A glove placement mechanism

A technology of gloves and components, applied in the field of knitting machinery, can solve problems such as affecting work efficiency and difficult to arrange products neatly, and achieve the effect of neat and uniform stacking and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

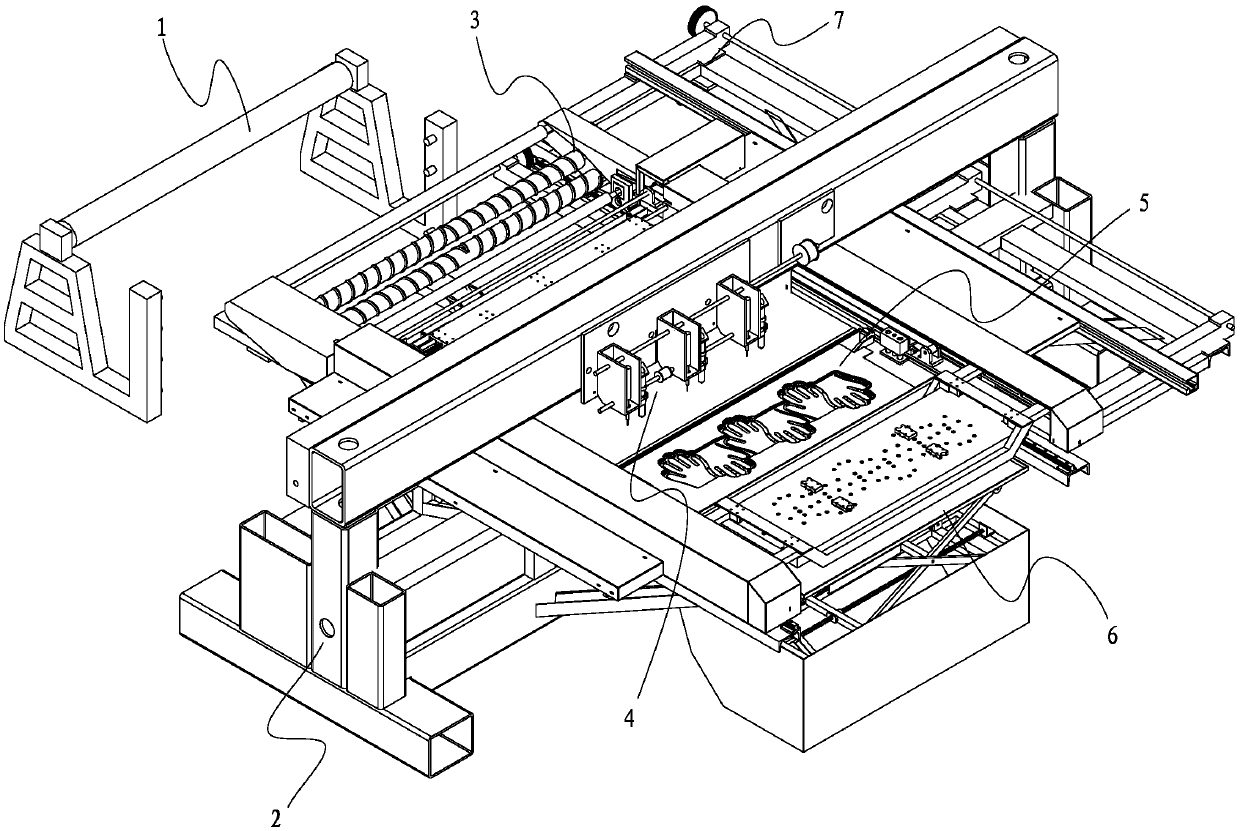

[0022] The cloth grabbing mechanism described in this embodiment is applied to an integrated glove machine, such as figure 1 As shown, the glove mechanism includes a cloth conveying mechanism 1, a machine base 2, and a cloth alignment mechanism 3 arranged on the machine base 2, a cloth embroidery mechanism 4, a cloth grabbing mechanism 5, a glove placing mechanism 6, and a driving mechanism 7 And the control mechanism, etc., the cloth can be cut and sewn finished gloves through the work of the above-mentioned mechanism.

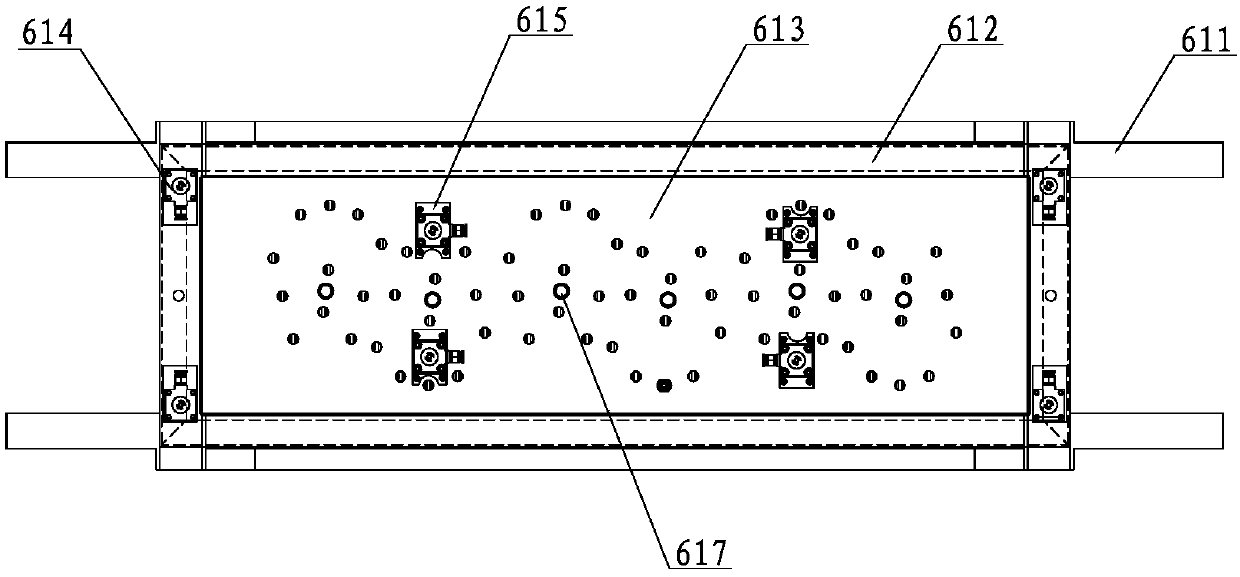

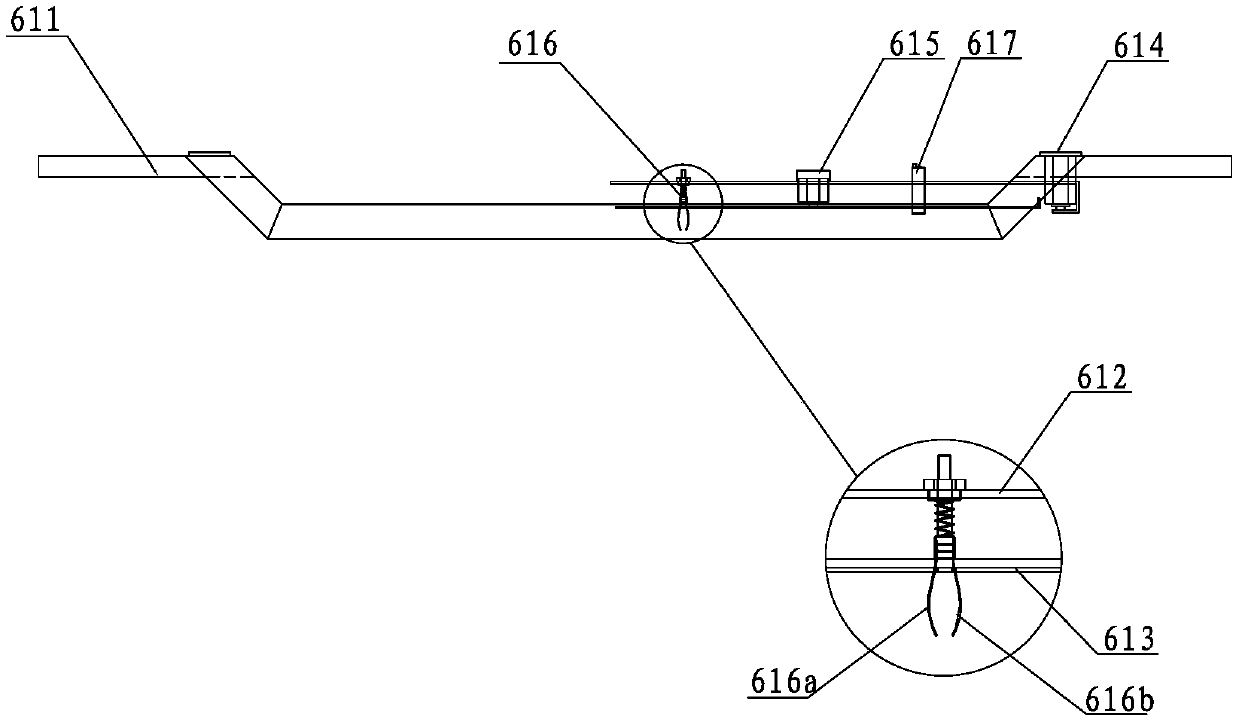

[0023] The glove placing mechanism 6 described in this embodiment includes a glove grabbing assembly 61 and a glove collecting assembly 62, wherein the glove grabbing assembly 61 includes a frame 611, a lifting plate 612, a pushing plate 613, a first cylinder 614 and a second cylinder 614. Two cylinders 615, the first cylinder 614 is fixedly installed on the frame 611, the telescopic rod of the first cylinder 614 is fixedly connected with the lifting plate 61...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com