Tobacco leaf carding device

A technology of tobacco leaves and a transmission device, which is applied in the directions of tobacco, tobacco preparation, application, etc., can solve problems such as irregular arrangement of tobacco leaves, and achieve the effects of being beneficial to coding and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

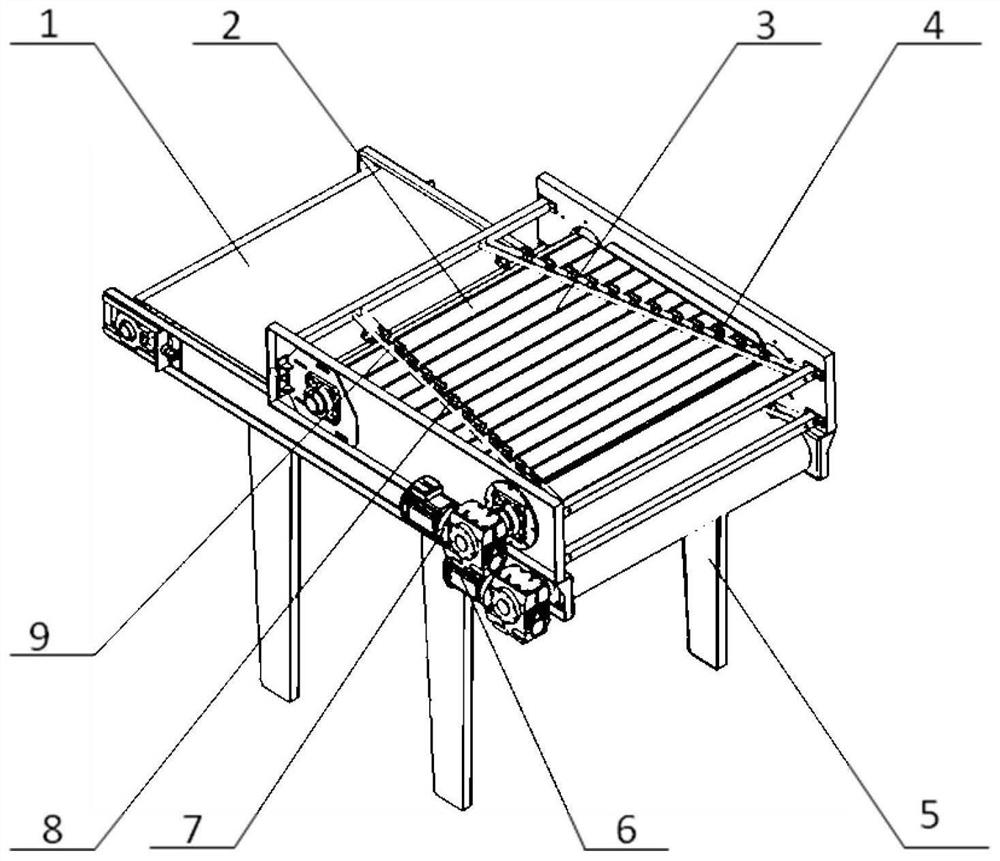

[0030] Figure 1-3 A preferred embodiment of the present invention is shown. like figure 1 As shown, a tobacco leaf carding device disclosed in the present invention includes:

[0031] The first conveying device includes a first conveying belt 1 and a first conveying belt driving device 6; the second conveying device includes a second conveying belt 2 and a second conveying belt driving device 7, and the second conveying device is arranged at the first Above the conveyor. The continuous operation of the tobacco leaf carding device is achieved by the continuous operation of the second conveyor belt 2 .

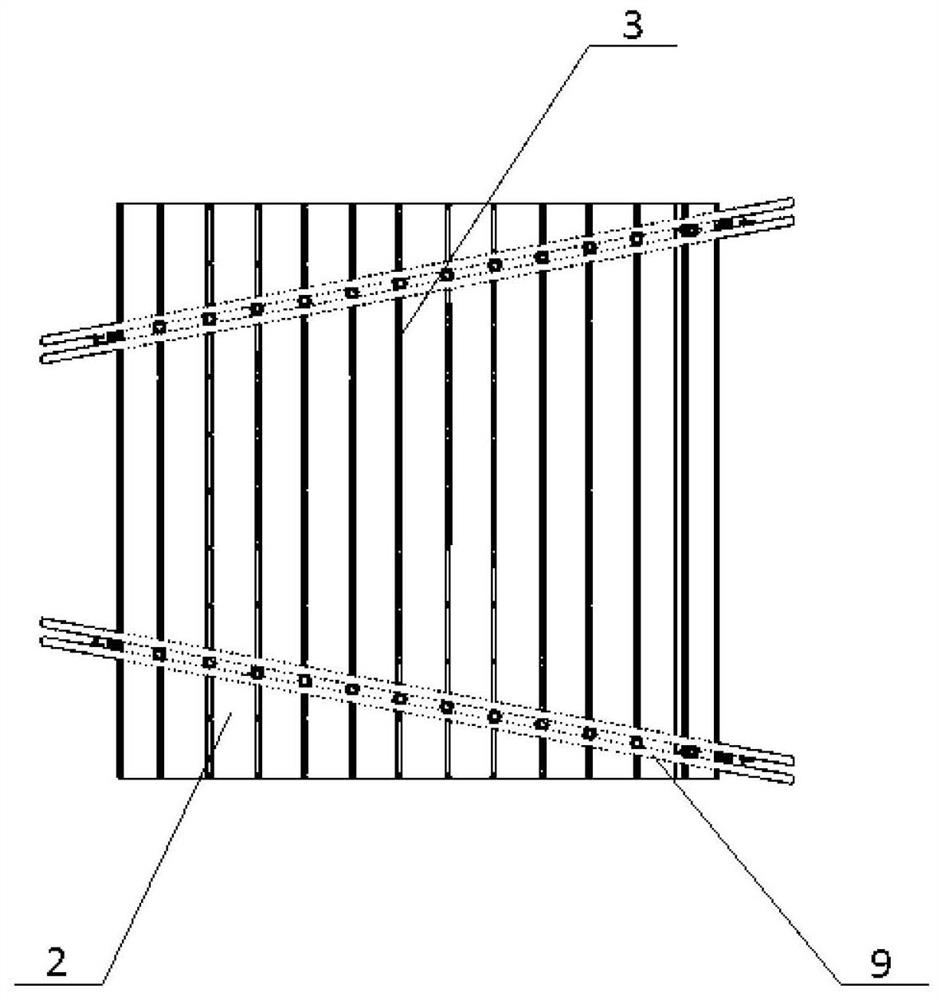

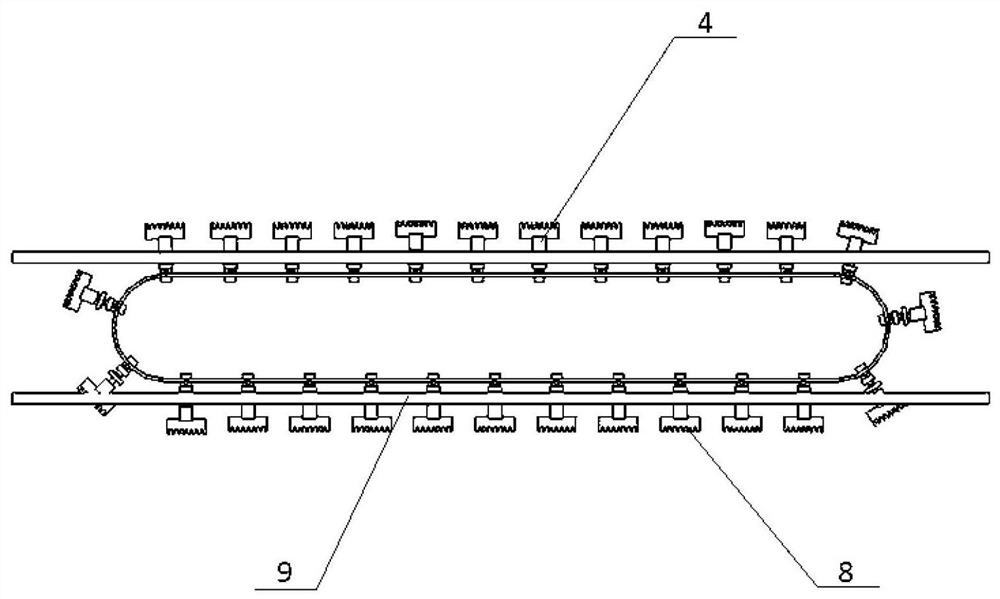

[0032] The second transmission device is provided with a guide rail slider mechanism and a slider guide rod 9. The guide rail slider mechanism includes a guide rail 3 and a slider 4 that can slide along the guide rail. The guide rail moves cyclically with the second conveyor belt 2. , the slider guide rod 9 is used to limit the displacement of the slider 4 on the guide rail...

Embodiment 2

[0035] On the basis of Embodiment 1, Embodiment 2 also includes the following technical solutions:

[0036] When the comb-shaped pressing plate 8 runs under the second conveyor belt 2, the distance between the comb-shaped pressing plate 8 and the first conveyor belt 1 is less than or equal to the thickness of the tobacco stems.

[0037] The first transfer device and the second transfer device are arranged in parallel and transfer synchronously.

[0038] The second conveyor belt 2 is provided with a plurality of guide rail and slider mechanisms that are arranged side by side and equally spaced. The guide rails 3 are fixed on the second conveyor belt 2 and circulate with the second conveyor belt 2 .

[0039] The slider guide rods 9 fixed on the frame 5 are respectively arranged above and below the second conveyor belt 2, and the slider guide rods 9 are used to limit the displacement of the slider 4, so that the slider 4 is in the second position. The bottom of the conveyor belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com