Multi-layer wire stripping equipment for seat ring heater cable

A heater and wire technology, which is applied in the direction of dismantling/armoring cable equipment, etc., can solve the problems of insufficient production capacity, poor versatility, unfavorable storage and transportation, etc., to reduce manpower use, reduce labor costs, and good winding effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings so that those embodiments can be easily realized by those having ordinary skill in the art to which the invention pertains. However, the present invention can also be realized in various forms, so the present invention is not limited to the embodiments described below, and in addition, in order to describe the present invention more clearly, parts not connected with the present invention will be omitted from the drawings.

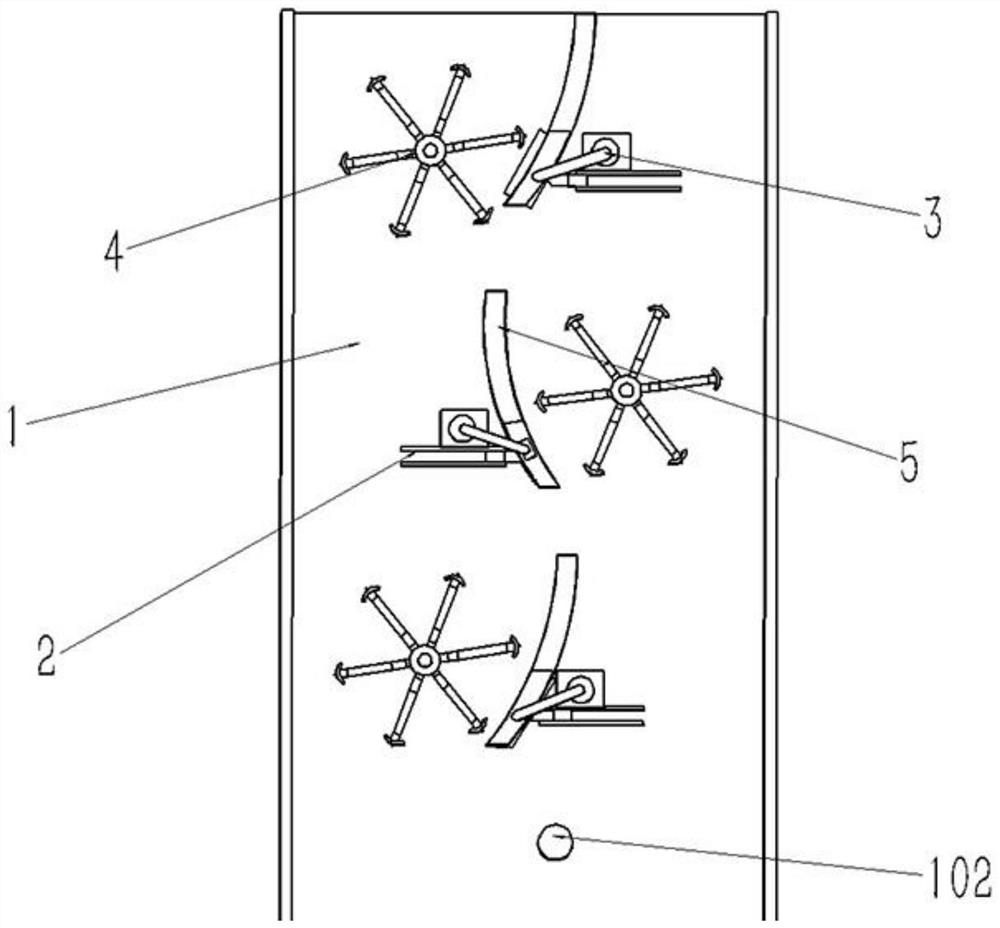

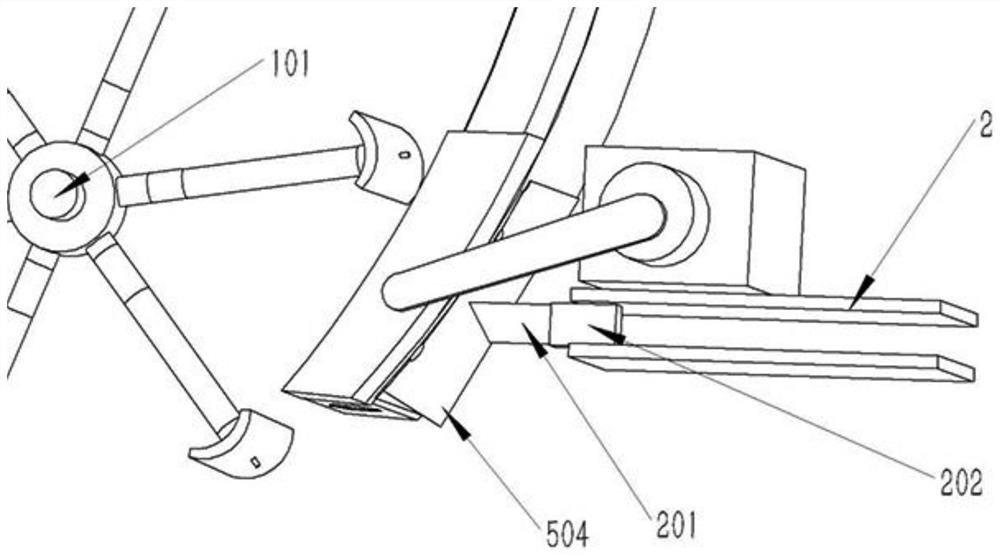

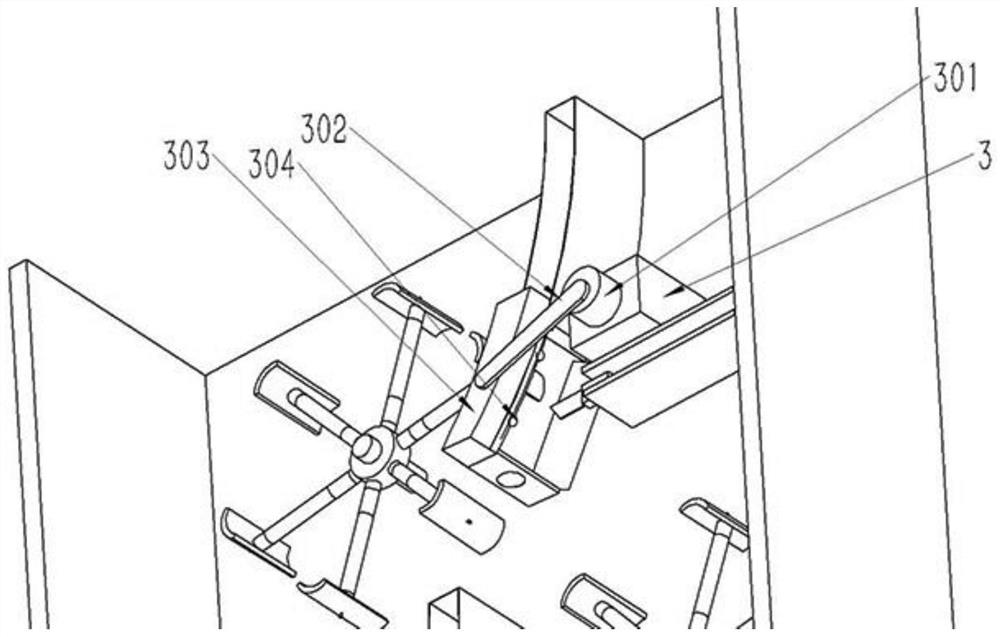

[0022] Such as Figure 1-5 As shown, a multi-layer wire stripping equipment for the seat ring heater cable includes: a workbench 1, the inside of which has a plurality of wire guide rails 5, and the upper and bottom of the wire guide rails 5 have wire through holes 501 , while limiting the wire, the wire is allowed to pass through the wire hole 501. On both sides of the lower part of the wire guide rail 5, a recovery window 503 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com