Automatic stacking device

A sorting device and automatic stacking technology, which is applied in stack receiving devices, thin material handling, transportation and packaging, etc., can solve the problems of reduced work efficiency, reduced yield, and damage to the four corners of the sheet, and achieves Improve work efficiency, reduce defective rate and save cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

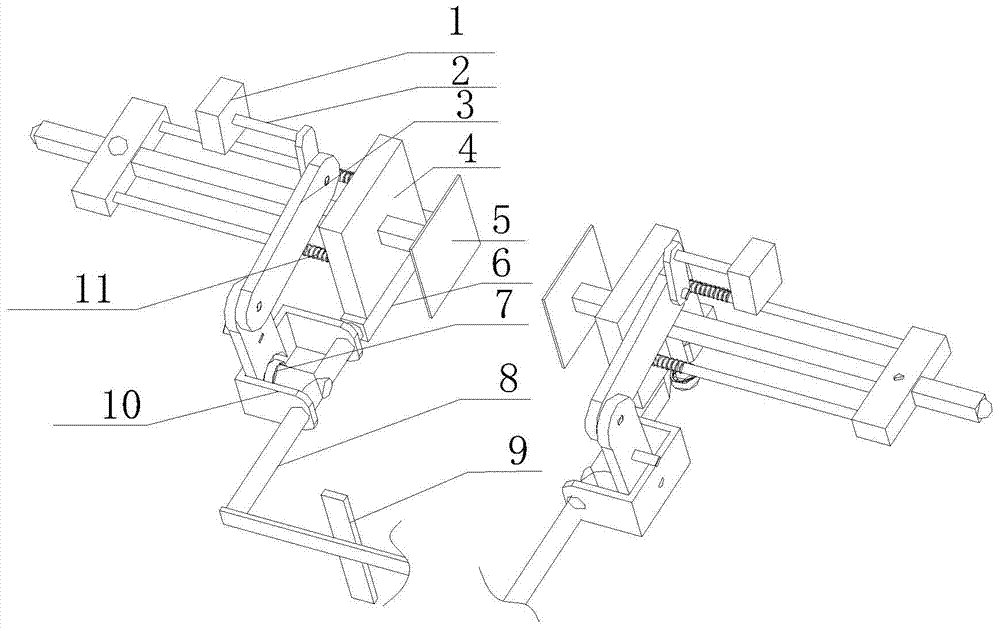

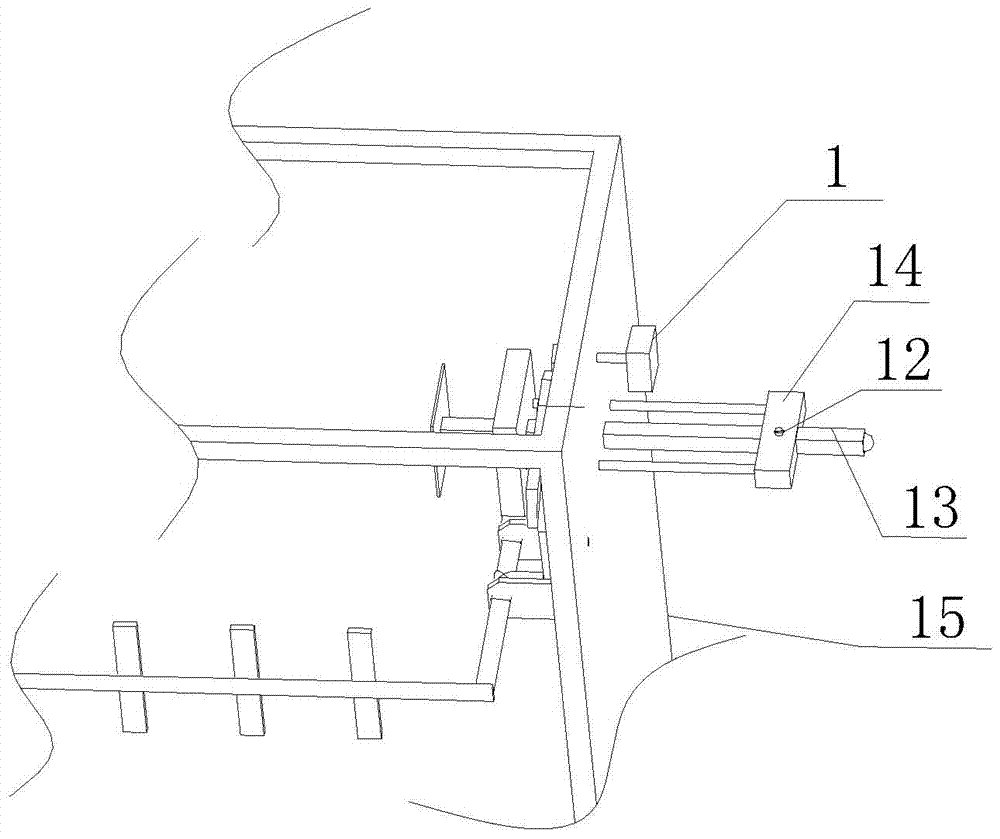

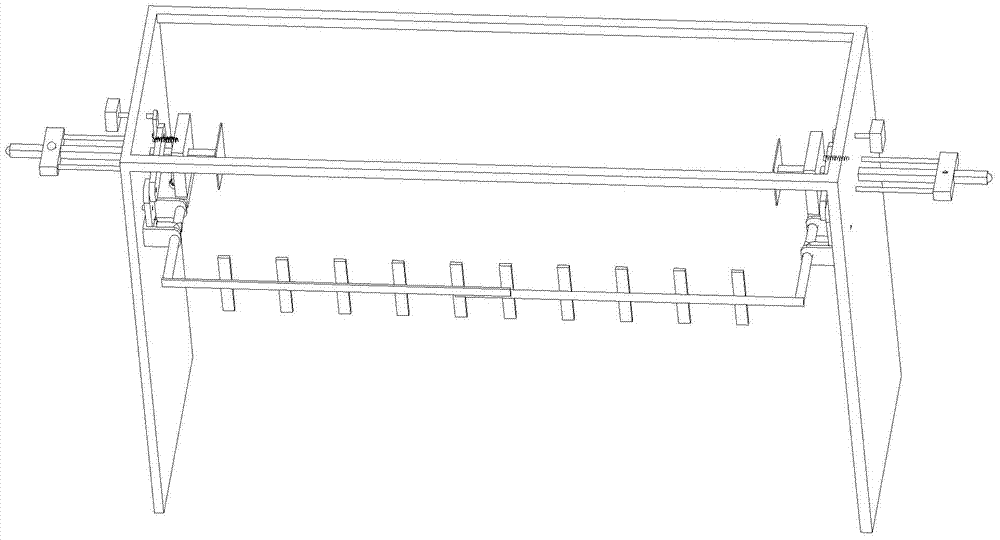

[0017] Such as Figure 1 to Figure 3 As shown, the automatic stacking and sorting device is generally installed in the process of stacking and sorting the plates after mechanical automation. It comprises frame 15, side finishing device and front finishing device, and described side finishing device and front finishing device are connected with frame 15 respectively, and described side finishing device comprises side transmission device and side finishing plate 5, and described side transmission device The side finishing board 5 is driven to perform horizontal and transverse telescopic movements. The front finishing device includes a front transmission device and a front finishing board 9. The front transmission device drives the front finishing board 9 to perform horizontal and longitudinal telescopic movements. The side finishing board 5 It is used to align the boards in the transverse direction, and the front finishing board 9 is used to align the boards in the longitudinal ...

Embodiment 2

[0021] The automatic stacking and finishing device includes a frame, a side finishing device and a front finishing device. The side finishing device and the front finishing device are respectively connected with the frame. The transmission device drives the side finishing board to perform horizontal and transverse telescopic movements. The front finishing device includes a front transmission device and a front finishing board. The front driving device drives the front finishing board to perform horizontal and longitudinal telescopic movements. The boards are aligned in the transverse direction, and the front finishing board is used to align the boards in the longitudinal direction. The side transmission device includes a drive motor and a horizontal horizontal transmission mechanism connected to the side finishing board, and the drive motor drives the horizontal horizontal transmission mechanism to move horizontally and horizontally. The front transmission device includes a dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com