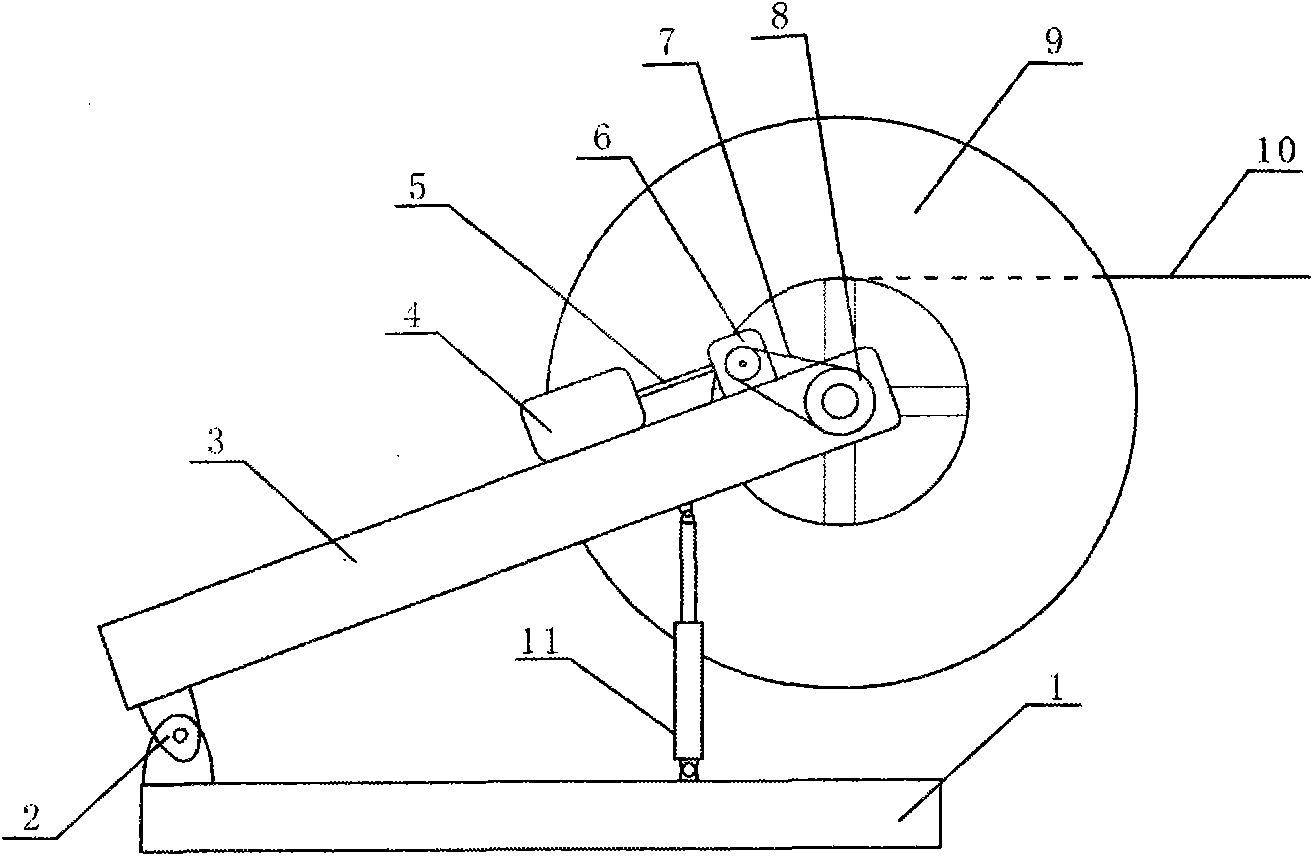

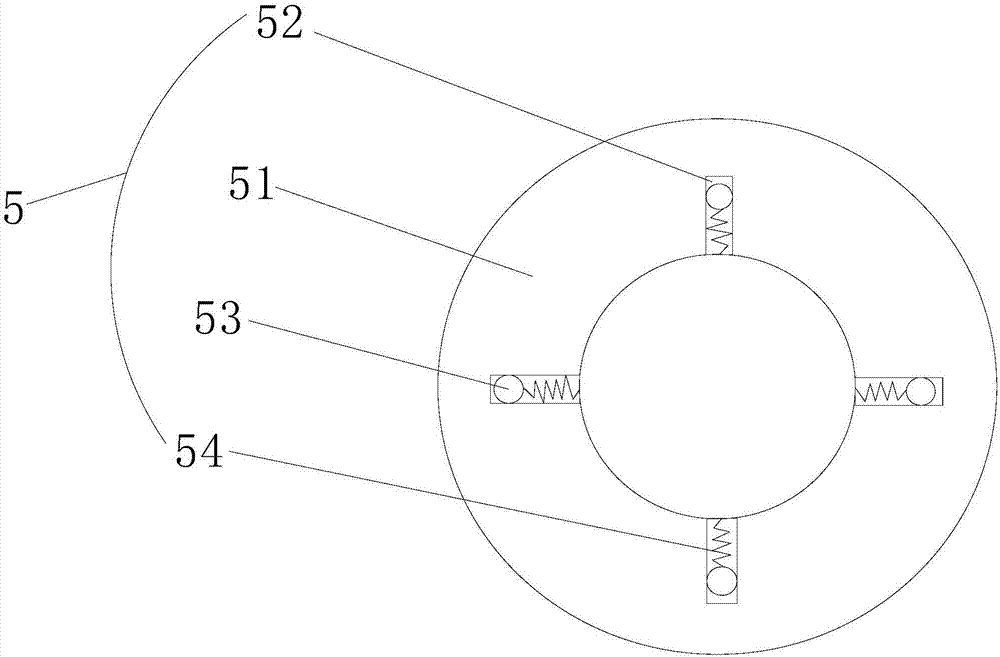

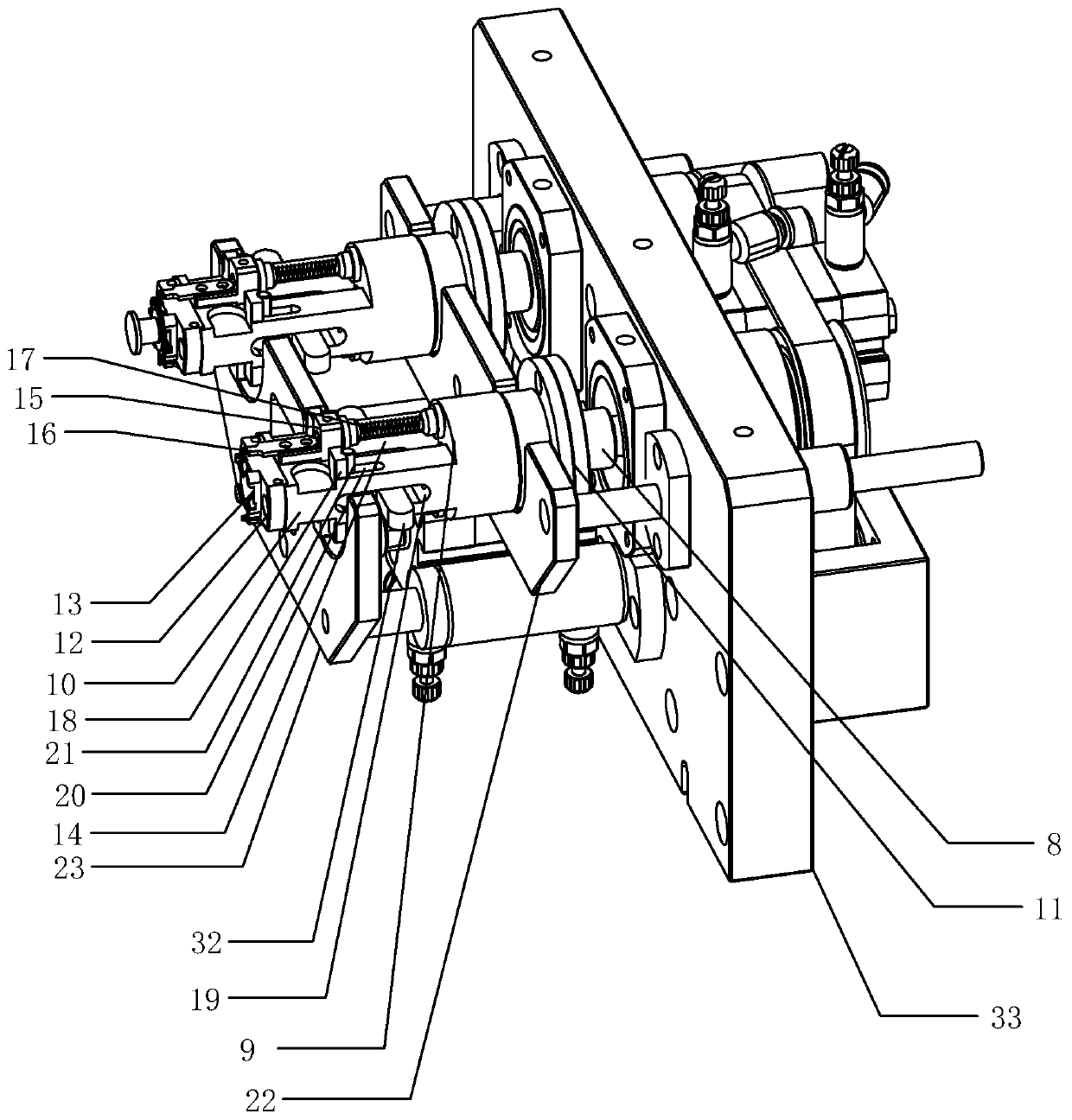

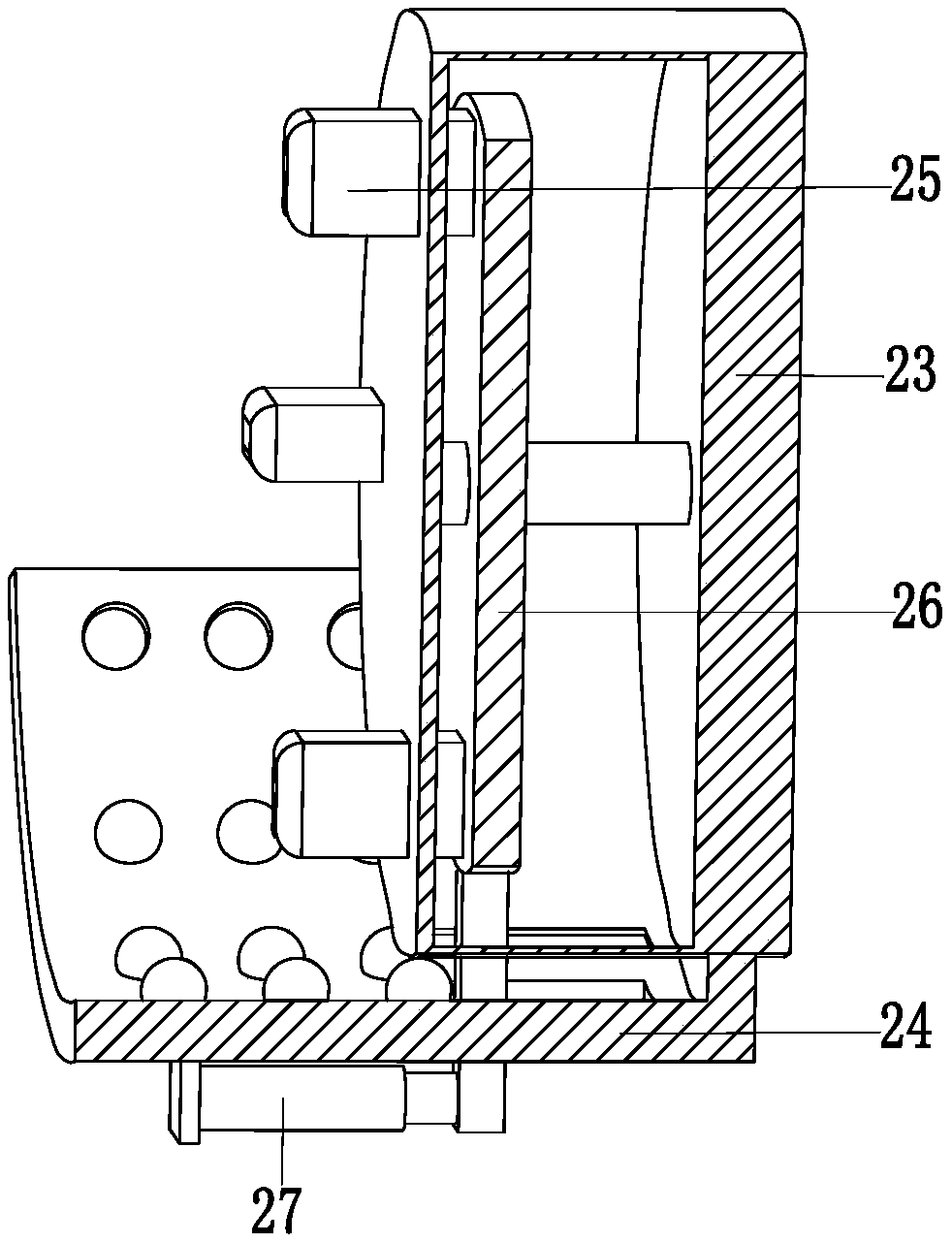

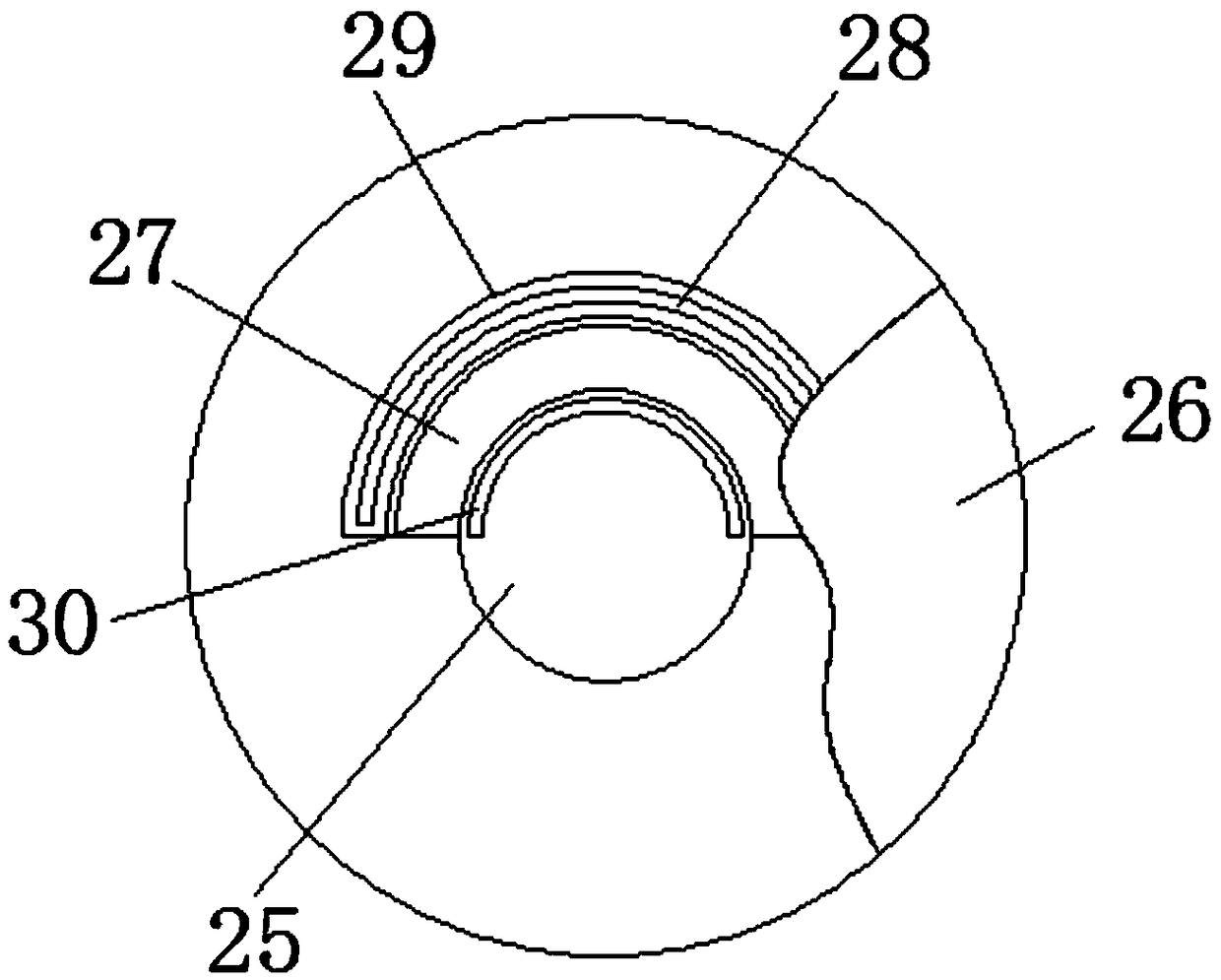

Evaporating pipe winding rotary table with pipe locking mechanism

InactiveCN105344770ATight windingAvoid human assistanceHeat exchange apparatusEngineeringRotary stage

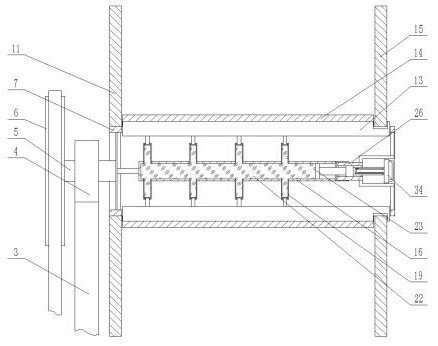

The invention discloses an evaporating pipe winding rotary table with a pipe locking mechanism. The evaporating pipe winding rotary table comprises a base, a rotary table body, a mold mounting mechanism and the pipe locking mechanism. The rotary table body is arranged on the base and connected with a rotating drive mechanism. The rotary table body is driven by the rotating drive mechanism to rotate on the horizontal plane around the vertical axis. The mold mounting mechanism is used for fixing an inner container mold to the rotary table body. The pipe locking mechanism is arranged on the rotary table body and used for locking the tail end of an evaporating pipe on the outer wall of the inner container mold. The pipe locking mechanism comprises a horizontal movement drive air cylinder, a pipe locking column and a horizontal movement frame. The horizontal movement frame is erected on a linear guide rail and connected with a piston rod of the horizontal movement drive air cylinder. The horizontal movement frame can be driven by the horizontal movement drive air cylinder to move in the horizontal direction along the linear guide rail. The pipe locking column is arranged on the horizontal movement frame. The evaporating pipe can be bent for the first time by the pipe locking mechanism and locked on the inner container mold, and therefore evaporating pipe winding equipment does not need manual assistance when starting to work.

Owner:ANHUI KINGPOWER EQUIP & MOLD MFR

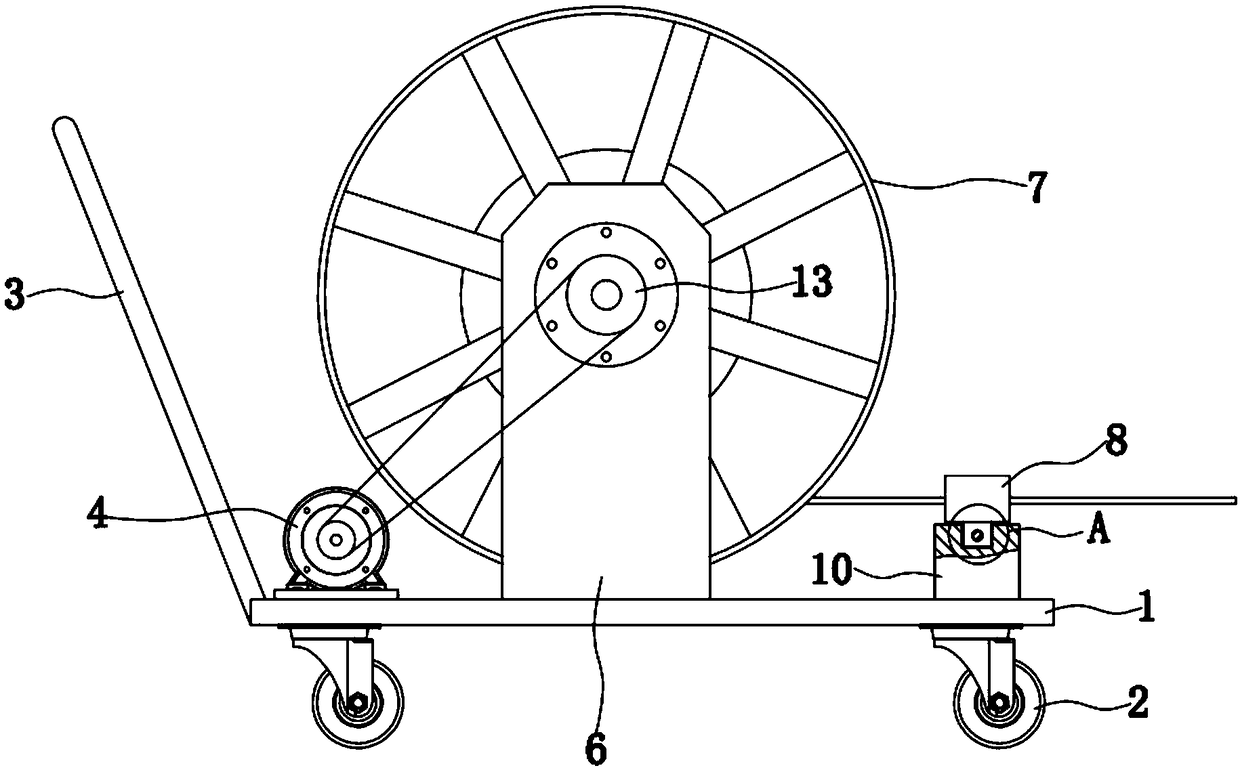

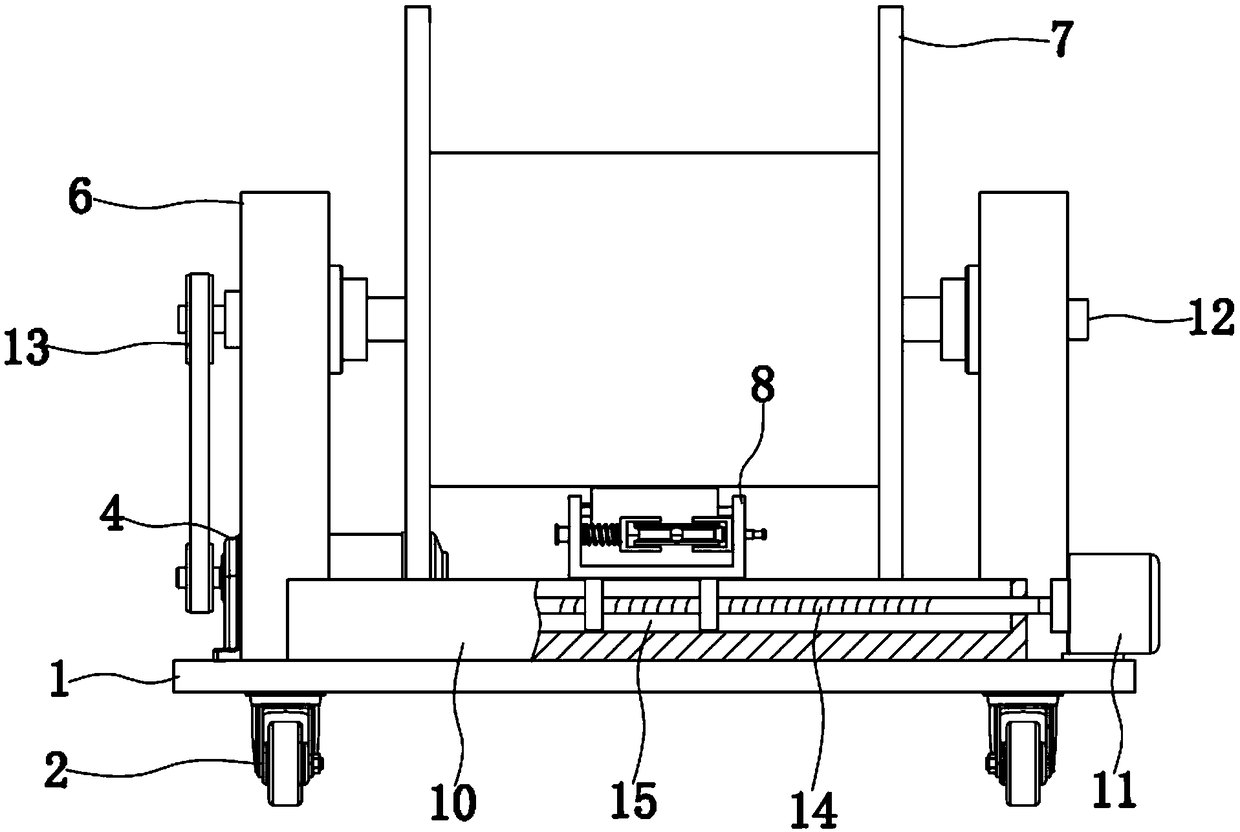

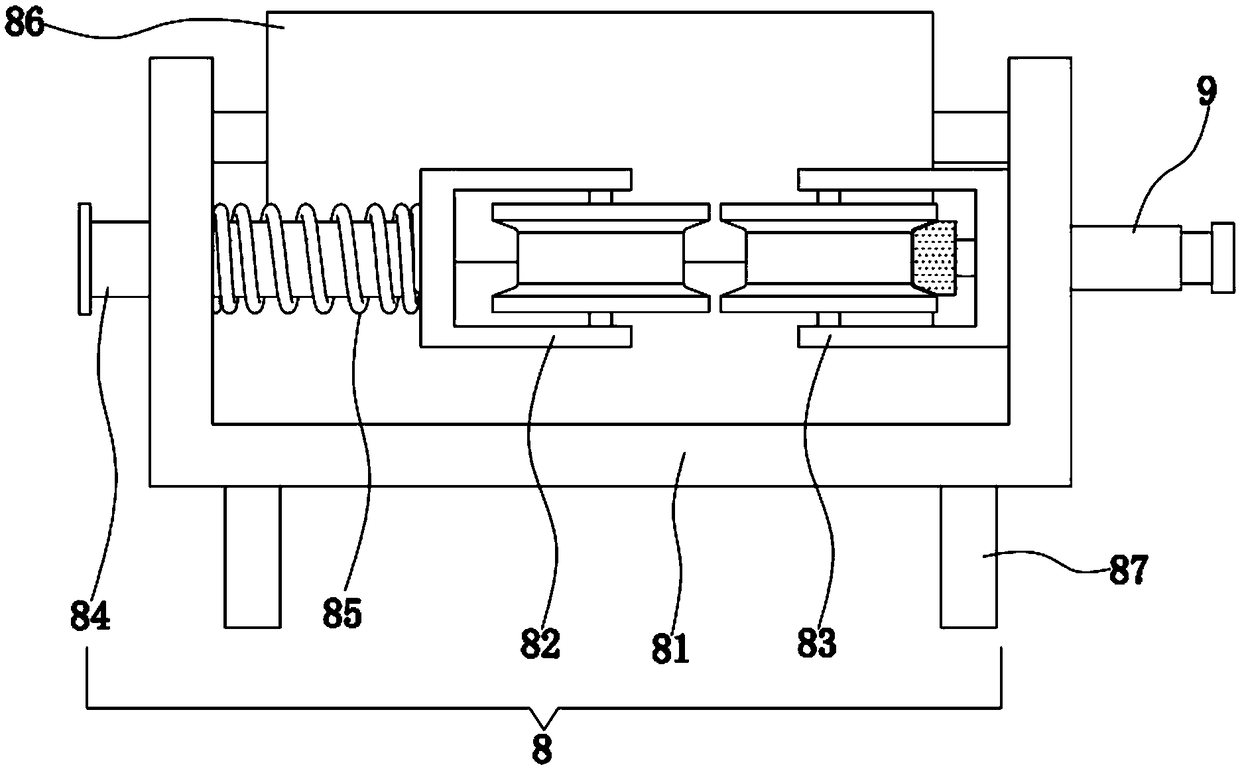

Winding and release device of communication engineering cable

The invention discloses a winding and release device of a communication engineering cable. The winding and release device comprises a base, and supporting pillars are mounted on the upper surface of the base; a rotating shaft is mounted between the two supporting pillars through bearings; the rotating shaft penetrates through the center of a winding wheel and is fixedly connected with the windingwheel; a first chain wheel is fixedly connected to the rotating shaft; a guide rail is mounted on the upper surface of the base; a sliding groove is formed in the guide rail; screw rods are rotatablyconnected to the two sides of the sliding groove; the screw rods are in threaded connection with mounting supporting lugs of the lower side of a guide mechanism; the guide mechanism comprises a U-shaped mounting base; a first guide wheel is mounted on the right side in the mounting base; a guide rod is connected to the left side of the mounting base in a sliding manner; a second guide wheel is fixedly connected to the right end of the guide rod; and a first spring is arranged on the guide rod in a sleeving manner. According to the winding and release device, a wound cable is compact and ordered and is prevented from being tangled, during cable release, the winding wheel driven by a first motor rotates reversely, operation is effort-saving and convenient, and efficiency is improved.

Owner:淮北市硕华机械设备有限公司

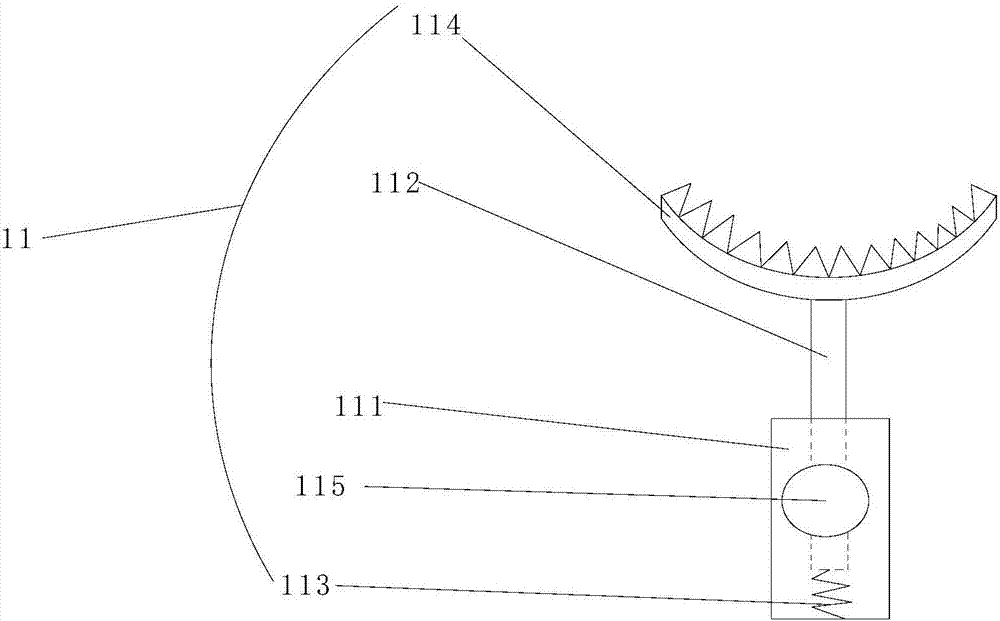

Rewinding machine

The invention discloses a rewinding machine, and belongs to paper sheet manufacturing equipment. The rewinding machine is characterized in that a winding assembly comprises a circular disc which is rotatably connected with support bases and two horizontal shafts which are rotatably connected with the circular disc, so that the circular disc and the horizontal shafts can be rotated along own axis;a first motor which can rotate the circular disc is arranged on one of the support bases; two second motors which can be used for separately driving the two horizontal shafts to be rotated are arranged on the circular disc; the winding assembly is also provided with a cutting assembly which can be used for cutting paper sheets; the cutting assembly comprises a horizontally-arranged rotating shaftand an arc plate which is fixedly connected with the rotating shaft; a third motor which can be used for driving the rotating shaft to be rotated is also arranged at one end of the rotating shaft; anda cutter which can do reciprocating motion in the length direction of the arc plate is arranged on the side wall, opposite to the rotating shaft, of the arc plate. By adopting the rewinding machine disclosed by the invention, the problem that the working efficiency is affected because of more troublesome replacement of a winding drum of a conventional rewinding machine is solved, and the effectsthat the winding drum can be quickly replaced and the working efficiency is improved are achieved.

Owner:武汉友发包装科技有限公司

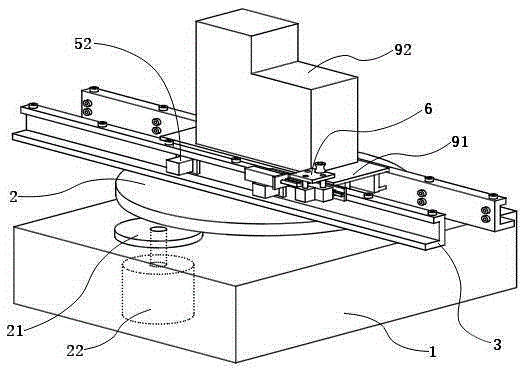

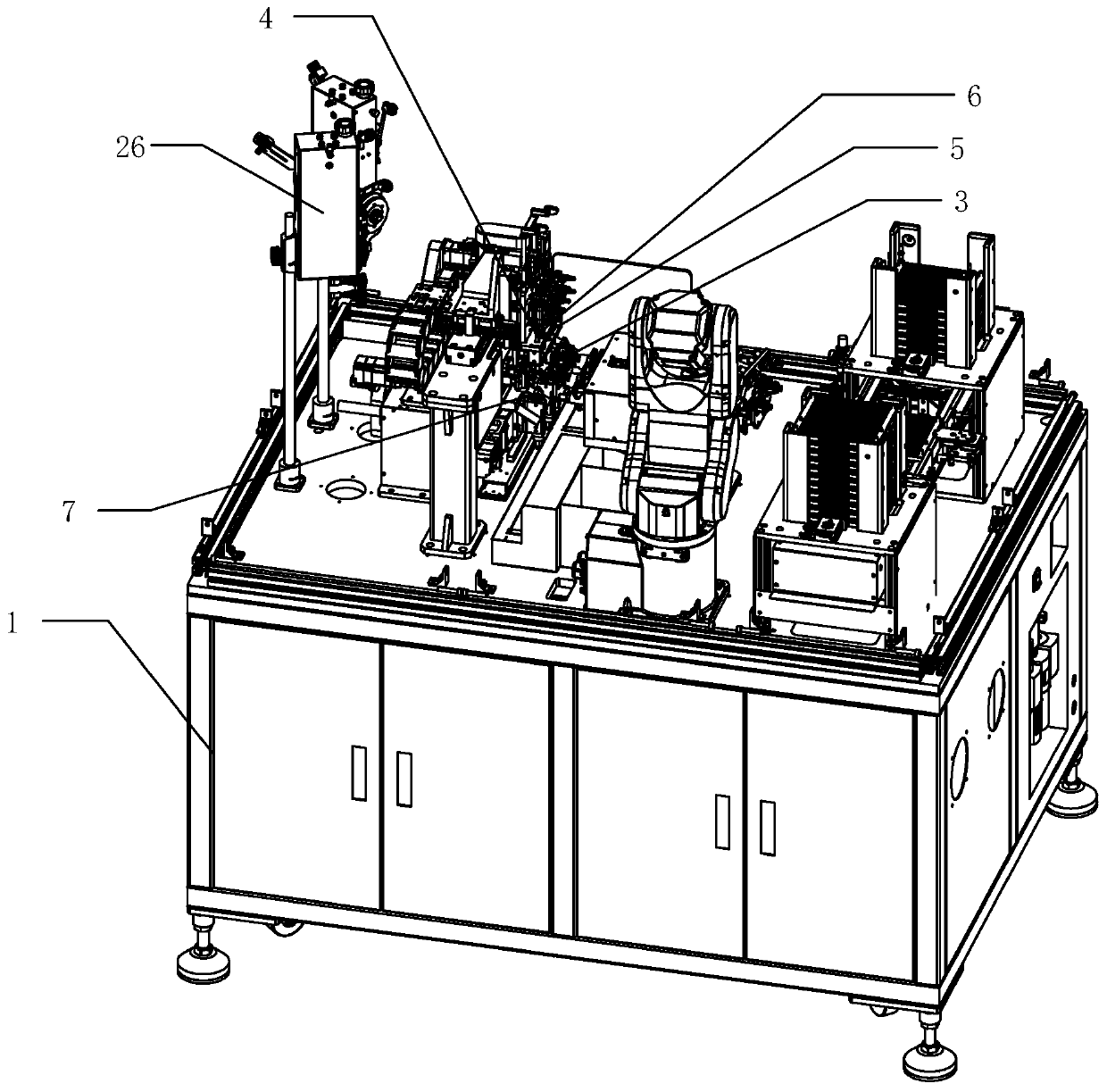

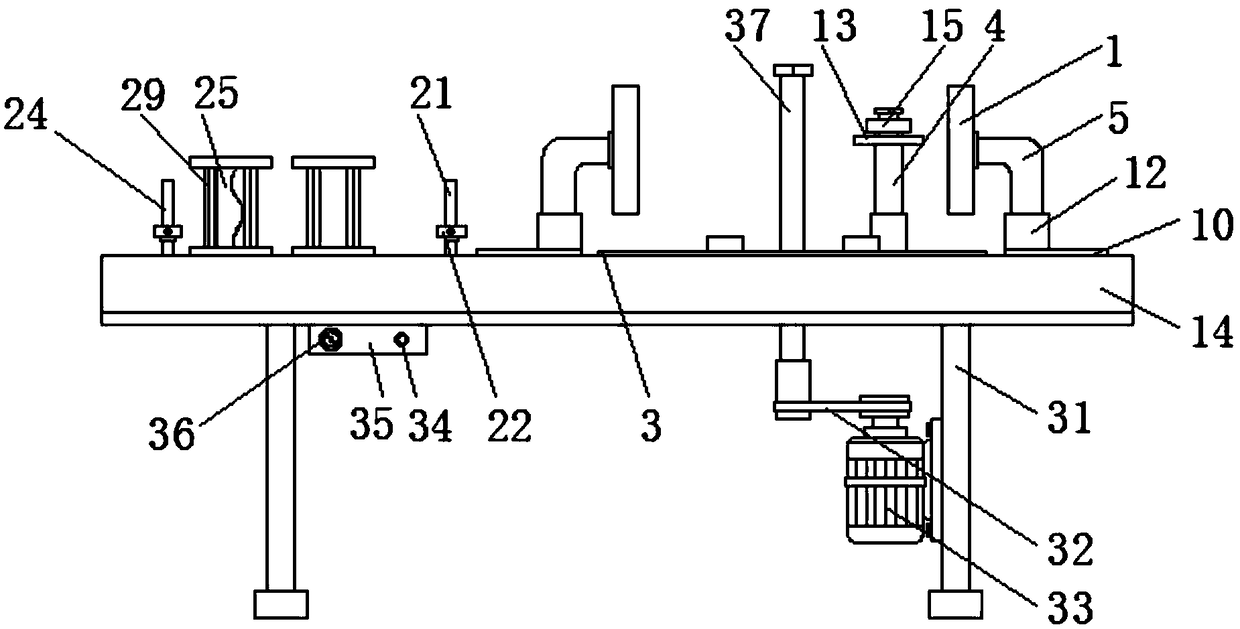

Automatic winding machine

PendingCN110504100ATightly woundWinding tightly and orderlyCoils manufactureWinding machineWire cutting

The invention discloses an automatic winding machine. The automatic winding machine comprises a machine frame, which is provided with a rotary motor, a portal frame, a mechanical arm, and a tray support. The tray support is connected with a rotary table in a driving way, and the rotary table is provided with a winding head, which is provided with a work piece accommodating groove. The tray supportis disposed on the right side of the rotary table, and the portal frame is provided with a forward and backward translation device, which is connected with a forward and backward translation plate ina driving way. The forward and backward translation plate is provided with a left and right translation device, which is connected with a left and right translation plate in a driving way. The left and right translation plate is provided with an elevating driving device, which is connected with an elevating plate in a driving way. The elevating plate is provided with an upper wire cutting assembly, a wire leading assembly, and wire clamping assembly. A lower part of a winding head is provided with a lower wire cutting assembly. The winding efficiency is improved, and the winding is stricter and ordered, and the quality is higher.

Owner:广东昭信智能装备有限公司

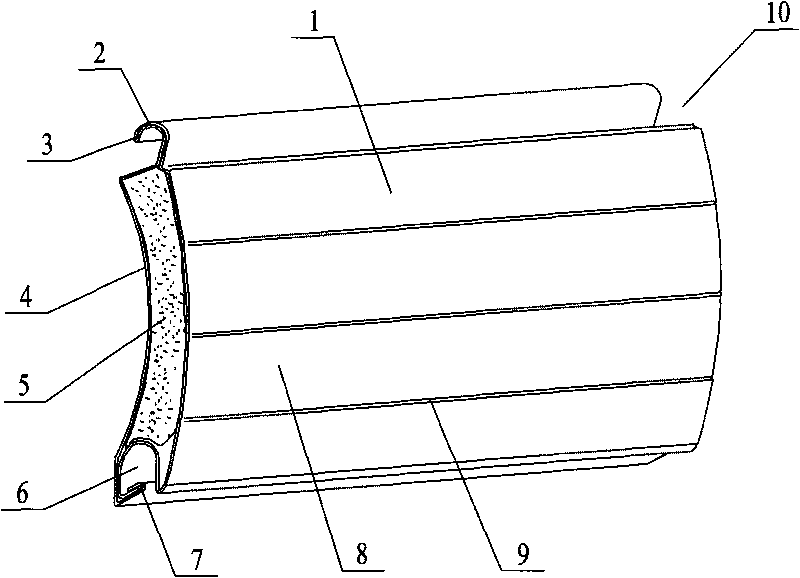

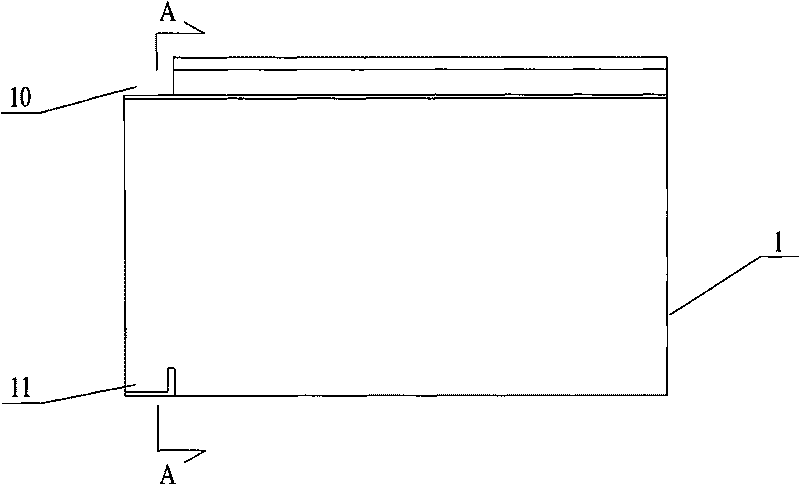

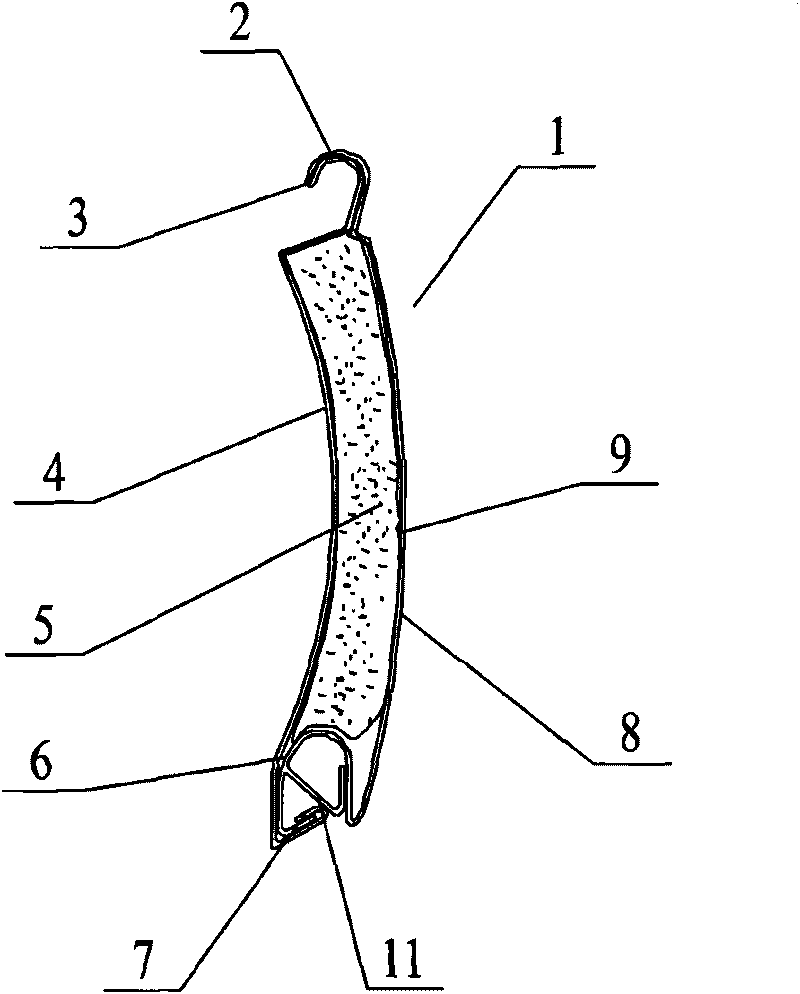

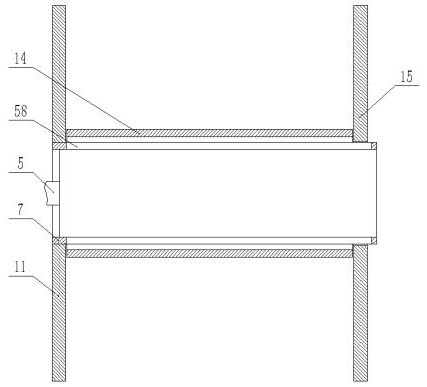

Roller blind piece

ActiveCN101736997AExtended service lifePrevent slippingShutters/ movable grillesFireproof doorsLow noiseThermal insulation

The invention relates to a roller blind piece applied to roller blind doors or windows. The roller blind piece comprises a piece body. An upper hook is formed through upward convex extension of the piece body and a lower hook is formed through depression of the lower part of the piece body. The upper hook can be connected with the adjacent lower hook of the piece body by buckling. The roller blind piece is characterized in that one end of the upper hook on the piece body is provided with a nick and the lower hook is provided with a retaining groove corresponding to the nick; the nick and the retaining groove are arranged at the same end of the same piece body; and when the upper hook on one roller blind piece is connected with the lower hook on the other roller blind piece by buckling, one end of the upper hook, which is provided with the nick, is blocked by the retaining groove. The roller blind piece has compact and reasonable structure, small friction when rolling or unrolling and low noise, is smooth in rolling and unrolling operations and safe and reliable in connection, and simultaneously has good compression strength, anti-bending property, anti-torsion strength and thermal insulation property.

Owner:WUXI JIEYANG ENERGY SAVING TECH

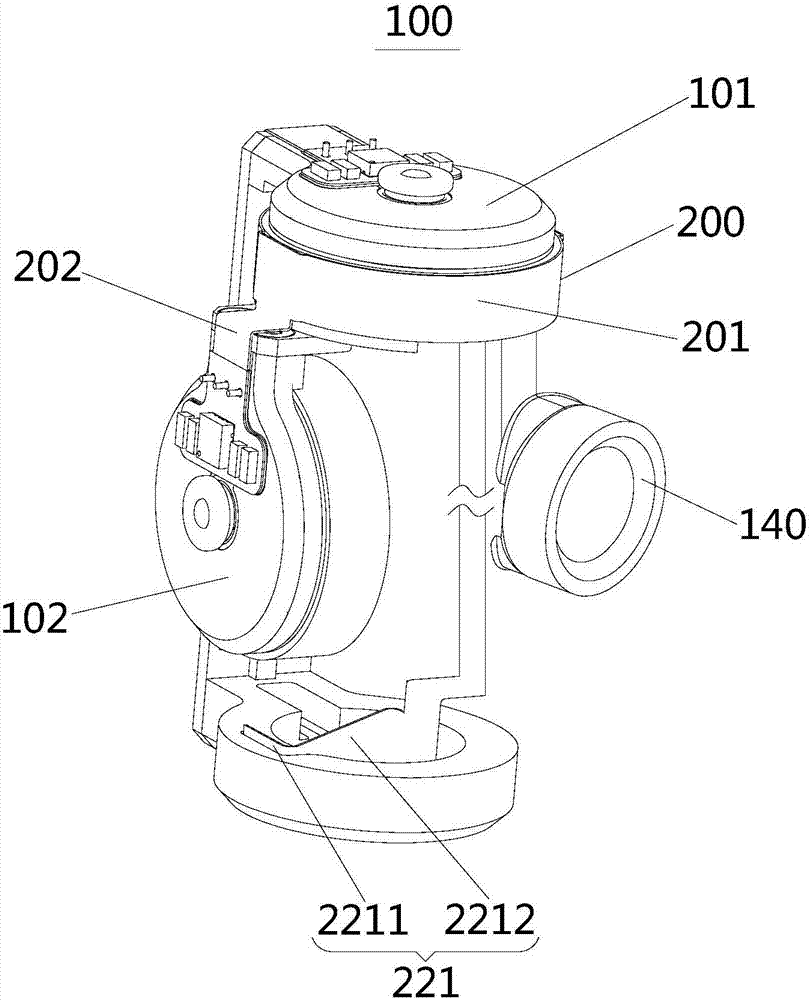

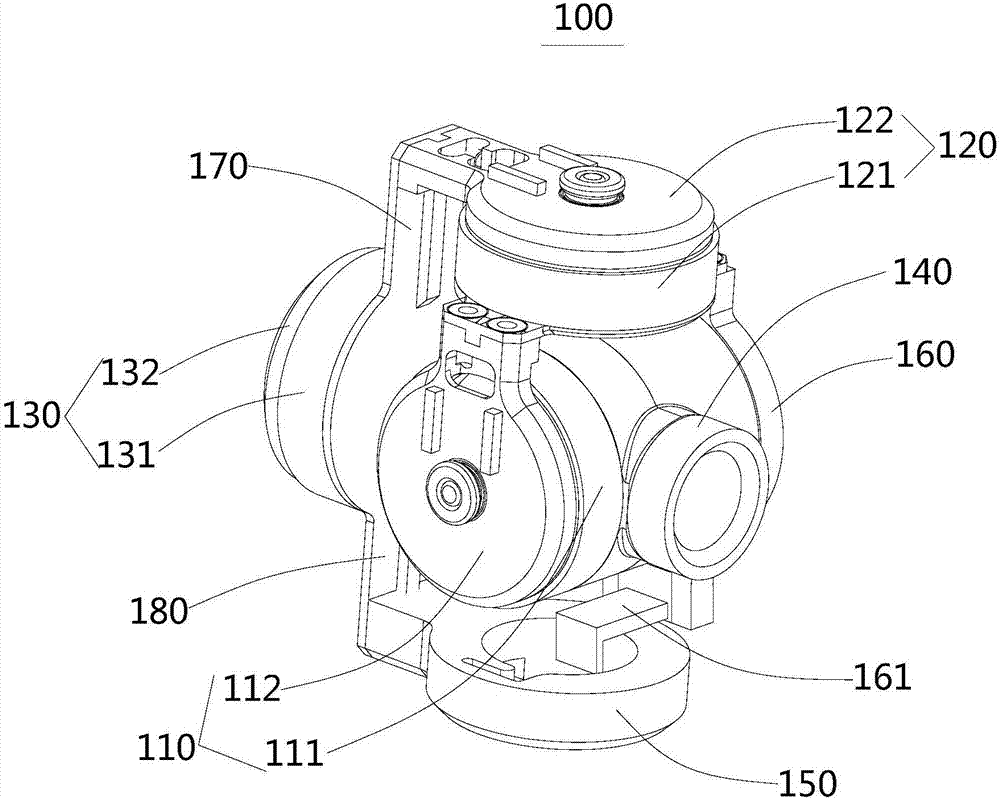

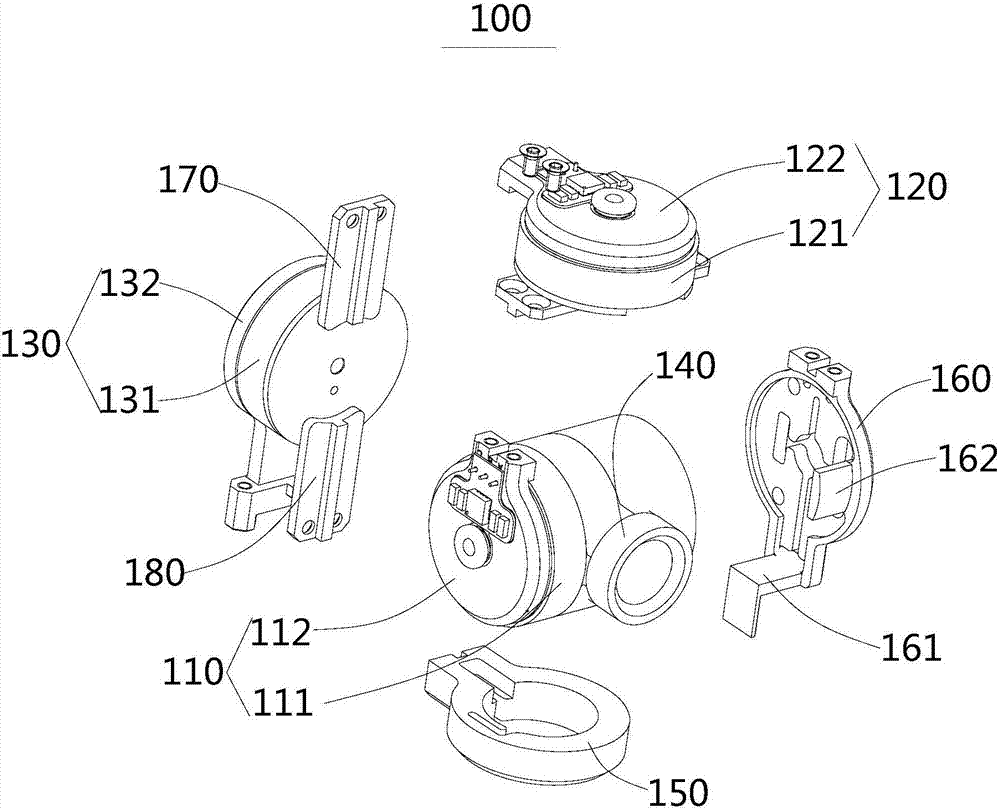

Cradle head winding method

ActiveCN107390456AAdapt to miniaturization designReasonable wiringPrinted circuit assemblingCircuit bendability/stretchabilityElectric machineryMiniaturization

The invention provides a cradle head winding method for winding an FPC wire around a cradle head, wherein the cradle head comprises a first motor and a second motor which are connected mutually; and a camera module is mounted on the cradle head. According to the cradle head winding method, one end of the FPC wire is connected with the camera module while the other end comprises a connecting unit and a connecting end which are connected mutually; the connecting unit is wound around the first motor; the connecting end is led by the connecting unit in an extension manner; and the connecting end is electrically connected with the second motor. By virtue of the cradle head winding method, wiring of the FPC wire can be more reasonable, a phenomenon of disordered winding of the FPC wire generated along with rotation of the motors can be prevented, wiring can be more compact, and the miniaturization design of the cradle head can be satisfied.

Owner:ZEROTECH (SHENZHEN) INTELLIGENCE ROBOT CO LTD

Thin film slitting device based on macromolecule material

ActiveCN108910568AAchieve diffusionImplement position swapMetal working apparatusArticle deliveryMechanical engineering

The invention discloses a thin film slitting device based on a macromolecule material. The thin film slitting device comprises an unwinding roll, an adjustable slitting mechanism and a winding roll, wherein the unwinding roll and the winding roll are respectively and rotationally connected with a bracket; the adjustable slitting mechanism is arranged between the unwinding roll and the winding roll, and is connected with electric telescopic rods which are symmetrically arranged at front side and back side; the adjustable slitting mechanism comprises a motor, fixed plates, slitting knives and aplurality of abutting plates; a rotary shaft is arranged between the two fixed plates; the multiple butting plates are arranged at the outer side of the rotary shaft along the circumference direction;the outer side of each abutting plate is clamped with the corresponding slitting knife. The thin film slitting device has the advantages that the design is novel; the adjusting rod is driven by an adjusting button to rotate, and drives a threaded sleeve cylinder to drive a sleeve ring to do face-to-face movement or opposite movement; in the face-to-face movement process of the sleeve ring, the abutting plates can be diffused; in the opposite movement process, the abutting plates can be approached, so as to adjust and replace the positions of the slitting knives, adjust the distance between the multiple slitting knives, and meet the different slitting width requirements.

Owner:CHONGQING EFAN THINREX PHOTOELECTRIC TECH CO LTD

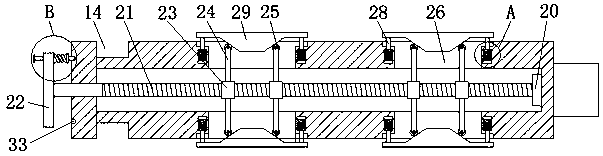

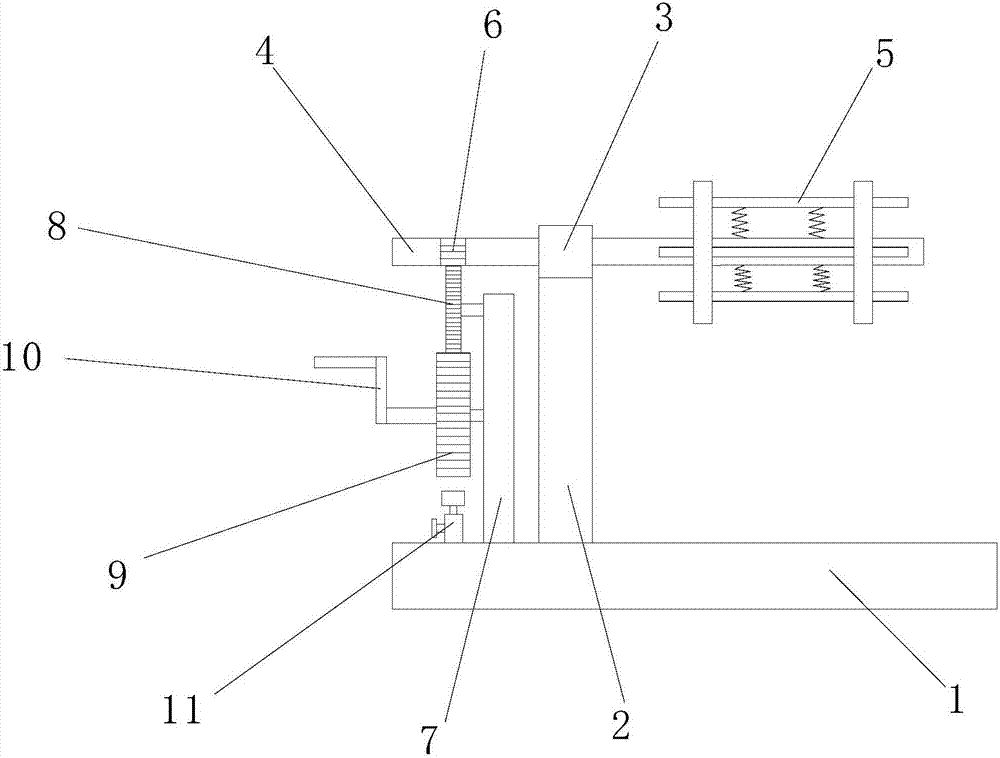

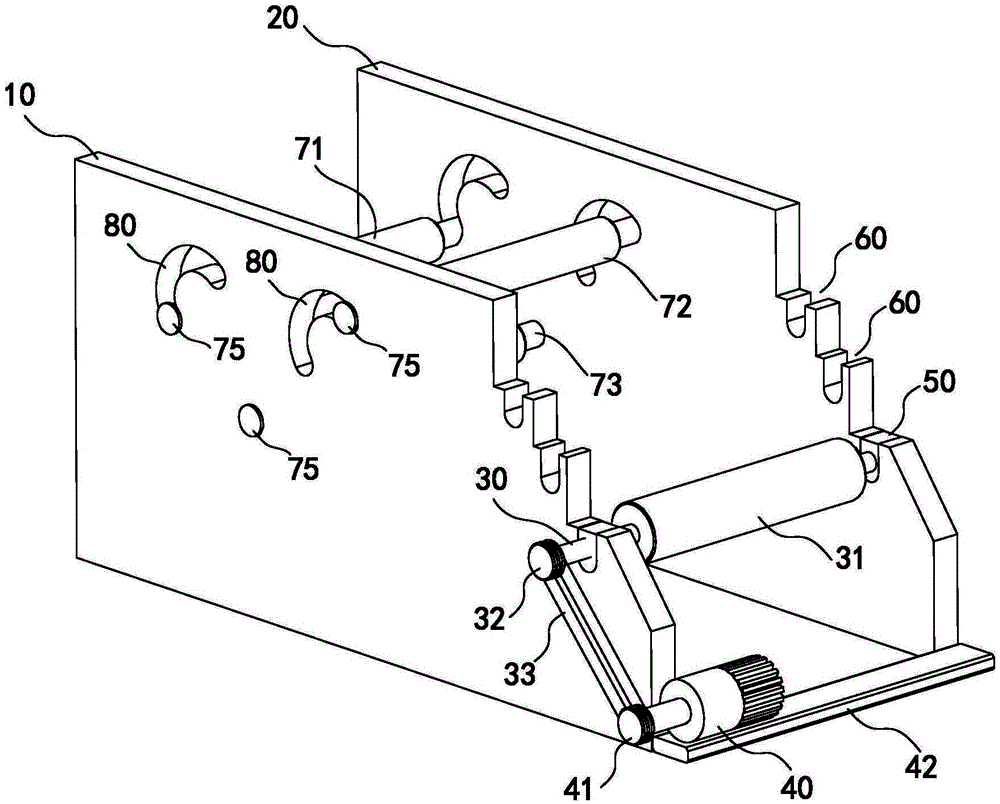

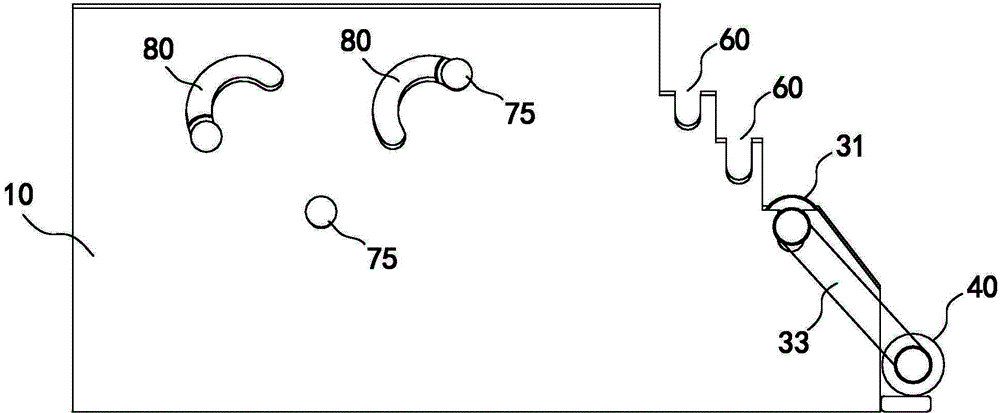

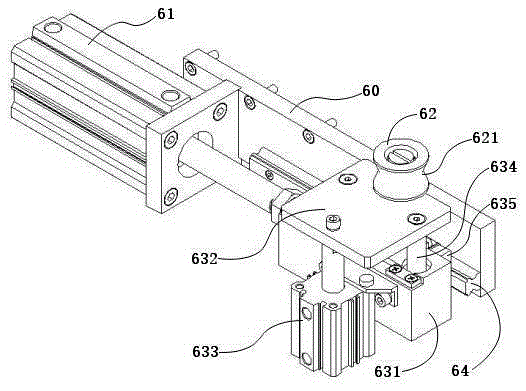

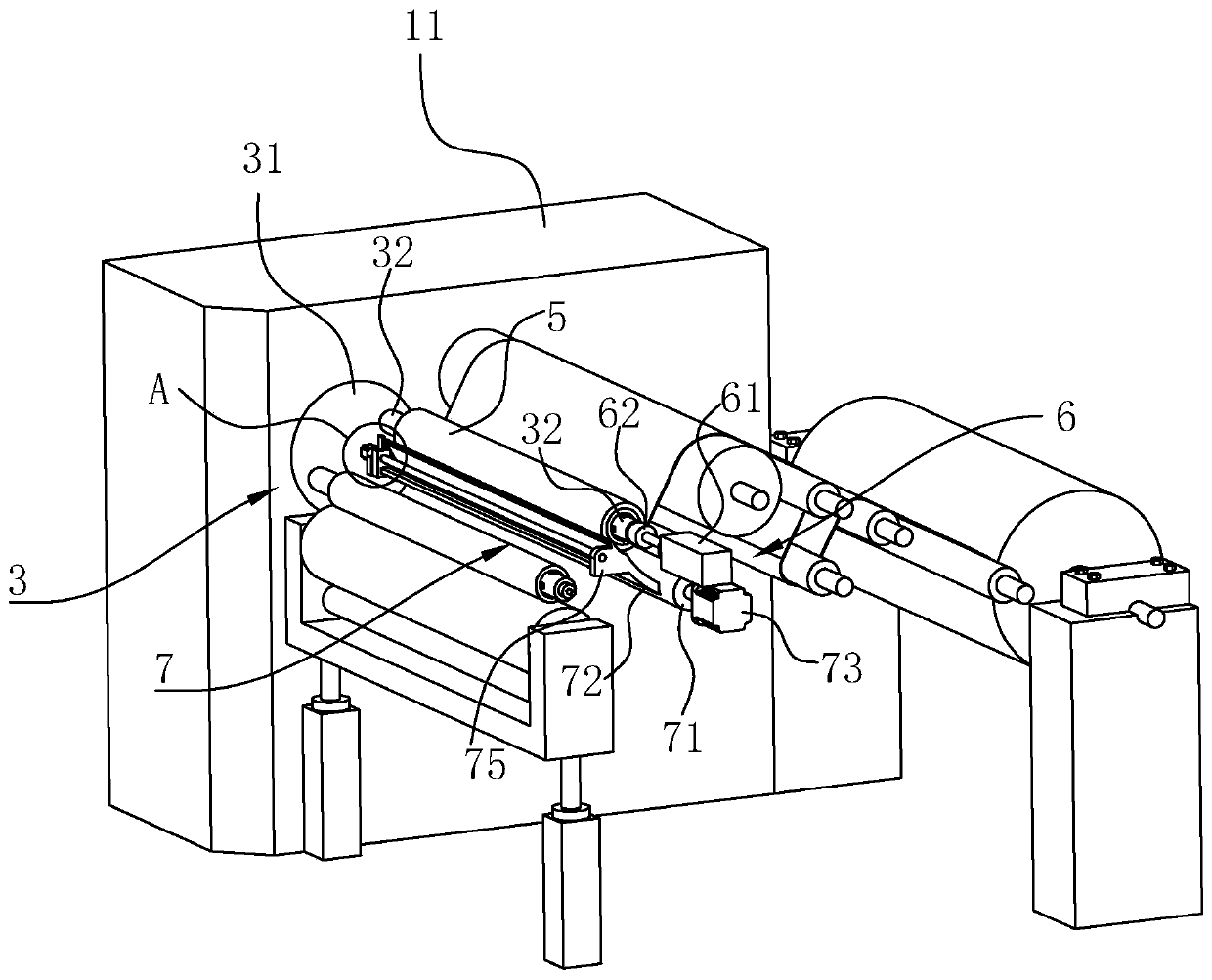

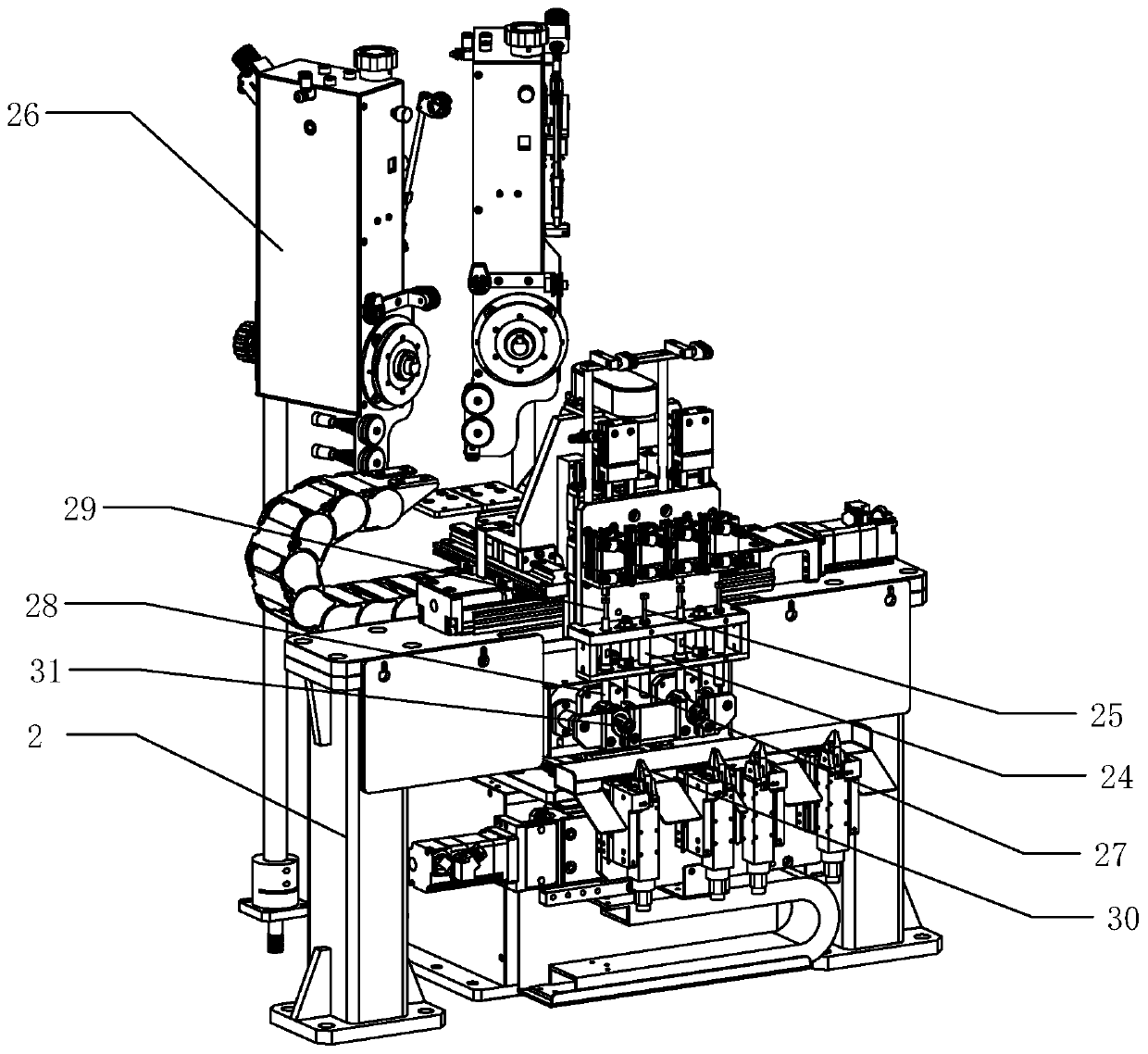

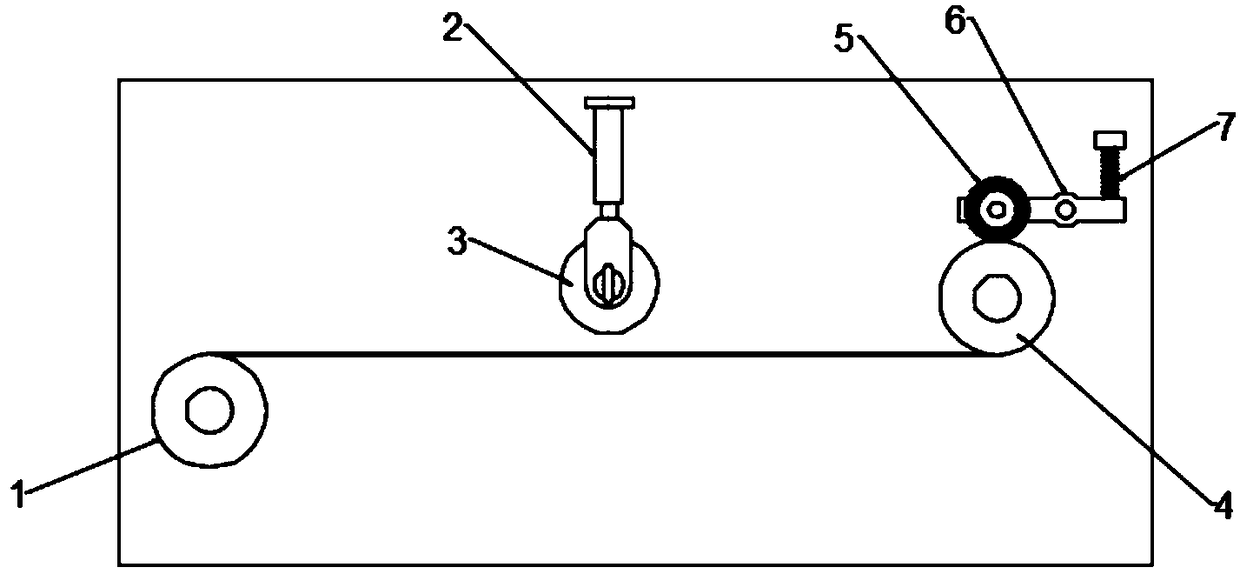

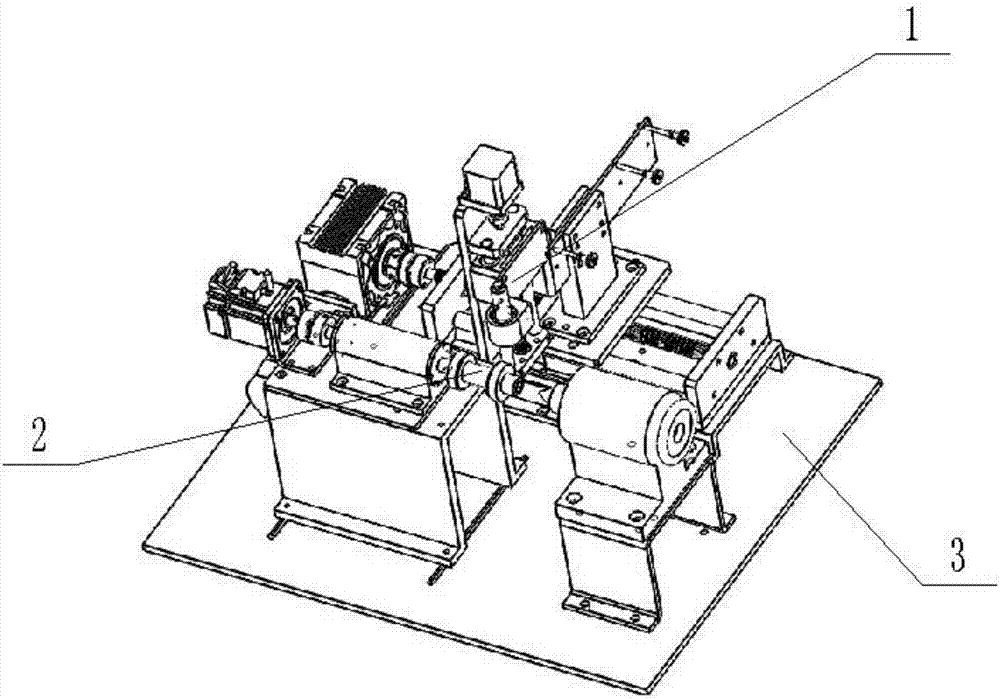

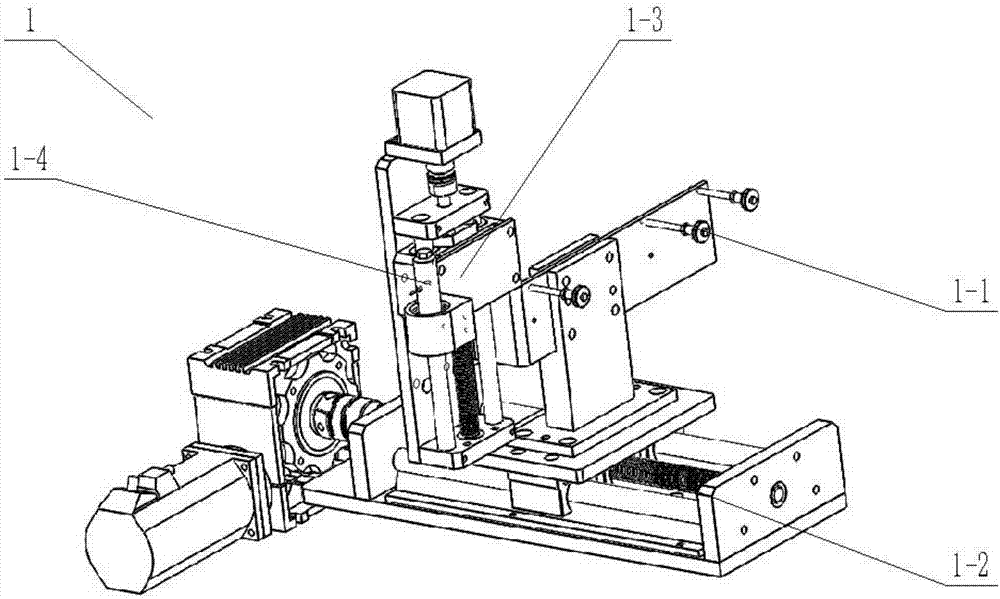

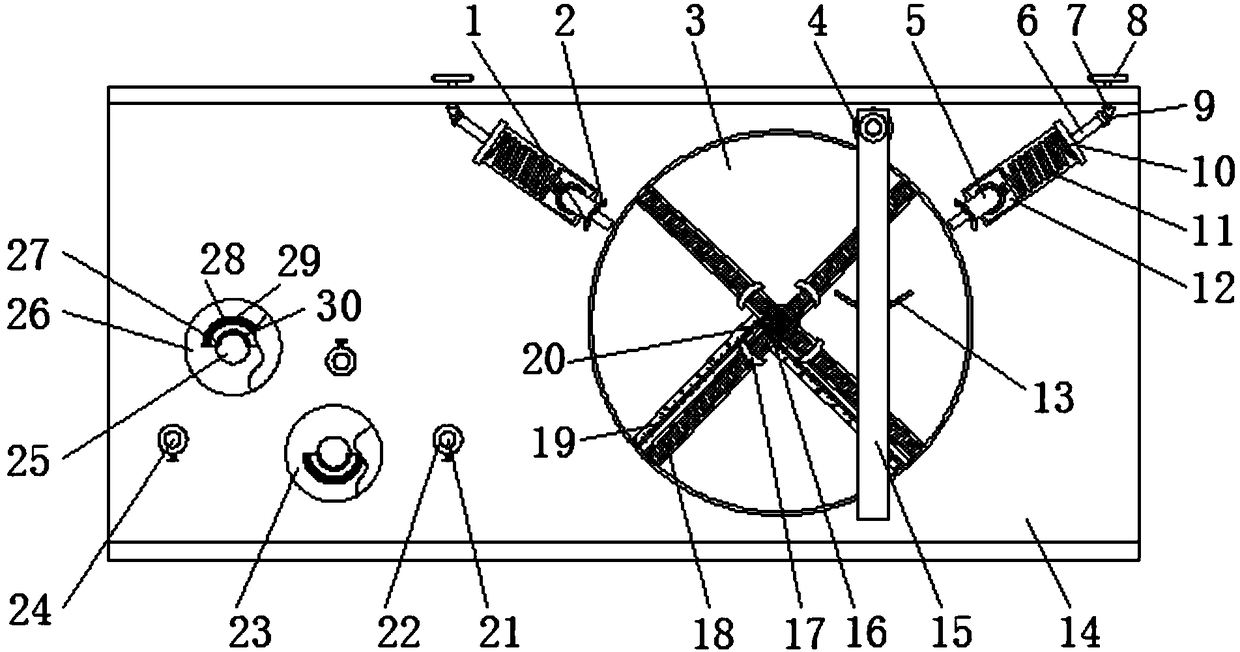

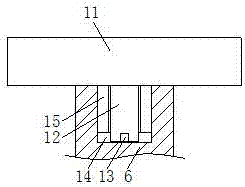

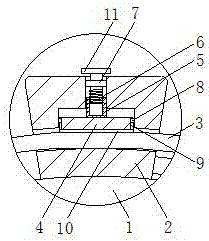

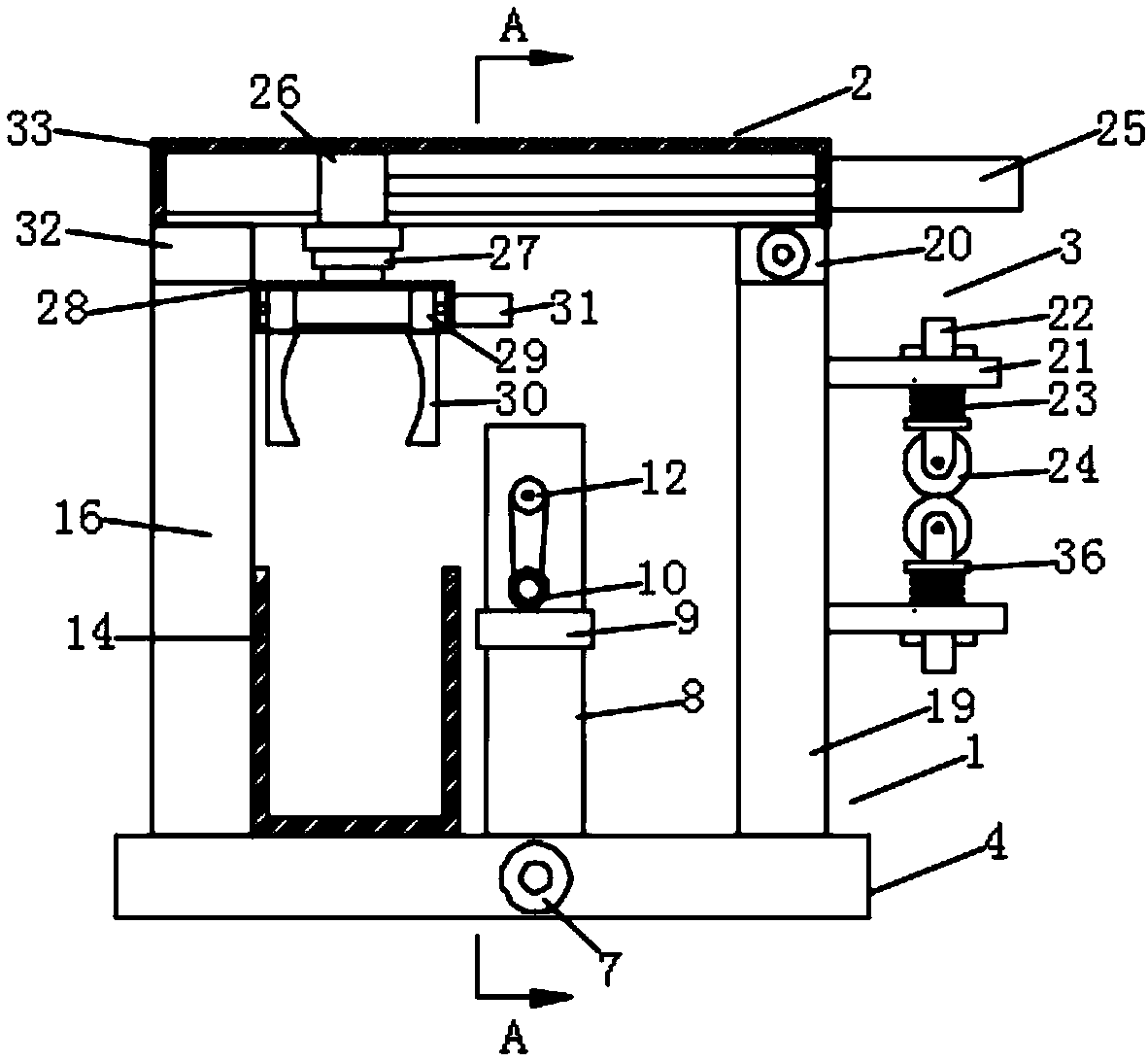

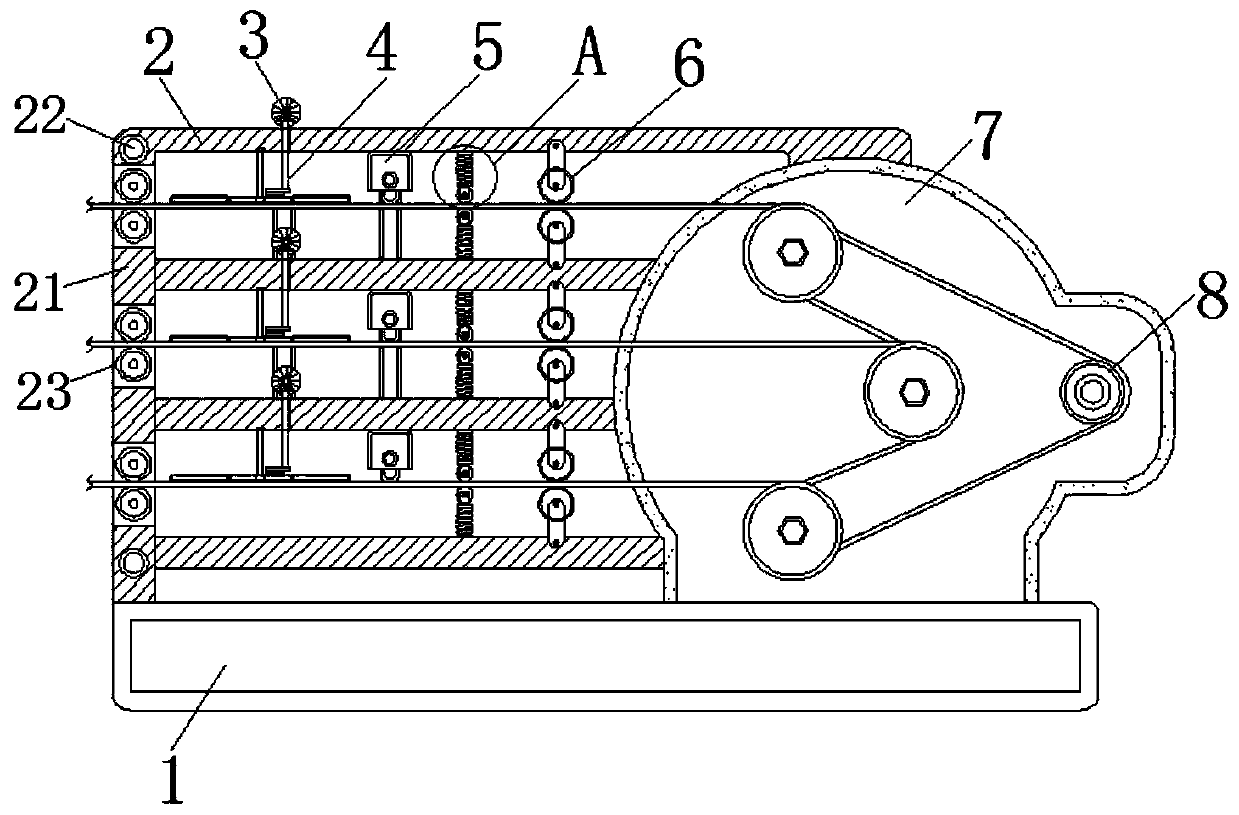

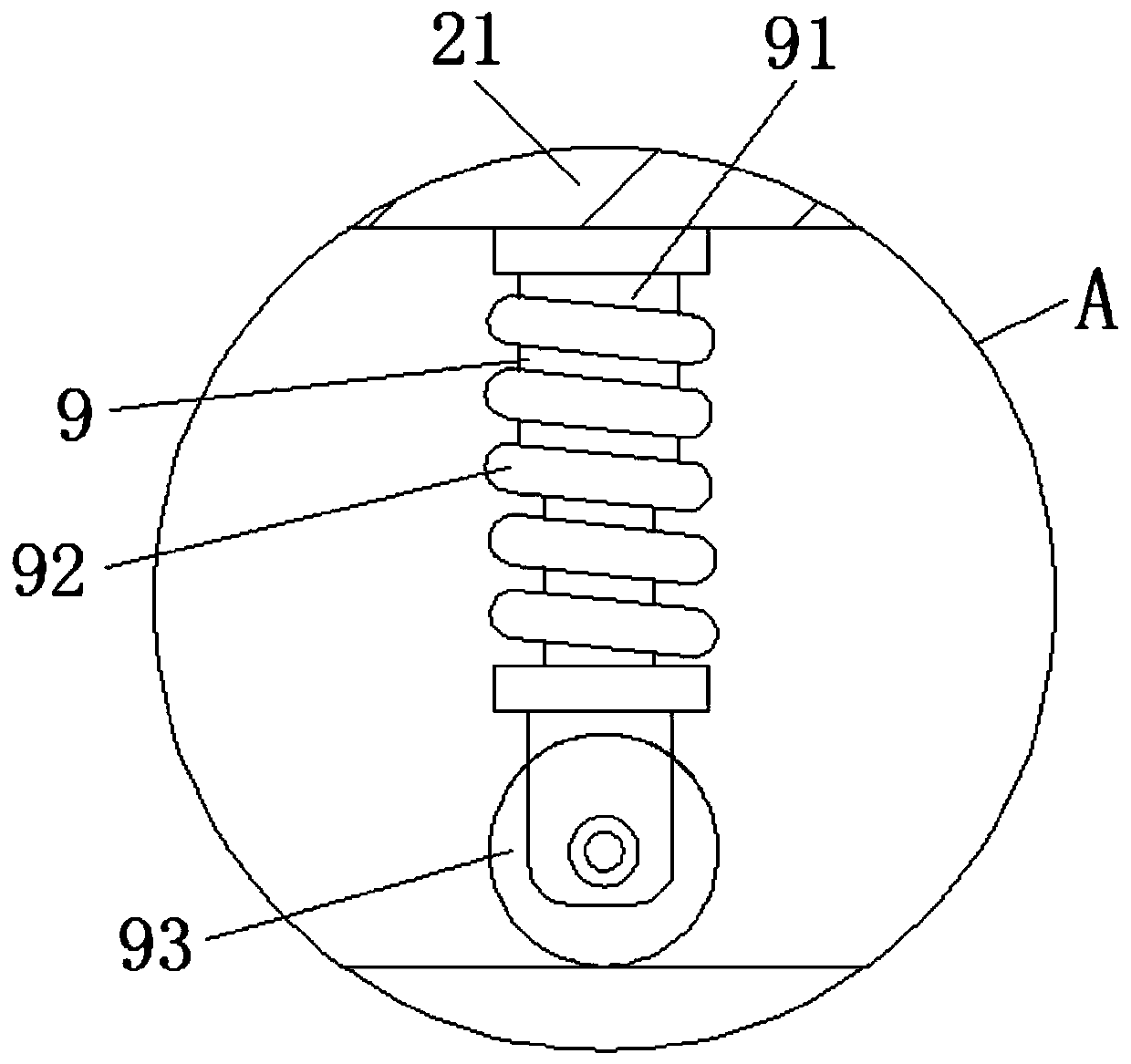

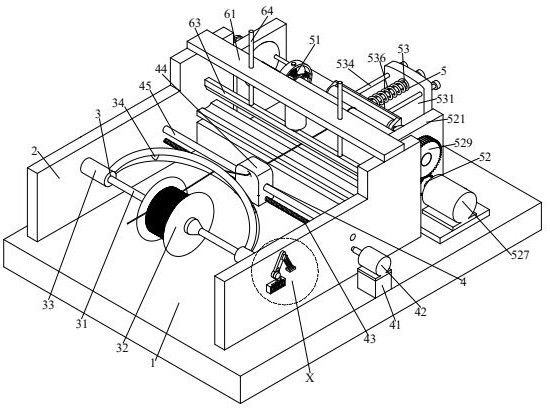

Automatic winding device for electromagnetic valve coil

ActiveCN107424836AImprove winding efficiencyImprove winding qualityInductances/transformers/magnets manufactureEngineeringConductor Coil

The invention relates to an automatic winding device and particularly relates to an automatic winding device for an electromagnetic valve coil. The automatic winding device comprises a wire arrangement mechanism, a winding mechanism and a base plate, wherein the wire arrangement mechanism and the winding mechanism are fixedly connected with two sides of the top end of the base plate; the wire arrangement mechanism comprises a wire passing wheel mechanism, a horizontal motion module, a vertical motion module and a guide pin mechanism; the wire passing wheel mechanism is connected with and arranged at the upper end of the horizontal motion module; the vertical motion module is connected with and arranged on the wire passing wheel mechanism; the horizontal motion module is connected with and arranged at the top end of the base plate; and the guide pin mechanism is connected with and arranged on the vertical motion module. The problems of relatively low production efficiency of the electromagnetic valve coil, poor coil winding quality and high coil production cost in the prior art can be effectively solved. The invention provides an automatic winding device capable of automatically winding the electromagnetic valve coil and replacing hands to wind the coil. The winding efficiency can be improved, the production cost can be reduced and the winding quality can be improved.

Owner:哈尔滨博信智能装备有限公司

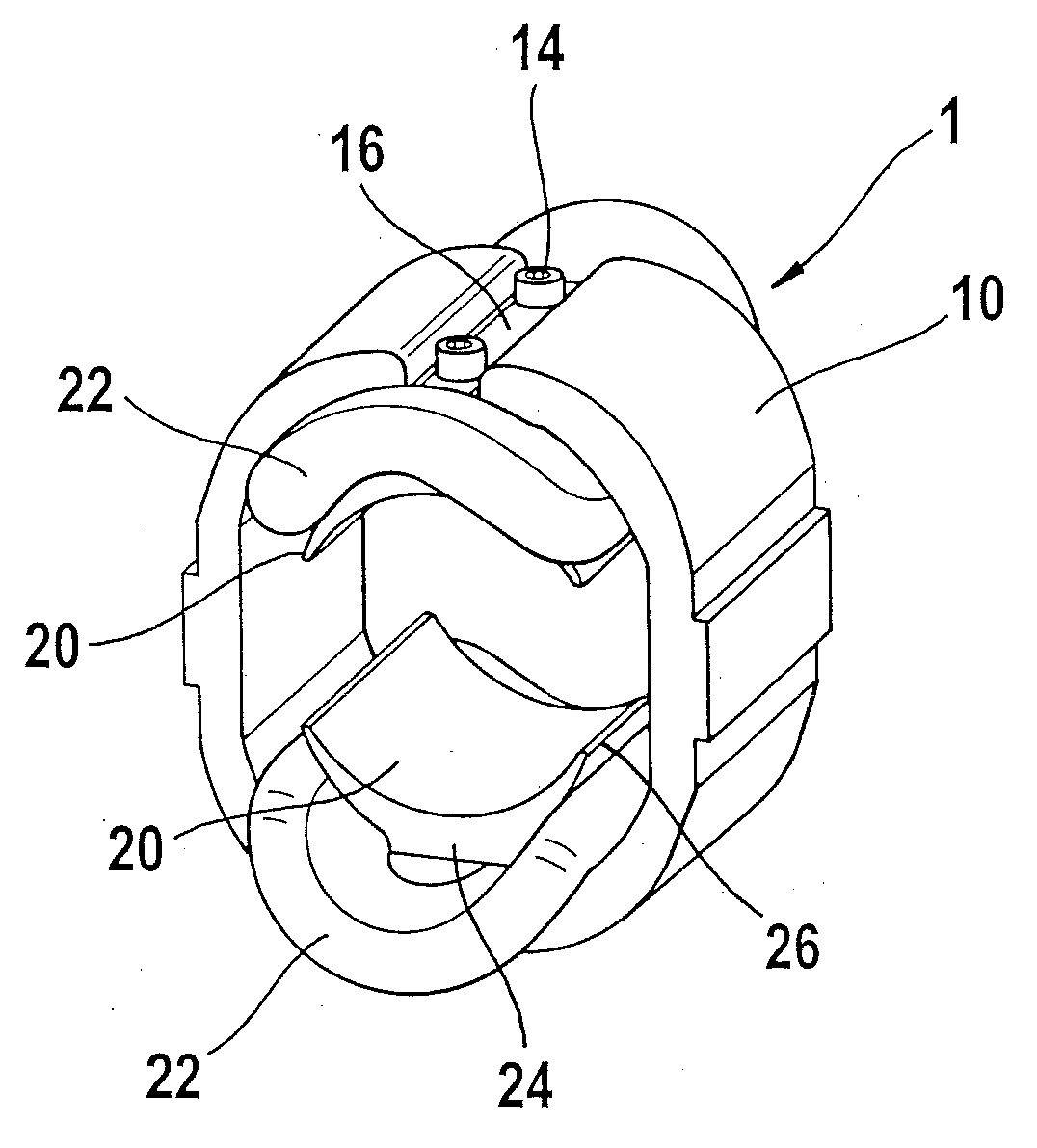

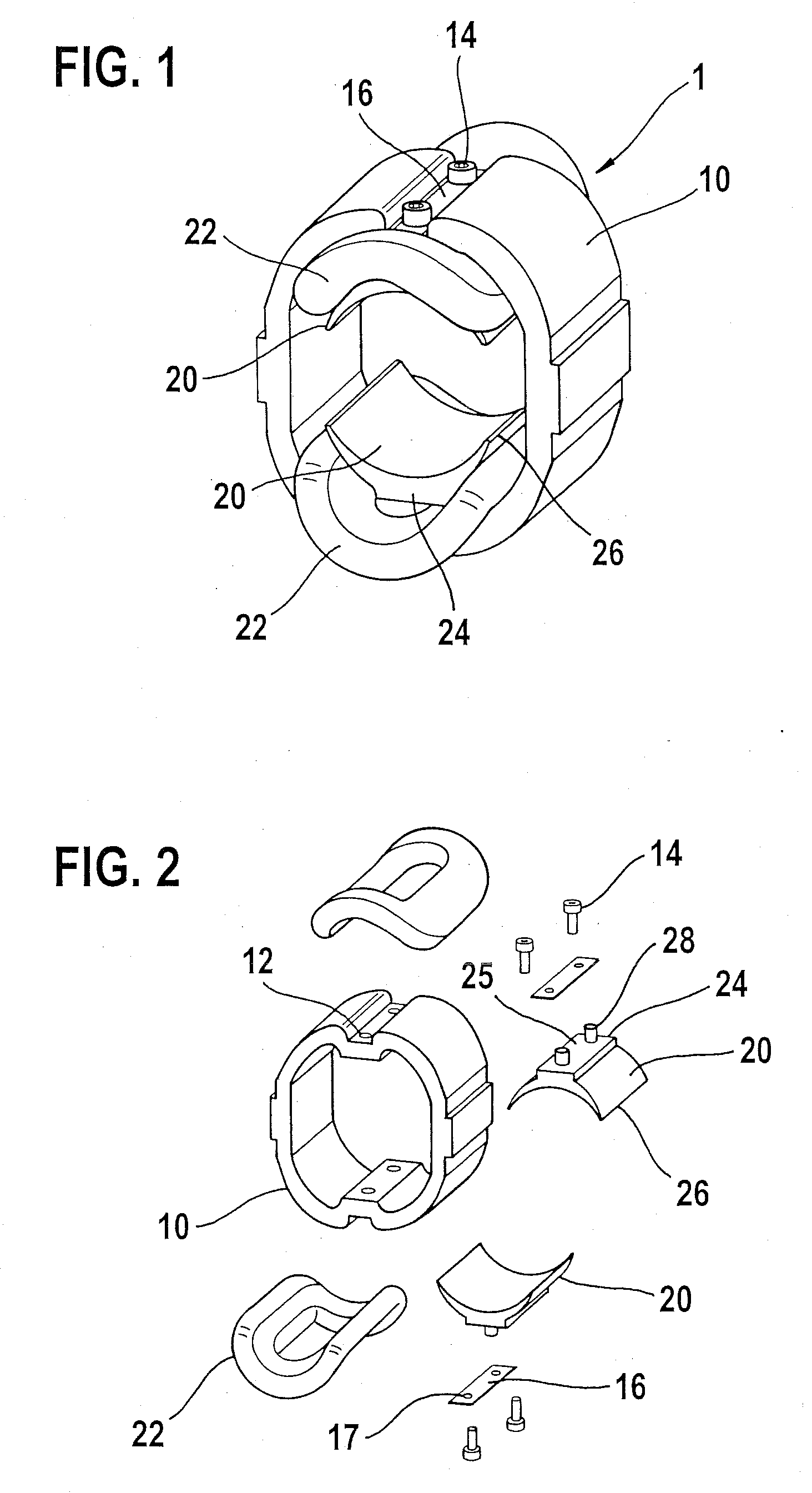

Main element for an electrical machine

InactiveUS20080001505A1Firmly connectedTightly woundMagnetic circuit stationary partsMechanical energy handlingElectric machineUniversal motor

A main element, in particular a stator, for an electrical machine, in particular for a universal motor, includes a flux return ring with at least two poles that are situated radially on the flux return ring, and each of which accommodates at least one coil, the poles can be connected with the flux return ring.

Owner:ROBERT BOSCH GMBH

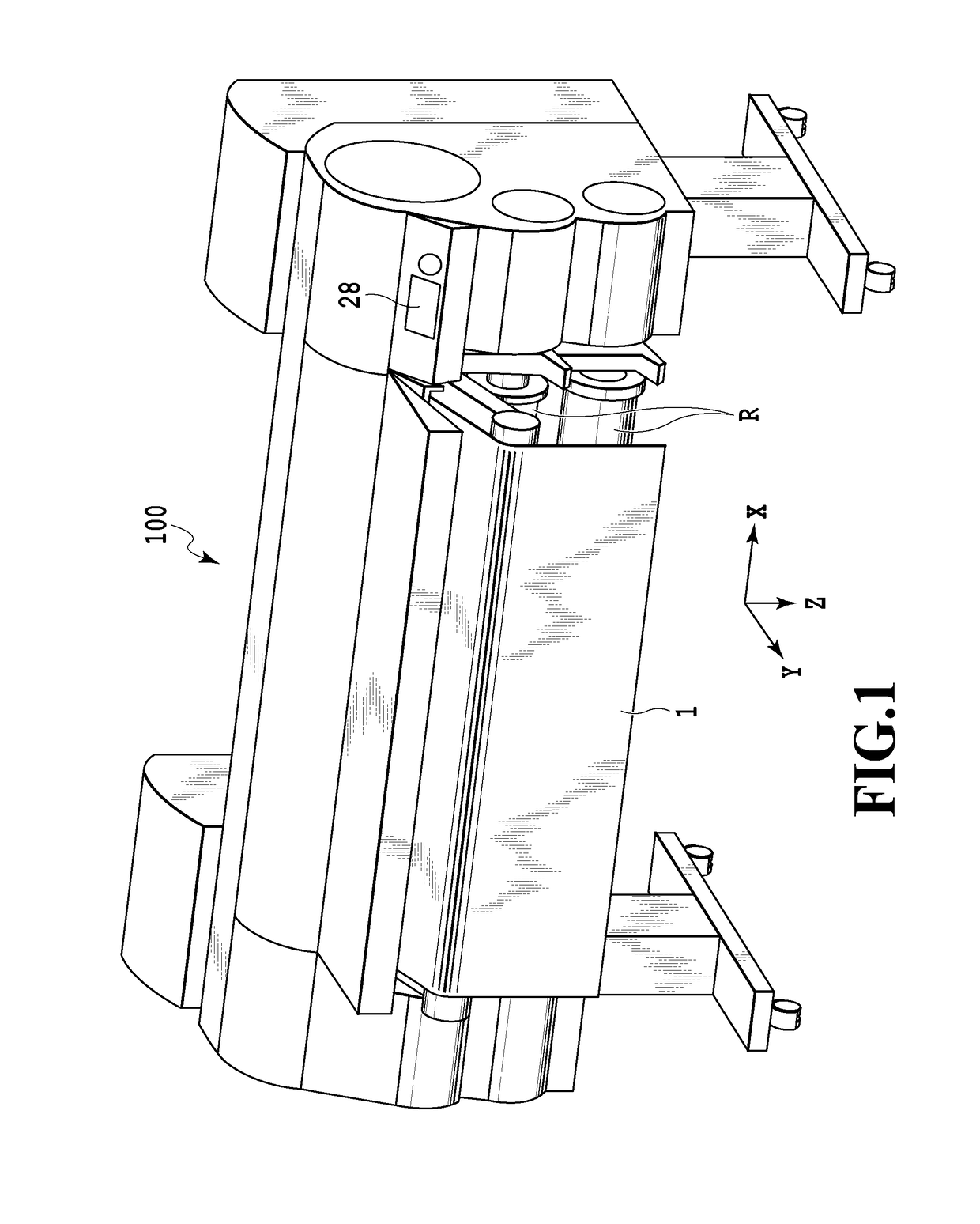

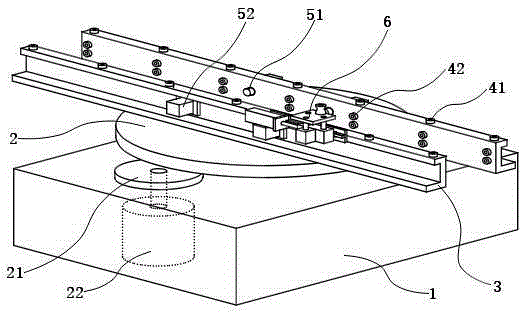

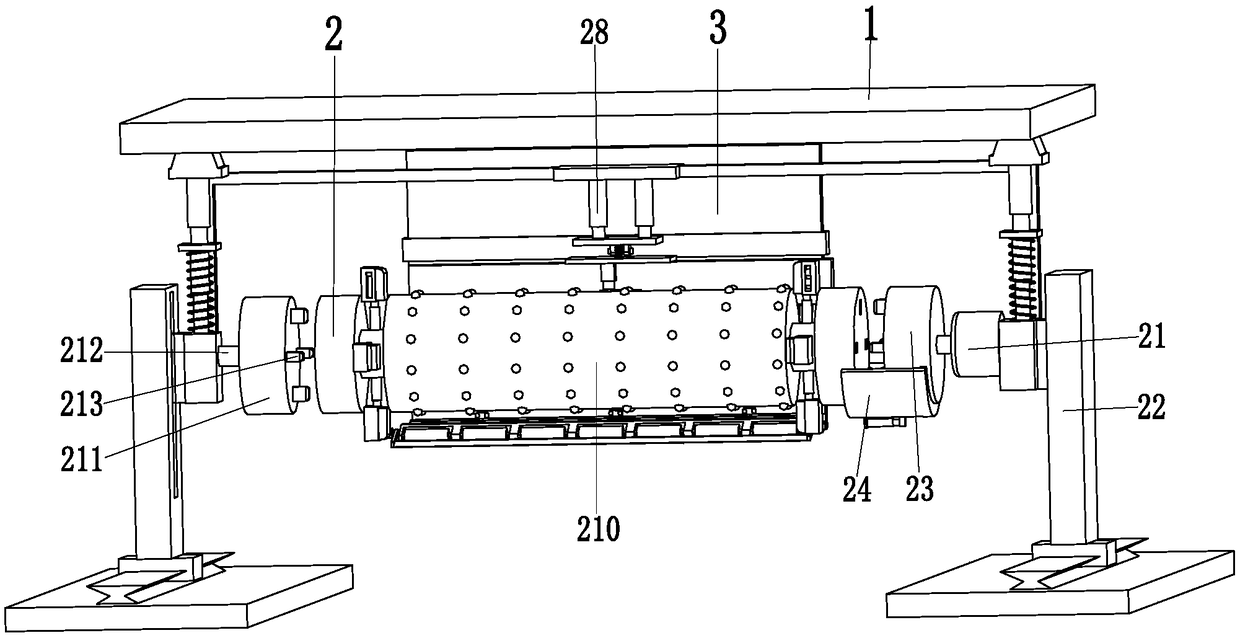

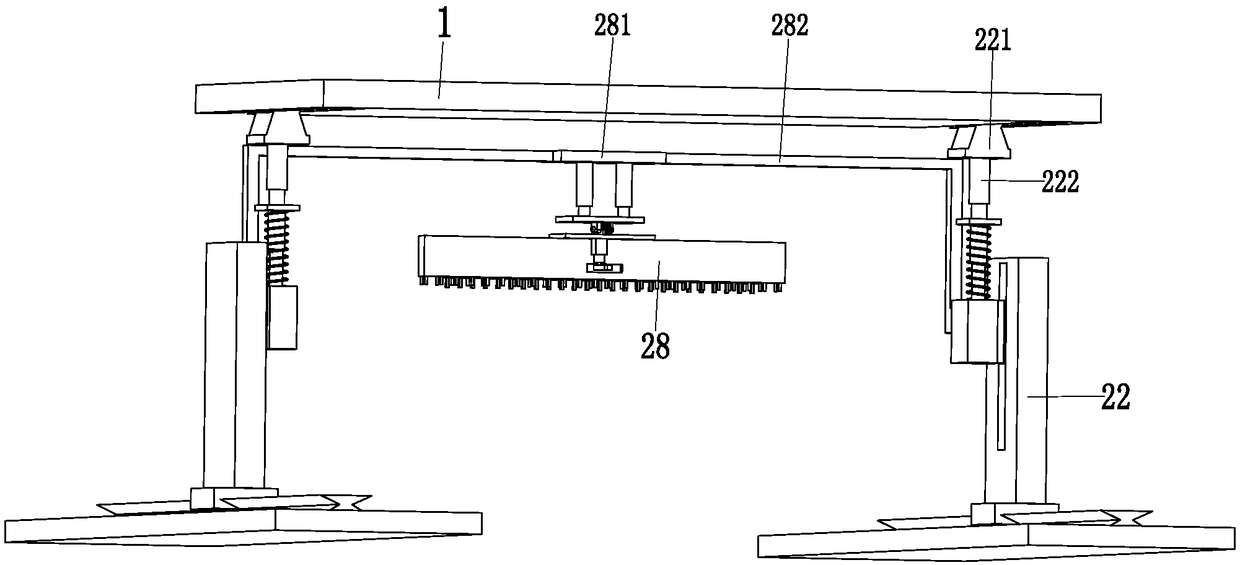

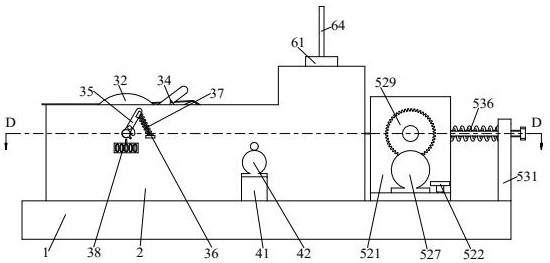

Aluminum plate automatic winding and stacking machine

ActiveCN108840136ATight windingRemove neatlyCleaning using toolsWebs handlingStack machineEngineering

The invention relates to an aluminum plate automatic winding and stacking machine. The aluminum plate automatic winding and stacking machine comprises a supporting top plate, a winding device and an auxiliary correcting device, sliding grooves are formed in the left and right ends of the bottom of the supporting top plate, the winding device is mounted at the lower end of the middle of the supporting top plate, and the auxiliary correcting device is installed at the bottom of the back side of the supporting top plate. The auxiliary correcting device comprises an electric sliding block unit, anauxiliary correcting telescopic plate, an auxiliary correcting and an auxiliary connecting plate, auxiliary correcting angle push rods, an auxiliary correcting telescopic rod, an auxiliary correctingspring, an auxiliary correcting frame and an auxiliary correcting mechanism. The auxiliary correcting mechanism comprises auxiliary correcting rollers, auxiliary correcting motors, auxiliary correcting rotary shafts and auxiliary correcting rotary frames. The aluminum plate automatic winding and stacking machine can solve the problem that during an existing casting aluminum plate winding, the labor intensity is high, the working efficiency is low, one end of the aluminum plate is lifted and fixed to a winding rod manually, the aluminum plate is disordered when winding, the aluminum plate is not tight, the aluminum plate taken down from the winding rod is difficult after winding, and adhesive sandy soil of the aluminum plate cannot be automatically cleaned when the aluminum plate is wound.

Owner:HENAN WANDA ALUMINUM

Belt winding machine for textile manufacturing

ActiveCN108423460AAccurately grasp the distanceImprove fixed applicabilityHeating/cooling textile fabricsWebs handlingWinding machineTextile manufacturing

The invention discloses a belt winding machine for textile manufacturing, the belt winding machine comprising a working platform, wherein support legs and an electric cabinet are fixedly connected tothe bottom of the working platform by bolts, the support legs are located on one side of the electric cabinet, a motor is fixed and connected to the outer wall of one side of one support leg by a bolt, a rotary table is in transmission connection to one end of the motor by a belt pulley set, second screw rods are mounted in the rotary table, a fourth bevel gear is welded to one ends of the secondscrew rods, clamping plates are in screwing connection to the second screw rods by threads, and a center pipe is welded to the center position of the top of the rotary table. According to the belt winding machine for textile manufacturing, the four clamping plates can fix cylinders with different diameters, the rolling radius can be adjusted as required while the fixing applicability is improved,the packing, storing and transporting requirements can be conveniently met, besides, calibrated scales are arranged on the rotary table so that the distance from the clamping plates to the center pipecan be accurately grasped, the rolling radius can be accurately grasped, and the rolling accuracy is improved.

Owner:山东滨州丰腾化纤绳网有限公司

Gauze roll convenient to wind

Owner:姚洁

Automatic winding device for recovery of power cable

The invention discloses an automatic winding device for recovery of a power cable. The device comprises a base and universal wheels with brakes, the universal wheels are mounted at four corners of thelower surface of the base, an automatic winding device is mounted at one side of the upper part of the base, a quick dismounting device is arranged on the automatic winding device, and a cable straightening device is mounted at the other side of the upper part of the base. The beneficial effects of the device are that a rubber soft cylinder and an annular movable baffle are loosened and fixed through stretching and retracting of a telescopic locking block so that the power cable can be rapidly detached from a winding sleeve after completion of the power cable, the use of workers is facilitated, the stretching and the retracting of the telescopic locking block are adjusted through an adjusting device, manual operation of workers can be effectively facilitated, multiple straightening sleeves are arranged, and the power cable is straightened through straightening balls distributed in the straightening sleeves in a staggered mode so that the power cable is wound more compactly, and the problem that winding is troublesome due to the fact that the power cable is bent excessively is solved.

Owner:苏州磊鑫垚自动化科技有限公司

Winding and packing device for manufacturing of waterproof cloth for teenagers

InactiveCN109534039ACompact structureCloth winding is compactPaper article packagingWebs handlingEngineeringMechanical engineering

The invention discloses a winding and packing device for manufacturing of waterproof cloth for teenagers. The winding and packing device comprises a supporting mechanism, a collection mechanism and aslitting mechanism. The supporting mechanism is composed of a fixed base, a distance adjusting lead screw, distance adjusting sliding blocks, a distance adjusting motor, distance adjusting support columns, a fixed table, a winding motor, a driving belt wheel, a driven belt wheel and a rotating shaft. The two distance adjusting sliding blocks are symmetrically in sliding connection in the fixed base, the distance adjusting lead screw is rotationally connected in the fixed base, and the outer side of the fixed base is fixedly connected with the distance adjusting motor. Through the arrangement of the slitting mechanism, during winding, the cloth can be conveniently stretched and tightened through telescopic springs and a cloth press roller, the cloth is wound more compactly, the cloth is prevented from being loosened when transported, slitting is achieved through a slitting blade after winding is completed, operation is convenient and rapid, and automatic cutting is achieved; and throughthe arrangement of clamping plates and a moving air cylinder, the wound cloth can be collected and packed conveniently, time and labor are saved, and the work efficiency of winding and packing is improved.

Owner:南京哈昵特户外用品有限公司

Vamp cloth rolling device of anti-deviation structure for production of cotton shoes

ActiveCN111422667AAvoid offsetTight windingMechanical cleaningPressure cleaningMechanical engineeringIndustrial engineering

Owner:RUIAN DAHU SHOES IND CO LTD

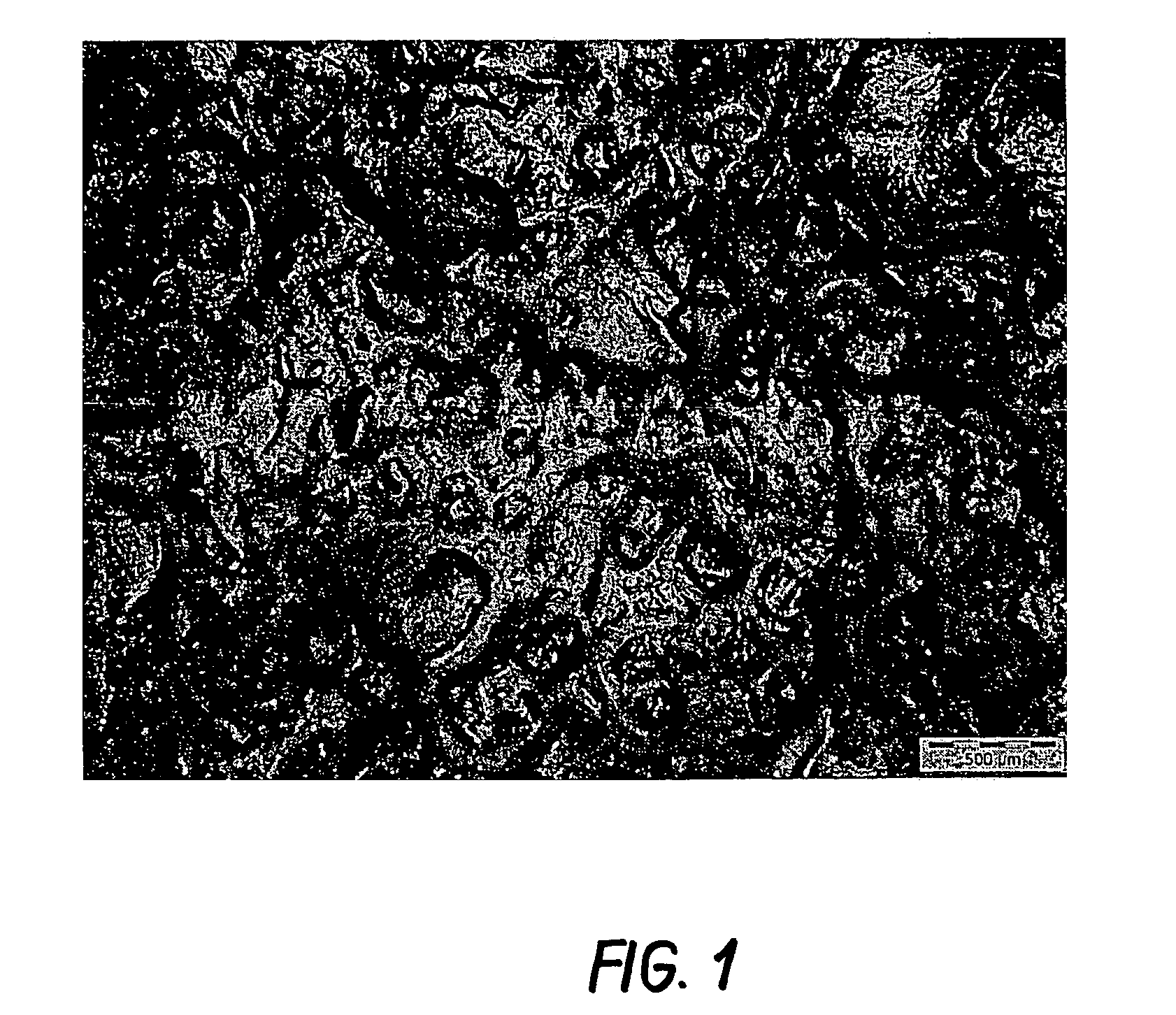

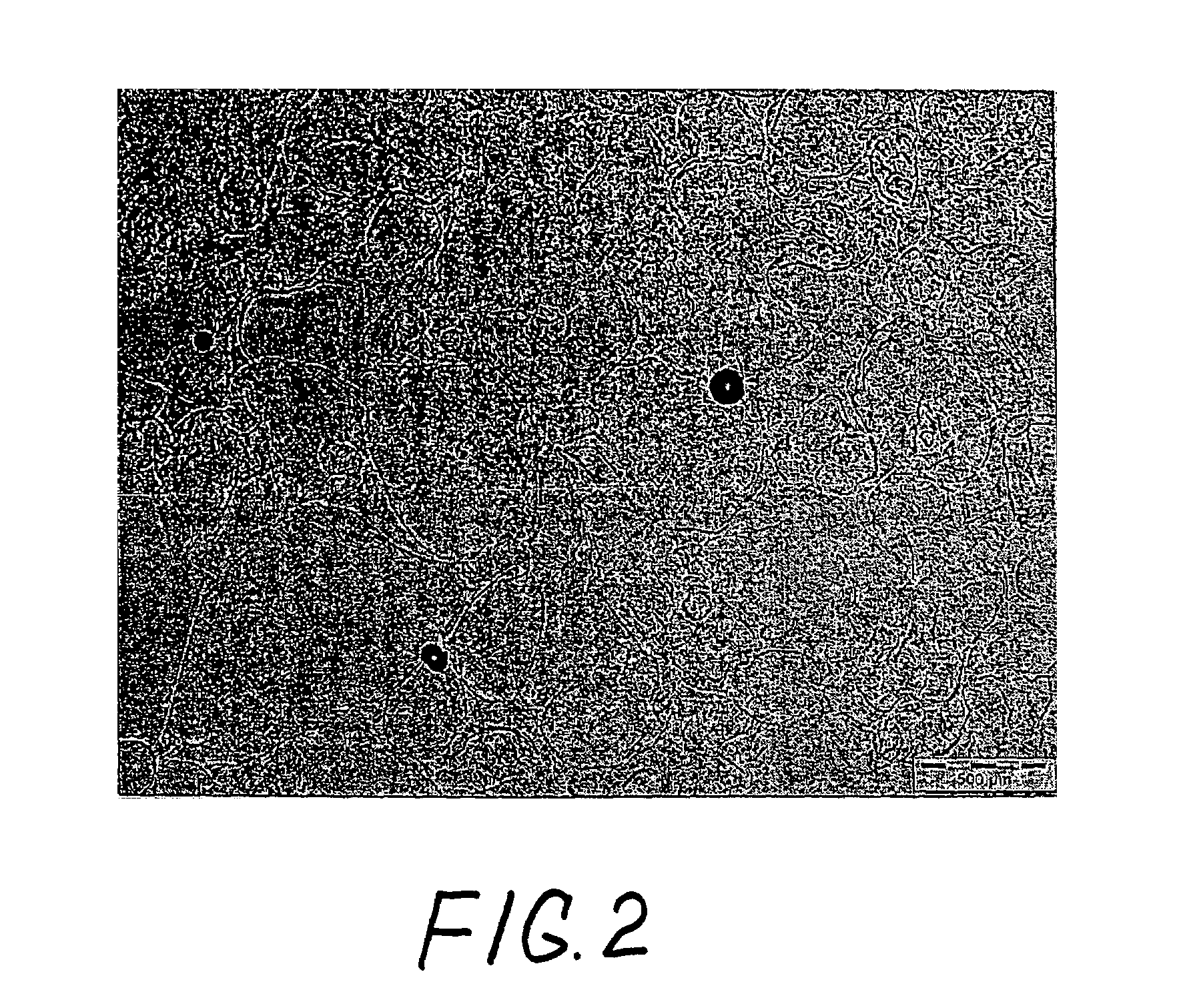

Cosmetic preparation in gel form

InactiveUS7455832B2High formulation costEasy to fixCosmetic preparationsHair cosmeticsMedicineGaseous substance

A cosmetic preparation in gel form is described which contains undissolved, water-swollen polymer particles and at the interface with gaseous substances forms reversibly a grainy, uneven, light-scattering surface and at the interface with solids forms reversibly a smooth, level, non-light-scattering surface. Preferred gel formers are superabsorbing polymers. A preferred use is the hair-end protection in permanent wave treatment.

Owner:WELLA GMBH

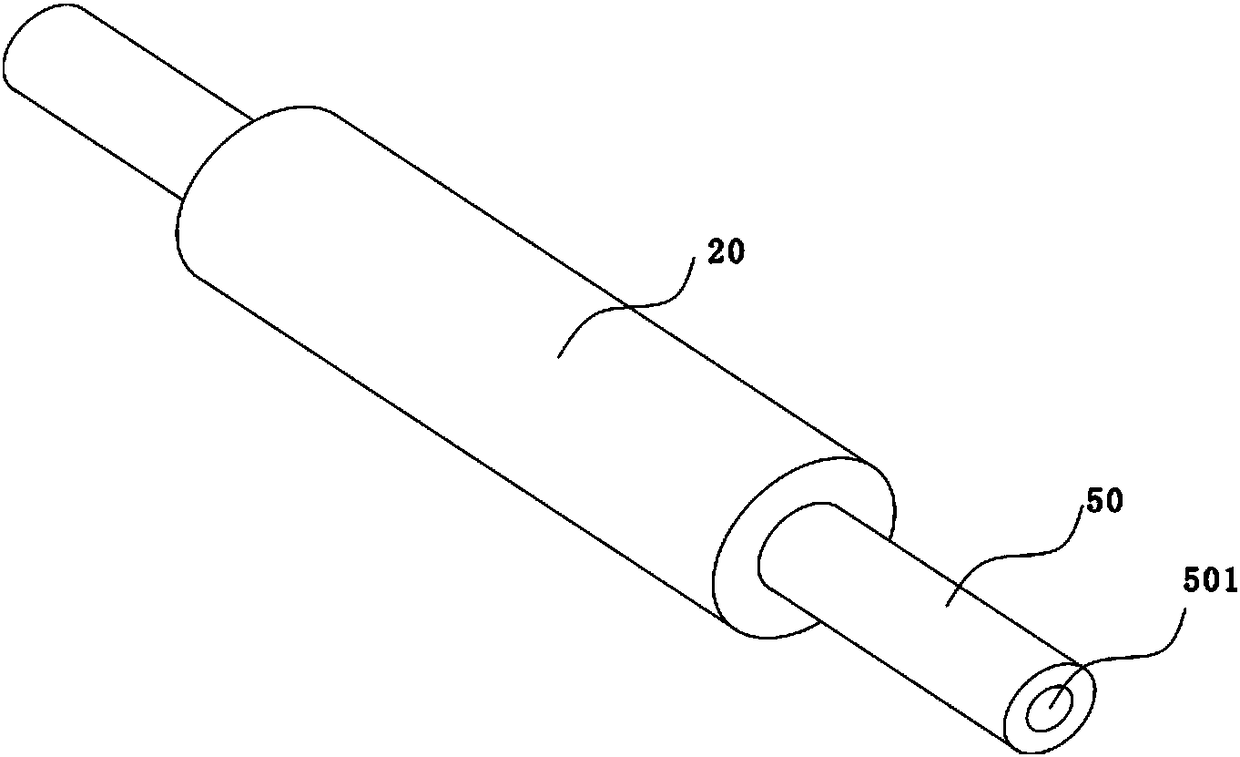

PVC film processing system

InactiveCN108262905AExtended service lifeReduce the number of replacementsWebs handlingMechanical engineeringMachining system

The invention discloses a PVC film processing system. The PVC film processing system comprises a heating mechanism, a pressing roll mechanism, a humidifying mechanism, a cooling mechanism and a rolling mechanism used for rolling a cooled PVC film; and the rolling mechanism comprises a rack, a collecting roll, a conveying roll and a balancing roll, the balancing roll comprises a supporting shaft and a roller movably arranged on the supporting shaft in a sleeving mode, and the supporting shaft is connected to the rack in a vertical floating mode. According to the PVC film processing system, thebalancing roll is arranged in the rolling mechanism, it is guaranteed that the cooled PVC film can be quickly and closely rolled up and the rolled PVC film is not prone to being folded, and the product quality is high.

Owner:娄军

Textile yarn fixed-length winding and rotating machine

ActiveCN114275629ATight windingAvoid inaccurate fixed lengthFilament handlingTextile disintegration and recoveryTextile yarnIndustrial engineering

The invention relates to the technical field of textile yarn manufacturing, in particular to a textile yarn fixed-length winding and rotating machine, and fixed-length winding of textile yarn is completed through cooperation of a bottom plate, a side plate, a length control device, a guide device, a winding device and a cutting device. According to the spinning yarn fixed-length winding and rotating machine, the problems that in the manual length fixing process, spinning yarn is manually measured firstly and then wound, so that the spinning yarn manufacturing efficiency is low, and existing spinning yarn manufacturing equipment usually measures the number of turns of wound spinning yarn in a mode of calculating the number of turns of rotation of a winding drum, so that the spinning yarn manufacturing efficiency is low can be solved. And the problems that the fixed length of the spinning yarn is not accurate and the like are easily caused by the fact that the outer diameter of the spinning yarn is gradually increased after the spinning yarn is wound by the winding drum and the tightness degree of the spinning yarn during winding are solved.

Owner:徐州和平化纤有限公司

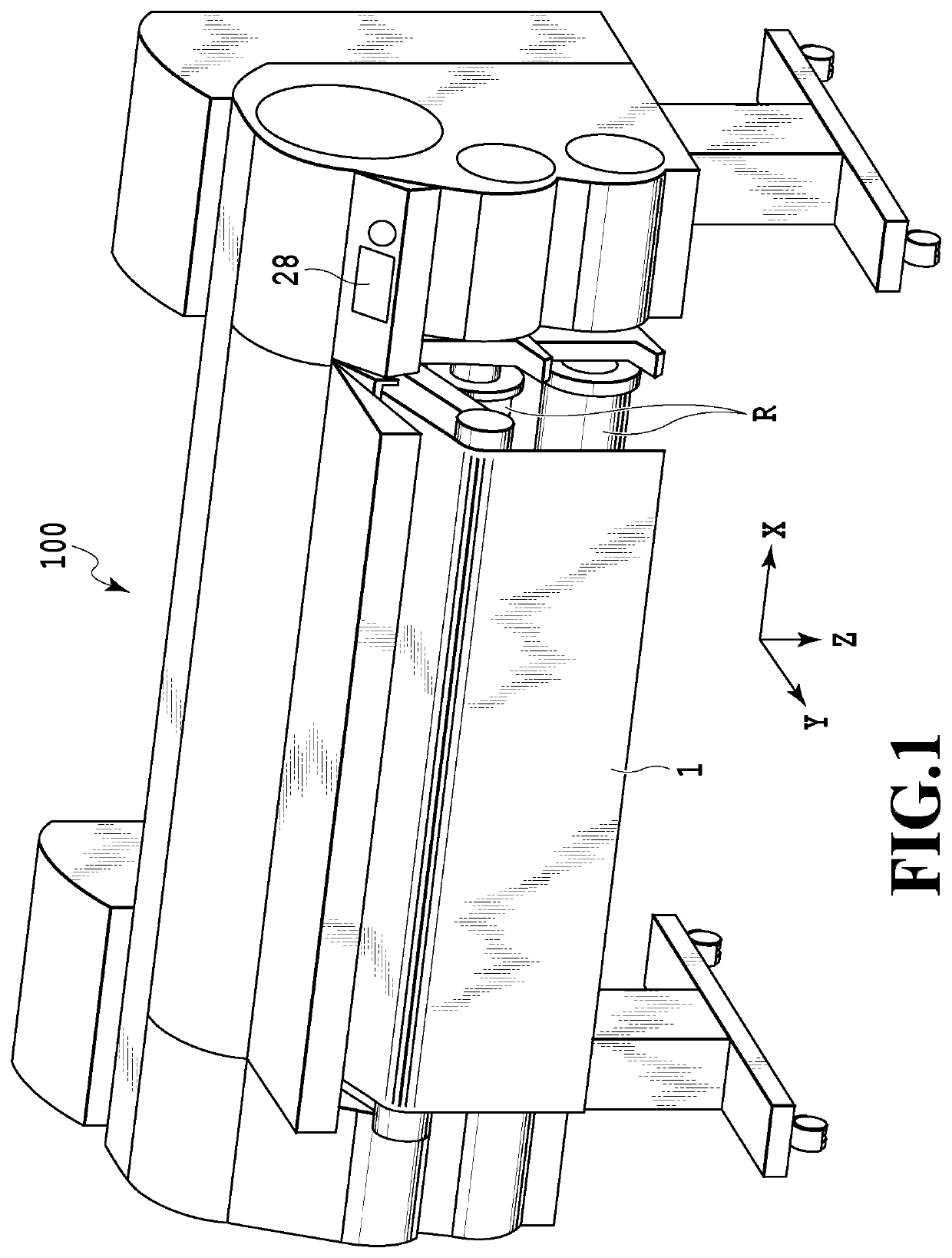

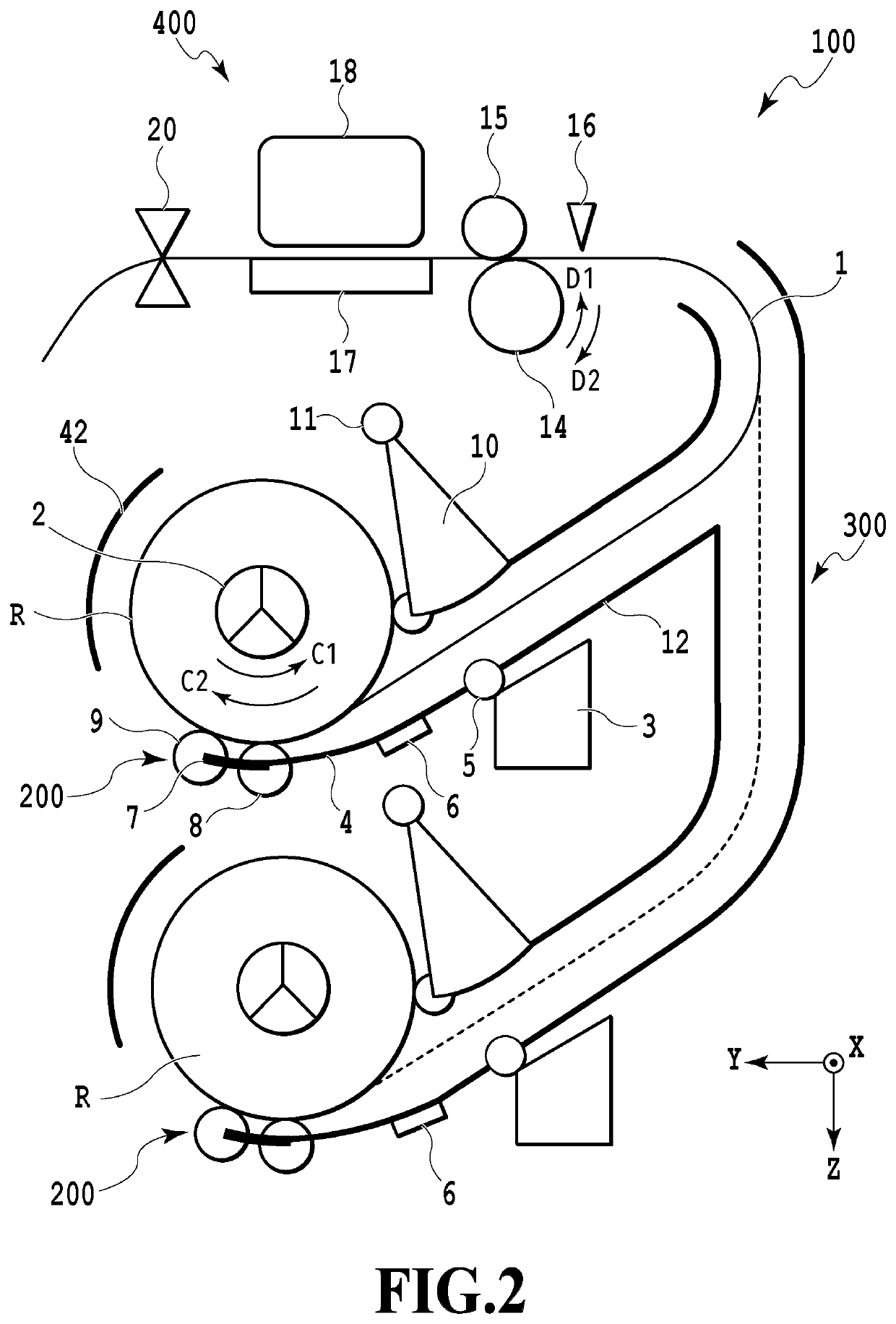

Sheet supplying apparatus and printing apparatus

ActiveUS10829329B2Tight windingFunction indicatorsOther printing apparatusEngineeringContinuous rotation

Owner:CANON KK

Embedded rolling device

The invention relates to an embedded rolling device which comprises a left machine frame, a right machine frame and a cloth rolling device. The cloth rolling device comprises a cloth rolling shaft a and a cloth rolling shaft b, and the cloth rolling shaft a and the cloth rolling shaft b rotate in the same direction. The rotation speed of the cloth rolling shaft a is larger than that of the cloth rolling shaft b. The cloth rolling shaft a and the cloth rolling shaft b are arranged in parallel, and a gap is reserved between the cloth rolling shaft a and the cloth rolling shaft b. The embedded rolling device further comprises an auxiliary winding device. The auxiliary winding device comprises a roller, fixing rods and springs. A cloth brush is arranged on the surface of the roller. The roller is driven by the cloth rolling shaft a to rotate, and the rotation direction of the roller is identical to that of the cloth rolling shaft a. Cloth penetrates through the gap and is rolled above the cloth rolling shaft a and the cloth rolling shaft b. The roller supports the cloth and assists in rolling. The problems that according to an existing cloth rolling device, a take-up roller is required by cloth rolling, rolled cloth is non-uniform and curly, the two sides of the cloth are not smooth, and the cloth is not tight enough are solved.

Owner:浙江艾布特纺织科技有限公司

PVC film coil stock processing system

The invention discloses a PVC film coil stock processing system. The PVC film coil stock processing system comprises a heating mechanism, a pressing roller mechanism, a humidifying mechanism, a cooling mechanism and a material coiling mechanism used for coiling a cooled PVC film; the material coiling mechanism comprises a rack, a material receiving roller, a material transferring roller and a balance roller; the balance roller comprises a supporting shaft and a roller movably arranged on the supporting shaft in a sleeving manner; the supporting shaft is connected to the rack in an up-down floating manner; the two ends of the material receiving roller are each provided with a connection shaft; and the rack is provided with slide grooves in cooperation with the connection shafts and a position adjusting device used for positioning the positions of the connection shafts. In the PVC film coil stock processing system, due to the fact that the position of the material receiving roller relative to the rack is adjustable, when a thick PVC film needed to be coiled, it is needed to control the material receiving roller to do certain movement in the direction of a raw material feeding roller,then it can be guaranteed that a film coil cannot be near to the feeding roller, and it is guaranteed that a good coiling effect is achieved.

Owner:娄军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com