PVC film coil stock processing system

A processing system and roll material technology, applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of PVC film wrinkles, lower product quality, and inconsistent heights on both sides of the film, so as to achieve less wrinkle and better quality The effect of high and good winding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

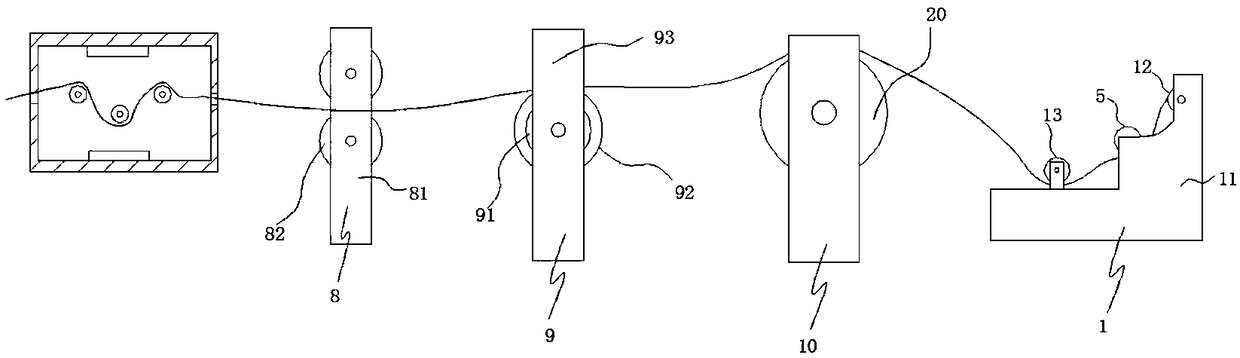

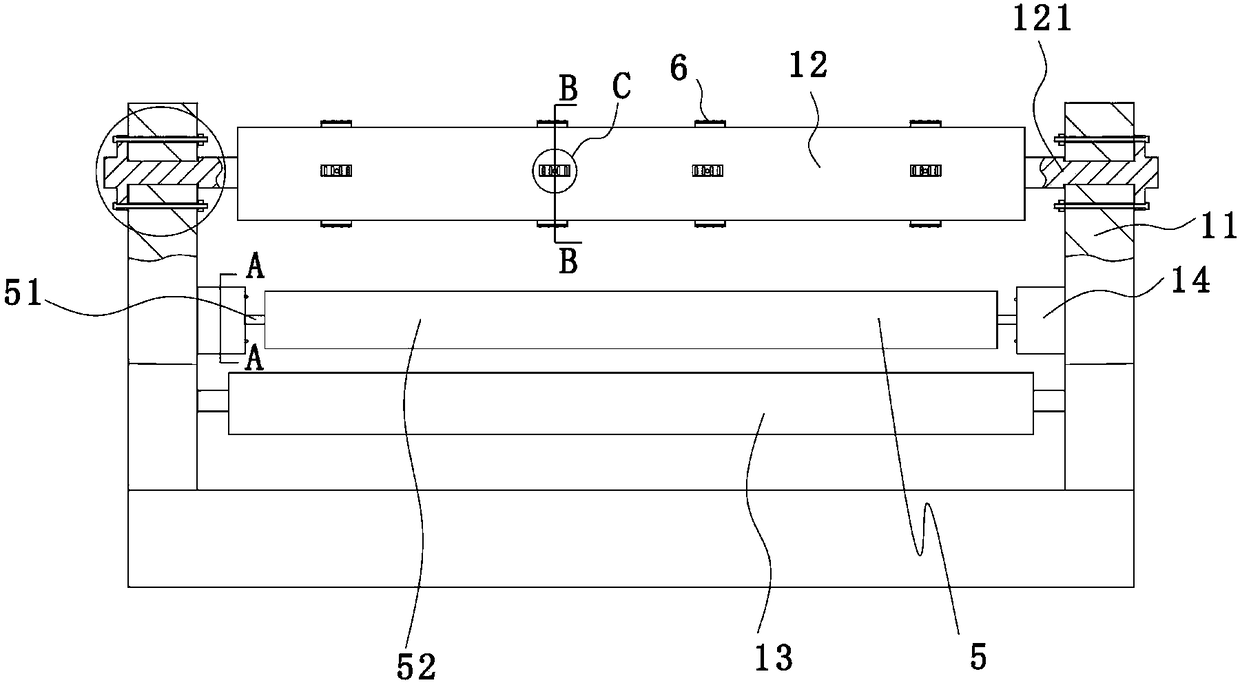

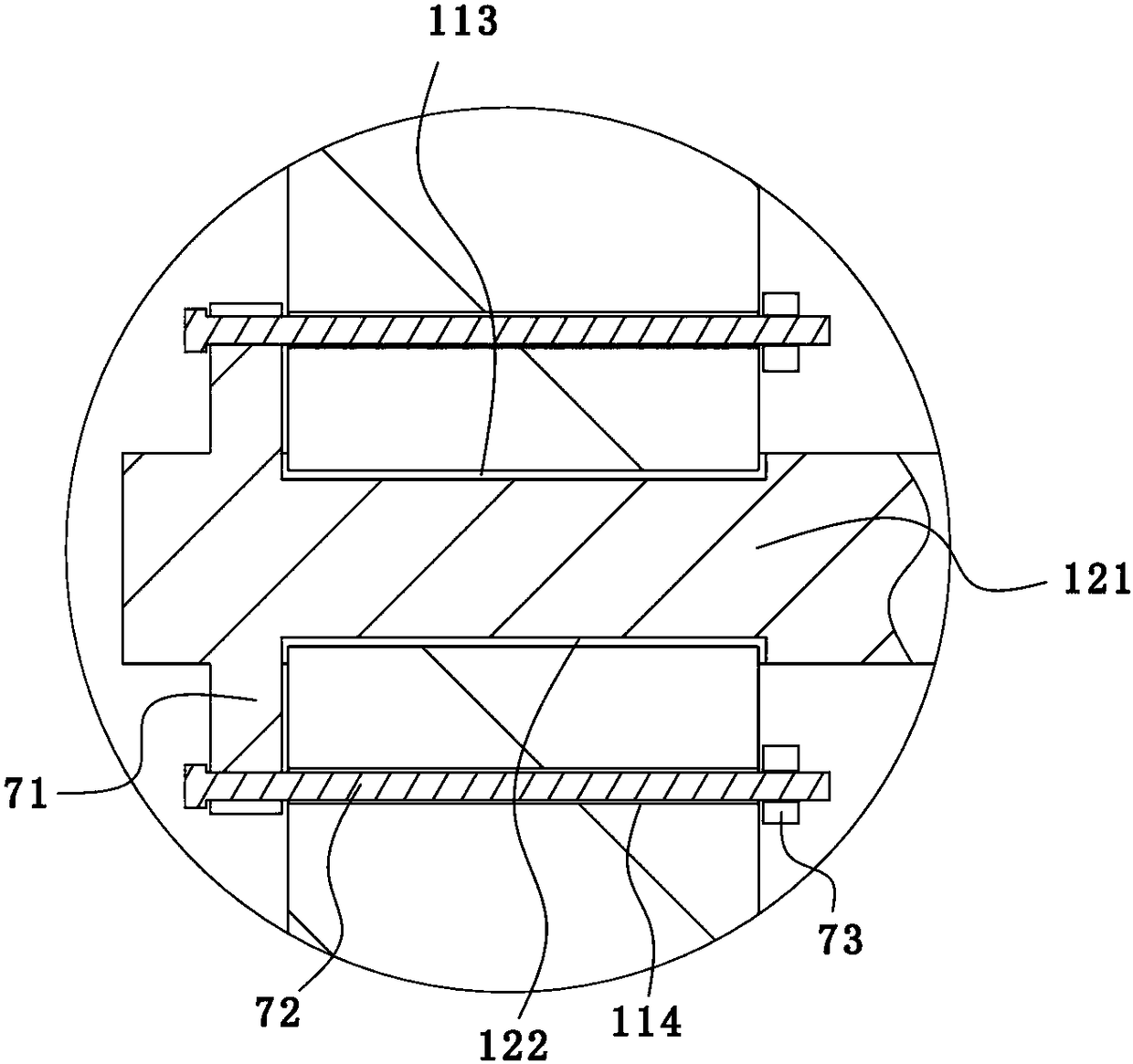

[0029] Such as Figure 1-14 Shown, a coil material processing system of PVC film, a coil material processing system of PVC film comprises a heating mechanism 7, a pressure roller mechanism 8, a humidifying mechanism 9, a cooling mechanism 10 and is used for cooling the PVC film. The coiling material mechanism 1 of winding, described coiling material mechanism 1 comprises frame 11, material receiving roller 12 and delivery roller 13, and described material receiving roller 12 is driven to rotate by driving motor, and described coiling material device also comprises balance roller 5. The balance roller includes a support shaft 51 and a roller 52 movably sleeved on the support s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com