Patents

Literature

31results about How to "Automatically arrange neatly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

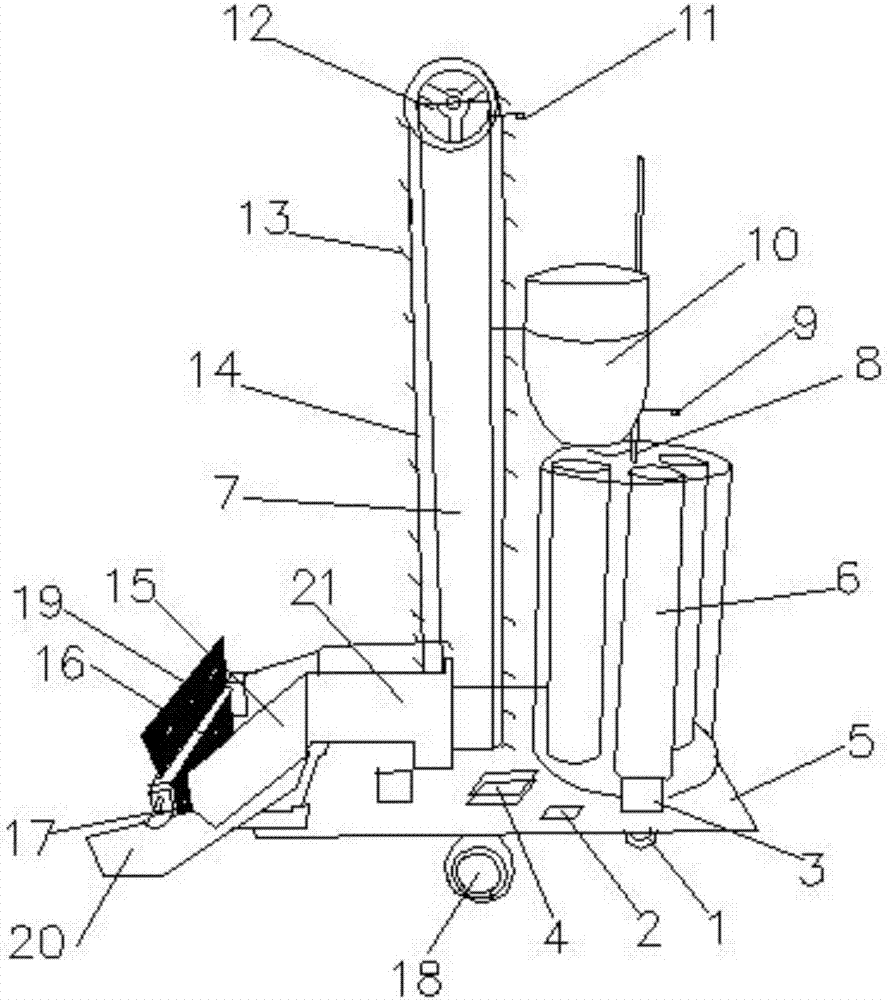

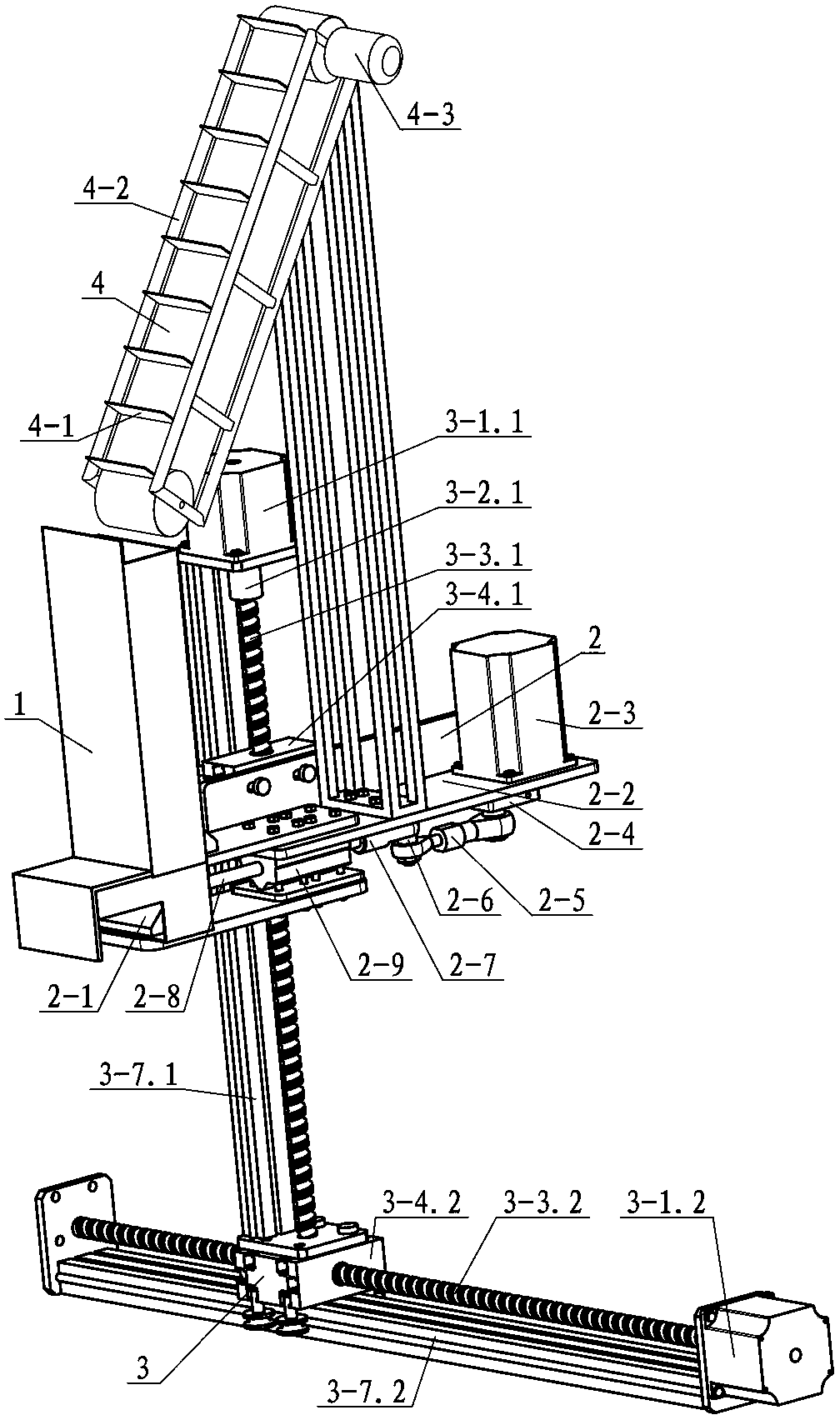

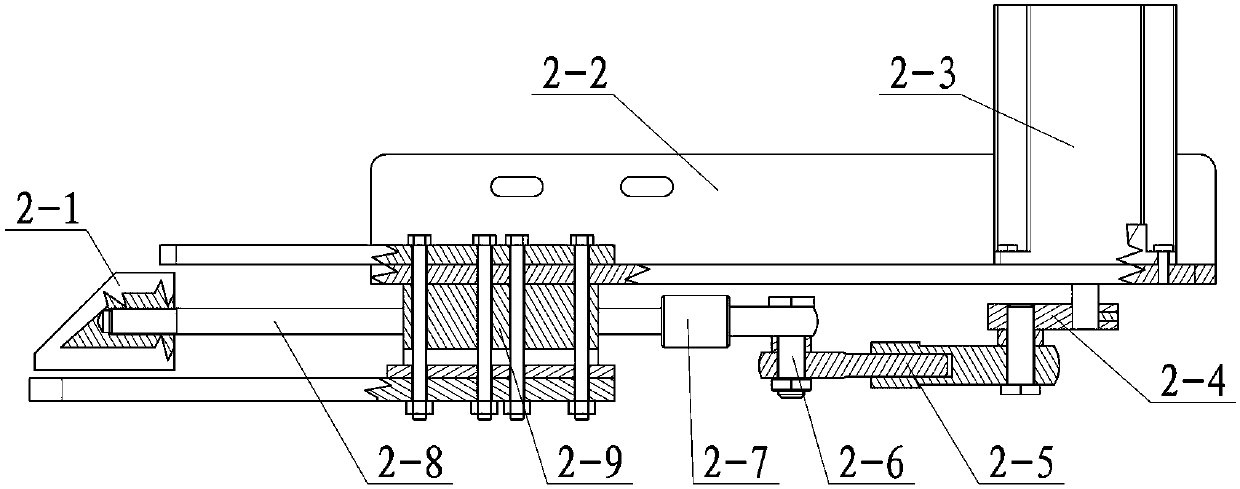

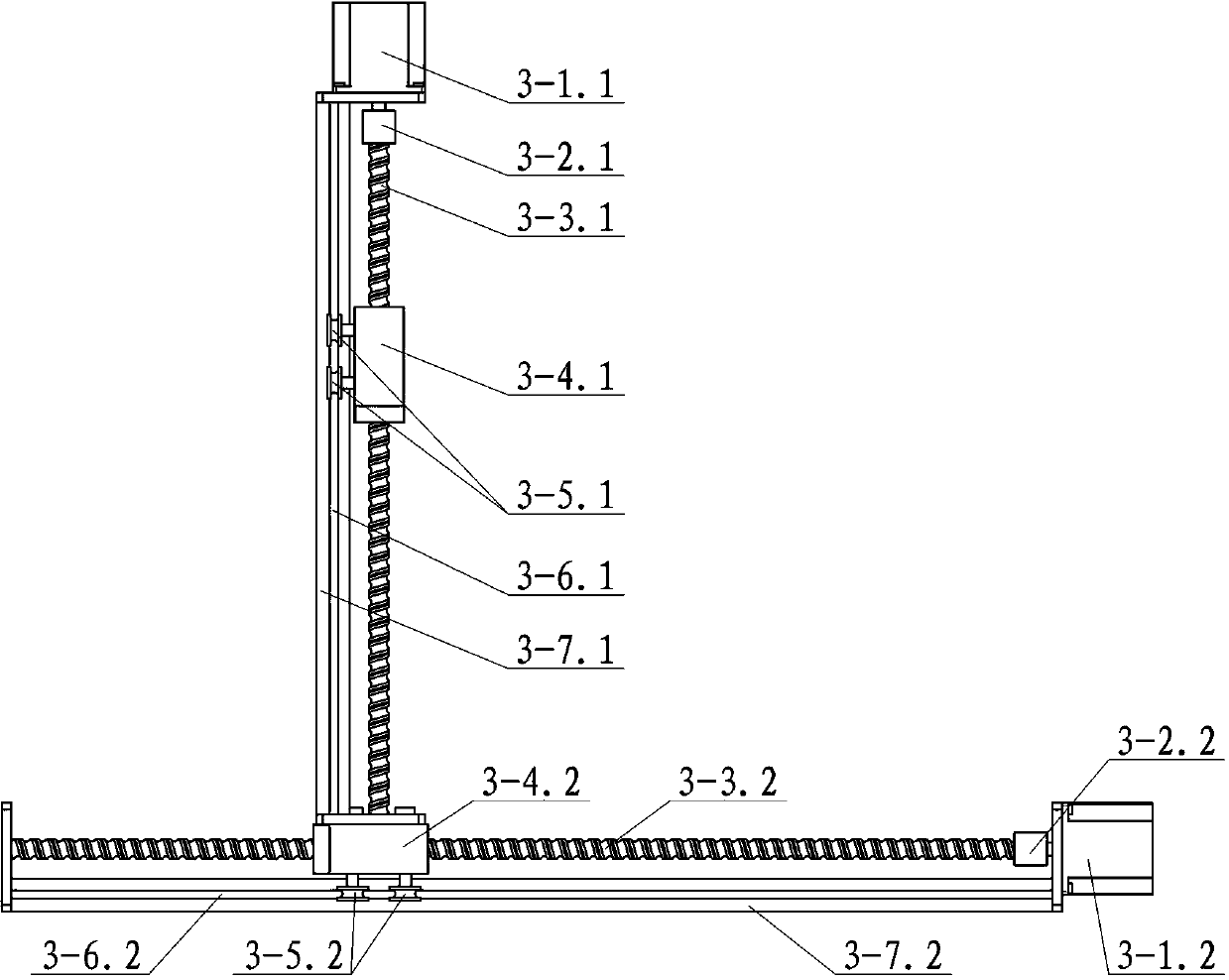

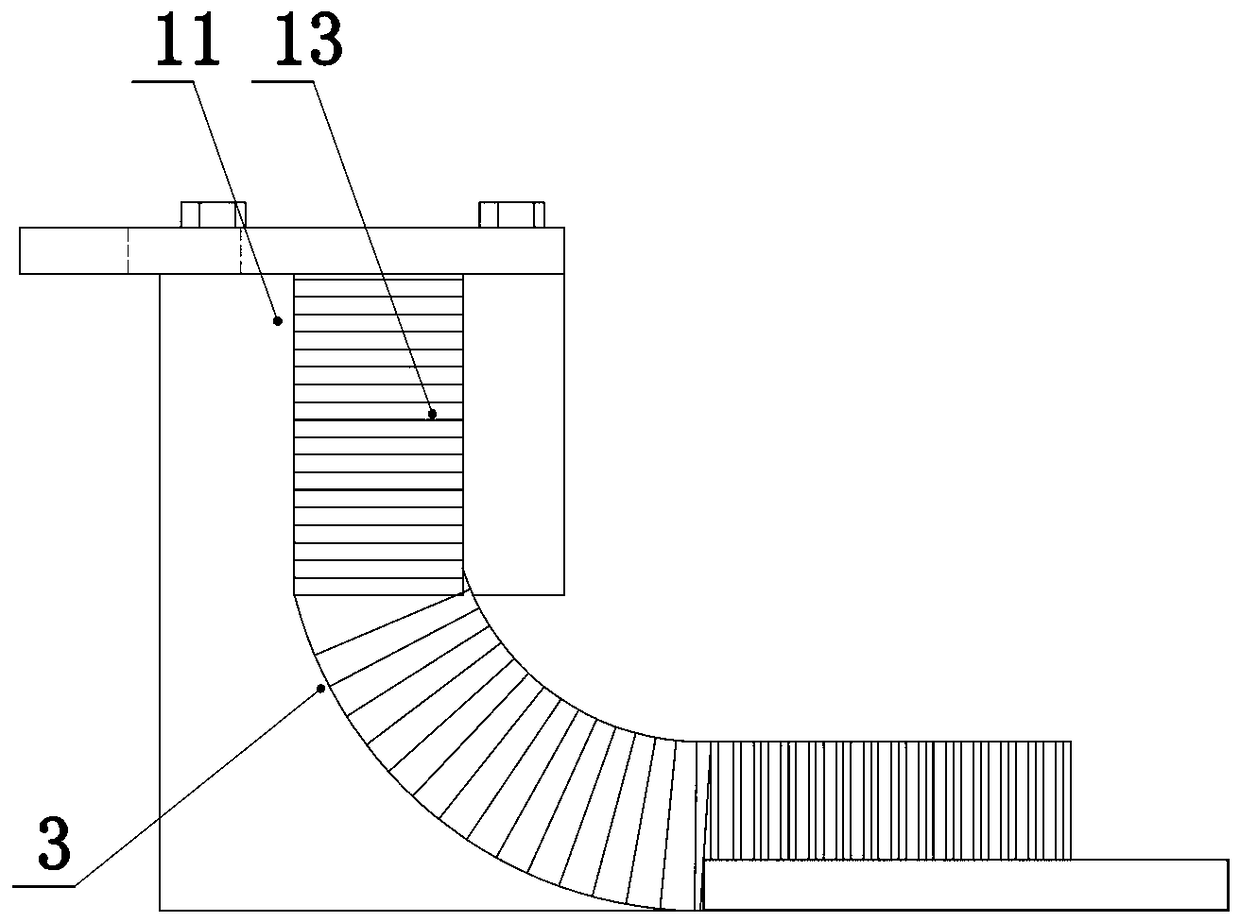

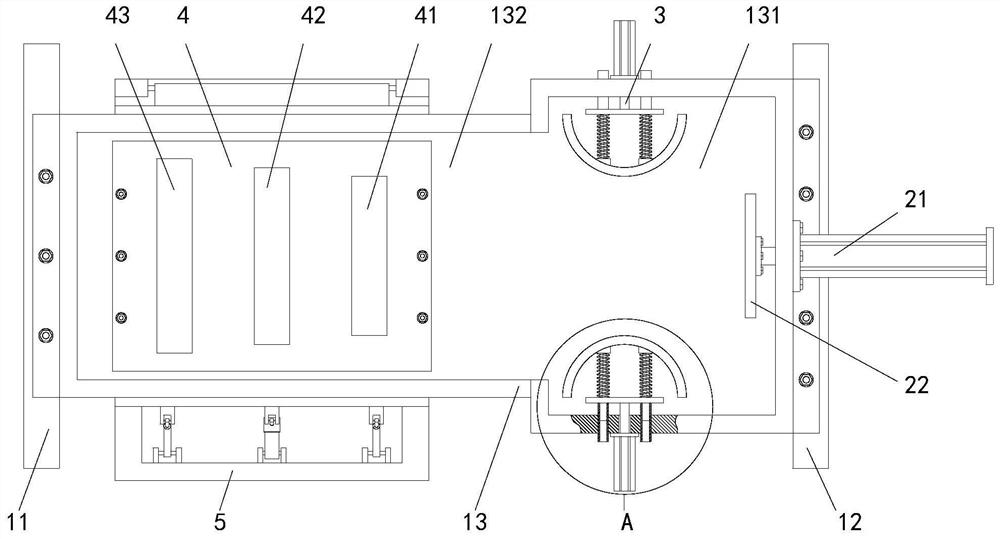

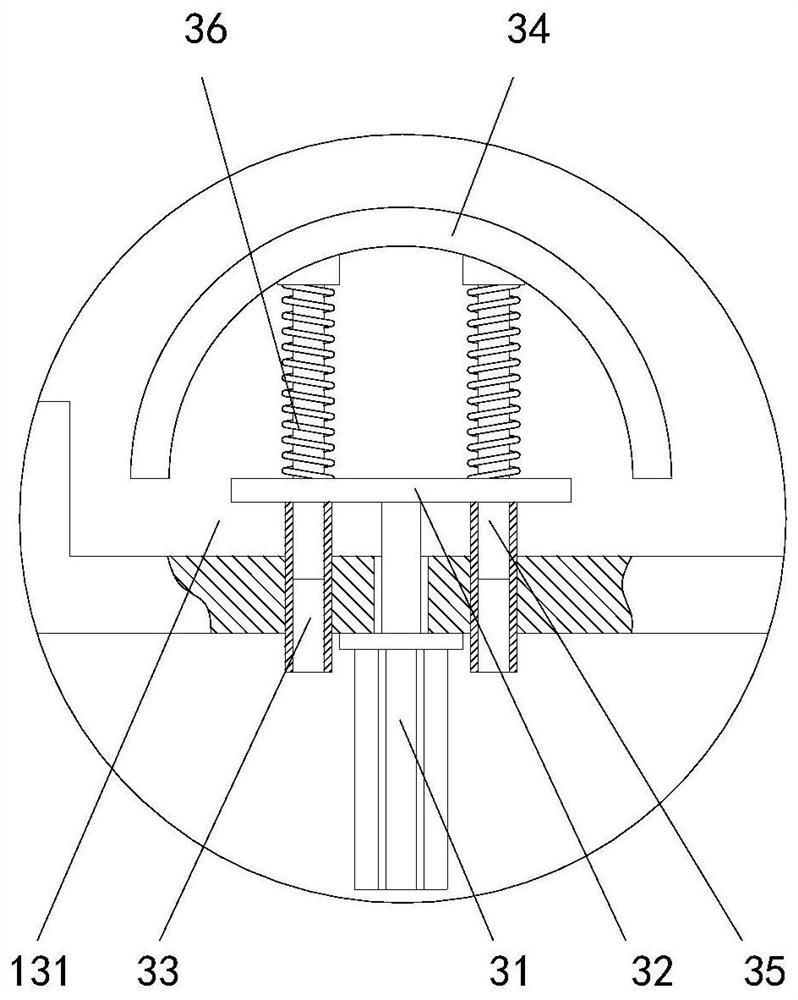

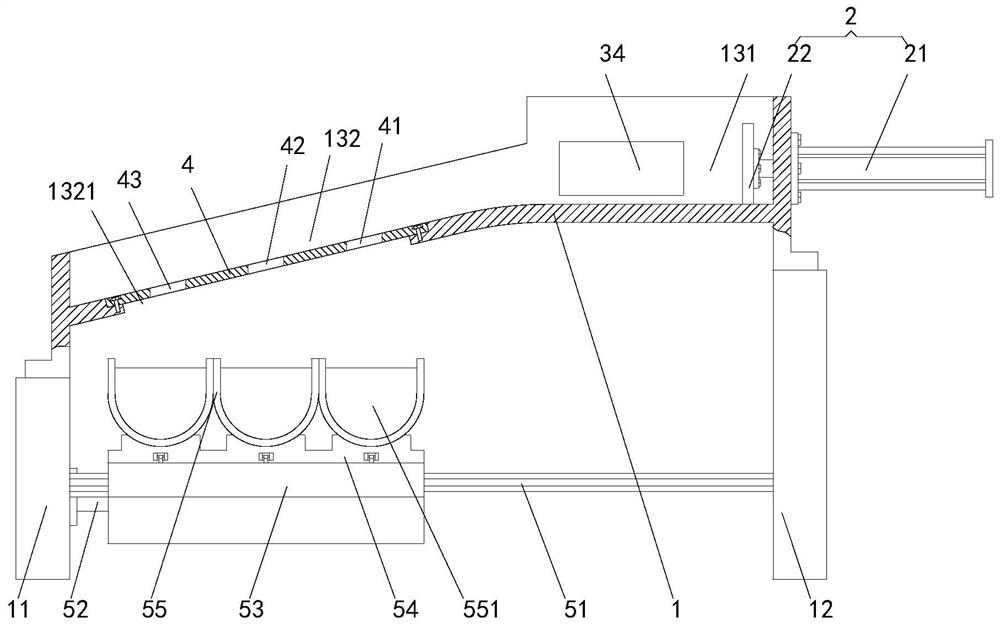

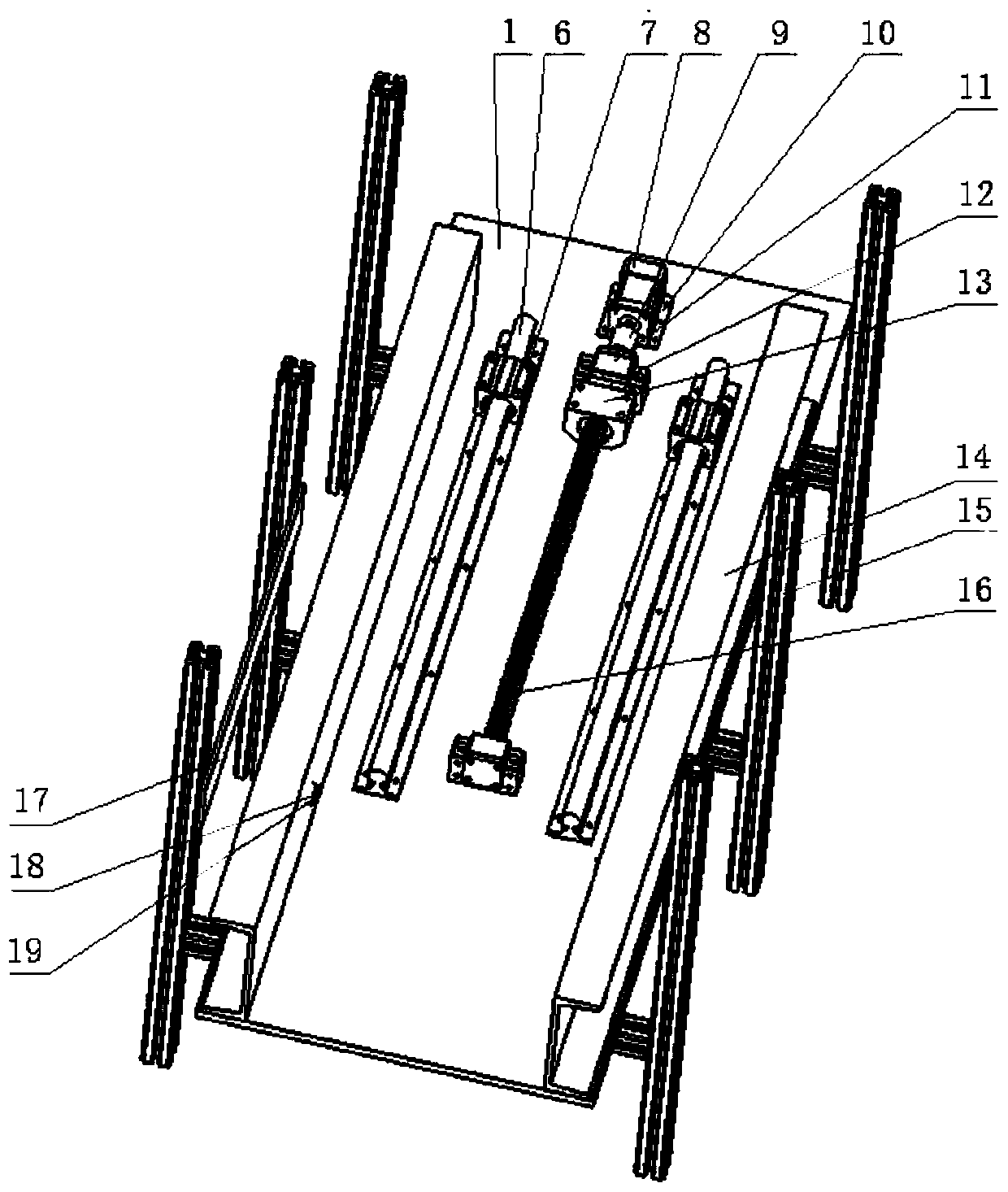

Shuttlecock picking robot based on ARM

InactiveCN107050782AAutomatically arrange neatlyWith automatic operation abilityBall sportsEngineeringRobot

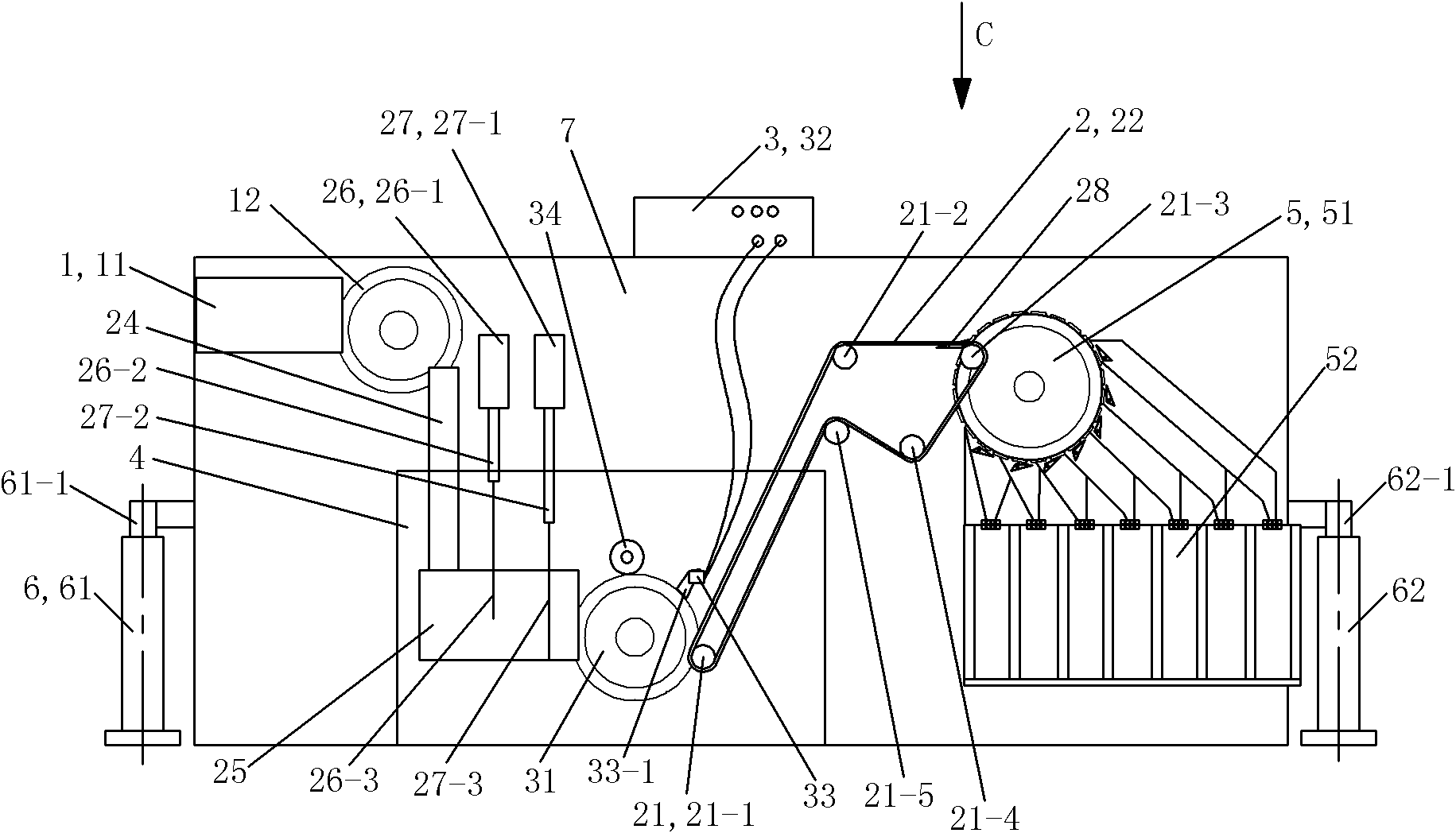

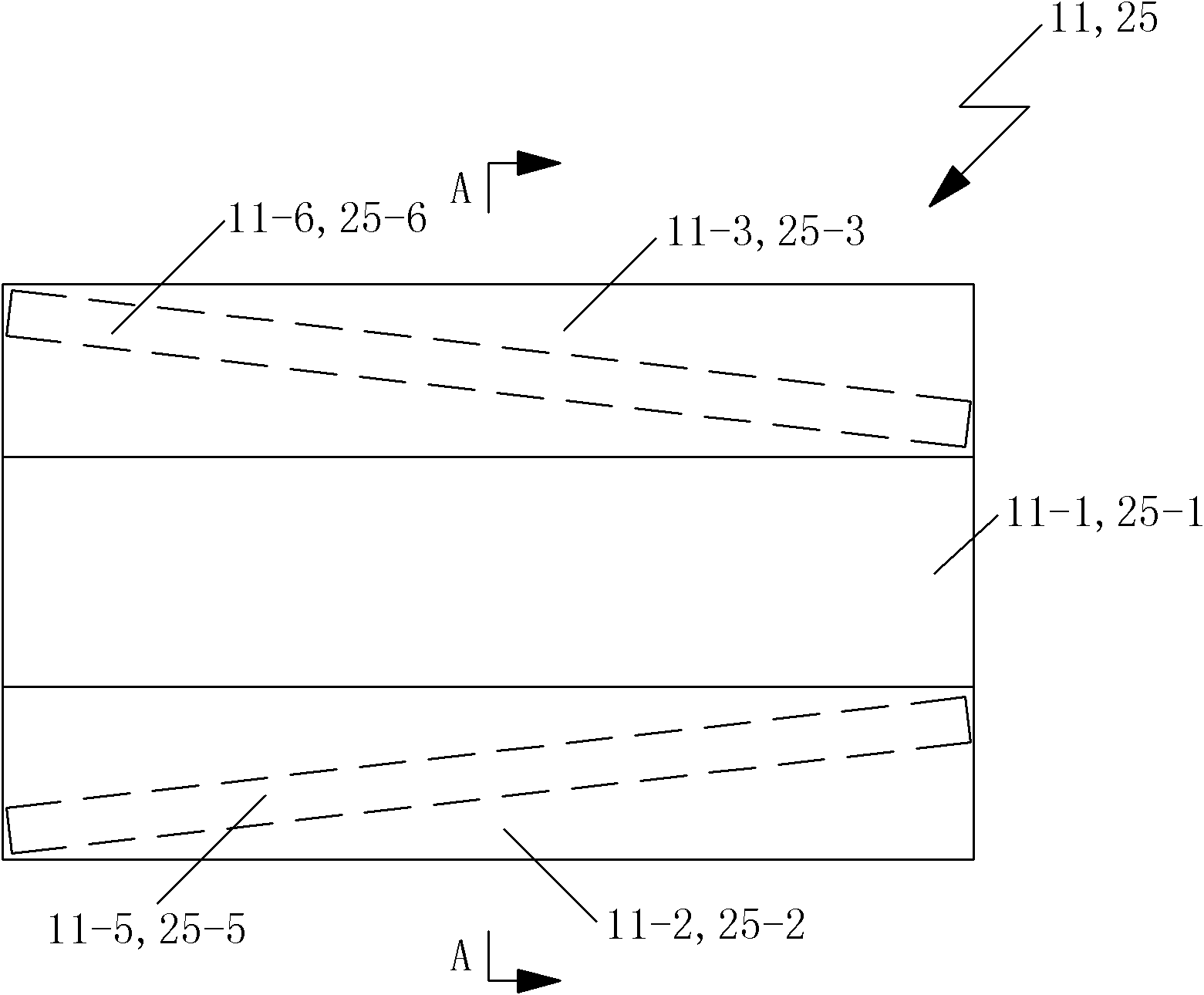

The invention discloses a shuttlecock picking robot based on an ARM. The shuttlecock picking robot comprises a shuttlecock shoveling device arranged on the horizontal plane, a vertically arranged conveying device and a collecting device. The shuttlecock shoveling device is arranged at the bottom end, the shuttlecock outlet end of the shuttlecock shoveling device is connected with the shuttlecock inlet end of the conveying device, and the shuttlecock outlet end of the conveying device is connected with the collecting device. The shuttlecock picking robot based on the ARM can collect and settle shuttlecocks, and is stable in performance.

Owner:XIAN UNIV OF SCI & TECH

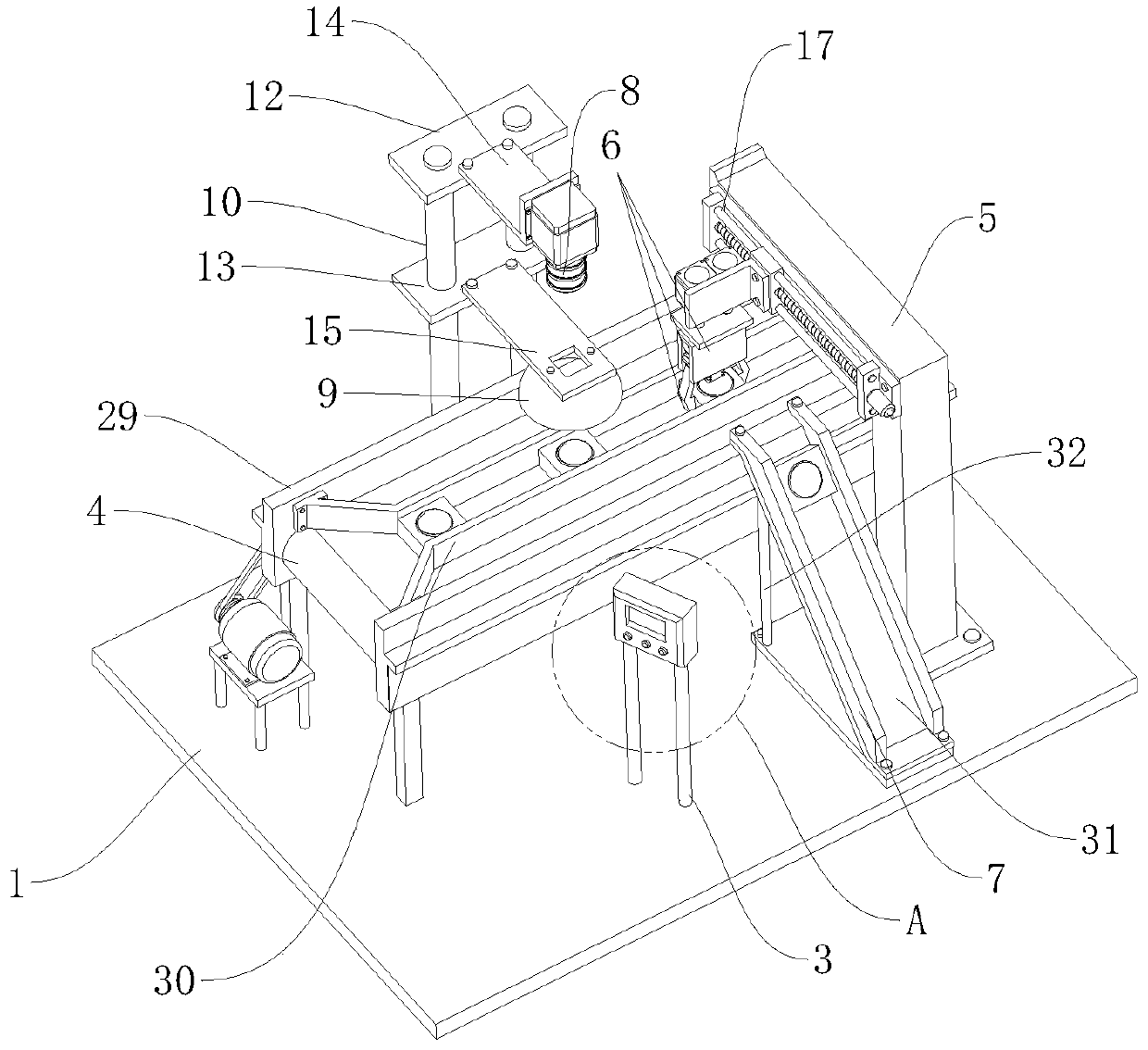

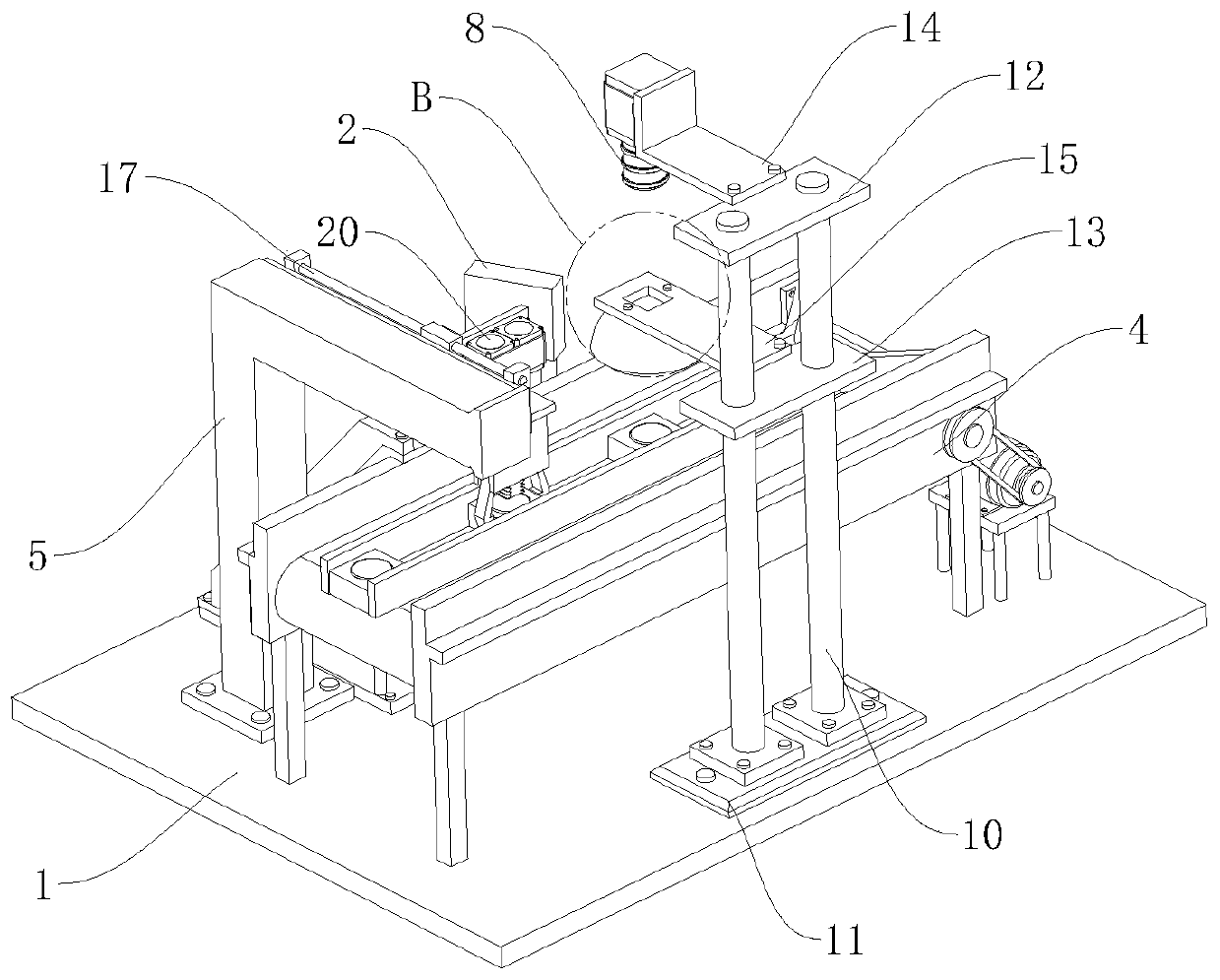

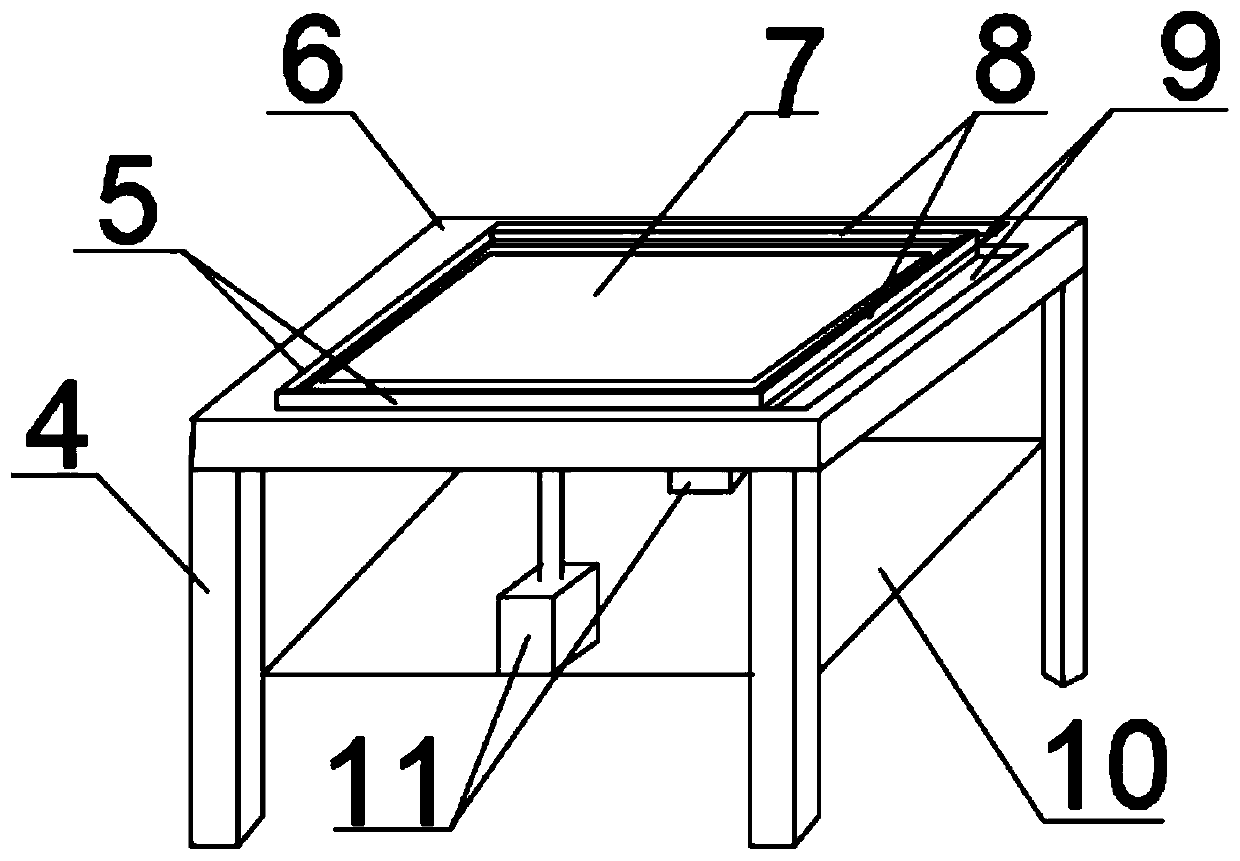

Chip detection device based on image recognition

InactiveCN110227655AAutomatically arrange neatlyReduce error rateMaterial analysis by optical meansSortingEngineeringMicroscopic exam

The invention relates to the field of detection devices, in particular to a chip detection device based on image recognition. The chip detection device comprises a base and a control desk and furthercomprises a conveyor, a detection mechanism and a discharge mechanism. The discharge mechanism comprises a reversed-L-shaped supporting plate, a clamping assembly and a slide way. The reversed-L-shaped supporting plate is vertically arranged on the top of the base. The bottom of the reversed-L-shaped supporting plate is fixedly connected with the top of the base. The clamping assembly is movably arranged on one side wall of the reversed-L-shaped supporting plate. The slide way is arranged beside the reversed-L-shaped supporting plate in an inclined manner. The chip detection device based on image recognition is used before the microscopic examination work, the number of defective products in the chip mass production can be decreased through the image recognition principle, the mistake occurrence probability in chip detection is also decreased while the work intensity of microscopic examination workers is lowered, and therefore the work efficiency is improved, the chip quality is further improved, and benefits are increased.

Owner:丽水奇异果信息技术有限公司

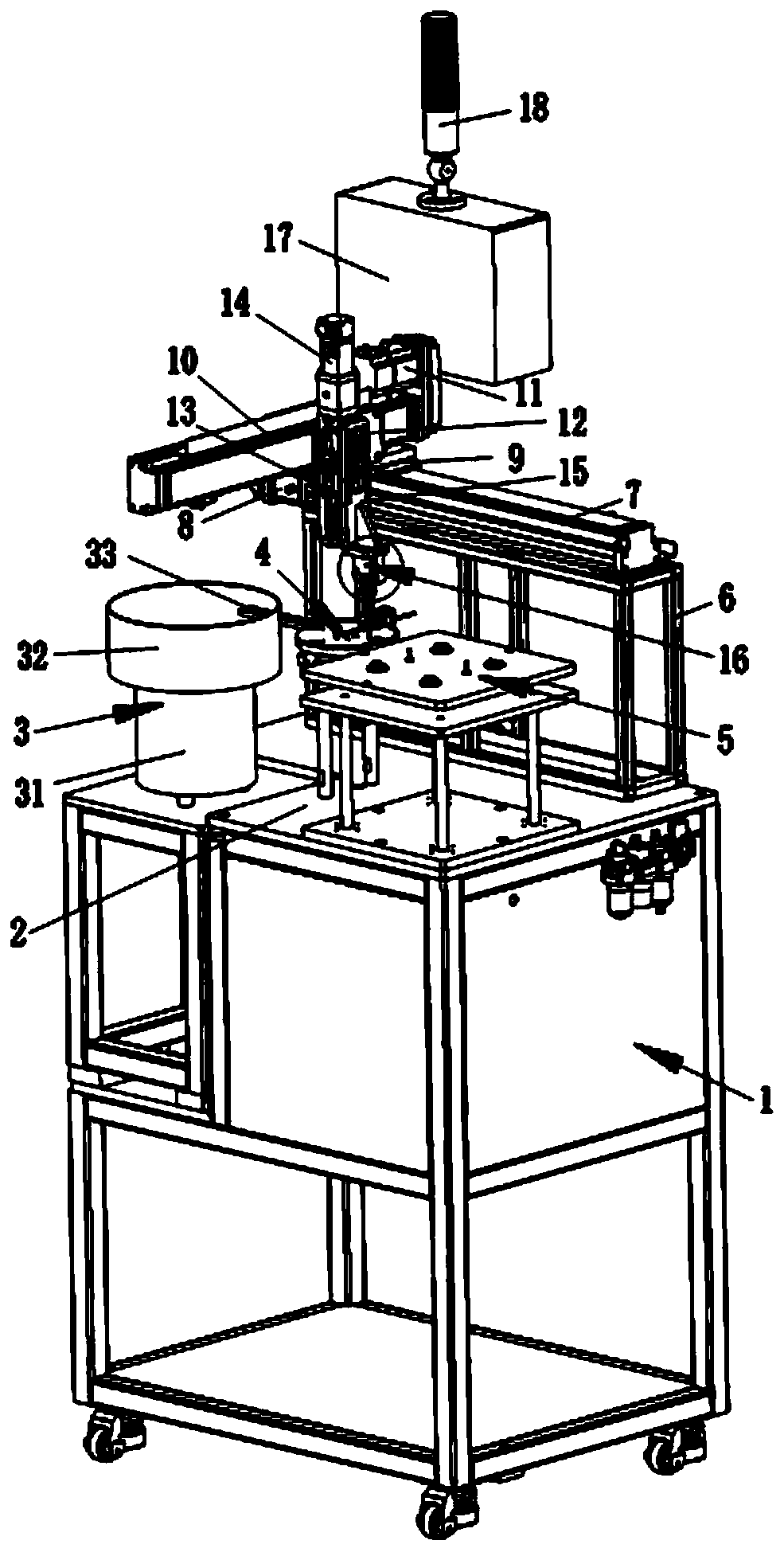

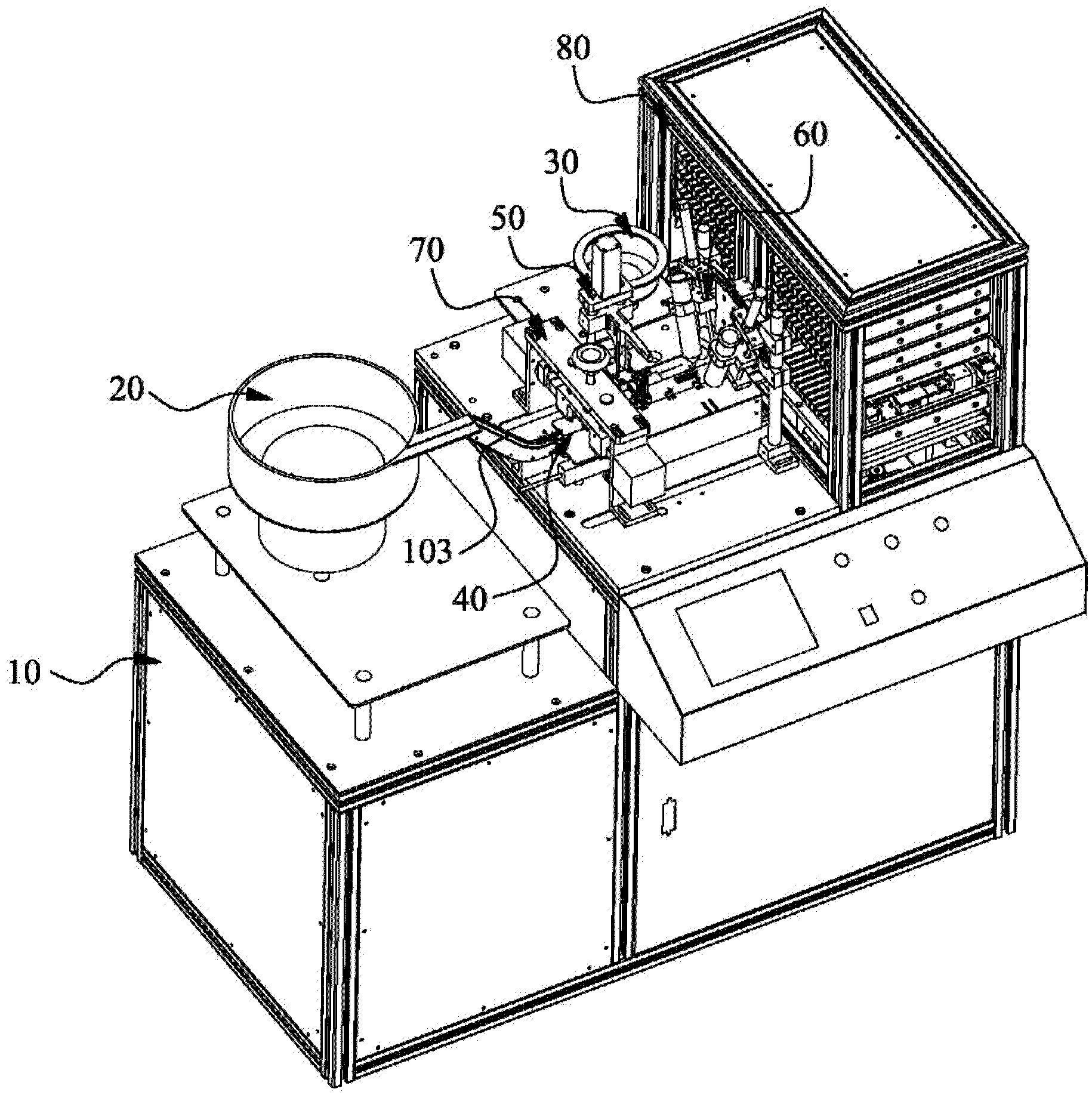

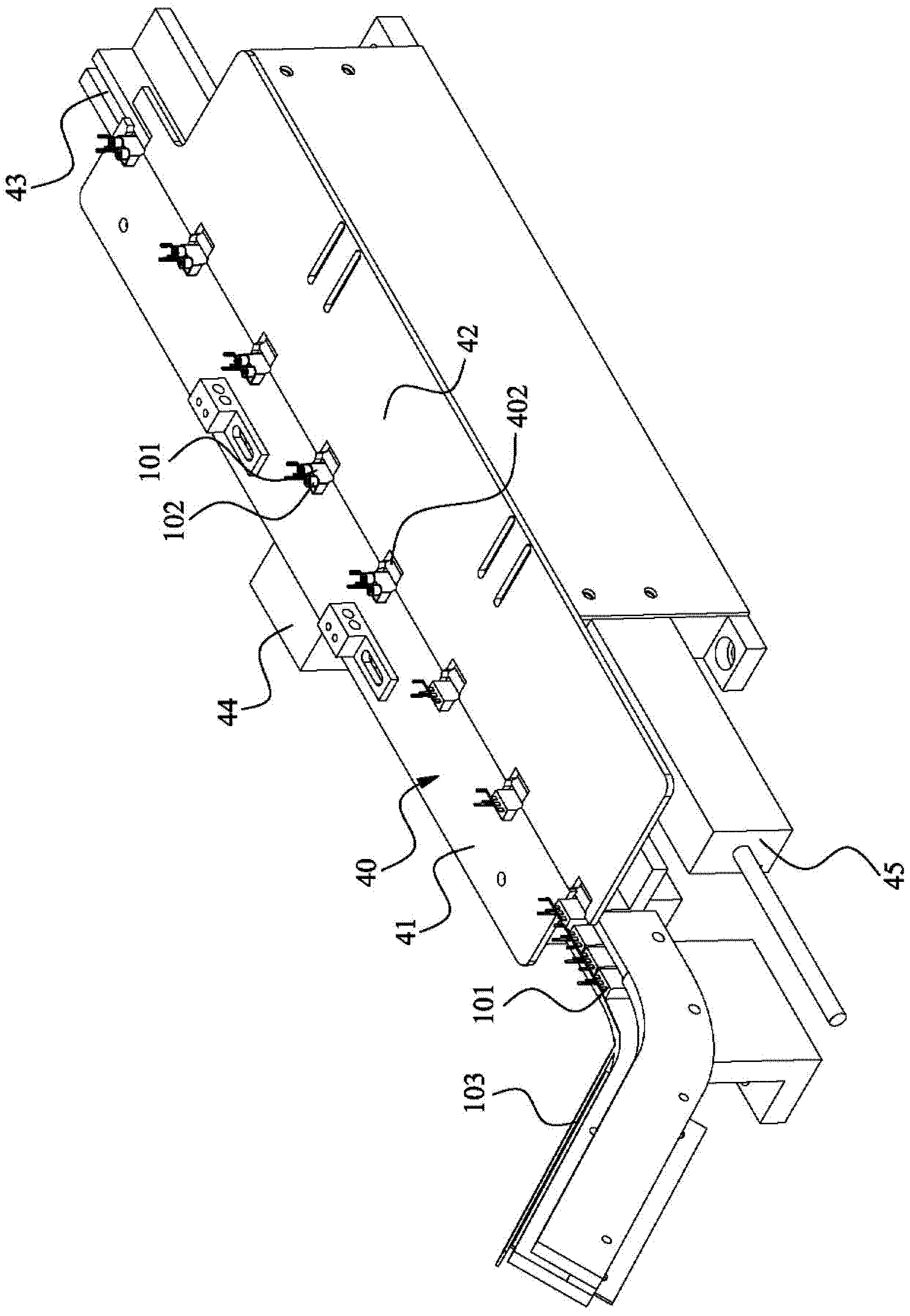

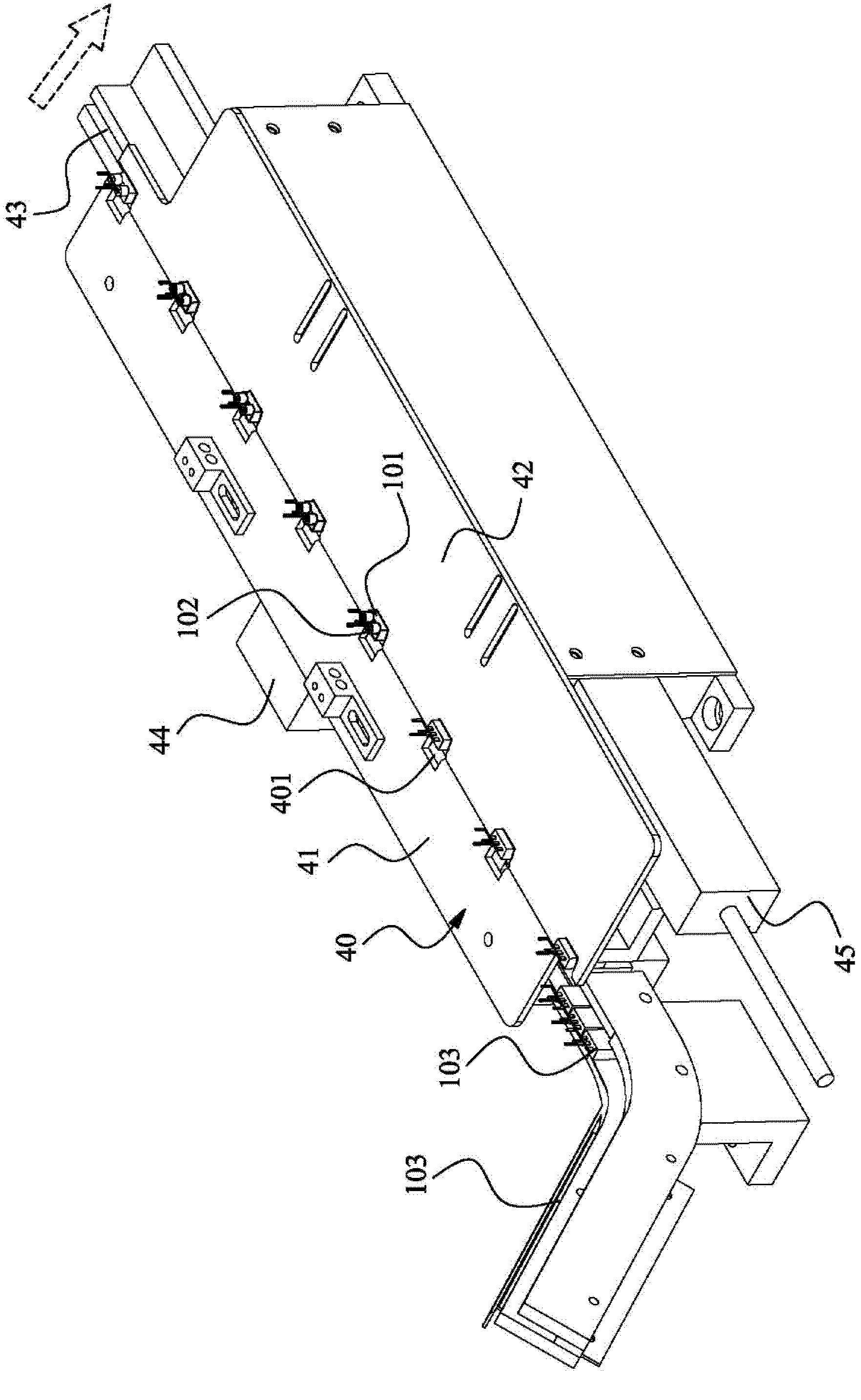

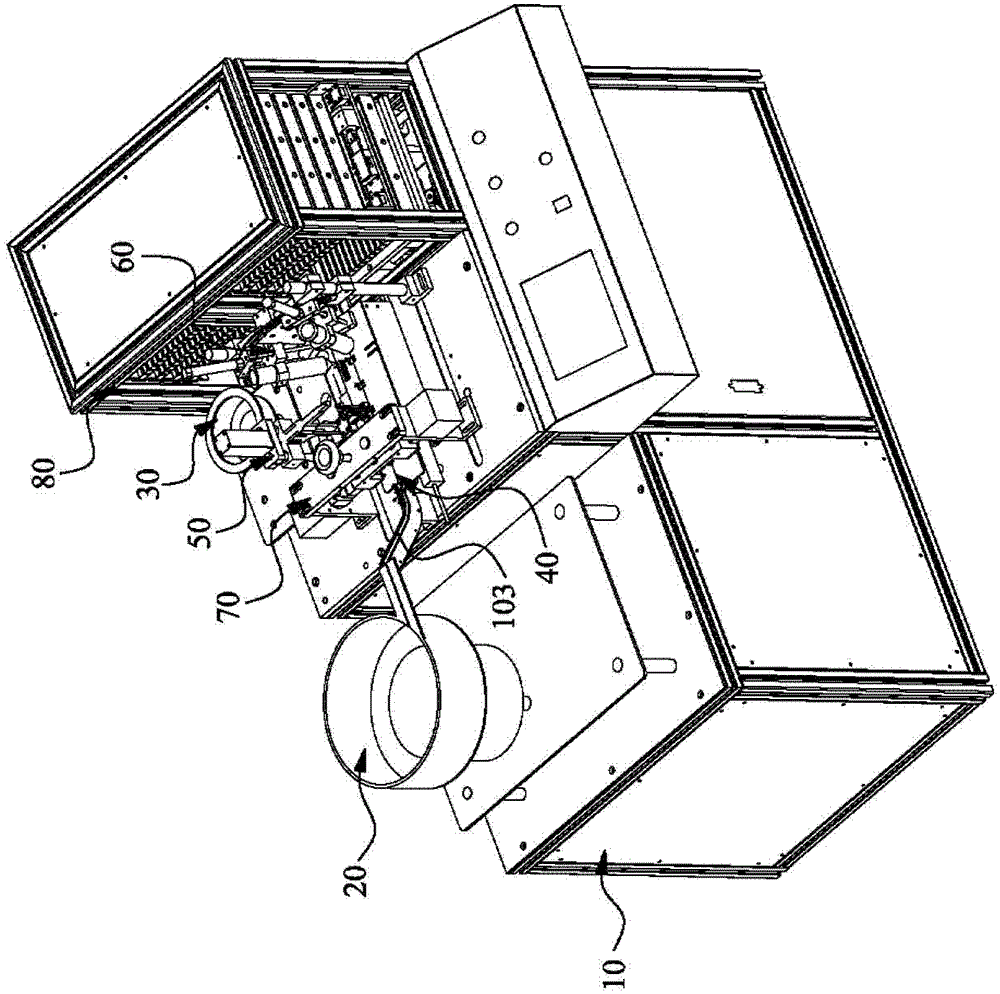

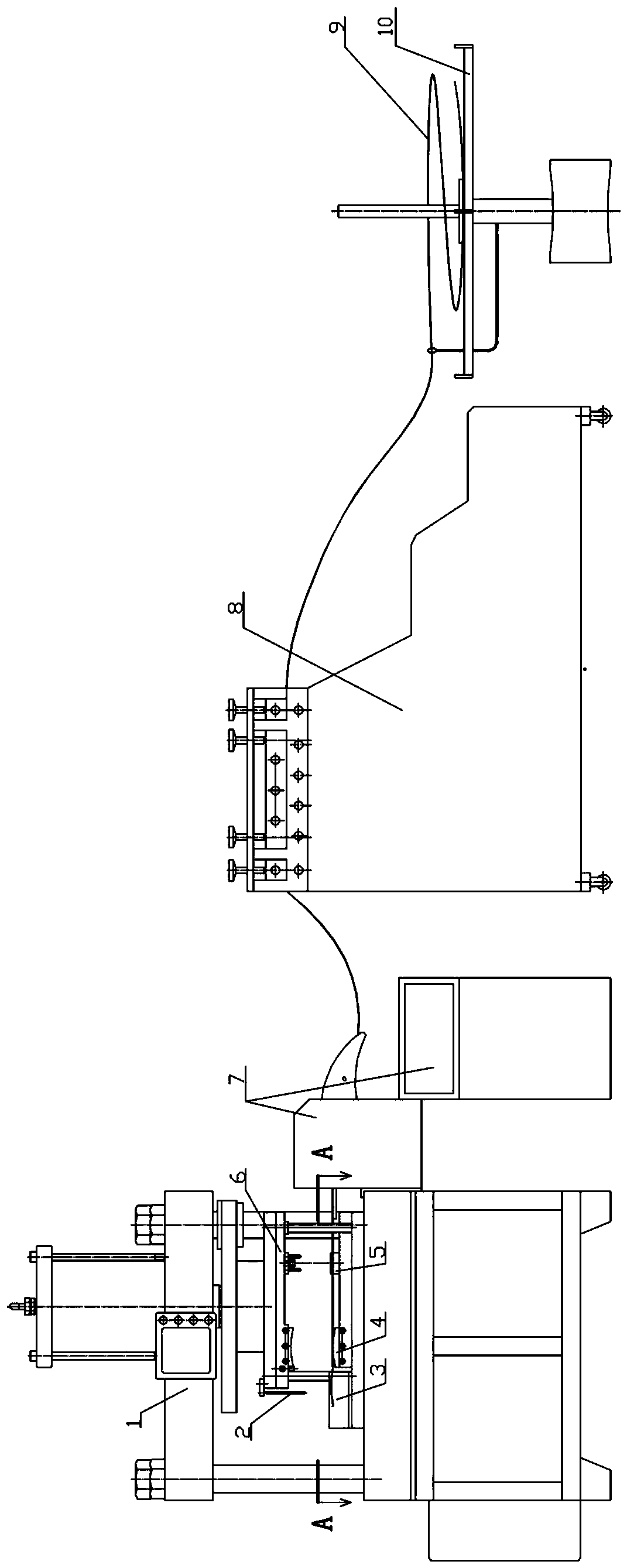

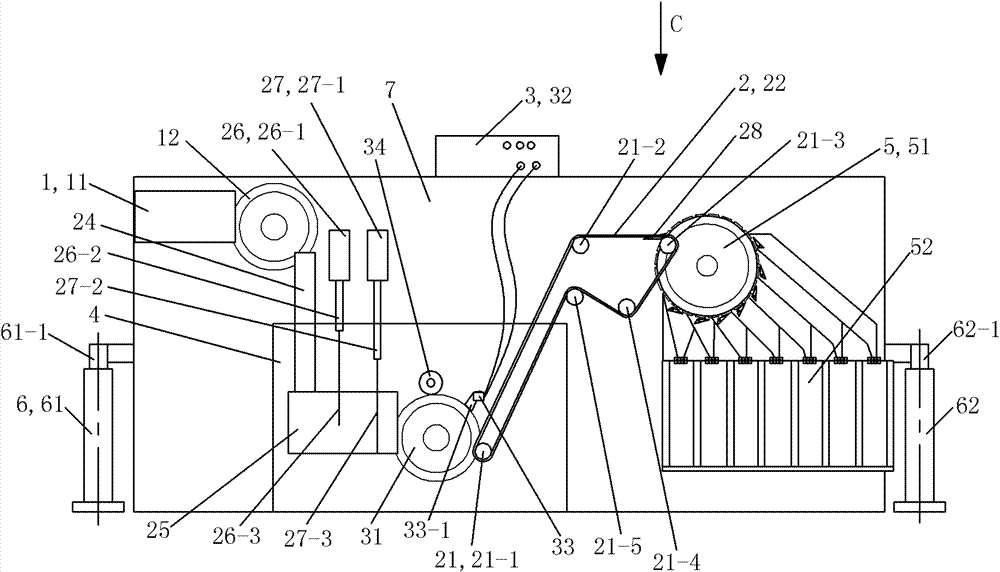

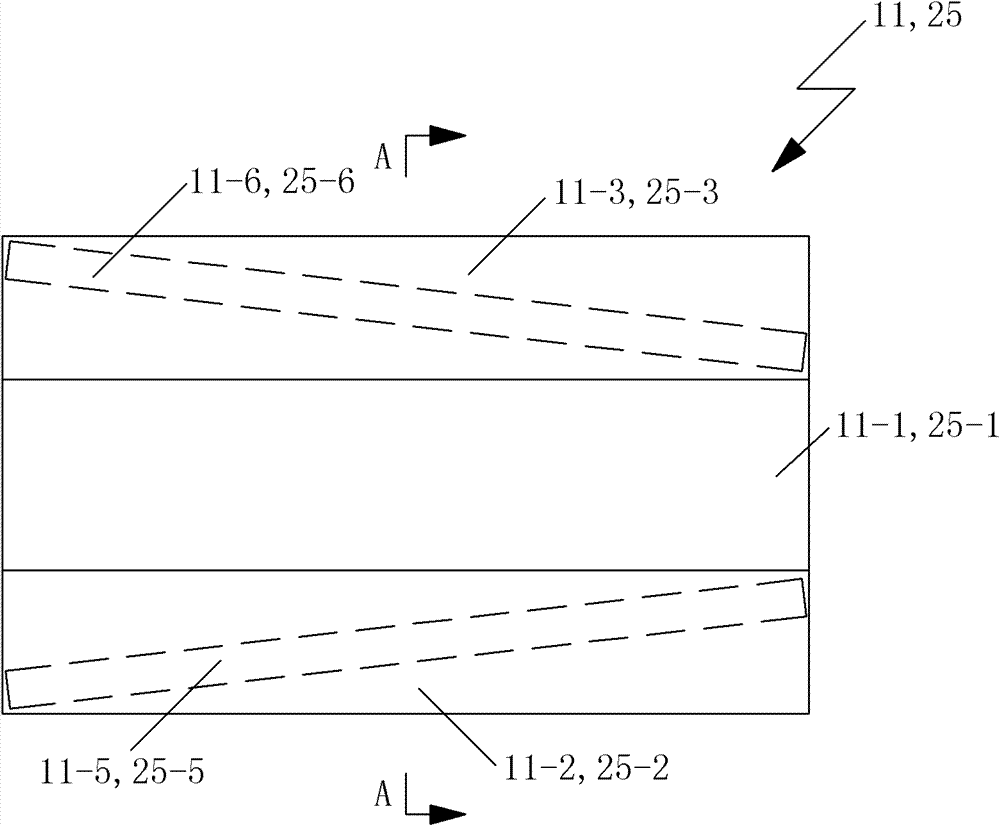

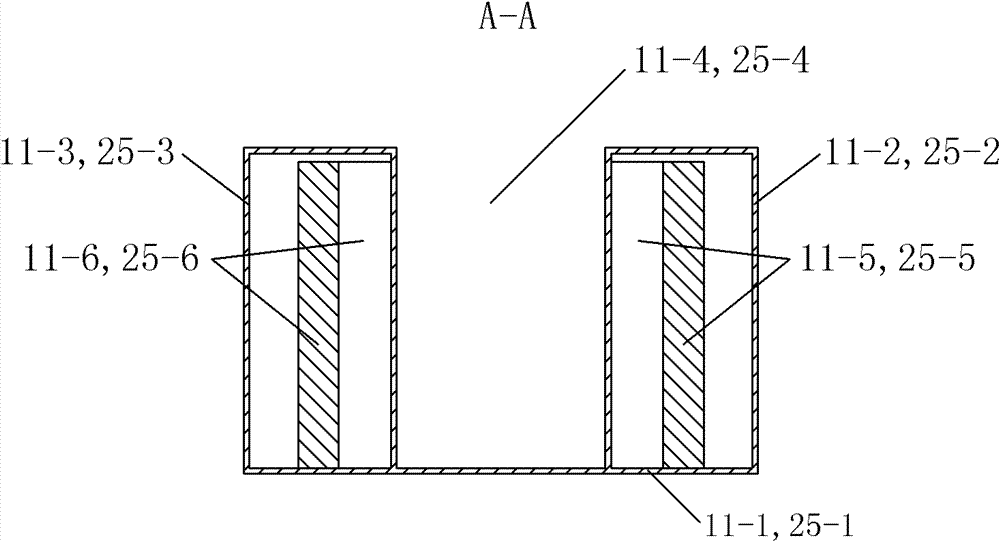

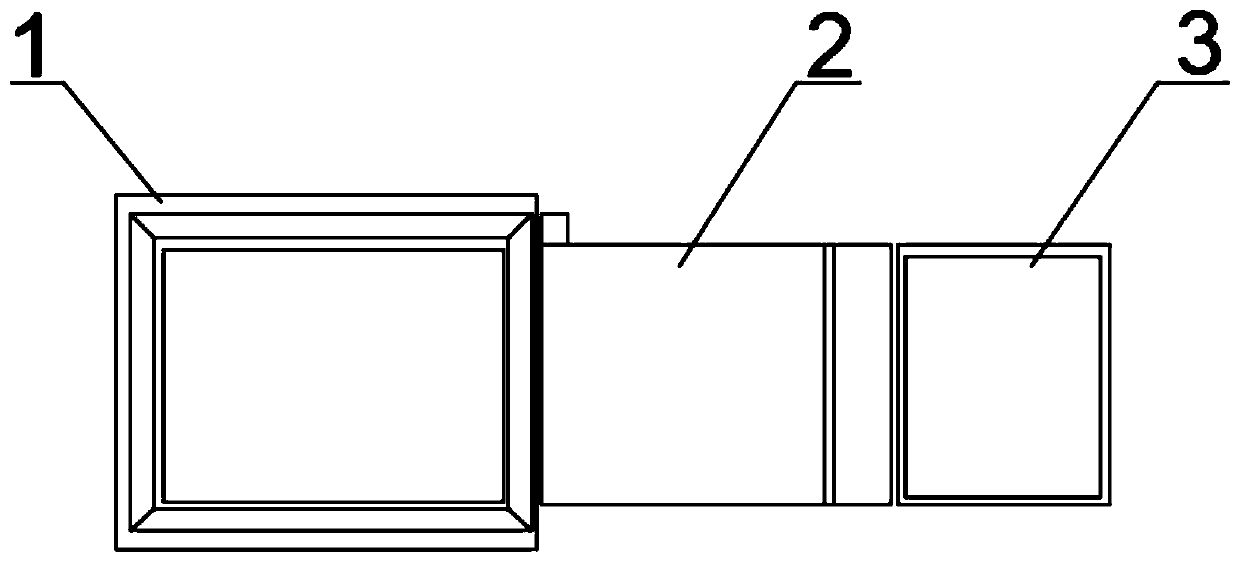

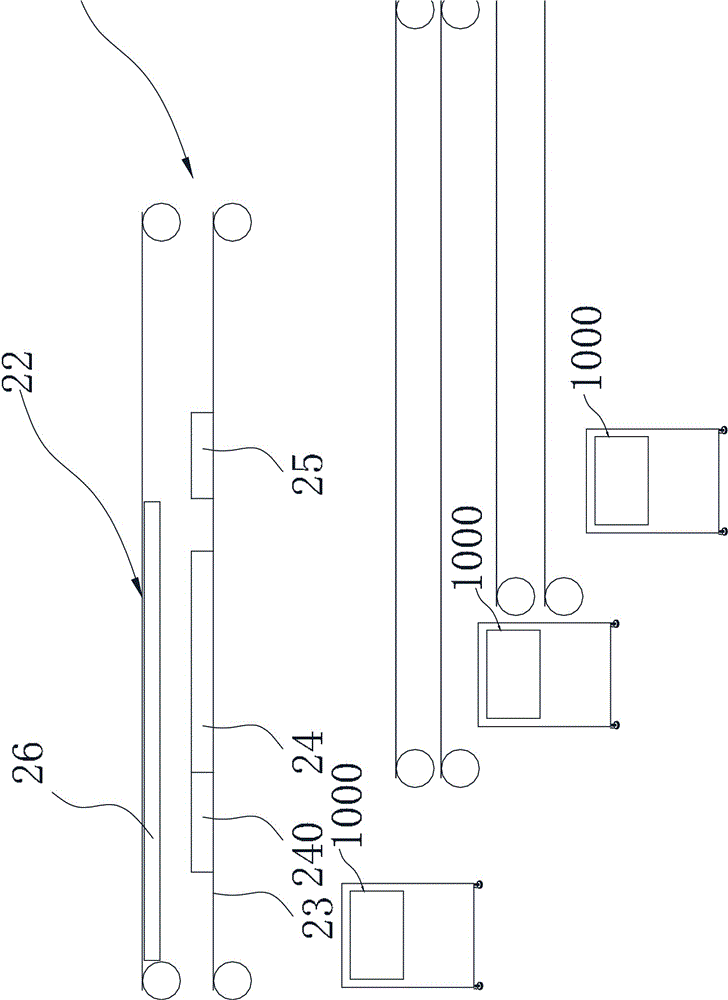

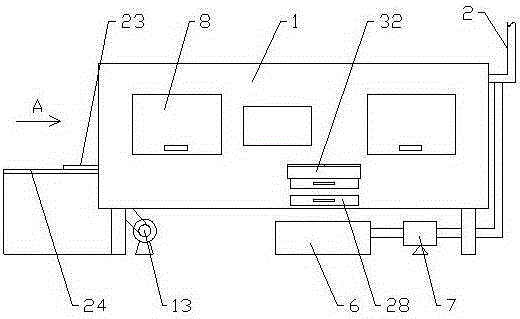

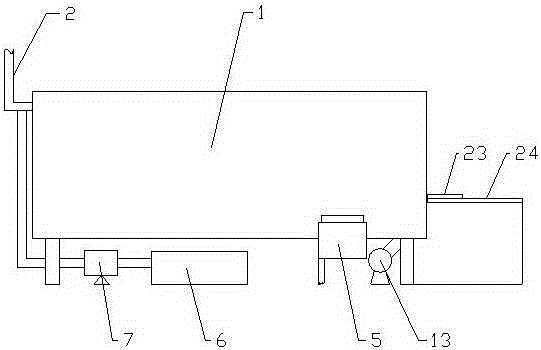

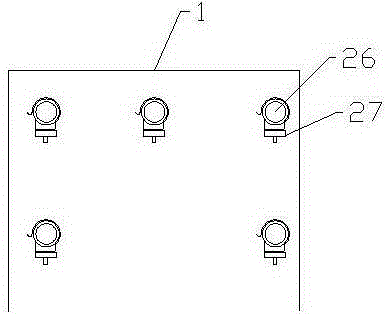

System for testing diode thermistor in high speed

ActiveCN102107190AThe process design principle is simpleCompact structureSortingHeat sensitiveEngineering

The invention provides a system for testing a diode thermistor in a high speed. The system comprises a material discharging device, a conveying device, a test device, a constant-temperature slot, a material receiving device, a lifting device, an engine seat, a transmission mechanism and a control device; the material discharging device, the conveying device, the test device, the material receiving device, the transmission mechanism and the control device are all arranged on the engine seat; the lifting device and the engine seat are arranged on the floor and the constant-temperature slot is formed on the floor; the material discharging device comprises a material discharging magnetic rail and a material discharging magnetic wheel; the conveying device comprises a chain wheel device, two material discharging chains, a conveying pipe, a feeding magnetic rail, a first stopping device, a second stopping device and a guide block; the test device comprises a test magnetic wheel, a tester and a probe; and the material receiving device comprises a stepping wheel, a material receiving box and a poking sheet. The system is used for testing the diode thermistor, and has high test speed and high stepping precision.

Owner:常州市科文传感器材料有限公司

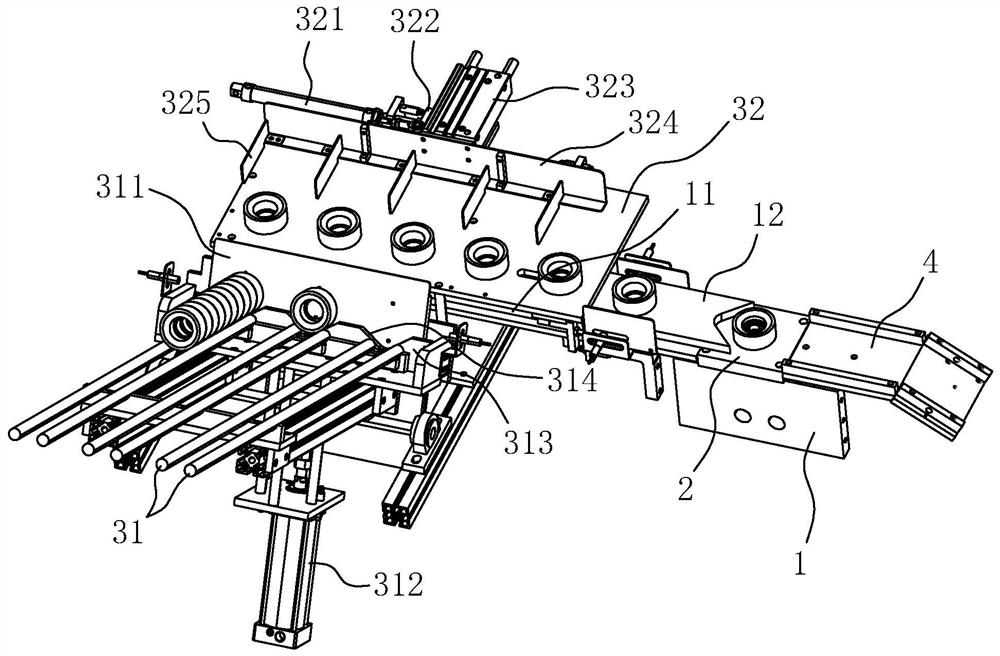

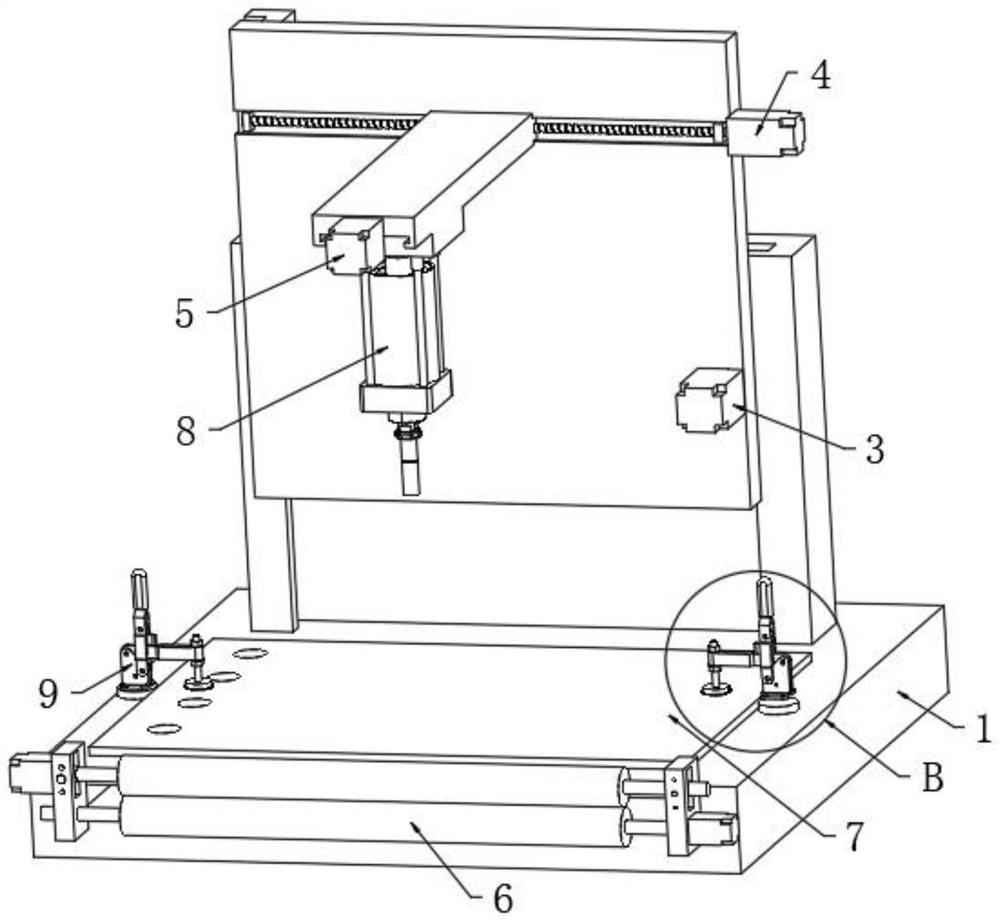

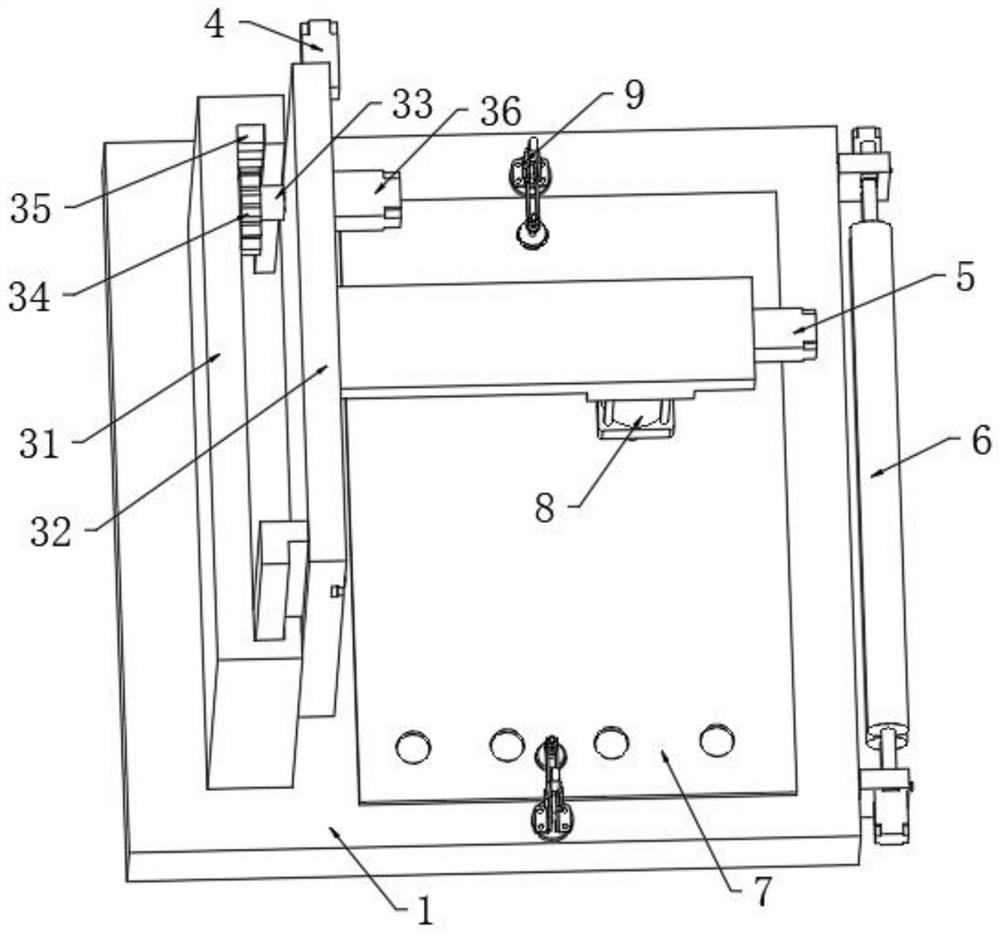

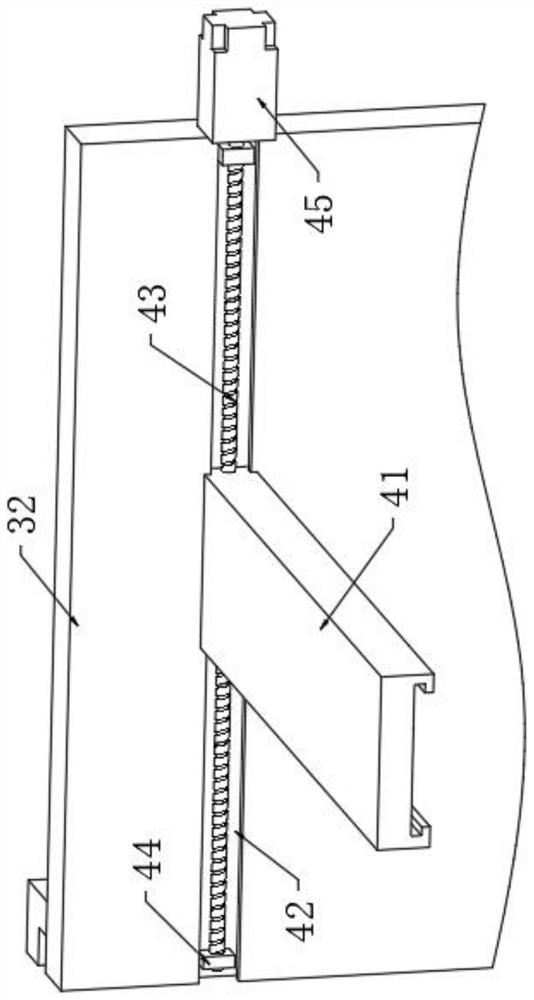

Automatic insert placing machine

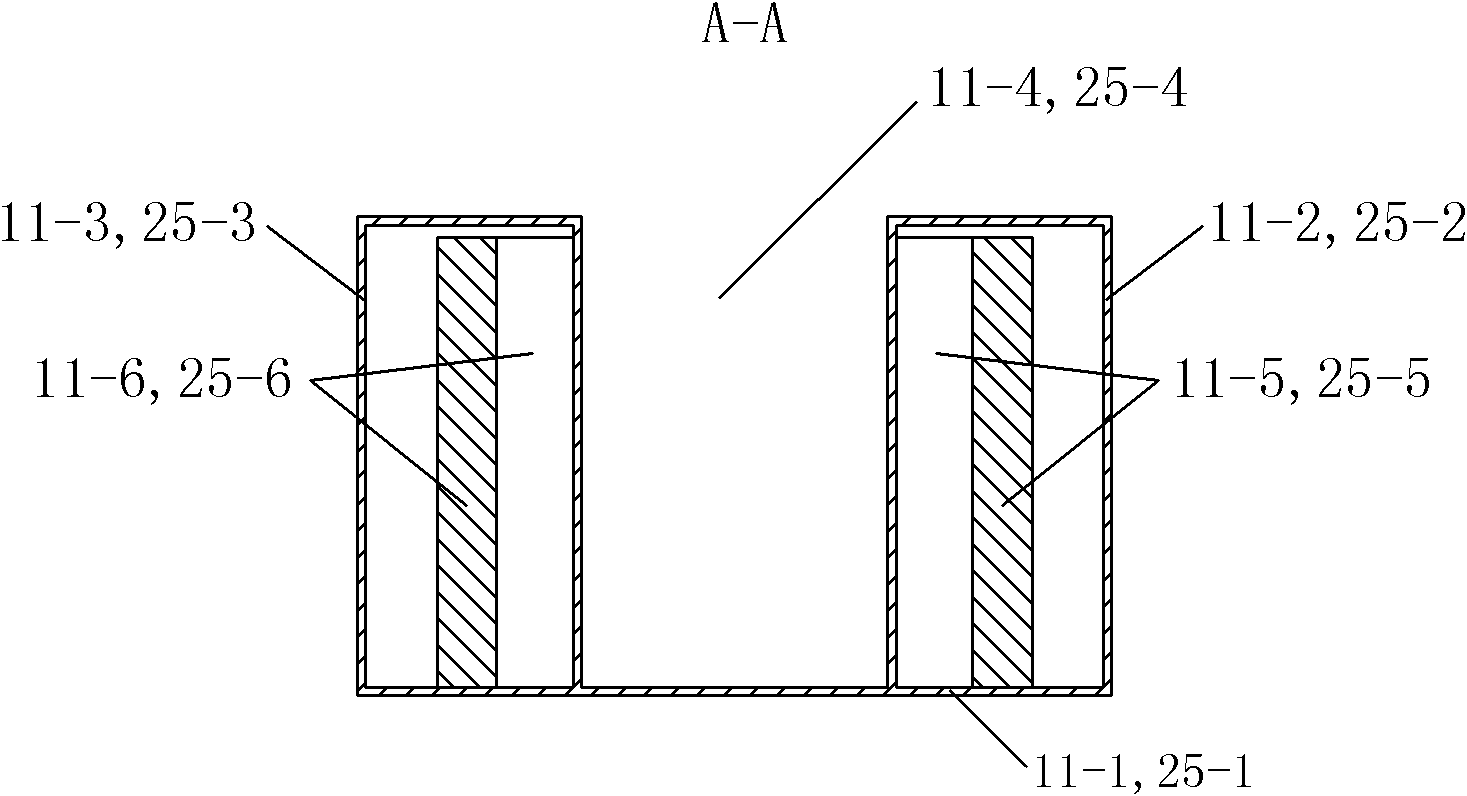

The invention relates to an automatic insert placing machine. The automatic insert placing machine comprises a machine frame, an electronic control device, a workbench, a feeding vibration disc, a misalignment mechanism, an insert positioning and bearing device, a three-coordinate device, a clamping head, and an operating panel. The automatic insert placing machine is simple and convenient to operate, during using, the electronic control device controls the feeding vibration disc to send the insets to the misalignment mechanism through the operating panel, a Y-axis moving track, a Z-axis moving track and the clamping head are driven to move to the misalignment mechanism through the an X-axis driving motor, a Y-axis driving motor, a Z-axis driving motor respectively, the inserts are clampedthrough the clamping head, then the inserts are moved to the insert positioning and bearing device to be arrayed and placed neatly, the inserts are conveniently, fast and accurately placed in a moldthrough a follow-up burying robot, in this way, the inserts of the many different types can be automatically, neatly, and accurately placed, and the purpose of the effective improving of the work efficiency of loading the inserts into the mold is achieved accordingly.

Owner:CIXI SANPEI MACHINE

Automatic brick arrangement machine

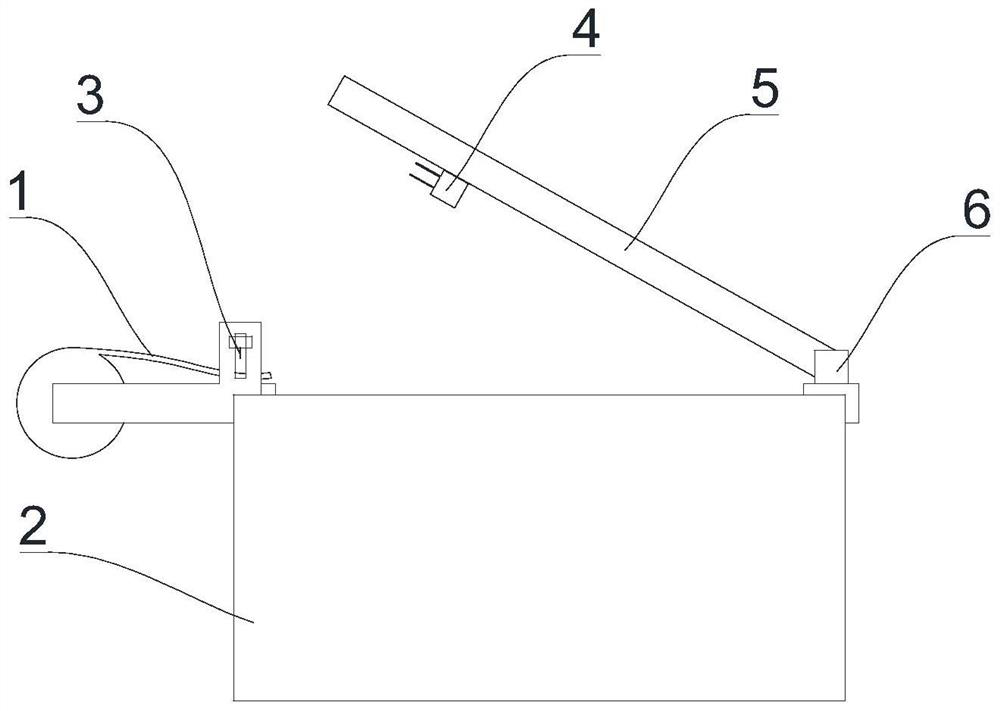

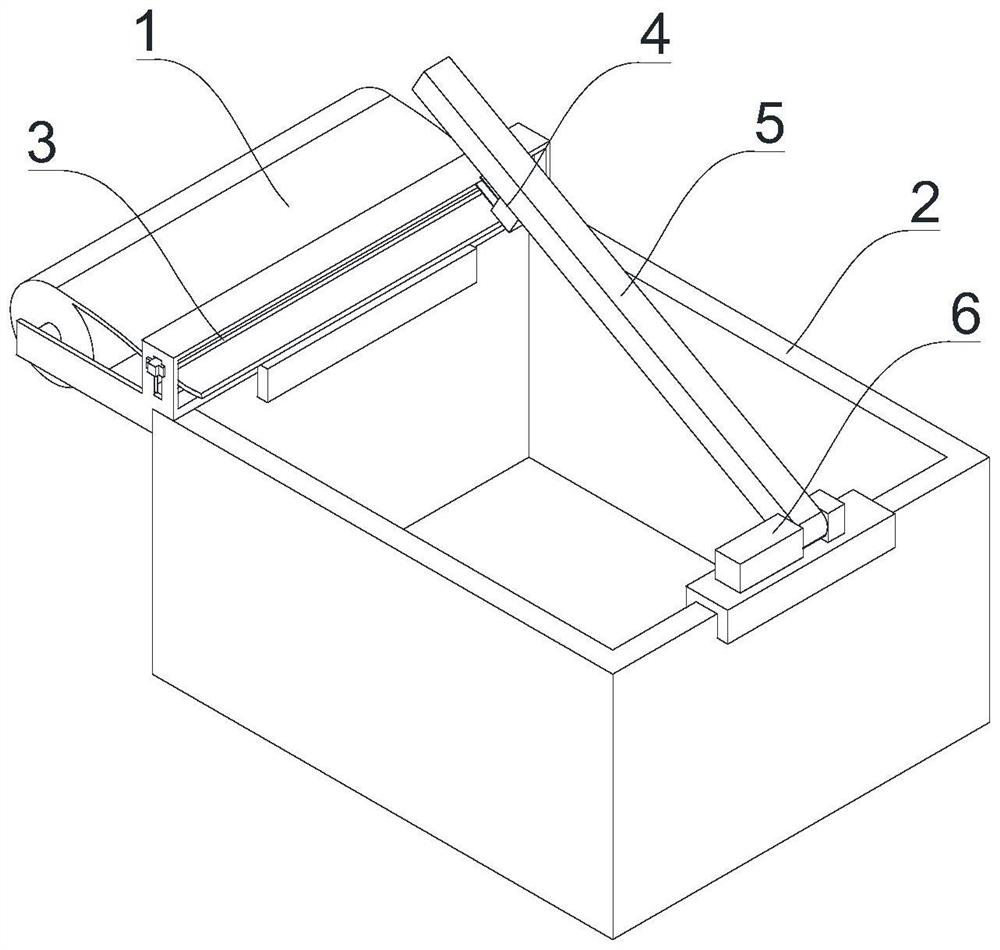

InactiveCN104179358AAutomatically arrange neatlyReasonable designBuilding material handlingPush outMaterial storage

The invention discloses an automatic brick arrangement machine. The automatic brick arrangement machine comprises a material storage tank, a brick pushing device, a material storage tank moving device, a feeding mechanism and a mortar storage box. The feeding mechanism is positioned above the material storage tank, and bricks are conveyed into the material storage tank through the feeding mechanism; the material storage tank is arranged above the brick pushing device, a pushing block arranged on the brick pushing device is capable of stretching out and retracting back, and the pushing block stretching out is capable of pushing out bricks in the material storage tank; the brick pushing device is arranged above the material storage tank moving device and capable of moving vertically and bilaterally along with the material storage tank moving device; the mortar storage box is arranged independently, cement in the mortar storage box is delivered through a hose connected with the mortar storage box, and an outlet end of the hose is arranged on the lateral side of the material storage tank. The brick pushing device has a major function of smoothly pushing the bricks out when the material storage tank moves to a designated position. The automatic brick arrangement machine is capable of mechanically, automatically and orderly arranging the bricks, reasonable and simple in design and high in automation degree, hands of workers are freed, and work efficiency is improved.

Owner:WENZHOU UNIVERSITY

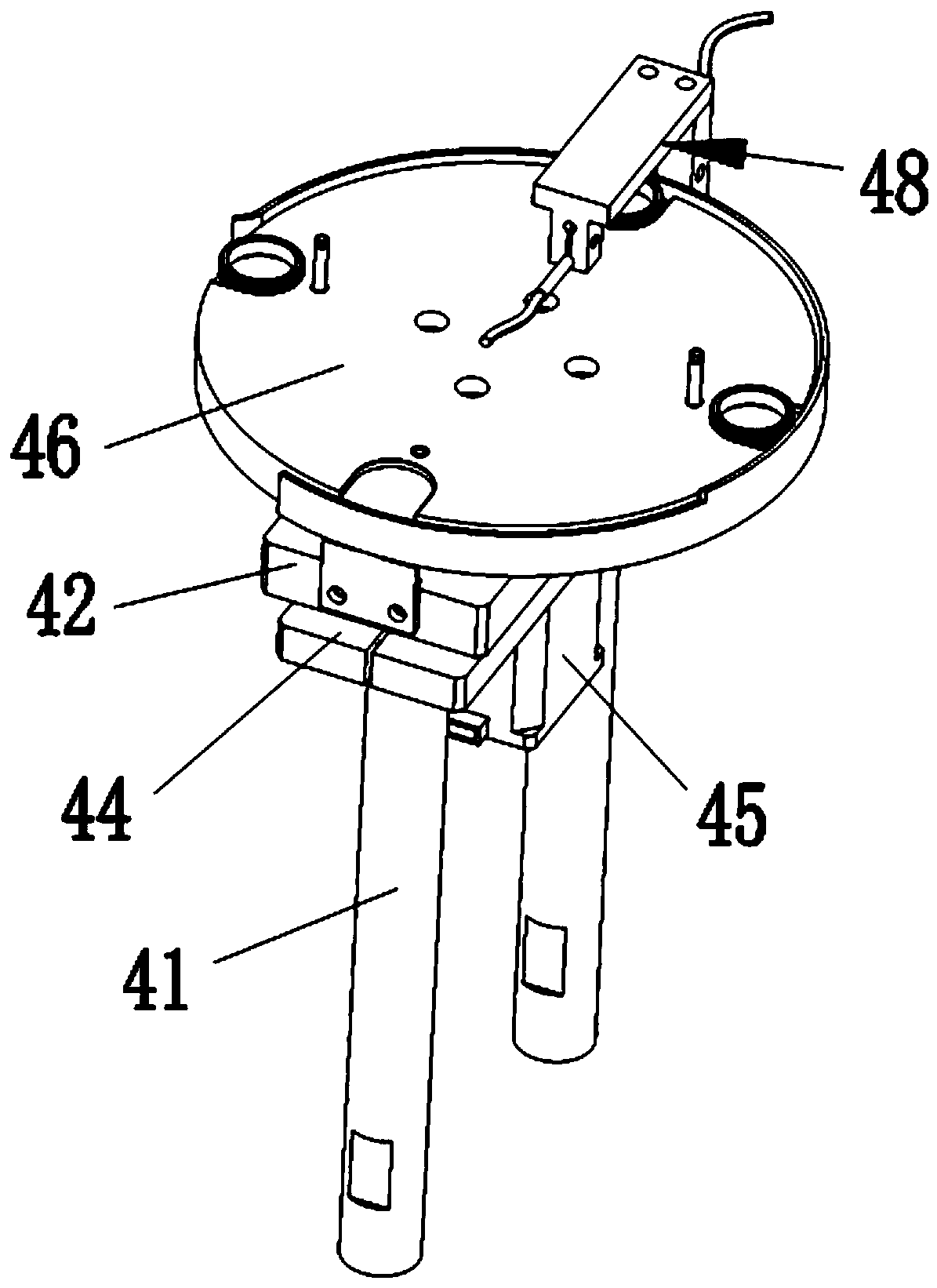

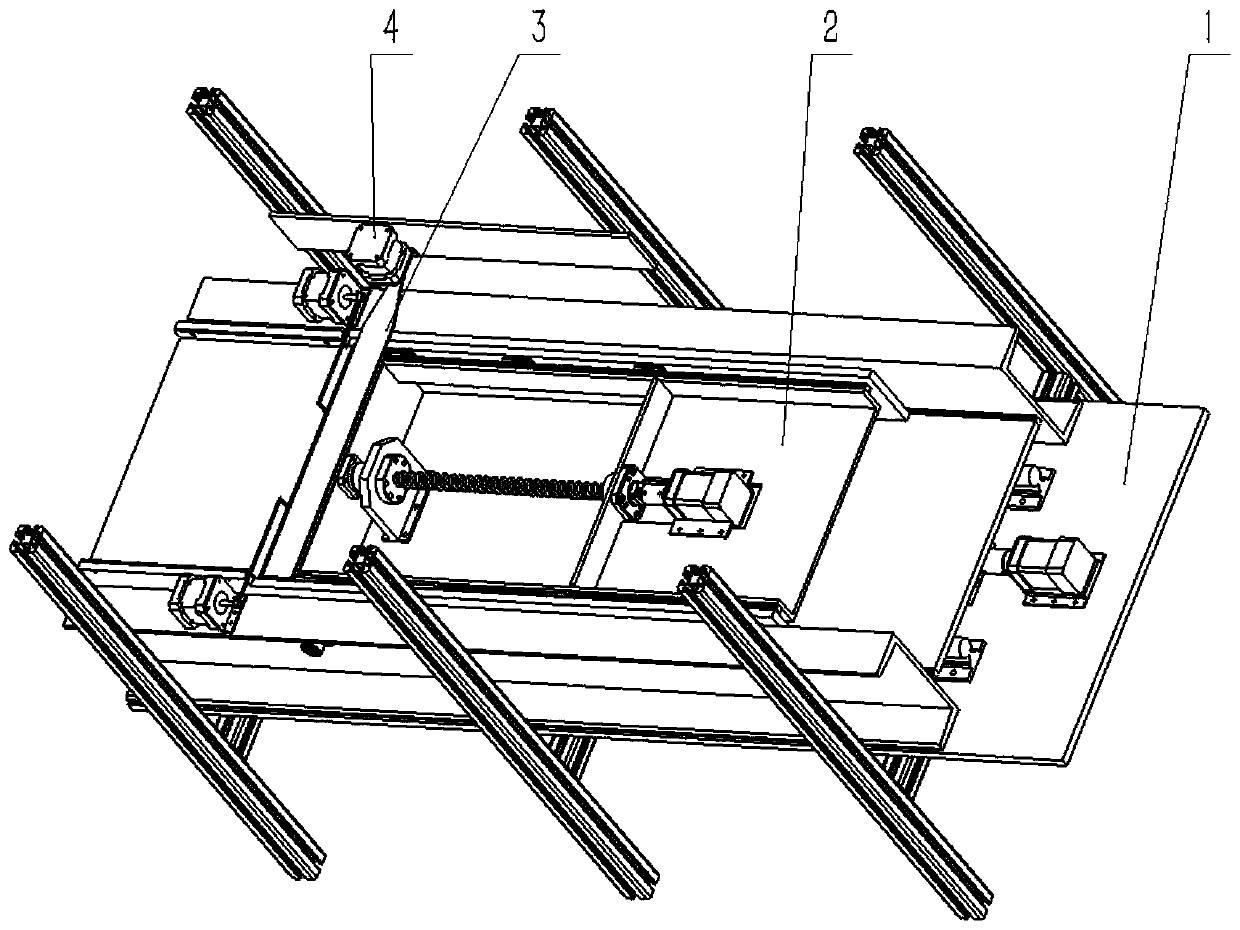

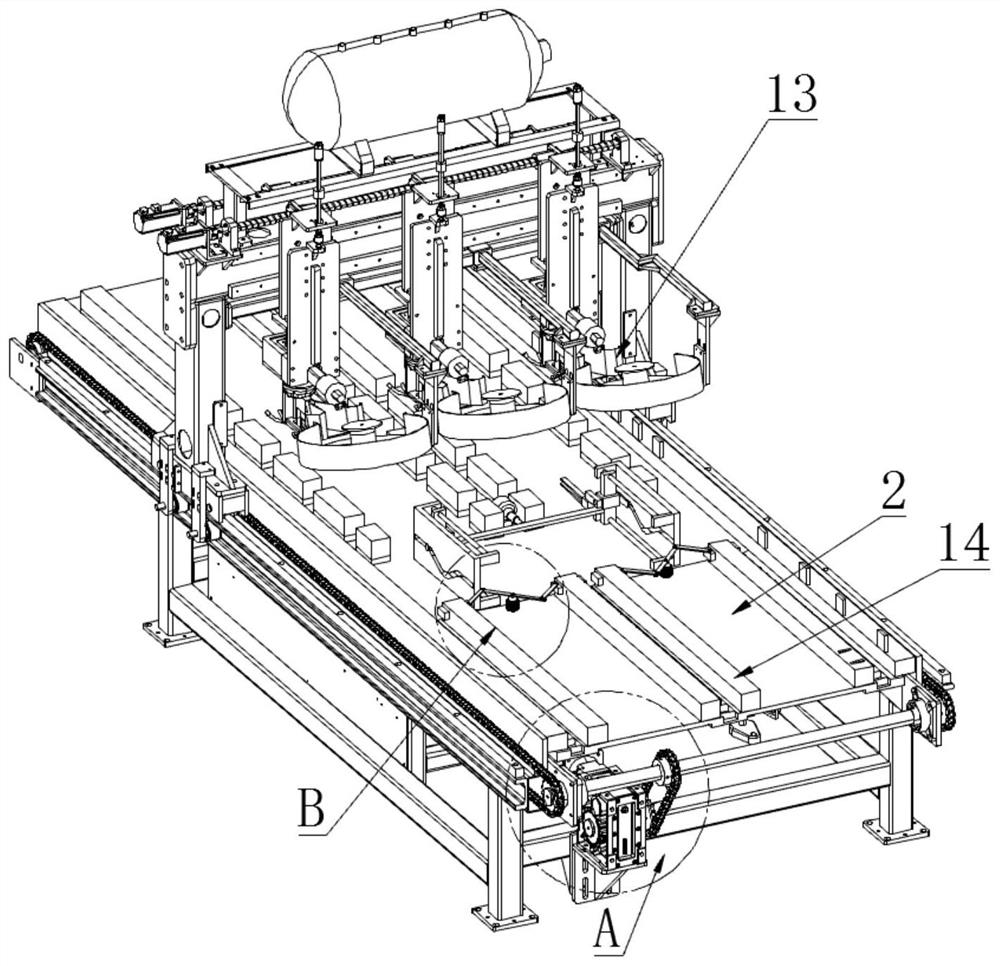

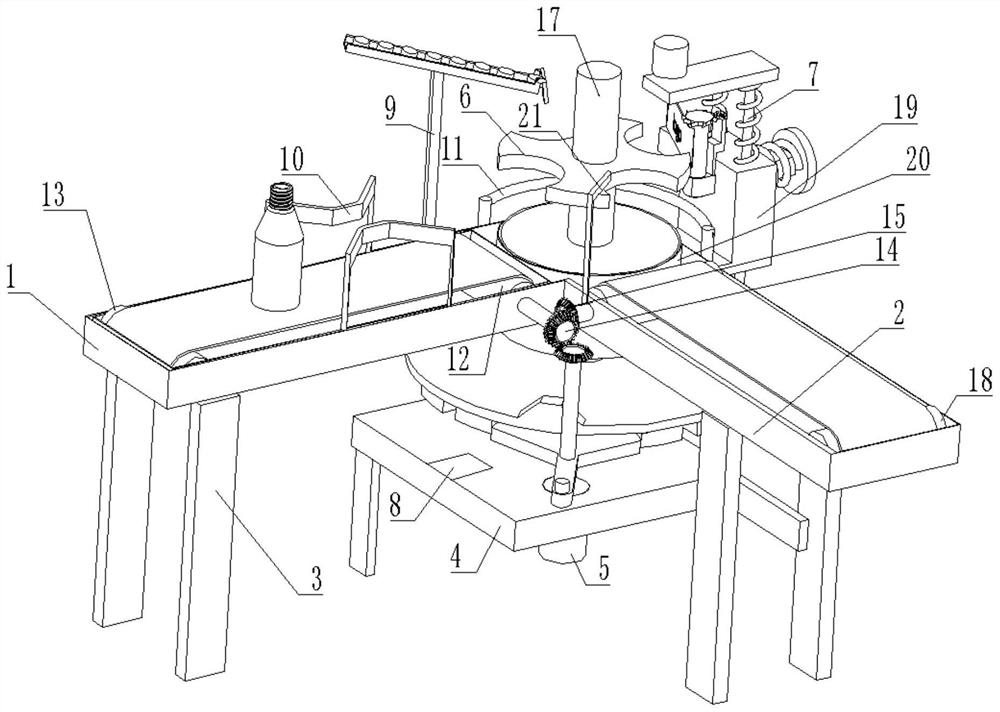

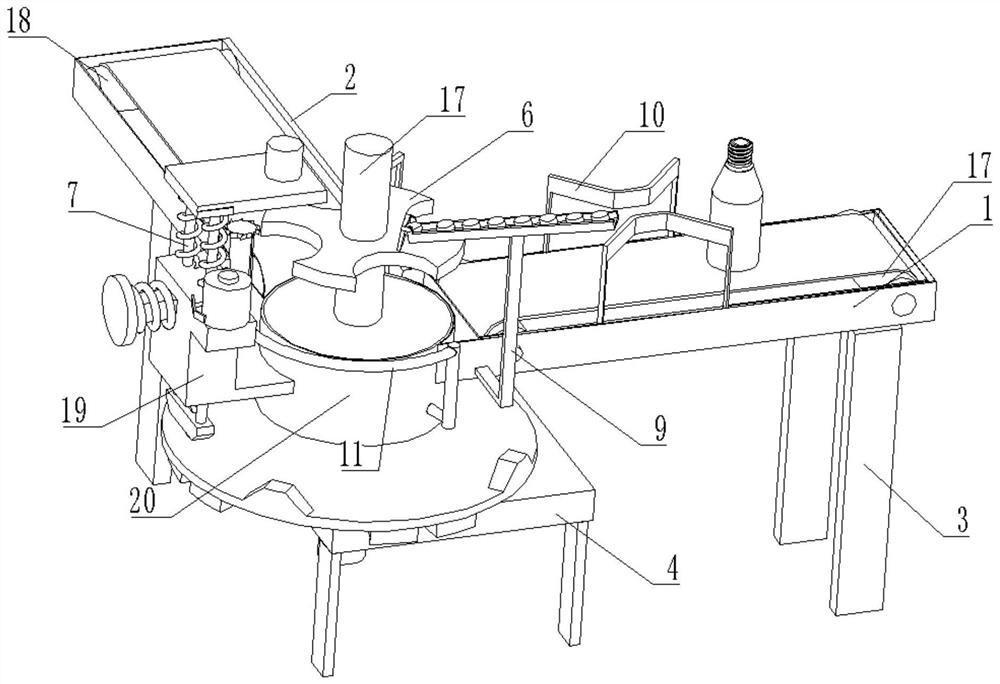

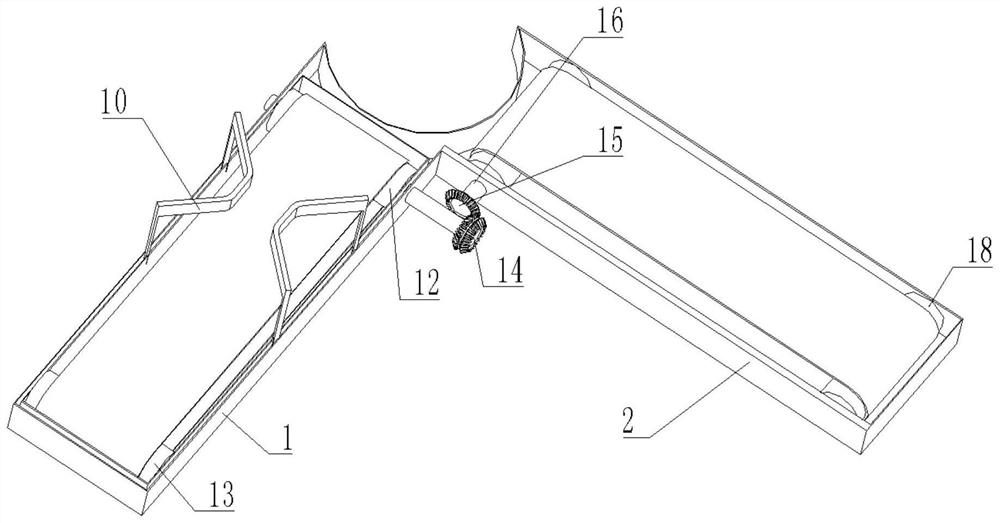

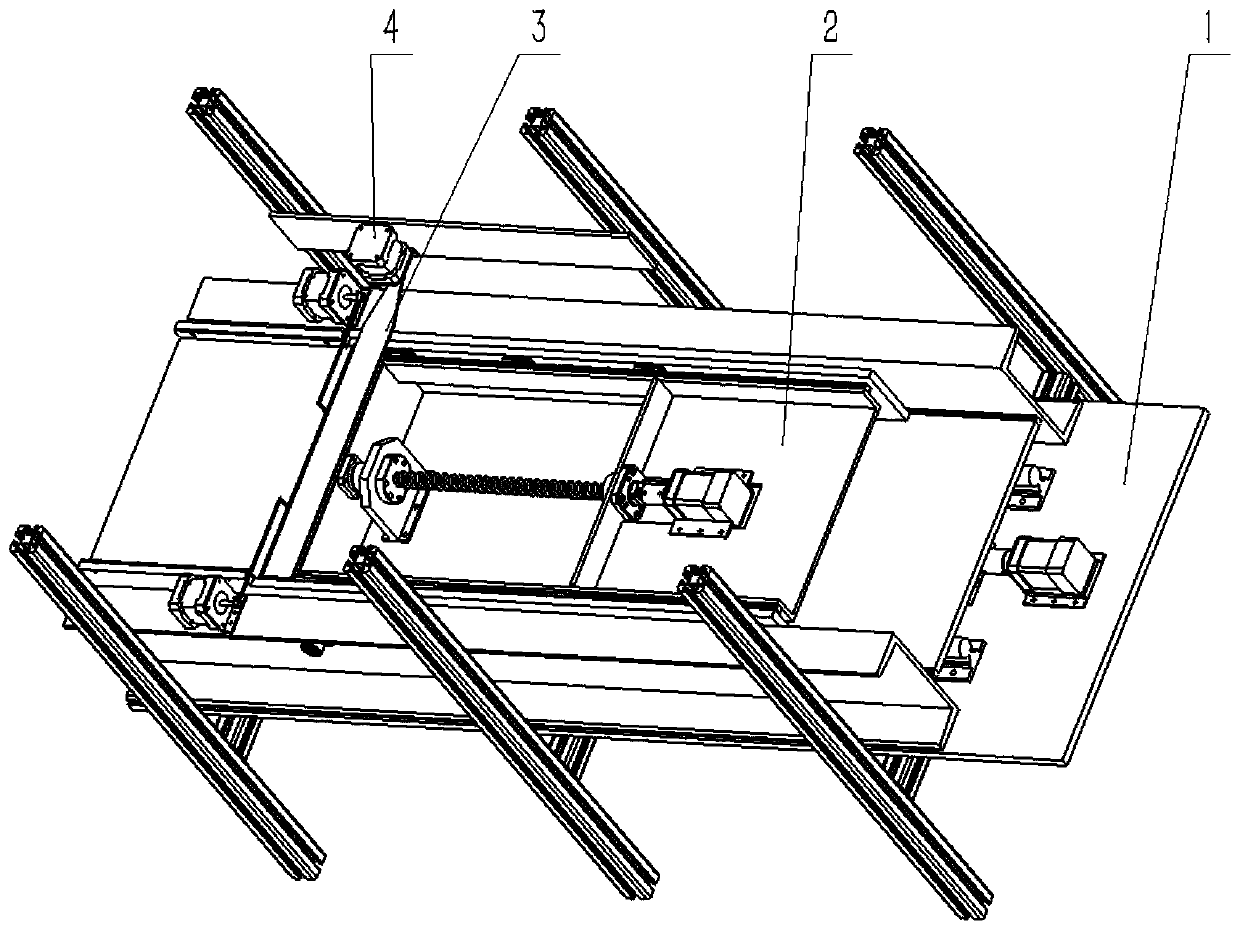

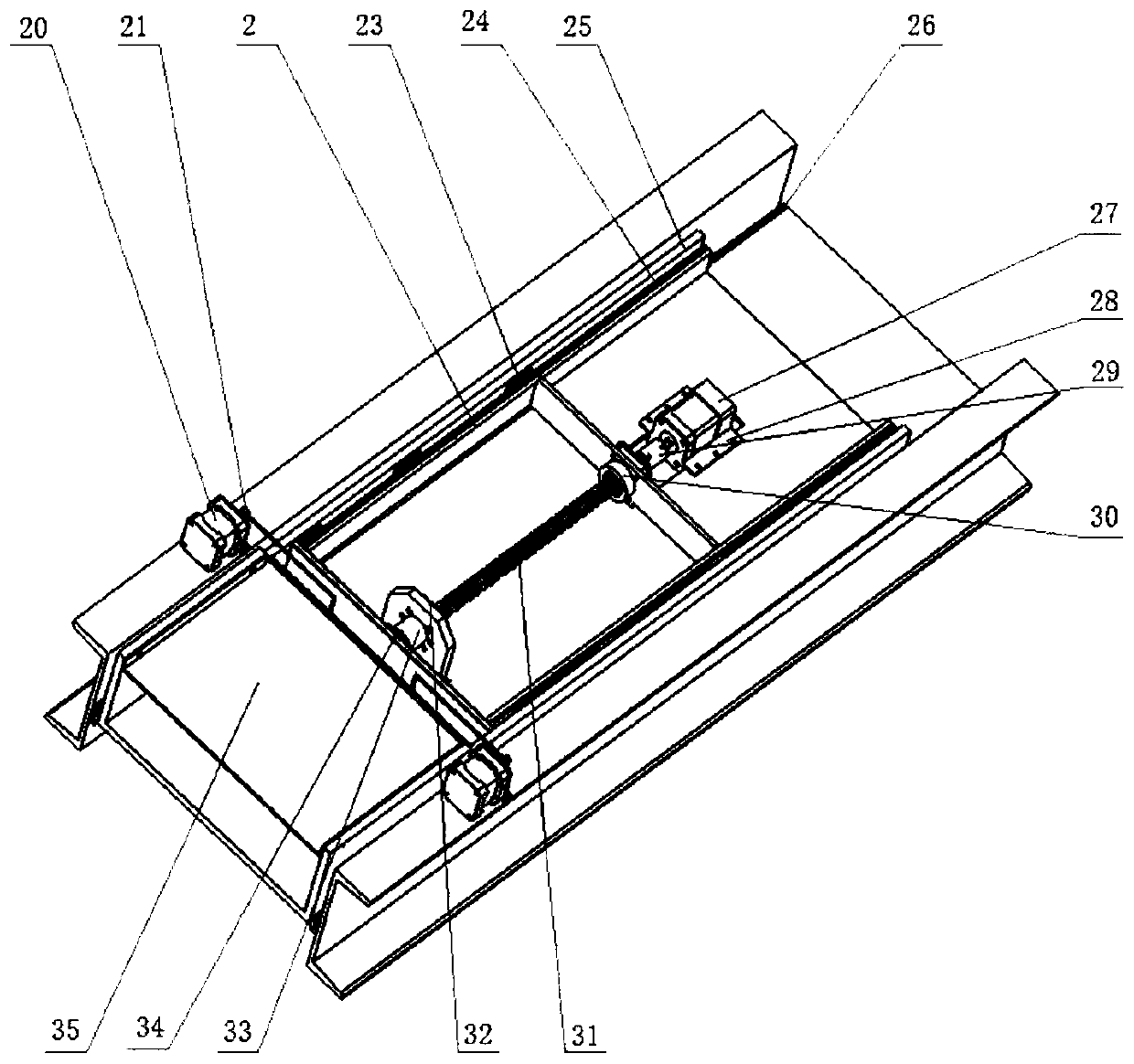

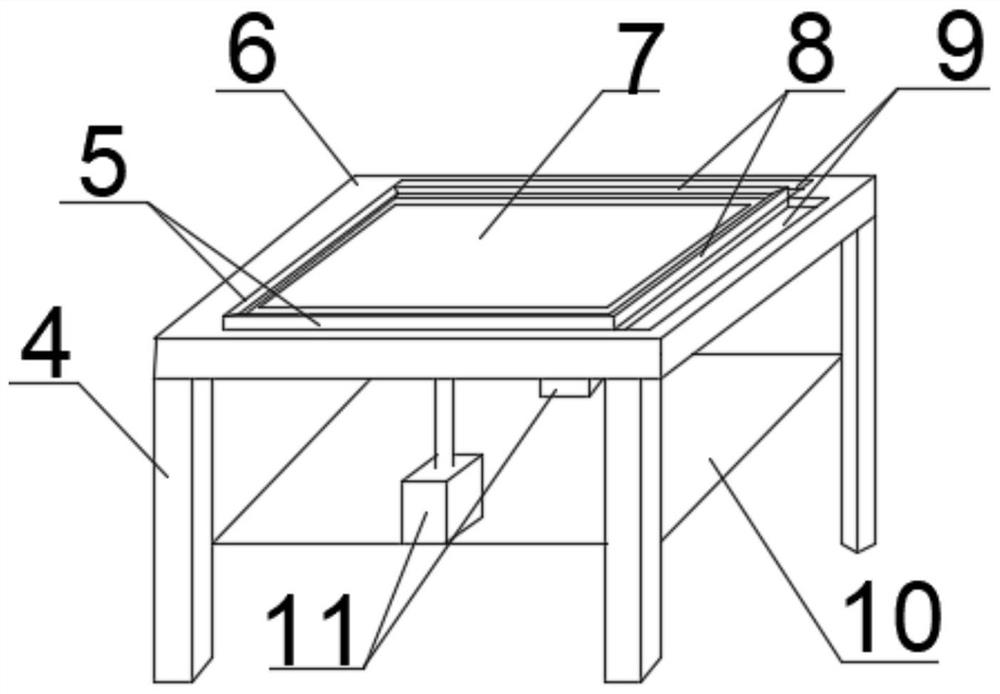

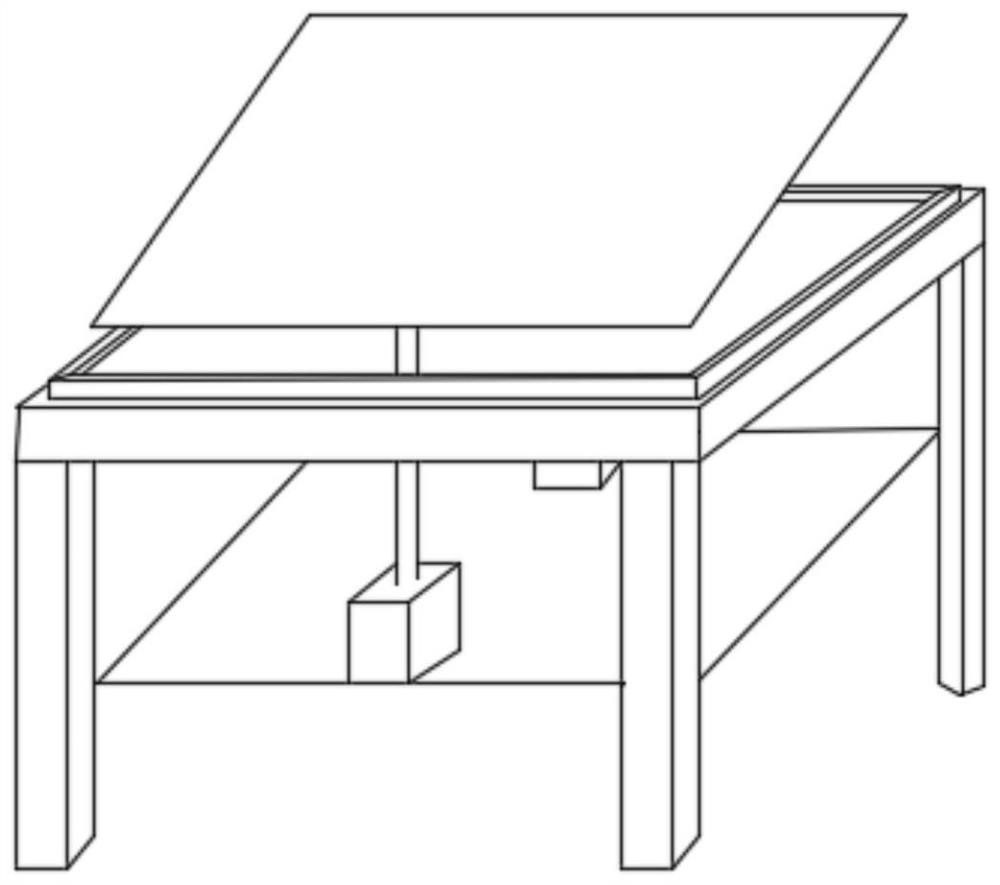

Automatic arranging machine for caps

The invention discloses an automatic arranging machine for caps. The automatic arranging machine comprises a frame supporting structure, a cap arranging mechanism and a cap feeding mechanism. The frame supporting structure comprises supporting pile legs formed by aluminum profiles, and connecting cross beams are arranged between the supporting pile legs. A bottom plate is arranged on the connecting cross beam, and groove steel is arranged on the two sides of the bottom plate. The cap arranging mechanism comprises a cap arranging push plate, a cap arranging lead screw driving device arranged onthe cap arranging push plate, a rotary device and a cap aligning device, and the rotary device and the cap aligning device are arranged on one side of the cap arranging push plate. The cap feeding mechanism comprises a lead screw driving device, cap feeding sliding devices symmetrically arranged on the two sides of the lead screw driving device, and cap feeding push plates arranged at the top ofthe lead screw driving device and the tops of the cap feeding sliding devices. The arranging machine achieves the operation of automatically arranging the disposable caps in order during production, and is low in cost, high in efficiency and complete in size and scale, the production quality is effectively controlled, and the production efficiency and the production security are improved.

Owner:HUAZHONG UNIV OF SCI & TECH

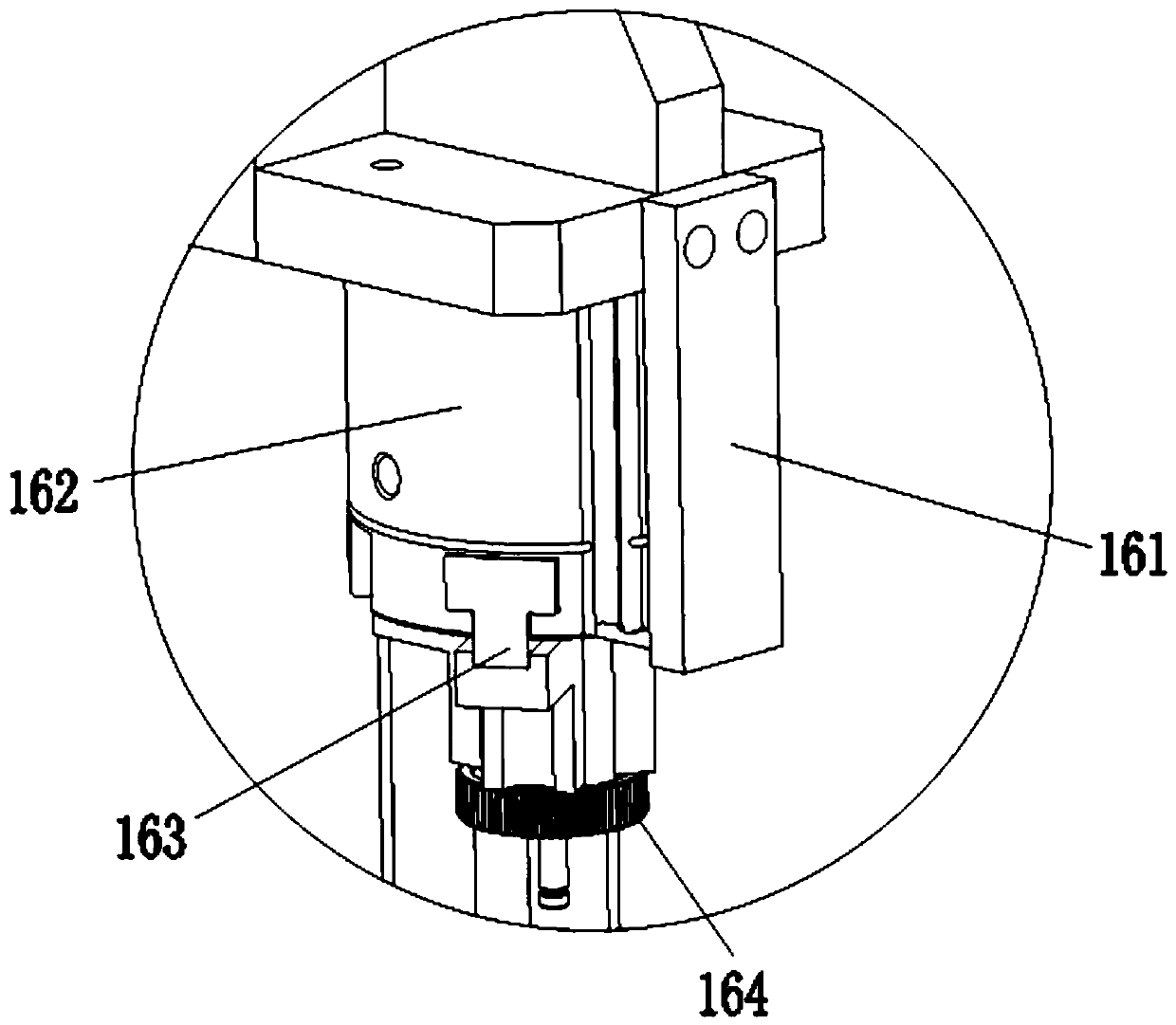

Assembling machine with transistor automatically sleeved with magnet ring

ActiveCN103260391APrecise positioningNo offsetPrinted circuit assemblingElectrical componentsPosition errorMagnetic loop

The invention discloses an assembling machine with a transistor automatically sleeved with a magnet ring. The assembling machine comprises a machine frame, a transistor vibrating disc feeding device, a magnet ring vibrating disc feeding device, a linear moving mechanism, a magnet ring sleeve device and a gluing device. The linear moving mechanism comprises a fixed board, a movable board and a movable material duct, wherein a first driving mechanism is arranged and corresponds to the movable material duct, a first locating groove is formed in the fixed board, a second locating groove is formed in the movable board, and a second driving mechanism is arranged and corresponds to the movable board. Therefore, the function of being automatically sleeved with the magnet ring is achieved by utilizing the linear moving mechanism to convey the transistor and utilizing the magnet ring sleeve device and the gluing device to install and fix the magnet ring on a pin of the transistor in a sleeved mode, operation efficiency can be effectively improved, due to the matched arrangement of the first locating groove and the second locating groove, the transistor can be well located in the process of being sleeved with the magnet ring and glued, excursion will not occur, errors of assembling positions are avoided, the accurate assembling positions are ensured, and accordingly the assembling quality of products can be improved.

Owner:东莞市展荣电子设备有限公司

Transistor automatic magnetic ring assembly machine

ActiveCN103260391BPrecise positioningNo offsetPrinted circuit assemblingElectrical componentsMagnetic loopTransistor

The invention discloses an assembling machine with a transistor automatically sleeved with a magnet ring. The assembling machine comprises a machine frame, a transistor vibrating disc feeding device, a magnet ring vibrating disc feeding device, a linear moving mechanism, a magnet ring sleeve device and a gluing device. The linear moving mechanism comprises a fixed board, a movable board and a movable material duct, wherein a first driving mechanism is arranged and corresponds to the movable material duct, a first locating groove is formed in the fixed board, a second locating groove is formed in the movable board, and a second driving mechanism is arranged and corresponds to the movable board. Therefore, the function of being automatically sleeved with the magnet ring is achieved by utilizing the linear moving mechanism to convey the transistor and utilizing the magnet ring sleeve device and the gluing device to install and fix the magnet ring on a pin of the transistor in a sleeved mode, operation efficiency can be effectively improved, due to the matched arrangement of the first locating groove and the second locating groove, the transistor can be well located in the process of being sleeved with the magnet ring and glued, excursion will not occur, errors of assembling positions are avoided, the accurate assembling positions are ensured, and accordingly the assembling quality of products can be improved.

Owner:东莞市展荣电子设备有限公司

Automatic nailing machine for wooden tray

ActiveCN114193569ARealize automatic feedingAutomatically arrange neatlyStapling toolsConveyorsWood plankMechanical engineering

The invention relates to the technical field of nailing equipment, in particular to a wooden tray automatic nailing machine which comprises a fixing frame, a nailing assembly is arranged above the fixing frame, a fixing plate is arranged at the top of the fixing frame, two overturning assemblies are arranged at the top of the fixing plate, and a vertical feeding assembly is arranged beside the two overturning assemblies. A vertical feeding assembly is arranged on the upper portion of the fixing frame, a feeding assembly is arranged on the lower portion of the fixing frame, two guiding assemblies are arranged above the feeding assembly, a horizontal feeding assembly is arranged beside the fixing frame, and a plurality of supporting rust-proof assemblies are arranged at the top of the fixing plate at intervals. Under the action of the overturning assembly, a tray can be automatically overturned, the two faces of the tray can be automatically nailed, and a wood plate is limited and fixed by arranging a clamping plate, so that the wood plate is prevented from shifting in the nailing process.

Owner:广东展丰智能设备有限公司

Processing device capable of packaging foods conveniently

ActiveCN112919384AImprove packaging efficiencyImplement automatic installationCapsThreaded caps applicationElectric machineryEngineering

The invention relates to the technical field of food packaging, and discloses a processing device capable of packaging foods conveniently. The processing device comprises a left rack, a right rack is welded on the surface of the left rack, supports are welded to the bottoms of the left rack and the right rack, a round box is fixedly connected in the left rack, a rotating shaft is rotatably connected in the round box, a driving mechanism is arranged on the surface of the rotating shaft, a packaging mechanism is arranged in a fixed frame, a transmission motor is fixedly installed in a fixed plate, and a discharging device is arranged on the surface of the left rack. According to the processing device capable of packaging foods conveniently, through driving of a motor, simultaneous operation of a conveying belt and an output belt is controlled, four grooves are formed in a classification plate, and therefore in the rotating process, four bottle materials can enter the processing device at a time, continuous operation is carried out, and therefore rapid and efficient operation of packaging is achieved, and the overall packaging efficiency is improved.

Owner:保定振宏食品股份有限公司

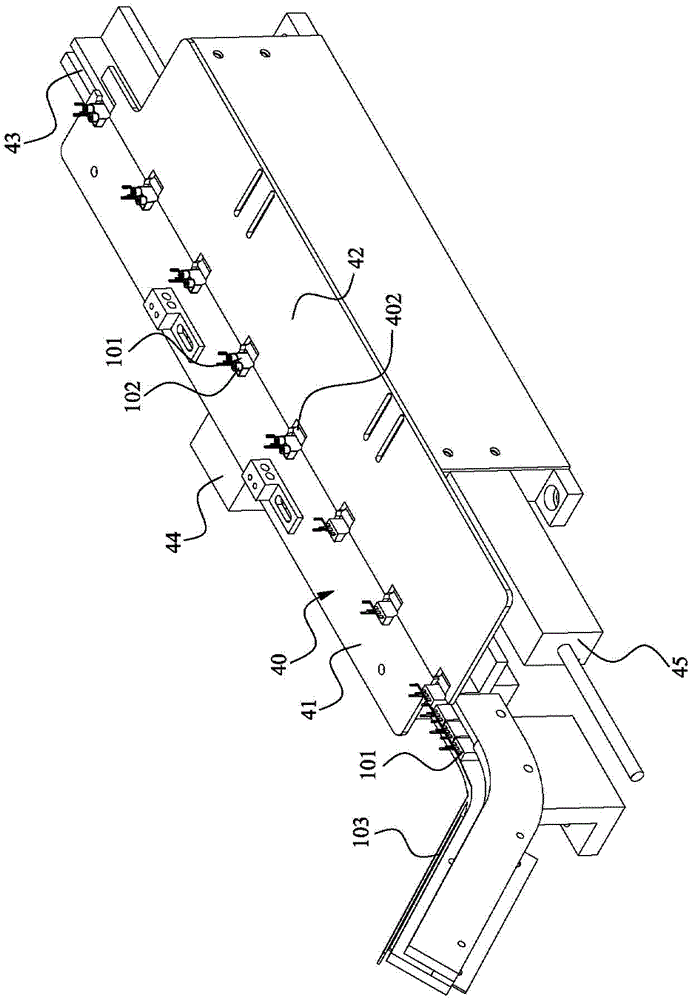

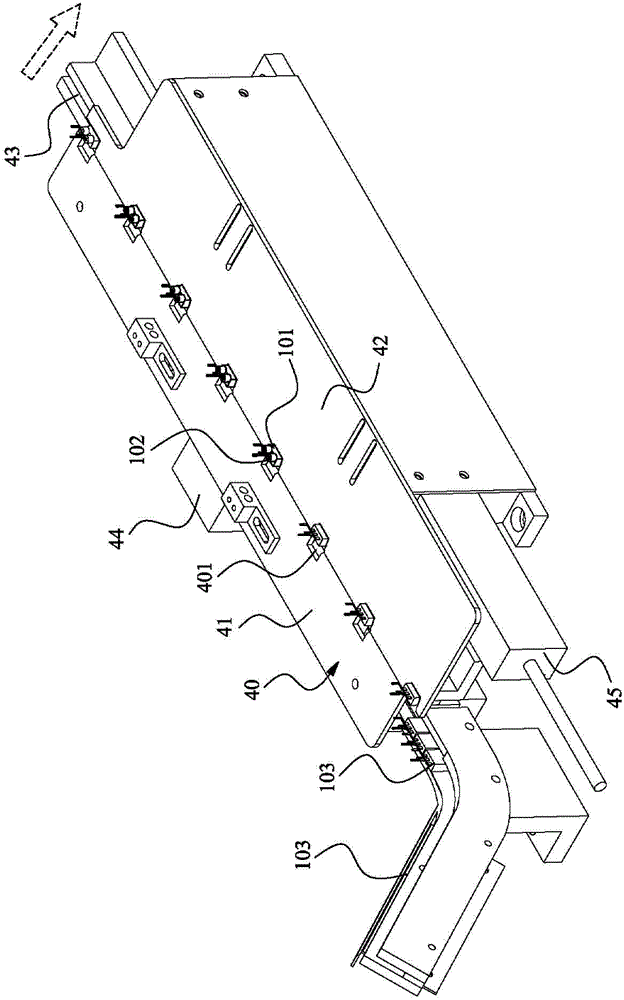

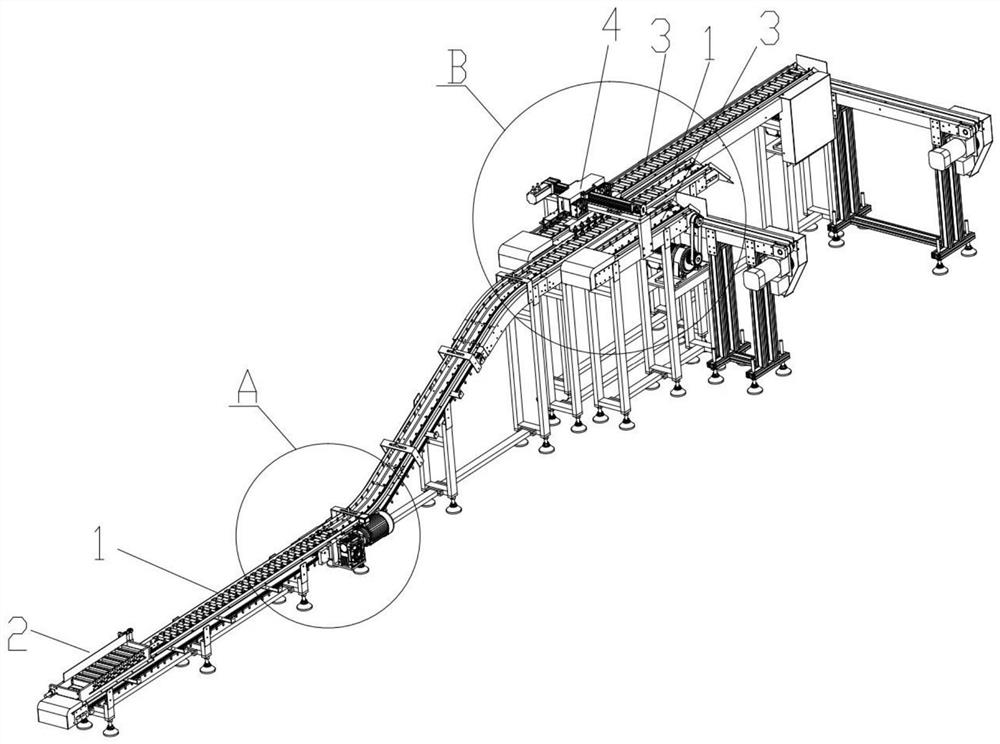

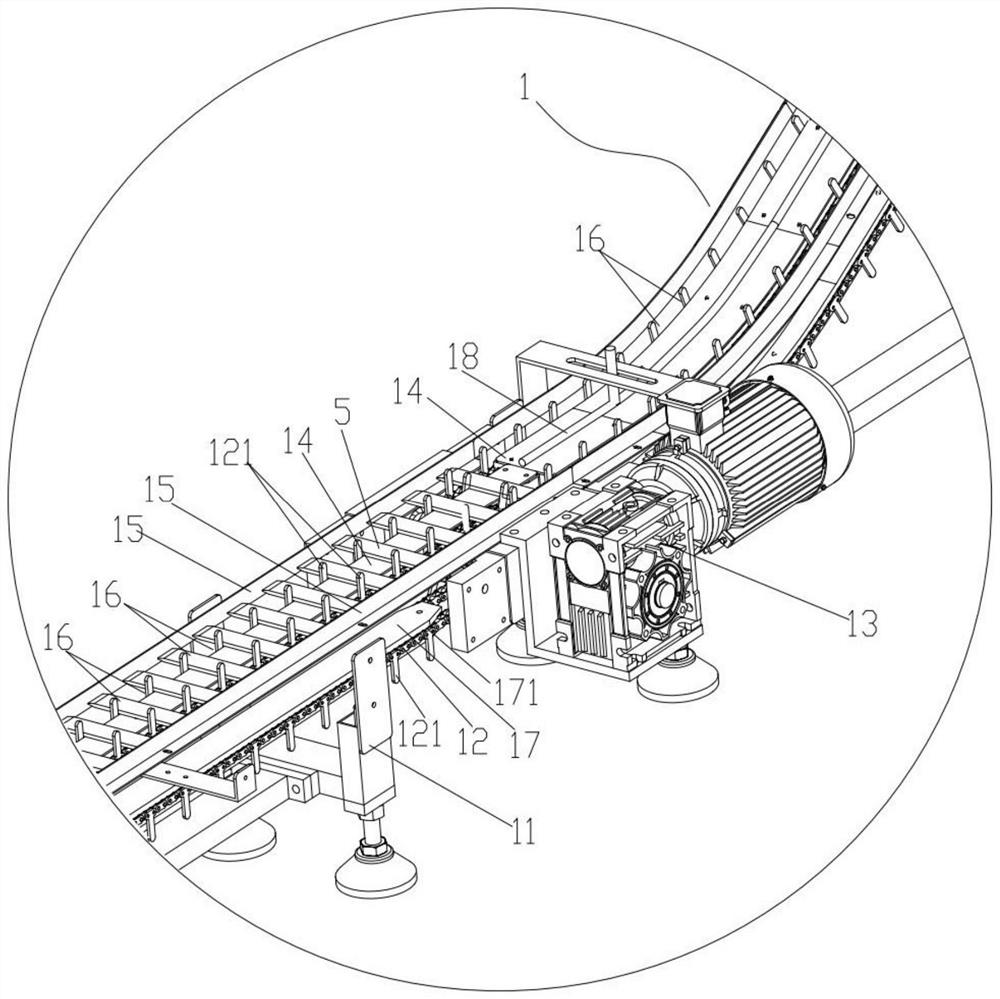

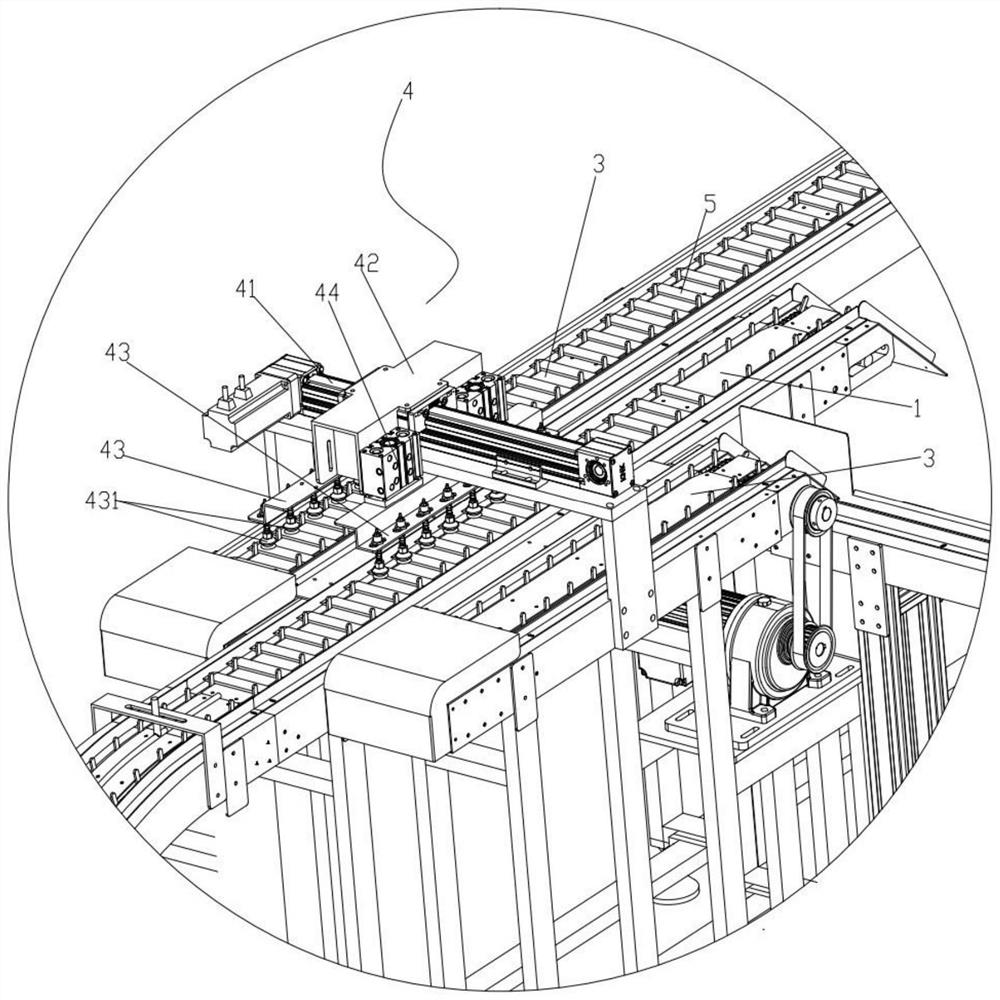

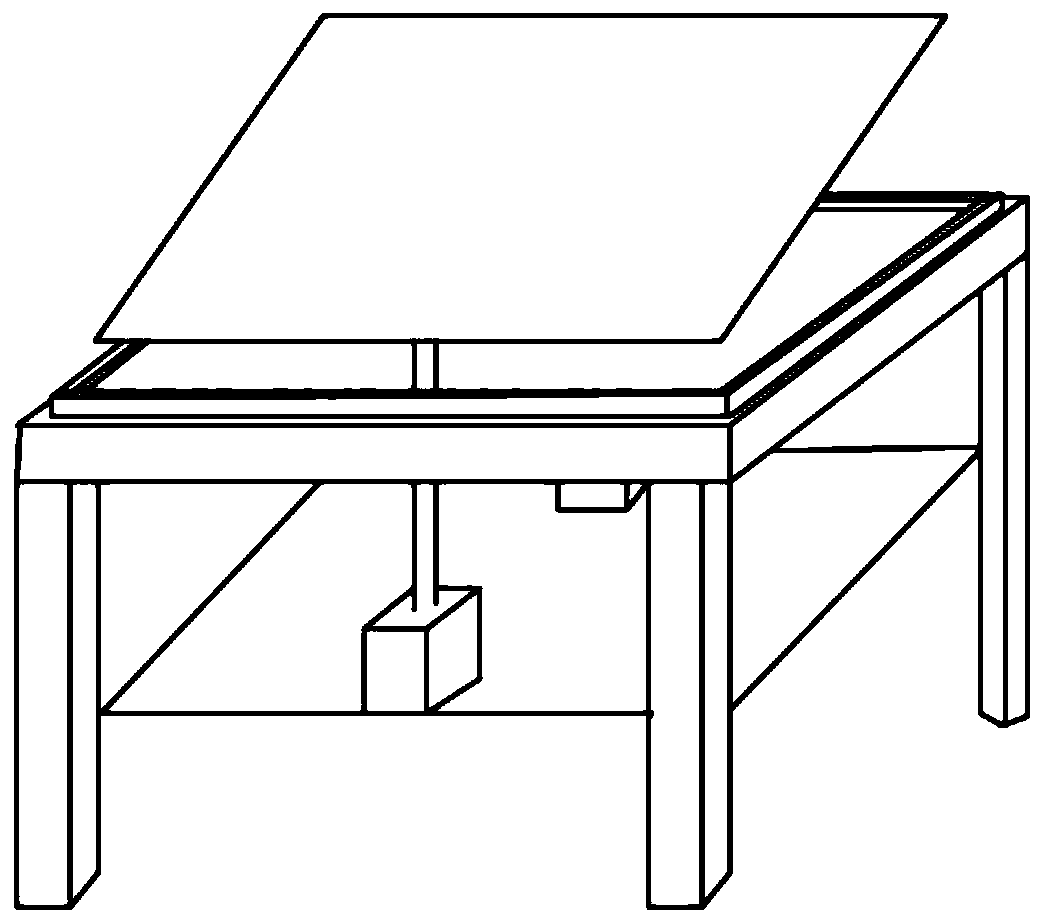

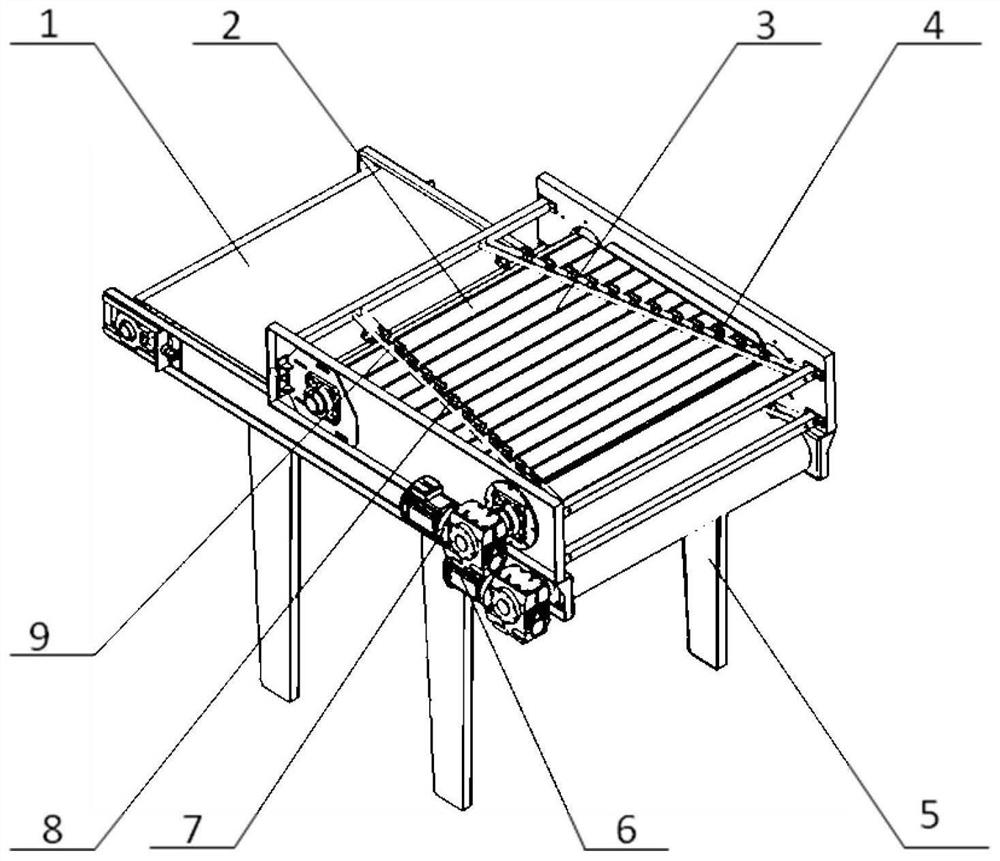

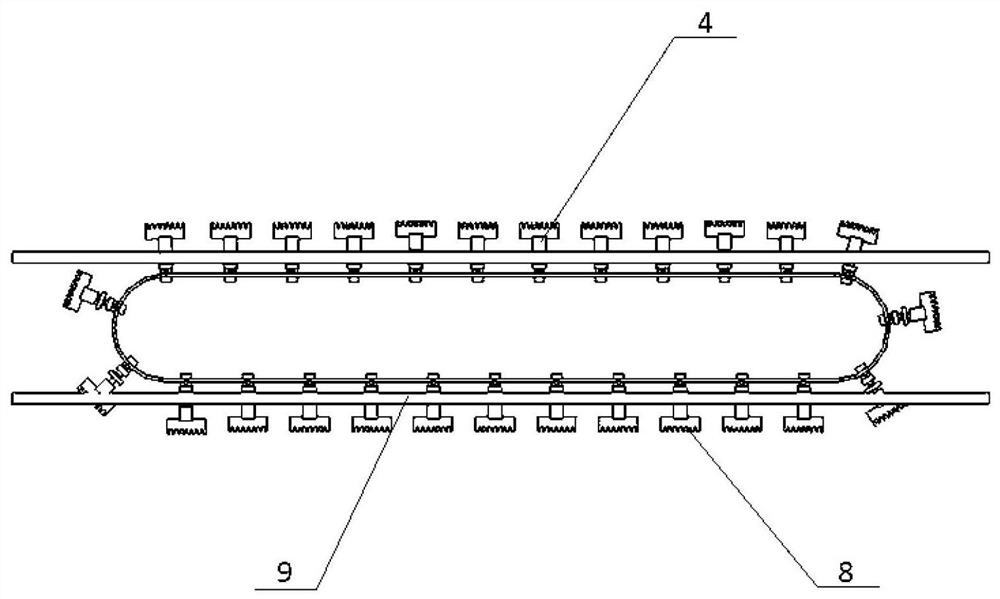

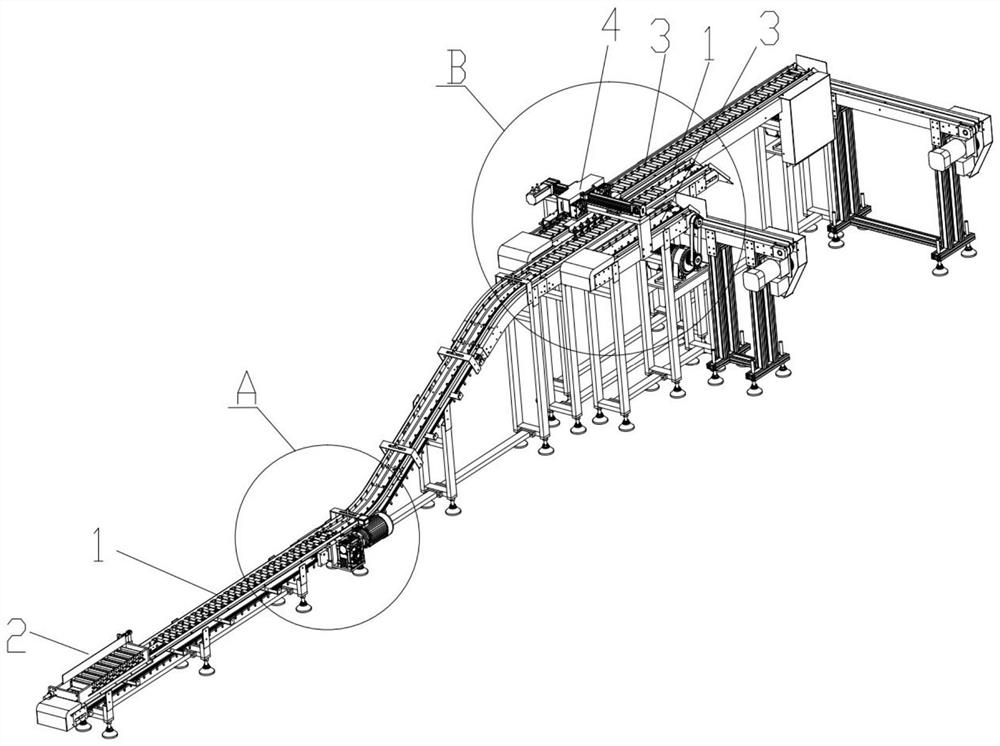

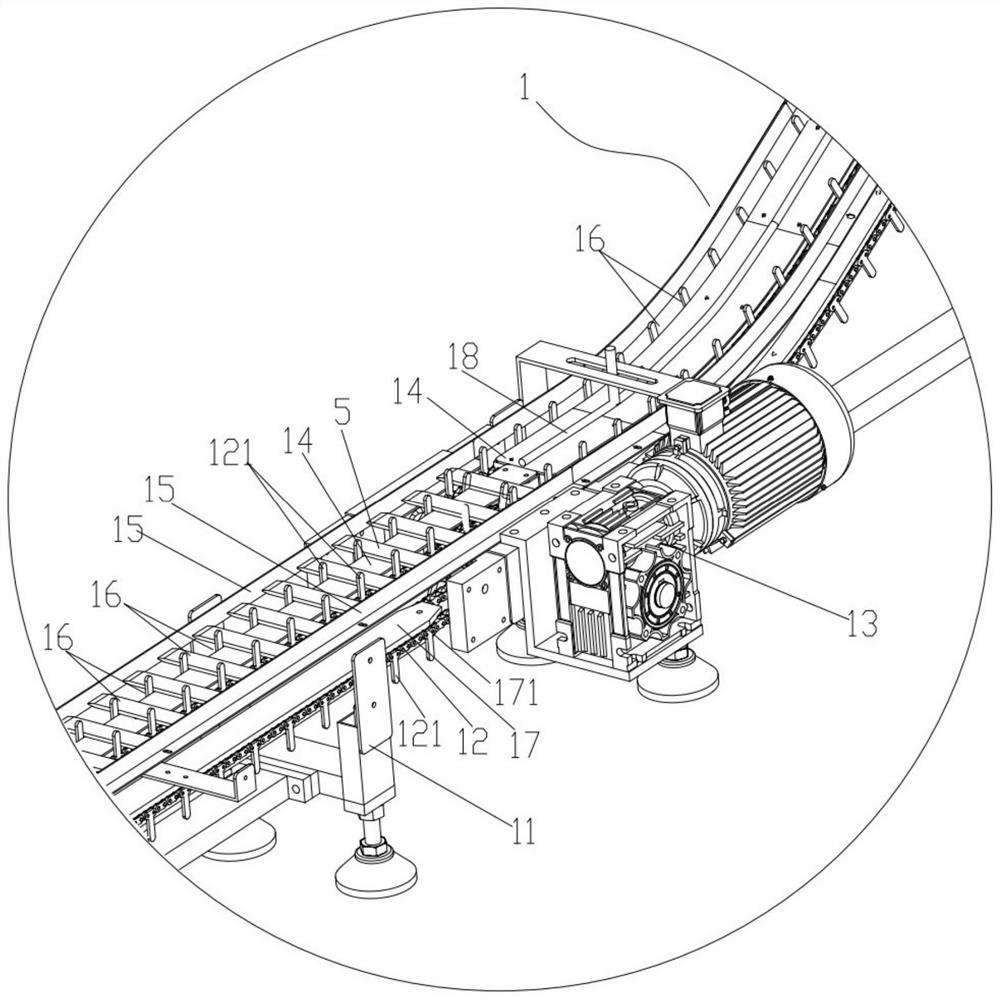

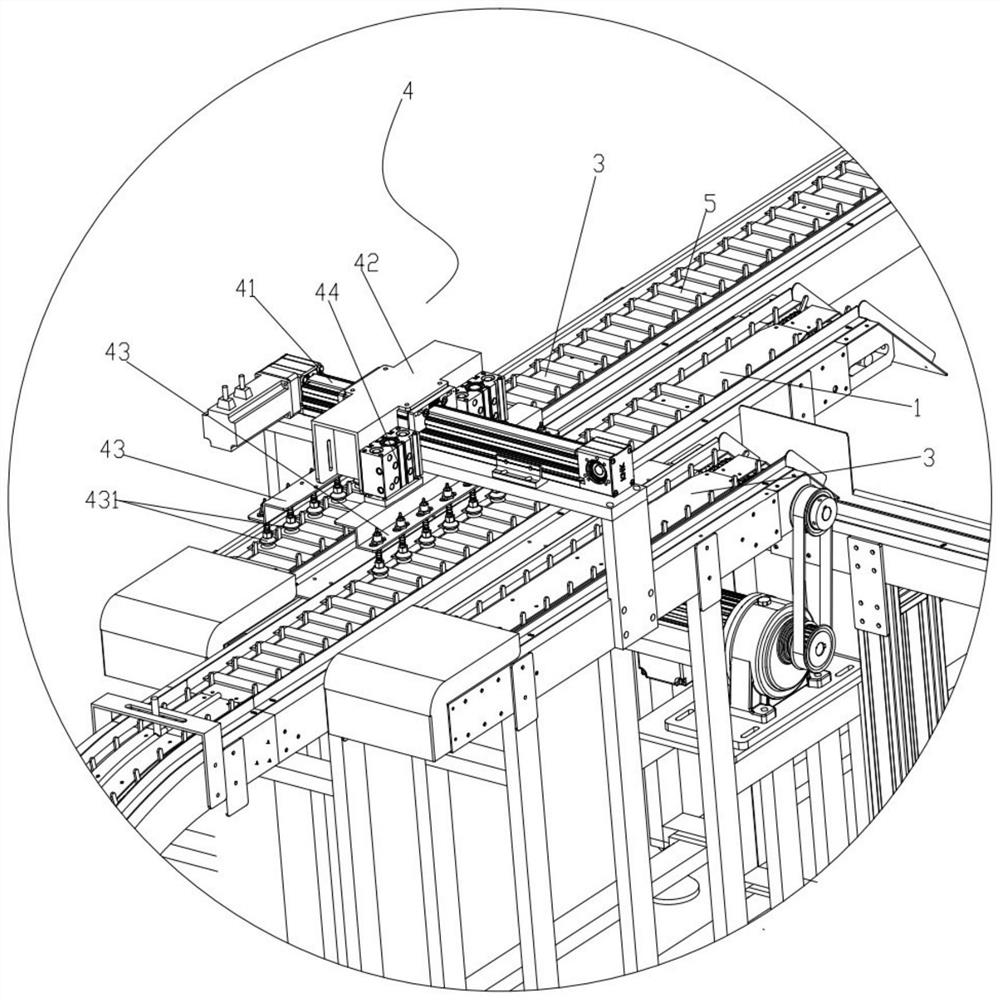

Material arranging and conveying device

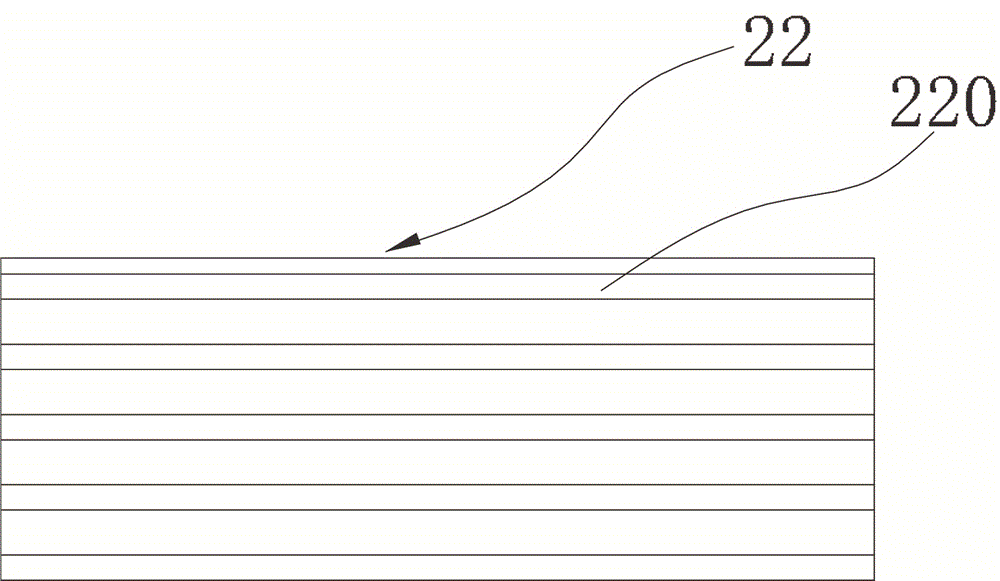

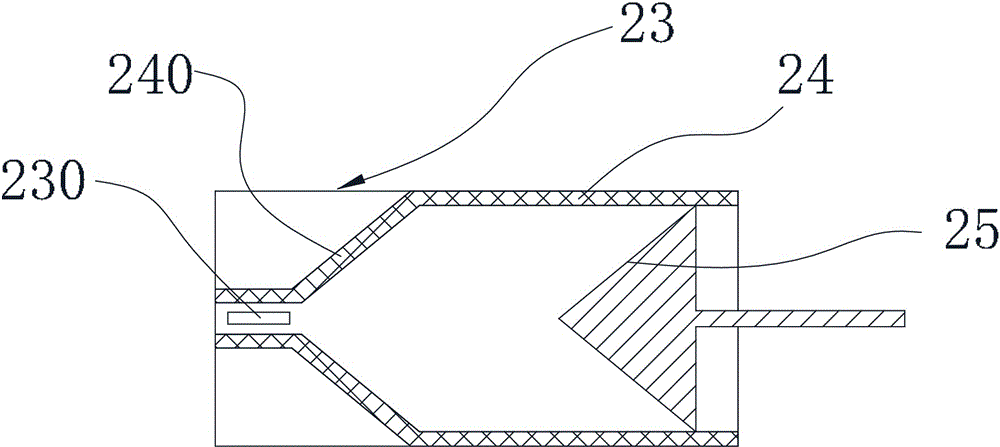

InactiveCN112278812AFast and precise automatic placementSimple structureConveyorsConveyor partsEngineeringChain conveyor

The invention relates to the technical field of packaging machinery, in particular to a material arranging and conveying device. The material arranging and conveying device comprises a material feeding conveyor belt and a material supply mechanism, wherein the material feeding conveyor belt is an automatic material arranging type chain conveyor belt, and comprises a frame, two annular chains and achain driving device; shifting teeth which are uniformly distributed at intervals are fixedly arranged on the chains; the shifting teeth on the two chains are arranged in one-to-one correspondence inthe left-right direction and in pairs; a carrying plate is further arranged between the two chains; side plates are further symmetrically arranged on the outer sides of the two chains; and the material supply mechanism comprises a material supply frame, a plurality of material supply cylinders, movable bottom plates separately arranged under the material supply cylinders, a connecting rod for connecting all the movable bottom plates, and a connecting rod driving device. The material arranging and conveying device has the advantages of quickly and accurately supplying materials to the conveyorbelt, automatically placing the materials on the conveyor belt in good order in the conveying process so as to complete the material arranging process without the need for additional arrangement of amaterial arranging device, eliminating the need for additional arrangement of a material carrying tray on the conveyor belt, achieving a simple and practical structure, and enabling manufacturing andmaintenance costs to be low.

Owner:金嘉成(佛山)智能装备有限公司

Automatic discharging device

ActiveCN108455275AAutomatically arrange neatlyNo manual operationConveyor partsEngineeringUltimate tensile strength

The invention provides an automatic discharging device. The automatic discharging device comprises a rack, a fetching assembly, a distribution assembly and a qualified product box. The fetching assembly comprises a clamping piece, a rotating part, a first driving part, a second driving part and a rotary driving part, wherein the rotary driving part drives the rotating part to rotate, and the firstdriving part and the second driving part drive the clamping piece to move. The distribution assembly comprises a base, two clamping plates, a third driving part, a fourth driving part and a tray, wherein the clamping plates, the third driving part, the fourth driving part and the tray are arranged on the base; the third driving part drives the two clamping plates to move close to or away from each other; and the fourth driving part drives the third driving part and the clamping plates to move close to or away from the tray, so that the clamping plates are moved to the position of the tray toclamp a product on the tray and then to convey the product to the qualified product box. By adoption of the automatic discharging device, produced products can be automatically conveyed into the qualified product box and can also be automatically arrayed in order, manual operation is not needed, the speed and efficiency are high, the work efficiency is greatly improved, and labor intensity is relieved.

Owner:SHENZHEN CHENGJIE INTELLIGENT EQUIP CO LTD

Workpiece conveying system

The invention relates to a workpiece conveying system and relates to the field of automatic equipment. The workpiece conveying system comprises a frame, a workbench, a discharging passage connected tothe workbench; an opening formed in the tail end of the discharging passage; a material blocking plate is arranged at the tail end of the discharging passage; a driving source and a rotating seat driven by the driving source to rotate are arranged on the frame; the rotating seat comprises a bottom plate and a side plate; the bottom plate is positioned in the opening; the top face of the bottom plate is connected with the top face of the discharging passage; a material placing frame is arranged on the side, deviating from the discharging passage, of the rotating seat; material placing rails are arranged on the material placing frame; the rotating seat can rotate to enable the bottom plate to rotate to the position of the side plate; and the side plate can rotate to a state that the plate face is inclined downwards. Workpieces passing through the workpiece conveying system can be automatically arranged in order in an end face abutting mode, so that storage, batch carrying and transportation of the workpieces are greatly facilitated. The material placing rails can be automatically switched, so that the material storage capacity of the material placing frame is improved, and meanwhile, workers can delay time to discharge the workpieces on the material placing rails; and by arranging a baffle and a pushing block I, the reliability of workpiece discharging is high.

Owner:温岭市微米自动化设备有限公司

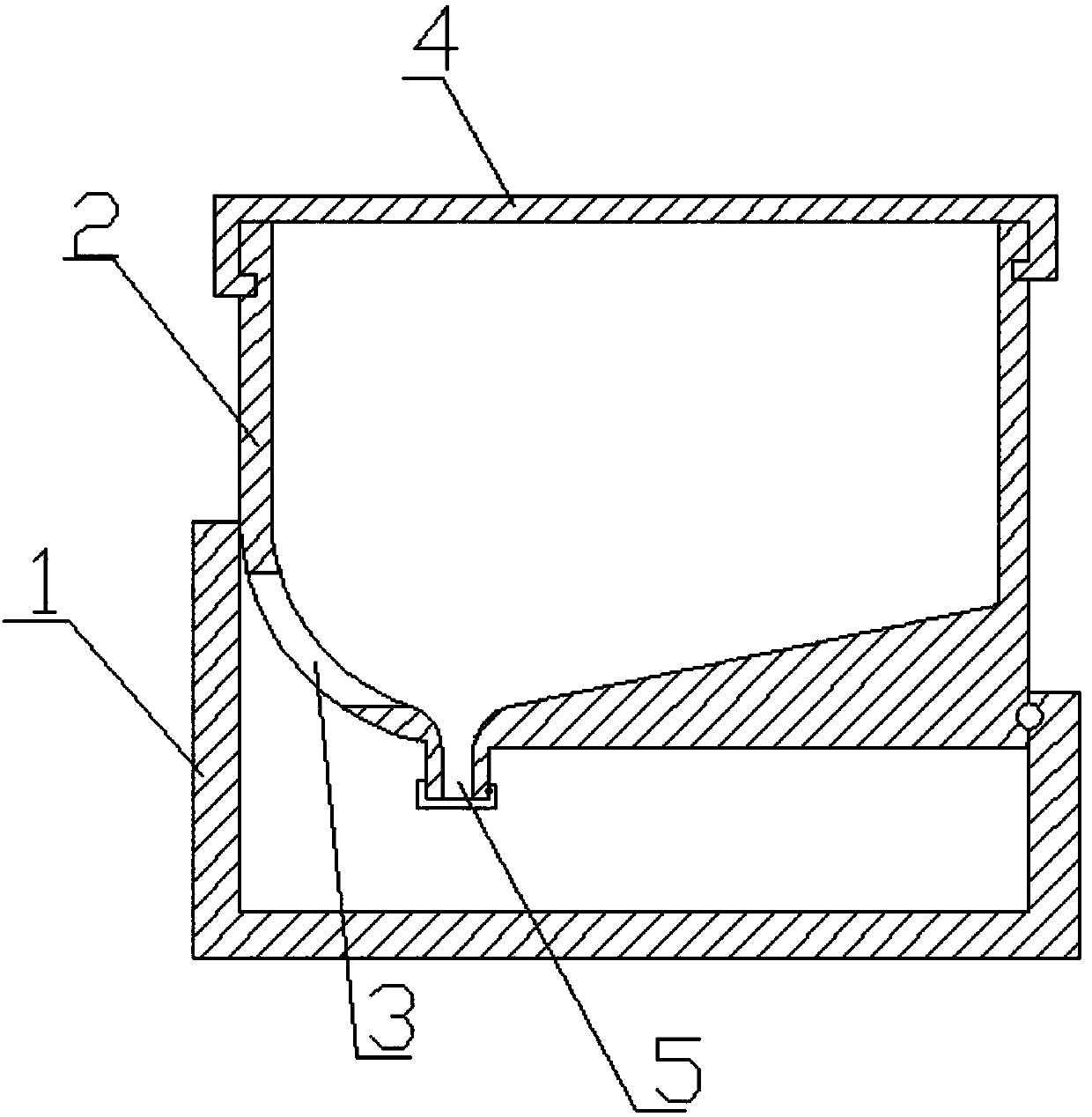

Bamboo toothpick box

InactiveCN107772985AAutomatically arrange neatlyEasy to take outTablewaresMechanical engineeringToothpick

The invention discloses a bamboo toothpick box. The bamboo toothpick box comprises a base and a box body, wherein the longitudinal cross section of the base is a right-angled trapezoid, and the sloping side of the trapezoid is located at the upper part, and an opening is formed in the upper part of the base; the longitudinal cross section of the box body is a cuboid with a circular-arc corner; anopening is formed in the upper part of the box body; a strip-shaped groove is formed in the circular-arc section of the box body; the extending direction of the strip-shaped groove is consistent withthat of the circular-arc section; the side wall, opposite to the circular-arc section, of the box body is hinged with the short edge of the base; the circular-arc section of the box body is supportedby the long edge of the base; an opening is formed in the top of the box body and covered with the cover body; a strip-shaped outlet is formed in the tail end of the circular-arc section at the bottomof the box body; distance between the front wall and the rear wall of the opening is equal to the length of toothpicks; the outlet is covered with the cover body; the surface opposite to the circular-arc section in the box body is an inclined plane; the toothpick box is made of bamboo boards. According to the bamboo toothpick box, the base is arranged, one side of the box body is hinged to the base, when the box body is rotated, toothpicks in the box body are arranged neatly automatically under the action of gravity, fingers can enter the box body through the strip-shaped groove to correct disordered toothpicks, and accordingly, the toothpicks are easier to take out.

Owner:贵州新锦竹木制品有限公司

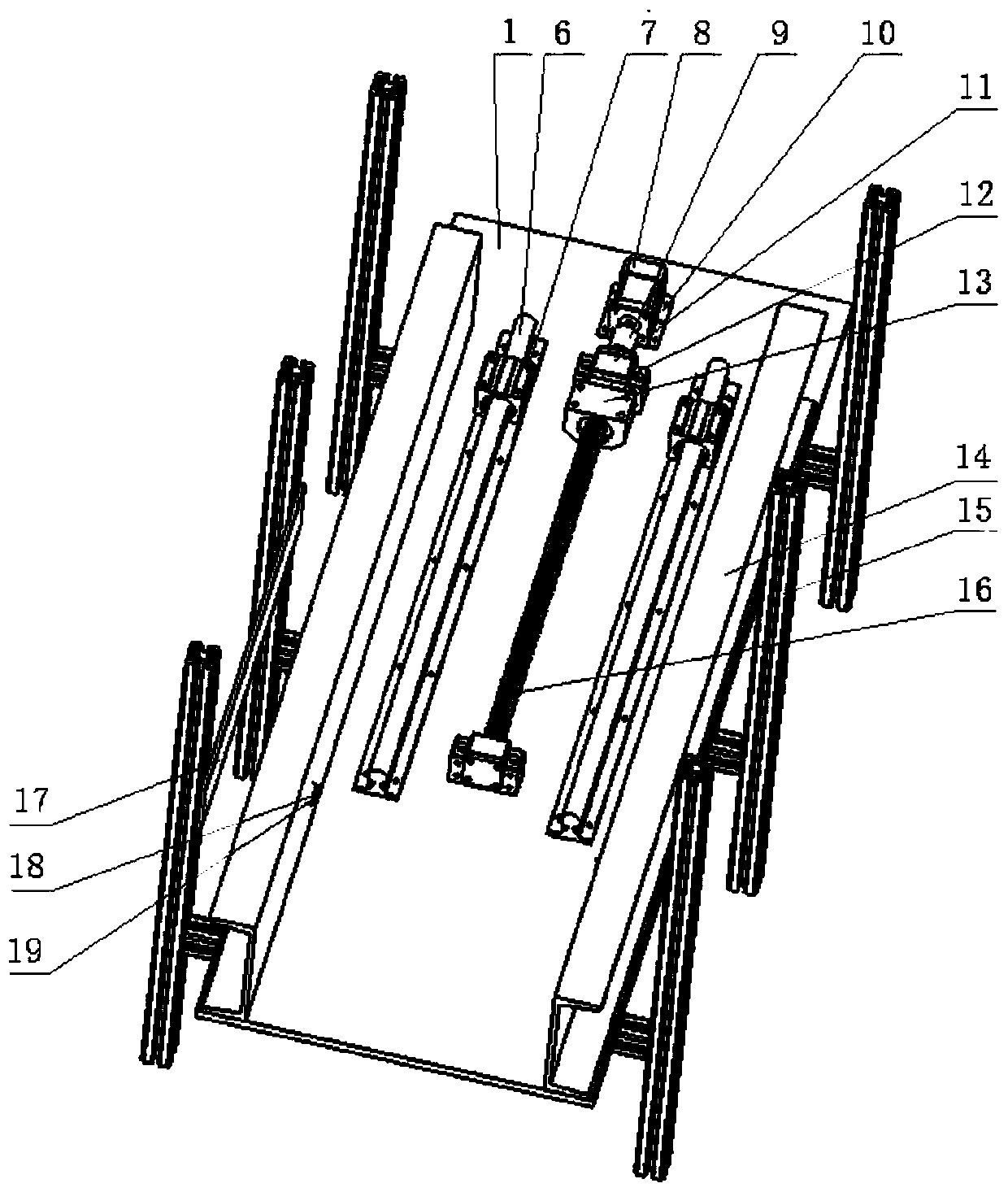

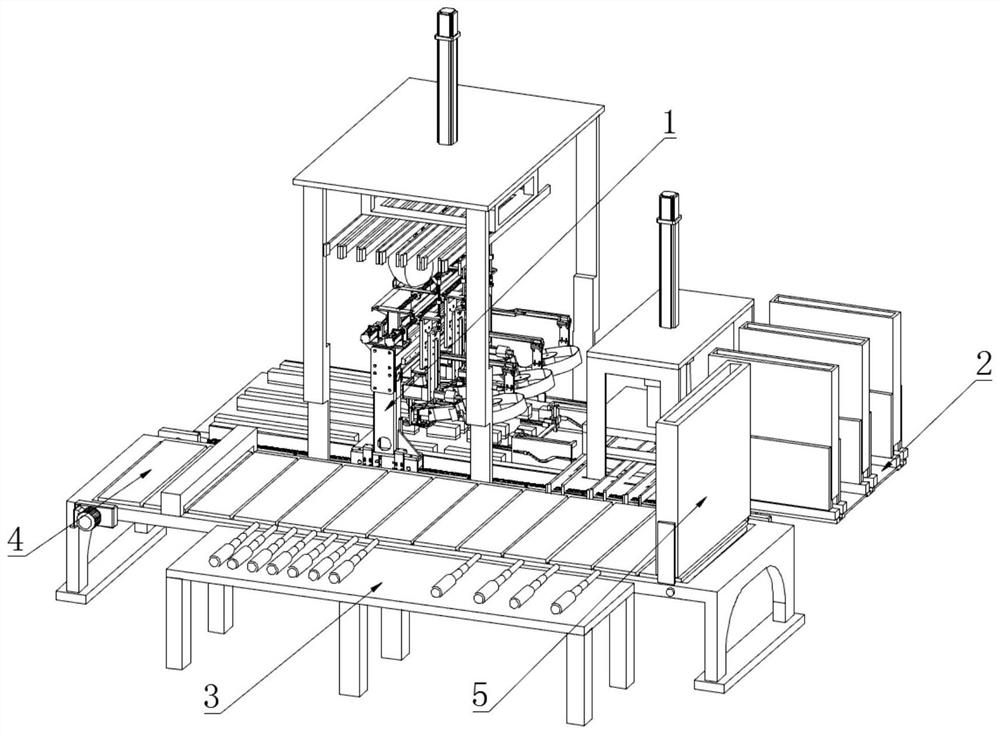

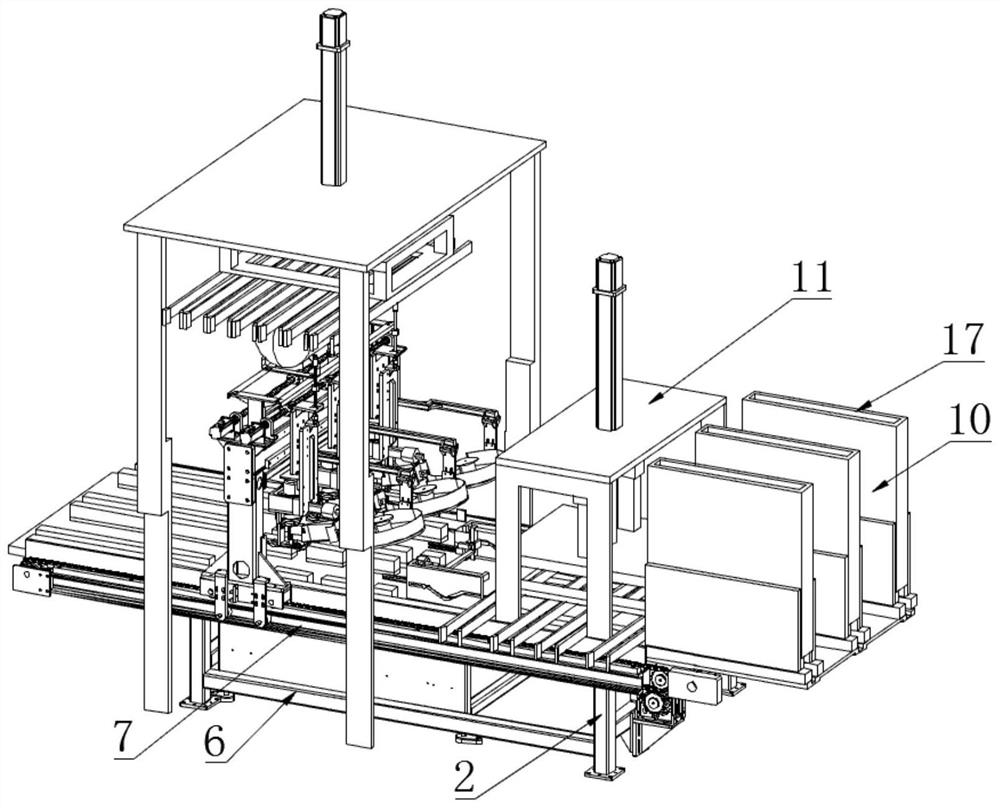

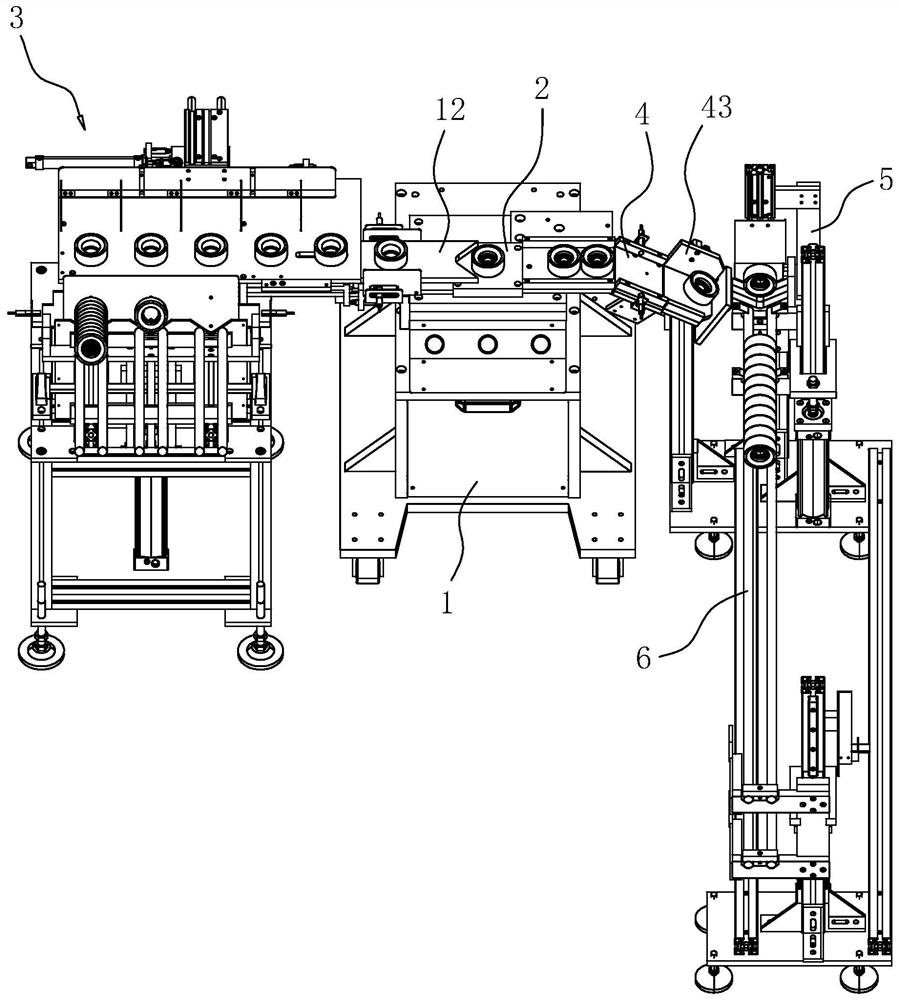

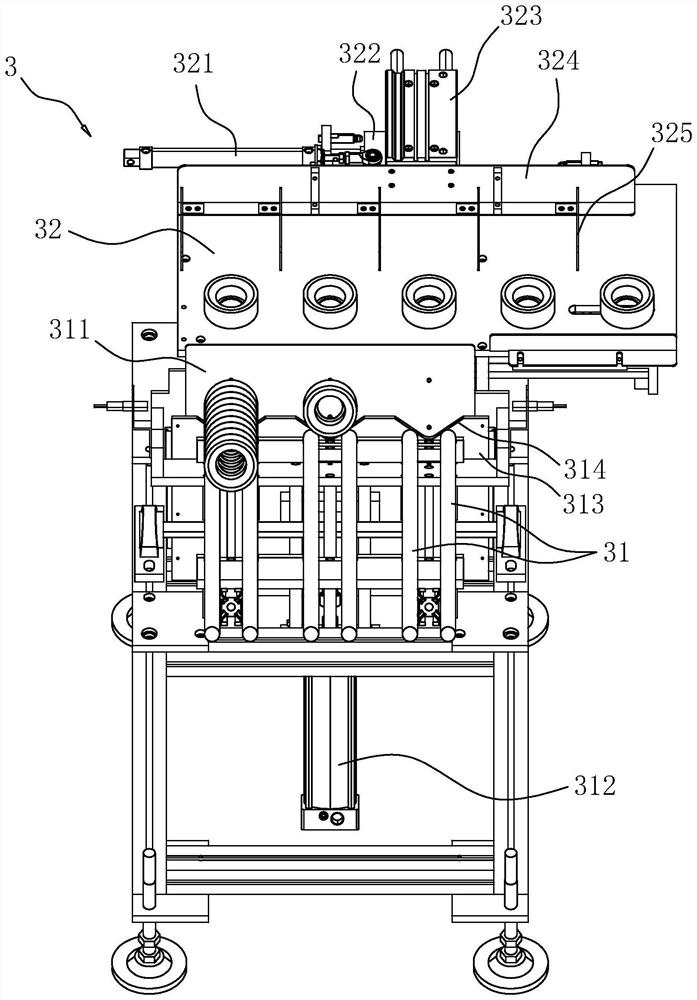

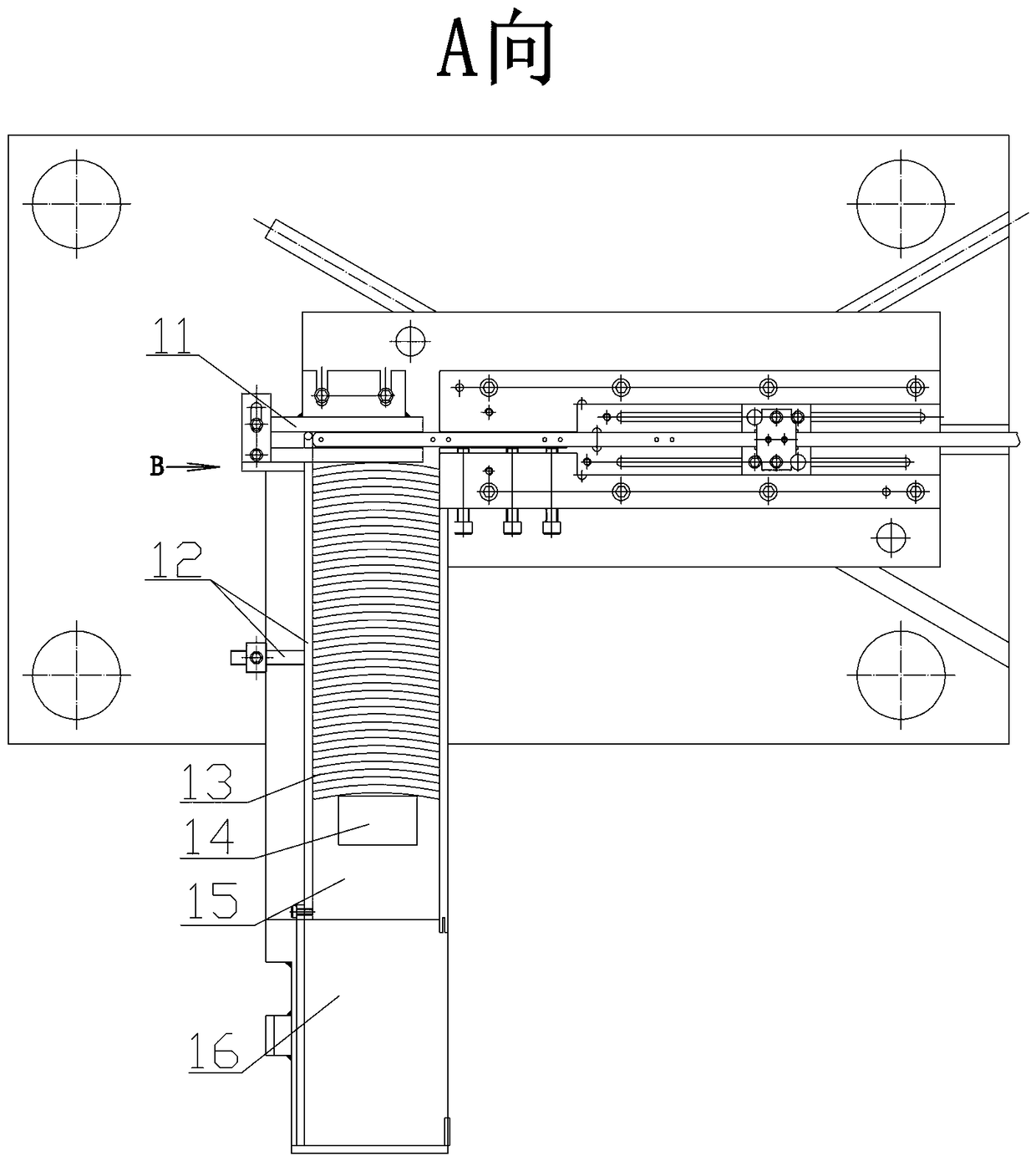

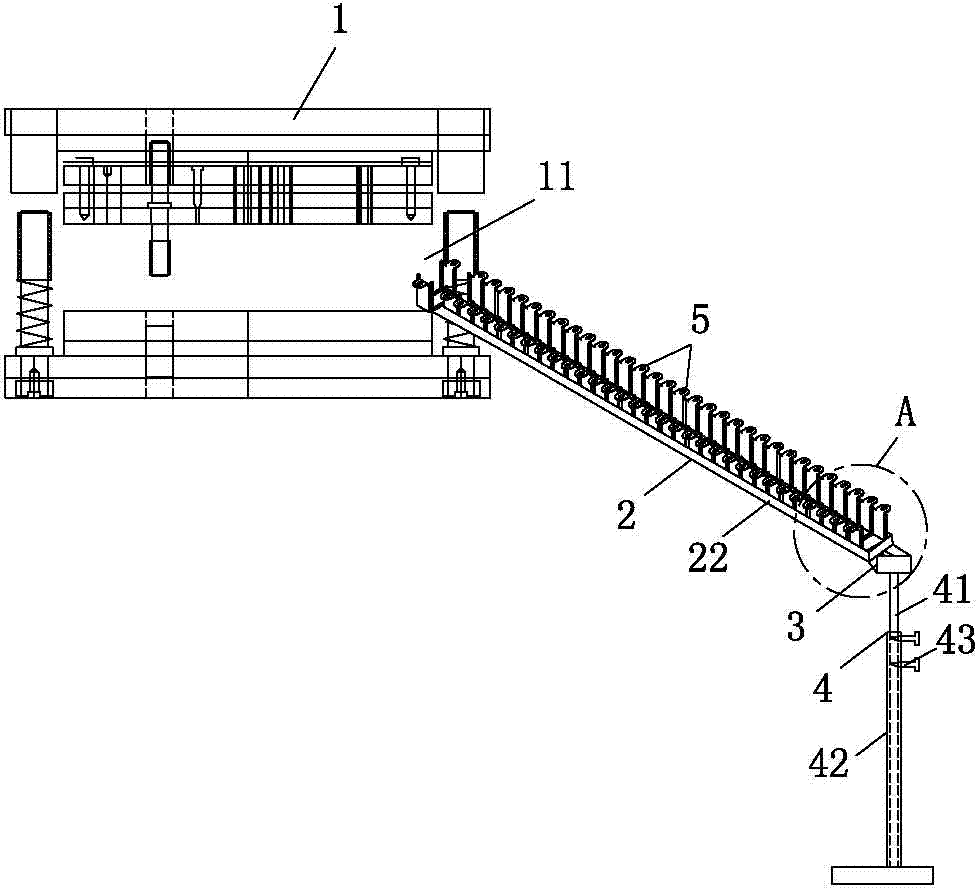

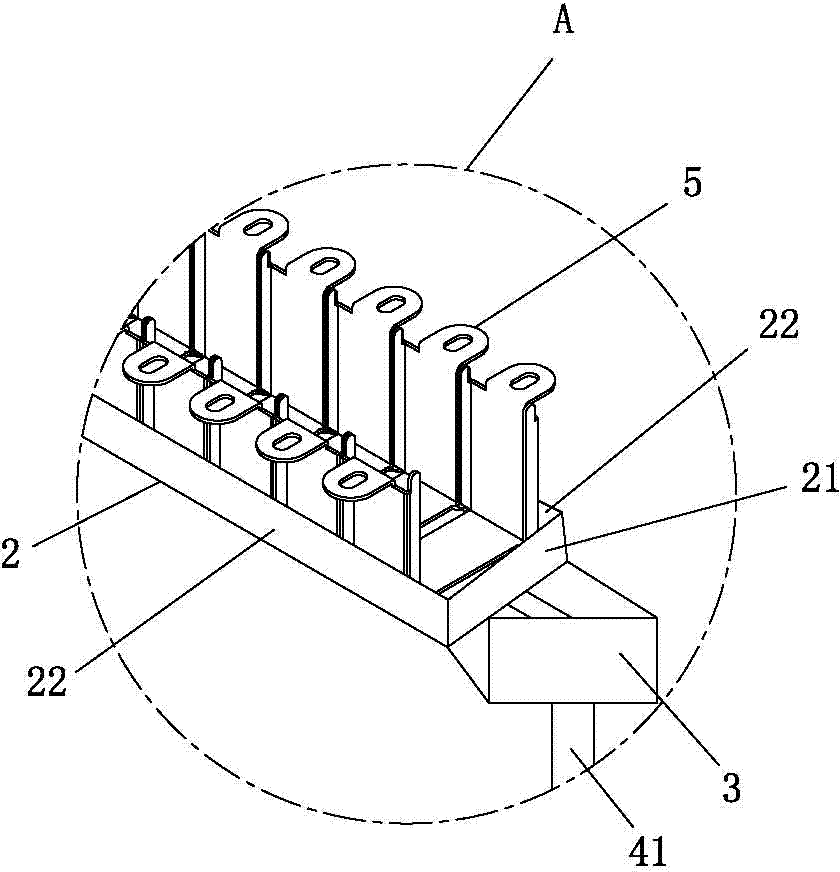

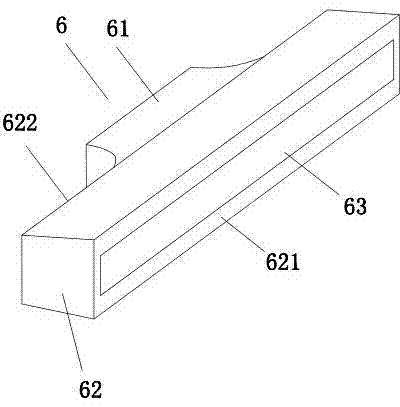

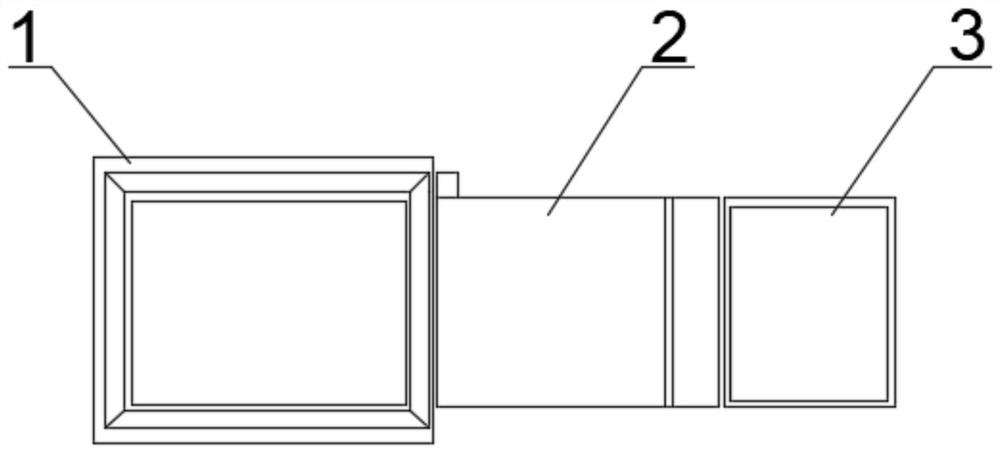

High-speed intelligent stamping system for shanks for footwear

PendingCN108262398AHigh speedStable productionMetal-working feeding devicesPositioning devicesHydraulic cylinderPunching

The invention discloses a high-speed intelligent stamping system for shanks for footwear, and aims to provide a special production system for shanks for footwear, which realizes high speed, high efficiency, low energy consumption and no pollution and can realize mechanics-electronics-hydraulics integration. In order to realize the purposes, according to the adopted technical scheme, the system comprises a hydraulic machine, a servo feeder, a leveler and an automatic material arrangement die frame which are arranged in sequence. The hydraulic machine is hydraulic cylinder vertically-arranged stamping equipment, the automatic material arrangement die frame with a punch and a forming die is installed on a middle plate at the lower end of a hydraulic cylinder, and a punching die and the forming die corresponding to the die above are installed on a working table top under the automatic material arrangement die frame. The punching die is provided with a limit block allowing a material bar topass, and a material arrangement device used for putting finished products in good order and in sequence is installed outside the forming die. The material arrangement device comprises baffles, a material baffle and a material arrangement sliding plate, the tail end of the material bar is located in the gap between the two baffles, and a material arrangement sliding groove is arranged between thebaffles and the horizontal material baffle.

Owner:ZAOZHUANG TIANZHU HARDWARE SHOE MATERIALS CO LTD

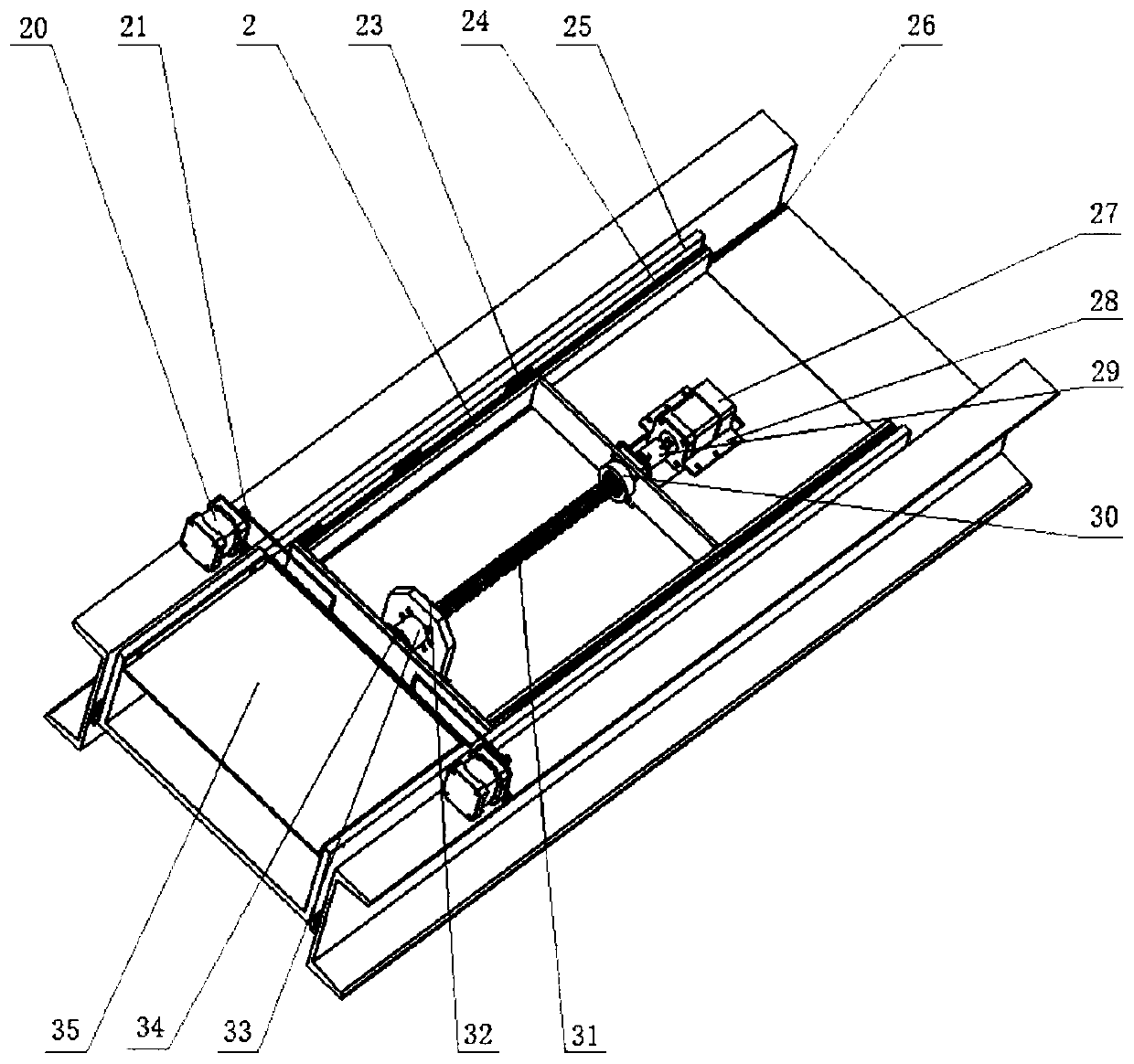

A pipe automatic sorting system

ActiveCN110586483BBlanking evenlyAvoid the hassle of putting rightGradingStructural engineeringMechanical engineering

The invention relates to a pipe automatic sorting system. The pipe automatic sorting system comprises a sorting frame, a pipe pushing mechanism, a pair of pipe position adjusting mechanisms, a sortingplate and a pipe loading mechanism; a small sorting opening, a medium sorting opening and a large sorting opening in shapes of long rectangles are arranged on the sorting plate along a slope in sequence from top to bottom; and the pipe loading mechanism comprises two guide rails arranged on the same horizontal plane in parallel, a push-pull cylinder vertically and fixedly mounted on the inner side wall of a first vertical plate, a slide platform slidingly mounted on the two guide rails, a limiting mounting plate positioned on the slide platform, a loading bucket fixedly mounted on the limiting mounting plate, a jacking cylinder and two extension rods. The sorting system is simple and reasonable in structural design, can sort pipes with different lengths, and can collect and stack the sorted pipes in a centralized mode.

Owner:山东迪捷聚合物科技有限公司

System for testing diode thermistor in high speed

ActiveCN102107190BThe process design principle is simpleCompact structureSortingEngineeringHeat sensitive

The invention provides a system for testing a diode thermistor in a high speed. The system comprises a material discharging device, a conveying device, a test device, a constant-temperature slot, a material receiving device, a lifting device, an engine seat, a transmission mechanism and a control device; the material discharging device, the conveying device, the test device, the material receiving device, the transmission mechanism and the control device are all arranged on the engine seat; the lifting device and the engine seat are arranged on the floor and the constant-temperature slot is formed on the floor; the material discharging device comprises a material discharging magnetic rail and a material discharging magnetic wheel; the conveying device comprises a chain wheel device, two material discharging chains, a conveying pipe, a feeding magnetic rail, a first stopping device, a second stopping device and a guide block; the test device comprises a test magnetic wheel, a tester and a probe; and the material receiving device comprises a stepping wheel, a material receiving box and a poking sheet. The system is used for testing the diode thermistor, and has high test speed and high stepping precision.

Owner:常州市科文传感器材料有限公司

Photo frame shaping device capable of achieving orderly transportation

ActiveCN110040493AEasy to transportPrevent looseningConveyorsControl devices for conveyorsHydraulic cylinderDrive wheel

The invention discloses a photo frame shaping device capable of achieving orderly transportation. The photo frame shaping device comprises a shaping mechanism, a conveying mechanism and a placing box.The shaping mechanism comprises fixed clamping plates, a work table and movable clamping plates. A supporting plate is arranged below the work table in an inclined manner. Two same hydraulic cylinders are arranged on the supporting plate in the inclination direction. An unloading plate is arranged at the middle position of the work table. Piston rods of the hydraulic cylinders are fixedly connected with the lower surface of the unloading plate. The fixed clamping plates and the movable clamping plates are arranged on the periphery of the unloading plate. Grooves are formed in the portions, outside the movable clamping plates, on the work table. The conveying mechanism comprises a conveyor belt and detection devices. A driving wheel and a driven wheel of the conveyor belt are connected through transverse rods. The detection devices and a support are arranged on the transverse rods. Each detection device is located on the side closer to the placing box. A stepping motor and a pendulum bob are arranged on the middle portion of the support. Automatic and orderly transportation of photo frames is achieved, the work efficiency is improved, and the production cost is reduced.

Owner:QINGDAO SHOUSHENG IND

Tobacco leaf carding device

ActiveCN111743194BRealize automatic cardingAutomatically arrange neatlyTobacco preparationVisual inspectionStructural engineering

Owner:CHINA TOBACCO MACHINERY TECH CENT +2

Automatic stacking method and device for preventing object extrusion

ActiveCN114275211AAutomatically arrange neatlyAvoid squeezingIndividual articlesStructural engineeringVisual recognition

The invention discloses an automatic stacking method and device for preventing objects from being extruded. The method comprises the following steps that the horizontal placing sequence of the objects is planned in advance according to a loading container; according to the planned horizontal placing sequence, the manipulator throws the objects into the loading container; detecting objects in the loading container in real time through a visual identification module and a depth detection module; the depth value of the object is compared with the theoretical depth of the current layer, and if the difference between the depth value of the object and the theoretical depth of the current layer is within a set error range, it is considered that the object is placed in order; otherwise, determining that the tea leaves are not tidily placed; after the front layer is fully paved, the bubble bag covers the placed object through the bag pulling driving mechanism, and then the bubble bag is separated from the main body through the bag cutting mechanism; and the operation is performed until the loading container is full. Objects can be automatically and neatly placed, the objects can be prevented from being excessively extruded, and the maximum space containing rate can be obtained.

Owner:JIHUA LAB

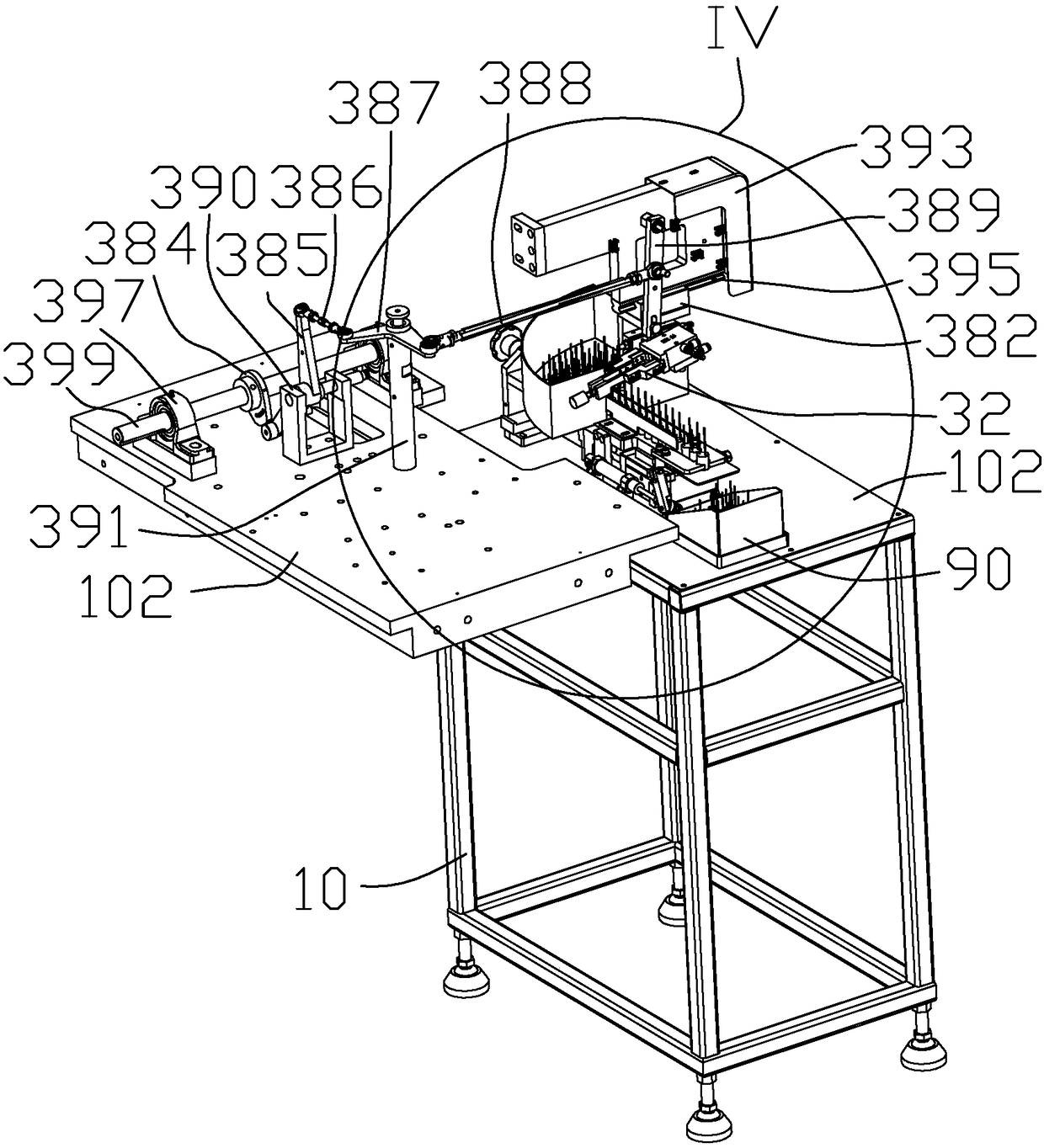

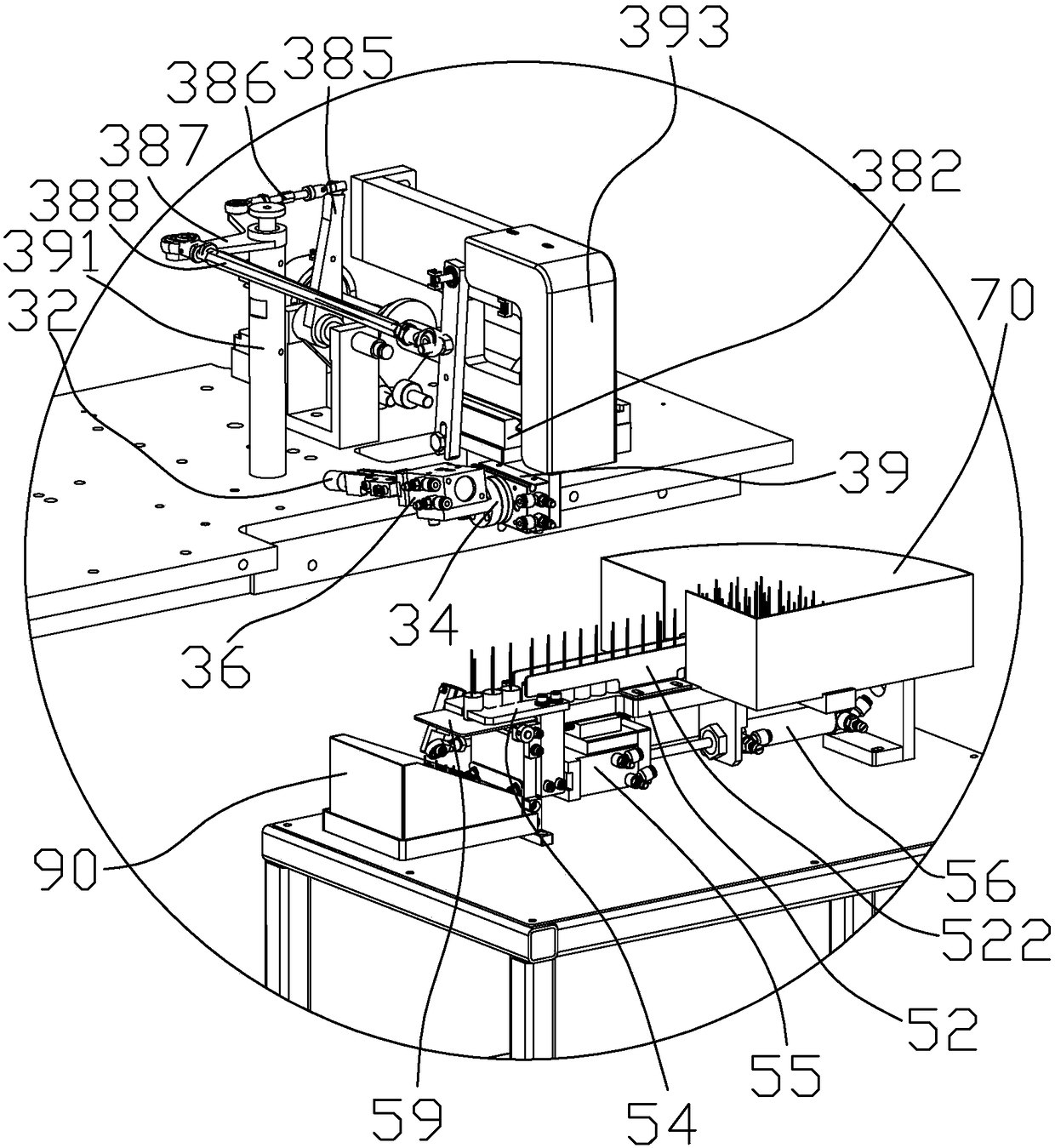

A kind of cap automatic arrangement machine

The invention discloses an automatic arranging machine for caps. The automatic arranging machine comprises a frame supporting structure, a cap arranging mechanism and a cap feeding mechanism. The frame supporting structure comprises supporting pile legs formed by aluminum profiles, and connecting cross beams are arranged between the supporting pile legs. A bottom plate is arranged on the connecting cross beam, and groove steel is arranged on the two sides of the bottom plate. The cap arranging mechanism comprises a cap arranging push plate, a cap arranging lead screw driving device arranged onthe cap arranging push plate, a rotary device and a cap aligning device, and the rotary device and the cap aligning device are arranged on one side of the cap arranging push plate. The cap feeding mechanism comprises a lead screw driving device, cap feeding sliding devices symmetrically arranged on the two sides of the lead screw driving device, and cap feeding push plates arranged at the top ofthe lead screw driving device and the tops of the cap feeding sliding devices. The arranging machine achieves the operation of automatically arranging the disposable caps in order during production, and is low in cost, high in efficiency and complete in size and scale, the production quality is effectively controlled, and the production efficiency and the production security are improved.

Owner:HUAZHONG UNIV OF SCI & TECH

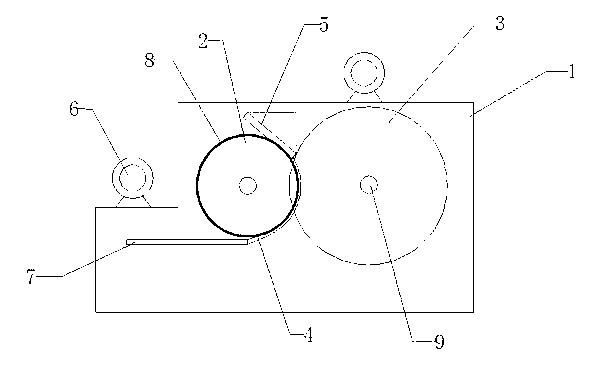

Double-end-surface grinding equipment of micro drillstock

InactiveCN103264331ANot easy to go off trackGrind evenlyGrinding machine componentsPlane surface grinding machinesEngineeringGrinding wheel

The invention belongs to grinding tools, and particularly relates to double-end-surface grinding equipment of a micro drillstock. The double-end-surface grinding equipment of the micro drillstock comprises a machine body, and is characterized in that a grinding assembly is arranged on the machine body and is composed of two grinding wheels and a rotary crankset arranged between the two grinding wheels in parallel, a feeding hopper is arrange above the grinding assembly, a collection mechanism is arranged under the grinding assembly, the feeding hopper and the collection mechanism are both tangent with the rotary crankset, and a pressing belt is arranged at the edge of the rotary crankset between two tangent points. The double-end-surface grinding equipment of the micro drillstock improves the yield to above 99.98%, simplifies the whole operation procedure of micro drill production, accelerates the material circulation, improves production efficiency, relieves labor intensity, and saves labor cost.

Owner:新野鼎邦实业有限公司

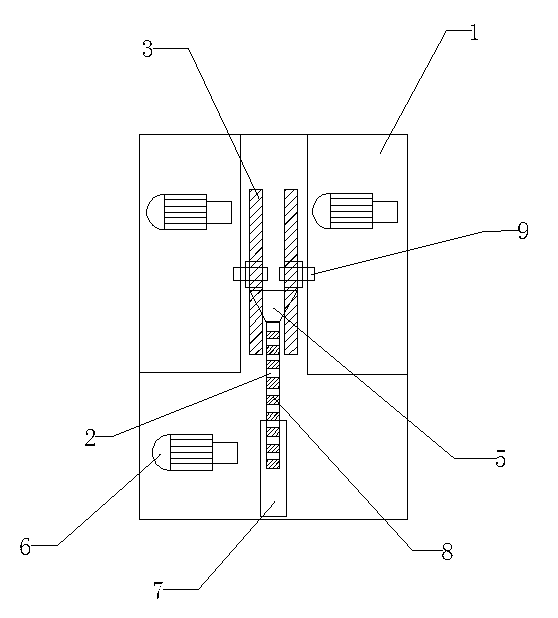

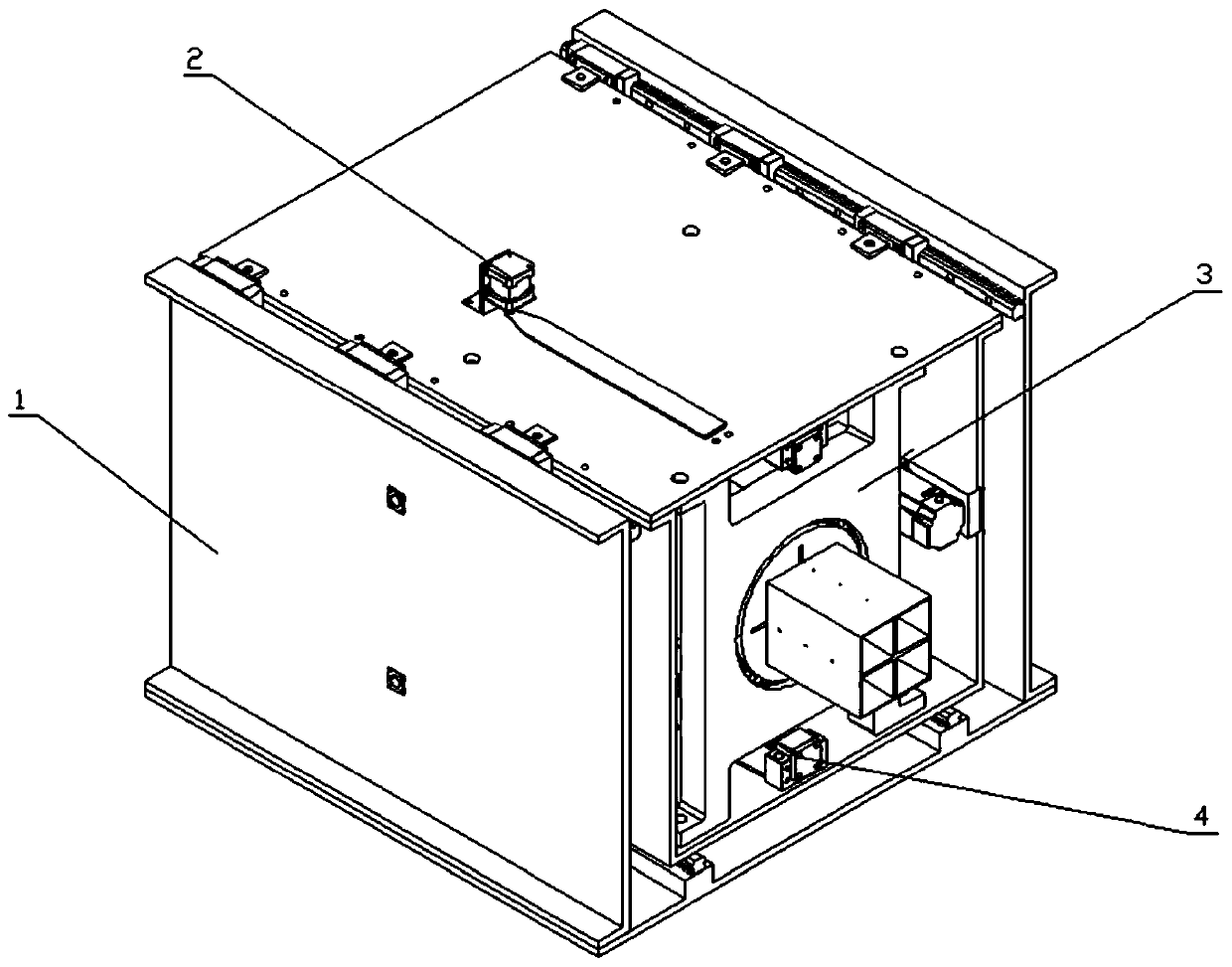

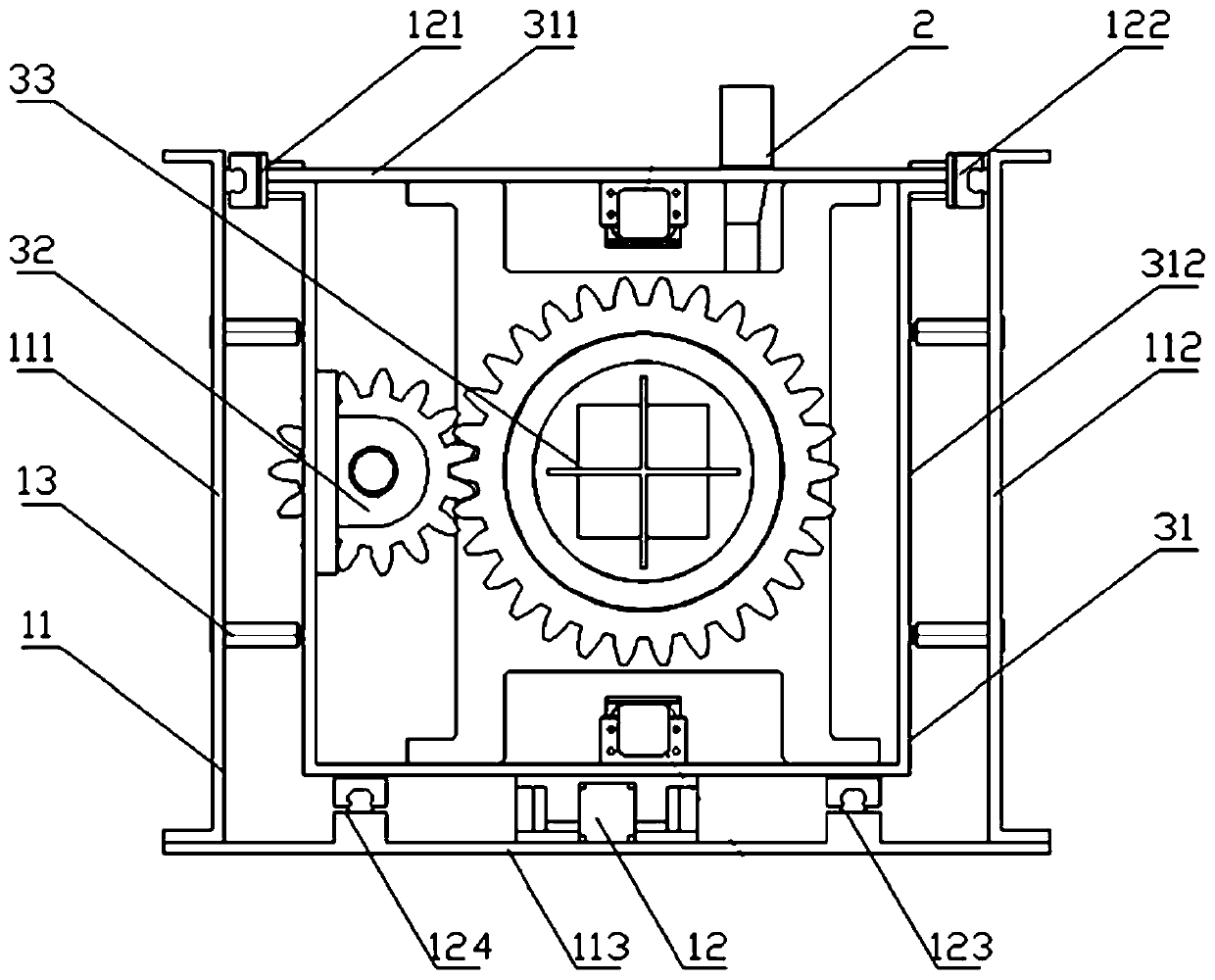

Punching device for binding financial data

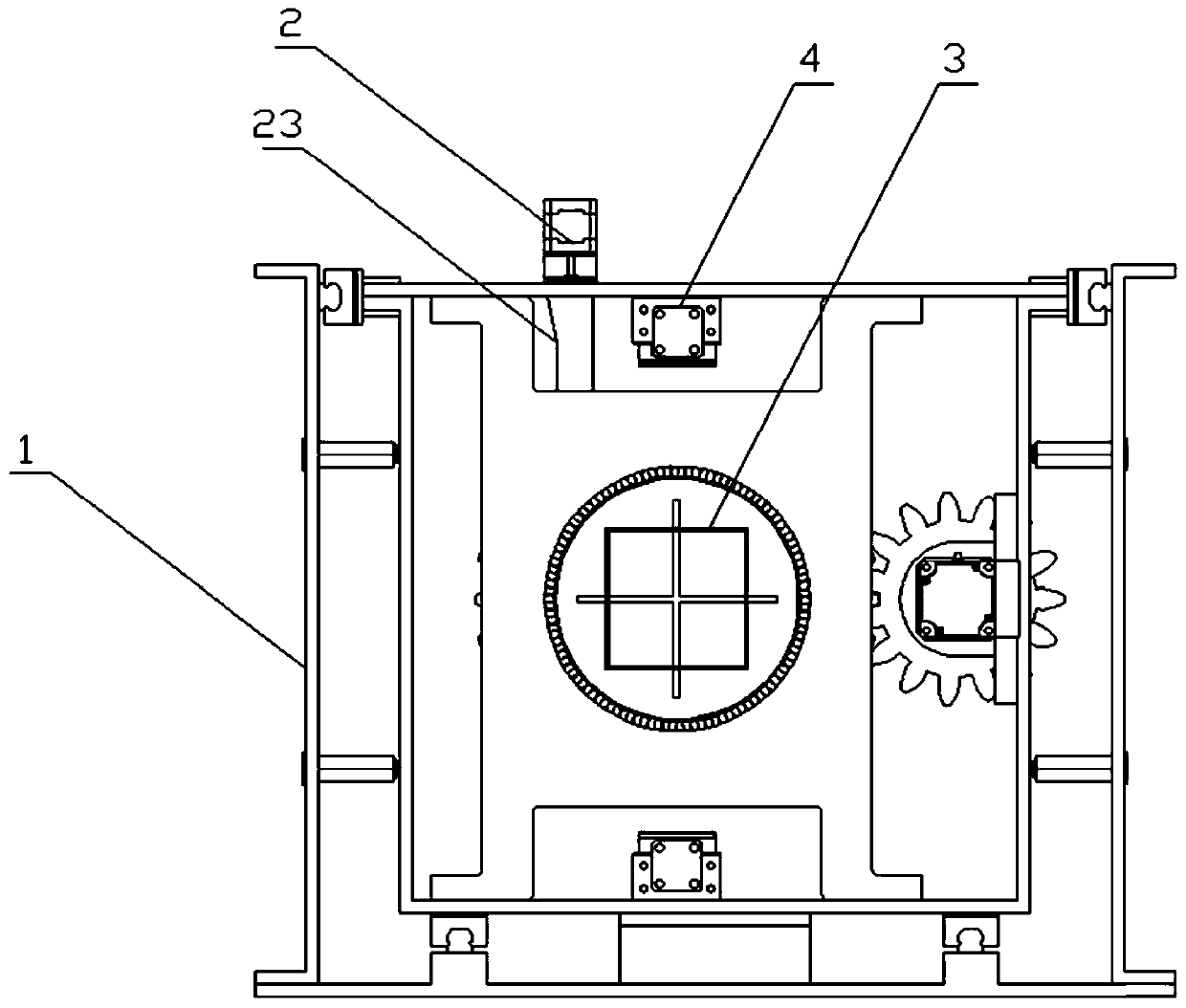

InactiveCN113492437AAutomatically arrange neatlyEasy to cleanMetal working apparatusPunchingGear wheel

The invention discloses a punching device for binding financial data. The punching device is composed of a lifting device, a transverse moving device, a longitudinal moving device, a punching mechanism, a supporting base, a paper feeding device, a cover plate and a base; through meshing connection between a gear and a gear groove, a movable plate moves in the direction of the gear groove and is used for adjusting the punching depth; a first screw rod is in threaded connection with a supporting plate and is used for adjusting the transverse punching direction; a second screw rod is in threaded connection with a connecting block, so that the position of the connecting block can be moved along the direction of the second screw rod, and the longitudinal punching direction can be adjusted; in order to keep the punching positions of the data to be the same, the paper feeding device is arranged, the size of the space below the cover plate can be adjusted through arranged compression springs, and the cover plate can fix the data conveniently; and according to the punching device, financial data can be automatically arranged and fixed, and meanwhile the punching depth and the punching position can be adjusted.

Owner:龚崇阳

Fish baking device

InactiveCN106550964AHigh degree of mechanizationSimple structureFish sortingOil/fat bakingCooking & bakingEngineering

The invention discloses a fish baking device. The fish baking device comprises a No. 1 baking machine, wherein the No.1 baking machine comprises a disc; a heating device is arranged at the bottom of the disc; a rotating shaft is arranged in the middle position of the disc in a penetrating manner; the rotating shaft can rotate along the own central axis of the rotating shaft under the action of a driving device; a cylinder is arranged at the top end of the rotating shaft; a plurality of heating plates are arranged at intervals in the circumferential direction of the cylinder; a No. 1 through groove is also formed in the bottom of the disc; a rotating barrel is arranged below the No. 1 through groove; spacers are arranged at intervals in the circumferential direction of the rotating barrel; a barrier board is arranged on the outer side of the spacers; the barrier board is mounted on a base; a No. 2 through groove for the falling of baked fish is formed in the upper end corresponding to the No. 1 through groove, of the barrier board; and a No. 3 through groove is formed in the lower end of the barrier board. The fish baking device disclosed by the invention is high in the degree of mechanization, simple in structure, convenient in movement, and particularly suitable for places such as a wharf where the device needs to be moved frequently; and the baked fish can be automatically and neatly arranged to enter a packaging device.

Owner:NINGBO ZHENHAI XIUYANG ADVERTISEMENT DECORATION

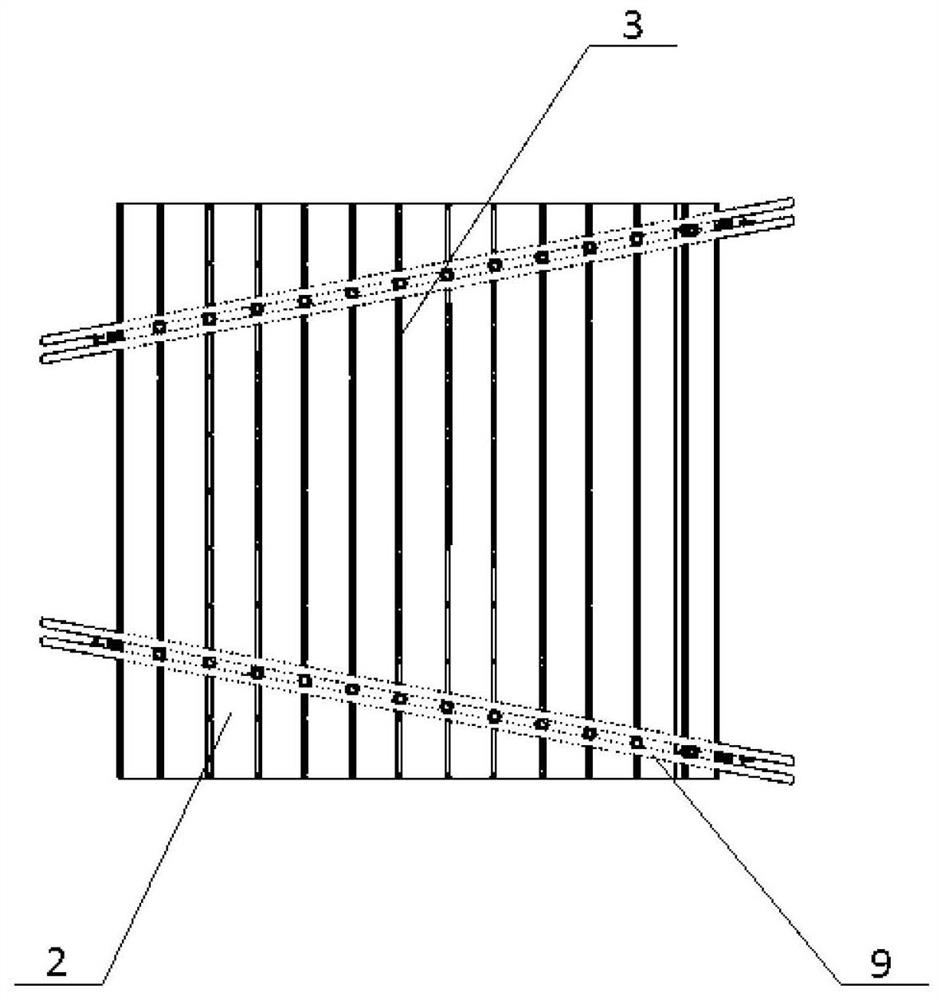

Material conveying device with material arranging function

PendingCN114524245ASimple structureReduce manufacturing costConveyorsConveyor partsEngineeringChain link

Owner:金嘉成(佛山)智能装备有限公司

a washing machine

InactiveCN103480621BAutomatically arrange neatlySave waterHollow article cleaningVegetable processingWater resources

The invention relates to vegetable processing machinery, in particular to a basket-washing machine. The basket-washing machine comprises a passageway. The passageway is internally provided with a conveying device and a water injector which is connected with a water pipe. A front drain port and a rear drain port are arranged under the conveying device, a front filter unit is matched with the front drain port and communicated with a drainage, a rear filter unit and a water tank are matched with the rear drain port, an input end of a water pump is communicated with the water tank, and an output end of the same is communicated with the water injector. The basket-washing machine takes the place of manual operation, working efficiency is improved, production cost is lowered, a basket can be washed clean thoroughly, washing water can be partially recycled, and water resources are saved.

Owner:山东龙升食品股份有限公司

Output collecting method for transformer clamping frames

Owner:DONGGUAN DAZHONG ELECTRONICS

A neatly transported photo frame shaping device

ActiveCN110040493BEasy to transportPrevent looseningConveyorsControl devices for conveyorsHydraulic cylinderDrive wheel

The invention discloses a photo frame shaping device capable of achieving orderly transportation. The photo frame shaping device comprises a shaping mechanism, a conveying mechanism and a placing box.The shaping mechanism comprises fixed clamping plates, a work table and movable clamping plates. A supporting plate is arranged below the work table in an inclined manner. Two same hydraulic cylinders are arranged on the supporting plate in the inclination direction. An unloading plate is arranged at the middle position of the work table. Piston rods of the hydraulic cylinders are fixedly connected with the lower surface of the unloading plate. The fixed clamping plates and the movable clamping plates are arranged on the periphery of the unloading plate. Grooves are formed in the portions, outside the movable clamping plates, on the work table. The conveying mechanism comprises a conveyor belt and detection devices. A driving wheel and a driven wheel of the conveyor belt are connected through transverse rods. The detection devices and a support are arranged on the transverse rods. Each detection device is located on the side closer to the placing box. A stepping motor and a pendulum bob are arranged on the middle portion of the support. Automatic and orderly transportation of photo frames is achieved, the work efficiency is improved, and the production cost is reduced.

Owner:QINGDAO SHOUSHENG IND

A strip cap rotary packaging device

ActiveCN110589077BReduce manufacturing costAvoid product qualityPackagingEngineeringStructural engineering

Owner:HUAZHONG UNIV OF SCI & TECH

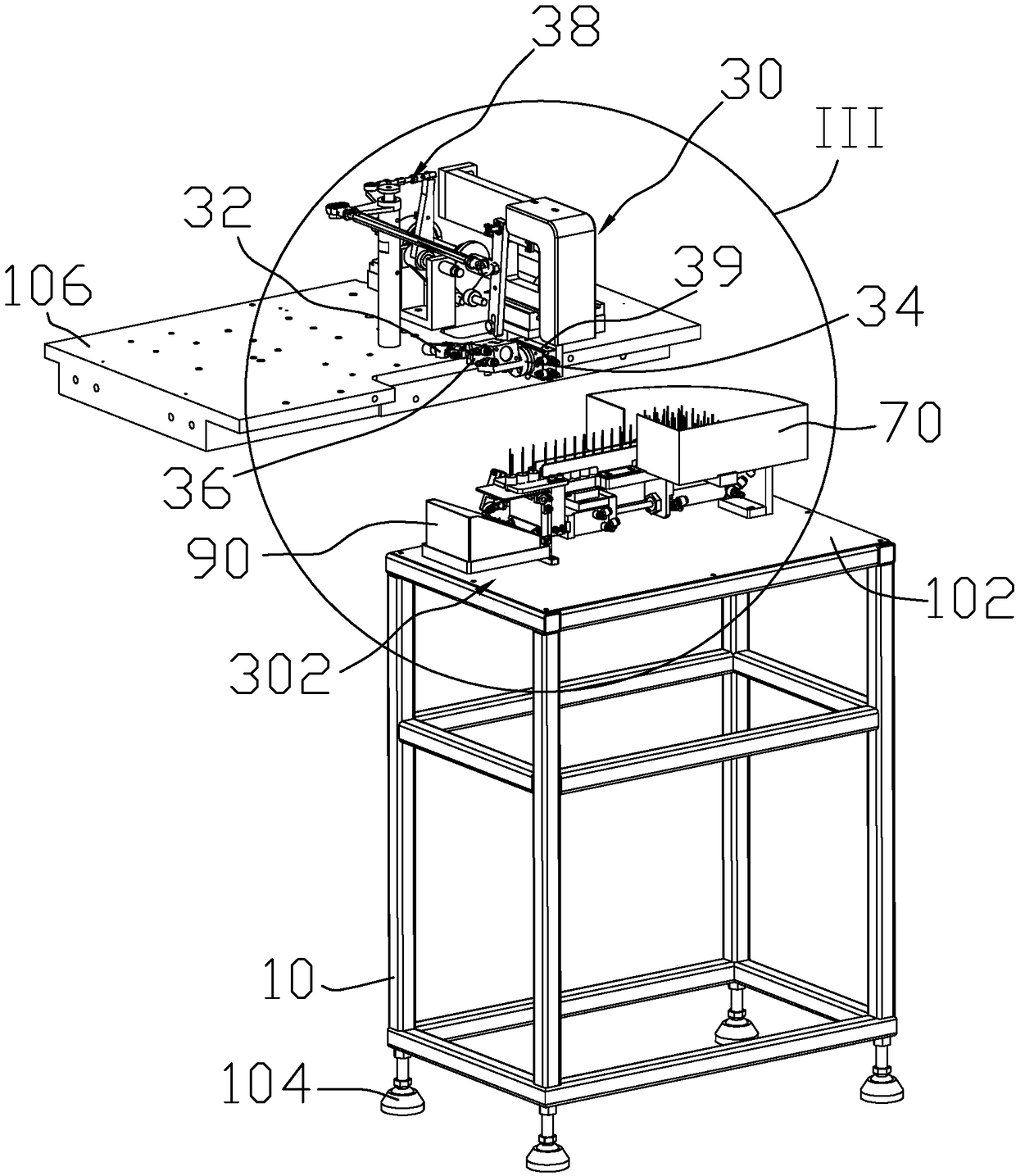

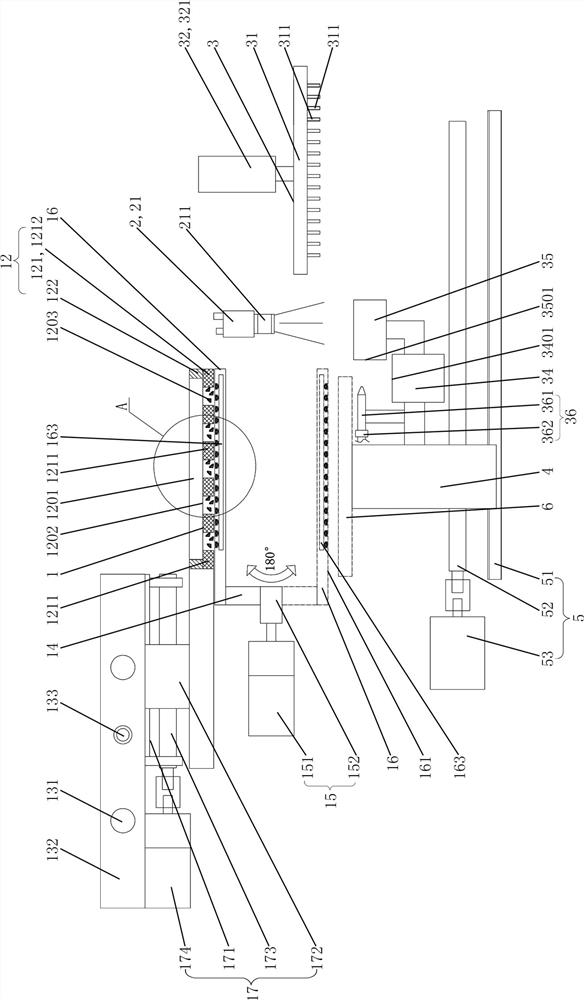

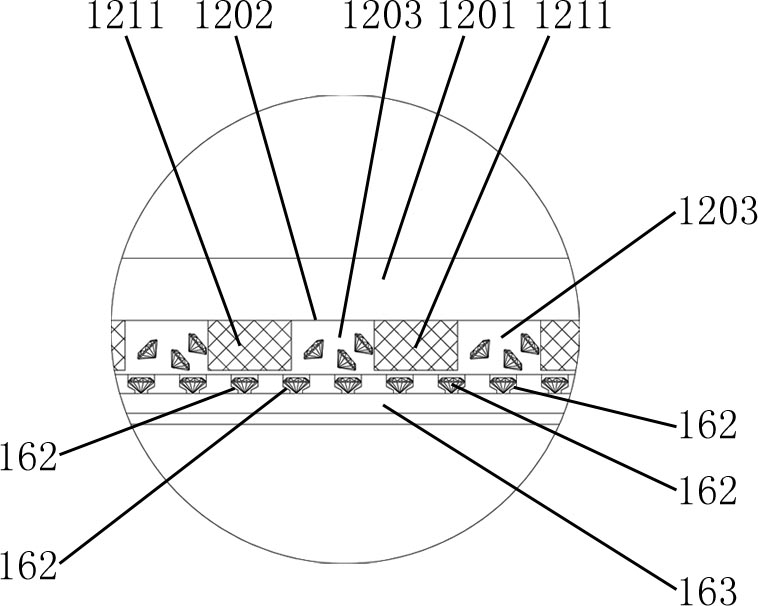

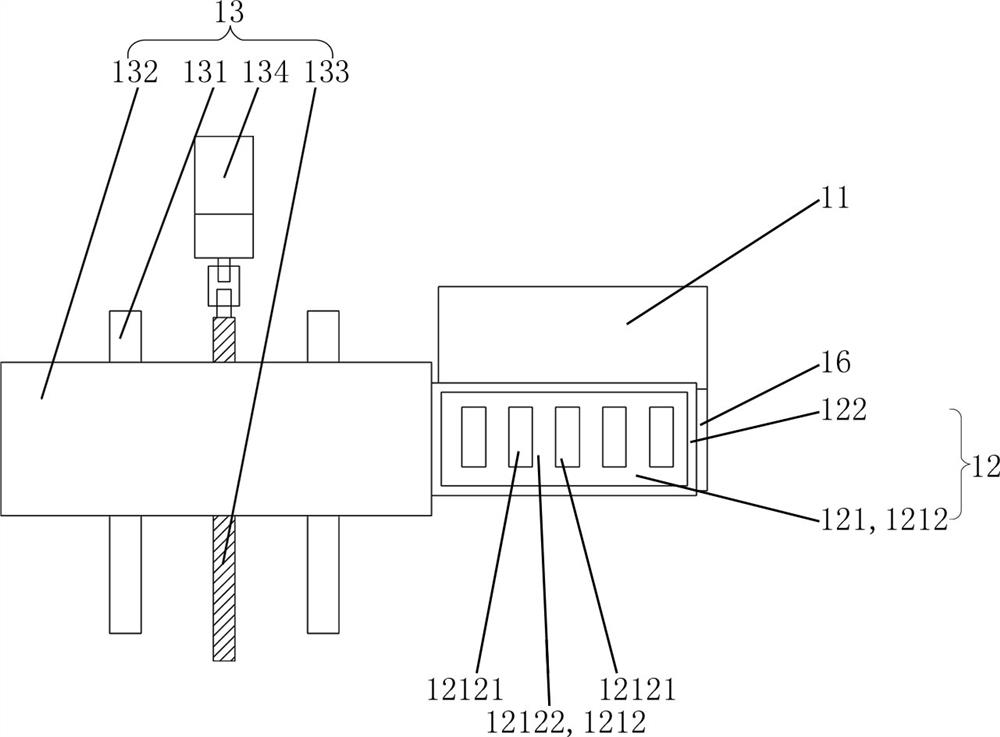

Automatic arranging and sorting machine for diamond-shaped products

An automatic arranging and sorting machine for diamond-shaped products comprises a rack, an automatic arranging device, a product detecting device, an automatic sorting device, a first translation seat, a front-back translation mechanism, a detecting platform and a control device. The automatic material arranging device comprises a material bearing plate, a material supplying and brushing device, a left-right translation mechanism, a rotating seat and a rotating mechanism, the material supplying and brushing device is provided with a material accumulating cavity, and the bottom of the material supplying and brushing device is provided with a material outlet and a material brushing mechanism; at least one overturning plate is installed on the rotating seat, a plurality of product containing grooves are formed in the first surface of the overturning plate, and a negative pressure cavity is formed in the overturning plate; when the overturning plate is overturned to the upper portion, the first surface of the overturning plate and the top face of the material bearing plate are connected and located on the same plane, and when the overturning plate is overturned to the lower portion, the first surface of the overturning plate is matched with the table top of the detection platform. According to the automatic material arranging device in the automatic diamond-shaped product arranging and sorting machine, small-particle diamond-shaped products can be arranged in order in the direction that the tips face upwards, the working efficiency can be improved, and the detection result can be guaranteed.

Owner:汕头翼能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com