Feeding mechanism of vertical multi-start hoop bending machine

A technology of feeding mechanism and hoop bending machine, which is applied in the field of feeding mechanism, can solve the problems that cannot be popularized and used in a large area, the stirrups cannot be arranged neatly, and the efficiency is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

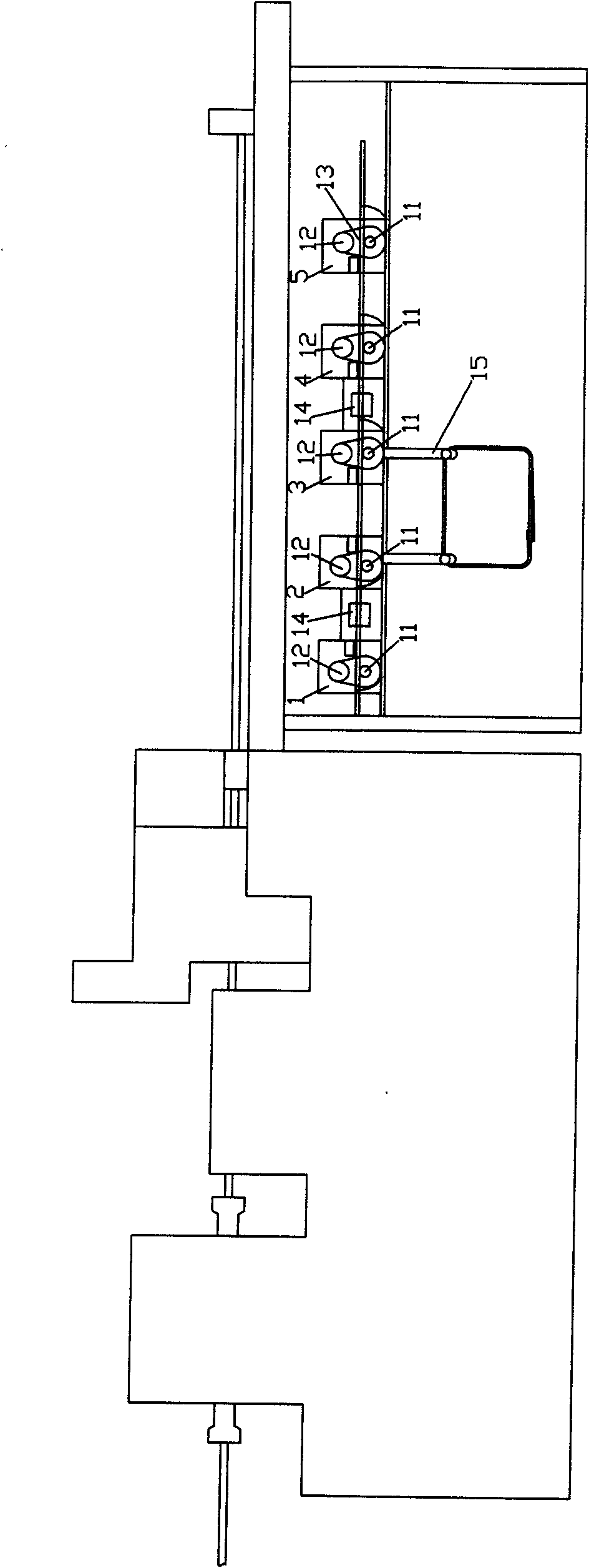

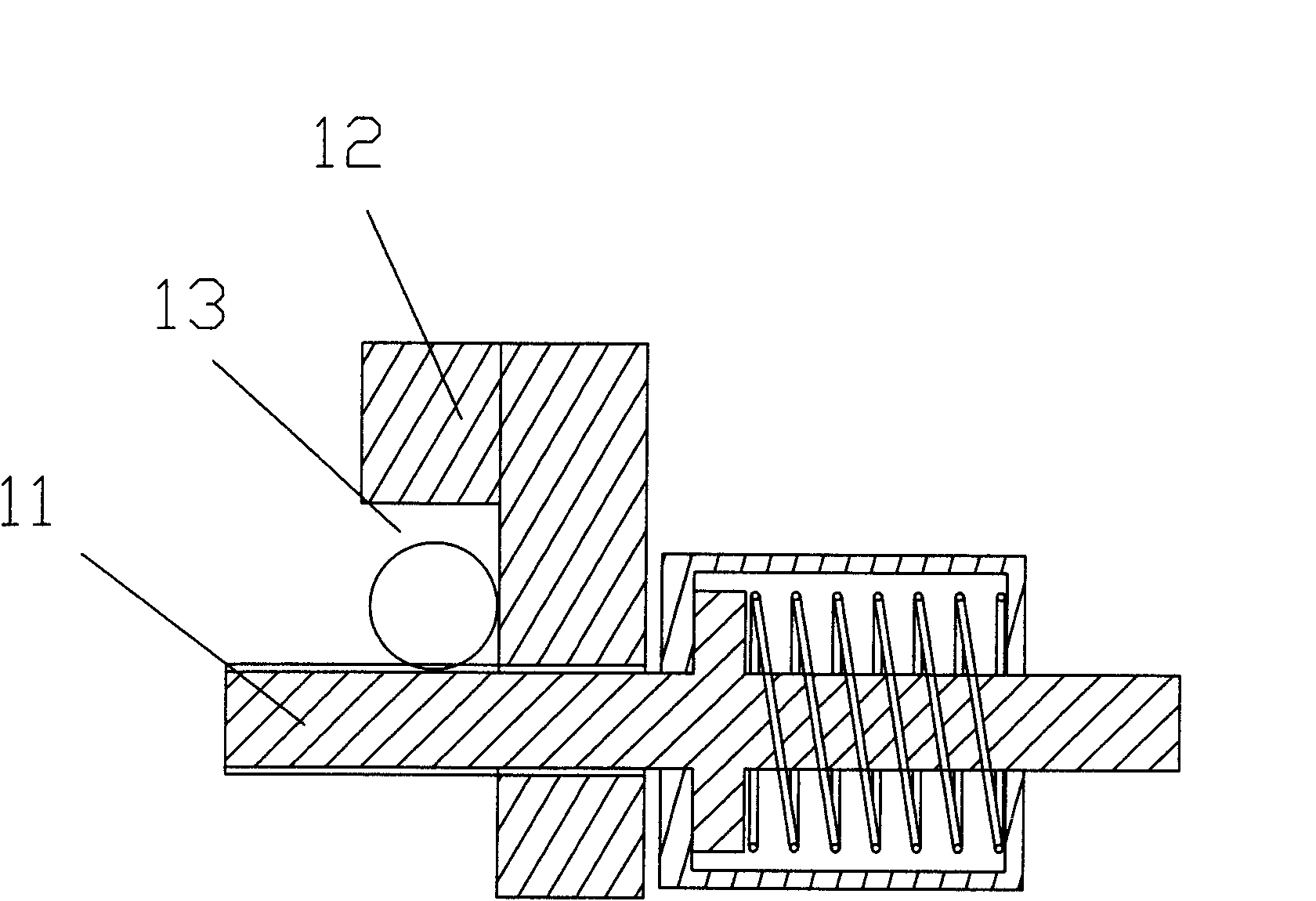

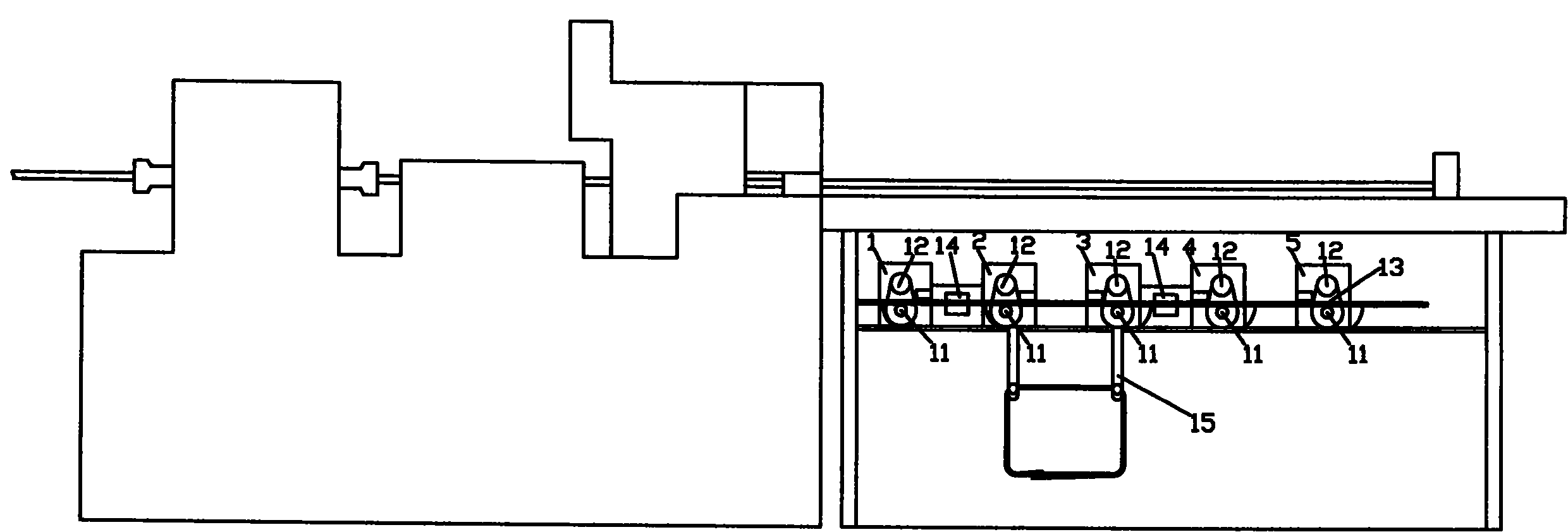

[0012] Such as Figure 1-2 As shown, five groups of hoop bending mechanisms are adopted in this embodiment, a feeding mechanism of a vertical multi-head hoop bending machine, including five groups of hoop bending mechanisms, a transmission mechanism and a driving mechanism, and the bending hoop mechanism includes a telescopic main shaft 11 And the bending hoop main shaft 12, the telescopic main shaft 11 can be stretched back and forth, and the bending hoop main shaft 12 rotates around the telescopic main shaft 11, and the five groups of bending hoop mechanisms are arranged in a straight line, forming a line between these telescopic main shafts 11 and the bending hoop main shaft 12. The accommodating passage 13 of the steel bar is provided with a magnet 14 at the rear portion of the accommodating passage 13, and the front end of the telescopic main shaft 11 protrudes forward compared with the hoop main shaft 12, and the feeding port of the accommodating passage 13 is arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com