Automatic wire-stripping machine for general cables

A technology of automatic wire stripping and wire stripping mechanism, which is applied in the direction of dismantling/armored cable equipment, etc., to achieve the effect of fast speed, safe and convenient operation, and accurate cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

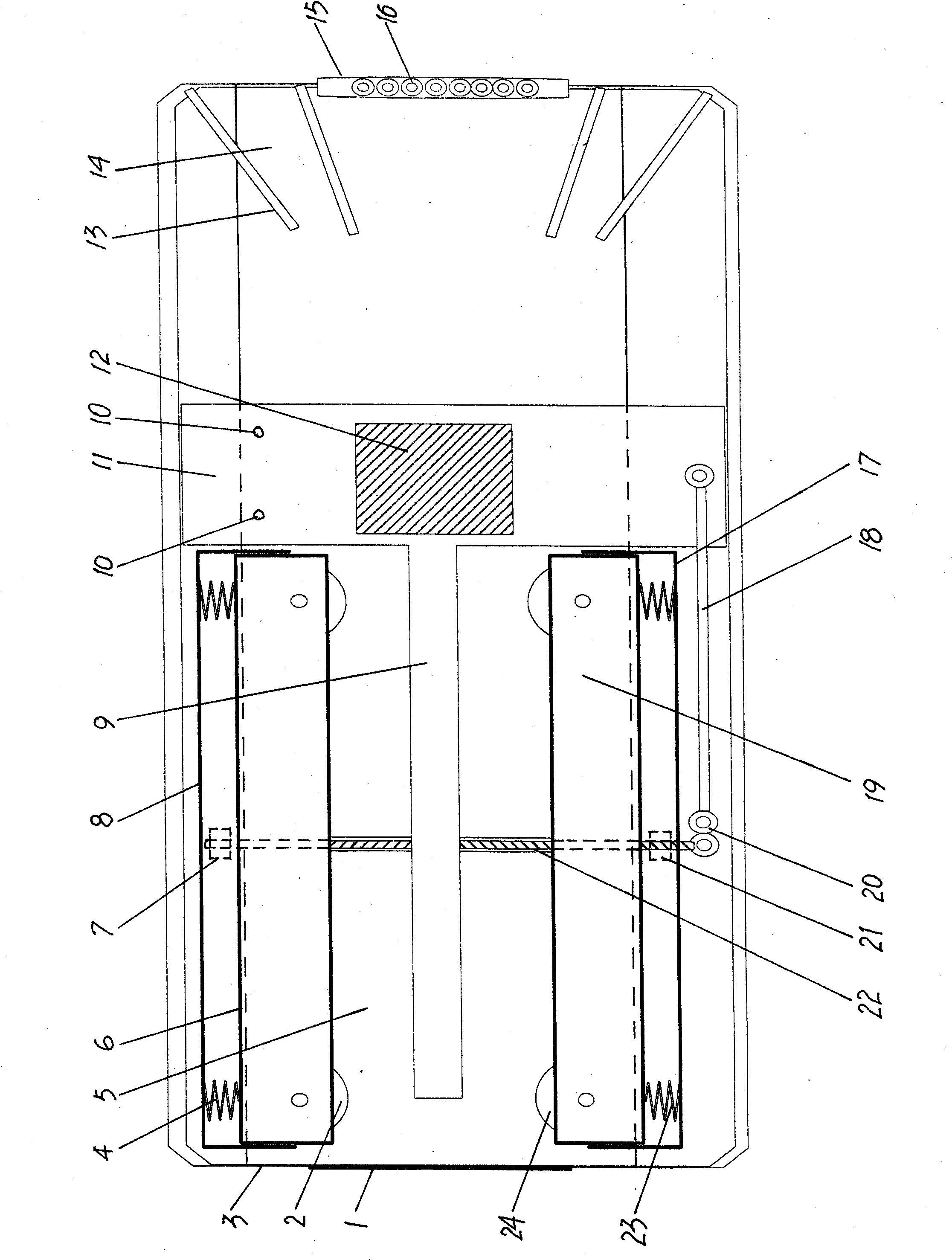

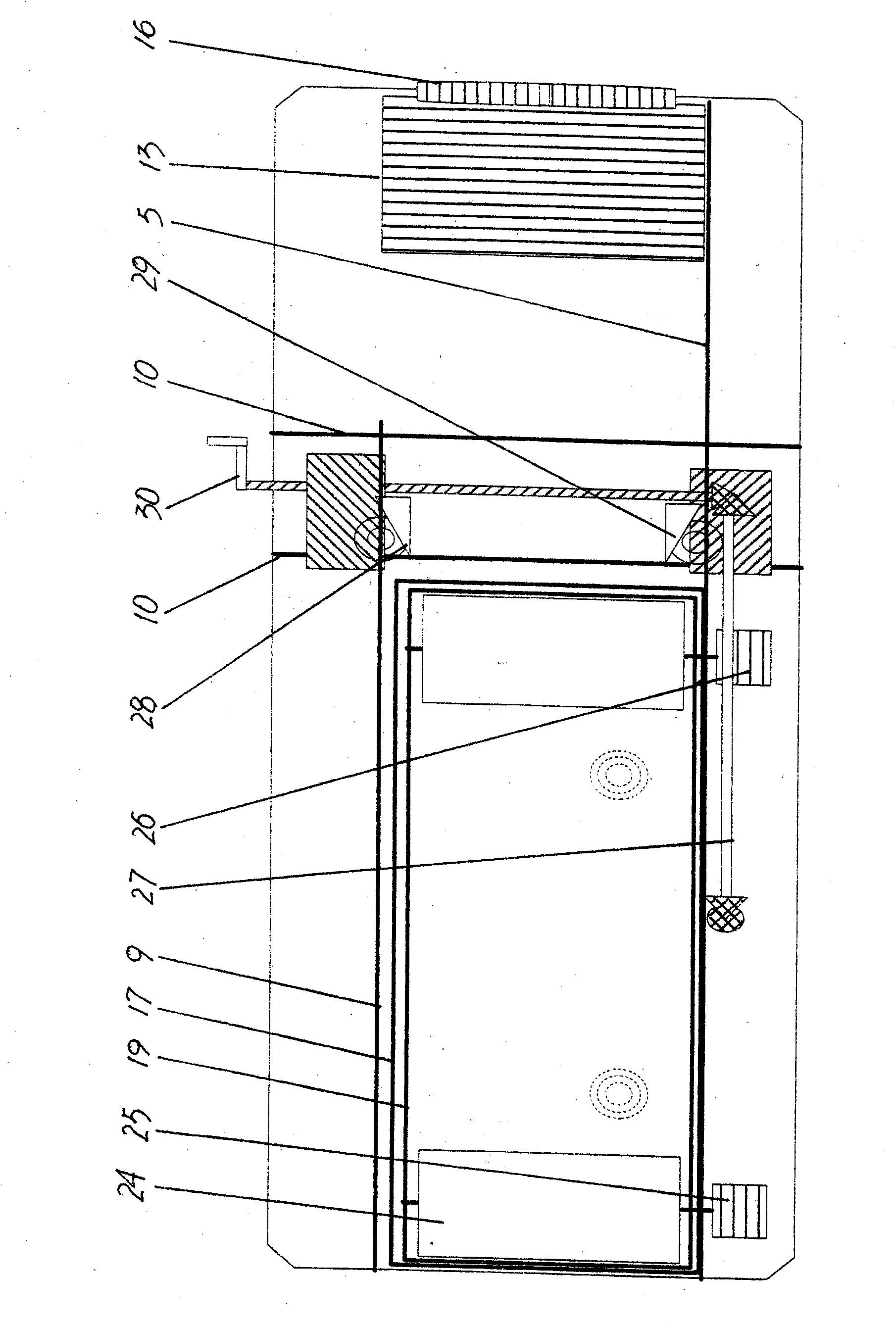

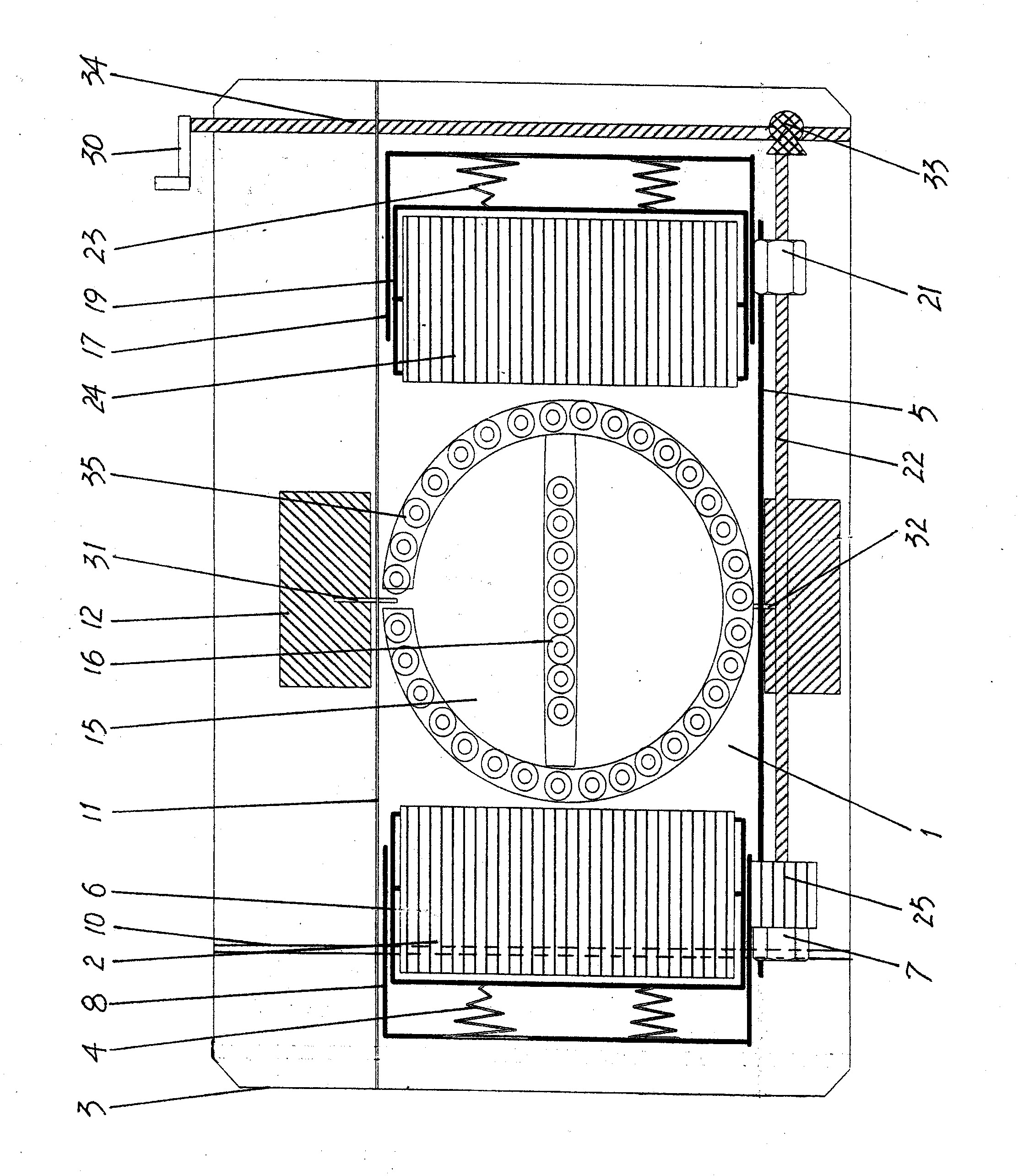

[0013] as attached figure 1 , 2 , 3, the device is mainly composed of a box body 3, a wire crimping mechanism, a cutting and stripping mechanism, an adjustment mechanism, a wire management mechanism and an electric control part. The box body 3 is rectangular, and the wire inlet 1 and the wire outlet 15 are respectively set On the end faces of the two ends of the box body 3, the crimping mechanism is located inside the wire inlet 1, and there are two corresponding platen boxes 6 and 19, two pairs of crimping rollers 2, 24, a wire feeder motor 25, and a wire withdrawal motor 26. The main supporting plate 5 and the upper pressing plate 9 are composed. The main supporting plate 5 is set at the lower part of the box body 3 and fixed at both ends of the box body 3; two pressing plate boxes 6 and 19 are symmetrically arranged on both sides of the inlet 1; Press plate box 6,19 backs are respectively provided with an outer press plate box 8,17, and adjustment spring 4,23 one ends are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com