Patents

Literature

46results about How to "No need for manual finishing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

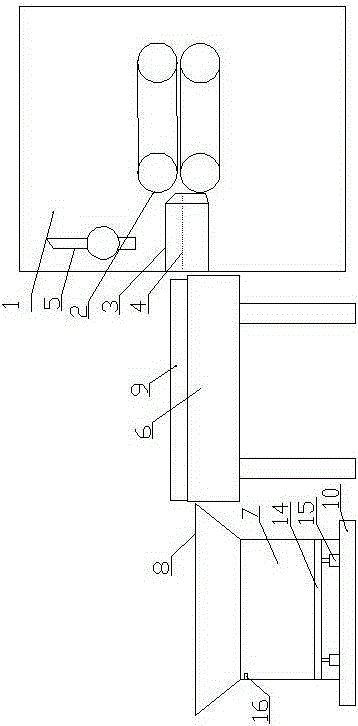

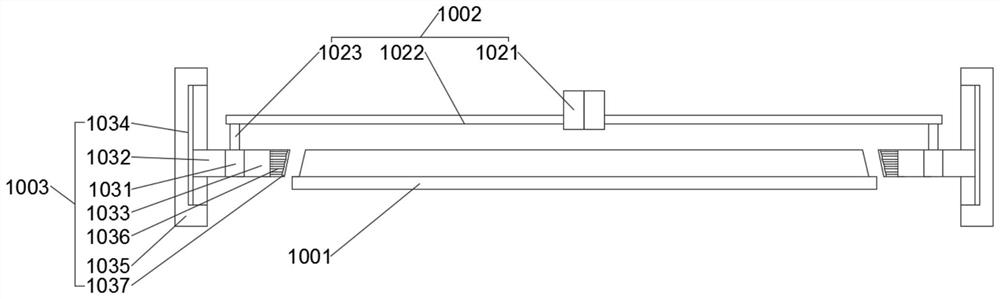

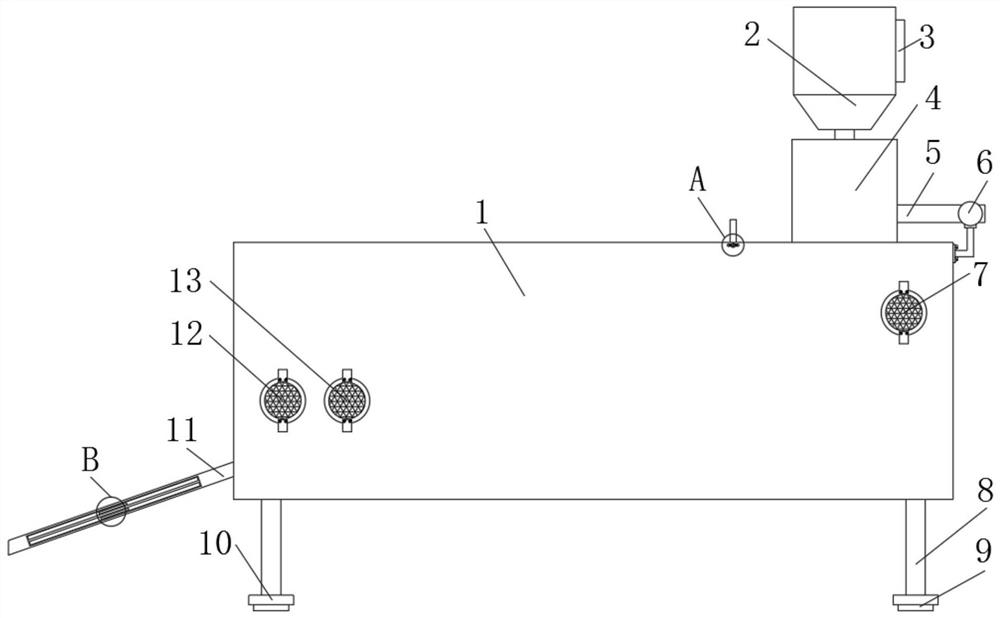

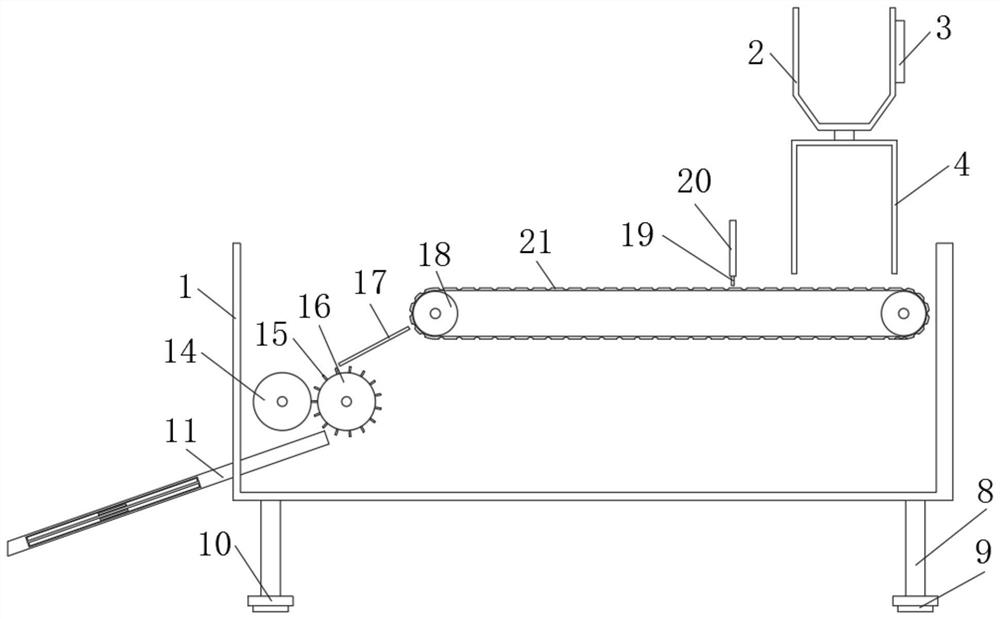

Wire cutting-off and collecting device

InactiveCN105217219AUniform collectionNo need for manual finishingConveyorsConveyor partsWire cuttingEngineering

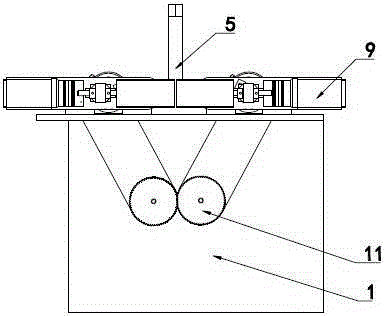

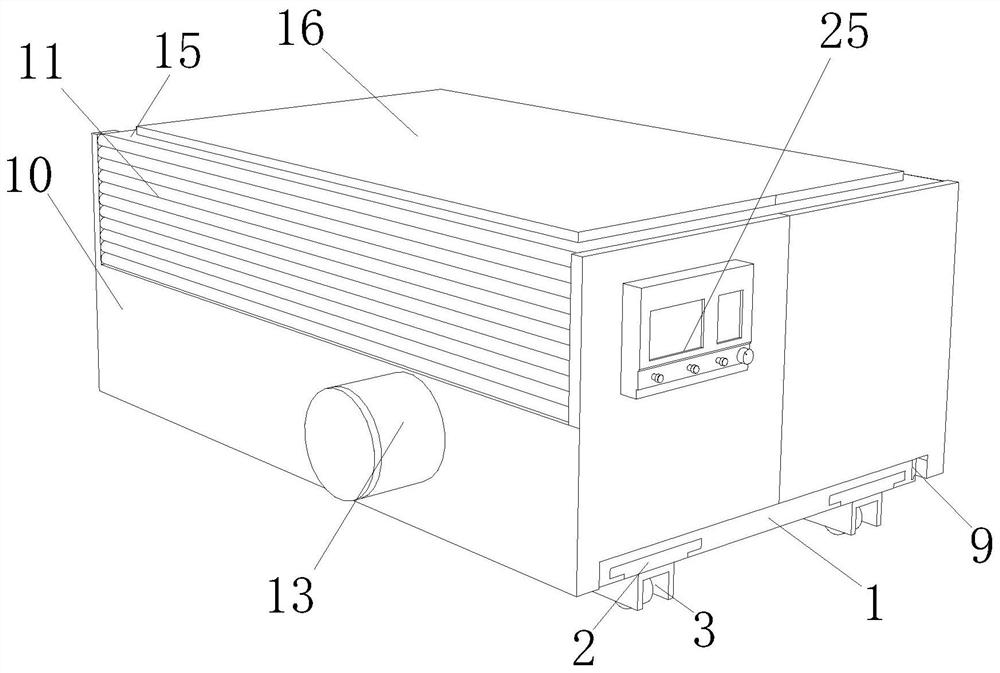

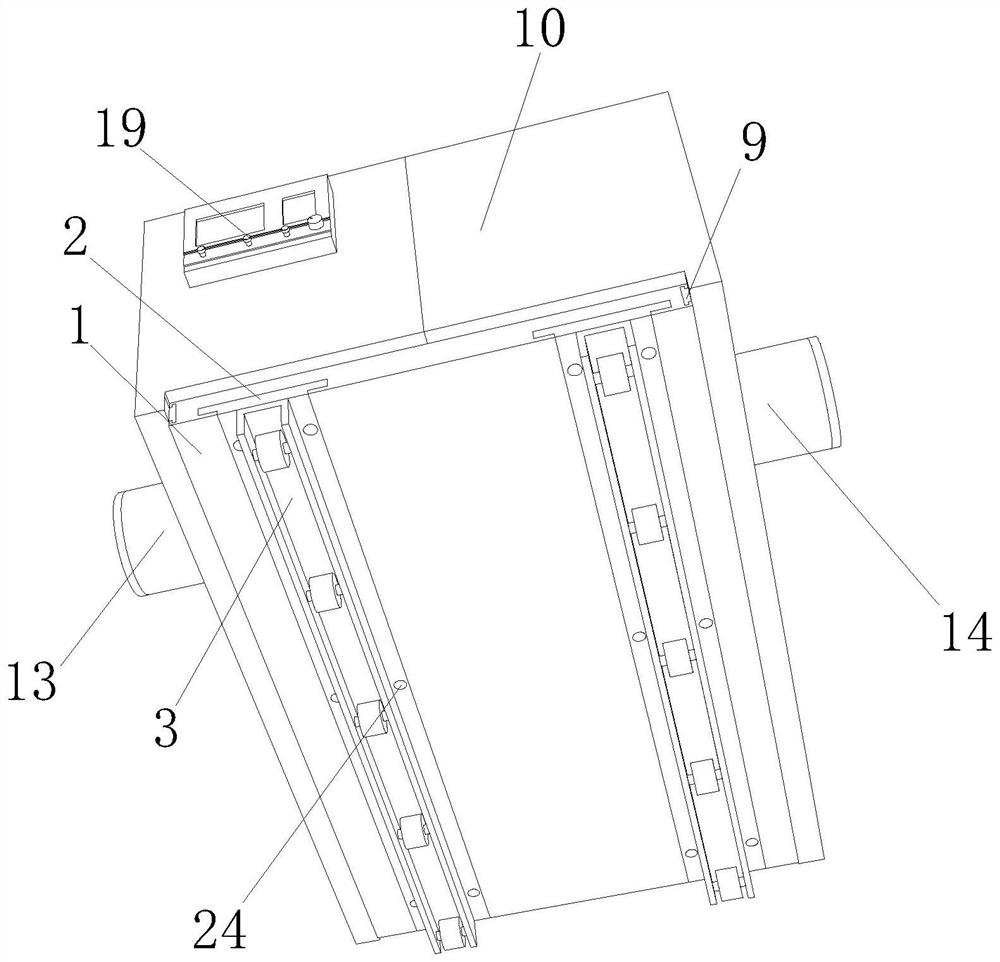

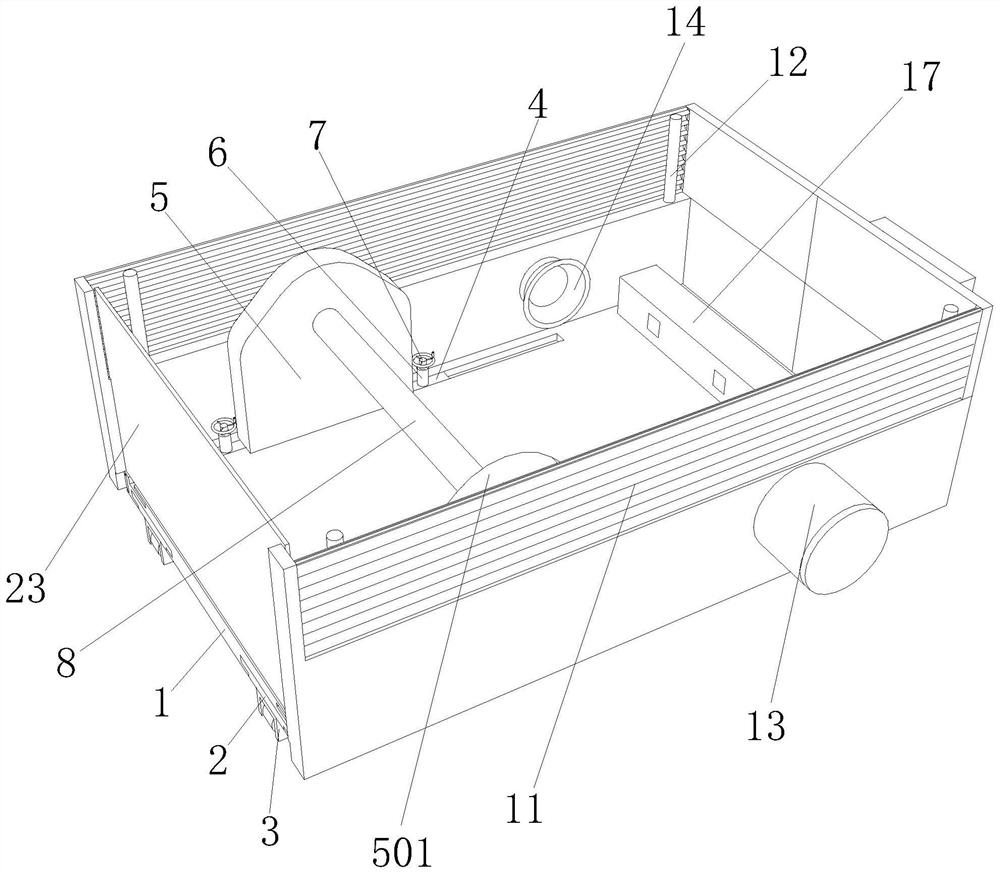

The invention provides a wire cutting-off and collecting device. Wires are conveyed into a cutting channel of a cutting table through a conveying belt and cut into a certain length through a rotary cutter. The cut wires are conveyed into a wire collecting box through the conveying belt, and the wire collecting box can slide forwards and backwards through a pushing cylinder, so that the wires are collected evenly and manual arrangement is not needed. The wires can be supported through a wire supporting plate capable of sliding upwards and backwards in the wire collecting box, the wire collecting height can be adjusted according to actual requirements, and the wires can be taken by people conveniently. The wire cutting-off and collecting device is simple in structure and easy to operate, the wires can be efficiently and quickly cut off and evenly connected, and the device is applicable to production.

Owner:WUHU SHUNCHENG ELECTRONICS

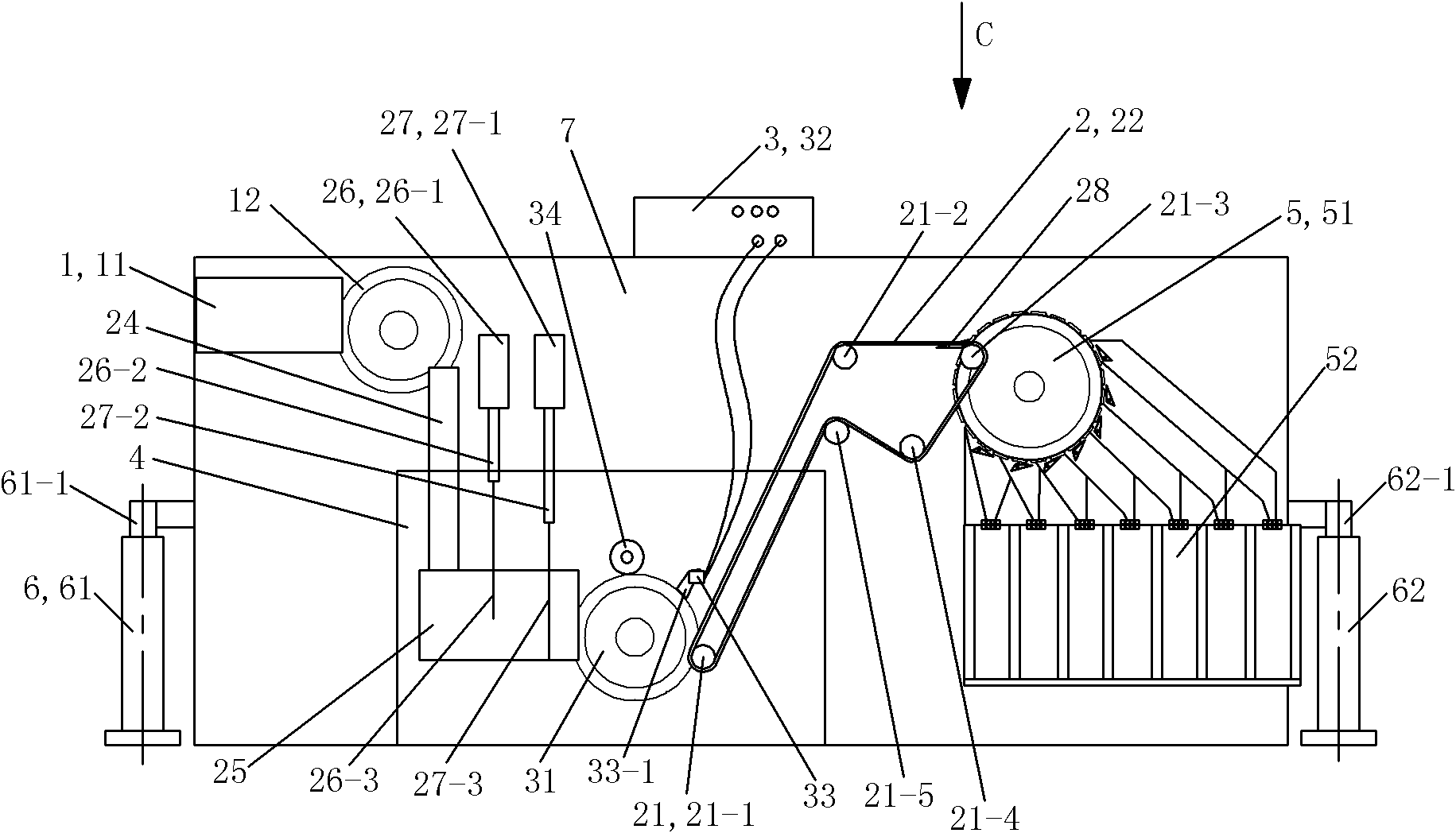

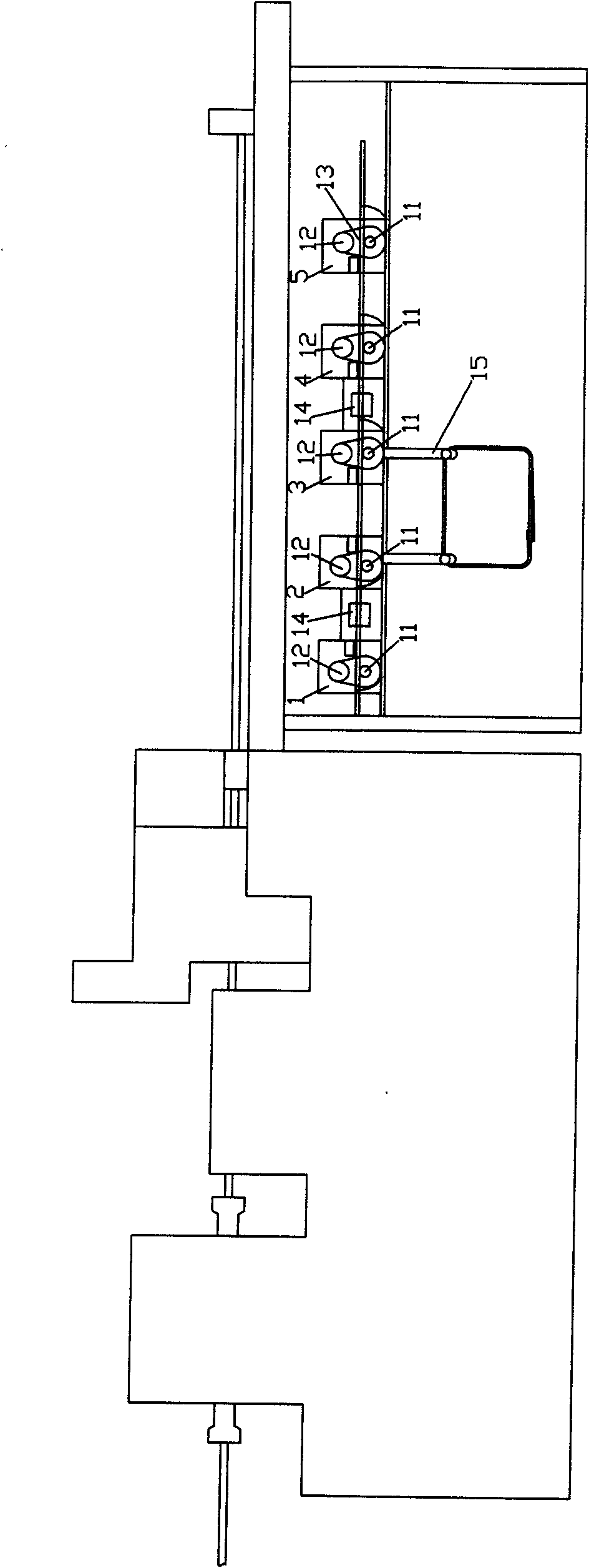

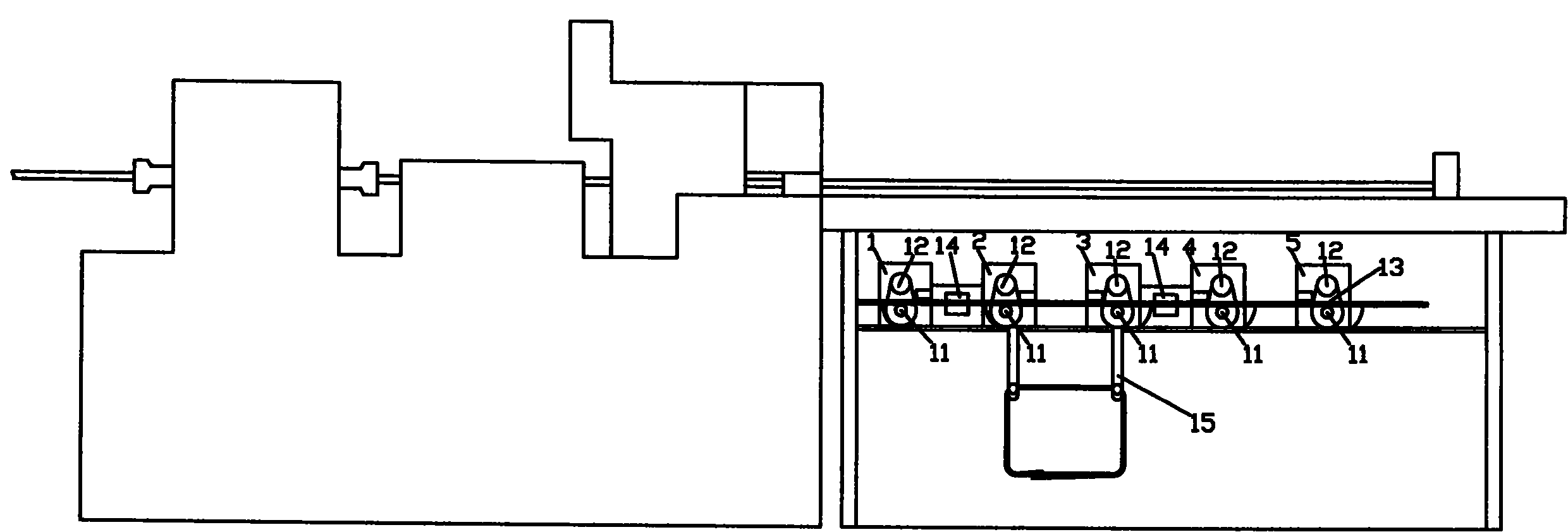

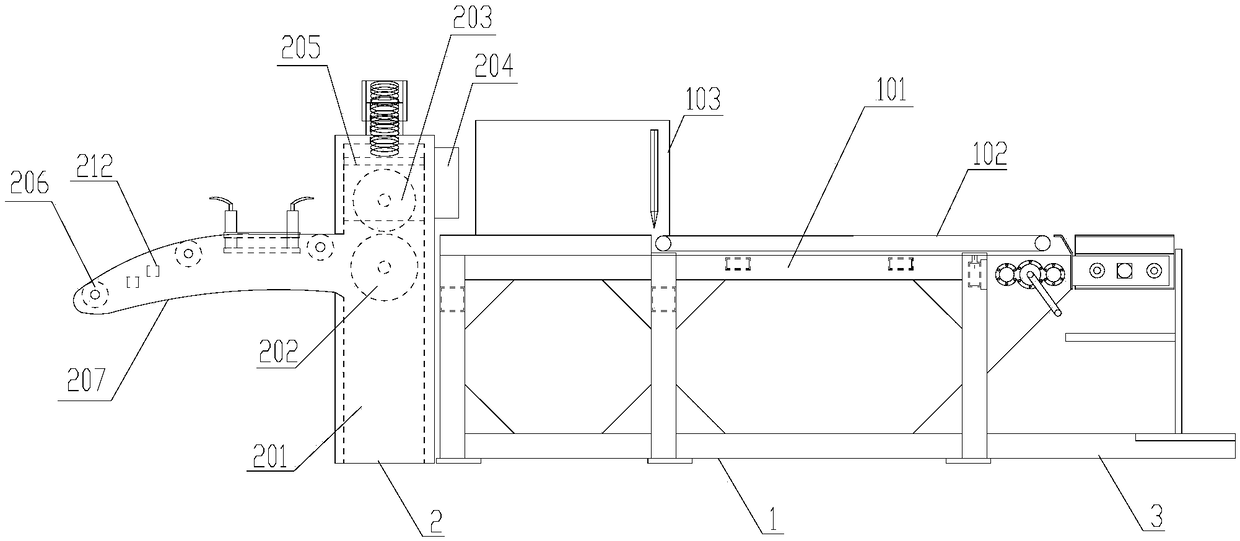

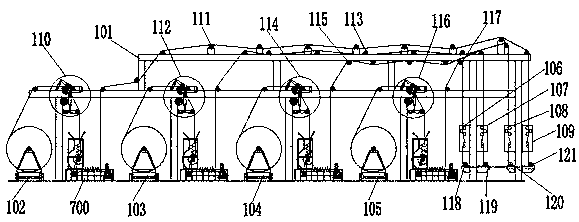

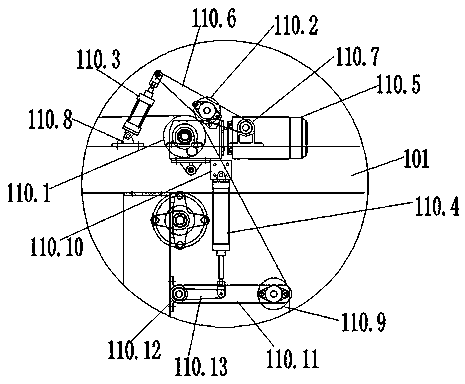

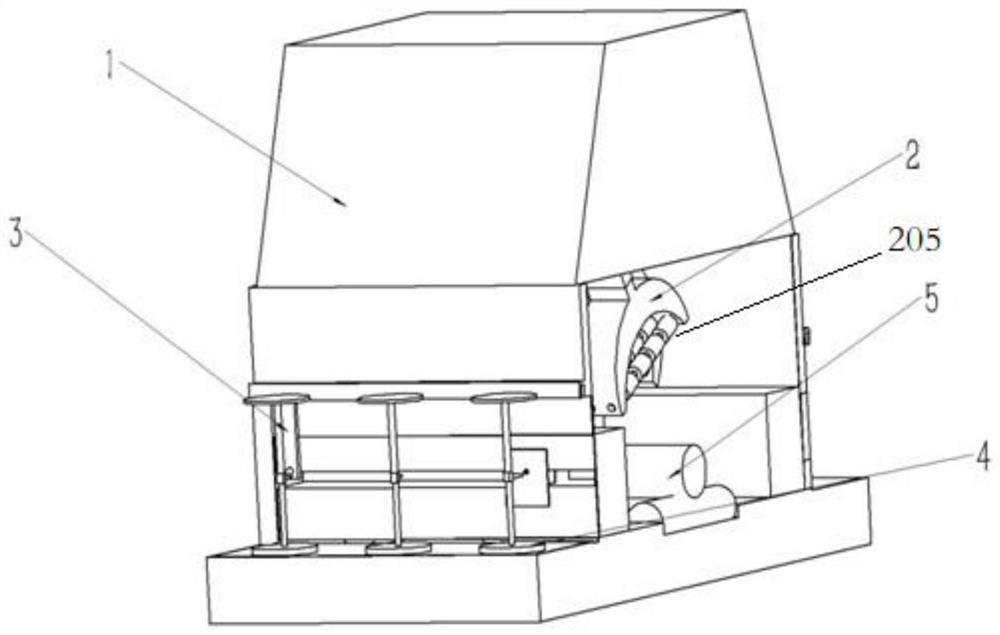

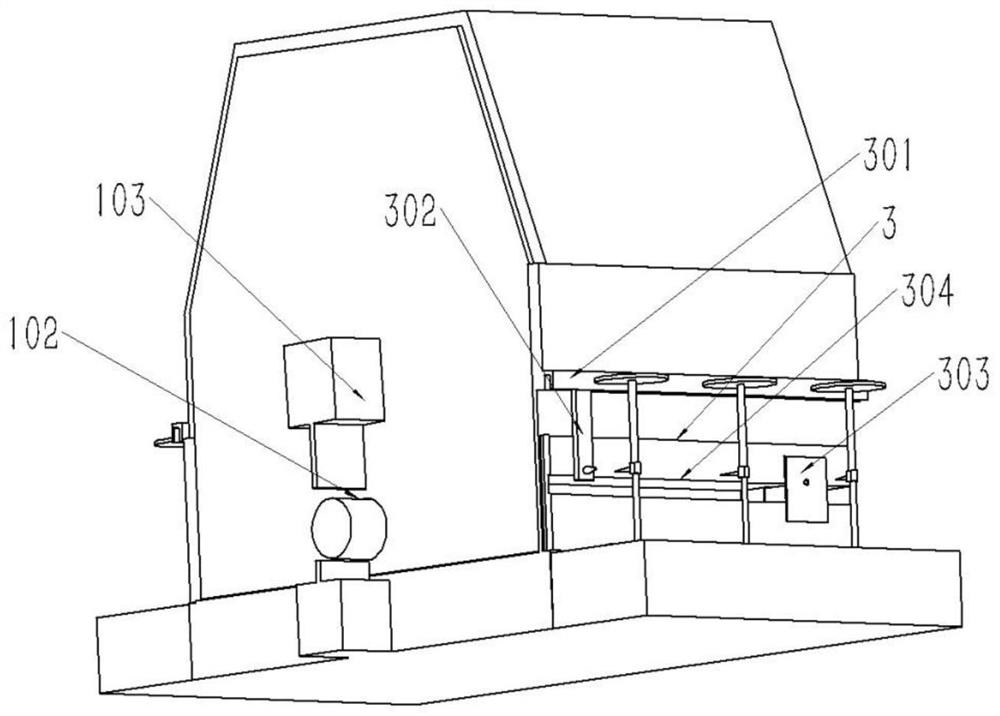

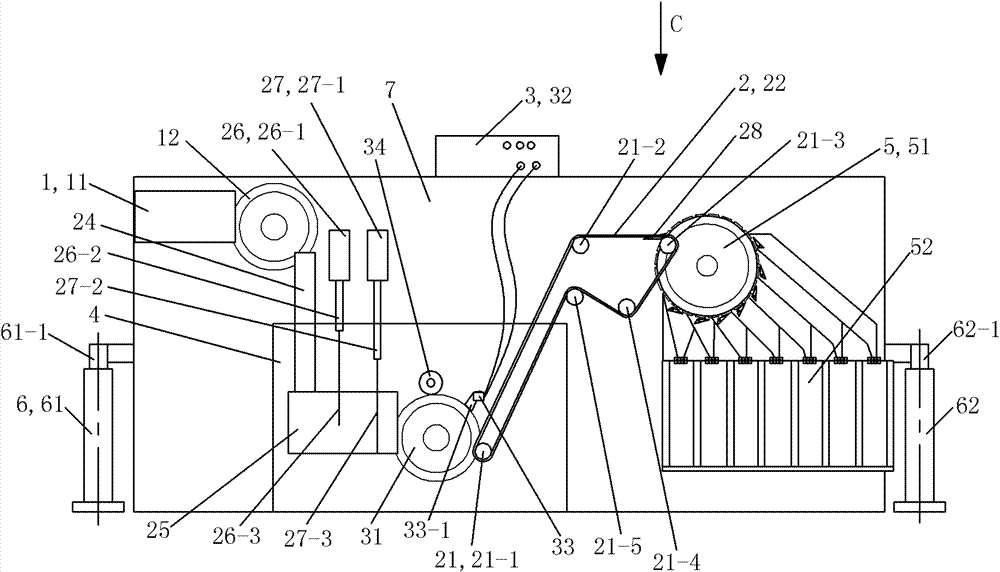

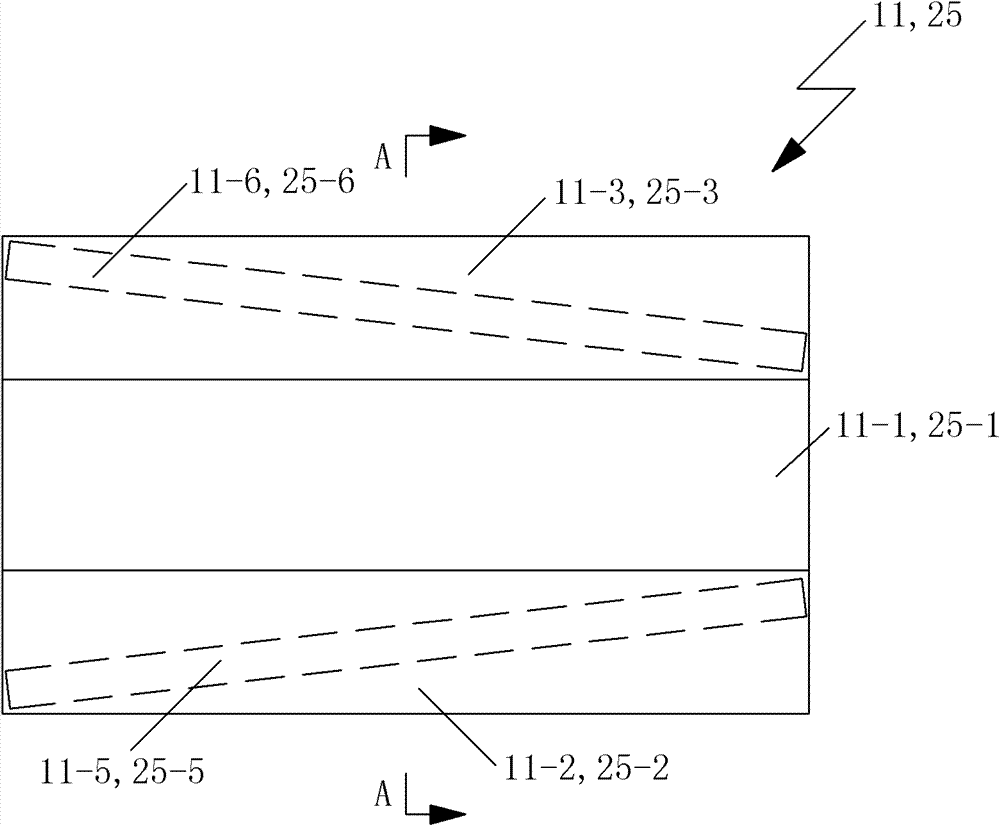

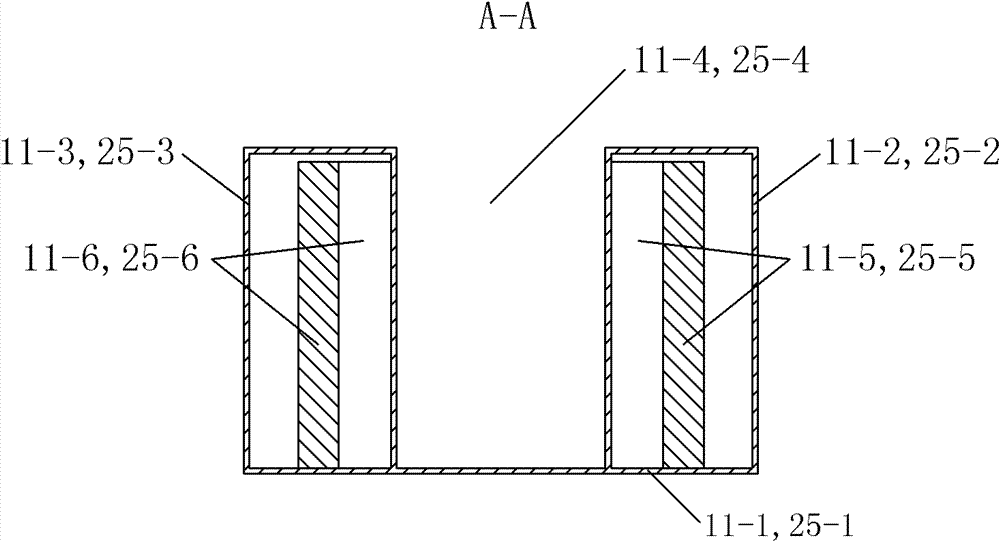

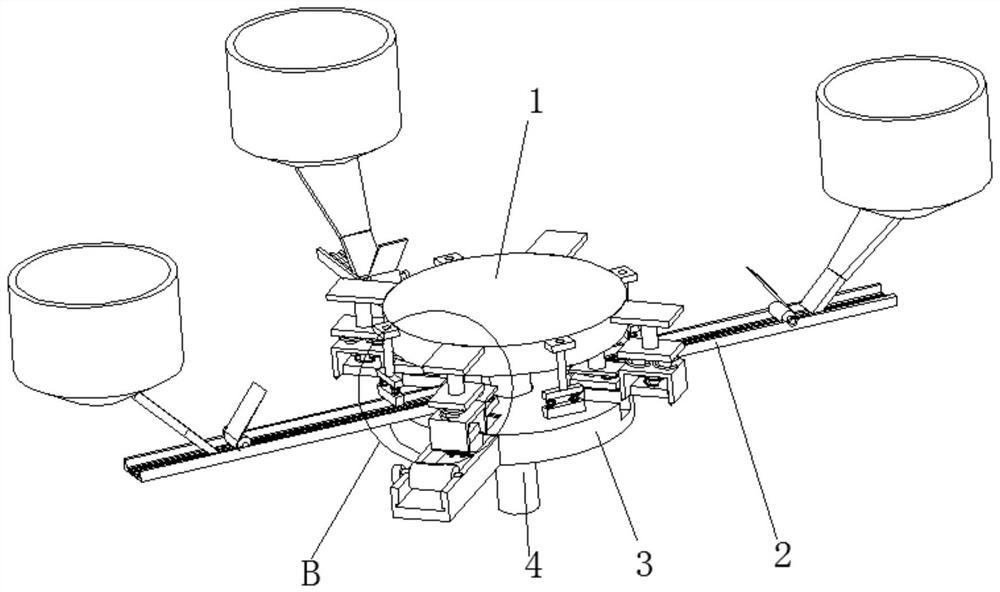

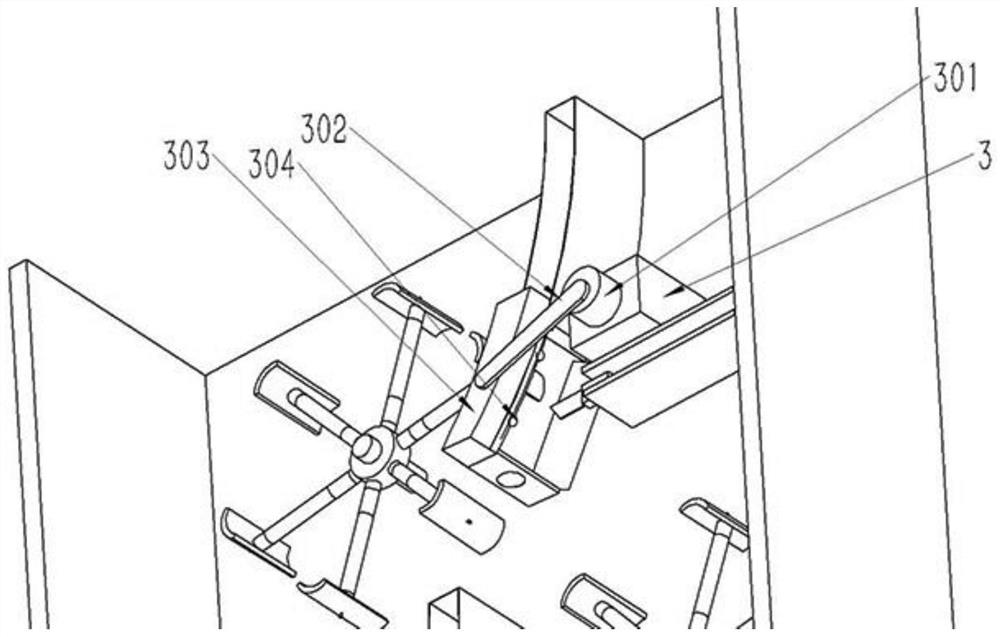

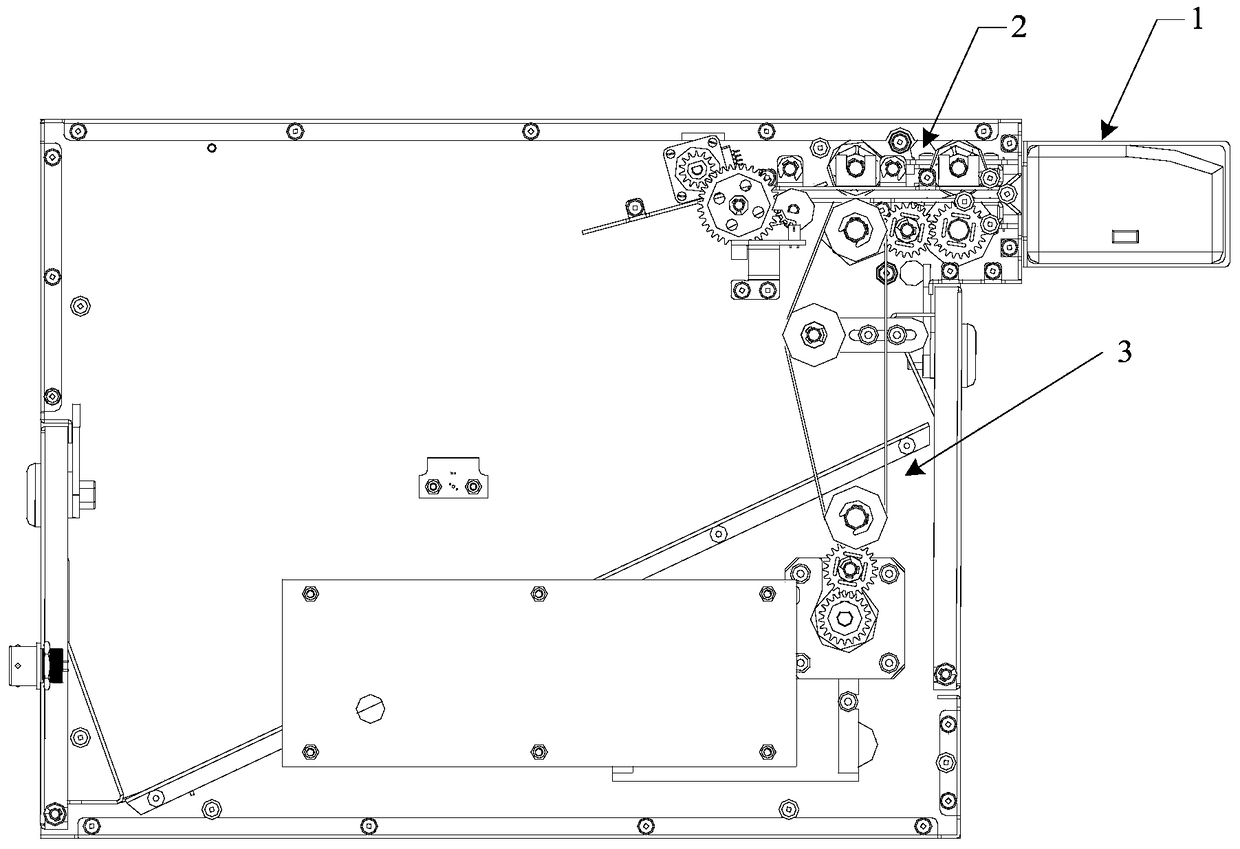

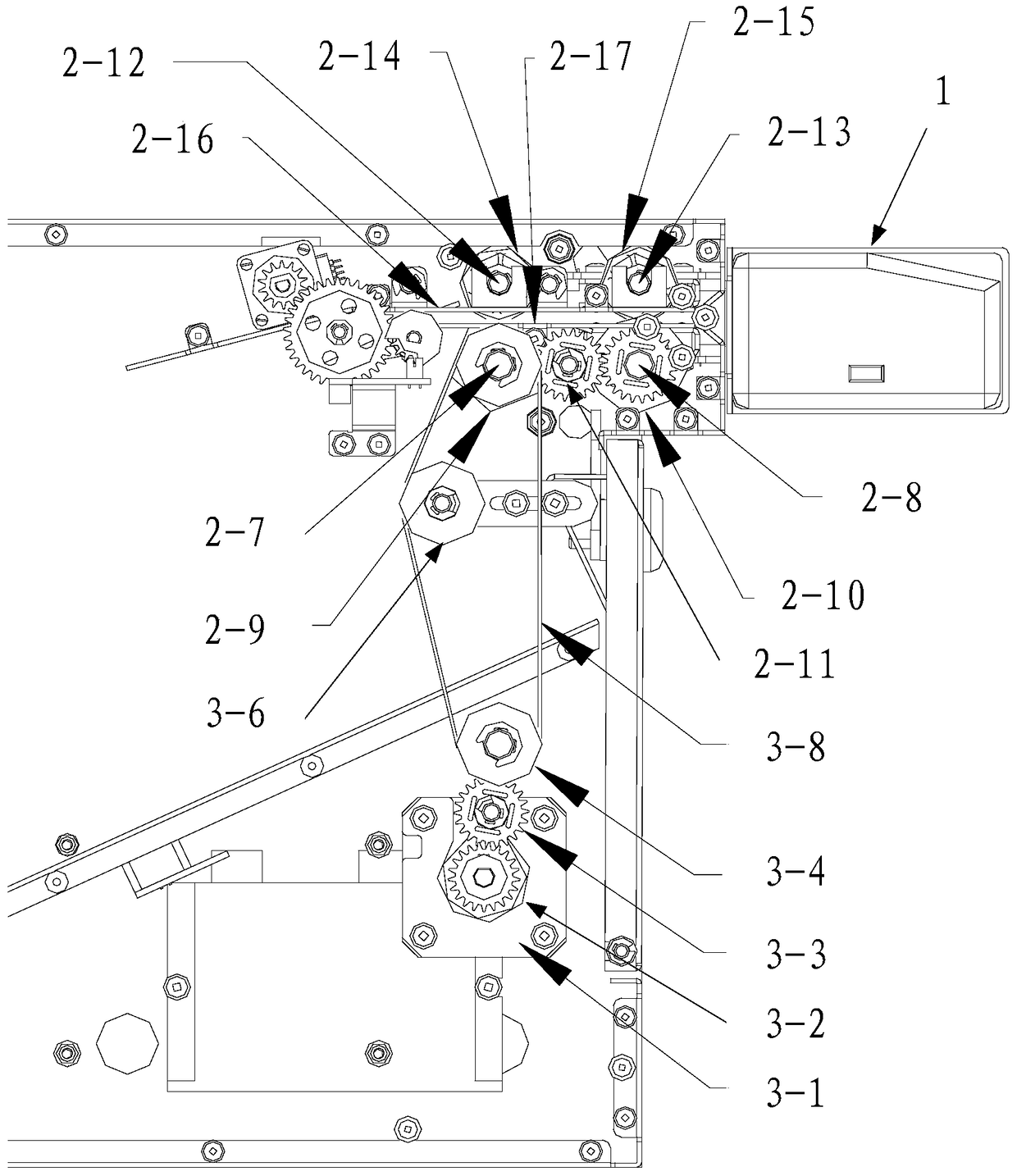

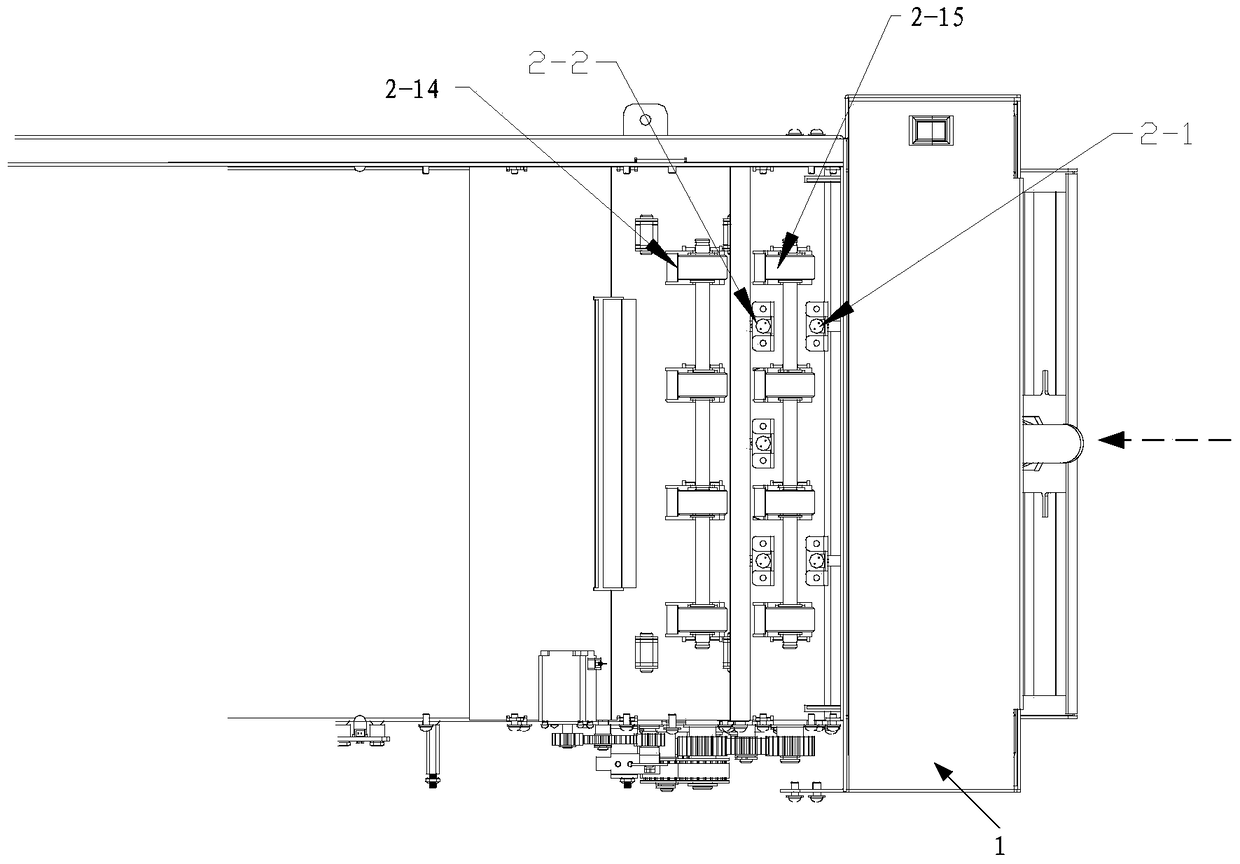

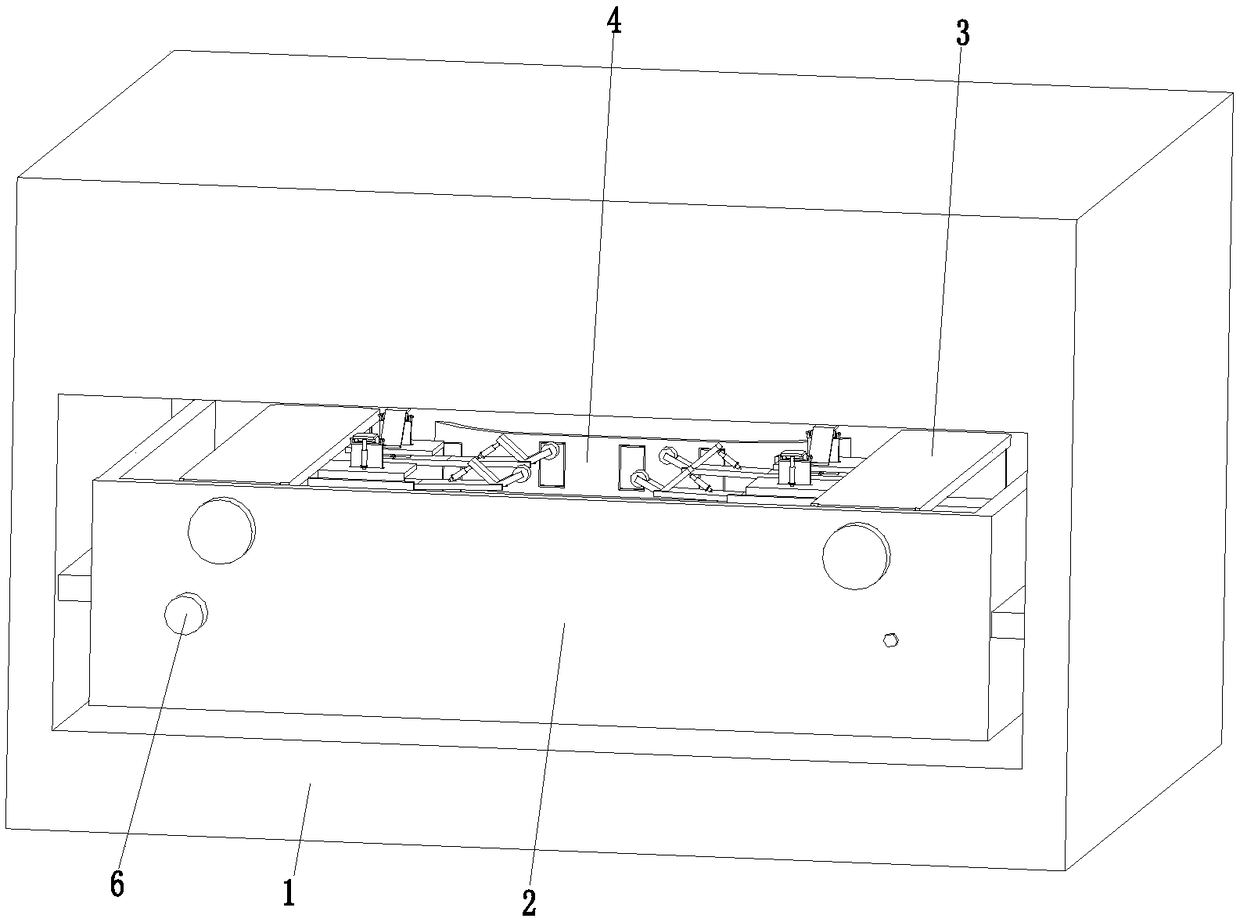

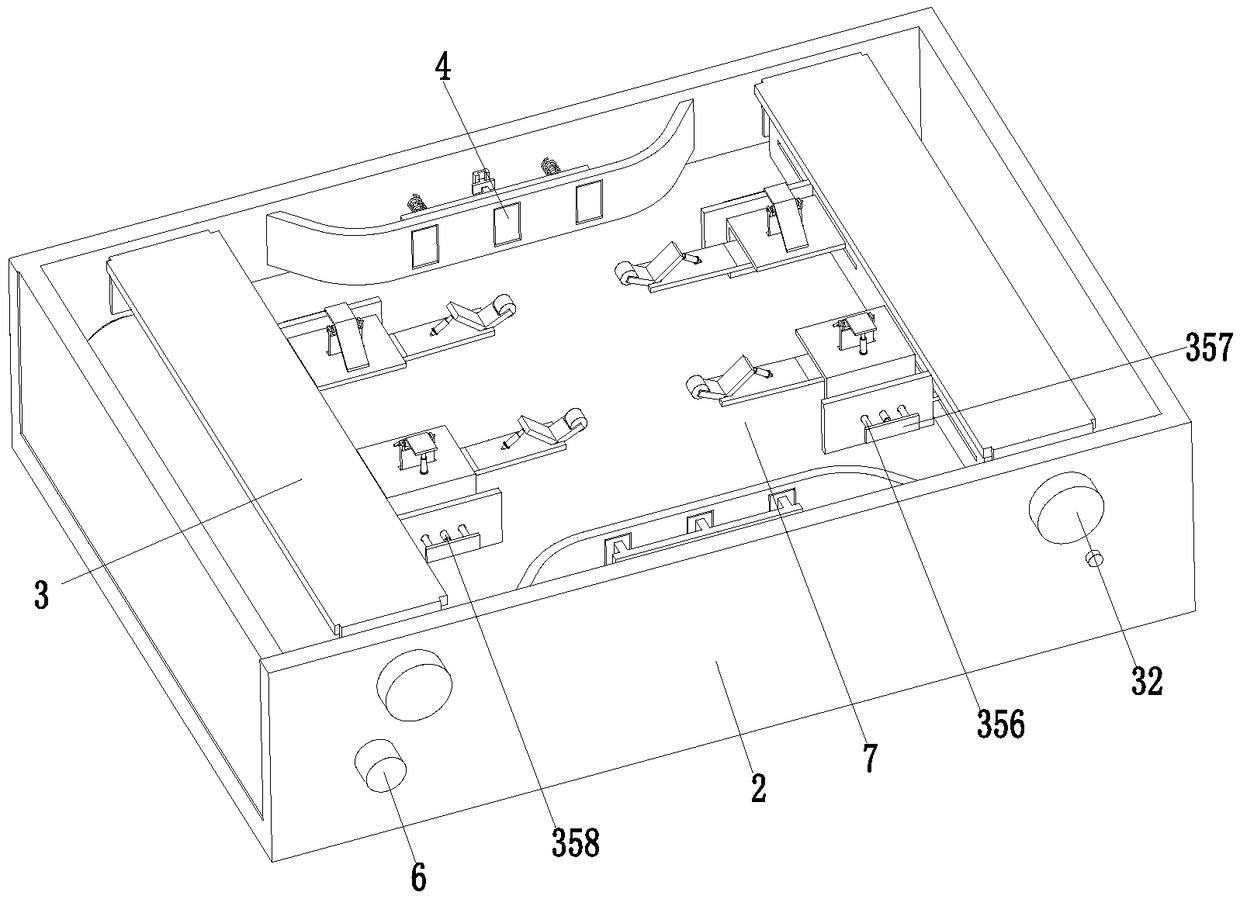

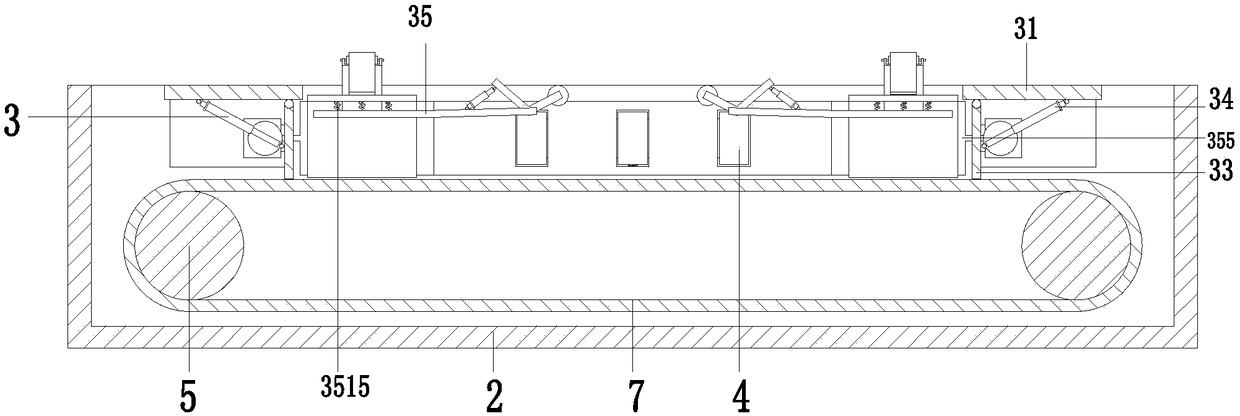

System for testing diode thermistor in high speed

ActiveCN102107190AThe process design principle is simpleCompact structureSortingHeat sensitiveEngineering

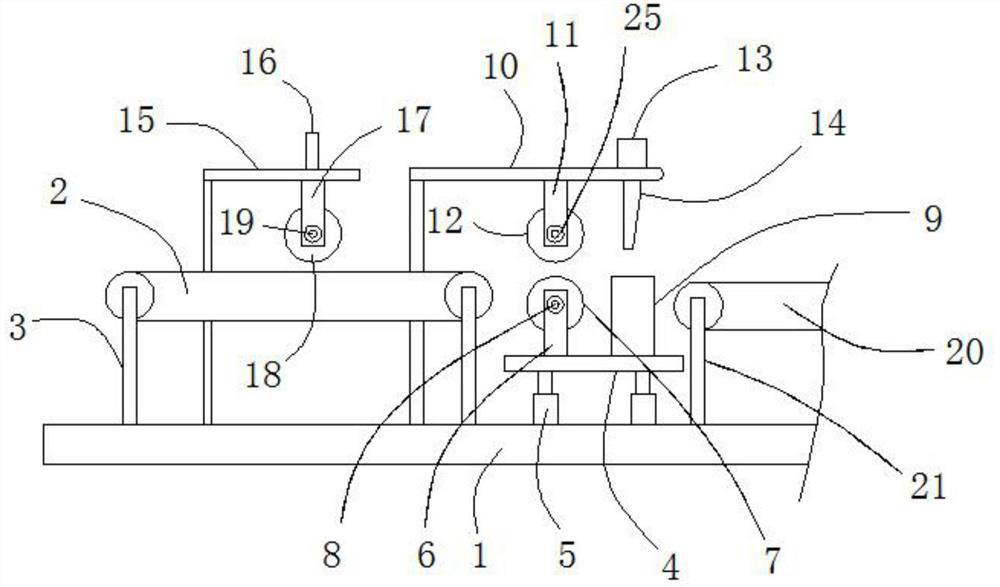

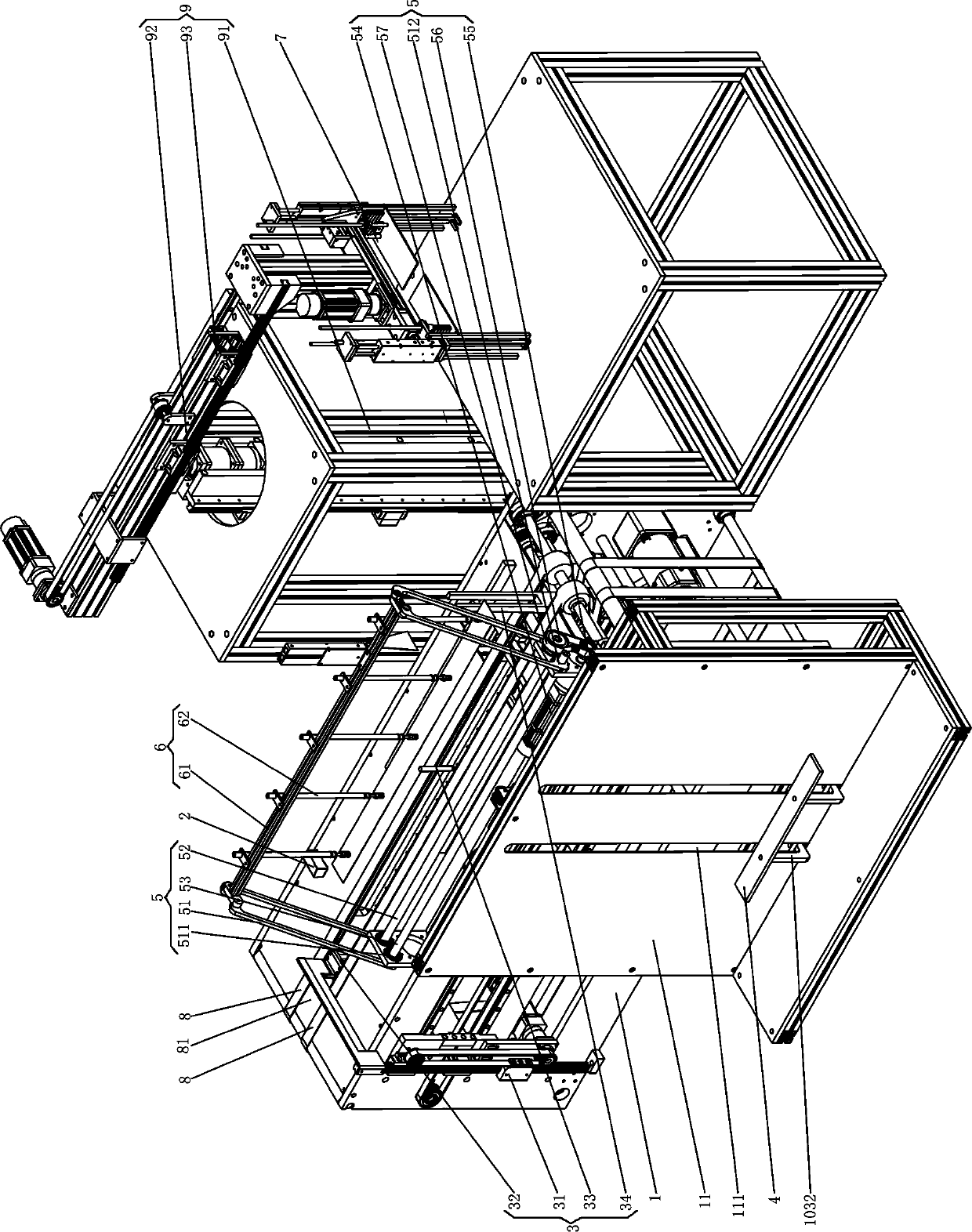

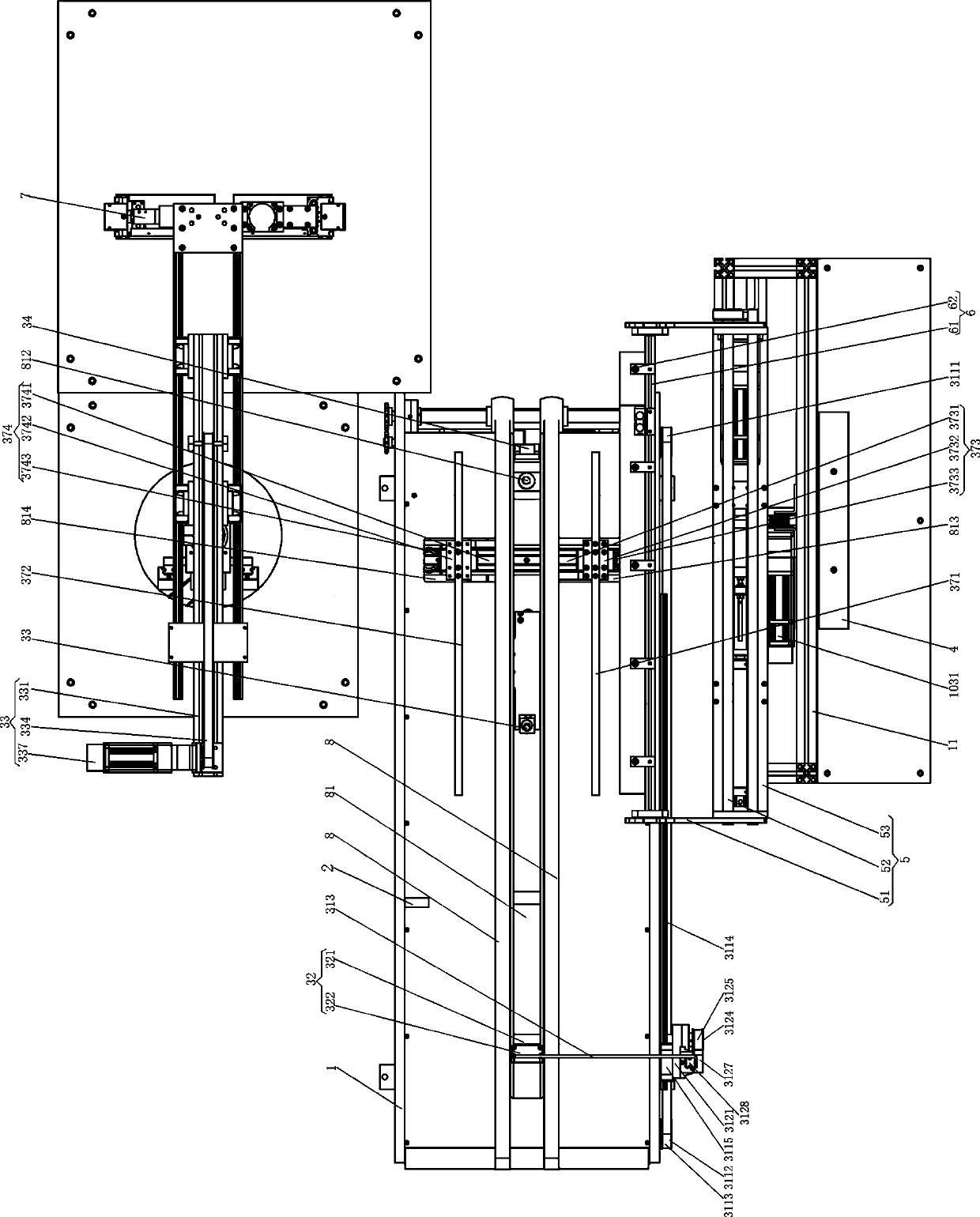

The invention provides a system for testing a diode thermistor in a high speed. The system comprises a material discharging device, a conveying device, a test device, a constant-temperature slot, a material receiving device, a lifting device, an engine seat, a transmission mechanism and a control device; the material discharging device, the conveying device, the test device, the material receiving device, the transmission mechanism and the control device are all arranged on the engine seat; the lifting device and the engine seat are arranged on the floor and the constant-temperature slot is formed on the floor; the material discharging device comprises a material discharging magnetic rail and a material discharging magnetic wheel; the conveying device comprises a chain wheel device, two material discharging chains, a conveying pipe, a feeding magnetic rail, a first stopping device, a second stopping device and a guide block; the test device comprises a test magnetic wheel, a tester and a probe; and the material receiving device comprises a stepping wheel, a material receiving box and a poking sheet. The system is used for testing the diode thermistor, and has high test speed and high stepping precision.

Owner:常州市科文传感器材料有限公司

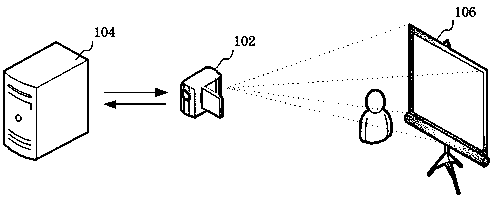

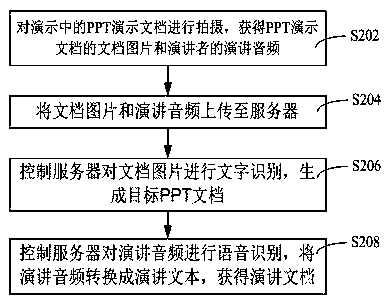

PPT presentation document recording method, apparatus, computer device, and storage medium

InactiveCN109492206ANo need for post-manual finishingNo need for manual finishingCharacter and pattern recognitionNatural language data processingDocumentationSubvocal recognition

The present application relates to a PPT presentation document recording method, apparatus, computer device and storage medium. The method comprises the following steps: customizing the PPT demonstration document in the demonstration, and obtaining the document picture of the PPT demonstration document and the speech audio of the speaker; uploading the document picture and the speech audio to theserver; the control server performs character recognition on the document picture to generate a target PPT document; the control server performs speech recognition on the speech audio, converts the speech audio into speech text, and obtains speech documents. The method can automatically convert the lecture content of the presenter into the form of the text and record the lecture content without the manual arrangement at the later stage, which is very convenient.

Owner:深圳市容会科技有限公司

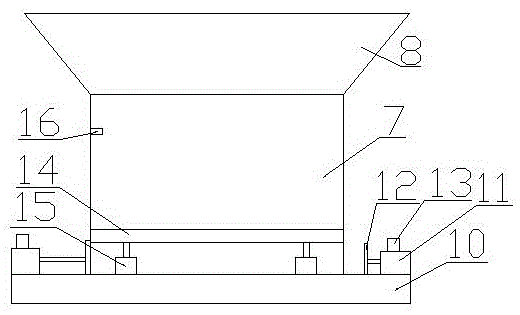

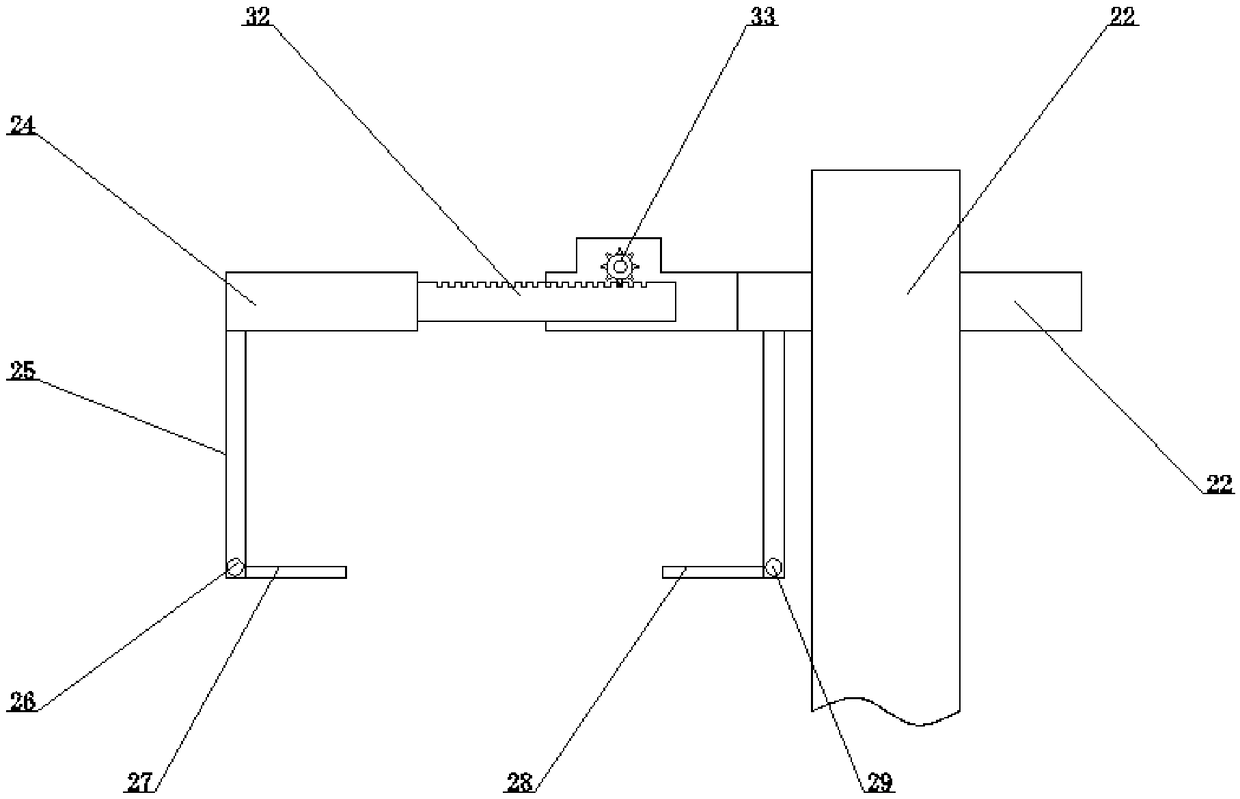

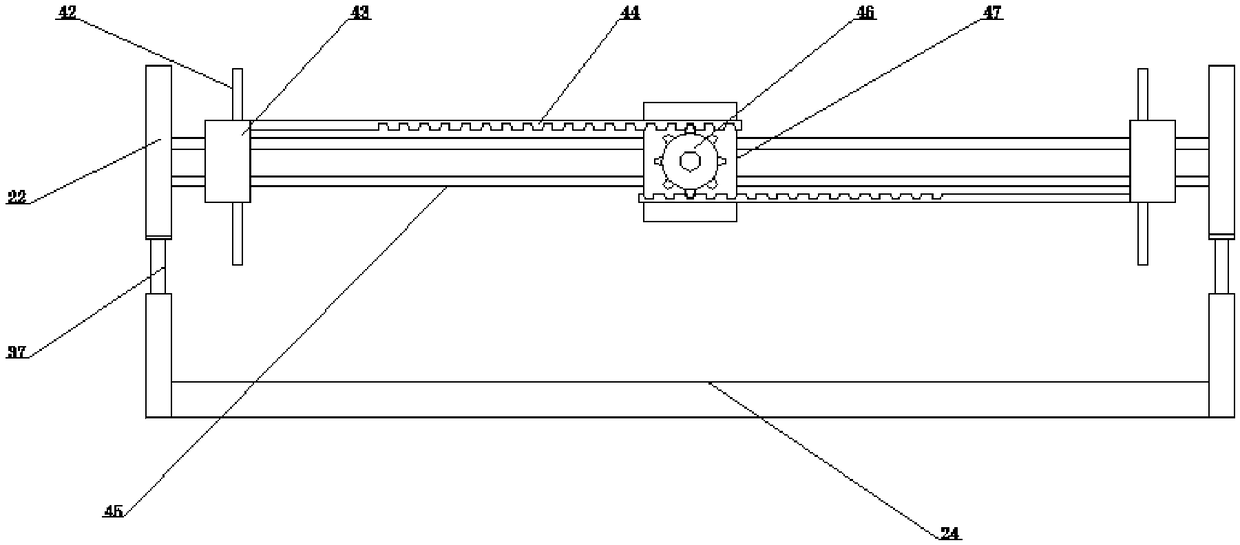

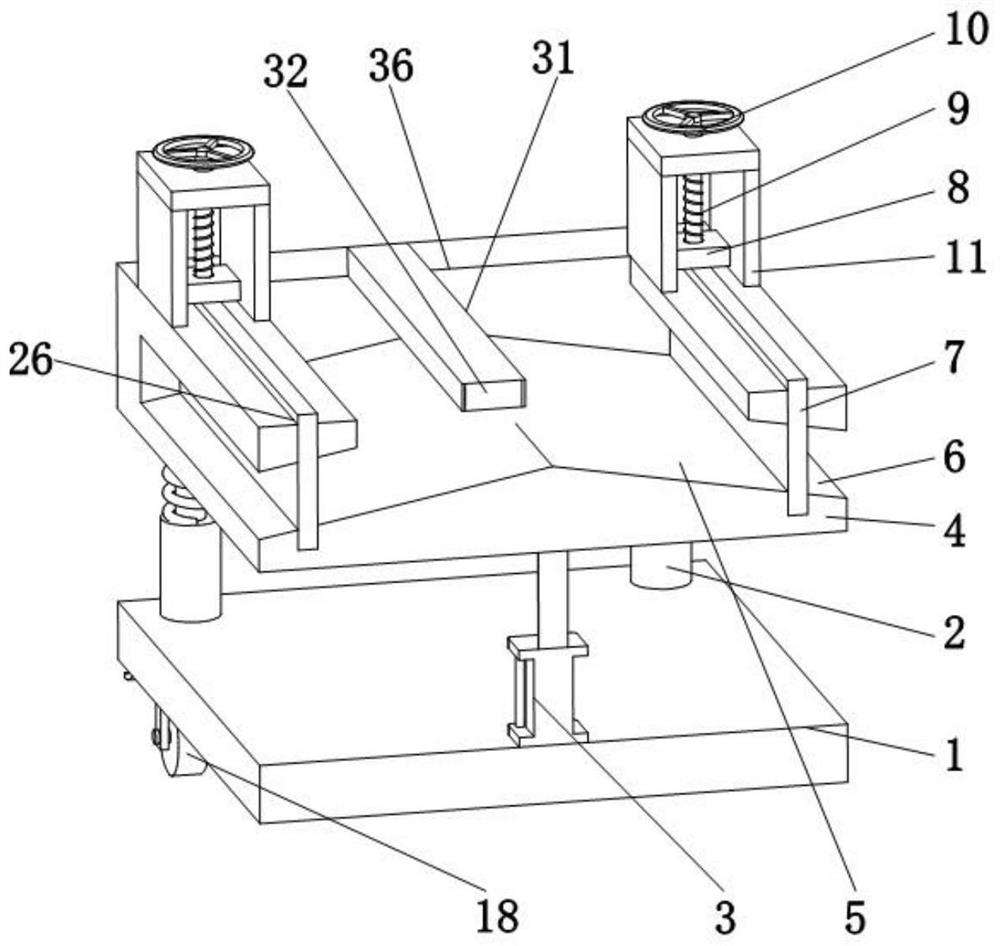

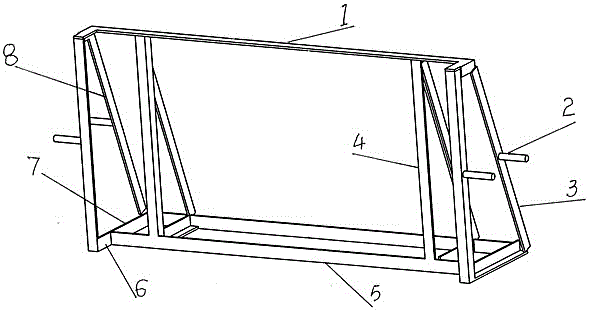

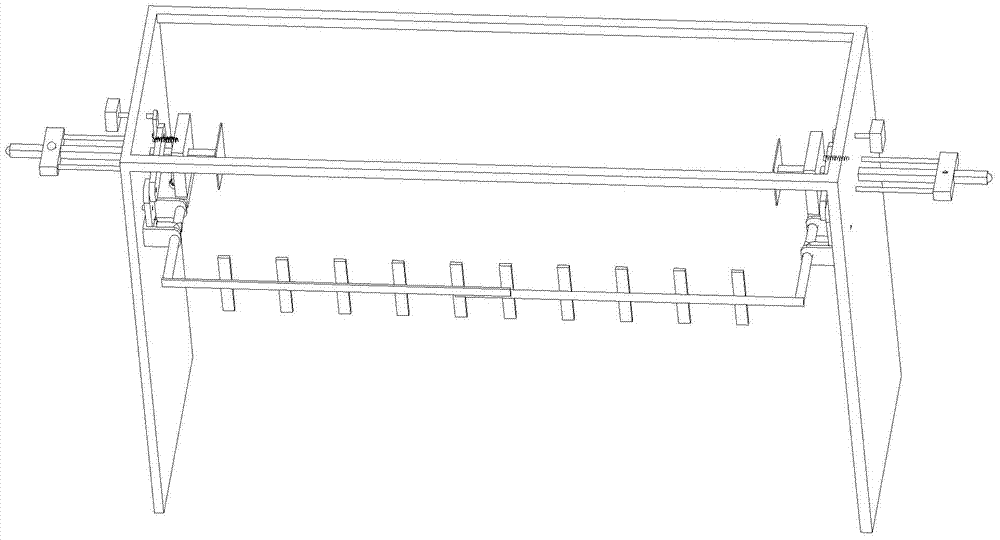

Automatic stacking and sorting device

ActiveCN105600563ANeatly stackedScattered will not come outPile receiversEngineeringMechanical engineering

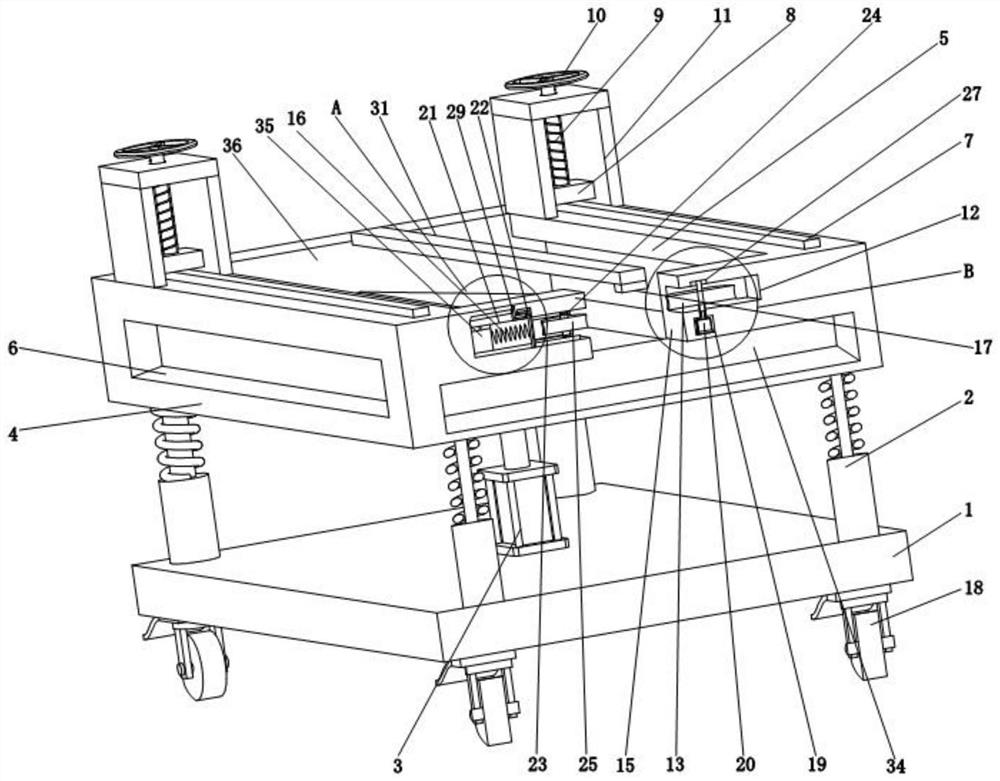

The invention relates to an automatic stacking and sorting device which is characterized by comprising a rack, a side face sorting device and a front sorting device. The side face sorting device and the front sorting device are respectively connected with the rack. The side face sorting device comprises a side face transmission device and a side face sorting plate. The side face transmission device drives the side face sorting plate to do telescopic motion in the horizontal transverse direction. The front sorting device comprises a front transmission device and a front sorting plate. The front transmission device drives the front sorting plate to do telescopic motion in the horizontal longitudinal direction. The side face sorting plate is used for enabling plates to be aligned in the transverse direction. The front sorting plate is used for enabling the plates to be aligned in the longitudinal direction. After the improvement, the sorting devices of the front and rear side faces as well as the front face enable the plates to be stacked on a tray neatly, the step of manual sorting is omitted, and working efficiency of corresponding working procedures is improved; after the improvement, the plates are stacked neatly, the situation that sheets are scattered and damaged by impact can be avoided, and the defective rate is reduced.

Owner:JIANGSU YUANXIANG INTERNET OF THINGS SCI & TECH

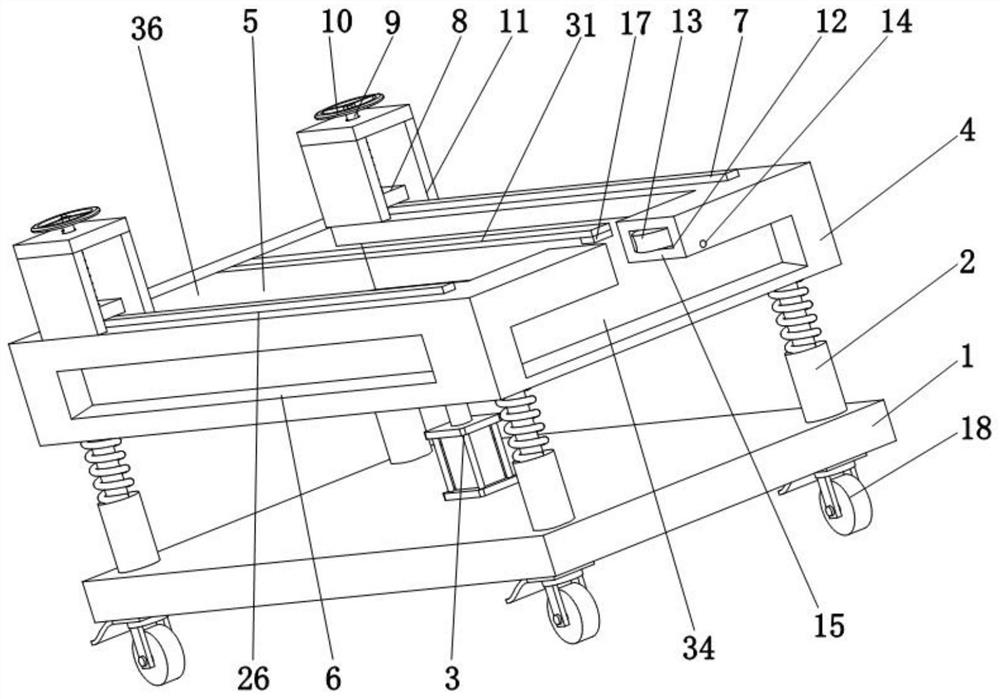

Uninterrupted efficient stacking machine

ActiveCN109095254ANeatly stackedAvoid misalignmentPile receiversArticle deliveryCardboardDrive motor

The invention discloses an uninterrupted efficient stacking machine comprising a conveying component, a material separation component, an adjusting component and an additional mechanism; the conveyingcomponent comprises a pedestal, a first hydraulic rod, a driving motor, a driving roller, a driving frame and a conveyor belt; the driving frame is rotationally connected with the pedestal; when in use, a hand wheel positioned on a cross rod is firstly rotated according to the width of a paper board to adjust the distance between a baffle plate and the cross rod, then a hand wheel positioned on adriving rod is rotated to adjust the distance between two side baffle plates, and meanwhile, the baffle plate and the side baffle plates are adjusted to proper positions. Compared with the existing stacking machine, the novel uninterrupted efficient stacking machine can stack the paper boards uninterruptedly and meanwhile adjust the proper distances between the paper boards, so as to prevent thepaper boards from being stacked disorderly due to overlarge or undersized stacking space during stacking, does not need to sort manually, and is simple and convenient to use, and improved in production efficiency.

Owner:安徽新雁印务股份有限公司

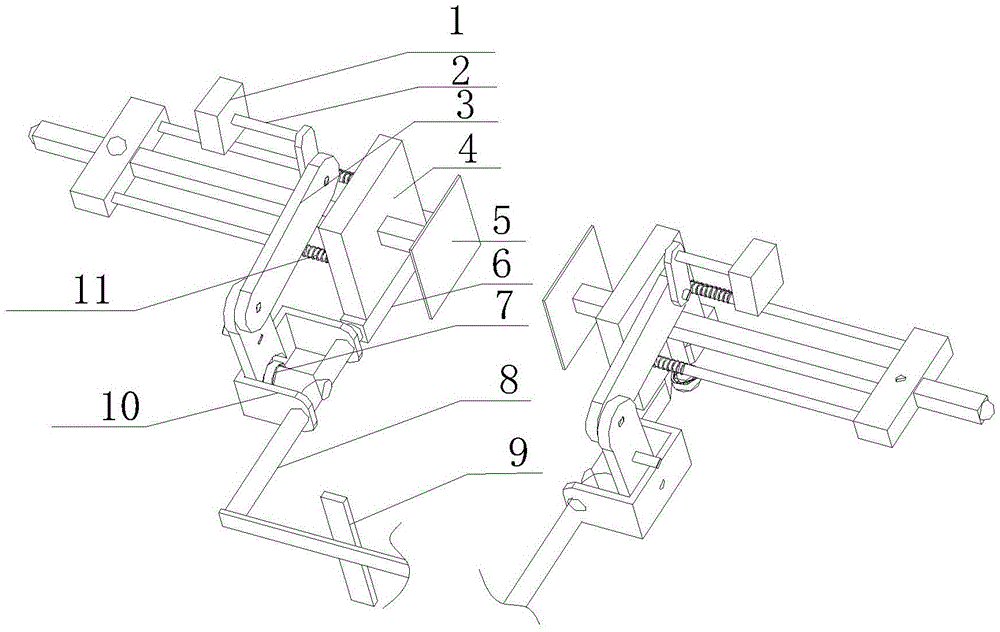

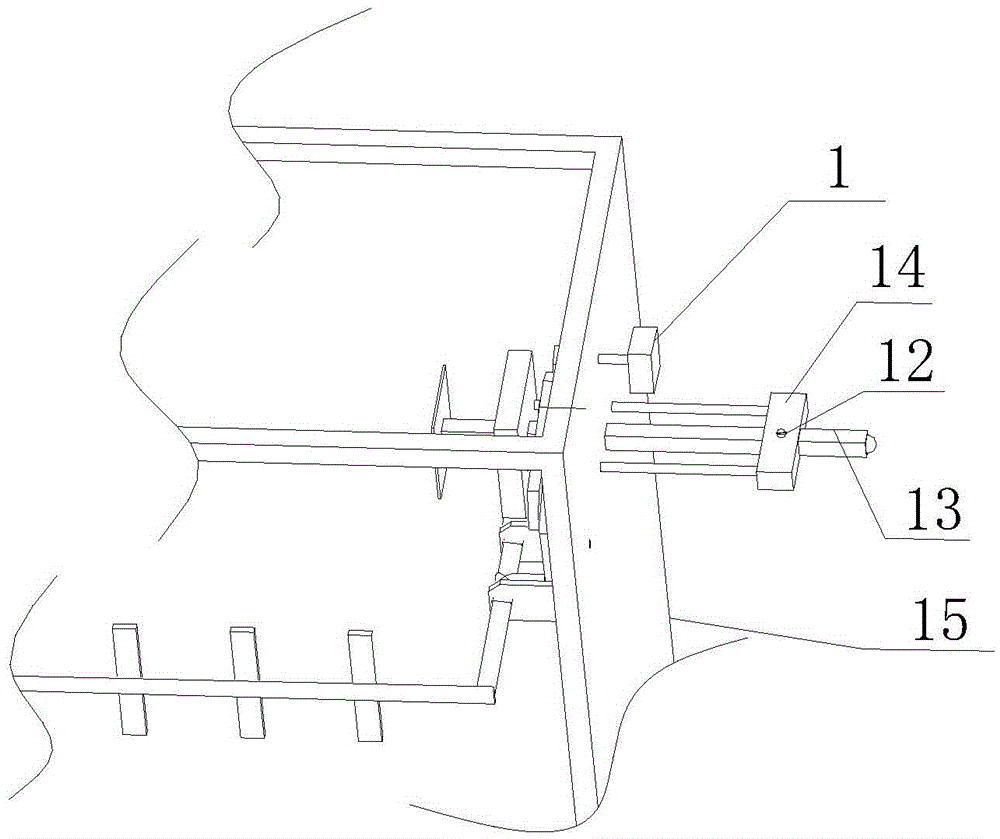

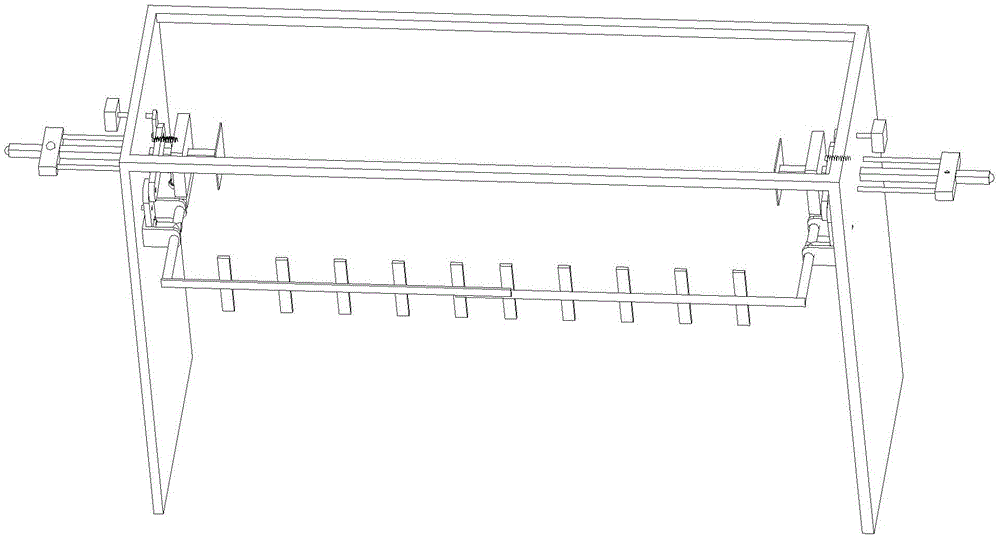

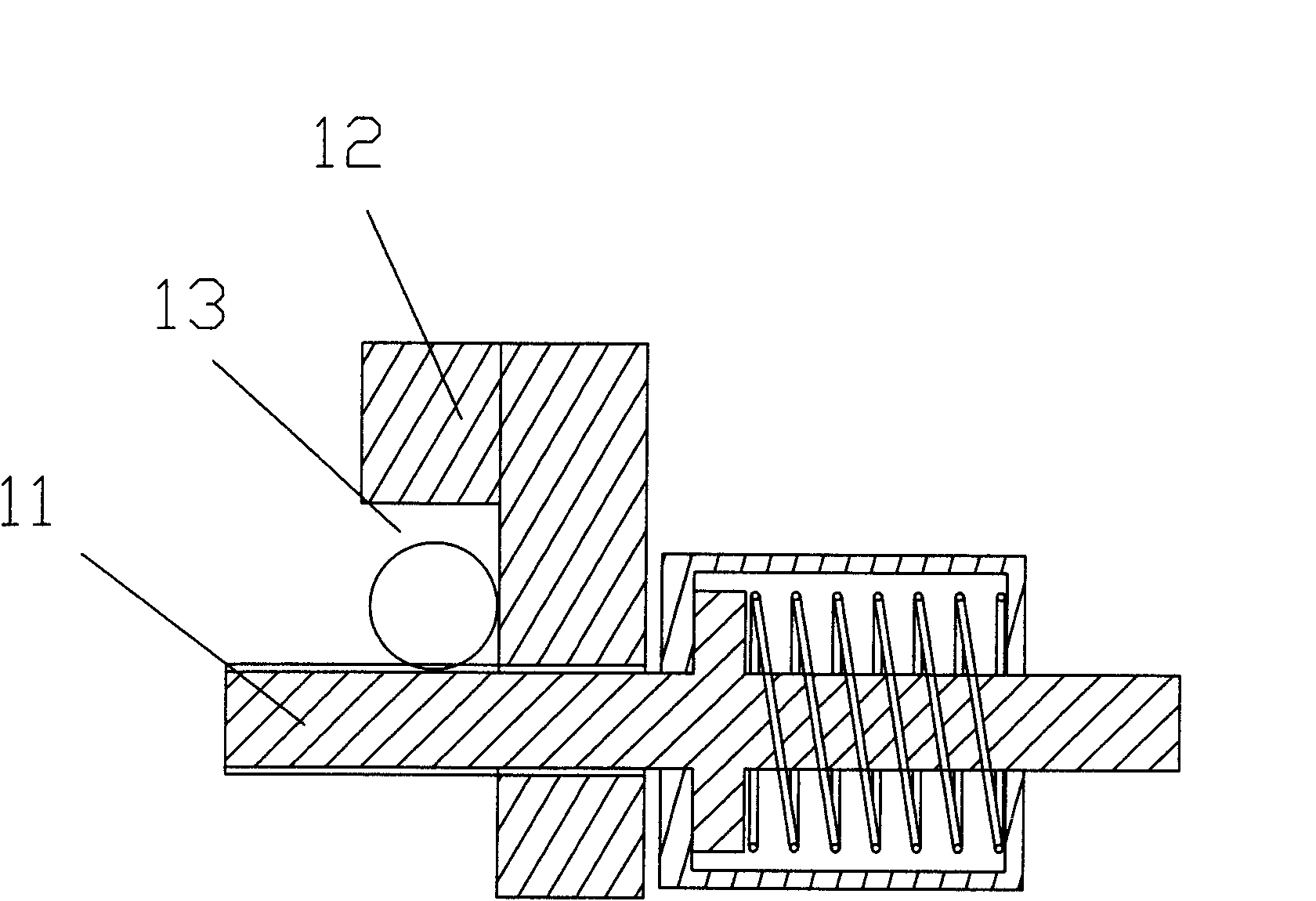

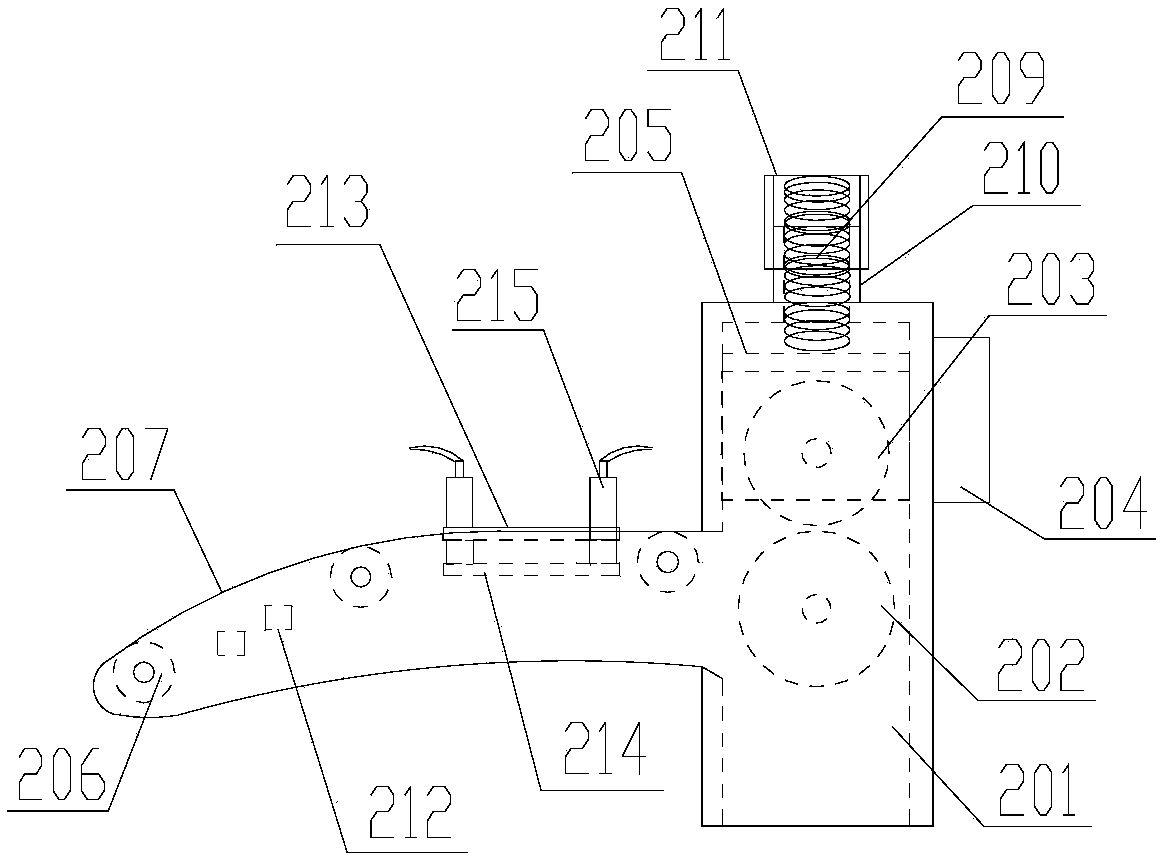

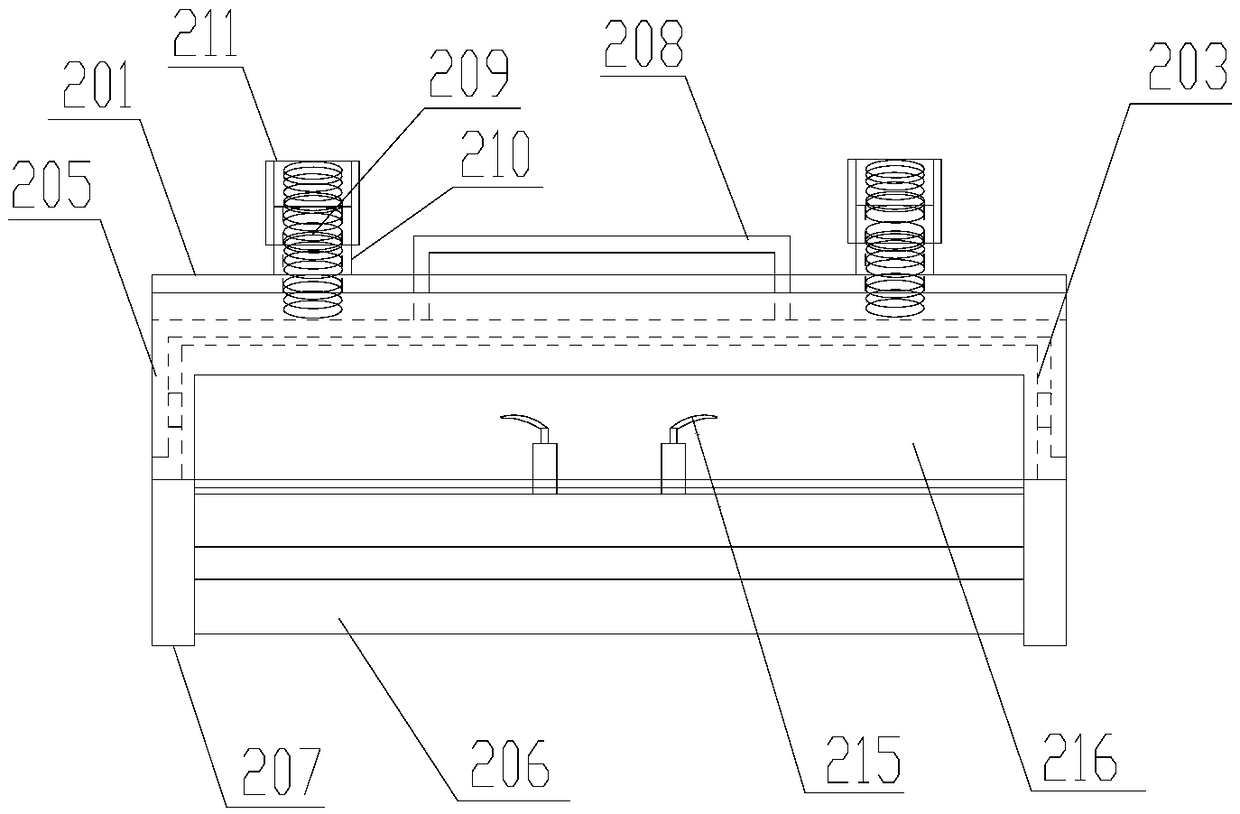

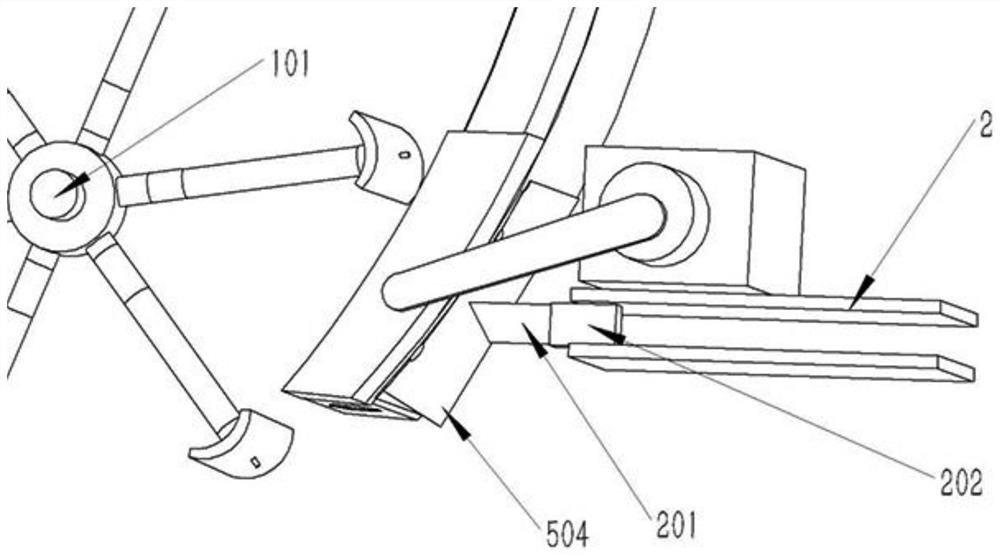

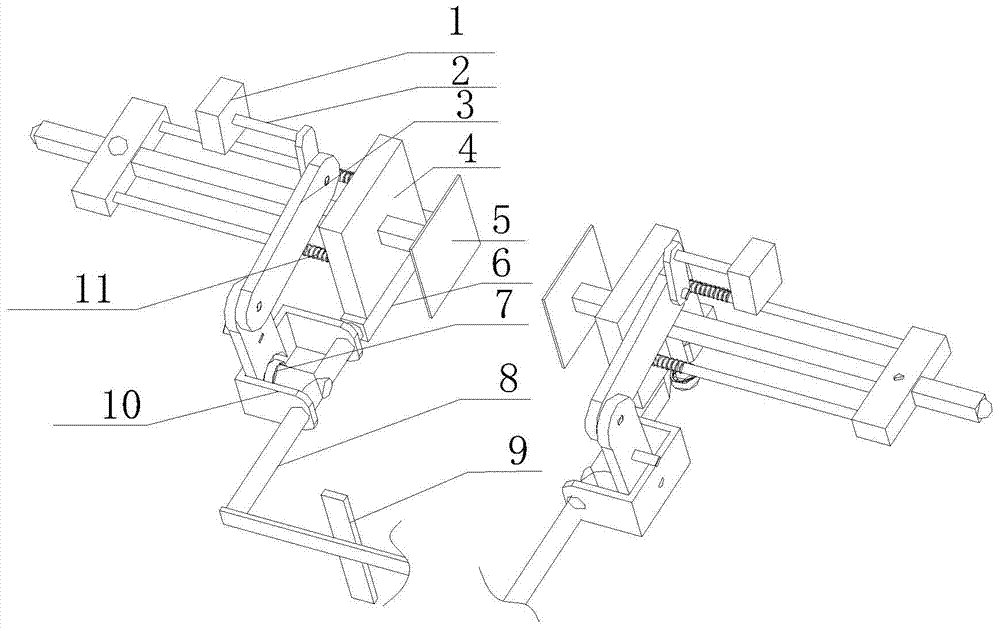

Feeding mechanism of vertical multi-start hoop bending machine

InactiveCN101920297AImprove the efficiency of bending hoopsNo need for manual finishingSteel barEngineering

The invention relates to a feeding mechanism of a vertical multi-start hoop bending machine, which comprises a plurality of groups of hoop bending mechanisms, a transmission mechanism and a driving mechanism, wherein the hoop bending mechanisms comprise telescopic main shafts and hoop bending main shafts; the telescopic main shafts can stretch and retract front and back, and the hoop bending main shafts rotate by taking the telescopic main shafts as a center; the plurality of groups of hoop bending mechanisms are arranged linearly; an accommodating channel for accommodating reinforcing steel bars is formed between the telescopic main shafts and the hoop bending main shafts; and a magnet is arranged on the rear part of the accommodating channel. The feeding mechanism has the advantages of high speed, simple and convenient operation and low manufacturing cost of the machine.

Owner:许友富

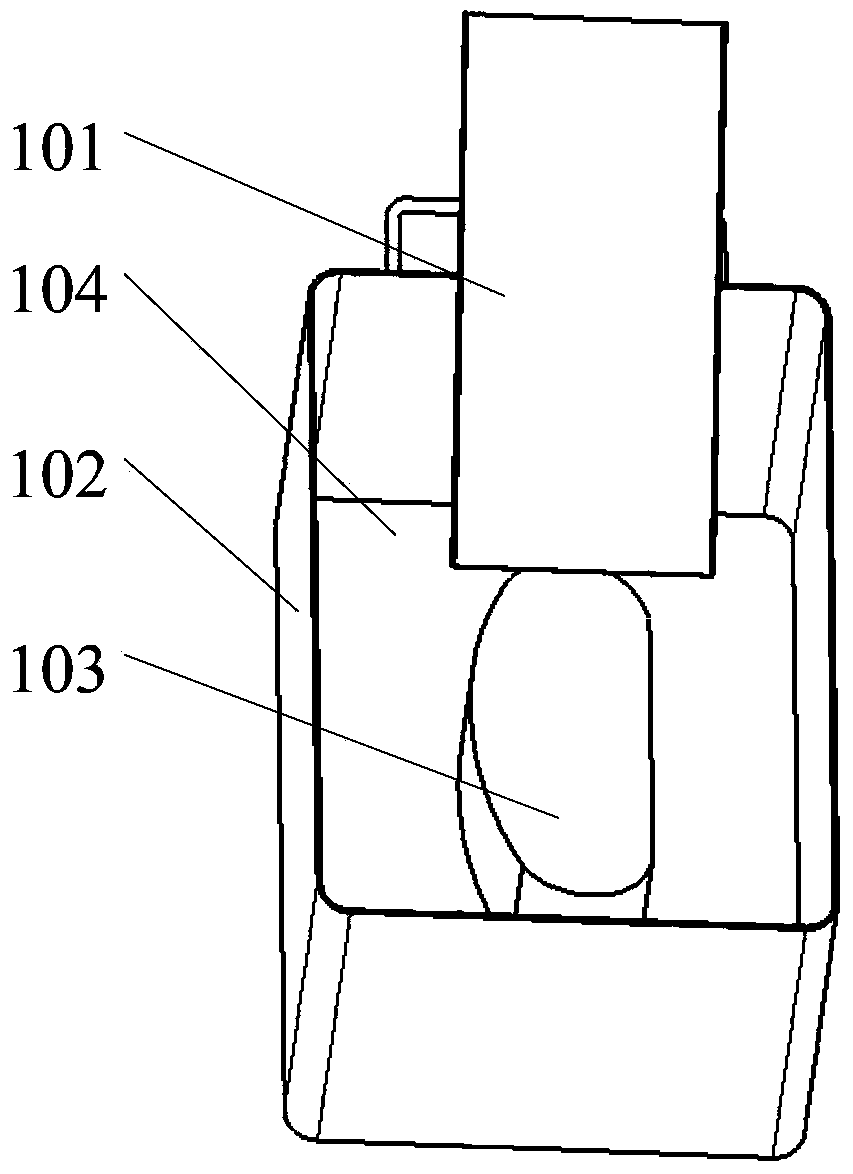

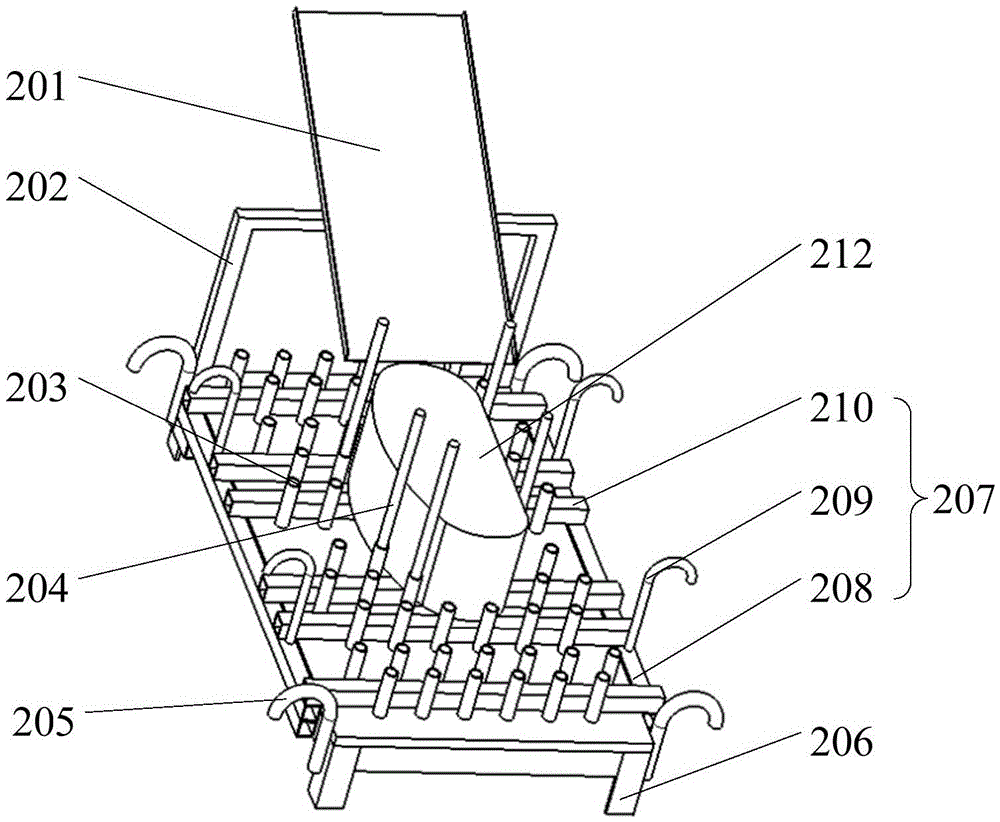

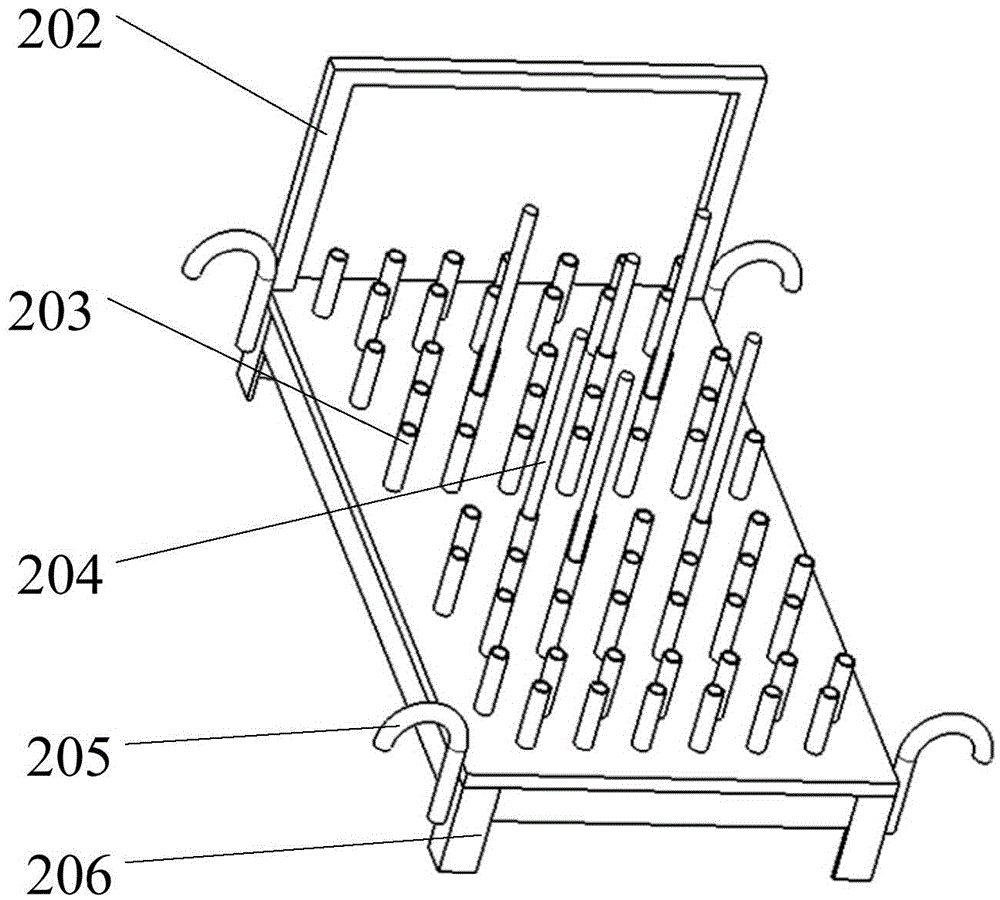

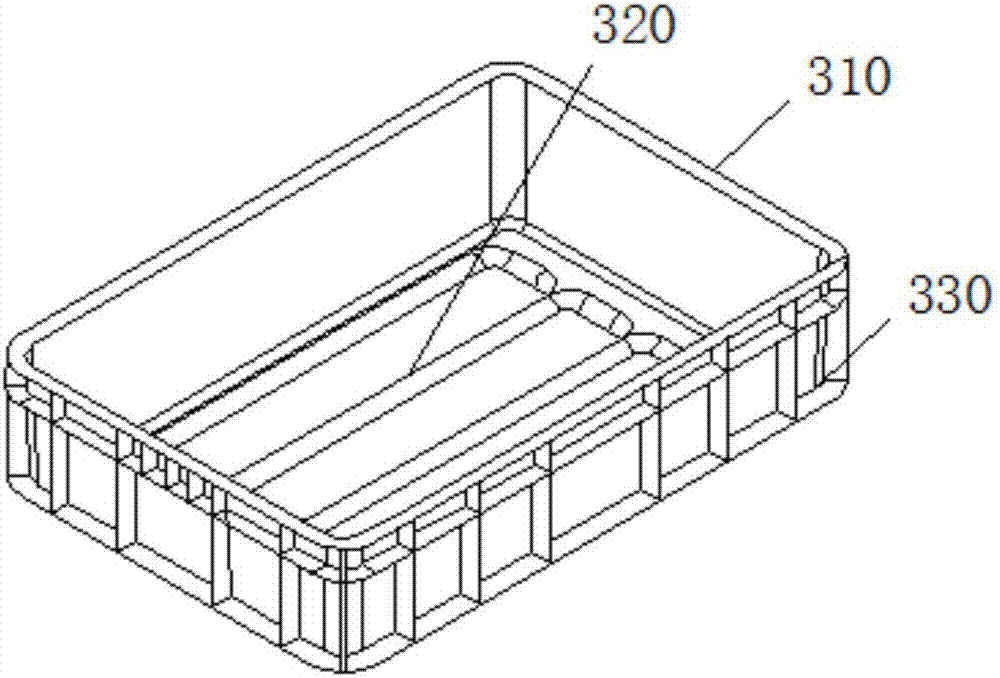

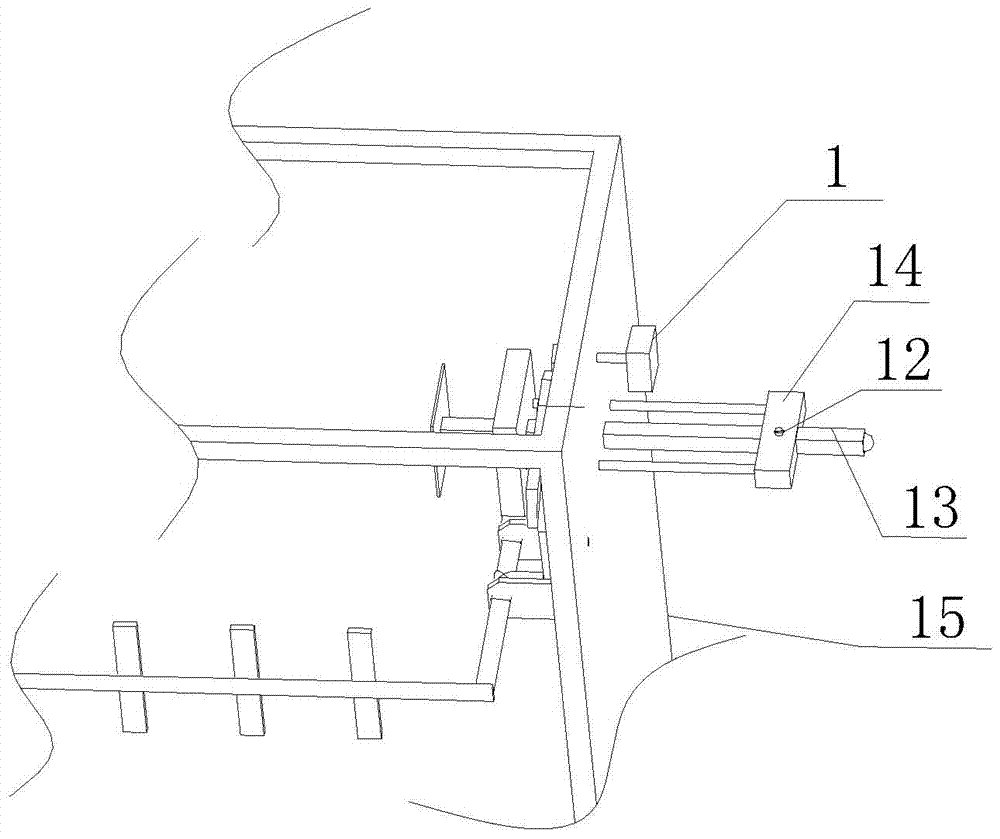

Waste collecting device

ActiveCN104190809AIncrease profitNot easy to scratchMetal-working feeding devicesPositioning devicesEngineeringWaste management

The invention belongs to the technical fields of producing and machining, and provides a waste collecting device. The waste collecting device comprises a sliding plate and a support. One end of the sliding plate is connected to the support in an erecting mode. The waste collecting device further comprises a base and a plurality of sleeves arranged on the upper surface of the base. The side, far away from the sliding plate, of the support is connected to the upper surface of the base. The waste collecting device further comprises at least two positioning fulcrum bars inserted into the sleeves. According to the waste collecting device, the sleeves and the positioning fulcrum bars are used for limiting positions of wastes sliding into the waste collecting device, the waste is automatically arranged in order after sliding into the device, manual secondary arranging is not needed, the labor cost is saved, and the production efficiency is increased; due to the fact that the waste is automatically arranged in order after sliding into the device, the surfaces of waste board pieces cannot be easily scratched, the waste board pieces can be used again, the use ratio of materials is increased, and the production cost is reduced.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

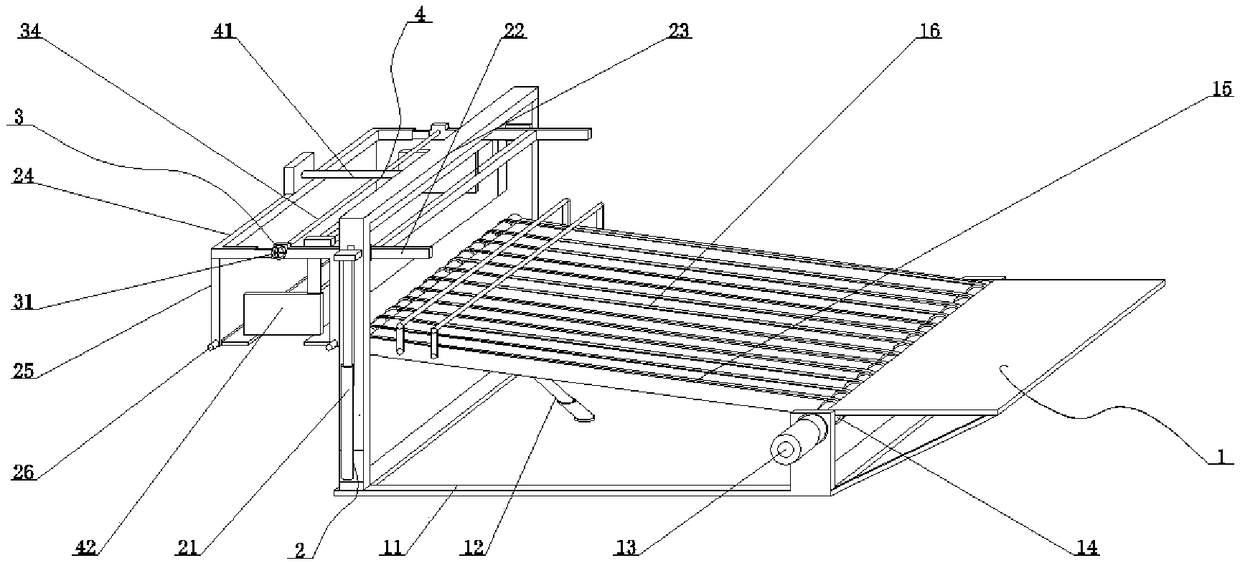

Adjusting, positioning and conveying integrated mechanism for gypsum board vertical edge forming

PendingCN114852638AAdjust production efficiencyAdjust production qualityConveyorsUsing optical meansVertical edgeEngineering

The invention discloses an adjusting, positioning and conveying integrated mechanism for gypsum board vertical edge forming, which comprises an adjusting mechanism, a positioning mechanism and a conveying mechanism which are sequentially arranged according to a processing sequence, and gypsum boards are uniformly processed and fed into the positioning mechanism after being adjusted to corresponding specifications by the adjusting mechanism. And the positioning mechanisms are arranged according to a specified interval and then are conveyed into the conveying mechanism to be output. According to the vertical edge adjusting mechanism, the distance between the vertical plate and the gypsum board is adjusted through the transverse moving mechanism and the vertical moving mechanism, the hydraulic telescopic shafts are adjusted in an independent adjusting mode of the hydraulic machine, and therefore the included angle between the vertical plate and the gypsum board is adjusted, and the vertical edge adjusting mechanism can meet the requirement of the gypsum board completely. And the plasterboards are automatically arranged and grouped through the arrangement locking assembly and the special-shaped conveying belt, the grouped plasterboards are clamped, and the plasterboards are automatically locked through the triggering assembly after a certain number is reached, so that the plasterboards are prevented from being scattered in the carrying process.

Owner:北新建材(天津)有限公司

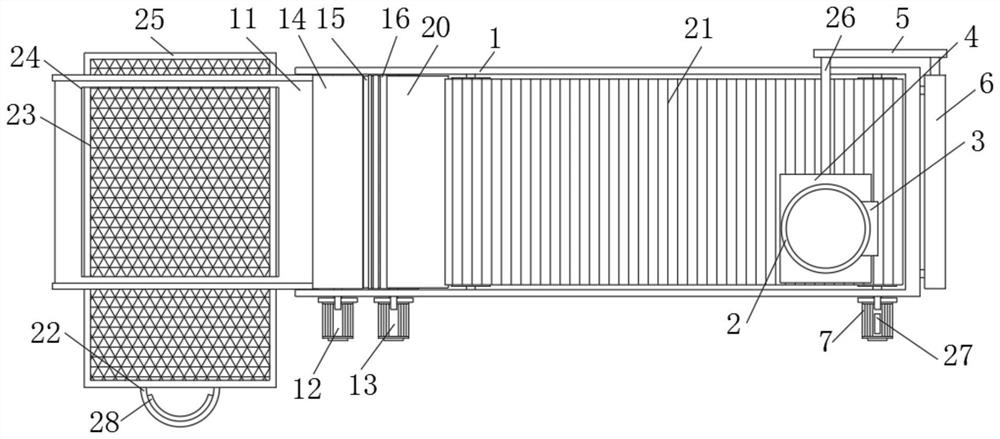

Metal plate shearing machine

PendingCN108723463AEasy to stack automaticallyNo need for manual finishingShearing machinesShearing machine accessoriesEngineeringMechanical engineering

The invention relates to the technical field of metal processing and discloses a metal plate shearing machine. The metal plate shearing machine comprises a levelling and length measuring mechanism, aplate shearing machine main body and a blanking and arranging mechanism, the plate shearing machine main body is located between the levelling and length measuring mechanism and the blanking and arranging mechanism; the plate shearing machine main body comprises a shearing mechanism and a conveying platform, the levelling and length measuring mechanism is used for conveying a levelled metal coiledmaterial to the shearing mechanism, and a sheared plate is conveyed to the blanking and arranging mechanism through the conveying platform. The levelling and length measuring mechanism is arranged ata feed end of the metal plate shearing machine, a levelling roller and a length measuring roller of the levelling and length measuring mechanism extrudes, so that the metal coiled material is kept level before shearing, the blanking and arranging mechanism at a discharge end also piles automatically conveniently; the blanking and arranging device is arranged at the discharge end, a first movableplate and a second movable plate move back and forth under the actions of the respective air cylinders, the blanking plate is clamped and loosened, the blanking plates are arranged orderly, the orderly arranged plates can be directly transported away and packaged without manual arranging, and the labor cost is saved.

Owner:重庆维富金属制品有限公司

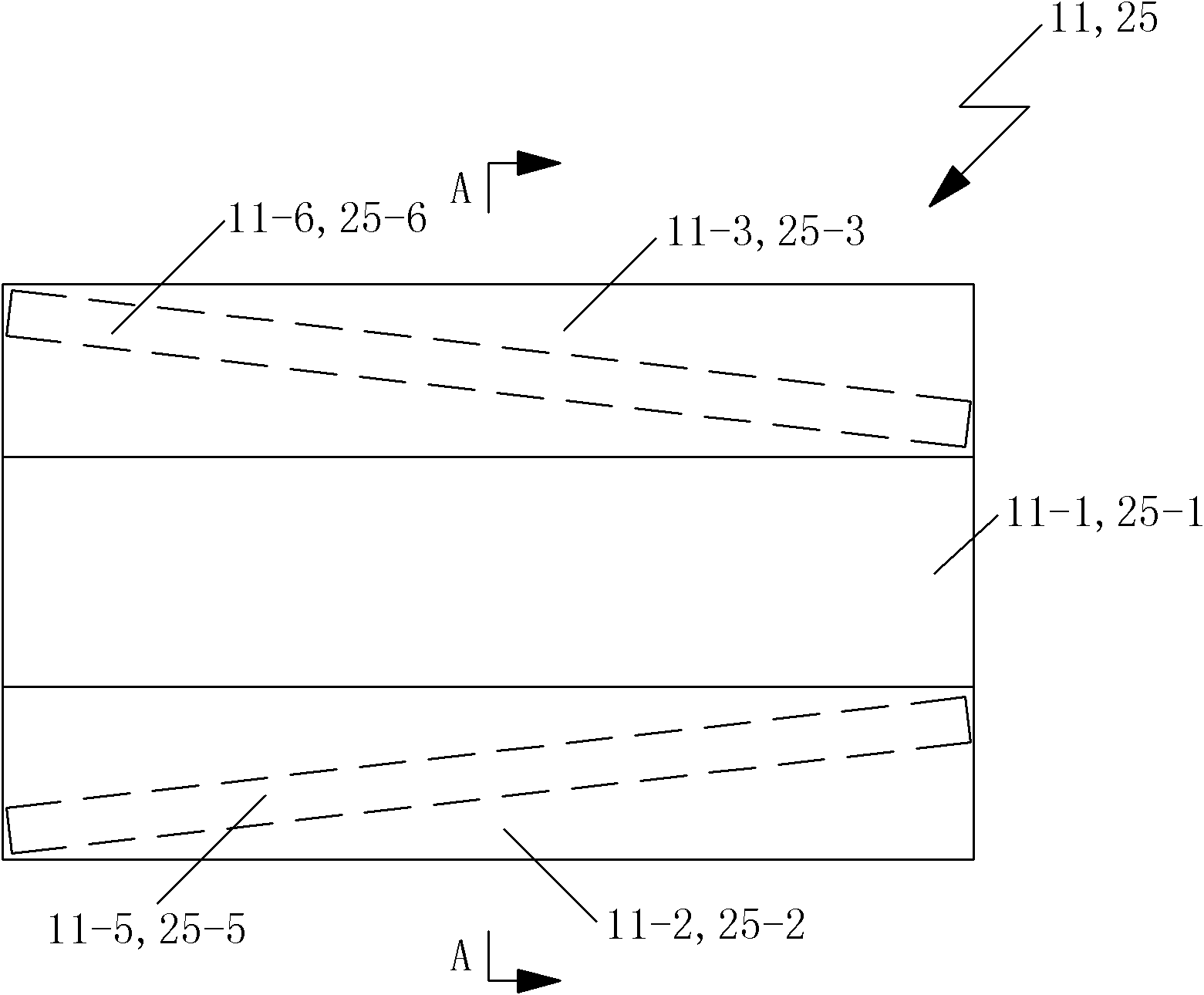

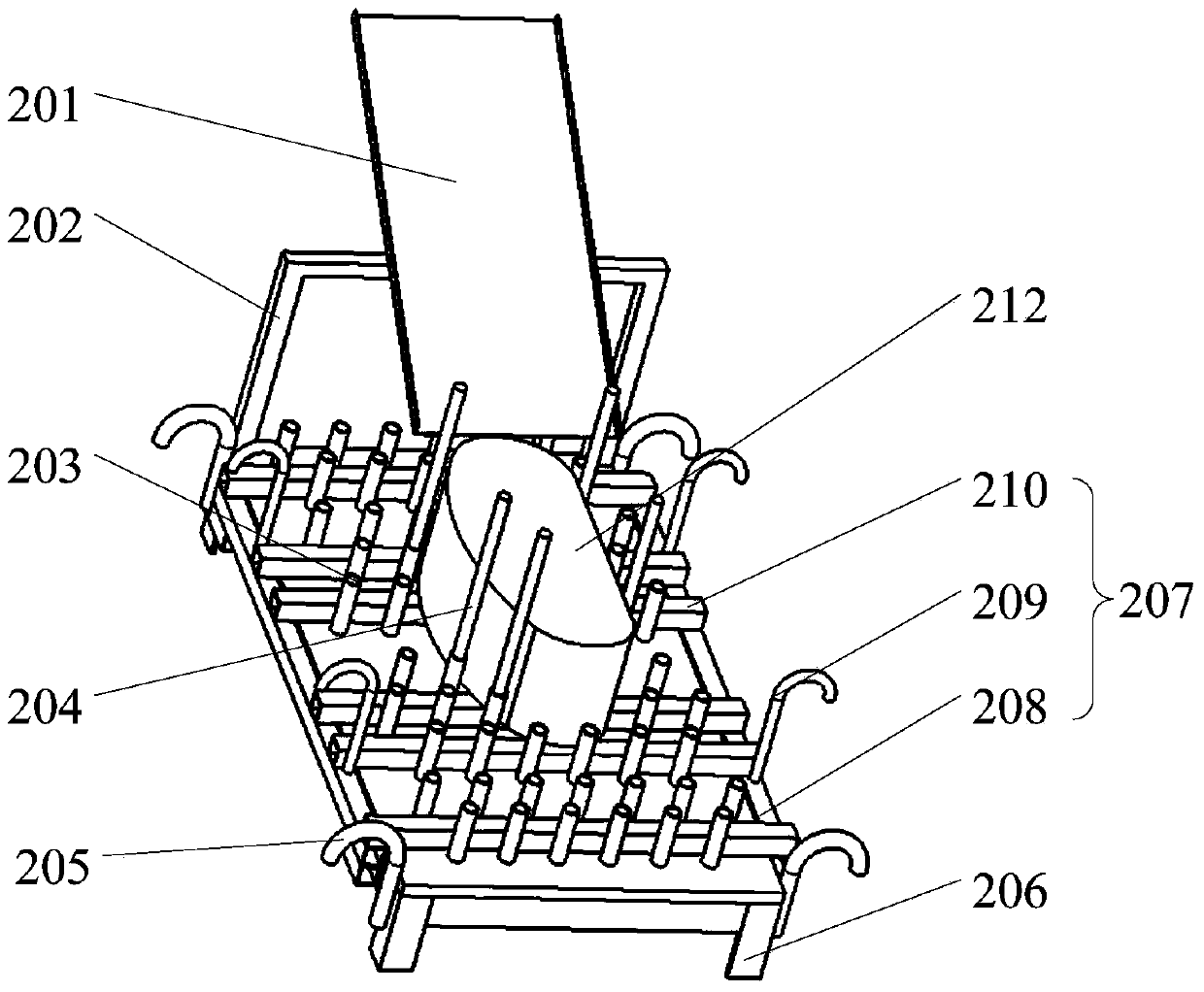

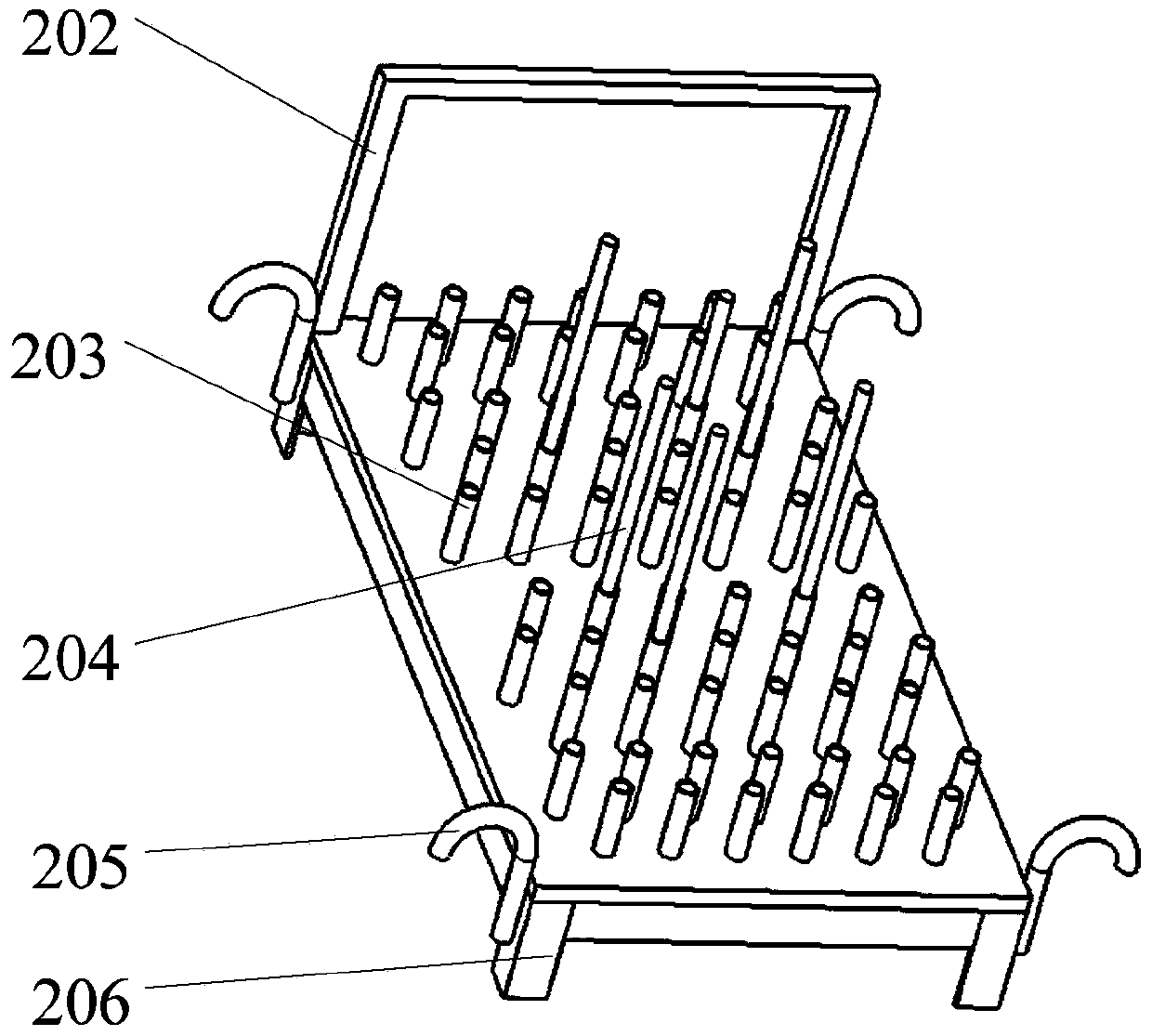

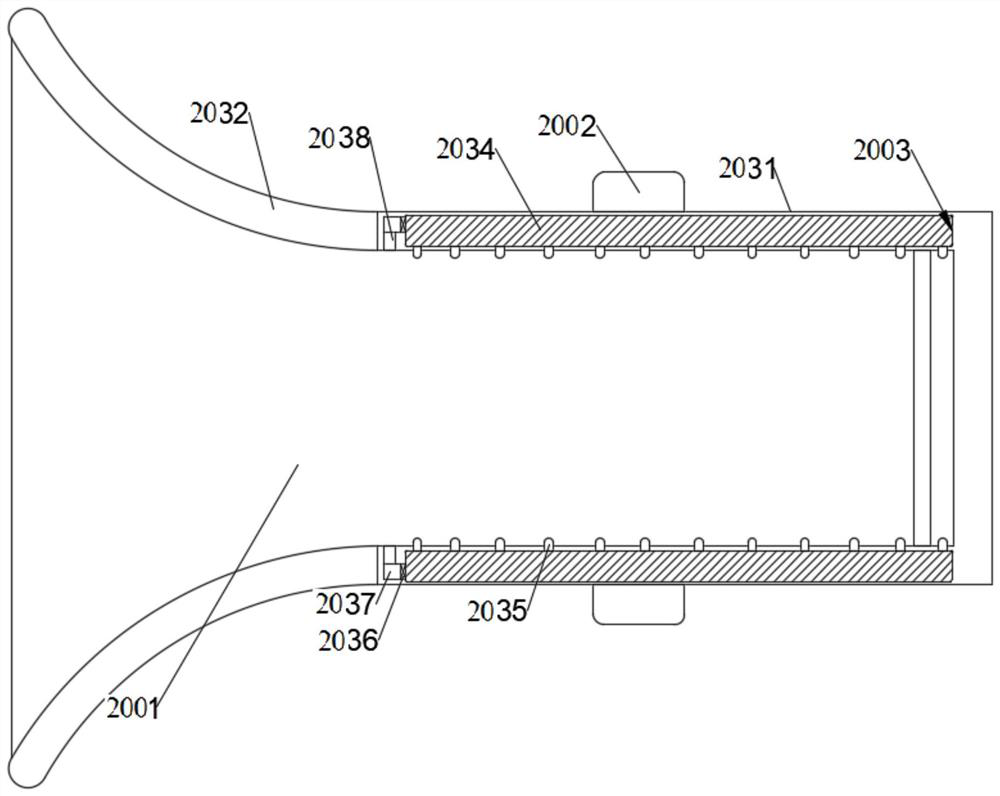

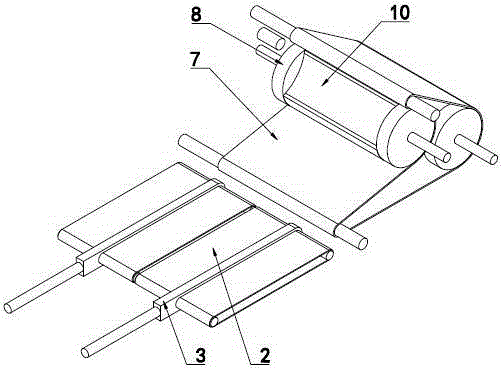

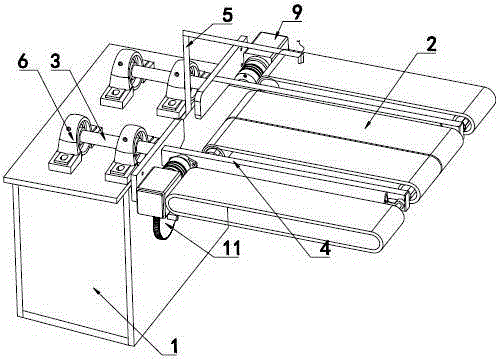

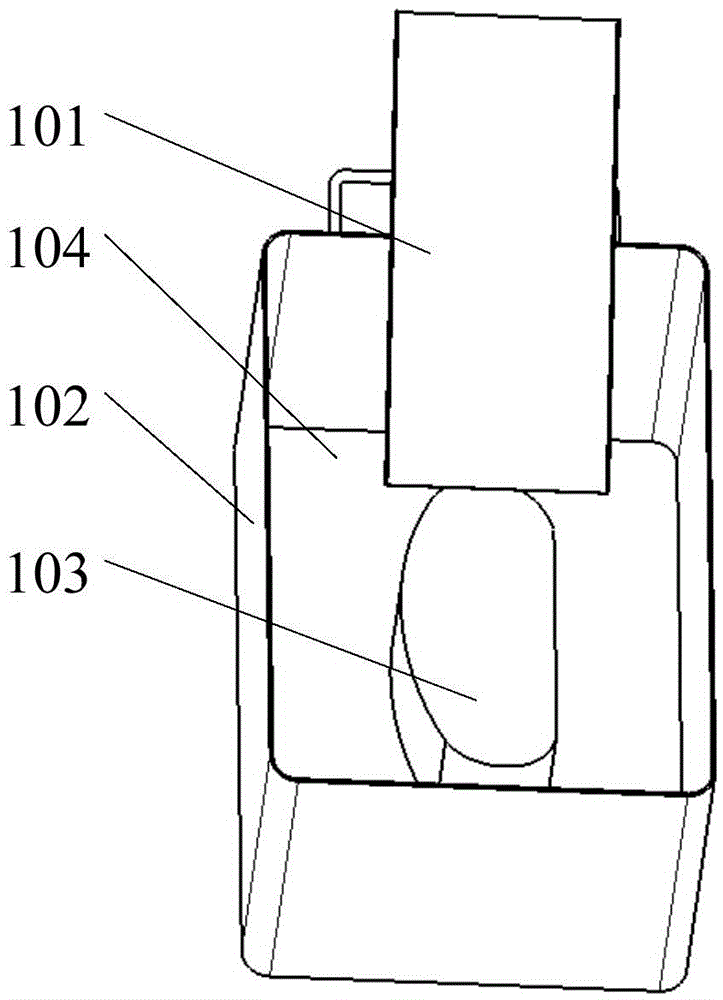

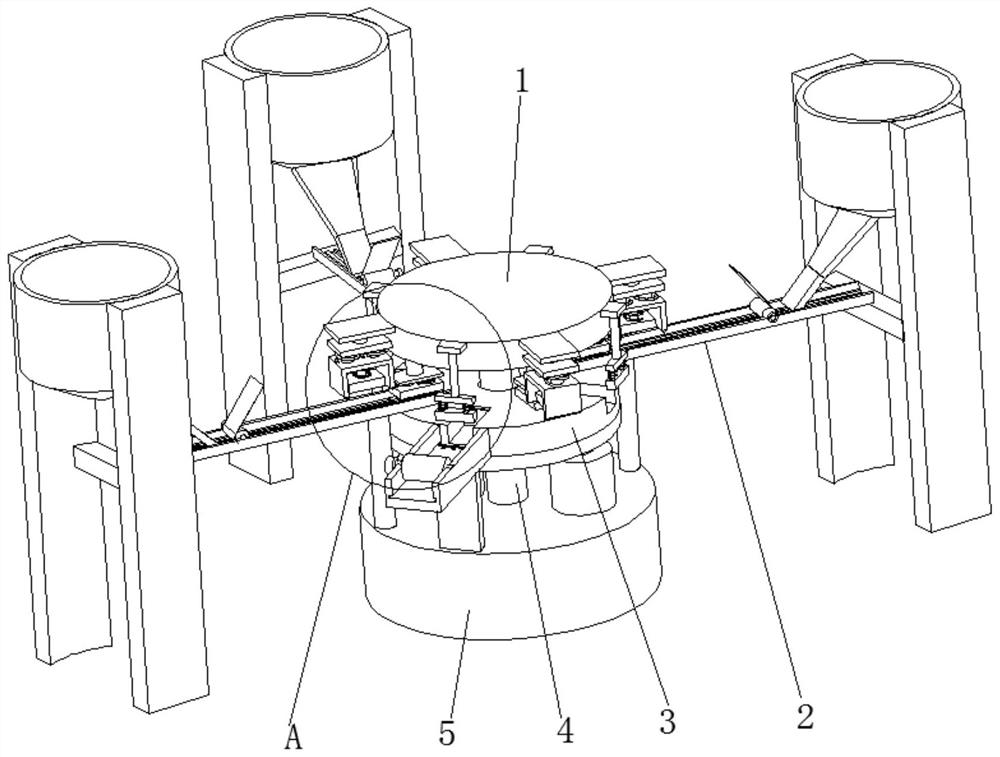

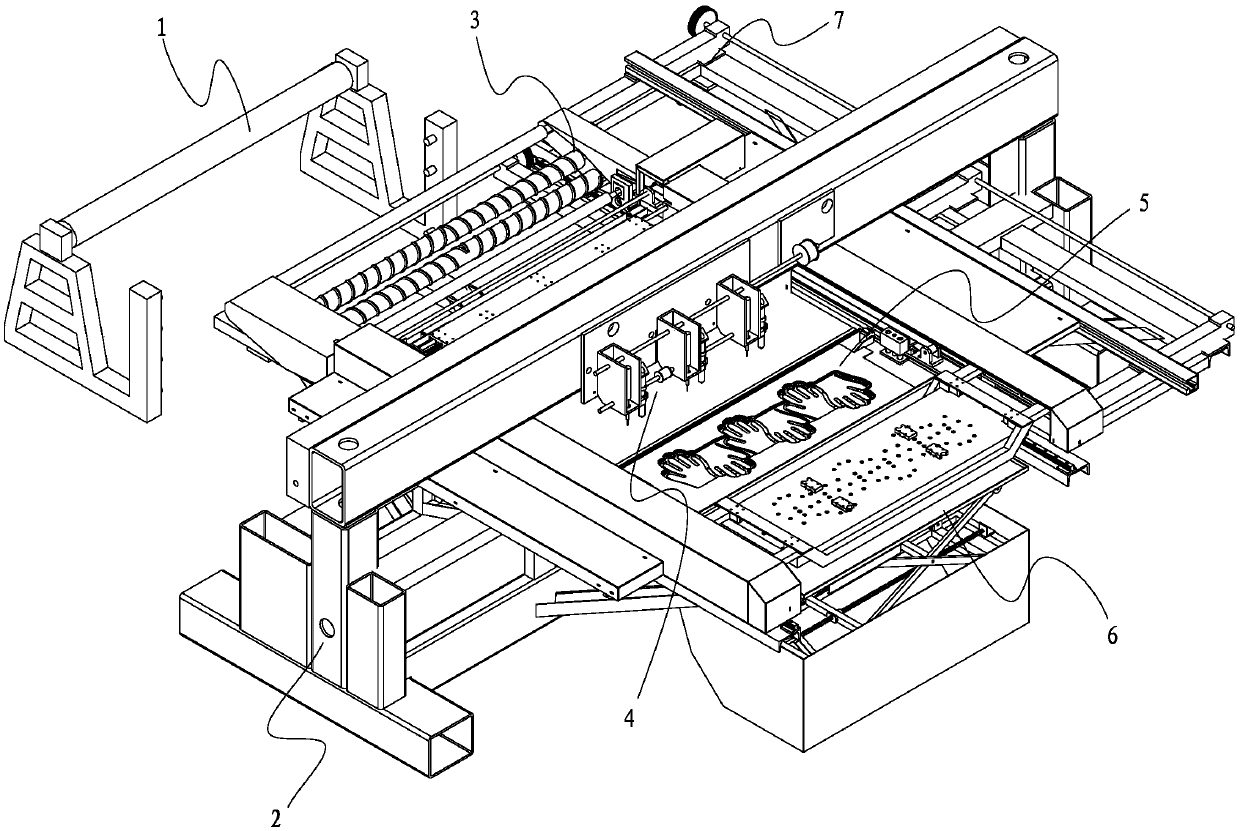

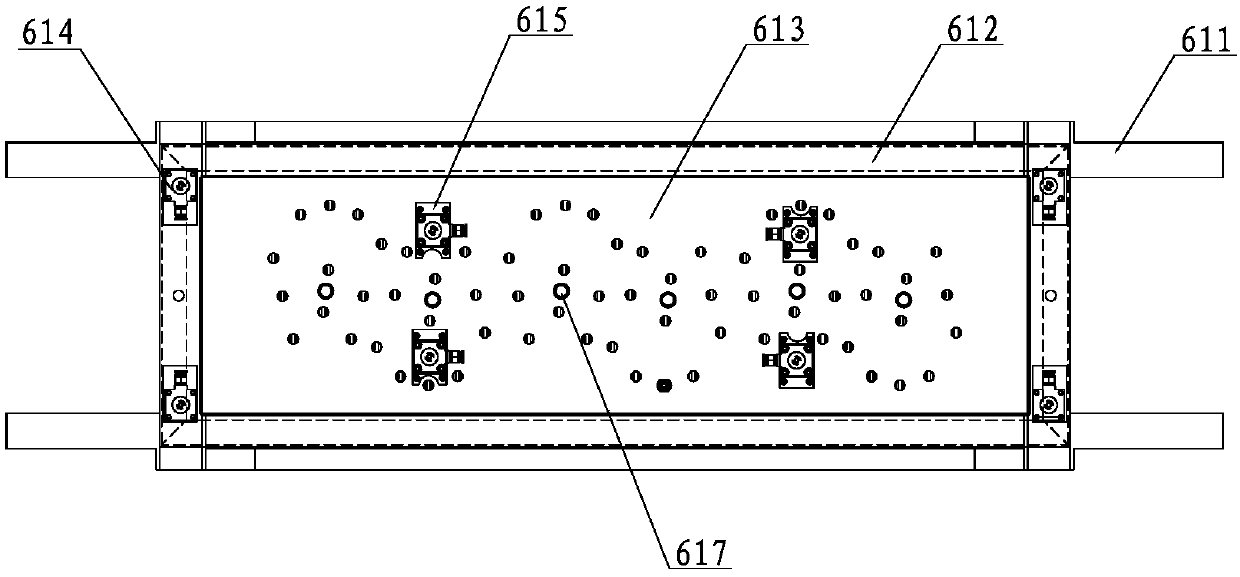

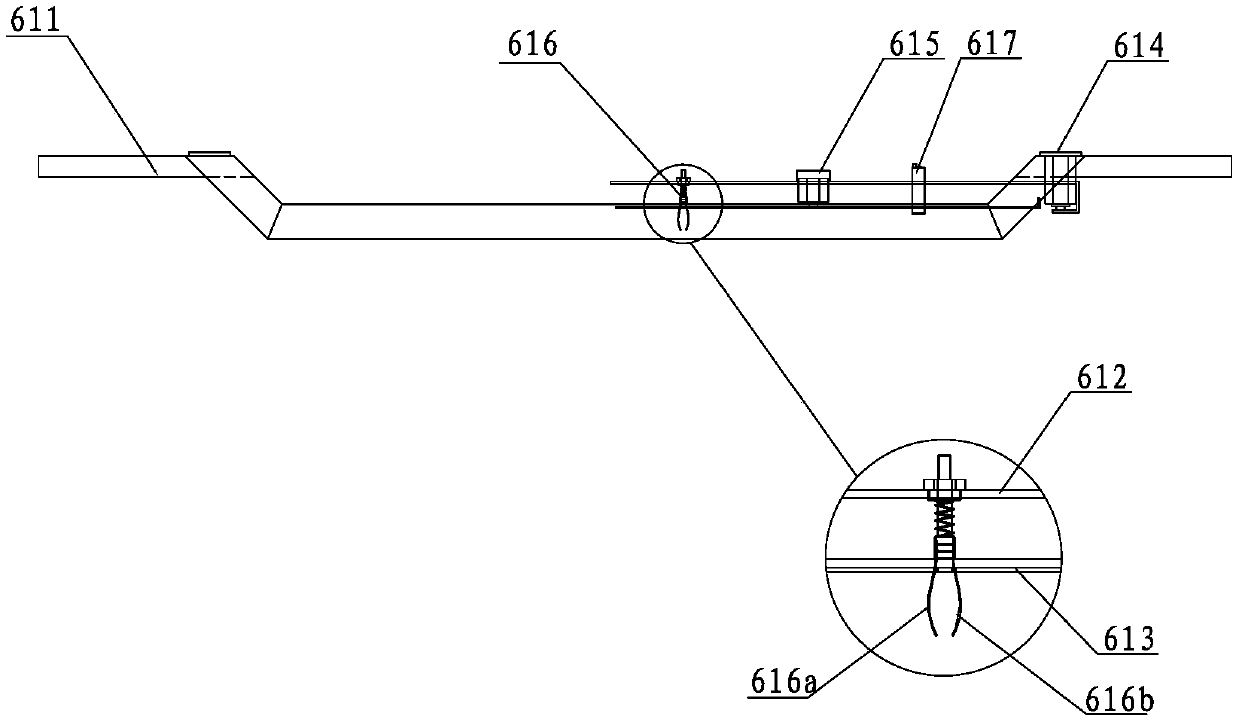

Glove picking and stacking machine

ActiveCN105172006ASimple structureEasy and quick removal of glovesStacking articlesCoatingsLeather beltEngineering

The invention discloses a glove picking and stacking machine and belongs to the field of production equipment for polyvinyl chloride (PVC), butyronitrile and latex gloves. The glove picking and stacking machine is characterized in that the machine comprises a glove picking device and a stacking device; the stacking device is installed on the lower rear portion of the glove picking device, and both the glove picking device and the stacking device are connected with a control system; the glove picking device comprises a plurality of rotating rollers and a picking belt (7) which conducts transmission around the rotating rollers, a picking roller (8) used for squeezing the picking belt (7) is arranged on the outer side of the picking belt (7), and a groove (10) allowing the lower portions of gloves to stretch in is formed in one side of the circumference of the picking roller (8); the gloves can be clamped and picked off under the action of the rotating picking roller (8) and the picking belt (7). The glove picking and stacking machine can precisely control the glove conveyed position, and the gloves can be stacked neatly; meanwhile, counting can be achieved, and thus working efficiency is improved.

Owner:ZIBO CHENGXUN AUTOMATION EQUIP

Medical gauze lifting belt automatic cutting and placing device

PendingCN112897188AAdaptableIroning effectSevering textilesArticle deliveryHydraulic cylinderMechanical engineering

The invention belongs to the field of gauze processing, and particularly relates to a medical gauze lifting belt automatic cutting and placing device. The medical gauze lifting belt automatic cutting and placing device comprises a base, a first conveying belt is installed on the left side of the top of the base, and the first conveying belt is fixed to the surface of the base through a first supporting column. According to the medical gauze lifting belt automatic cutting and placing device, a first hydraulic cylinder can drive a transverse plate to lift, so that a first pressing roller is adjusted, the distance between the first pressing roller and a second pressing roller is adjusted, and therefore the device can adapt to different follow-up gauzes, and the adaptability is high.

Owner:佛山市宾宏设备有限公司

Automatic collecting and boxing device for paper products

ActiveCN111086910AAccurate Quantitative CountingStacking is compact and tightIndividual articlesArticle deliveryMechanical engineeringIndustrial engineering

The invention discloses an automatic collecting and boxing device for paper products. The automatic collecting and boxing device comprises a rack, a counting sensor, a stacking device, a paper strip base plate, a sucker displacement driving mechanism, a base paper strip suction mechanism, a manipulator body, two paper product conveying synchronous belts as well as a manipulator displacement driving mechanism for driving the manipulator body to perform lifting, rotation and translation; and the two paper product conveying synchronous belts are mounted on the rack side by side, and a conveying channel in a front-back direction is arranged between the two paper product conveying synchronous belts. The automatic collecting and boxing device can realize accurate quantitative counting, completely fix the periphery of the whole paper product columns by fixing the lower ends of the paper product columns by base paper strips, fixing the front ends of the paper product columns by clamping rods and fixing the back ends of the paper product columns by shift forks, avoid gaps between two adjacent paper products, automatically stack vertical paper product columns, keep the whole paper product columns vertical, stack the paper product columns compactly and tightly, require no manual arrangement, reduce the labor intensity, save time and labor and effectively improve the working efficiency.

Owner:汕头市顺鑫隆印刷机械有限公司

Net-belt cloth piling wheel device

PendingCN110042605AUniform thicknessUniform and consistent pile volumeTextile treatment containersSucessive textile treatmentsEngineeringSprocket

Owner:新建特阔漂整(南通)有限公司

Normal-section slicing machine for red dates in rows

PendingCN112092056AImprove sorting efficiencyAvoid Uncut PhenomenaSievingDispersed particle filtrationAnnular arrayFood processing

The invention belongs to the technical field of food processing, and discloses a normal-section slicing machine for red dates in rows. The normal-section slicing machine for the red dates in rows comprises a main body, a slicing assembly, a conveying assembly, a discharging assembly and a supporting assembly. The supporting assembly is used for supporting the main body; the conveying assembly is used for conveying the red dates; the discharging assembly is used for conveying the sliced red dates; the slicing assembly comprises a rotating roller; the rotating roller is installed in the main body and rotates circumferentially around the main body; cutters are installed on the circumferential surface of the rotating roller in an annular array mode; and a rubber roller is rotatably connected to the side, close to the rotating roller, of the main body. According to the normal-section slicing machine for the red dates in rows provided by the invention, two moving plates move through throughholes and are pulled in opposite directions, so that two sorting nets move to the positions required by a user, the sliced red dates are sorted through a sorting cavity formed between the two sortingnets, the red date slices with different specifications are sorted, workers do not need to re-sort the red date slices in the later period, and the sorting efficiency of the red date slices is improved.

Owner:YANGZHOU POLYTECHNIC INST

waste collection device

ActiveCN104190809BIncrease profitNot easy to scratchMetal-working feeding devicesPositioning devicesSlide plateWaste management

The invention belongs to the technical fields of producing and machining, and provides a waste collecting device. The waste collecting device comprises a sliding plate and a support. One end of the sliding plate is connected to the support in an erecting mode. The waste collecting device further comprises a base and a plurality of sleeves arranged on the upper surface of the base. The side, far away from the sliding plate, of the support is connected to the upper surface of the base. The waste collecting device further comprises at least two positioning fulcrum bars inserted into the sleeves. According to the waste collecting device, the sleeves and the positioning fulcrum bars are used for limiting positions of wastes sliding into the waste collecting device, the waste is automatically arranged in order after sliding into the device, manual secondary arranging is not needed, the labor cost is saved, and the production efficiency is increased; due to the fact that the waste is automatically arranged in order after sliding into the device, the surfaces of waste board pieces cannot be easily scratched, the waste board pieces can be used again, the use ratio of materials is increased, and the production cost is reduced.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Cable traction device for electric power engineering and use method thereof

PendingCN114498431AEasy connection workAvoid entanglementSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsPower engineeringSlide plate

The invention relates to the technical field of cable traction, in particular to an electric power engineering cable traction device which comprises a bottom plate, a sliding groove and a threaded hole are formed in the bottom of the bottom plate, a connecting groove is formed in the top of the bottom plate, and a connecting mechanism with a sliding plate is arranged on the bottom plate. And a control mechanism with a pneumatic push rod is arranged on the bottom plate. The fixing clamp is driven to move through movement of the sliding end of the linear module, after winding is completed, the device is moved to a designated traction position through the pulley, the device can conduct traction work in different directions through movement of the output end of the electric push rod, work of workers is facilitated, manual arrangement is not needed, and the device is quite convenient to use and high in practicability. And the temperature sensor and the humidity sensor transmit signals to the controller, the warm air blower or the dehumidifier is turned on, cables and internal parts are protected in different use environments, and the service life is prolonged.

Owner:安徽浙鑫电力科技有限公司

Transportation method used in steel pipe machining process

PendingCN114803450ARealize the collectionRealize transportationConveyor partsDrive wheelElectric machinery

The invention belongs to the technical field of steel pipe machining, and discloses a transportation method used in the steel pipe machining process. According to the method, a steel pipe is placed in a pipe inlet, the steel pipe is placed between a driving wheel and the pipe inlet, the steel pipe is clamped by the driving wheel and the pipe inlet under the action of a spring, and the driving wheel is driven by a motor to rotate; and through the arrangement of a through hole, a second air bag, a third air bag and a fixing block, the device achieves collection and transportation of the long steel pipes, the problem that the steel pipes are prone to falling off and injuring workers due to the fact that traditional steel pipe hoisting is not stable is solved, and the steel pipe hoisting device has the advantages of being good in stability and high in safety.

Owner:康景许

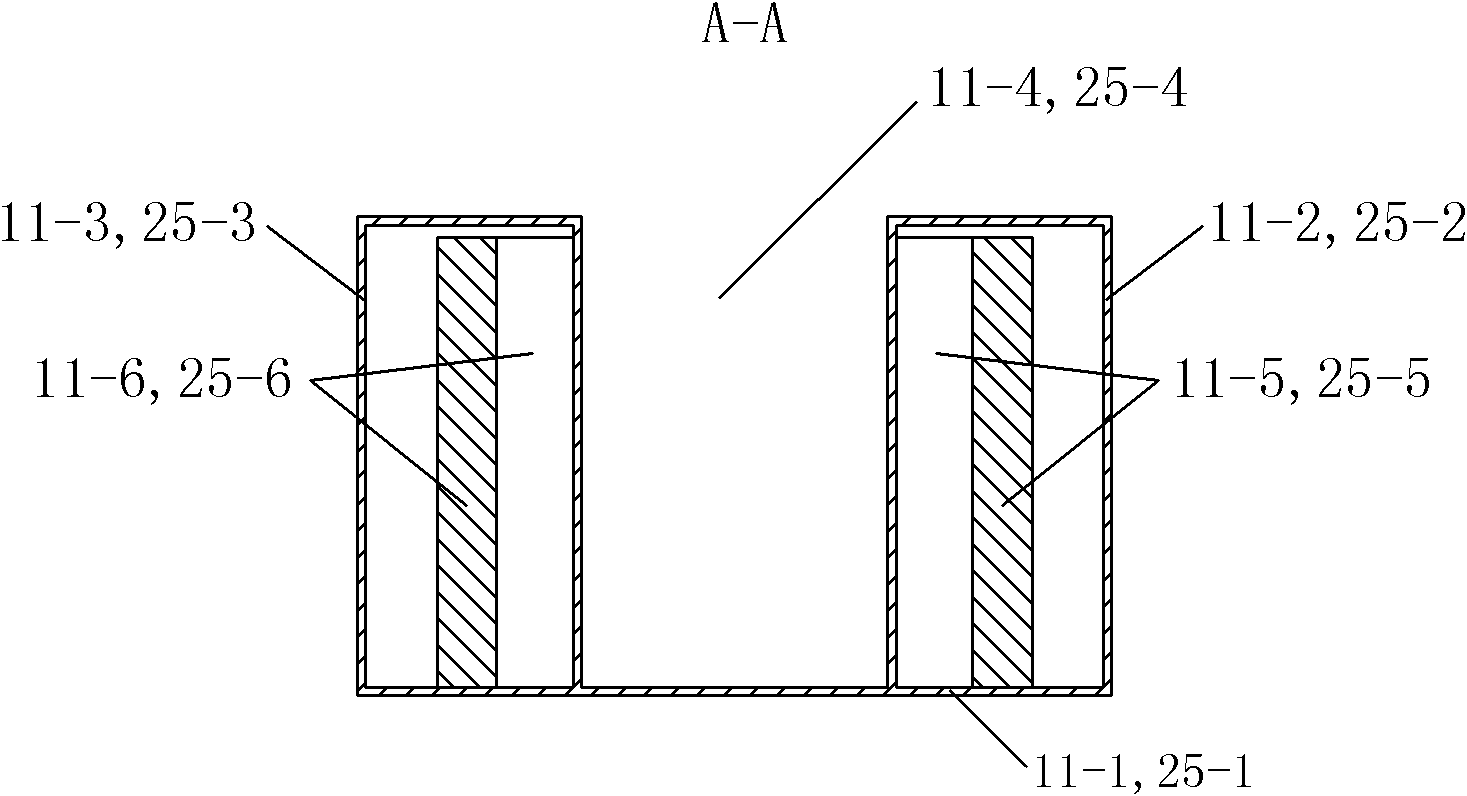

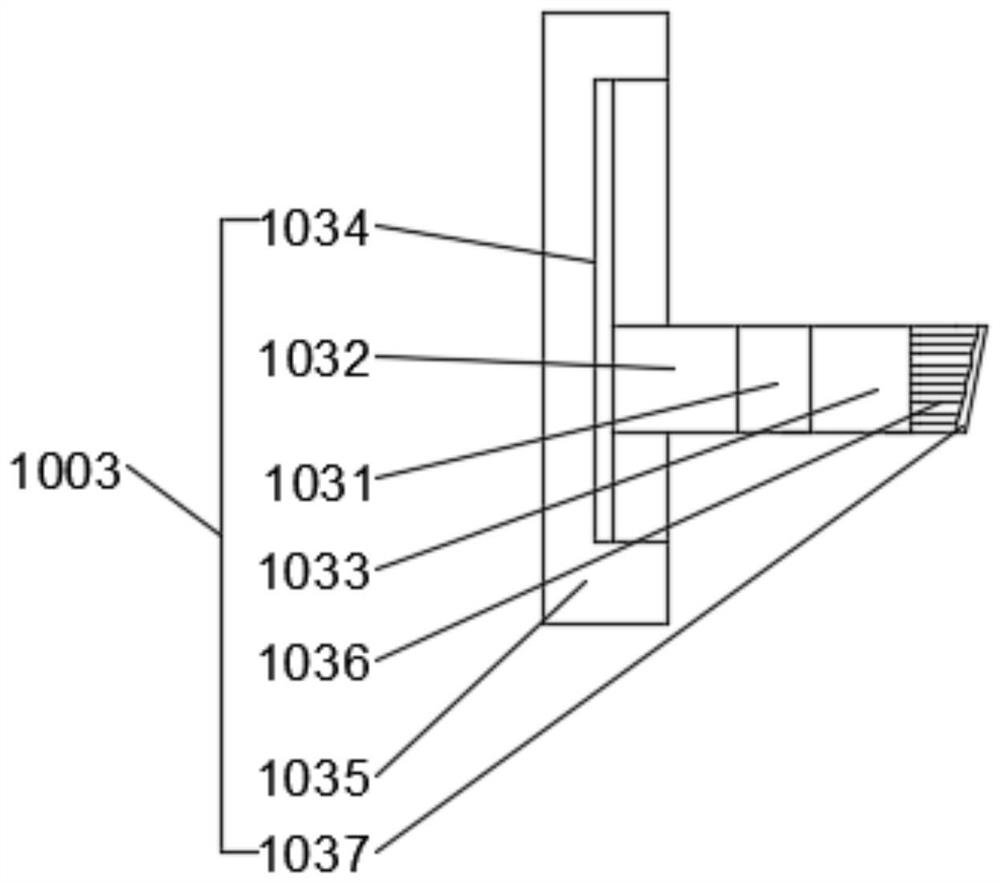

High-speed peeling and recycling device for seat ring heater cable

PendingCN113991547AAvoid replacementNo need for manual finishingBasic electric elementsApparatus for removing/armouring cablesEngineeringWork cell

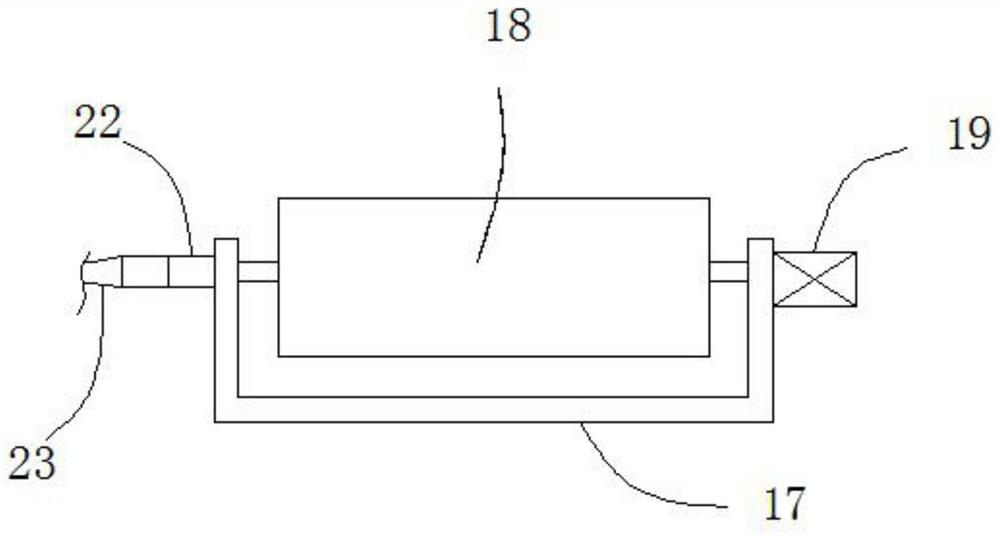

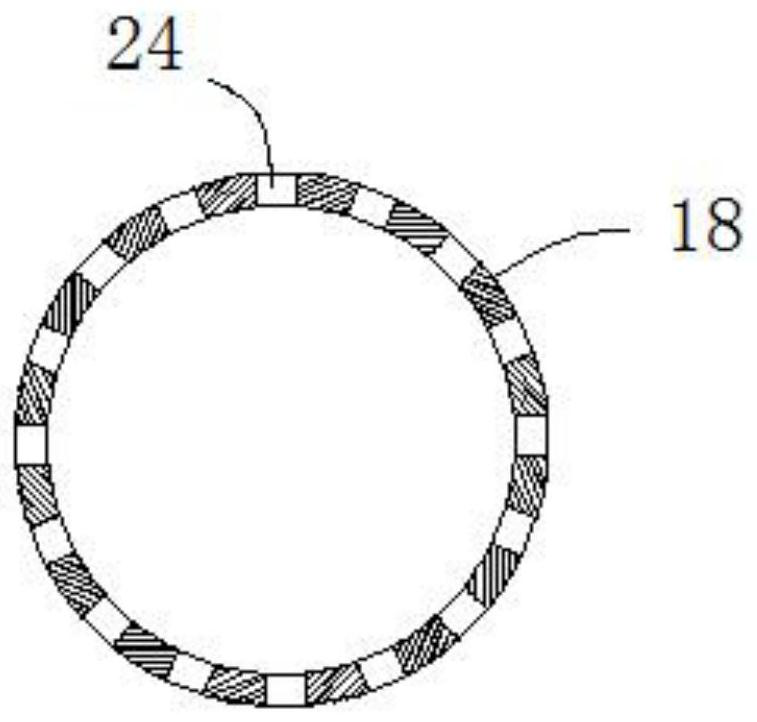

The invention relates to the technical field of cable peeling, in particular to a high-speed peeling and recycling device for a seat ring heater cable, which comprises a work cell, a clamping device, transfer parts, a recycling device and a wire, the clamping device is arranged in the work cell, the transfer parts are arranged on the outer walls of the two sides of the work cell, and the recycling device is arranged below the transfer parts. Bottom rolling wheels are arranged at the lower end of the interior of the work cell, a wire through hole is formed in the outer side of one end of the work cell, telescopic blades are arranged at the upper end and the lower end of the wire through hole and located on the side wall of the work cell, the clamping device comprises rotating shafts, a telescopic arm, a clamping piece, a skin cutting device and an auxiliary pulley, and multiple groups of rotating shafts are set at the upper end inside the work cell. One end of the telescopic arm is connected with the rotating shafts, and the requirements of single-wire, multi-batch and any-length rubber-insulated wires are met through various wire rotating wheels while the rubber-insulated wires are quickly peeled by using rotating force.

Owner:宁国市天瑞电热电器有限公司

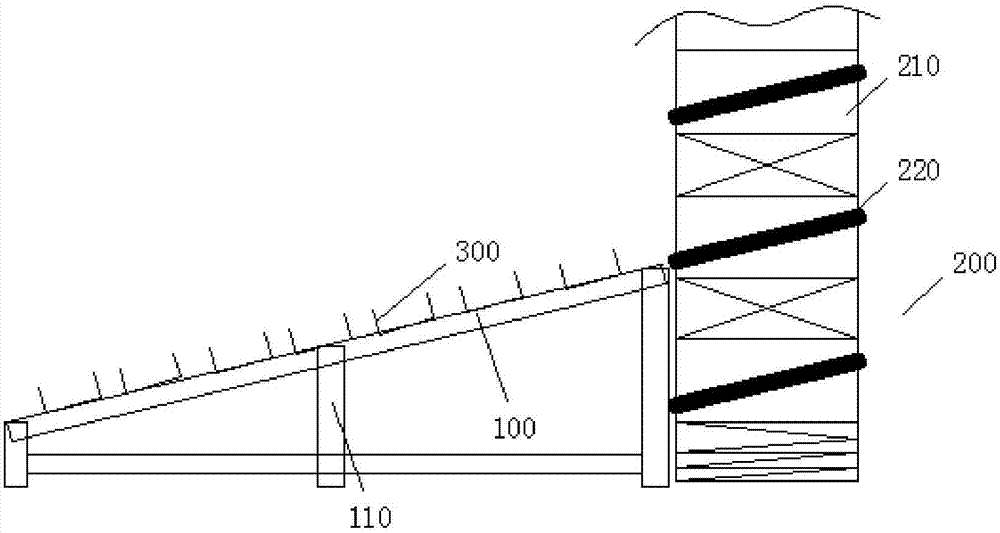

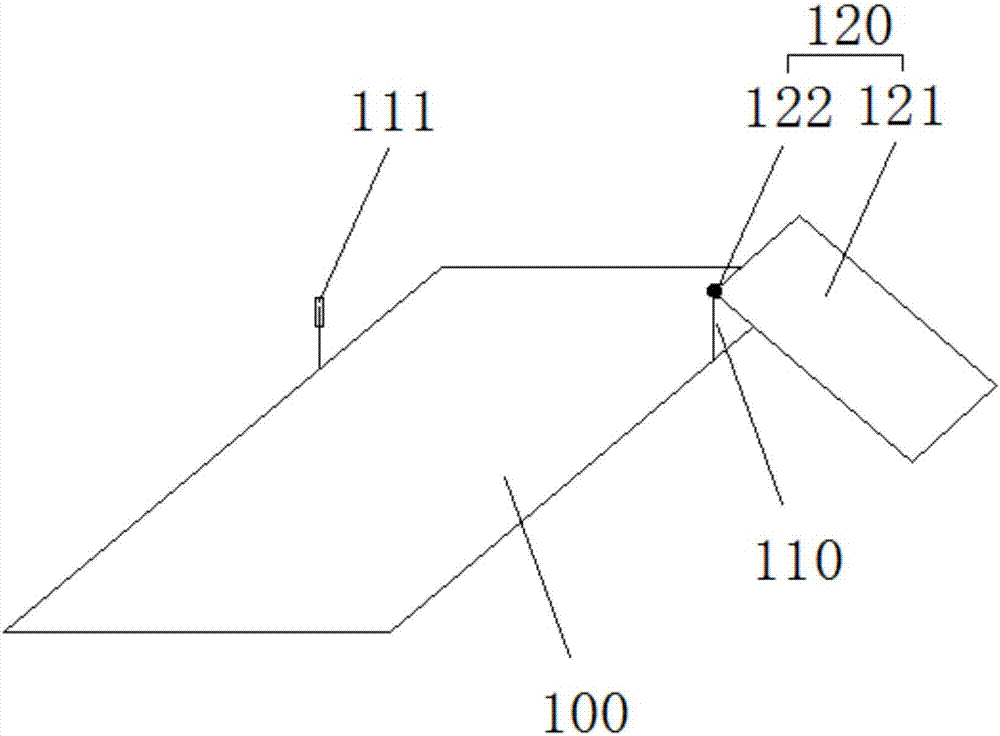

Breeding basin conveying device and Hermetia illucens breeding basin conveying device

PendingCN107986029ADoes not cause stackingSimple structureConveyorsStacking articlesHermetiaEngineering

The invention provides a breeding basin conveying device and a Hermetia illucens breeding basin conveying device and relates to the technical field of insect breeding. The breeding basin conveying device comprises a conveyor and a lift; the conveyor is inclined; a moving baffle is arranged at the top end of the conveyor; the lift is provided with multiple interlayers in the vertical direction; a separating plate is arranged in each interlayer; and the inclination angle of each separating plate is identical with that of the conveyor. When breeding basins are placed, the lift rises until the separating plate in the interlayer at the lowest end is collinear with the top of the conveyor, the moving baffle is opened, the breeding basins are conveyed into the interlayers, the moving baffle is locked, the lift moves downwards continuously, and the breeding basins are conveyed into all the interlayers; when the breeding basins are taken out, the lift descends until the separating plate in theinterlayer at the top end is collinear with the top of the conveyor, the moving baffle is opened, the breeding basins are conveyed into the conveyor, the moving baffle is locked, the lift moves upwards continuously, and the breeding basins are conveyed onto the conveyor. By the aid of the breeding basin conveying device and the Hermetia illucens breeding basin conveying device, the breeding basinscan be taken sequentially.

Owner:GUANGDONG XIFU ENVIRONMENTAL PROTECTION TECH

System for testing diode thermistor in high speed

ActiveCN102107190BThe process design principle is simpleCompact structureSortingEngineeringHeat sensitive

The invention provides a system for testing a diode thermistor in a high speed. The system comprises a material discharging device, a conveying device, a test device, a constant-temperature slot, a material receiving device, a lifting device, an engine seat, a transmission mechanism and a control device; the material discharging device, the conveying device, the test device, the material receiving device, the transmission mechanism and the control device are all arranged on the engine seat; the lifting device and the engine seat are arranged on the floor and the constant-temperature slot is formed on the floor; the material discharging device comprises a material discharging magnetic rail and a material discharging magnetic wheel; the conveying device comprises a chain wheel device, two material discharging chains, a conveying pipe, a feeding magnetic rail, a first stopping device, a second stopping device and a guide block; the test device comprises a test magnetic wheel, a tester and a probe; and the material receiving device comprises a stepping wheel, a material receiving box and a poking sheet. The system is used for testing the diode thermistor, and has high test speed and high stepping precision.

Owner:常州市科文传感器材料有限公司

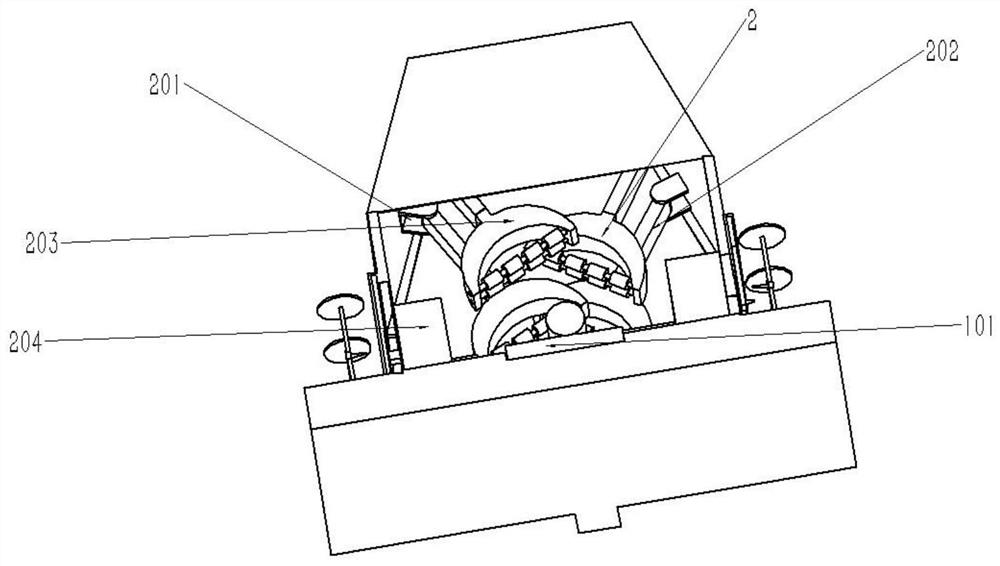

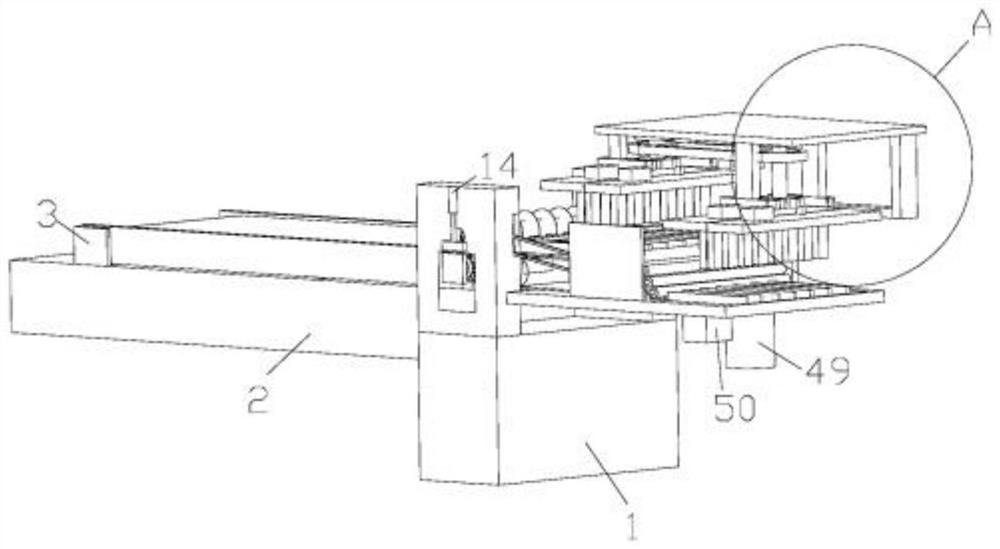

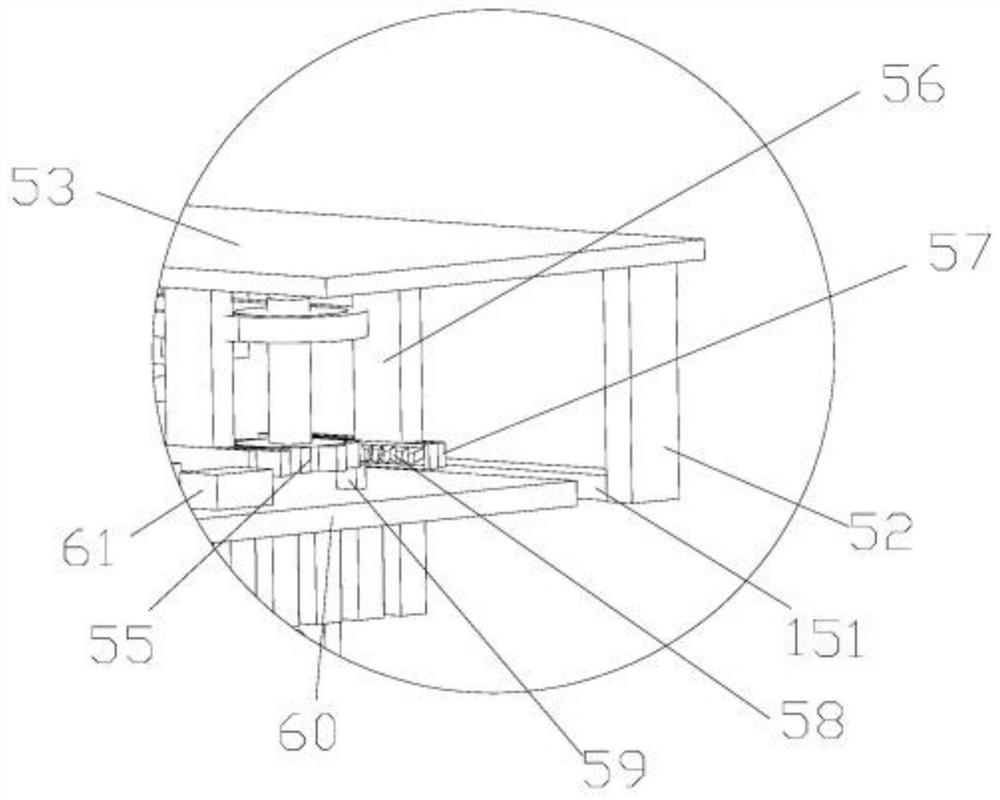

A packaging machine for packaging aluminum foil plates for capsules

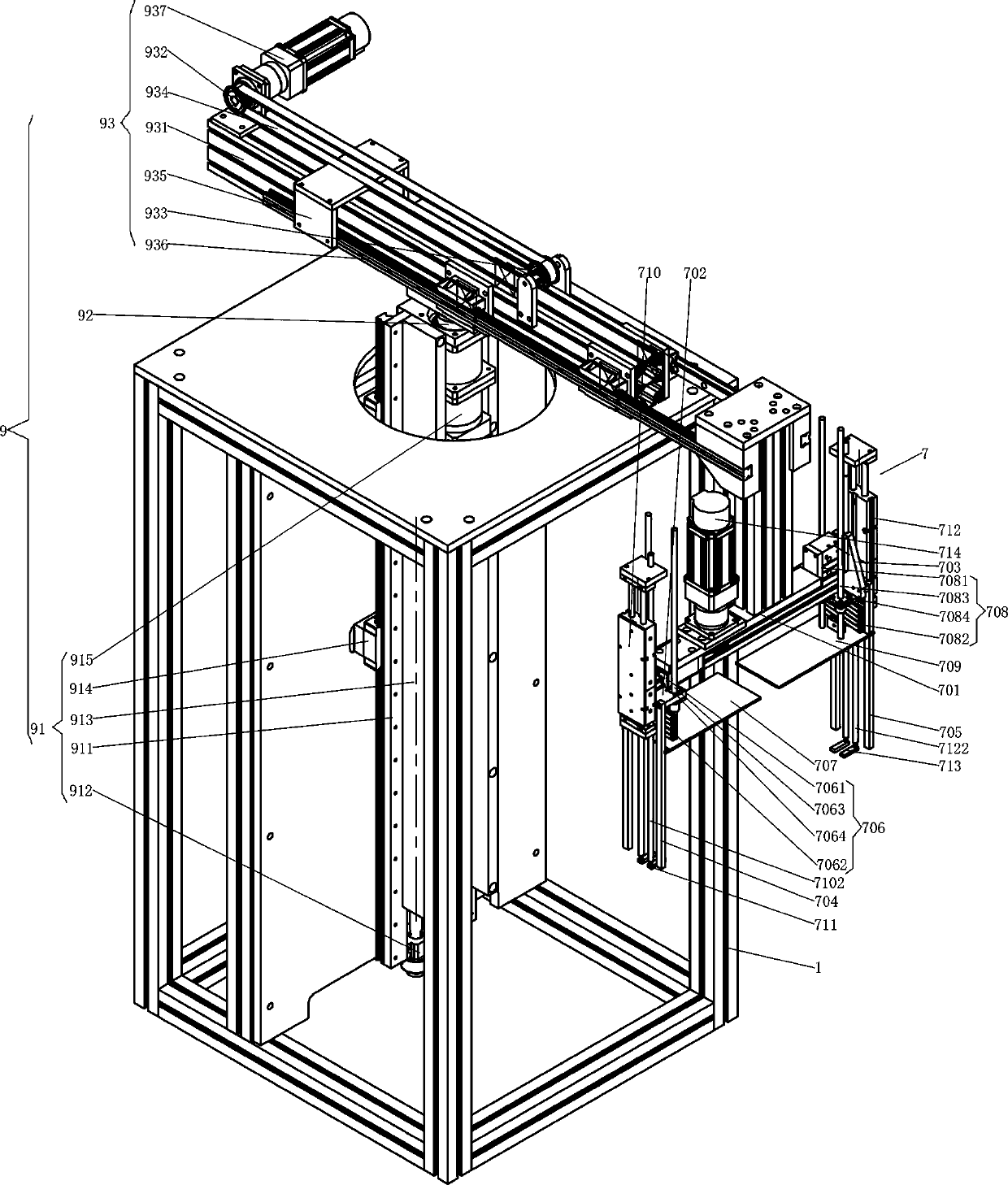

ActiveCN109080882BFast processNo need for manual finishingPackagingStructural engineeringAluminum foil

The invention discloses a packing machine for packing capsule aluminum foil plates, and belongs to the field of capsule packing. The packing machine for packing the capsule aluminum foil plates comprises a base, capsule filling conveying plates and a capsule bag conveying plate. A rotary shaft is rotatably connected to the base, an upper packing rotary disk is fixedly connected to the top end of the rotary shaft, and a lower packing rotary disk is rotatably connected to the rotary shaft. The conveying ends of the capsule filling conveying plates are arranged between the upper packing rotary disk and the lower packing rotary disk, the capsule filling conveying plates are connected to the base through supporting columns in a supporting mode, and the conveying end of the capsule bag conveyingplate is in contact with the side wall of the lower packing rotary disk. According to the packing machine for packing the capsule aluminum foil plates, cutting, packing and sealing of a capsule medicine plate are realized through the upper packing rotary disk and the lower packing rotary disk on the rotary shaft, the procedure is fast, manual arrangement is not required, the labor intensity is effectively reduced, and the working efficiency is improved.

Owner:SHANGHAI UNIV OF MEDICINE & HEALTH SCI

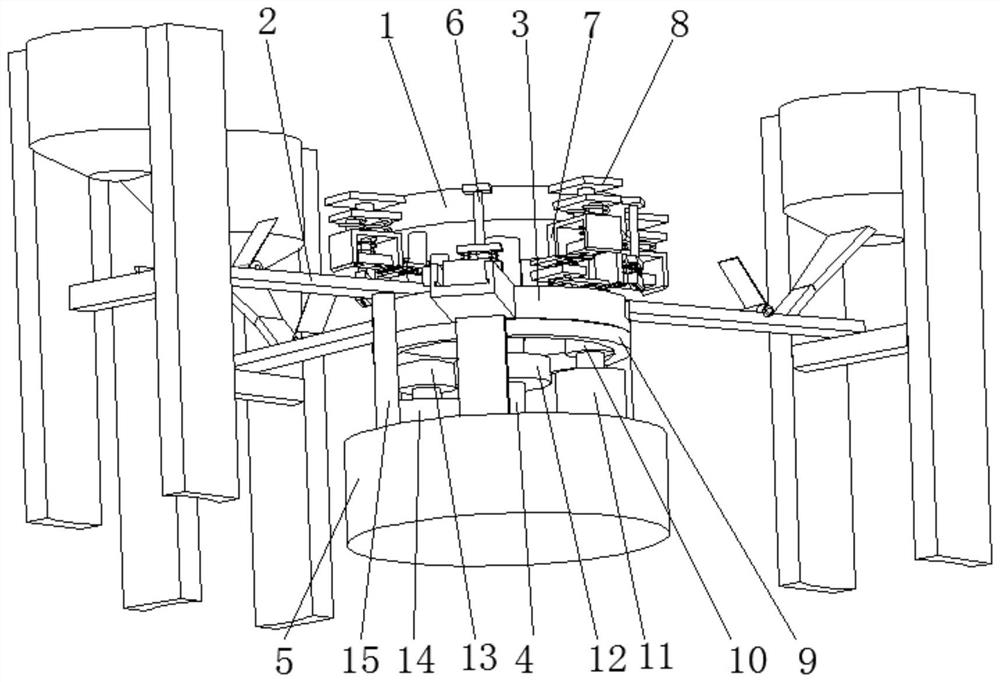

Fibreboard packaging rack

InactiveCN106364729ANo need for manual finishingEasy to bundleBundling machine detailsEngineeringFiberboard

The invention discloses a fibreboard packaging rack. Two ends of a base and rear end of a cross rod on the bottom surface of an external support are aligned and welded to form a frame; the front end of two ends of the base and the cross rod form a 90-degree limiting right angle; an internal support is ridden on the base of an inner box of the frame; a height-limiting rod is welded at tops of the external support and the internal support; a handle is welded on each sway rod; the external support is composed of one cross rod and two sway rods; the sway rods are welded at two ends of the cross rod; the internal support is herringbone; two ends of the height-limiting rod are L-shaped and are welded with the top end of the external support through L shapes; the limiting right angle is just the limiting angle for limiting dislocation of stacked fiberboards; and the height-limiting rod is used for limiting overlapped and stacked height of the fiberboards. According to the technical scheme, the fiberboards can be stacked in order at one time without manual arrangement to save time and labor and are convenient to bundle and transport.

Owner:河南鑫饰板业有限公司

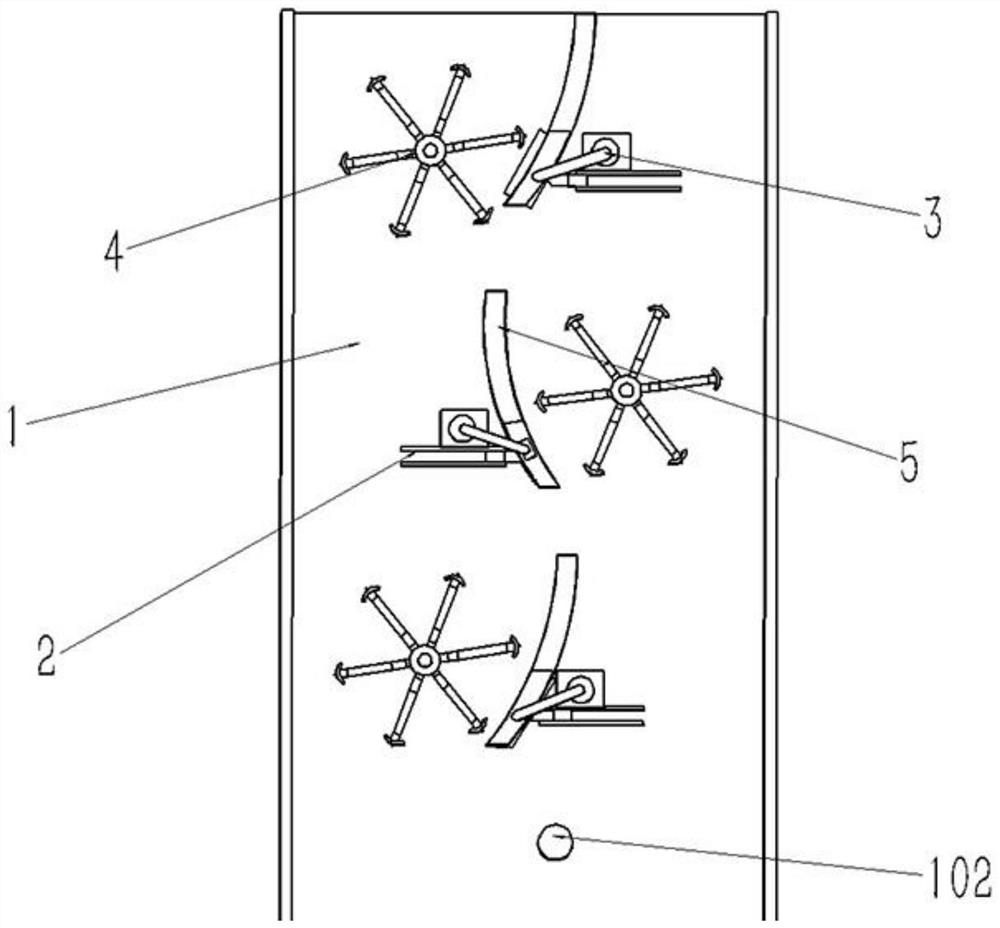

Multi-layer wire stripping equipment for seat ring heater cable

PendingCN113904271AGood winding effectReduce manpower utilizationApparatus for removing/armouring cablesElectronic waste recyclingCopper wireKnife blades

The invention relates to the technical field of cable processing, in particular to multi-layer wire stripping equipment for a seat ring heater cable. The equipment comprises a workbench, a cutting guide rail, a clamp holder, a recovery device and wire through rails, wherein multiple sets of wire through rails are arranged on one side of the workbench, the recovery device is arranged on the left side of the wire through rails and located on the workbench, the cutting guide rail is arranged on the right side of the wire passing rails and located on the workbench, the clamp holder is arranged at the upper end of the cutting guide rail and located on the workbench, the cutting guide rail comprises a sliding blade and a movable sliding block, the movable sliding block is located on the inner side of the cutting guide rail, and the sliding blade is located at one end of the movable sliding block. According to the invention, the stripped cable sheath is recovered through a mechanical winding device, and after the winding wheel is full, the cable sheath is cut off, a copper wire does not need to be cut off, and the stripped wire does not need to be manually arranged.

Owner:宁国市天瑞电热电器有限公司

Non-setting adhesive wall sticker manufacturing method convenient to operate

InactiveCN112049342AEasy to implementOrganize automaticallyCovering/liningsFilm/foil adhesivesWallpaperIndustrial engineering

The invention discloses a non-setting adhesive wall sticker manufacturing method convenient to operate. The processing method can comprise the steps of unreeling, printing, polishing, gold stamping, die cutting and slitting. The method is convenient to implement, non-setting adhesive wallpaper can be automatically tidied after being slit, and therefore manual tidying is not needed, and the workingefficiency is improved.

Owner:ZHEJIANG SUOFAN ADHESIVE PROD

Automatic stacking device

The invention relates to an automatic stacking and sorting device, which is characterized in that it includes a frame, a side sorting device and a front sorting device, the side sorting device and the front sorting device are respectively connected with the frame, and the side sorting device includes a side transmission device and side finishing board, the side transmission device drives the side finishing board to perform horizontal and transverse telescopic movement, the front finishing device includes a front transmission device and a front finishing board, and the front transmission device drives the front finishing board to perform horizontal and longitudinal expansion and contraction Movement, the side finishing boards are used to align the boards in the transverse direction, and the front finishing boards are used to align the boards in the longitudinal direction. After the improvement, there are front and rear, left and right side and front finishing devices, so that the plates are neatly stacked on the pallet, eliminating the need for manual finishing steps and improving the work efficiency of the corresponding process. After the improvement, the boards are stacked neatly, and there will be no scattering and crashing of the boards, thus reducing the defective rate.

Owner:JIANGSU YUANXIANG INTERNET OF THINGS SCI & TECH

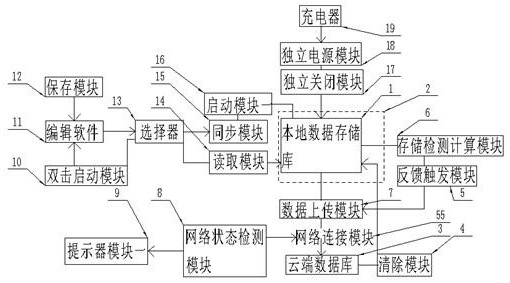

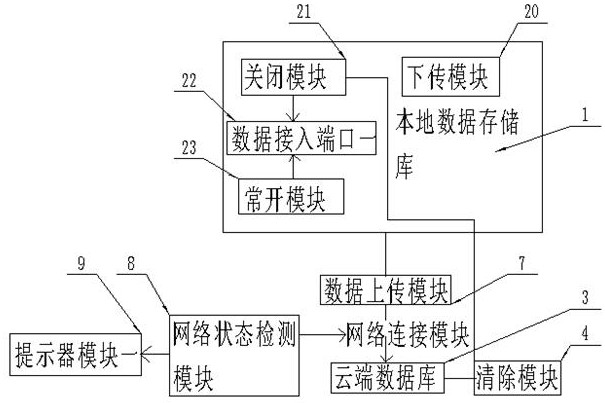

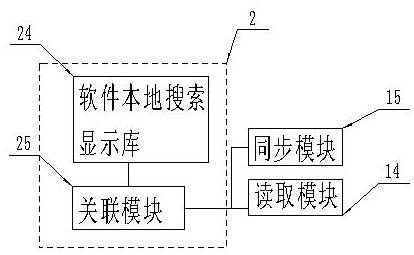

Local real-time transition storage cloud data synchronization system and synchronization method thereof

PendingCN112783870AFor follow-up viewingAvoid cracking operationsDatabase distribution/replicationDigital data authenticationData contentCloud database

The invention discloses a local real-time transition storage cloud data synchronization system and a synchronization method thereof. The system comprises a local data storage library, an independent computer mainboard, editing software and a cloud database, the local data storage library is loaded on the independent computer mainboard, and the editing software is provided with a double-click starting module; the local data storage library comprises a data access port I, a starting module, a synchronization module, a reading module, an independent power supply module, an independent closing module and a selector. When a user edits related character and pattern data in the editing software, the reading module transmits a change data content edited in real time in the editing software to the local data storage library to be stored, local temporary backup is achieved, and a network is not needed; meanwhile, due to the fact that the independent computer mainboard depends on the independent power module to supply power, data loss is avoided. And the data uploading module transmits the new data into the cloud database under the condition that the network state is normal, so that synchronous storage of the data is realized.

Owner:乔健

Document recovery device

ActiveCN105374107BImprove recycling efficiencyReduce the burden onCoin/currency accepting devicesElectricityException handling

Owner:BEIJING C&W ELECTRONICS GRP

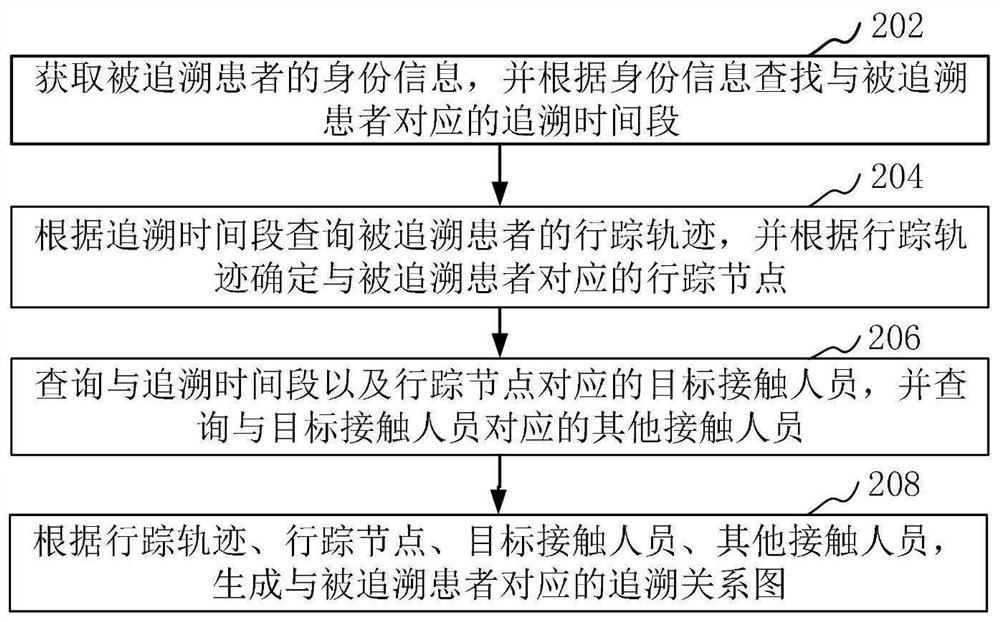

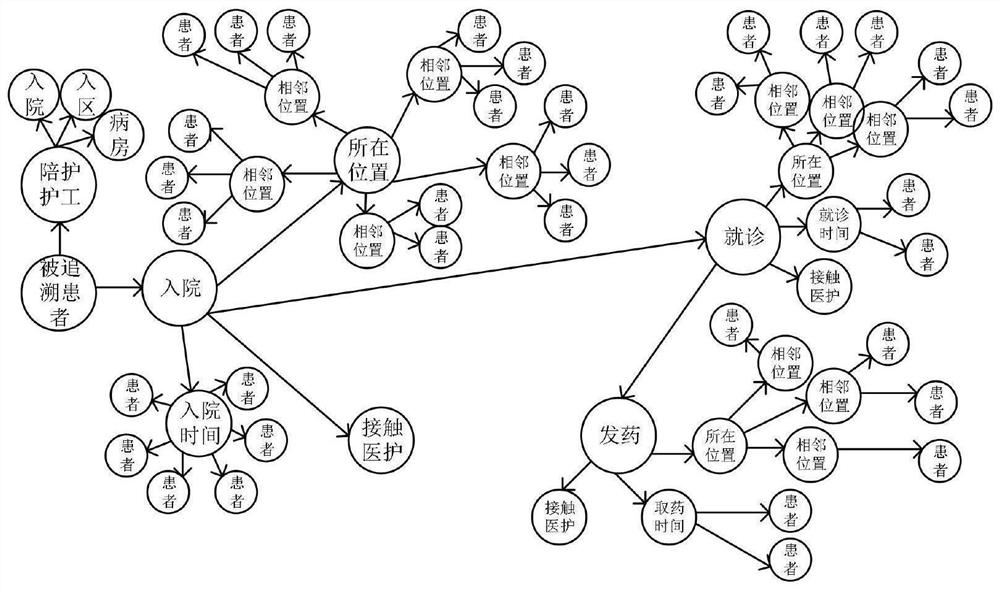

Patient track tracing method and system, computer equipment and storage medium

PendingCN113539513ANo need for manual finishingObservation is intuitiveMedical data miningEpidemiological alert systemsComputer graphics (images)Algorithm

The invention relates to a patient track tracing method and system, computer equipment and a storage medium. The method comprises the following steps: acquiring identity information of a traced patient, and searching a tracing time period corresponding to the traced patient according to the identity information; querying a track of the traced patient according to the tracing time period, and determining a track node corresponding to the traced patient according to the track; querying a target contact person corresponding to the tracing time period and the track node, and querying other contact persons corresponding to the target contact person; and generating a tracing relation graph corresponding to the traced patient according to the track, the track node, the target contact person and other contact persons. The traceability event list is inquired according to the identity information of the traced patient, and then the traceability relation graph is generated without manual arrangement, so the track traceability is faster; by generating the tracing relation graph corresponding to the traced patient, people who have contacted with the traced patient can be observed more visually.

Owner:WINNING HEALTH TECHNOLOGY GROUP CO LTD

Smart printer capable of automatically arranging and stacking printing paper

ActiveCN109160351AReduce labor intensityDecrease productivityPile receiversArticle deliveryPulp and paper industryOpen structure

The invention relates to a smart printer capable of automatically arranging and stacking printing paper. The smart printer capable of automatically arranging the stacking printing paper comprises a printer body. A sorting frame is arranged at the paper exit of the printer body in a slidably fitted mode, the upper end of the finishing frame is of an open structure, horizontal end flattening mechanisms are symmetrically arranged on the left end and the right end of the sorting frame, and longitudinal end alignment mechanisms are symmetrically arranged on the front end and the rear end of the sorting frame. According to the smart printer capable of automatically arranging and stacking the printing paper, the problems that the existing printer needs to manually arrange and stack the printing paper, so as to waste time, and the manual finishing of the printing paper is easy to be mixed due to mistakes, and the labor intensity is high and the work efficiency is low are solved, the function of arranging and stacking the printing paper is automatically realized, manual operation is not needed, the labor intensity of the staff is reduced, and the work efficiency is improved.

Owner:CHANGCHUN NORMAL UNIVERSITY

A glove placement mechanism

ActiveCN106429416BNo need for manual finishingImprove efficiencyConveyor partsEngineeringMechanical field

Owner:Zhejiang Baixiang Technology Co Ltd

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com