Transportation method used in steel pipe machining process

A transportation method and technology of processing process, which is applied in the field of steel pipe processing, can solve the problems of easily falling and injuring operators, low safety, and low transportation efficiency, and achieve simple internal structure transformation, high transportation efficiency, and high safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

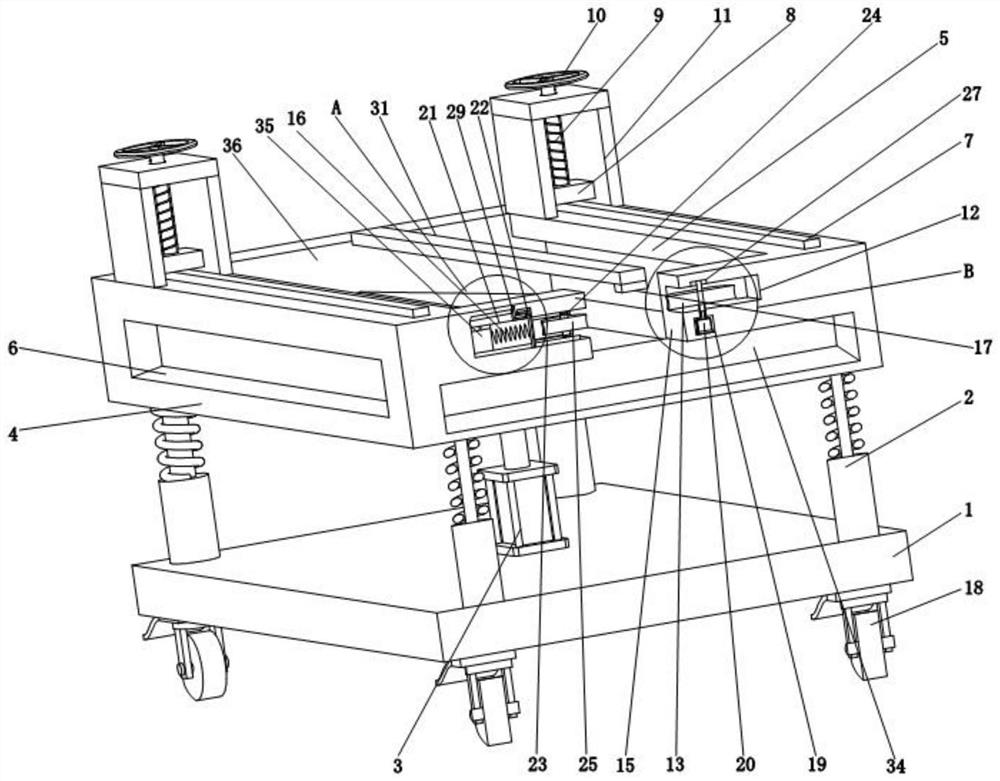

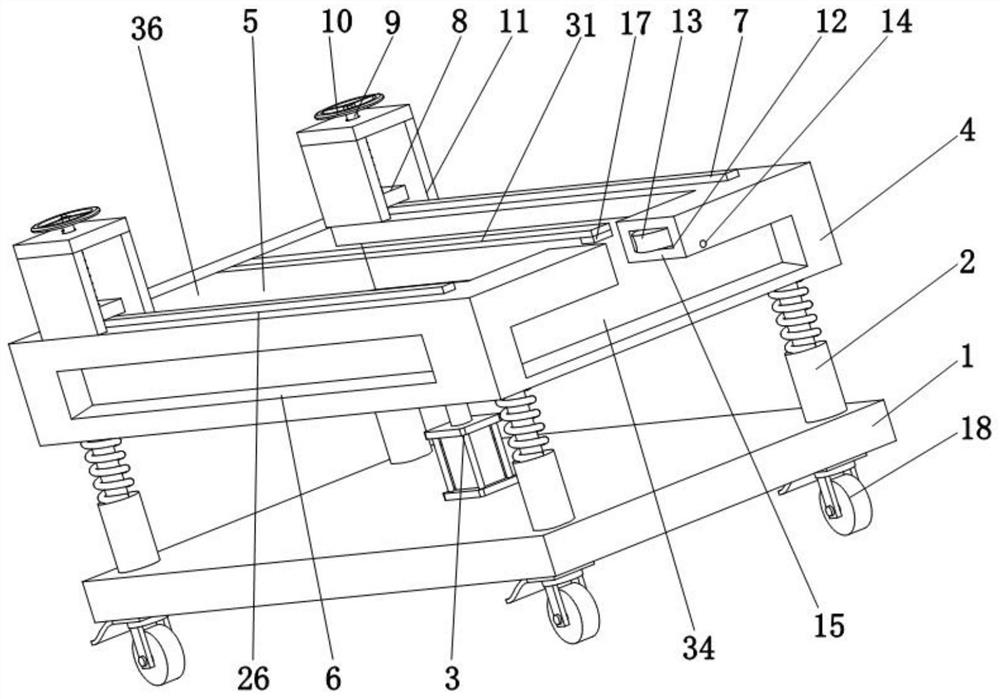

[0036] like Figure 1 to Figure 8As shown, the present invention provides a mobile transportation device for steel pipe processing, comprising a base 1, a cylinder 3 is fixedly installed in the middle of the top surface of the base 1, and a workbench 4 located directly above the base 1 is fixedly installed at the telescopic end of the cylinder 3 , the four corners of the top of the base 1 are fixedly installed with a buffer fixing device 2, and the buffer fixing device 2 is fixedly connected with the bottom of the workbench 4. The top of the workbench 4 is provided with a placement area 5, and the right side of the workbench 4 is provided with an inlet pipe Port 15, the inlet port 15 is communicated with the placement area 5, the right side of the inlet port 15 is provided with a wheel groove 12, the inside of the wheel groove 12 is movably sleeved with the driving wheel 13 through the bearing 27, and the inside of the workbench 4 is provided with a The motor seat cavity 19 di...

Embodiment 2

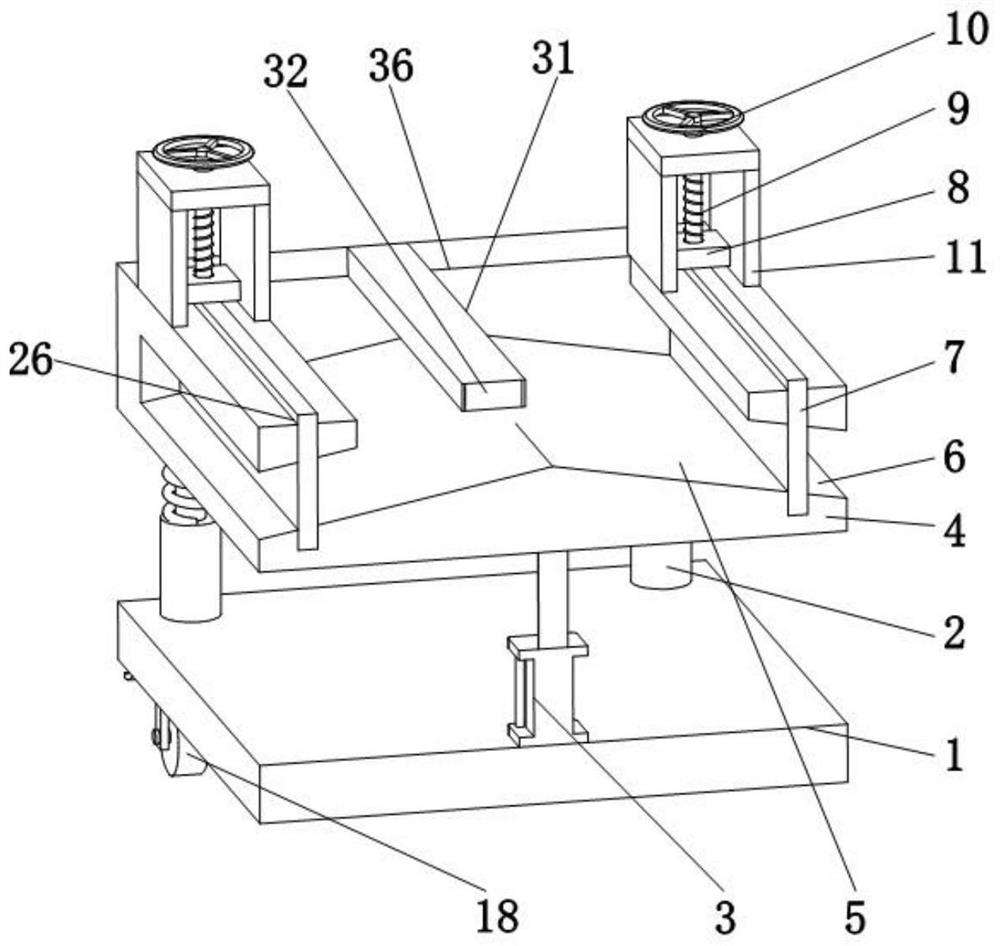

[0046] In use, the applicant found that the length of steel pipes is often long. In Example 1, the device can transport more steel pipes at a time, which solves the problem that only one steel pipe can be transported at a time when the existing steel pipes are moved and transported. Only steel pipes whose length is less than the length of the device can be transported. In order to solve the problem of transporting longer steel pipes, on the basis of Example 1, the applicant has opened a through hole 34 below the pipe inlet 15, and the through hole 34 is connected to the pipe inlet 15. At the same time, the applicant has a second airbag 30 fixedly connected to the left side of the workbench 4 , and a movable plate 36 is fixedly connected to the other side of the second airbag 30 , and the shape of the movable plate 36 is the same as that of the left side of the workbench 4 . The shape is the same and is slidably connected to the front and rear sides of the workbench 4. The secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com