Patents

Literature

40results about How to "Improve strip quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

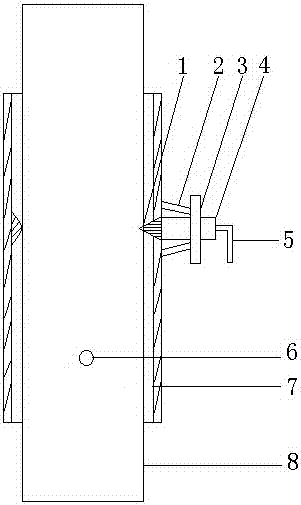

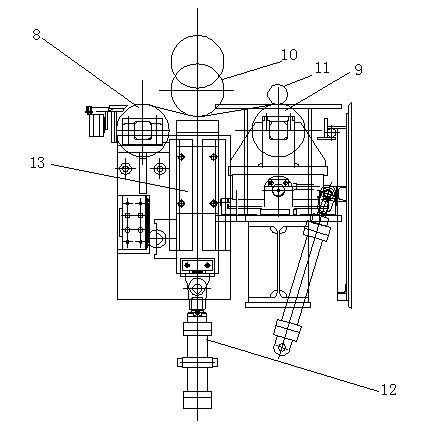

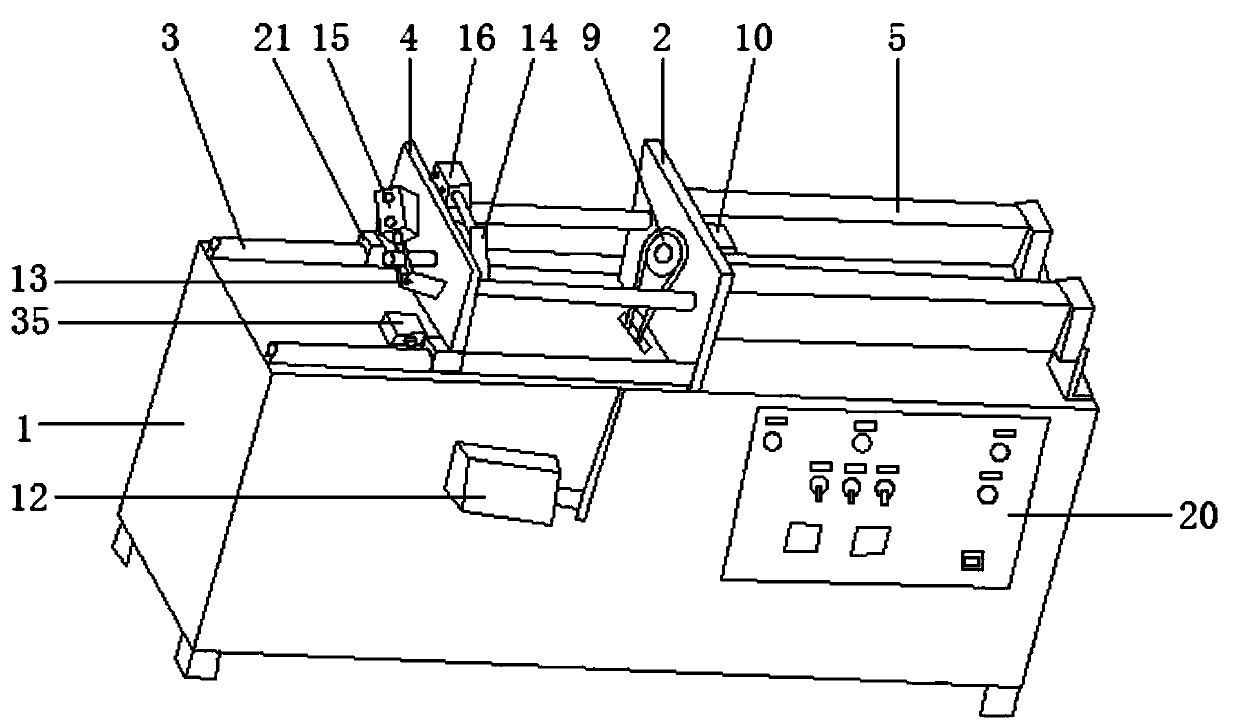

Vehicle wire harness girdling and peeling device

InactiveCN106229899AAchieve orientationNo guidance requiredApparatus for removing/armouring cablesCouplingEngineering

The invention relates to a vehicle wire harness girdling and peeling device which comprises a first support plate. Two moving lugs are respectively arranged on the side wall of the first support plate, and a movable screw is arranged between the two moving lugs through a bearing. A moving motor is arranged on the right end of the movable screw through a coupling, and the moving motor is arranged on a motor bracket. A moving block is arranged on the central section of the movable screw through threads, the upper and lower ends of the moving block are symmetrically provided with two moving slide bars, and the two moving slide bars are respectively mounted on two first linear slide rails. The two ends of each first linear slide rail is mounted on the side wall of the first support plate through screws. Four fixing posts are symmetrically welded on the side wall of the moving block, and a mounting plate is welded on the tail end of the four fixing posts. A wire peeling mechanism is arranged on the left side of the side wall of the mounting plate, and a girdling mechanism is arranged on the right side of the side wall of the mounting plate. Integrated processing function of automatically girdling and wire-peeling can be realized during vehicle wire harness processing.

Owner:YJH ELECTRICAL EQUIP

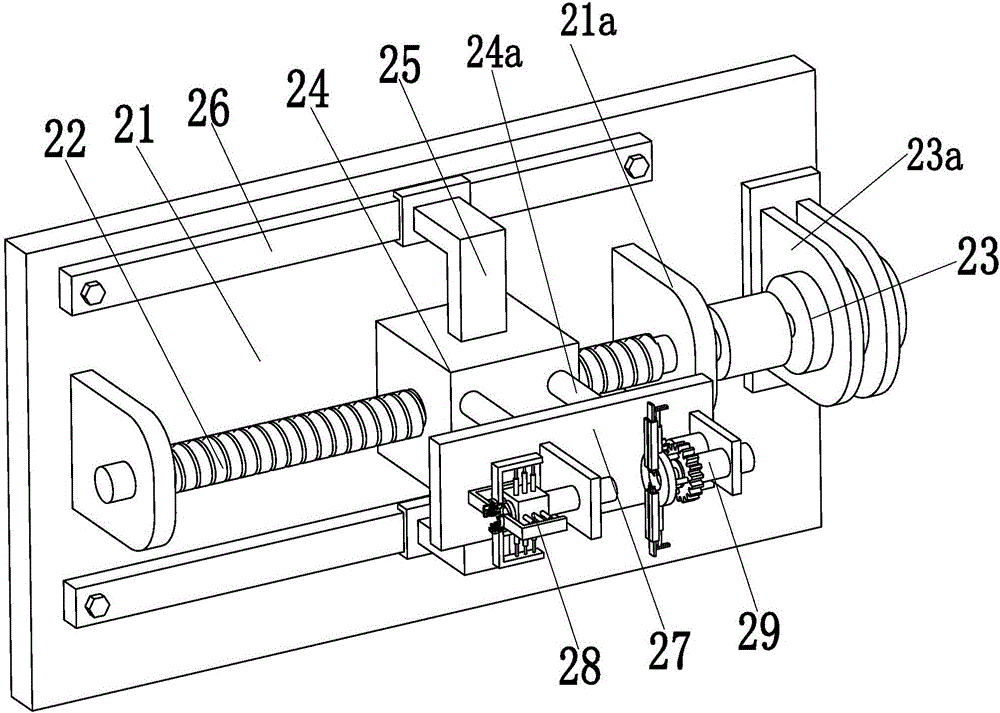

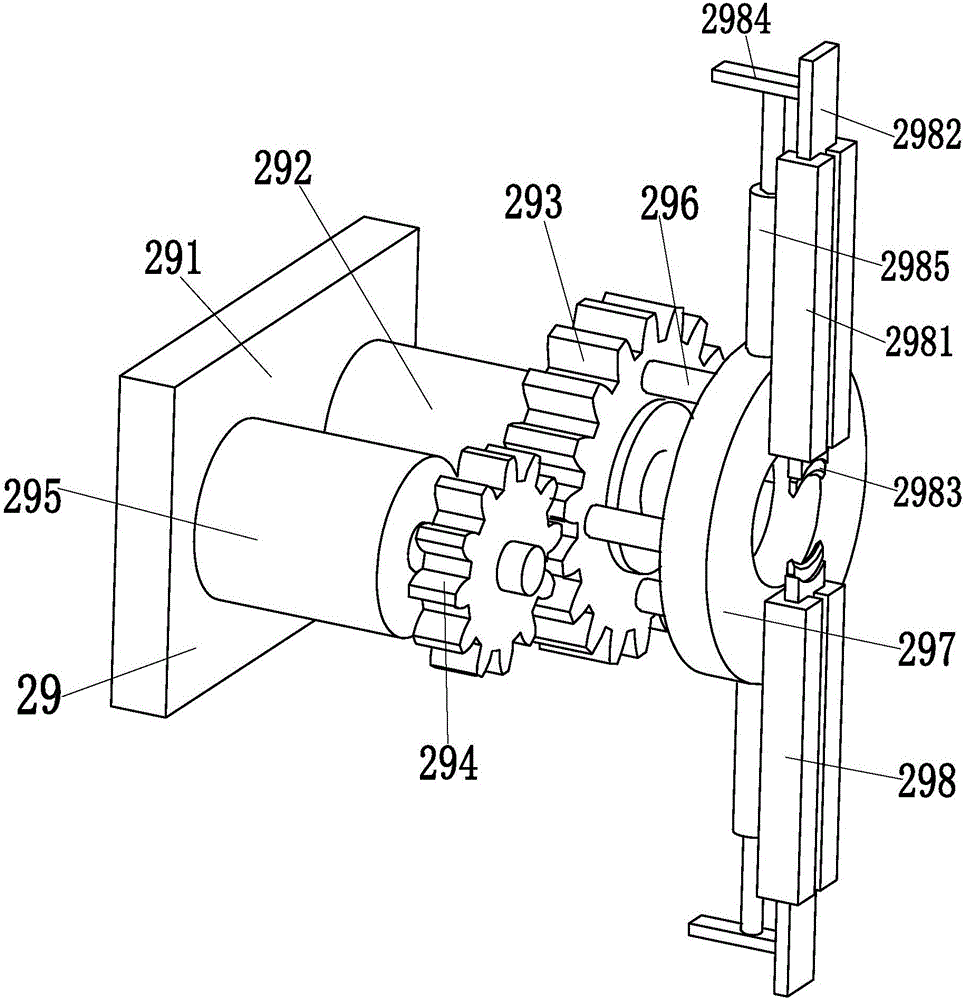

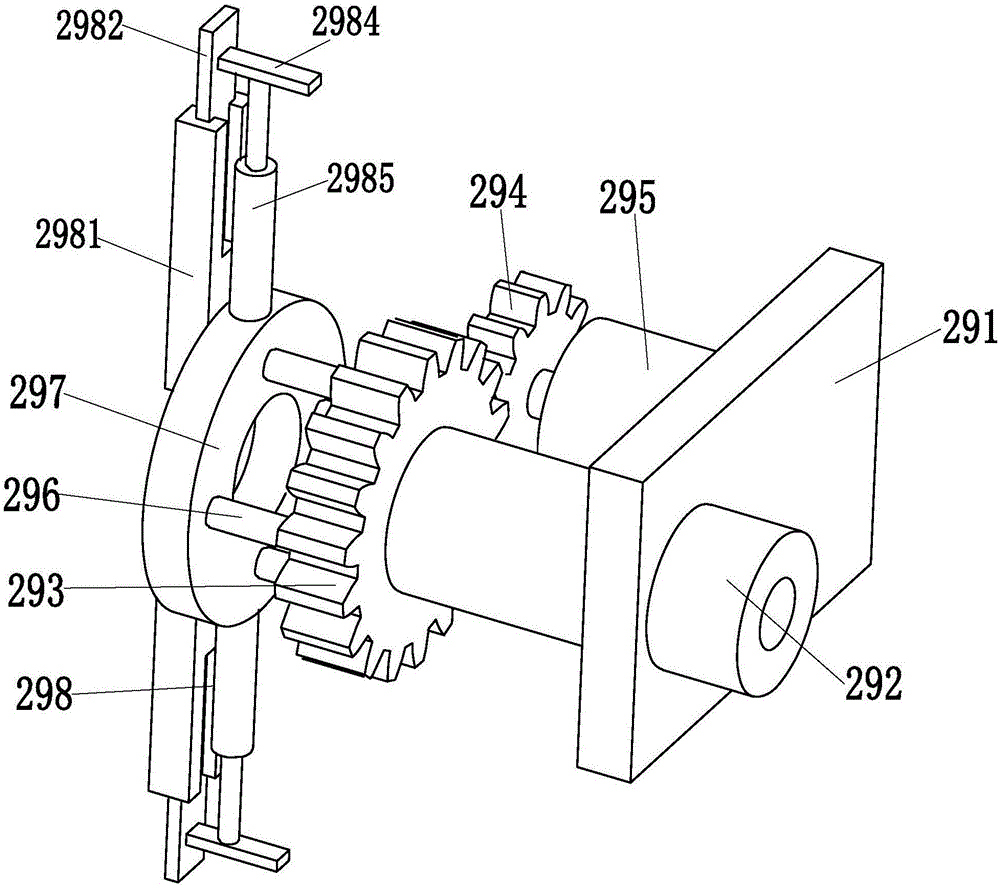

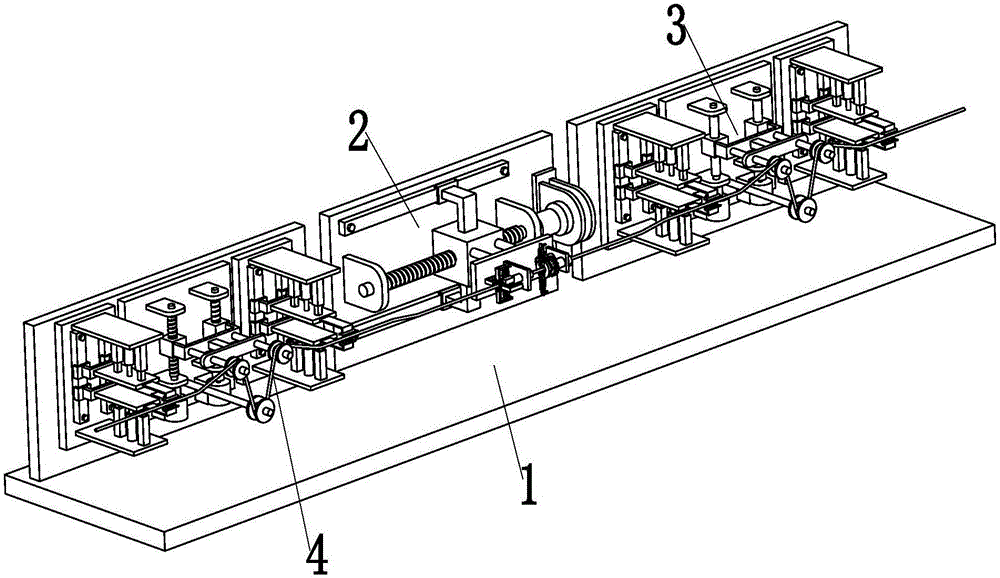

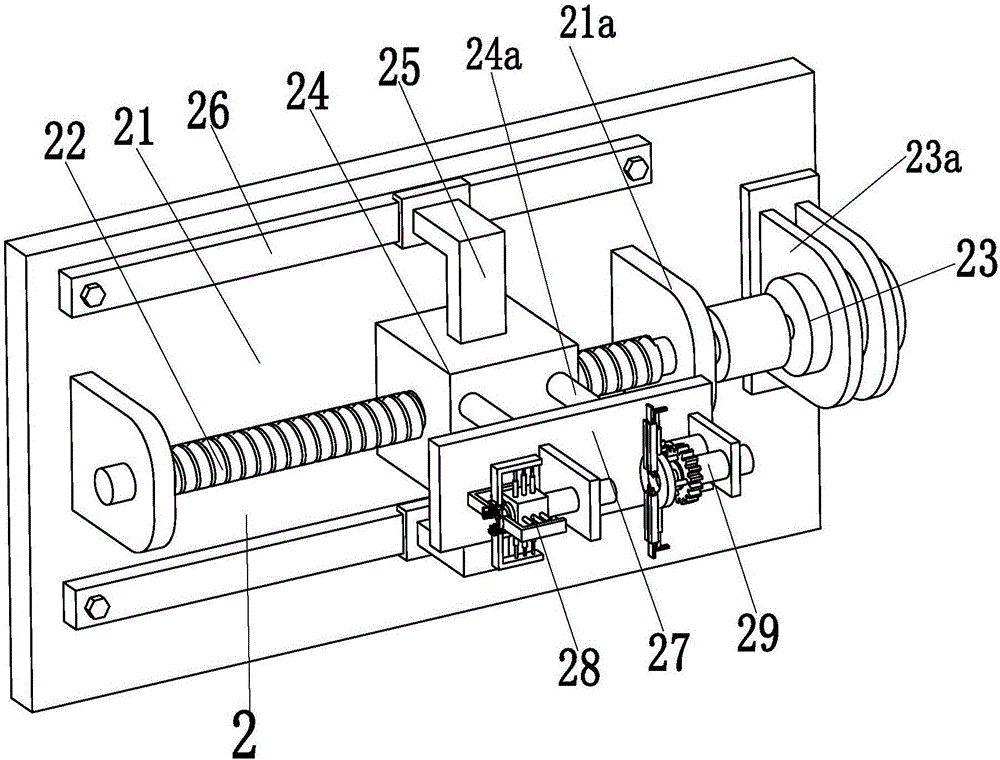

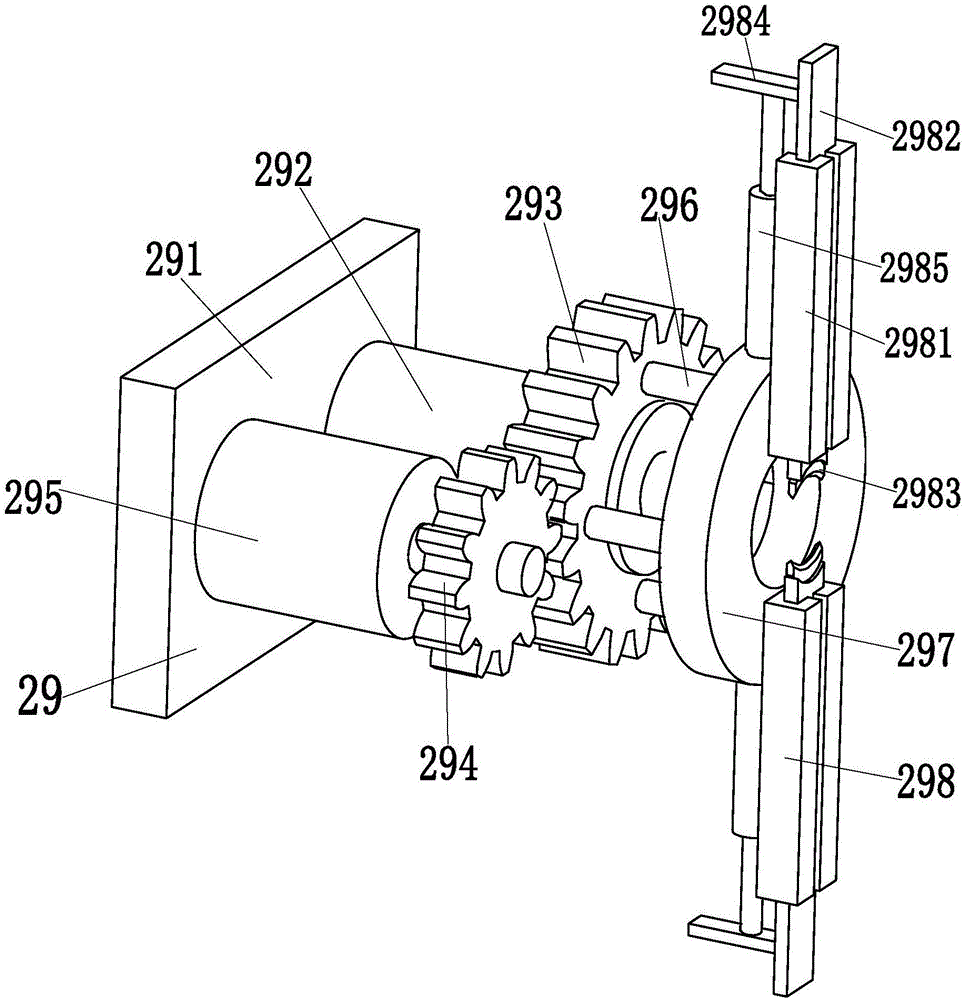

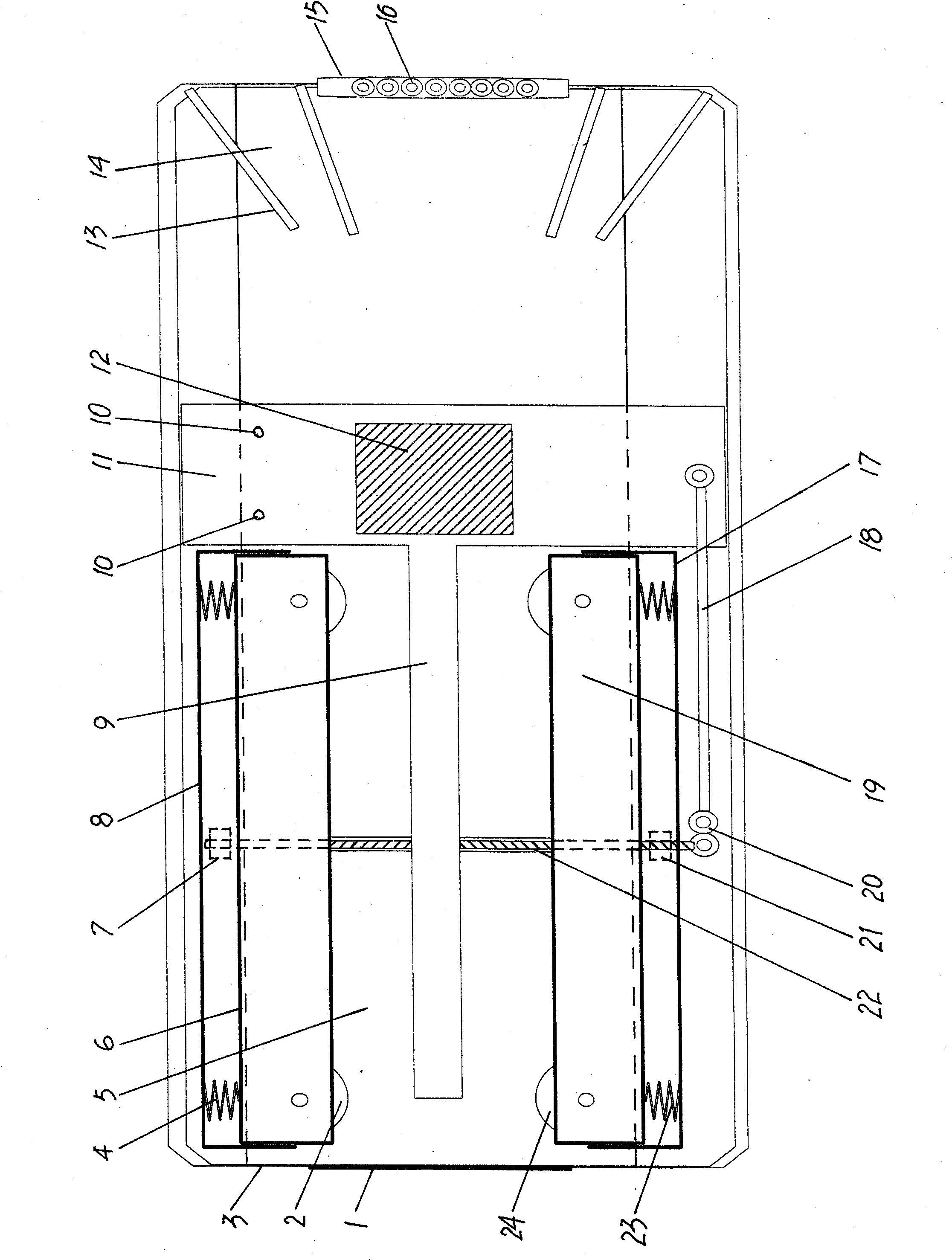

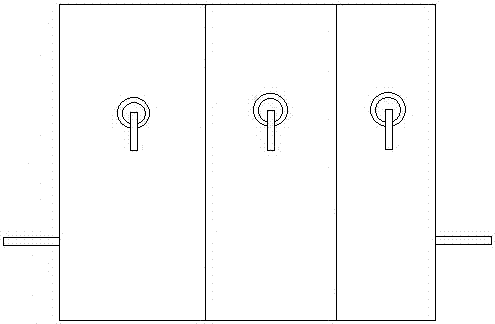

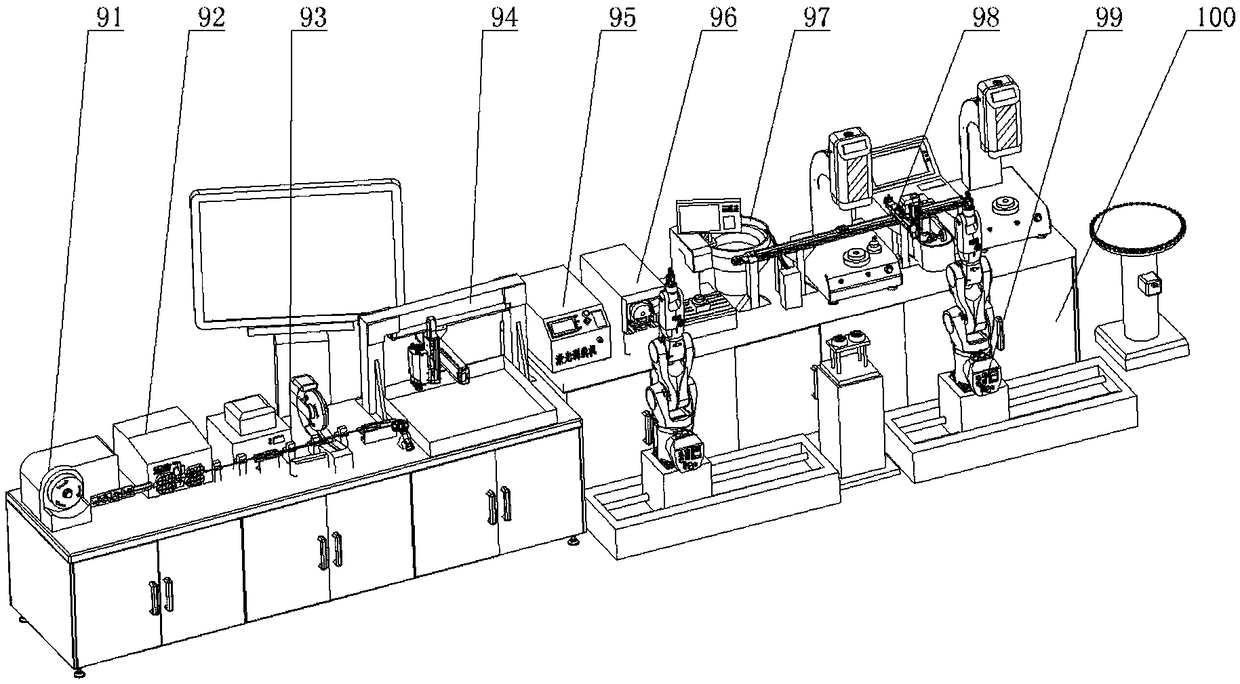

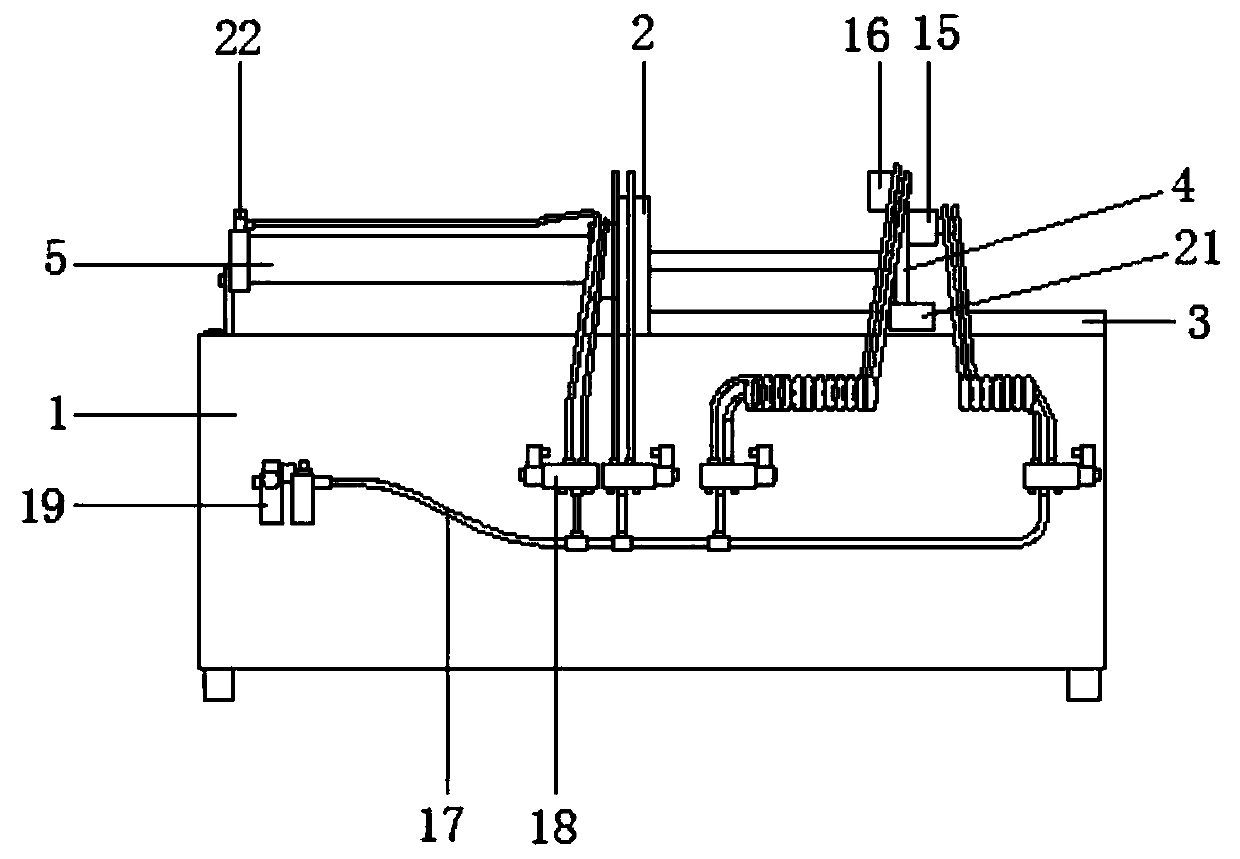

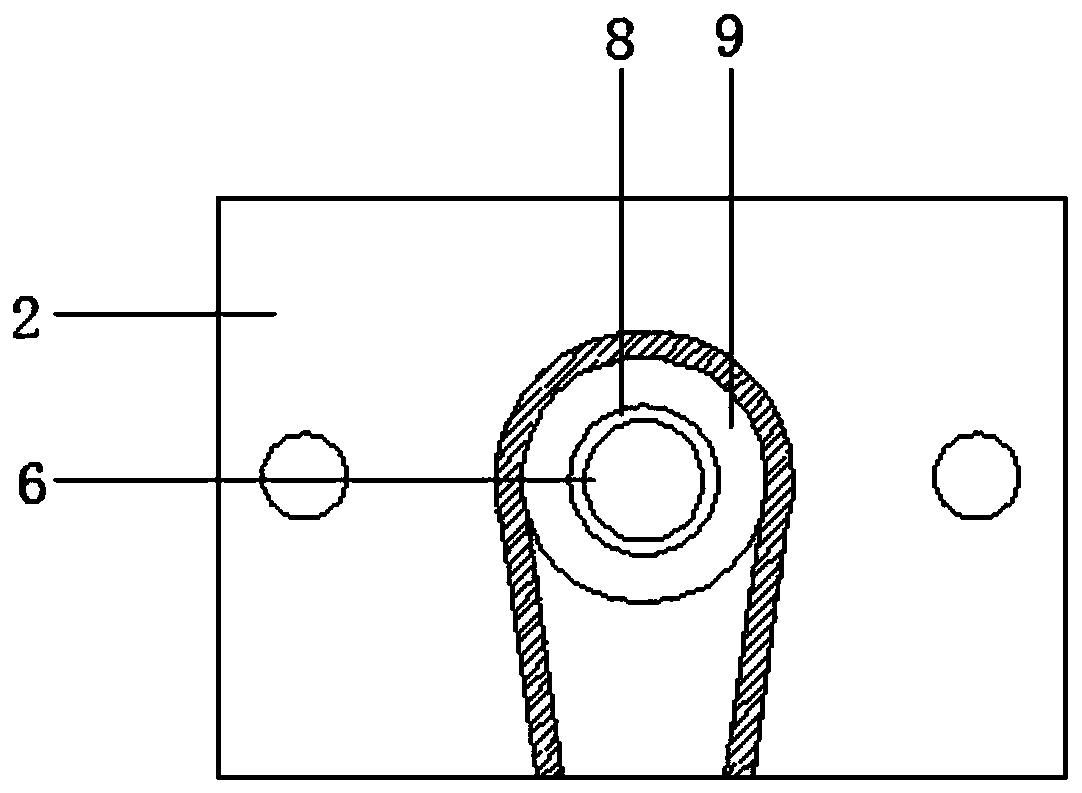

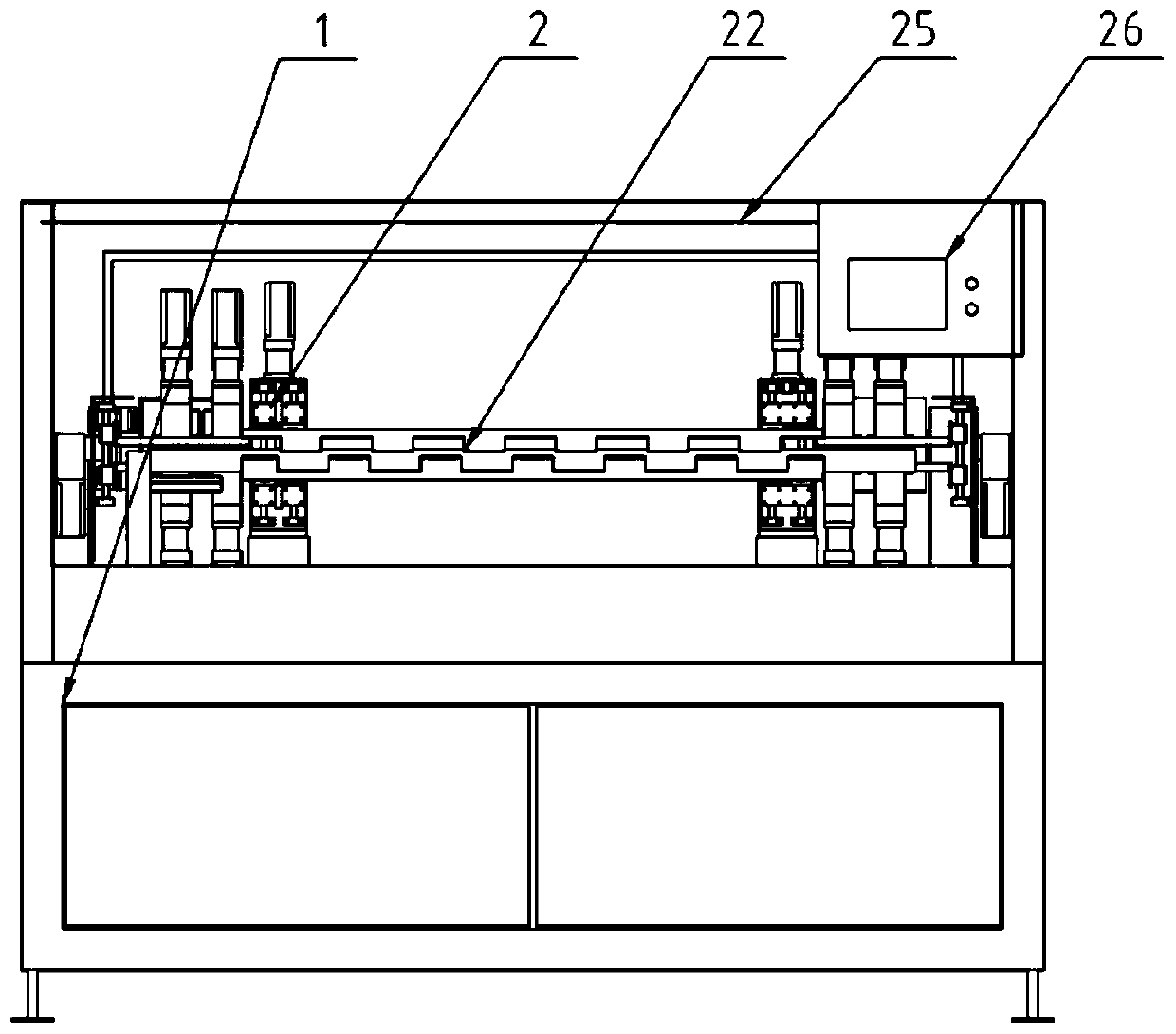

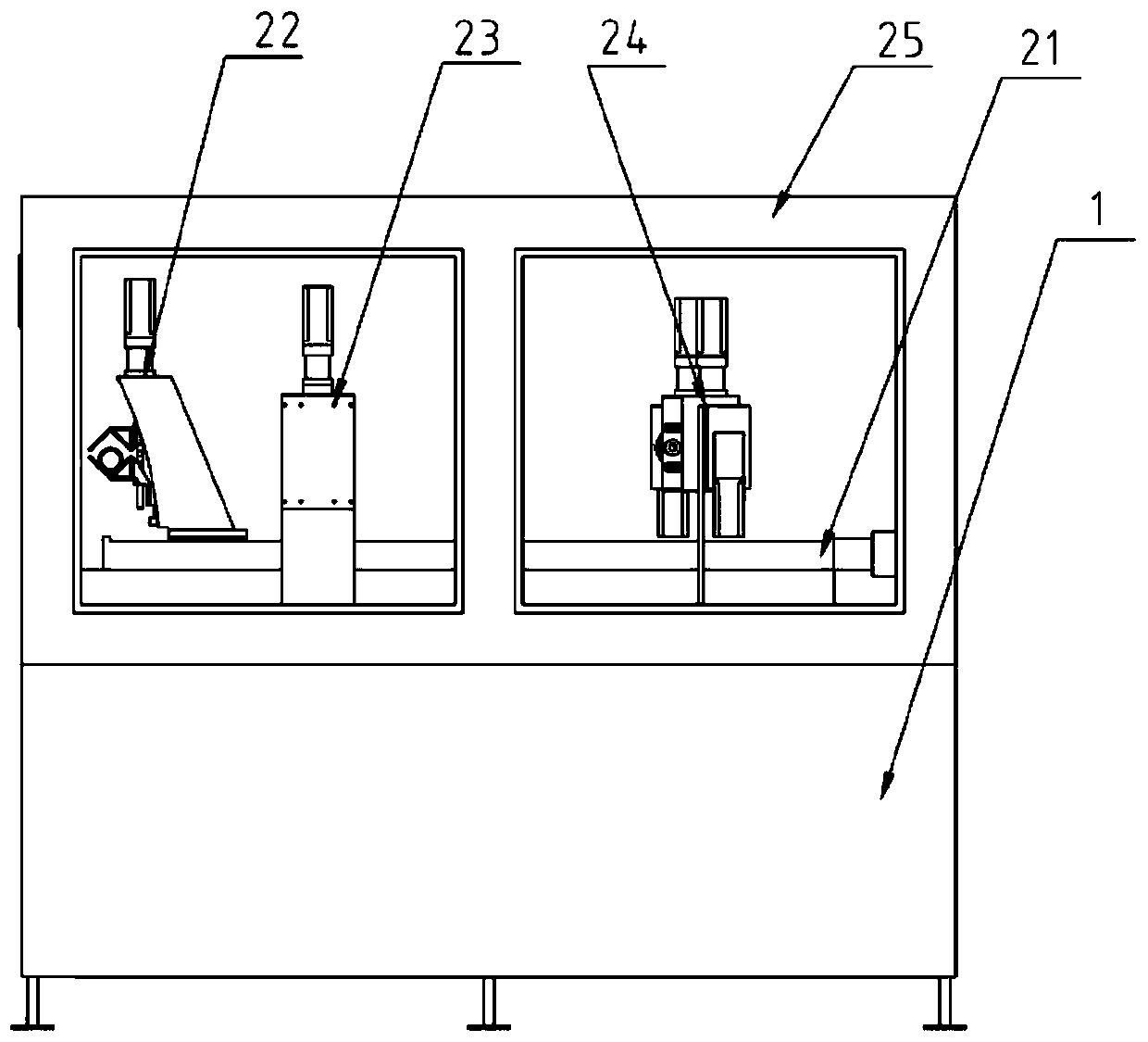

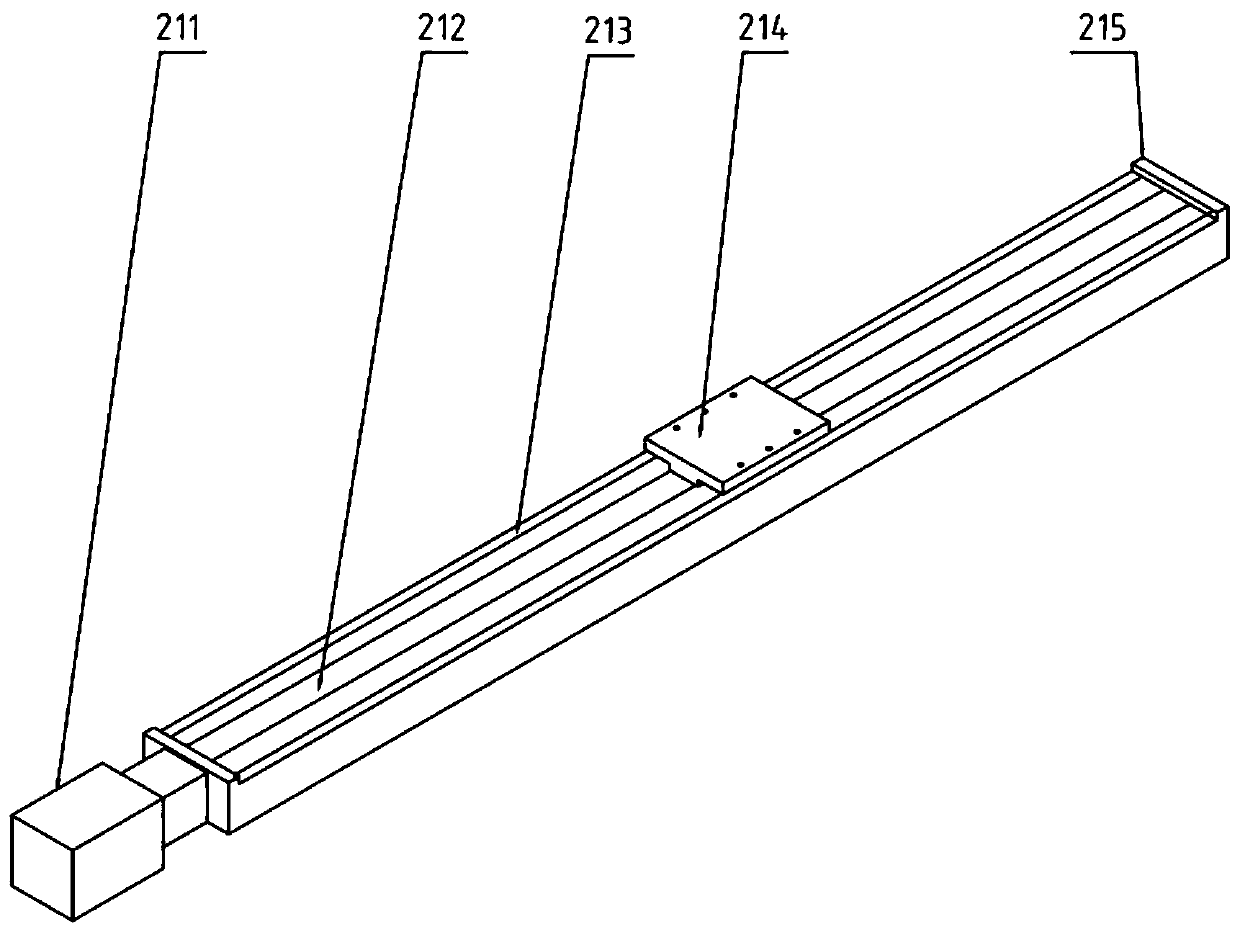

Vehicle wire harness full-automatic processing device

InactiveCN106129779AGood clamping effectFast and even automatic strippingVehicle connectorsLine/current collector detailsAutomatic processingCable harness

The invention relates to a fully automatic processing equipment for vehicle wire harnesses, comprising a base plate and a wire harness body, a ring cutting and stripping device is installed in the middle of the upper end surface of the base plate, and two clamping and tensioning devices are symmetrically installed on both sides of the upper end surface of the base plate; the wire harness body The two ends of the wire harness are passed through two clamping and tensioning devices respectively, and the middle part of the wire harness body is passed through the ring cutting and stripping device. The ring cutting and stripping device can realize the automatic ring cutting and wire stripping function during the processing of the wire harness body. The tensioning device can realize the automatic tensioning and clamping functions during the processing of the wire harness body. The invention can realize the integrated processing functions of automatic tensioning, clamping, ring cutting and wire stripping during the processing of vehicle wire harness, without manual operation, manual ring cutting, manual stripping, manual adjustment of tension force, and manual adjustment The clamping force has the advantages of good automatic ring cutting effect, good wire stripping quality, high wire stripping efficiency, good tension adjustment performance, good tension adjustment effect, poor clamping effect and high work efficiency.

Owner:YJH ELECTRICAL EQUIP

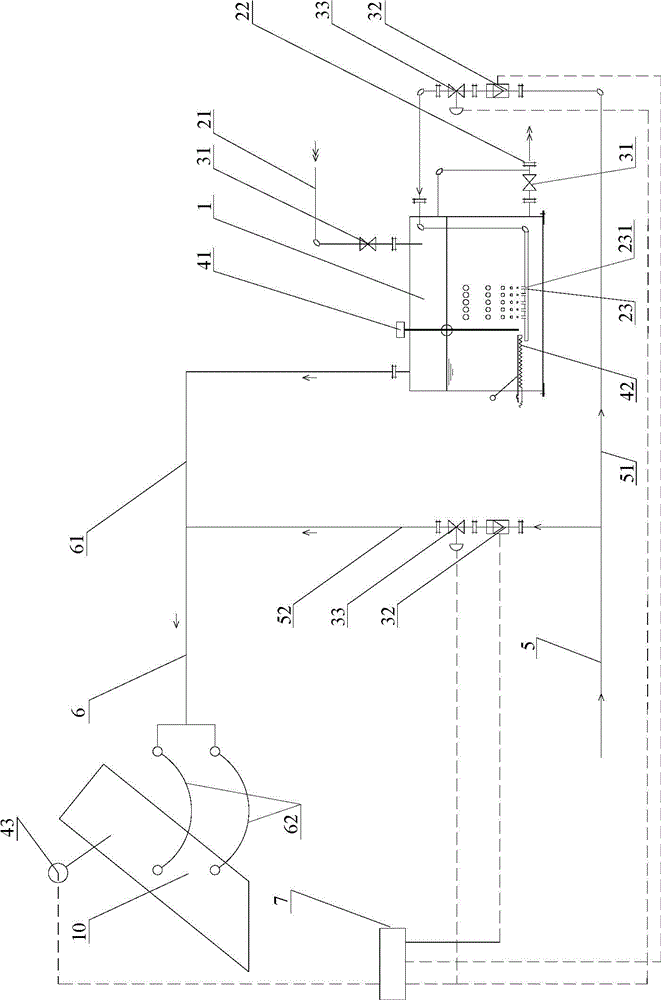

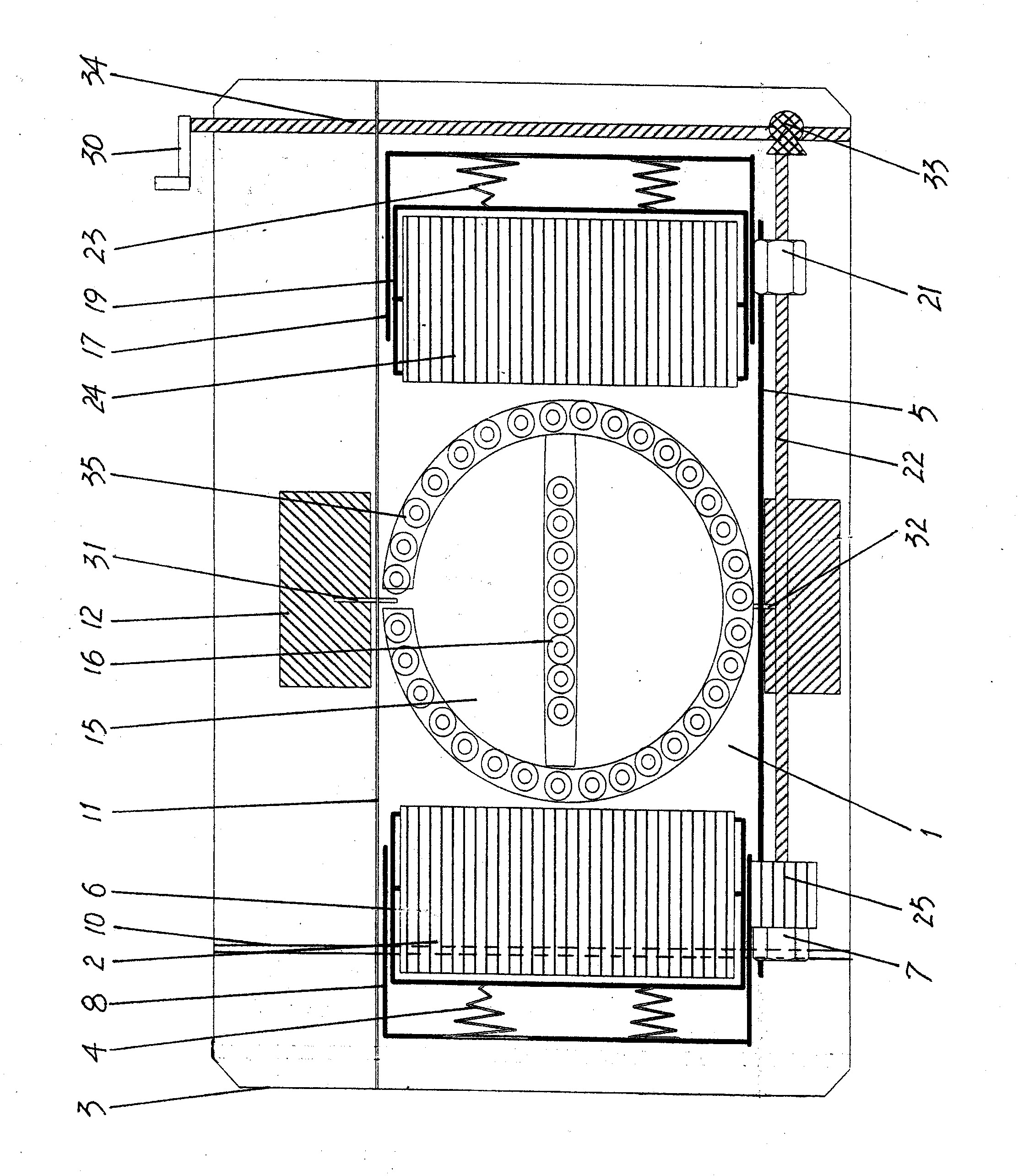

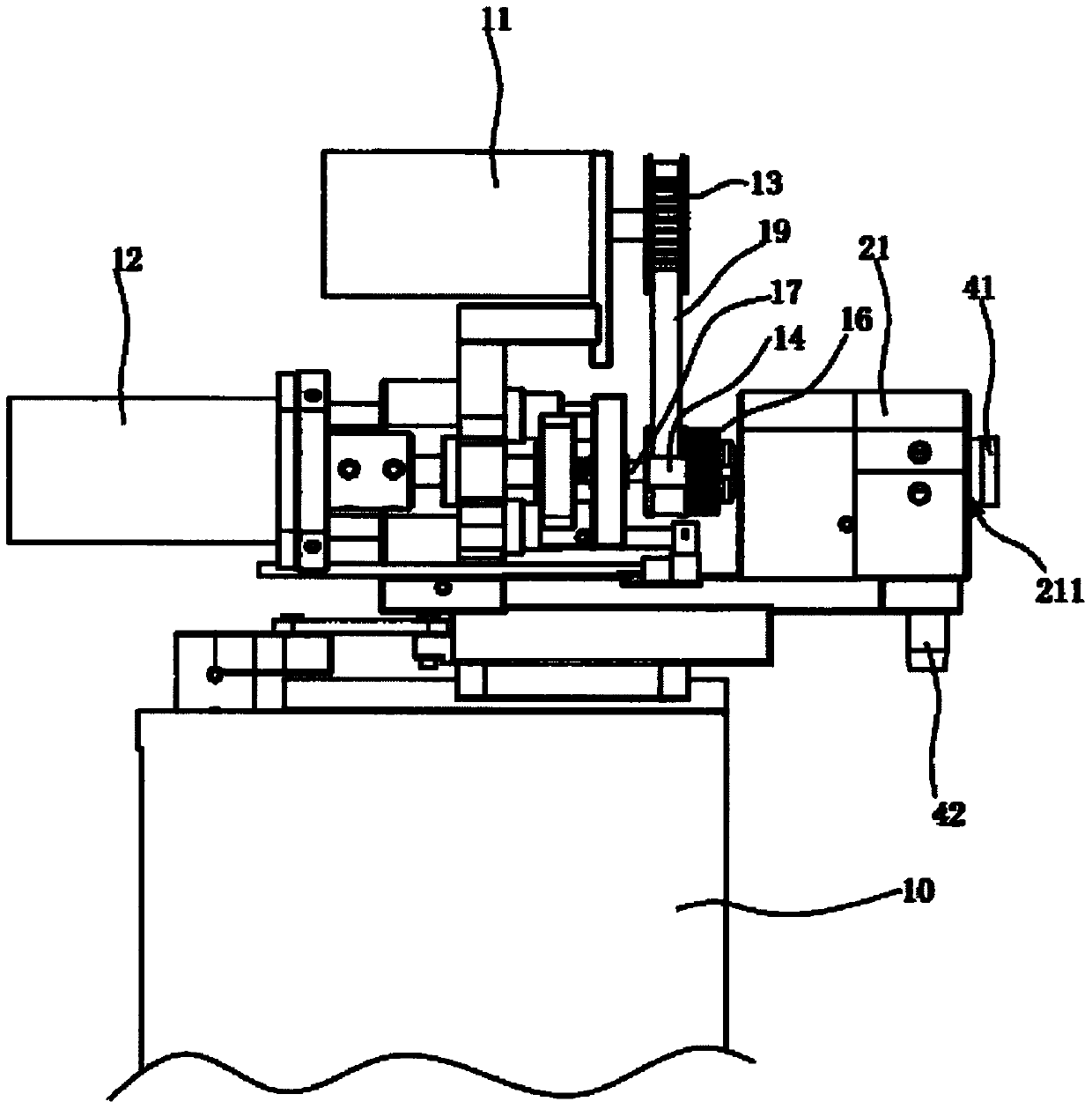

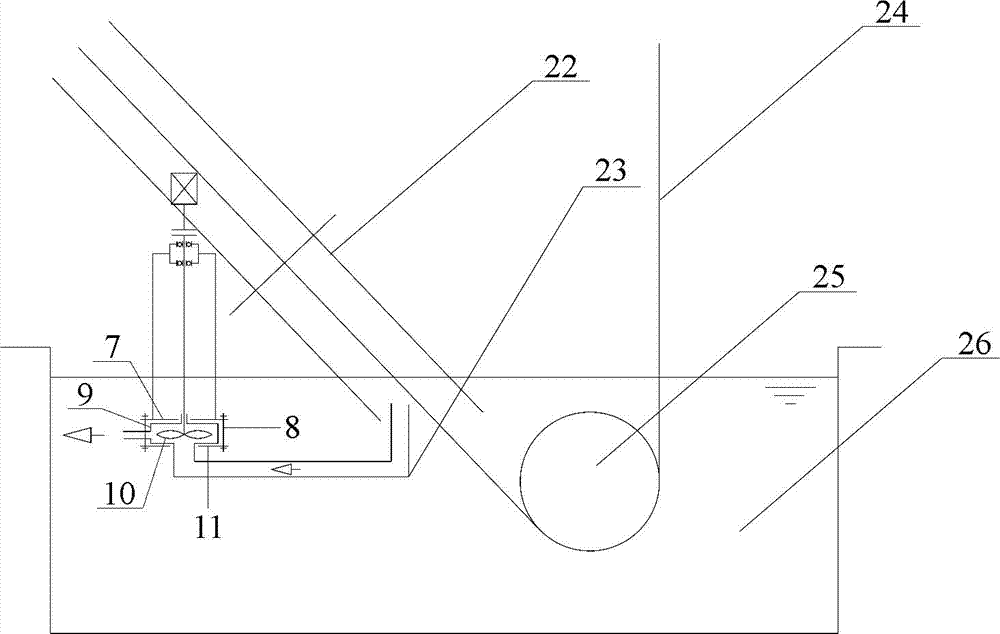

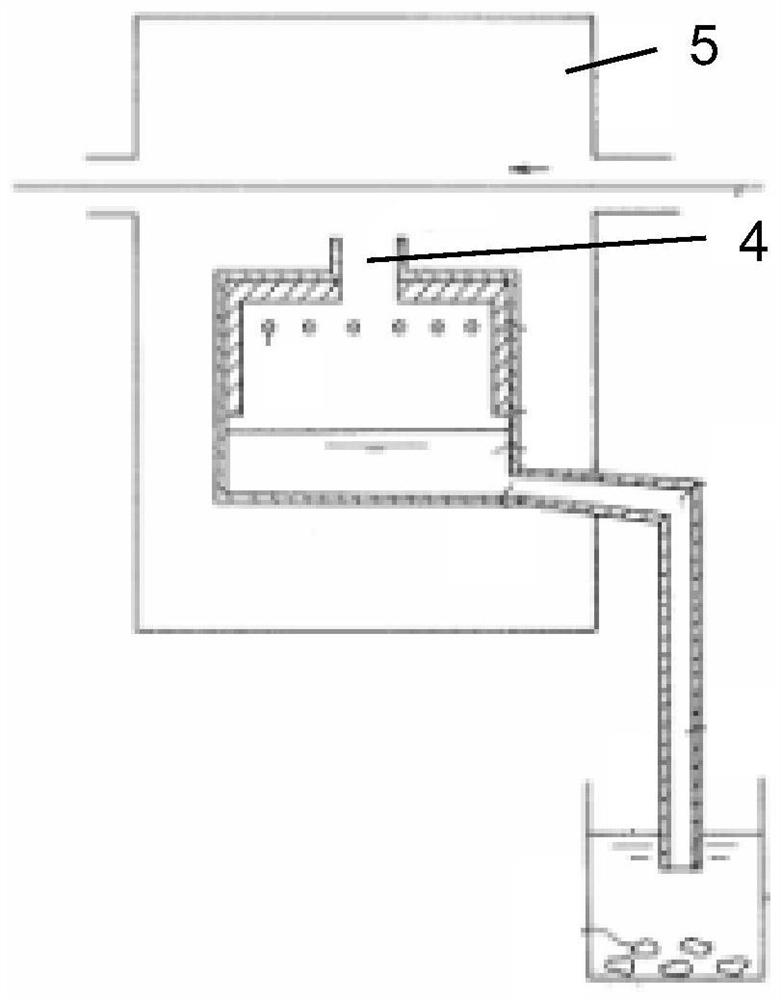

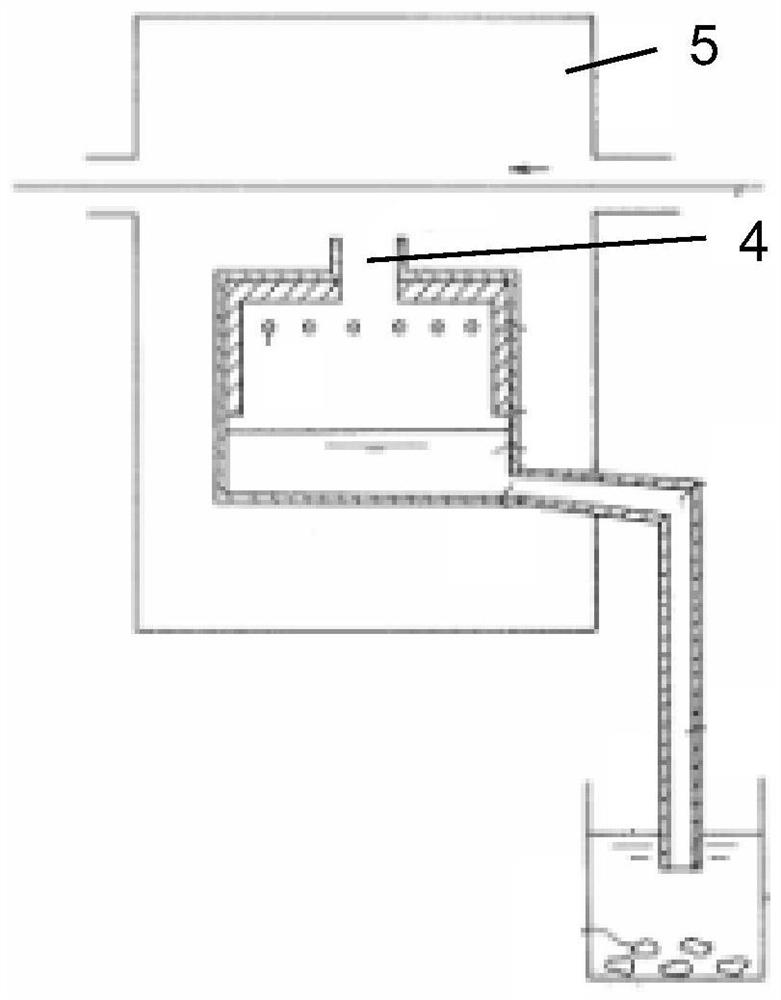

Dry and wet gas mixing and humidifying device for inhibiting zinc ash in hot galvanizing and use method thereof

PendingCN106480388ASuppress generationStop evaporationHot-dipping/immersion processesWater dischargeAlloy

The invention relates to the fields of hot-dip galvanizing alloy technology and auxiliary equipment used therefor, and specifically relates to a dry and wet gas mixing and humidifying device for inhibiting zinc ash in hot galvanizing and a use method thereof. The device comprises a furnace nose (10), and is characterized by also comprising a water tank (1), a water inlet pipe (21), a water discharge pipe (22), an air inlet pipe (23), a flow meter (33), a water level gauge (41), a heater (42), a dew-point instrument (43), a dry gas header pipe (5), a dry wet gas mixing pipe (6), and a control device (7). The use method comprises the following steps in sequence: (i) introducing dry gas; (ii) humidifying the dry gas; (iii) mixing dry gas and wet gas; and (iv) regulating the dew point. The device and method have the advantages that the zinc ash is well inhibited, the strip steel quality is high, the control is accurate, and the automation degree is high.

Owner:SHANGHAI DONGXIN METALLURGY TECH ENG

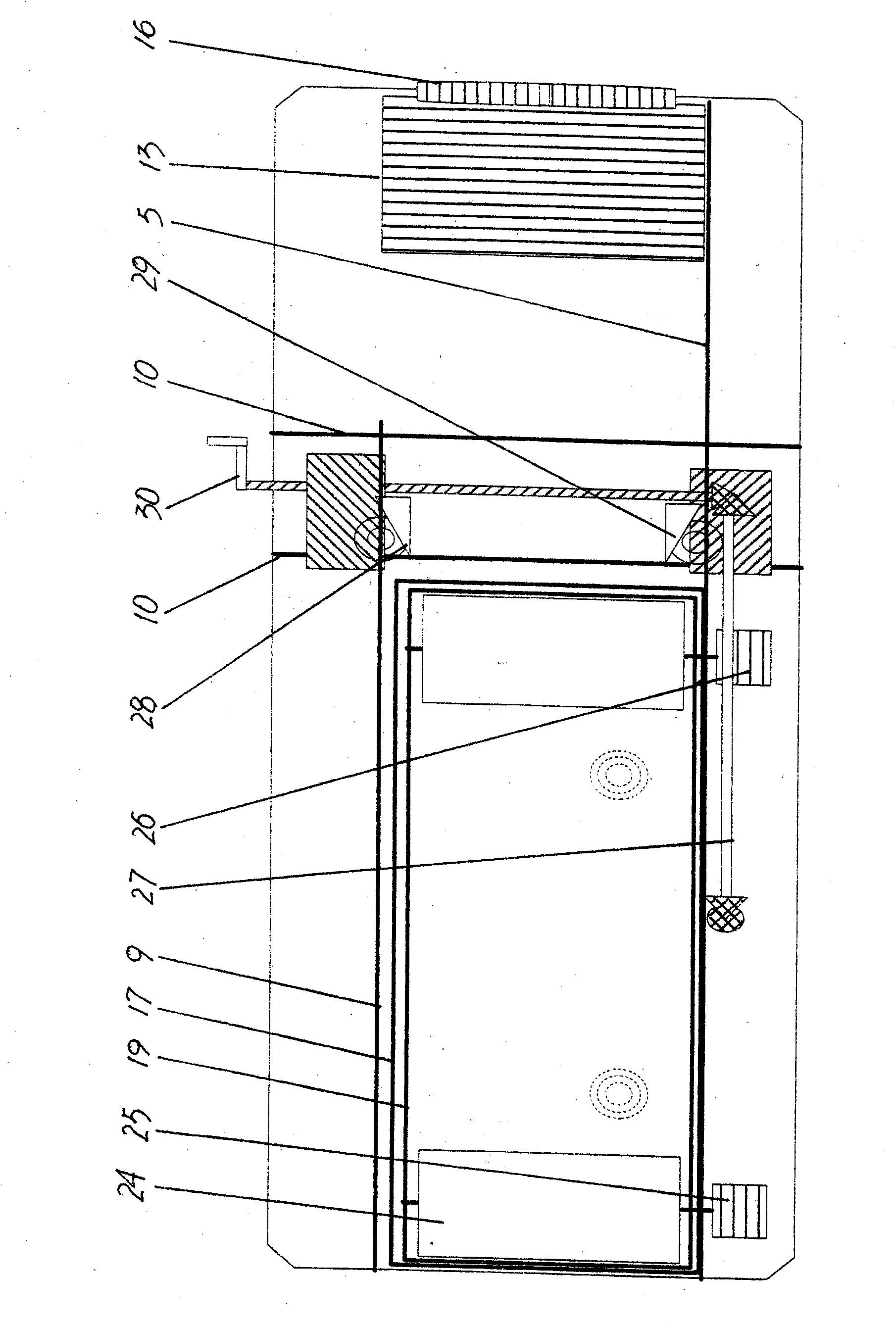

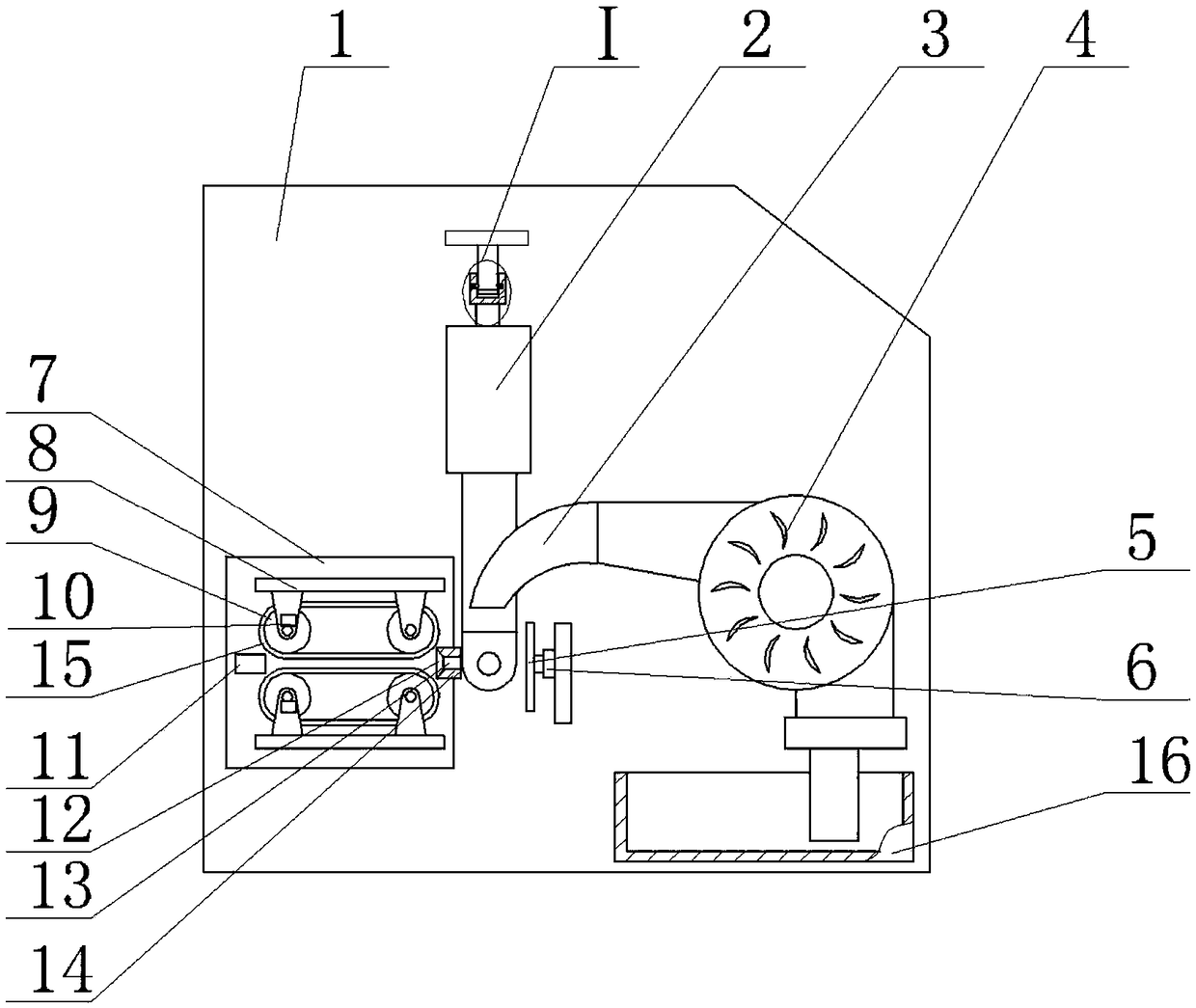

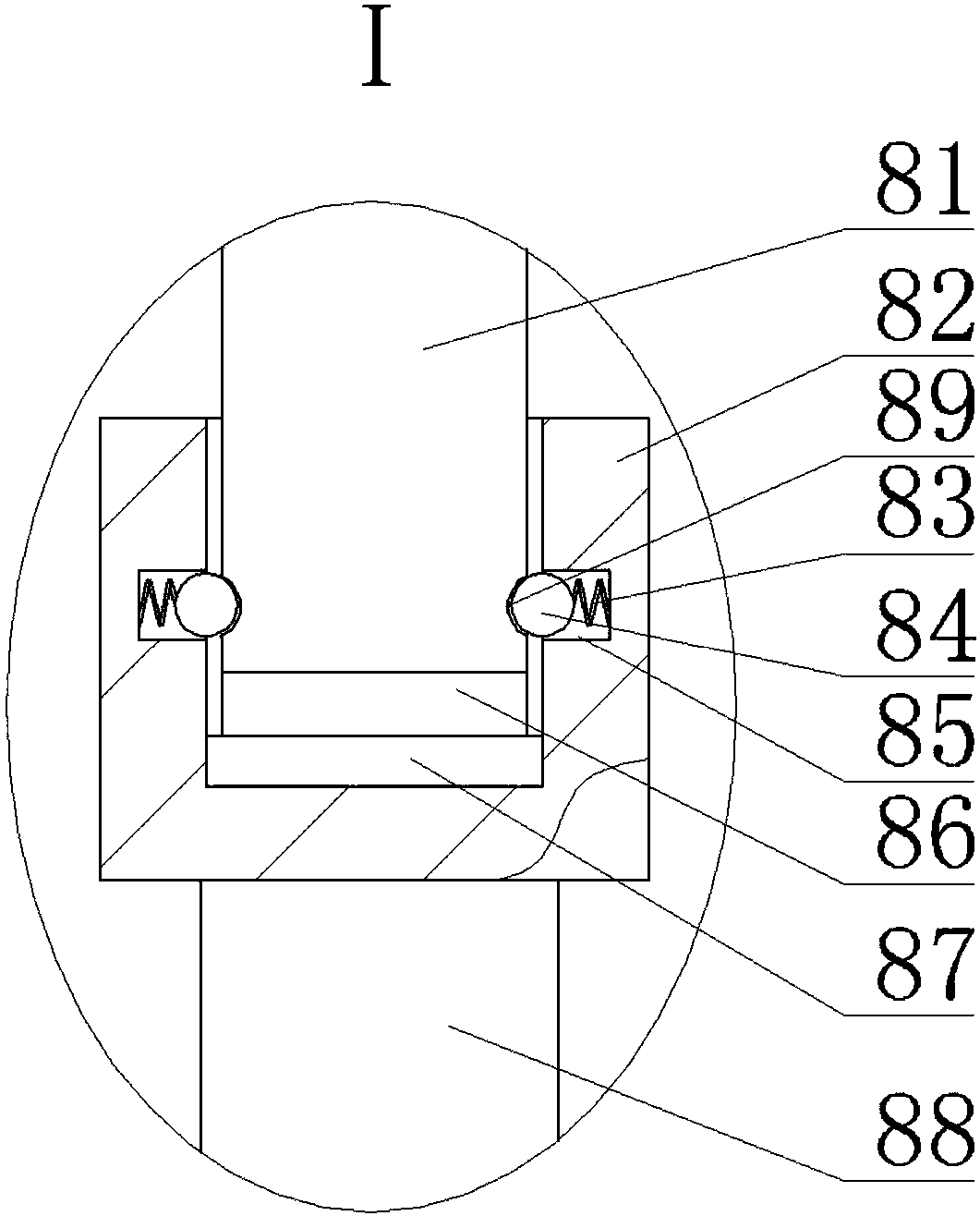

Automatic wire-stripping machine for general cables

InactiveCN102110962ASolve thick skinSolve protection problemsApparatus for removing/armouring cablesEngineeringElectric control

The invention relates to an automatic wire-stripping machine for general cables, which mainly comprises a box body, a wire pressing mechanism, a cutting and wire-stripping mechanism, an adjusting mechanism, a wire trimming mechanism and an electric control part, wherein the box body is rectangular, a wire inlet and a wire outlet are respectively arranged on the end surfaces at two ends of the box body, the wire pressing mechanism is arranged in the wire inlet, two pressure plate boxes are oppositely mounted, a main supporting plate is arranged in the lower box body, an upper pressure plate is mounted above the main supporting plate; and the cutting and wire-stripping mechanism is arranged at the middle part of the box body and comprises two groups which are correspondingly mounted at the upper part and the lower part, and the wire trimming mechanism is arranged at the back part of the box body. The machine adopts electric double-sided cutting and automatic wire trimming, is particularly applicable to wire stripping of armored cables, and can cut a multi-layer outer skin of the armored cable, automatically straighten multiple strands of wire cores, return the strands of the wire cores, which are sequenced according to the wire number, in a linear manner, automatically comb each strand of a cable core and further realize the functions of wire stripping and straightening. The automatic wire-stripping machine has the characteristics of convenience in use, no harm to a conducting wire, time-saving and labor-saving properties, and safety and reliability in operation, and can overcome the deficiencies of low working efficiency, unsafety, fatigue and time-consuming property of the prior art.

Owner:SHANGQIU POWER SUPPLY ELECTRIC POWER OF HENAN

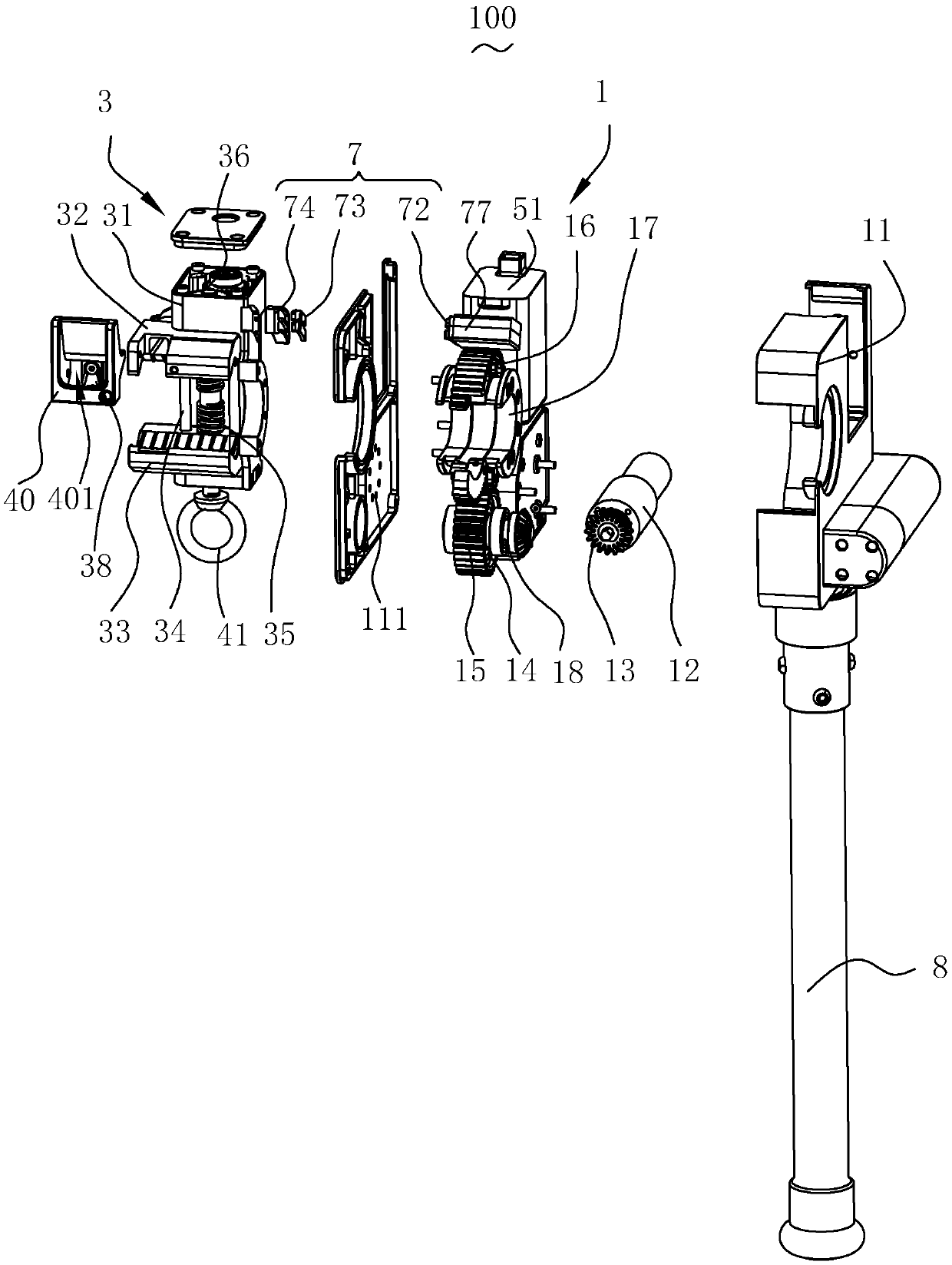

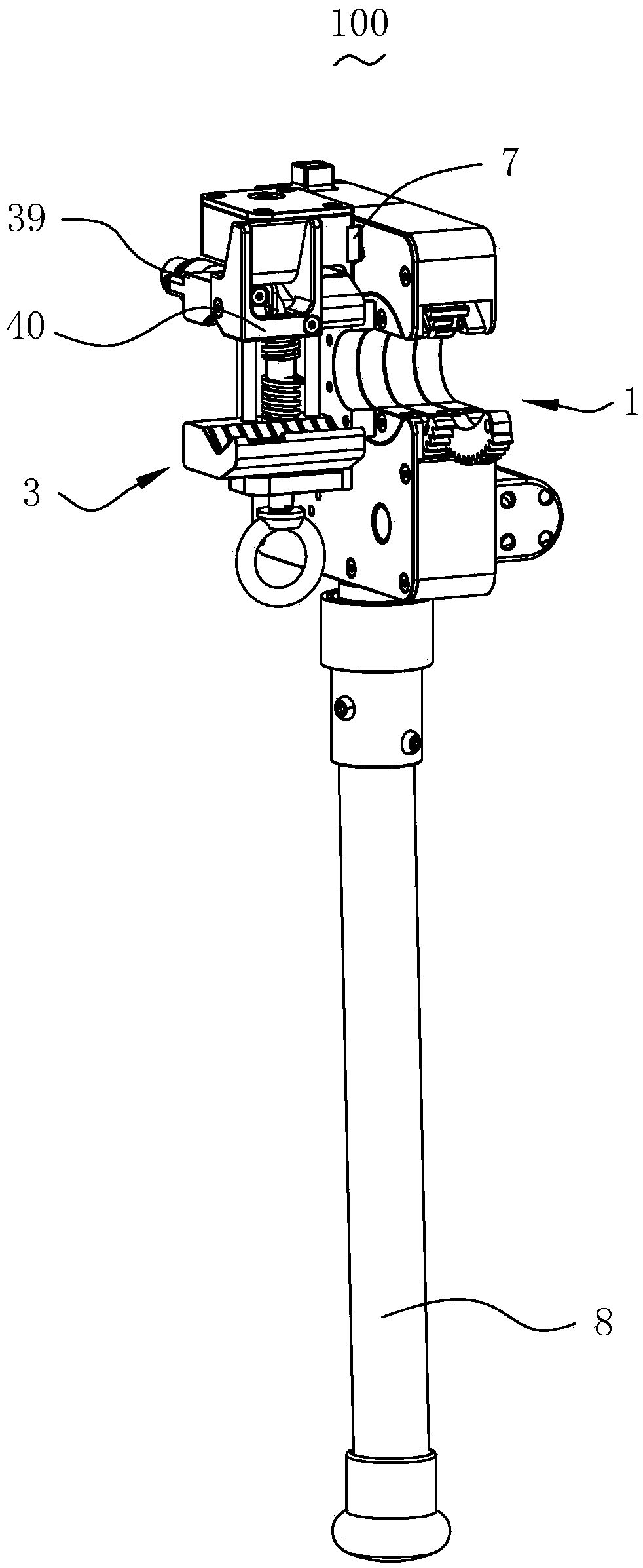

Intelligent wire stripper

PendingCN109616961AReduce labor intensityImprove stripping qualityLine/current collector detailsApparatus for removing/armouring cablesAutomatic controlEngineering

The invention provides an intelligent wire stripper. The intelligent wire stripper comprises a wire stripping device, a rotary drive device, a control device and a sliding contact device, the wire stripping device is connected with the rotary driving device; wherein one part of the sliding contact device is mounted on the wire stripping device, the other part of the sliding contact device is mounted on the rotary driving device, the rotary driving device drives the wire stripping device to rotate, and the control device controls the rotary driving device to rotate to a preset position while controlling the rotary driving device to start and stop, so that the two parts of the sliding contact device are mutually contacted to trigger the wire stripping device to open and close. According to the intelligent wire stripper, the control device is arranged to control the rotation driving device to move, the purpose of replacing manual operation with automatic intelligent control is achieved, the wire stripping accuracy can be controlled through the arrangement of the control device, and the working efficiency is greatly improved. Meanwhile, opening and closing of the wire stripping deviceare controlled through mutual contact triggering of the two parts of the sliding contact device, and automatic control is further achieved.

Owner:浏阳市金锋机械科技有限公司

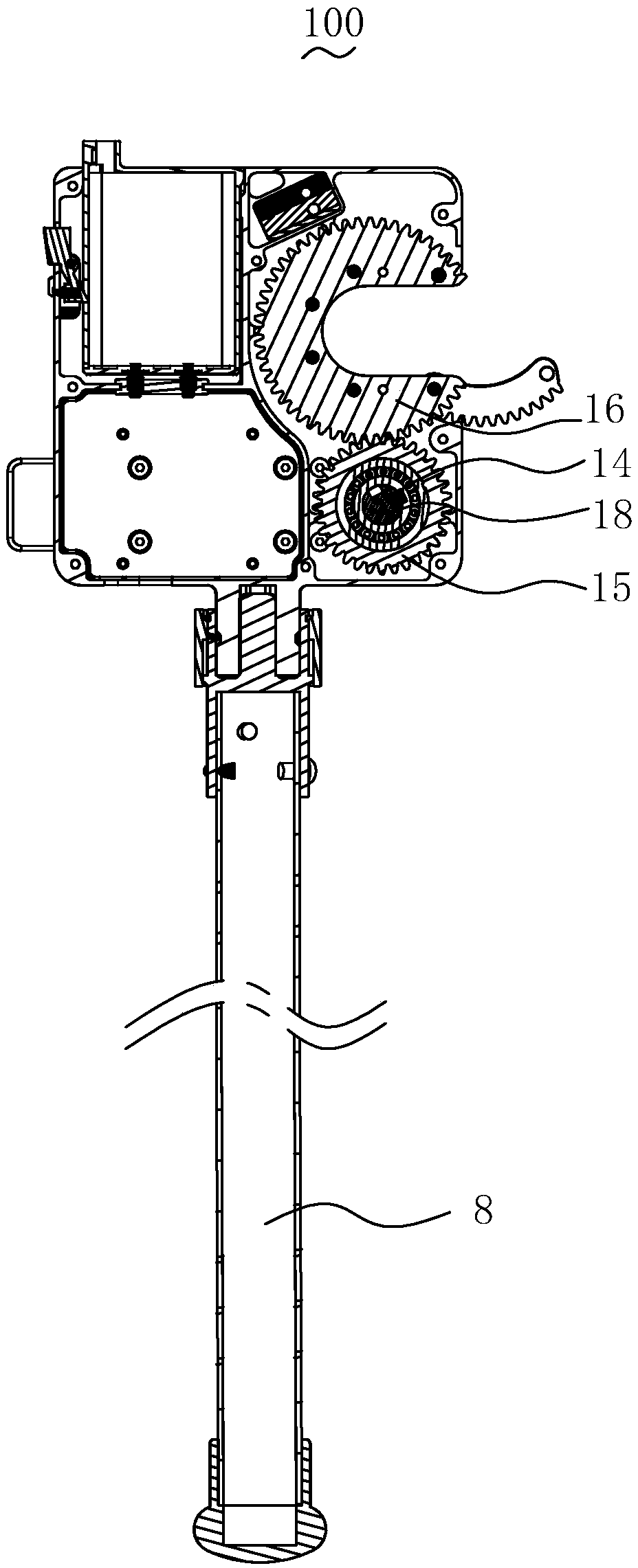

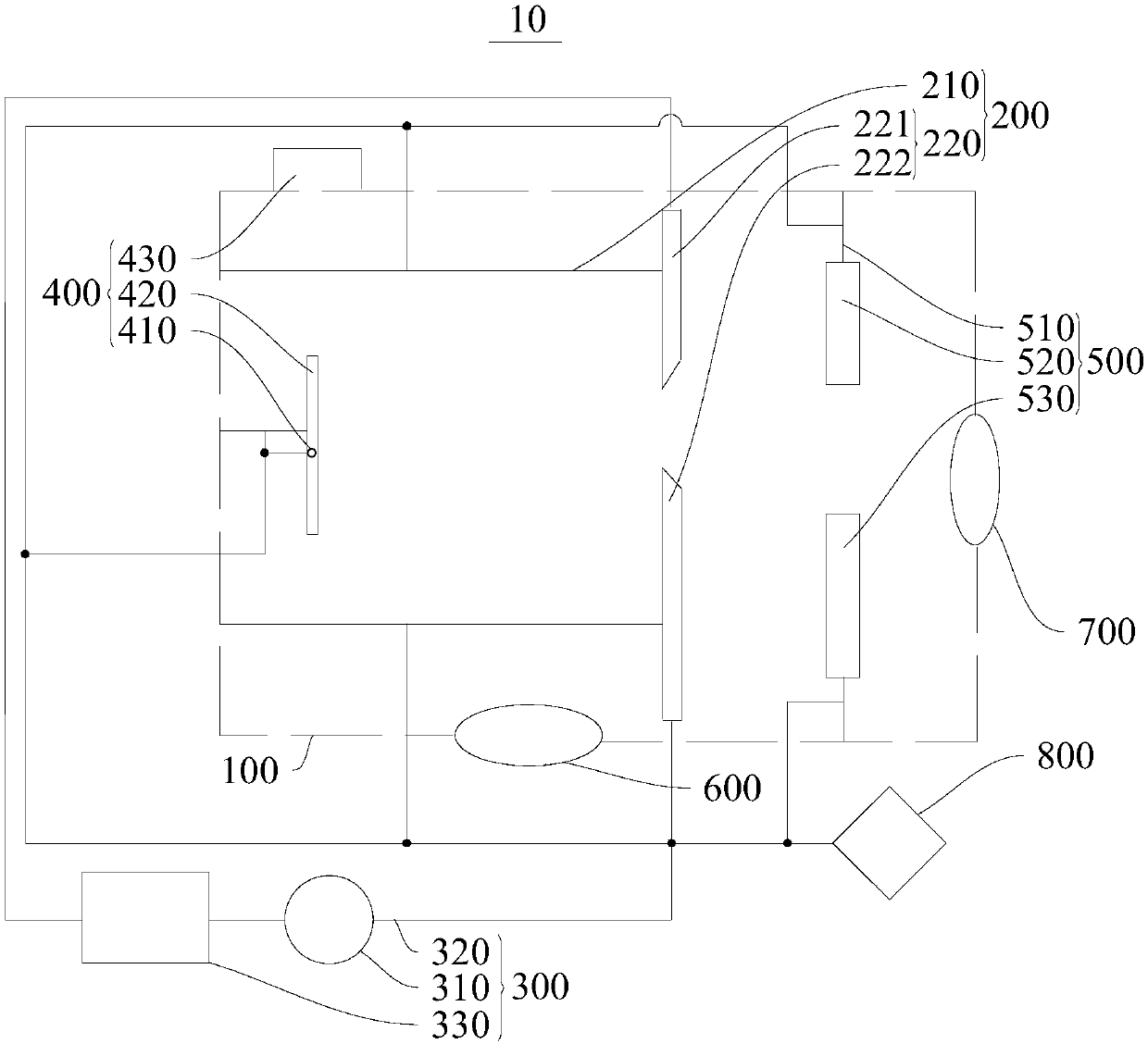

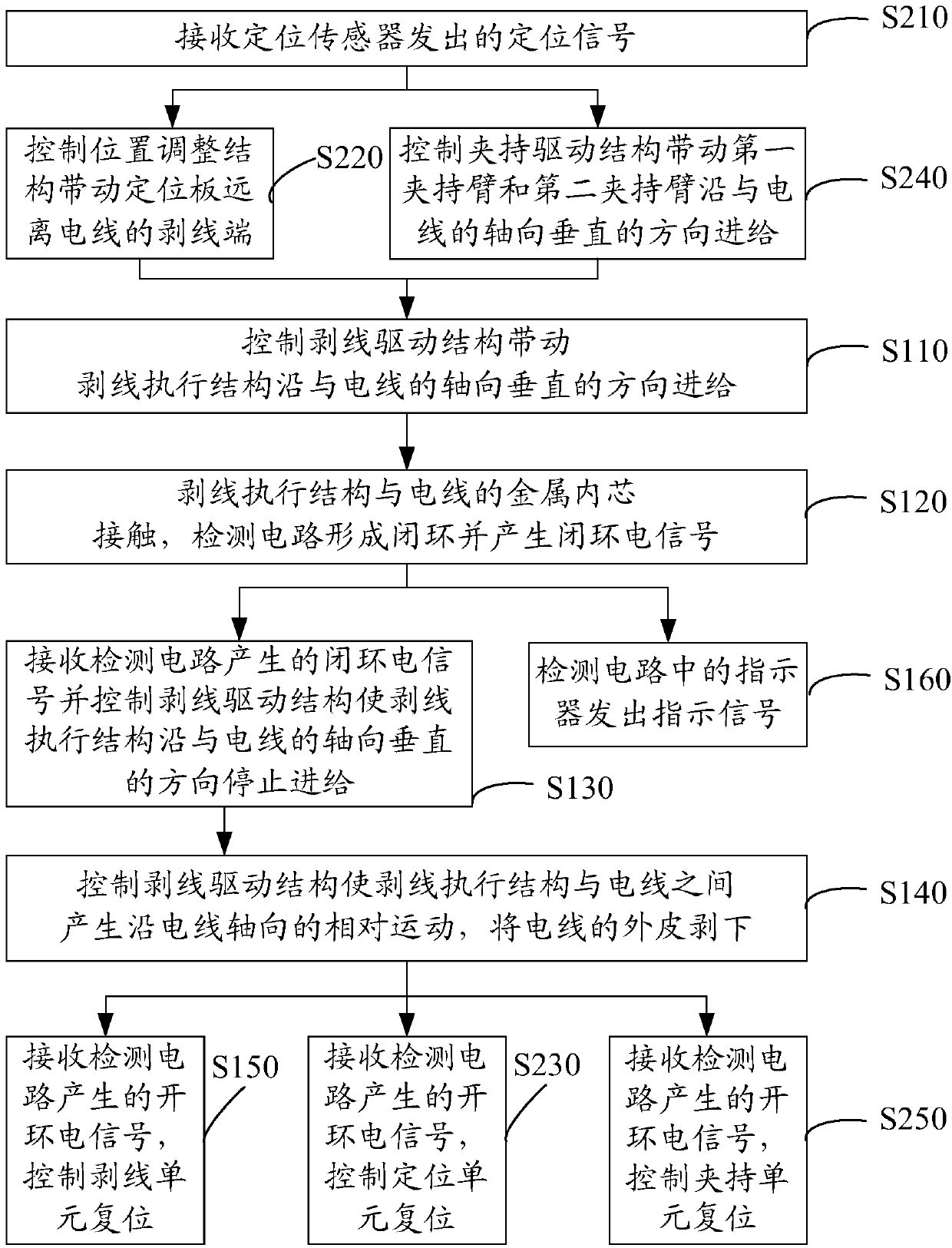

Stripping machine

PendingCN107611859AImprove stripping efficiencyImprove strip qualityLine/current collector detailsApparatus for removing/armouring cablesStripping - actionEngineering

The invention relates to a stripping machine, and includes a support structure, a stripping unit, a detection circuit, and a controller. The stripping unit arranged in the support structure includes astripping driving structure and a stripping performing structure. The stripping driving structure is connected with the stripping performing structure in a transmission way to drive the stripping performing structure to complete a stripping action. The detection circuit is electrically connected with the stripping unit. The stripping performing structure can form a loop and open circuit with thedetection circuit. The controller is respectively electrically connected with the stripping driving structure and the detection circuit. The stripping machine detects whether the stripping performingstructure is contacted with a metal inner core or not through the detection circuit in the stripping process of the stripping machine. When the stripping performing structure is contacted with the metal inner core, the controller controls the stripping unit to complete the subsequent stripping process. The stripping process is all controlled and completed by the controller, has the advantage of high efficiency stripping, and formed stripping mouths after processing by the stripping performing structure can be always matched with the metal inner core. The stripping is in high quality.

Owner:GREE ELECTRIC APPLIANCES INC

Cable stripper

InactiveCN107394687AImprove strip qualityAvoid injuryApparatus for removing/armouring cablesPower equipmentEngineering

The invention relates to a tool for electric equipment, in particular to a cable stripper for peeling cables during construction and maintenance. hole, the outer wall of the guide tube is provided with a fixed nut coaxial with the through hole through the bracket, a knife rod connected with the fixed nut is provided in the through hole, a knife is provided at the front end of the knife rod, and an adjusting handle is provided at the rear end of the knife rod. The cutter is in the form of an isosceles triangle, the bottom edge of the cutter is connected with the cutter bar, the waist of the cutter is respectively provided with a blade, and the inner wall of the guide tube corresponding to the blade is provided with an arc-shaped boss. The present invention adopts the above structure, and has the advantages of precise control of stripping It has the advantages of increasing the stripping speed and improving the work efficiency; it has the advantages of avoiding the scratching of the staff by the electrician's knife and ensuring the safety of the staff.

Owner:WEIHAI WENDENG POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO

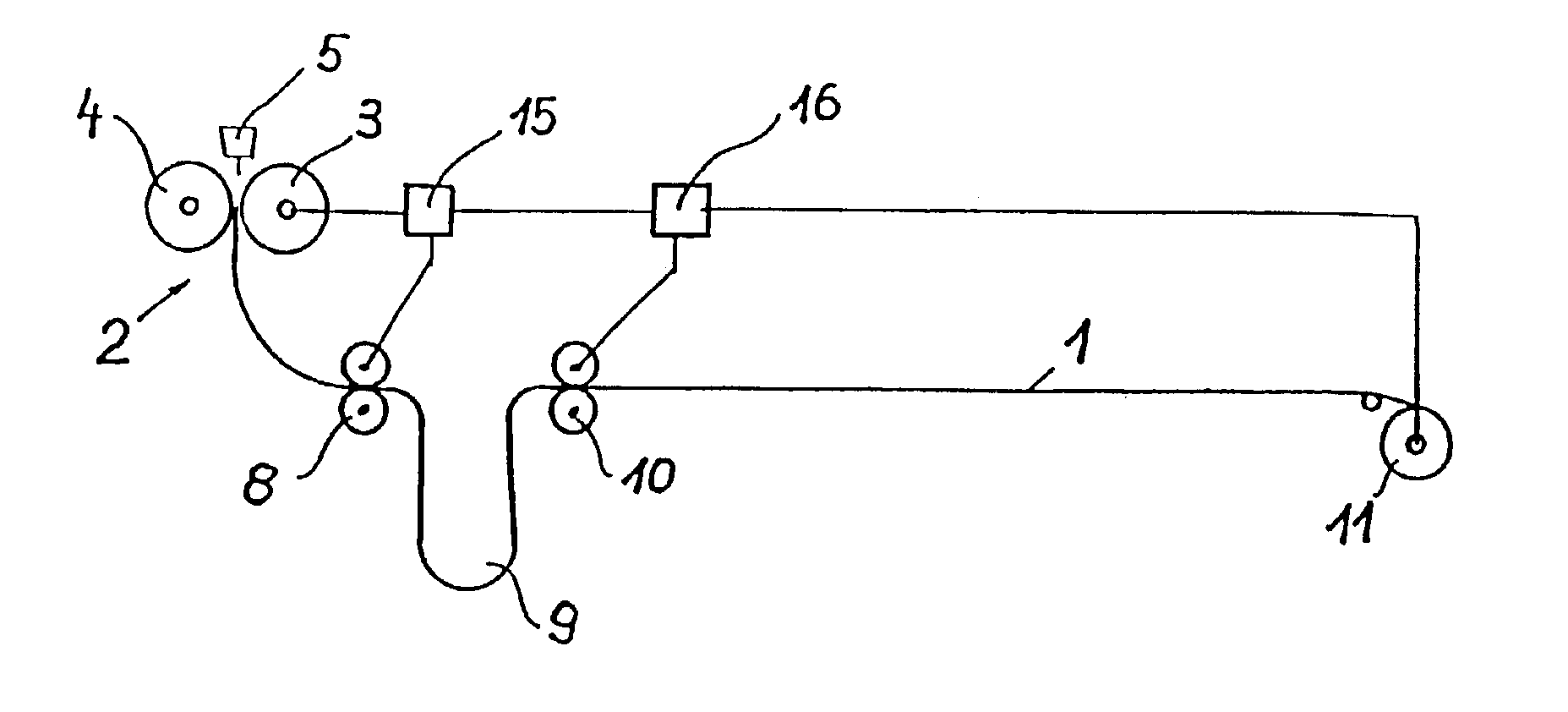

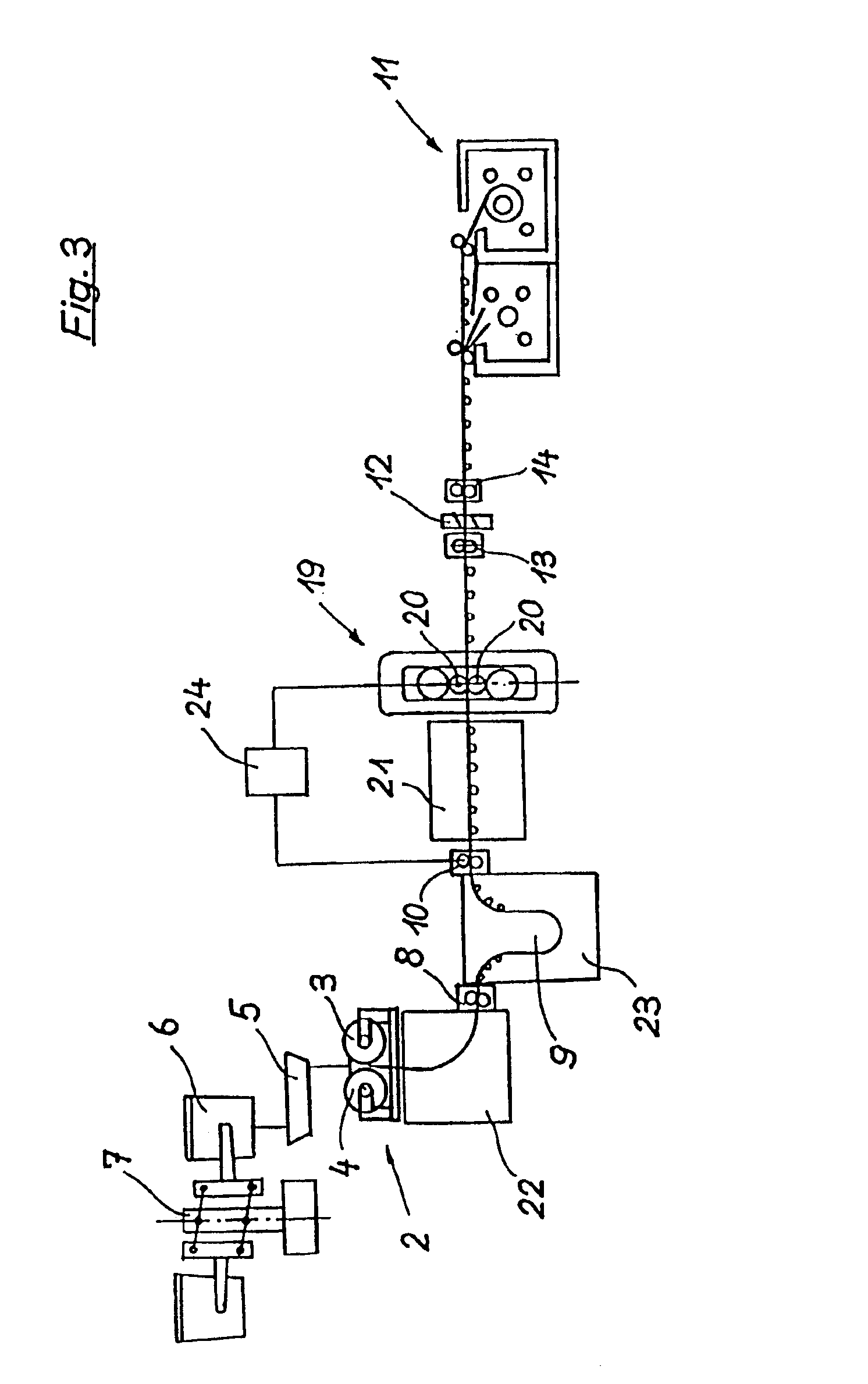

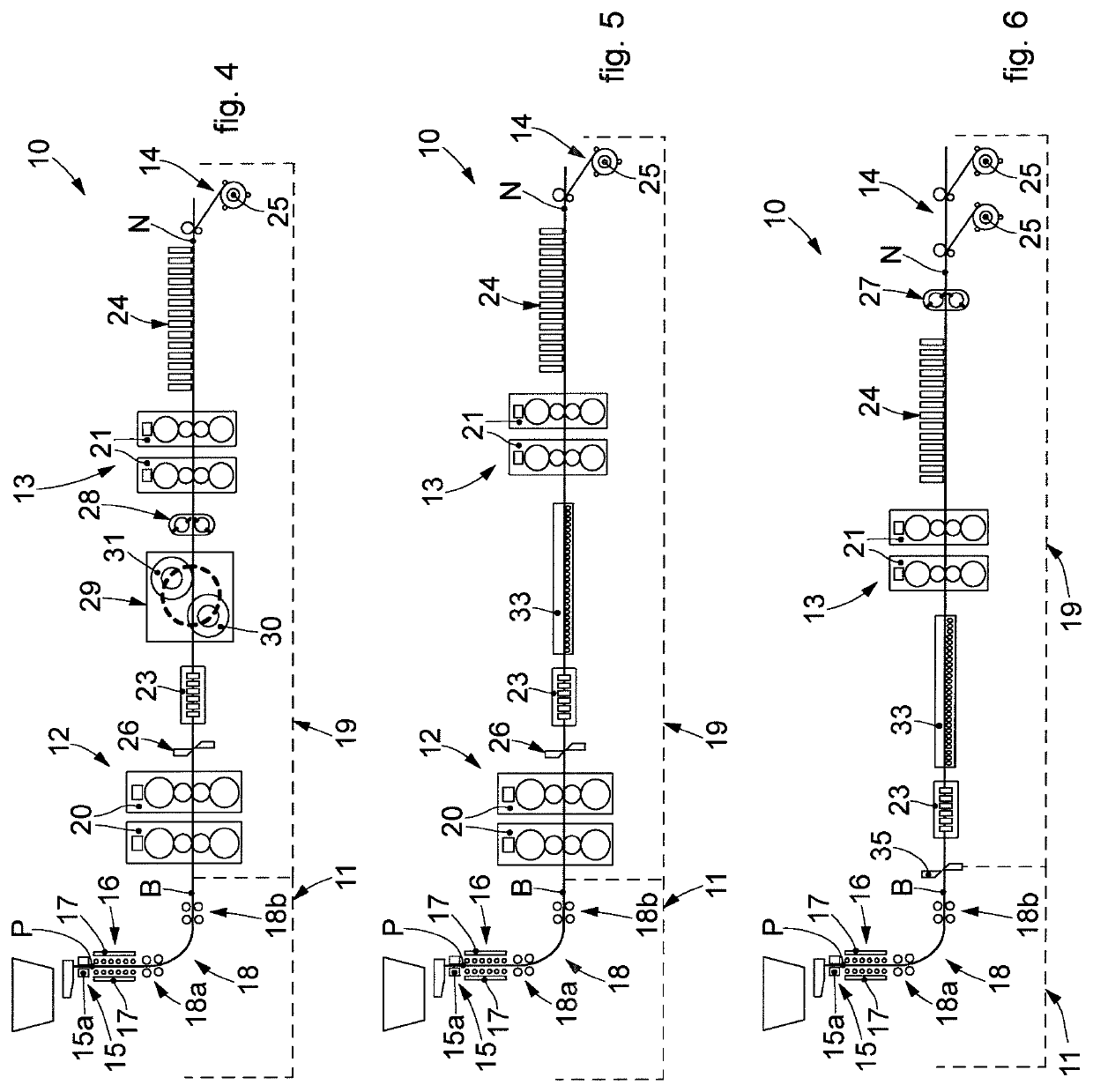

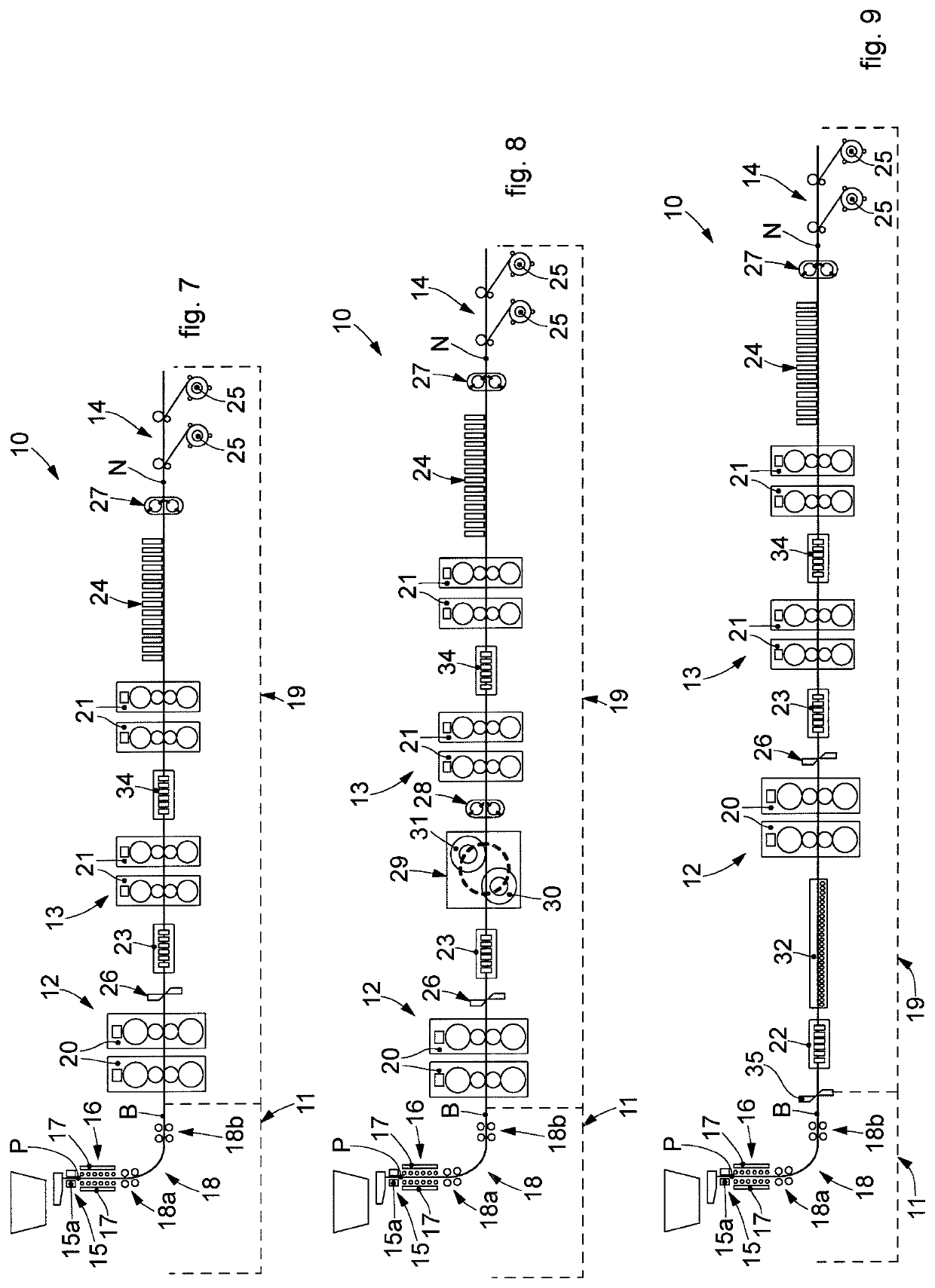

Method and installation for producing a metal strip

InactiveUS6907915B2High possible strip qualityAvoid disadvantagesWork treatment devicesMaterial accumulating devicesRotational axisControl manner

The invention relates to a method and to an installation for producing a metal strip. The aim of the invention is to make sure that the metal strip formed in the casting installation passes through the first cooling and grain texturing phase substantially without being subjected to stress and without effects on the subsequent installations. To this end, the molten bath is fed to a two-roll casting device and a cast metal strip is formed in the casting gap between two casting rolls whose rotational axes lie in a horizontal plane (two-roll casting method), the thickness of the cast strip ranging between 1.0 to 20 mm, preferably between 1.5 to 12 mm. The cast metal strip that freely emerges downwards from the two-roll casting installation is directly deflected from the vertical casting direction to a substantially horizontal transport direction. The metal strip is taken up and conveyed in a controlled manner by means of a first drive roll stand that operates at a first transport speed. The metal strip is then stored for a short time in a strip accumulator, and is then taken up and conveyed by means of a second drive roll stand that operates at a second transport speed. In a final step, the metal strip is coiled up to a bundle under pretension.

Owner:VOEST ALPINE AG

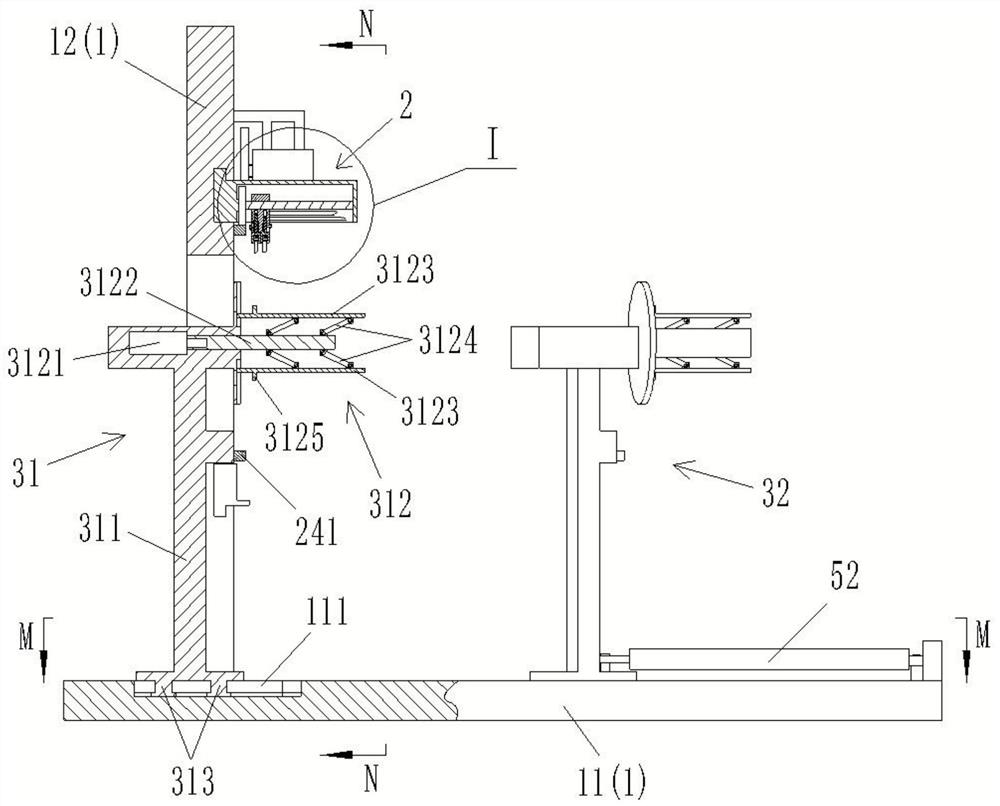

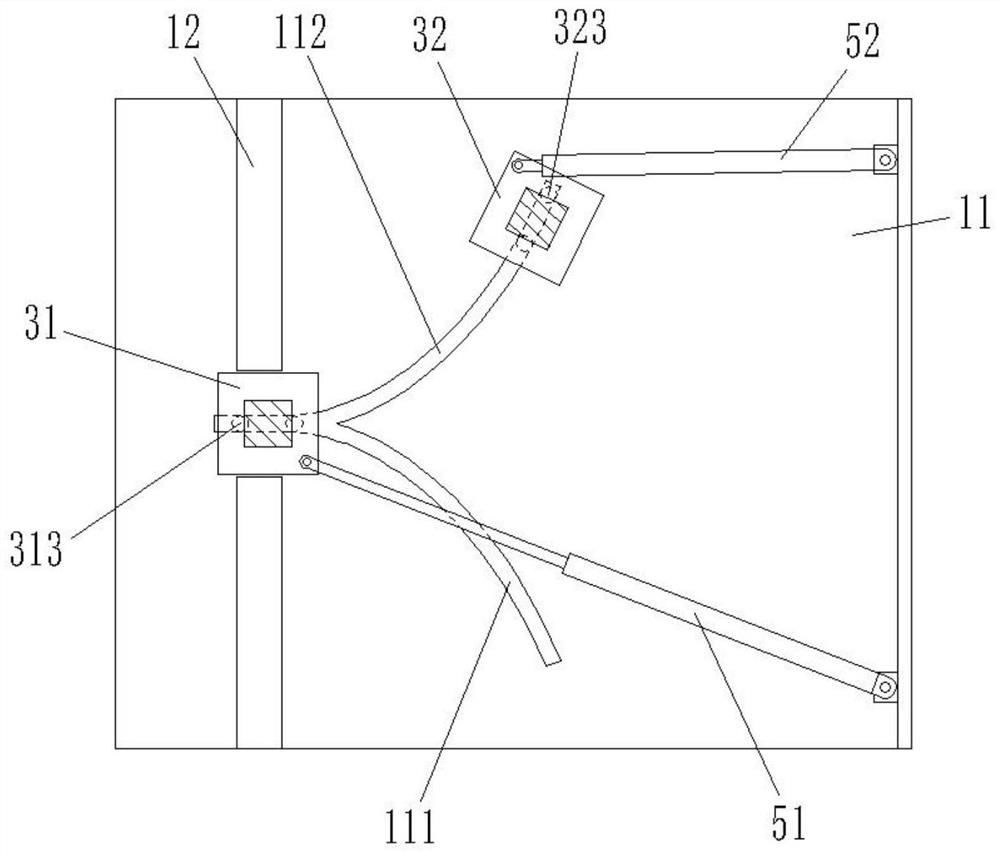

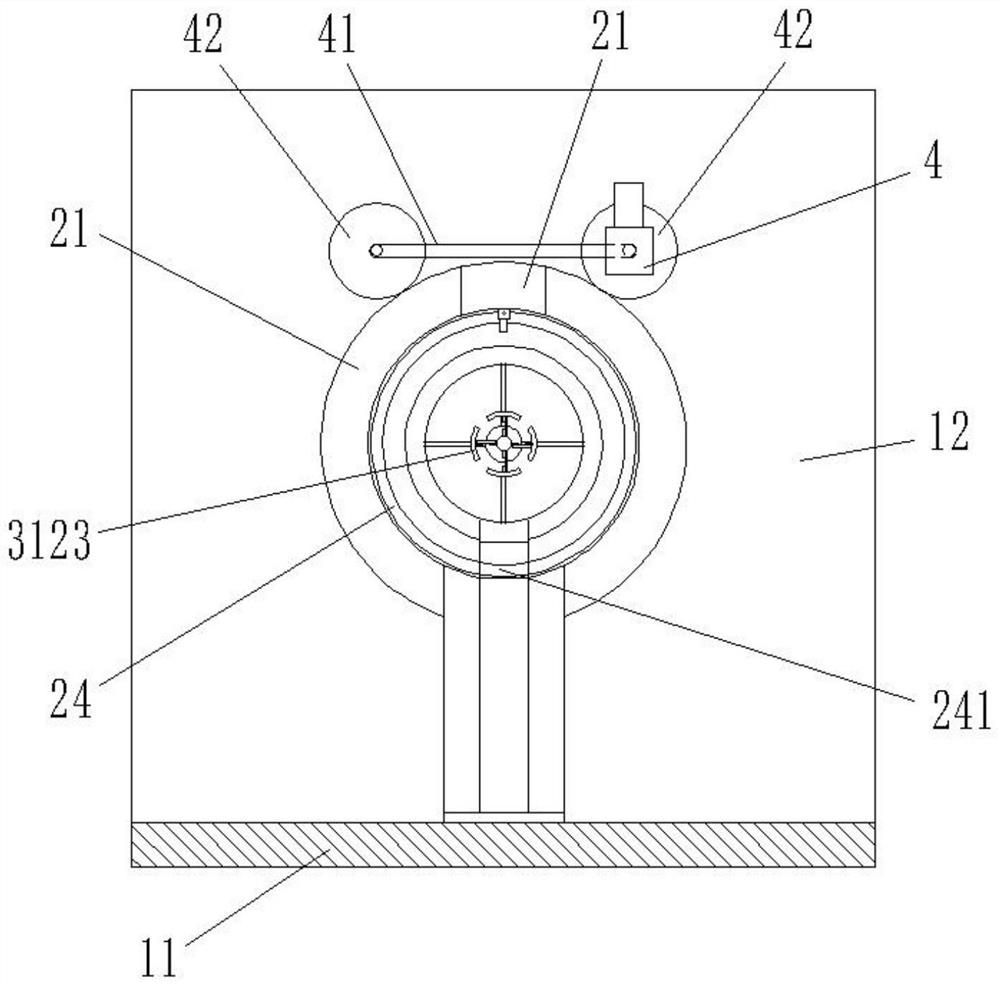

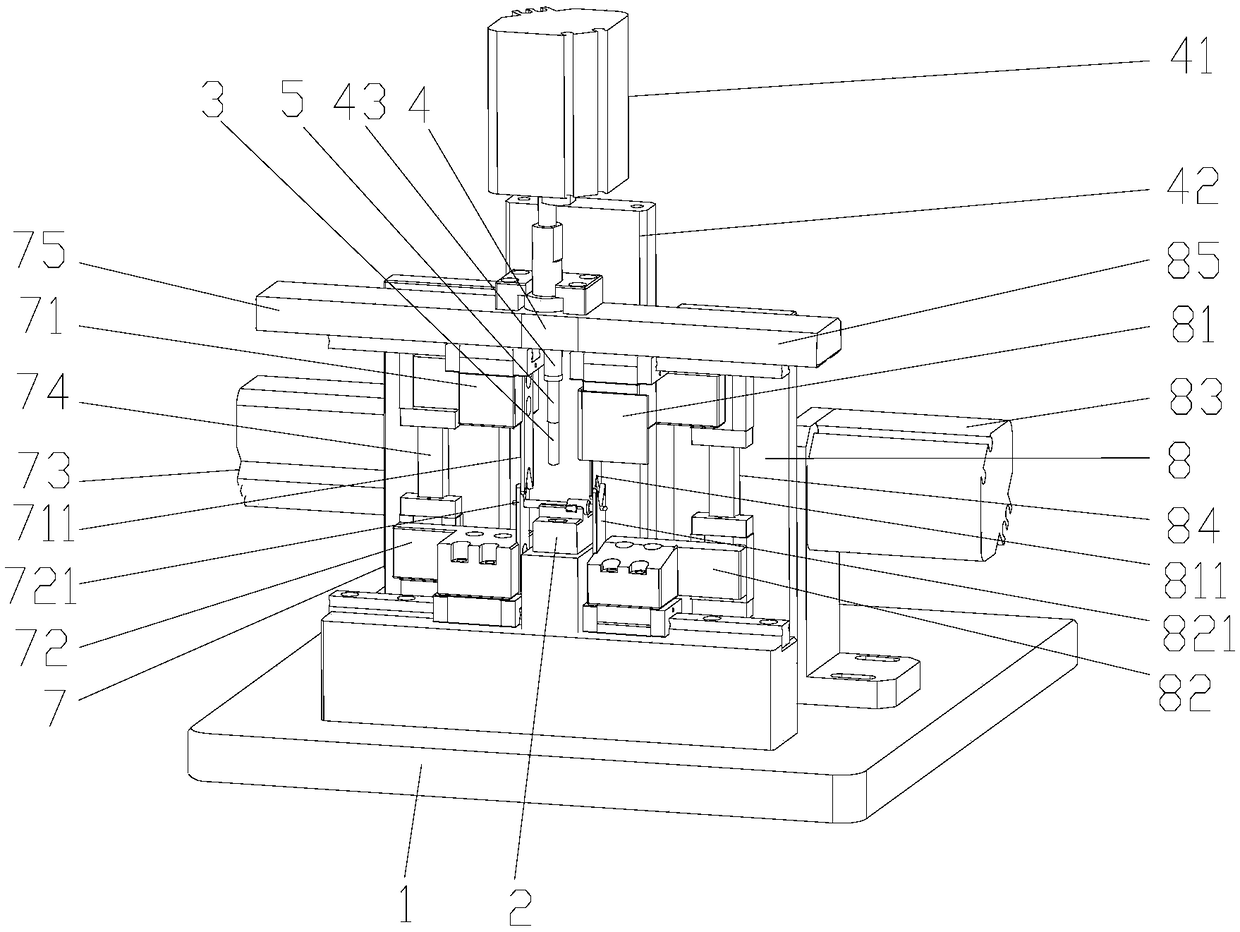

Rubber hose rubber stripping machining system and machining method

ActiveCN113183227AEliminate the need for hand-held fixationImprove fixation stabilityRevolution surface grinding machinesMetal working apparatusElectric machineryDrive motor

The invention belongs to the technical field of rubber hose stripping, and discloses a rubber hose stripping machining system. The rubber hose rubber stripping machining system comprises a machining table, a cutting and grinding unit, a clamping unit and a driving motor, wherein the machining table comprises a bottom plate and a support, and the support is perpendicularly fixed to the bottom plate; the cutting and grinding unit comprises a cutting and grinding frame, a cutting and grinding rod and a cutting and grinding head, the cutting and grinding frame is rotationally connected with the support, the cutting and grinding rod is connected with the cutting and grinding frame, the cutting and grinding head is slidably connected with the cutting and grinding rod, and a cutter and a grinding head are arranged on the cutting and grinding head; the clamping unit comprises a clamping table and a clamping head; the clamping table is in sliding connection with the bottom plate, and the clamping head is fixed to the clamping table so that the rubber hose can be clamped and fixed to the rotating center position of the cutting and grinding frame; the driving motor is connected with the cutting and grinding frame so as to drive the cutting and grinding frame to drive the cutting and grinding rod to rotate. When the rubber hose stripping machining system is used for rubber hose stripping treatment, the manual workload can be reduced, the efficiency can be improved, the safety of rubber stripping operation can be improved, and the rubber stripping quality can also be improved.

Owner:阔丹-凌云汽车胶管有限公司

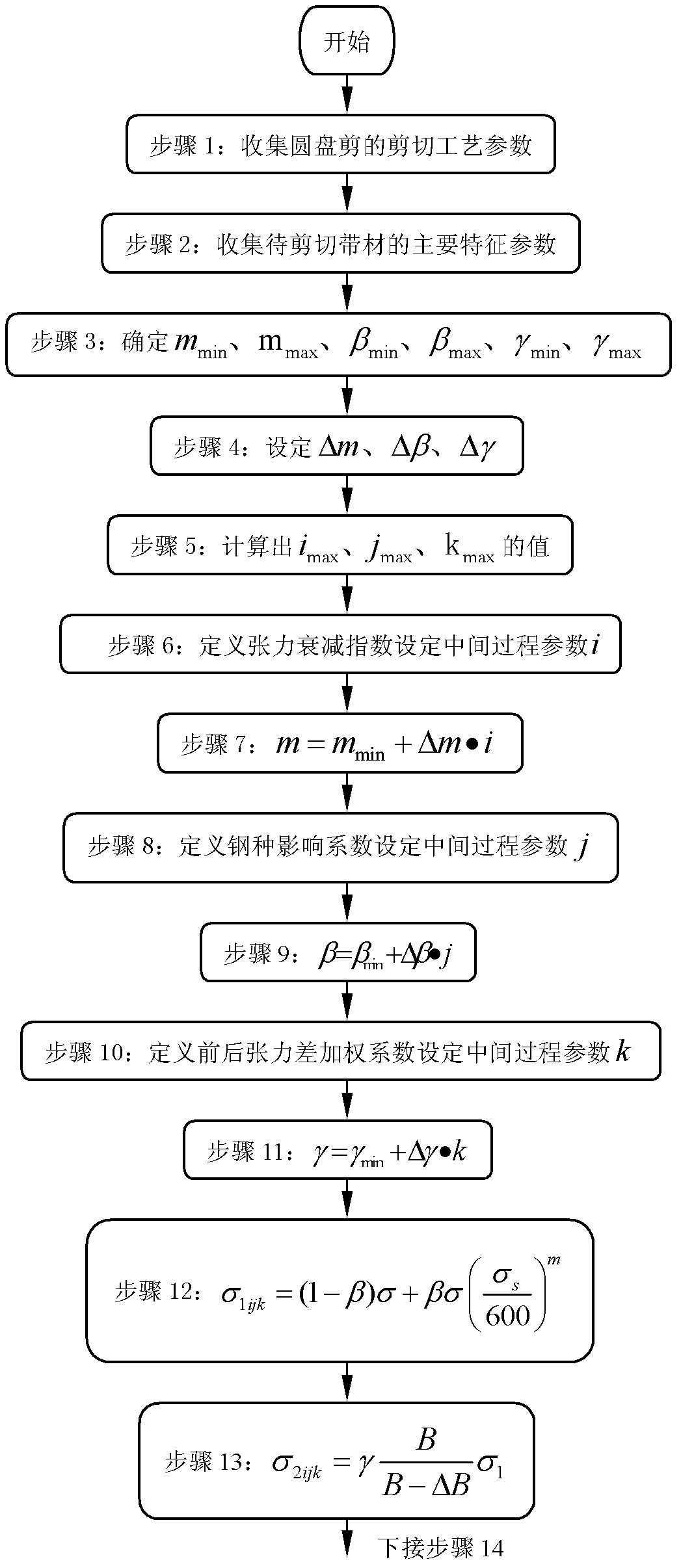

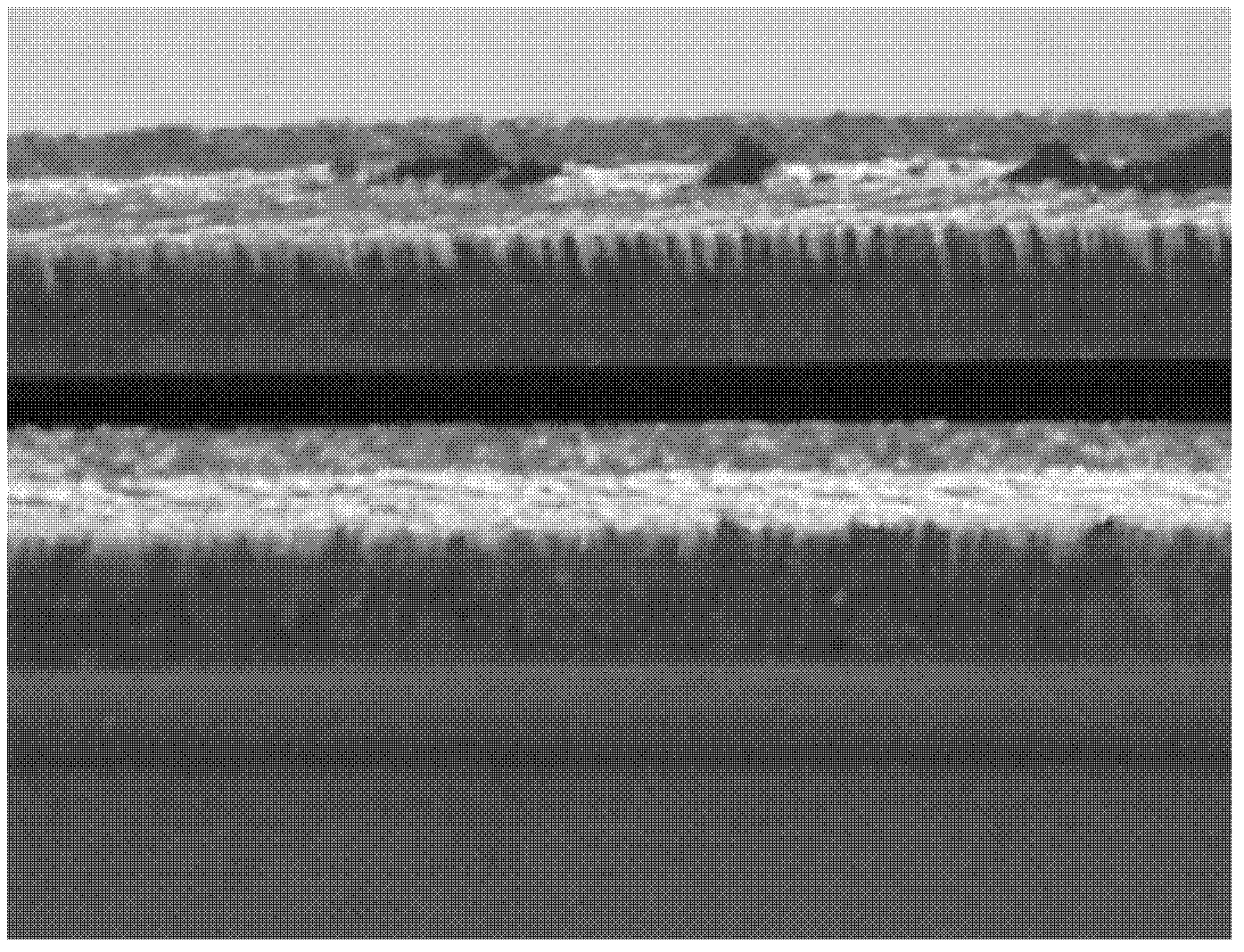

Comprehensive optimization setting method for front and back reference tension of disk shear of PL-TCM (pickling line tandem cold rolling mill)

ActiveCN103223522AOptimal tension settingAvoid interferenceShearing machinesUltrasound attenuationMetalworking

The invention provides a comprehensive optimization setting method for front and back reference tension of a disk shear of a PL-TCM, and belongs to the field of metal processing. The comprehensive optimization setting method comprises the steps of collecting shearing process parameters of the disk shear and major character parameters of a strip to be sheared; defining various indexes; setting the changed step size, the search frequency, the tension attenuation index, the steel grade influence coefficient and the front and back tension difference weighting coefficient of each parameter to obtain set values of the front and back tension; eliminating n groups of tension whose adjacent tension difference is lower than 0.5%; performing a shearing test on the spot; and sampling the sheared strip after sheared, picking out a test specimen with the optimal shearing quality to obtain the optimal front and back tension set values of the disk shear with a shear strength of sigma s in a steel grade process, and then setting the shearing tension of the steel grade with the strength of sigma s. according to the comprehensive optimization setting method, the influence of the matching of the steel grade, the strength and the front and back tension on the shearing quality is considered; the parameters such as the tension attenuation index, the steel grade influence coefficient, the front and back tension difference weighting coefficient and the like are led in; and a set of novel front and back tension setting method suitable for driving and driven disk shears simultaneously is provided.

Owner:BAOSHAN IRON & STEEL CO LTD

Ramie peeling and washing integrated device

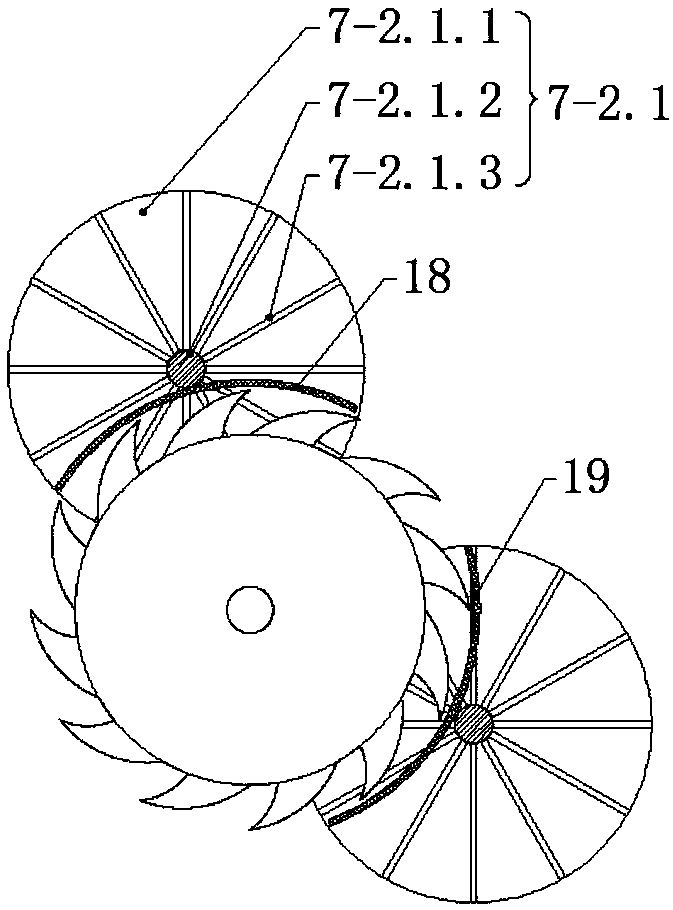

PendingCN107761175ALow impurity contentImprove strip qualityMechanical fibre separationClimate change adaptationRatchetConveyor belt

The invention discloses a ramie peeling and washing integrated device, relates to the technical field of ramie textiles, and aims at solving the problems of large manual labor capacity, low ramie peeling efficiency and poor quality in the prior art. The ramie peeling and washing integrated device comprises a raw material box provided with breaking rolls; a conveyor belt a and a conveyor belt b arearranged below the raw material box in parallel; a gap is formed between the conveyor belt a and the conveyor belt b, and is provided with a ramie pre-peeling mechanism; ramie post-peeling mechanisms, each of which comprises a ratchet wheel corresponding to the gap and ramie peeling wheel devices which are matched with the ratchet wheel, are arranged at the tail ends of the conveyor belt a and the conveyor belt b; each ramie peeling wheel device comprises ramie peeling wheels arranged on the two axial sides of the corresponding ratchet wheel; a plurality of ramie peeling blades are arranged on the end surface, near one side of the corresponding ratchet wheel, of each ramie peeling wheel; a ramie washing water tank is arranged below the ramie post-peeling mechanisms; and the ratchet wheelsand the lower end parts of the ramie peeling wheel devices are arranged in the ramie washing water tank. The ramie peeling and washing integrated device provided by the invention has the advantages of simple structure, automatic ramie peeling with feeding at one time, less manual labor and good ramie peeling quality.

Owner:SICHUAN JB RAMIE

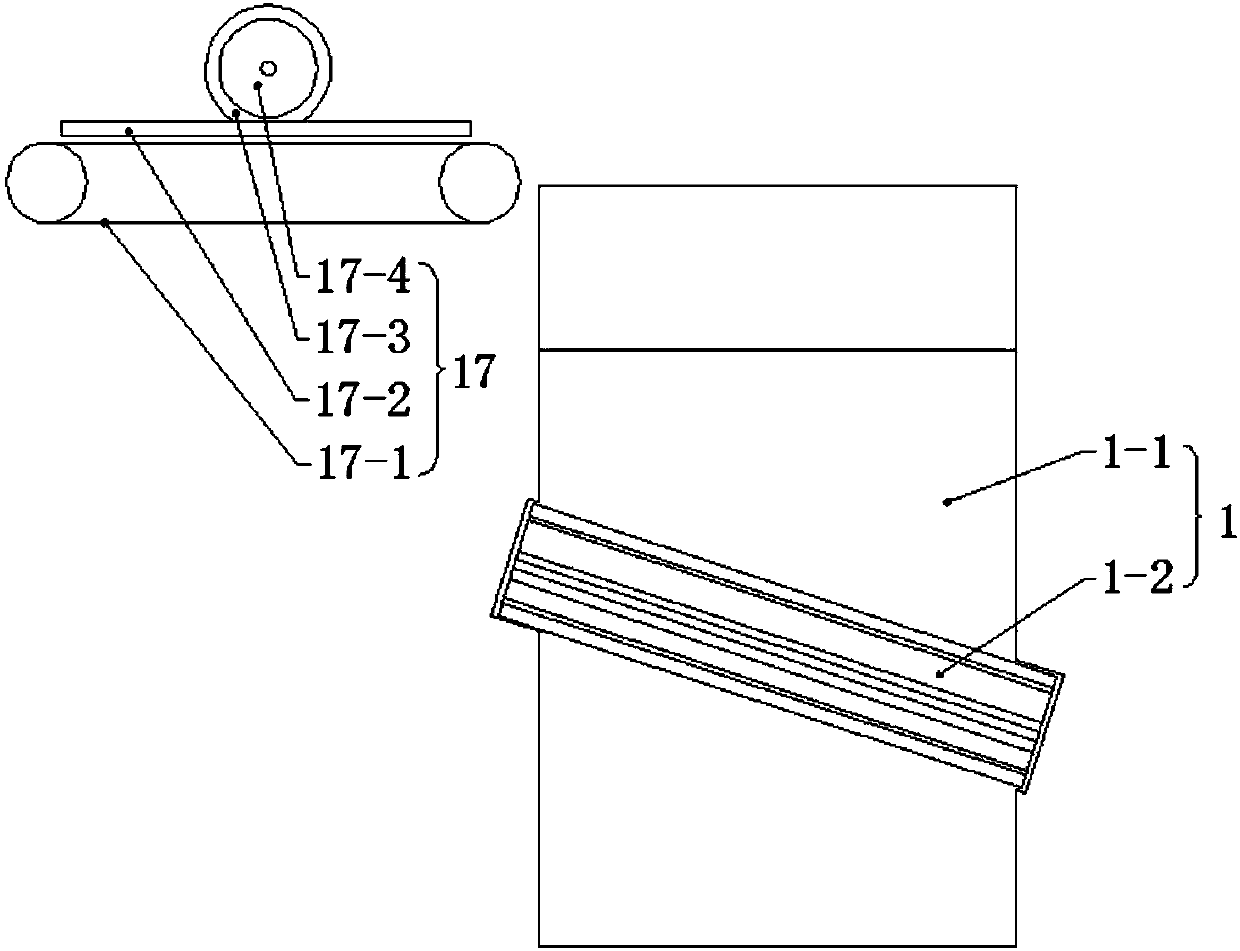

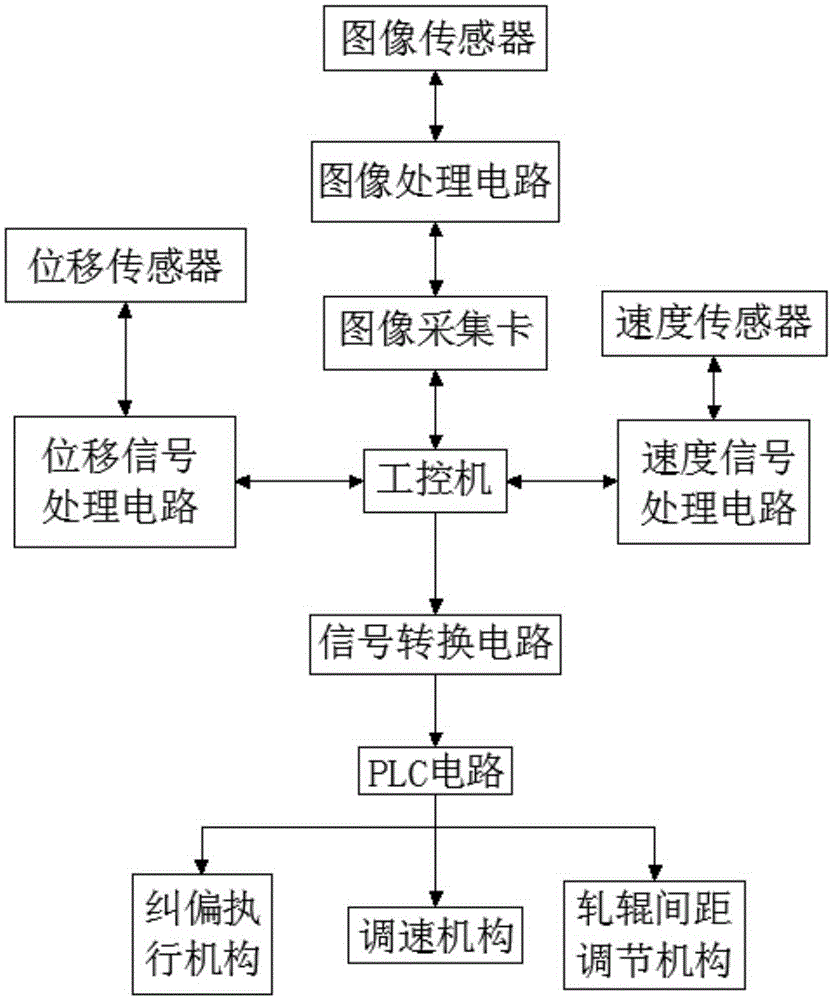

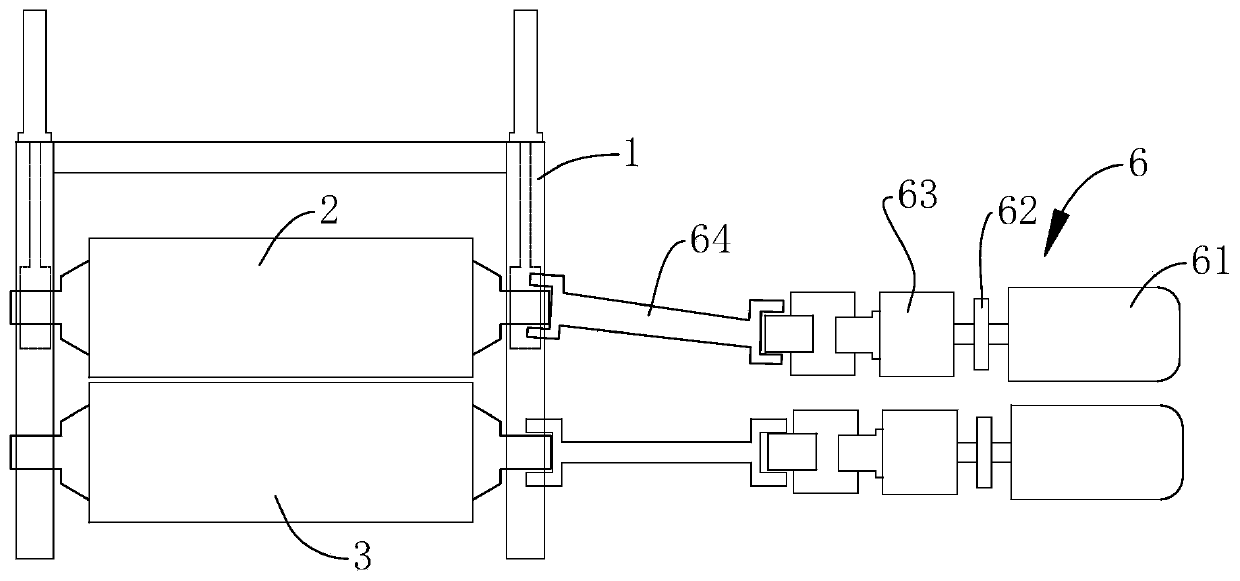

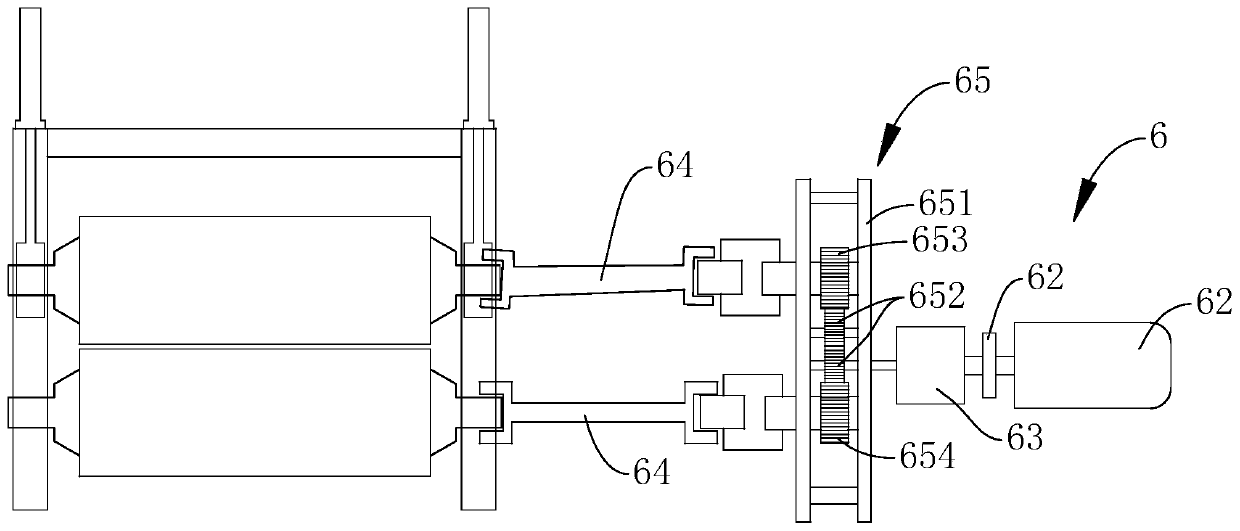

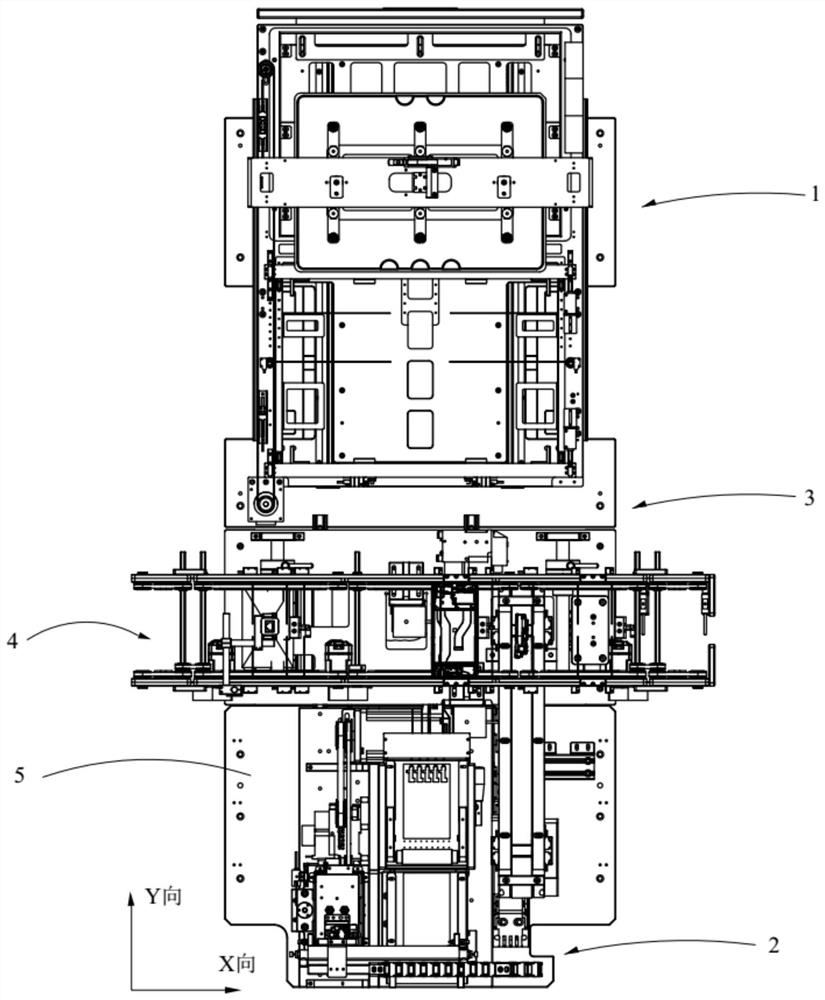

Deviation rectifying, speed adjusting and roller interval adjusting system for producing boards

InactiveCN105314440AImprove strip qualityImprove pass rateWebs handlingSignal processing circuitsInterference resistance

The invention discloses a deviation rectifying, speed adjusting and roller interval adjusting system for producing boards. The deviation rectifying, speed adjusting and roller interval adjusting system comprises a picture processing system, a displacement sensing system, an industrial personal computer, a speed sensing system and a regulating circuit. The industrial personal computer is connected with the picture processing system, the displacement sensing system, the speed sensing system and the regulating circuit. The regulating circuit is internally provided with a signal processing circuit, a deviation rectifying executing mechanism, a speed adjusting mechanism and a roller interval adjusting mechanism. The industrial personal computer is connected with the signal processing circuit. The signal processing circuit is connected with the deviation rectifying executing mechanism, the speed adjusting mechanism and the roller interval adjusting mechanism. Deviation rectifying treatment of strips can be effectively conducted; besides, a speed adjusting technology and a roller interval adjusting technology are combined, so that the strip quality can be effectively controlled during the production, and accordingly the whole strip quality is improved and the product yield is increased; the deviation rectifying, speed adjusting and roller interval adjusting system has the characteristics of being simple in structure, low in cost, high in detection precision, real-time performance and interference resistance and the like.

Owner:CHONGQING GUANGJI IND

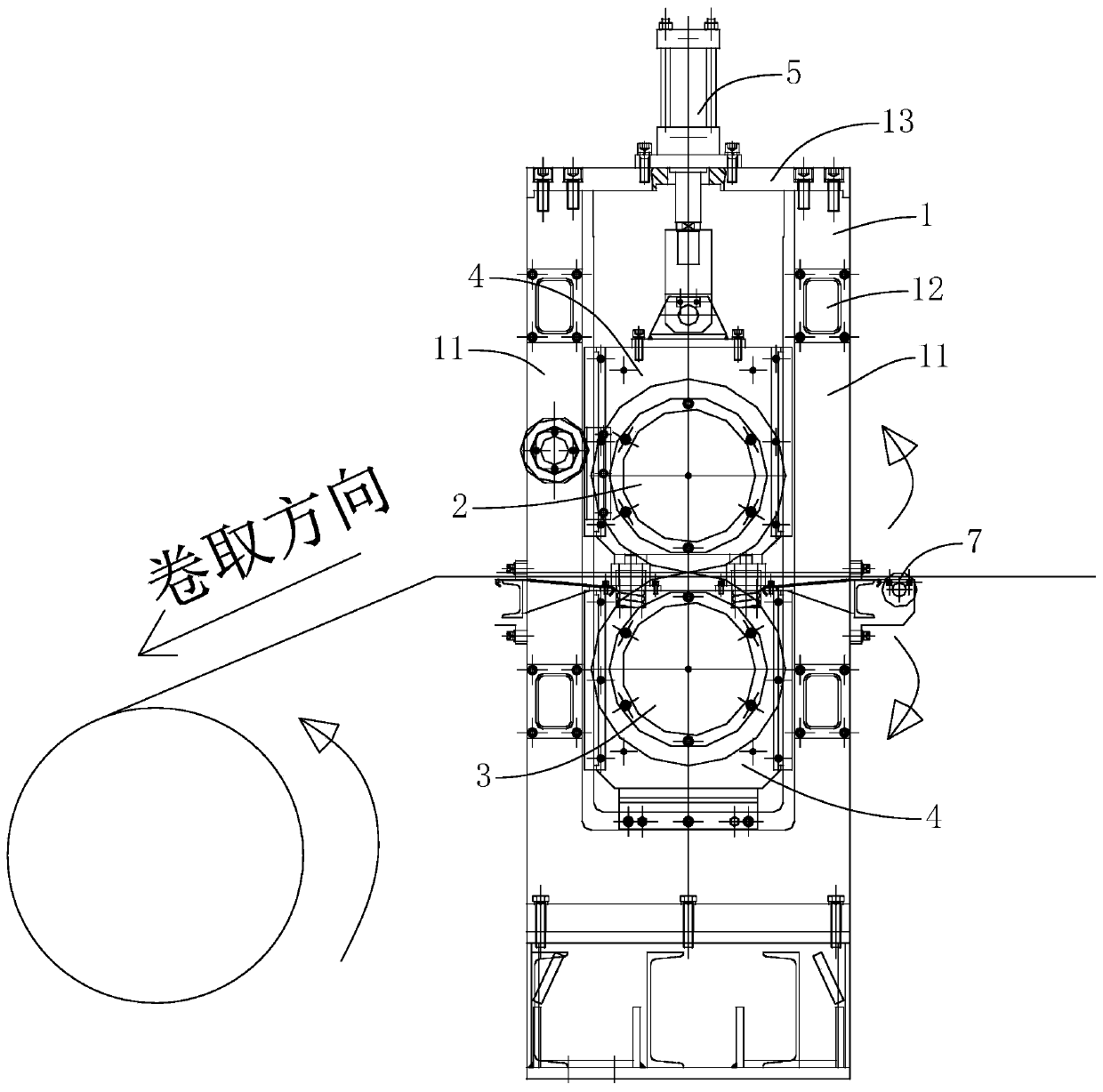

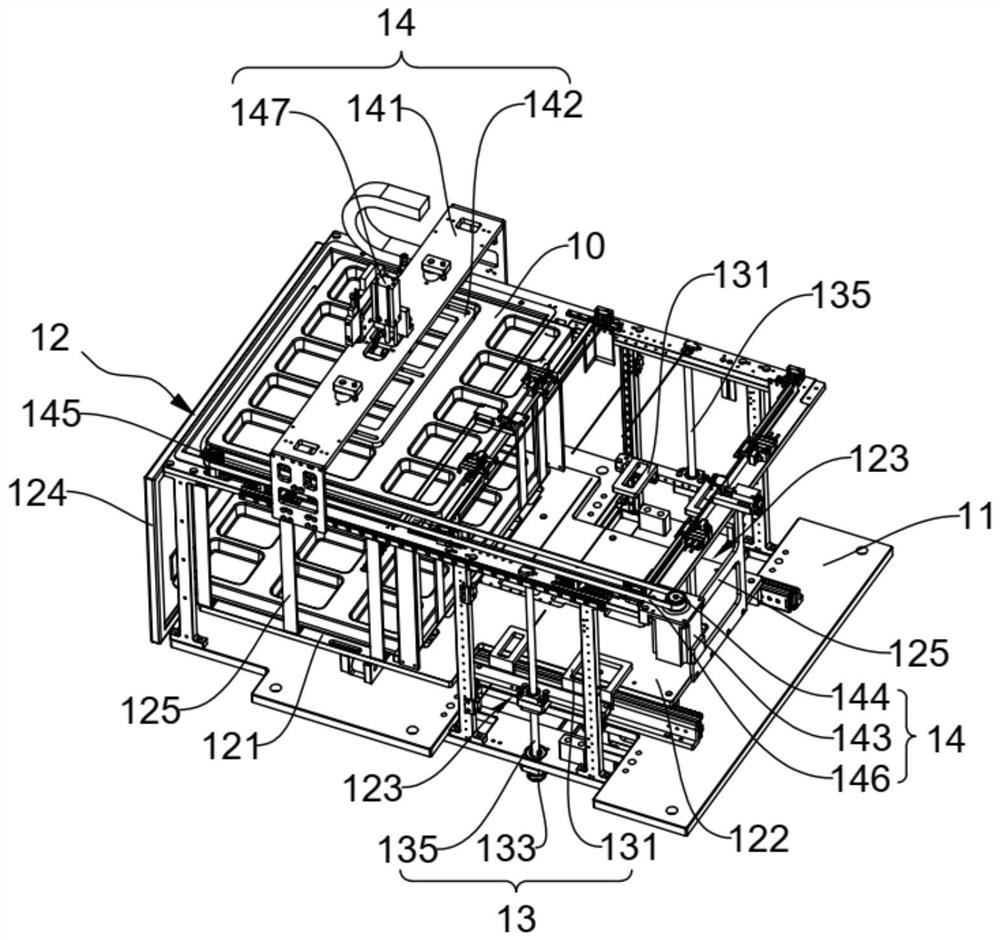

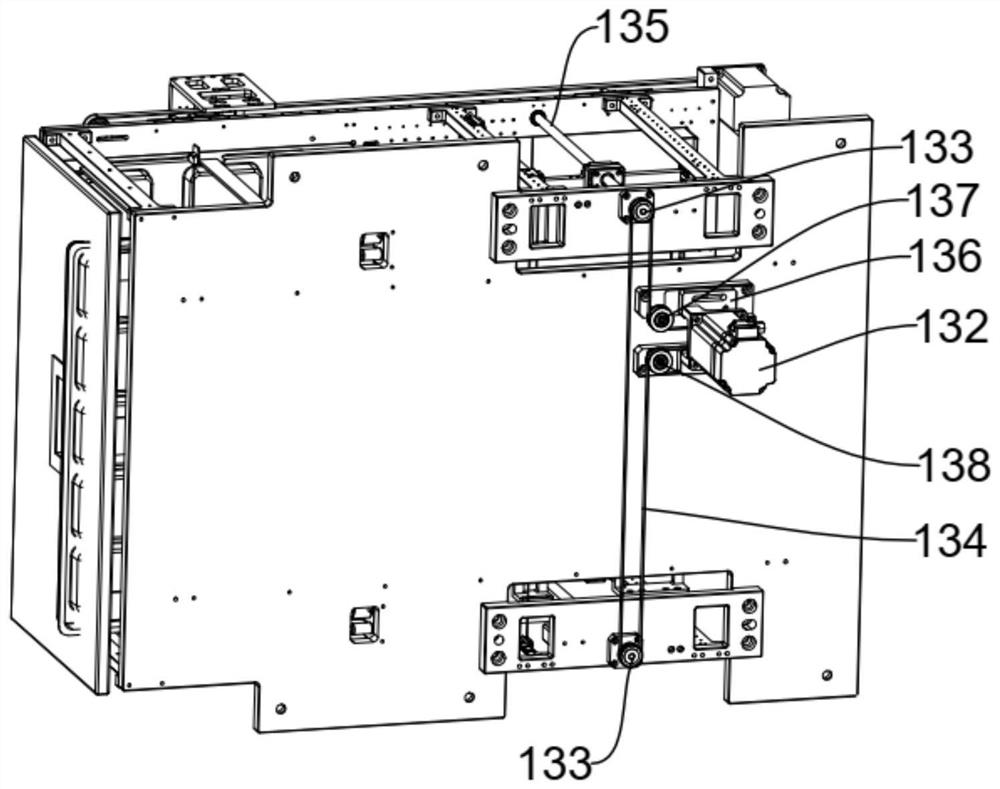

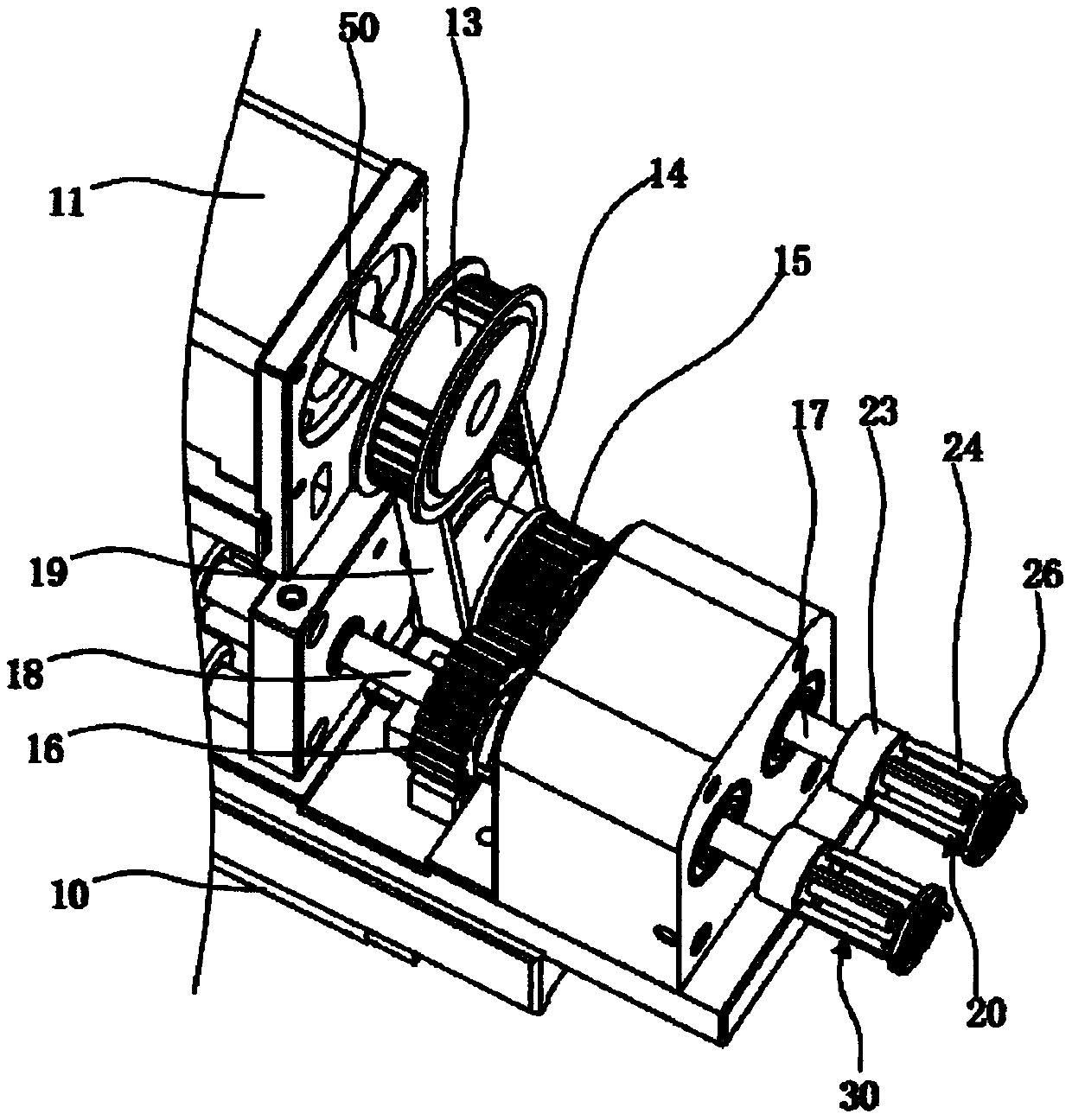

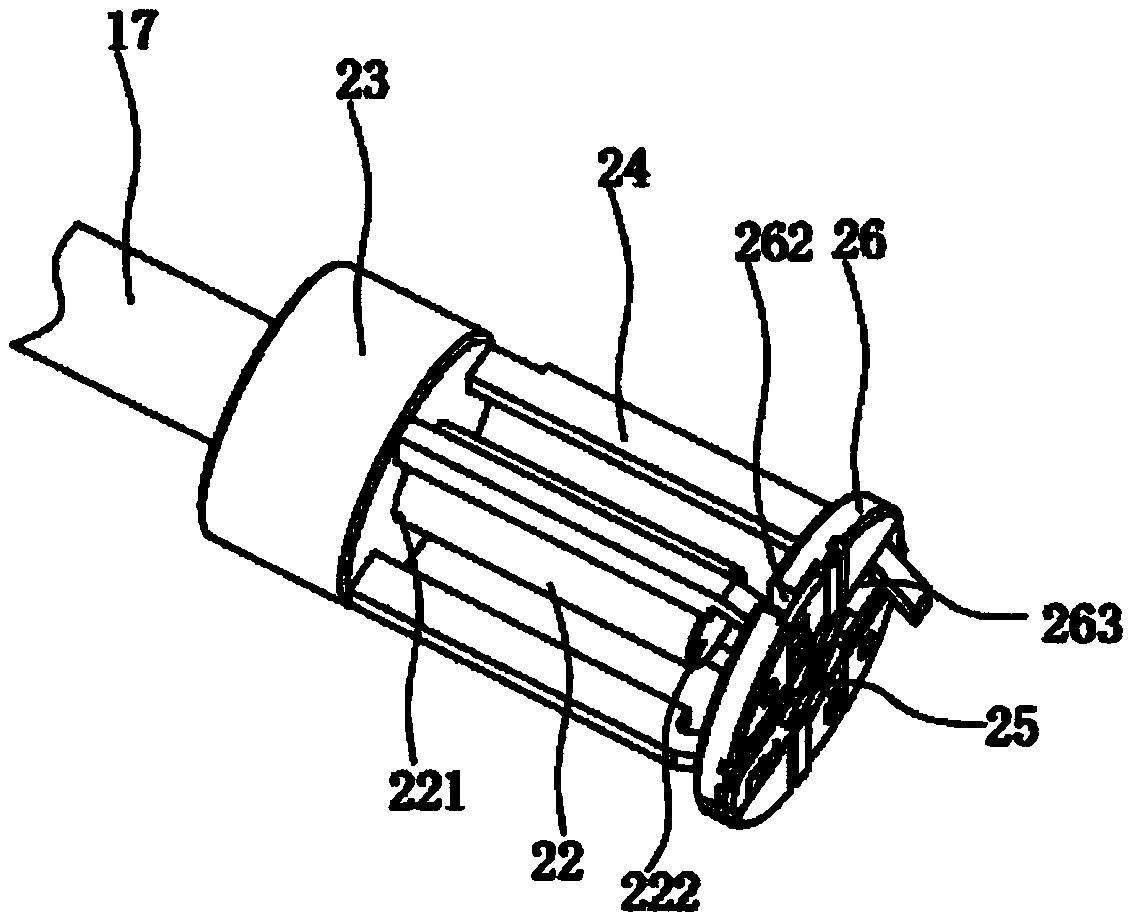

Roller-type tension machine

PendingCN110723583AIncrease level one yieldImprove strip qualityWebs handlingSteel beltStructural engineering

The invention provides a roller-type tension machine. The roller-type tension machine comprises a rack, an upper roller, a lower roller, bearing pedestals, a pressure adjustment mechanism and drivingdevices; the rack comprises two parallel supporting plates, the two ends of the upper roller are rotatably installed between the two supporting plates through the two bearing pedestals respectively, and the two ends of the lower roller are rotatably installed between the two supporting plates and located under the upper roller through the two bearing pedestals respectively; a predetermined gap exists between the upper roller and the lower roller and is used for a steel belt to pass through, the pressure adjustment mechanism is arranged on the rack, and connected with the bearing pedestals at the two ends of the upper roller to drive the upper roller to lift and fall, and the driving devices are used for driving the upper roller and the lower roller to rotate. By means of the roller-type tension machine, reduction of the production cost is facilitated, the quality of the steel belt is improved, high automation is conveniently achieved, and the production efficiency is improved.

Owner:ZHAOQING HONGWANG METAL IND

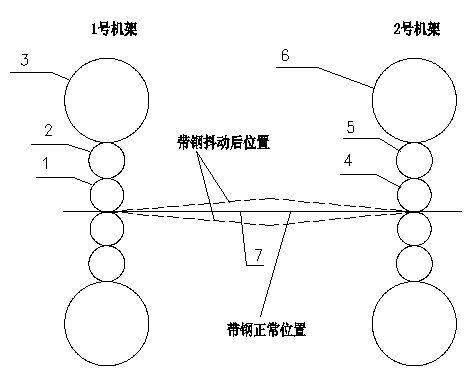

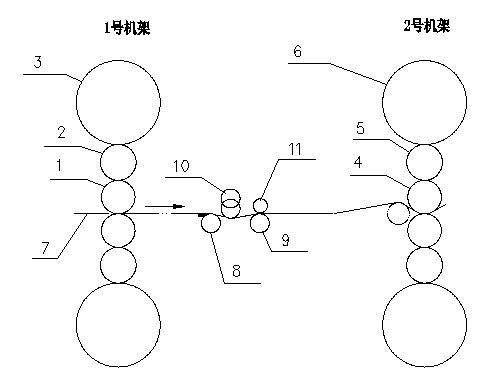

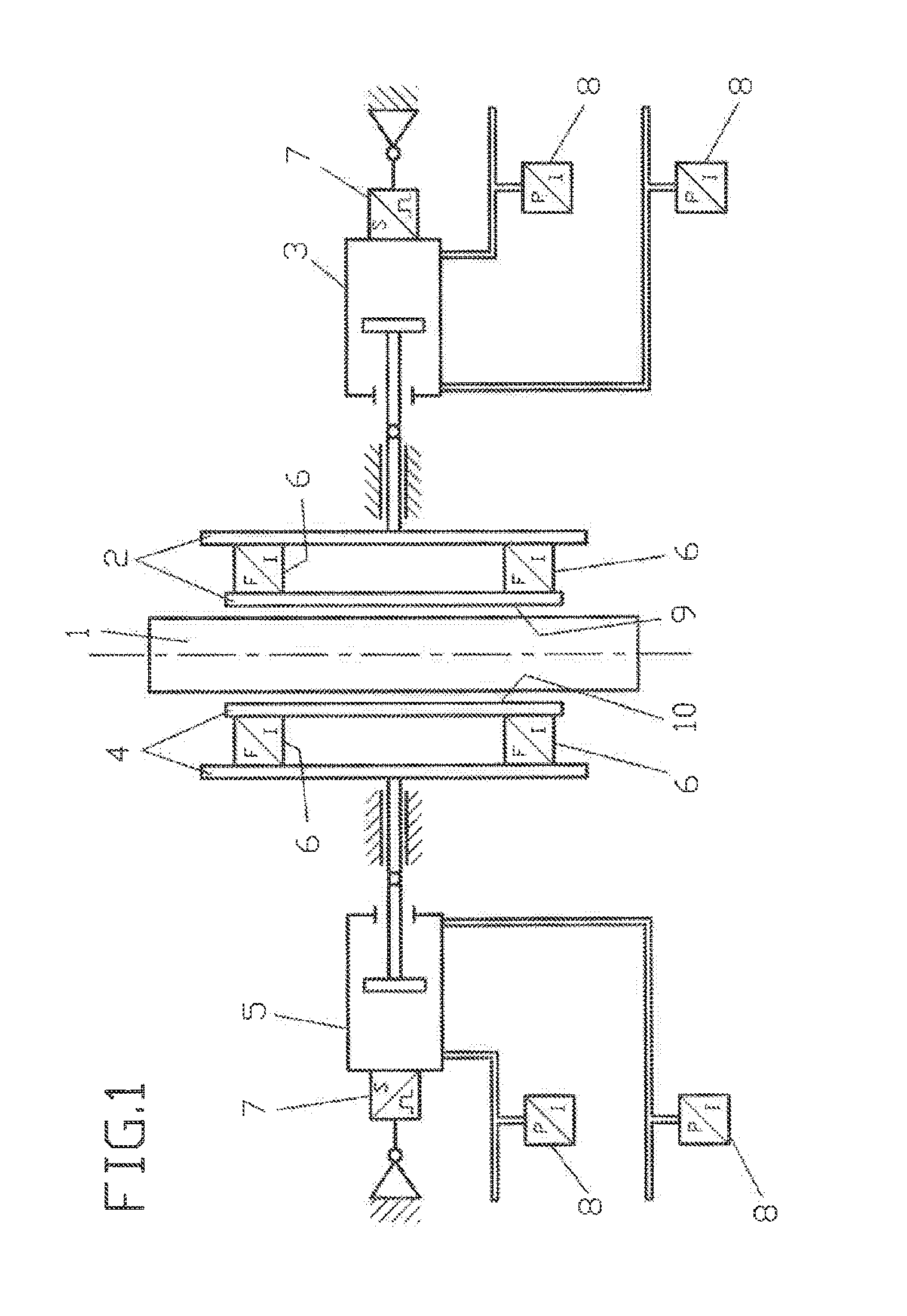

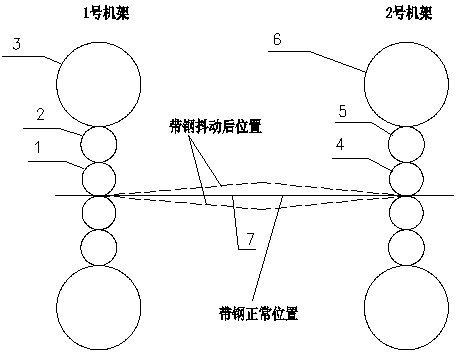

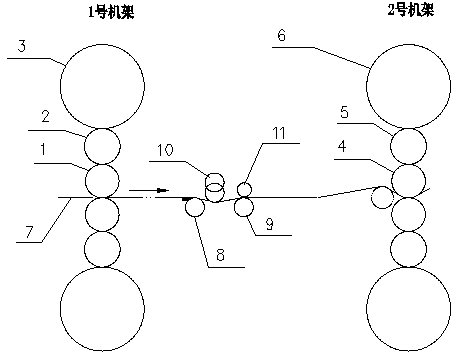

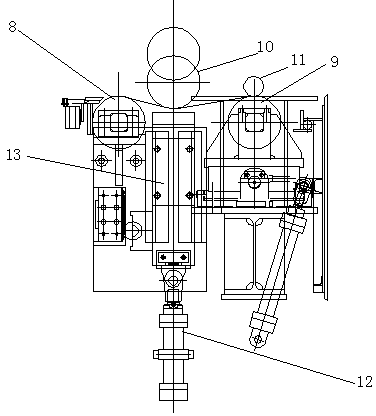

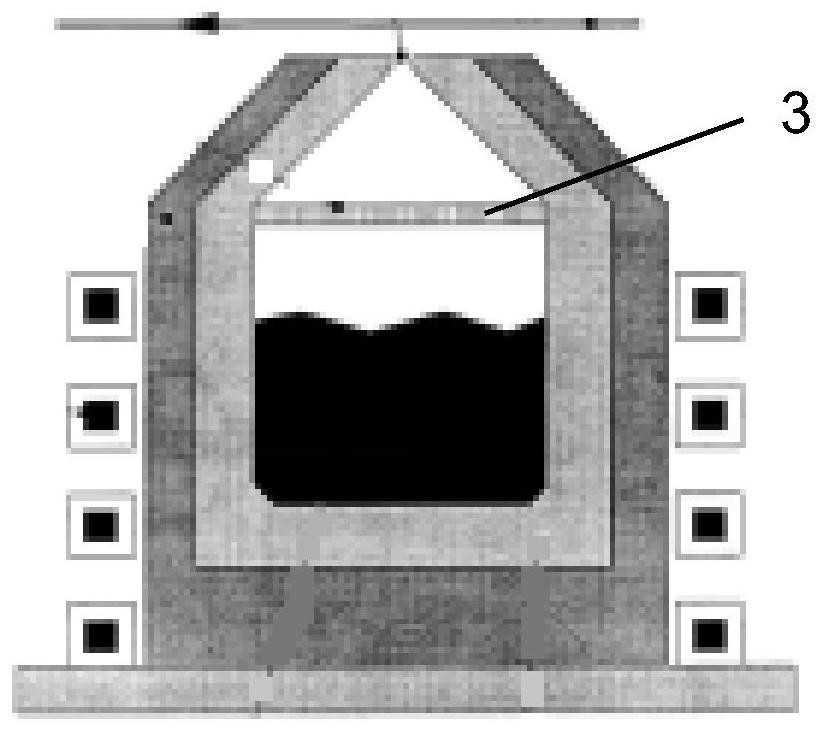

Stable anti-shaking device of double-stand leveling unit band steel and control method thereof

ActiveCN102688890AAddress tension controlImprovement of finished strip qualityRolling equipment maintainenceMeasuring devicesEngineeringTension control

The invention discloses a stable anti-shaking device of double-stand leveling unit band steel and a control method thereof. The anti-shaking device comprises four rollers, wherein the first roller (8) and the second roller (9) are located below a rolling line; the third roller (10) and the fourth roller (11) are located above the rolling line; the third roller realizes lifting through a hydraulic cylinder (12) and a synchronizing mechanism (13); the fourth roller realizes leveling as well as lifting up and pressing down in the tape threading process through the hydraulic cylinder; the third roller is located between the first roller and the second roller; the fourth roller is located above the second roller; in the rolling process of the leveler, the first roller, the second roller and the third roller operate and the fourth roller lifts up; and the anti-shaking device is mounted between a stand 1 and a stand 2 of the leveling unit. The stable anti-shaking device disclosed by the invention can be used for solving the problems of shaking in the operation process of the double-stand leveling unit band steel as well as tension control among the band steel stands and stable tape threading, realizes single-stand rolling of the double-stand leveling unit and improves the quality of the finished product of band steel.

Owner:BAOSHAN IRON & STEEL CO LTD

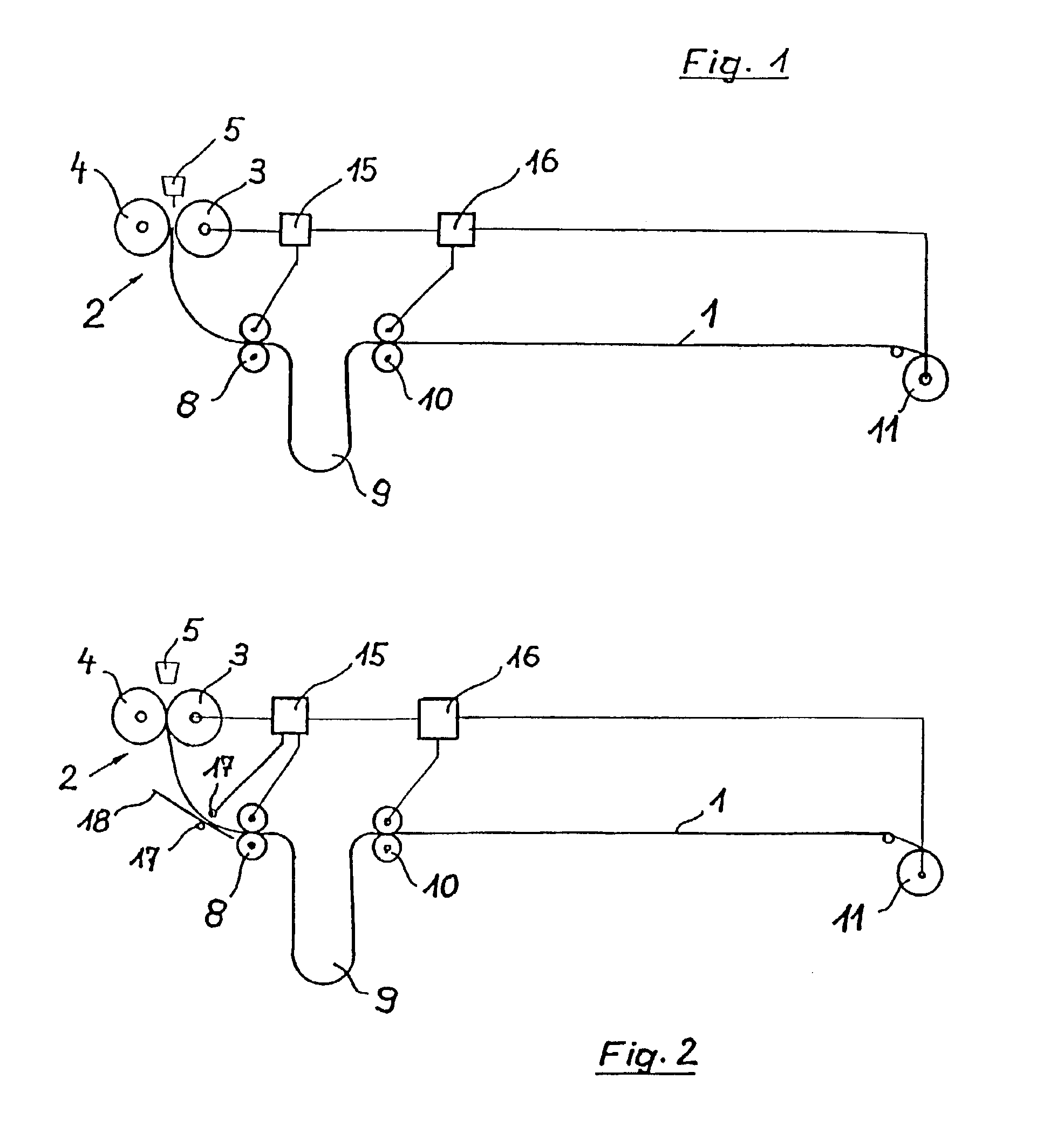

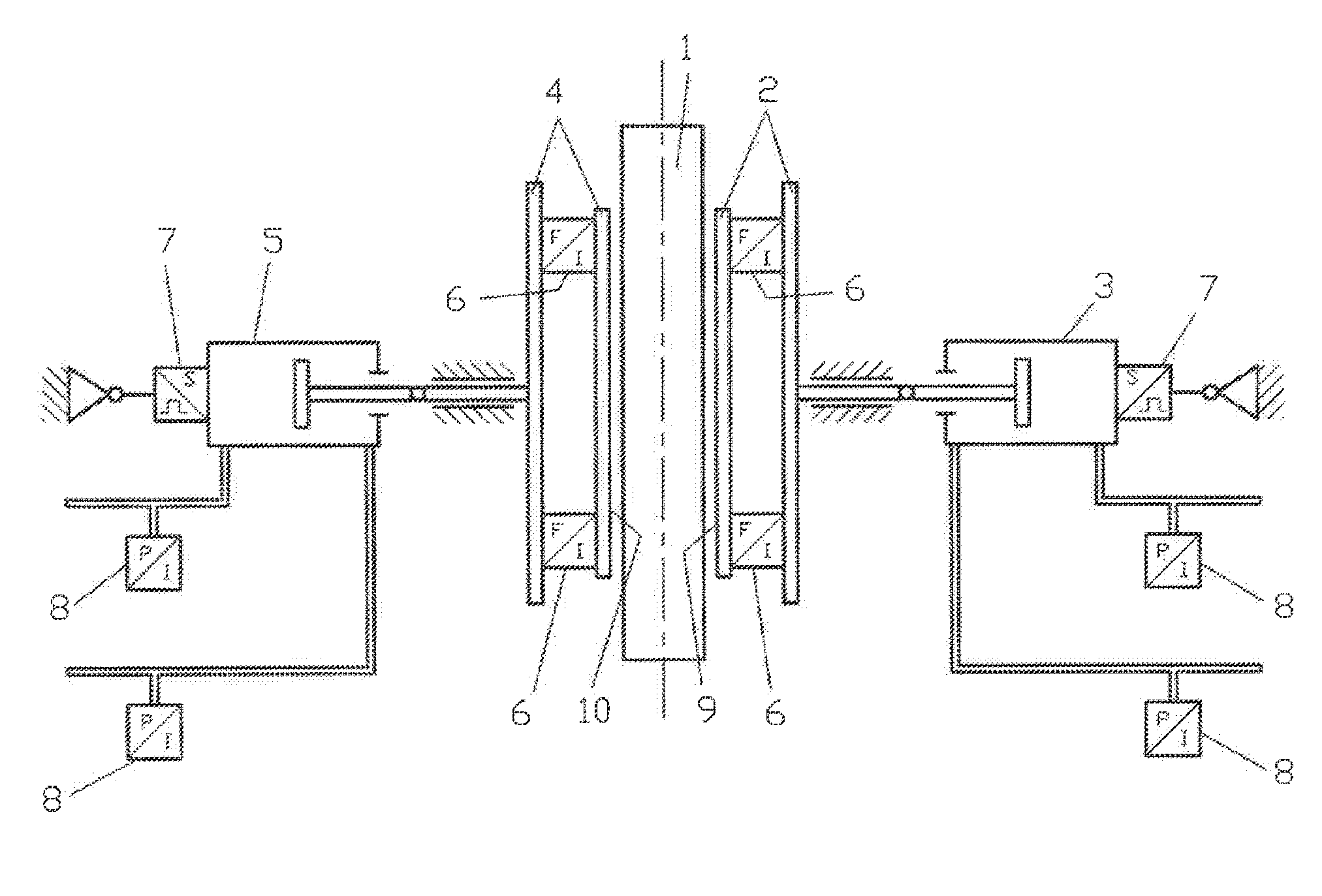

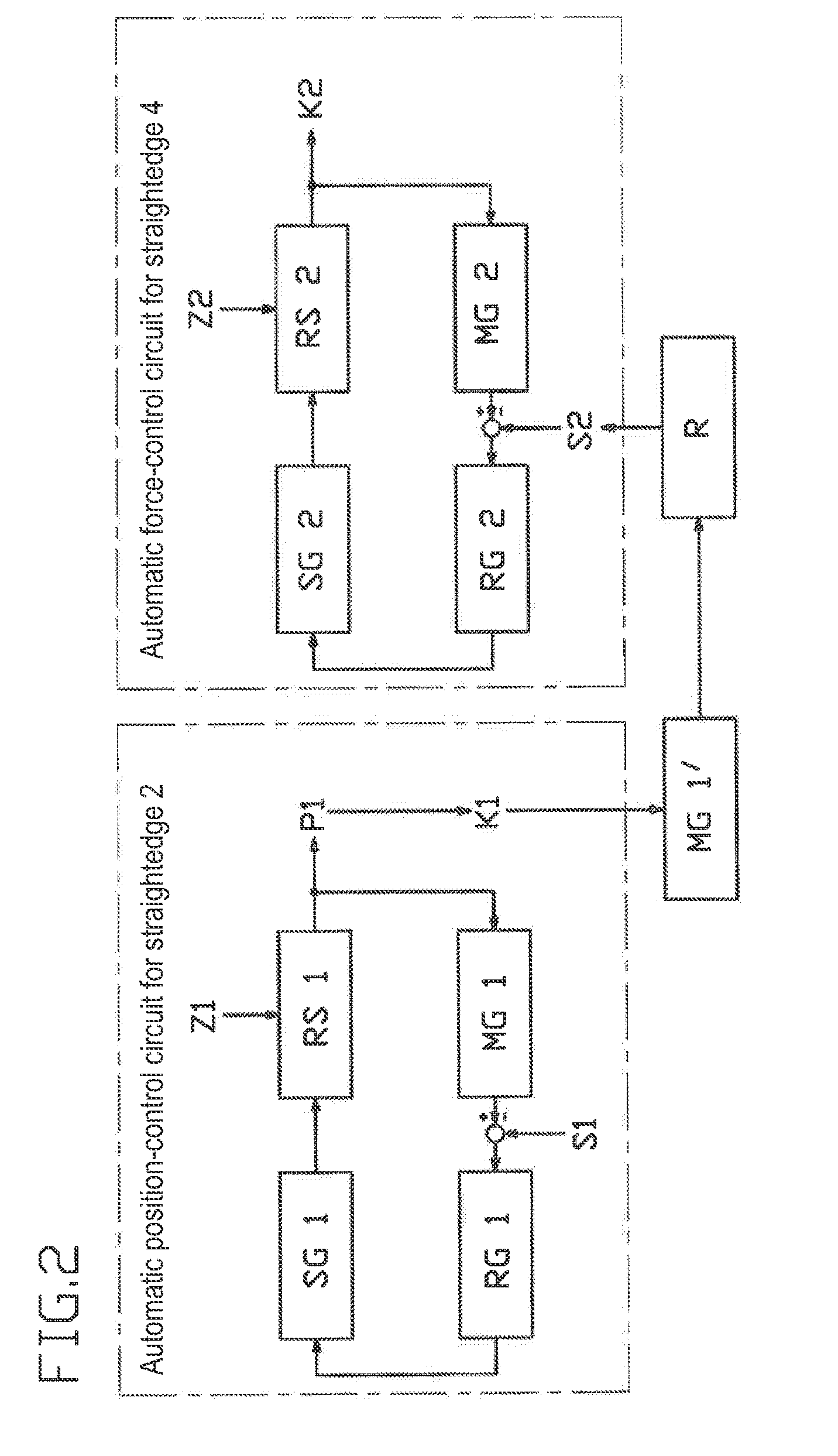

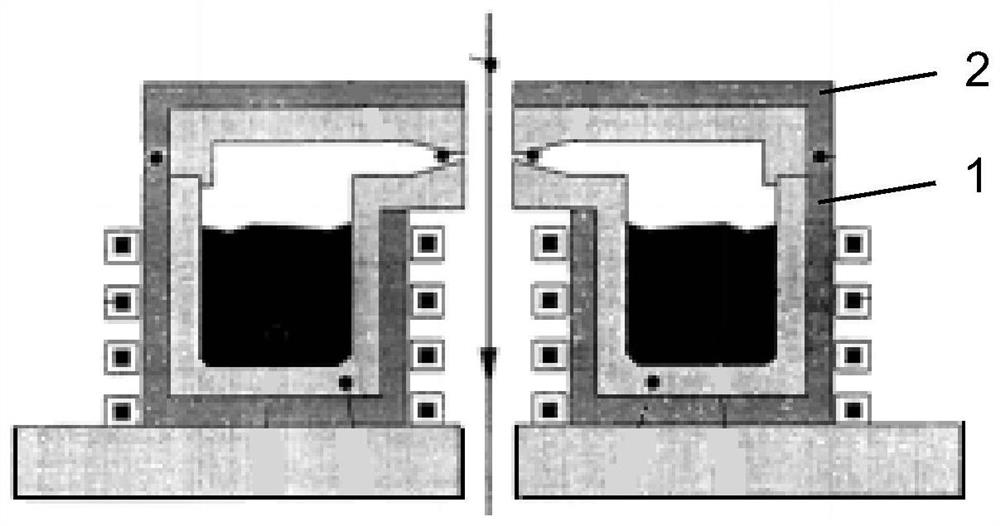

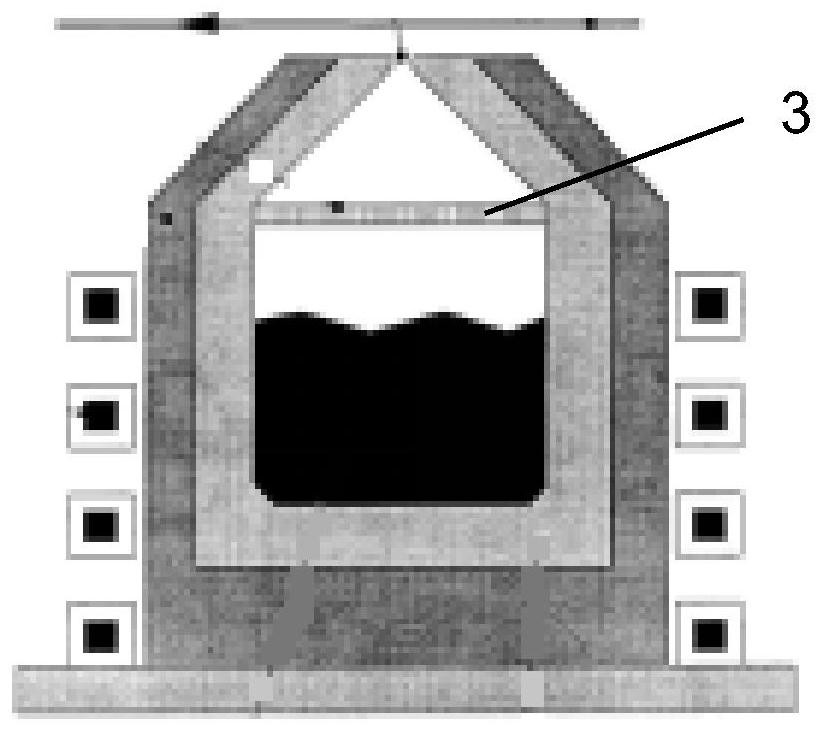

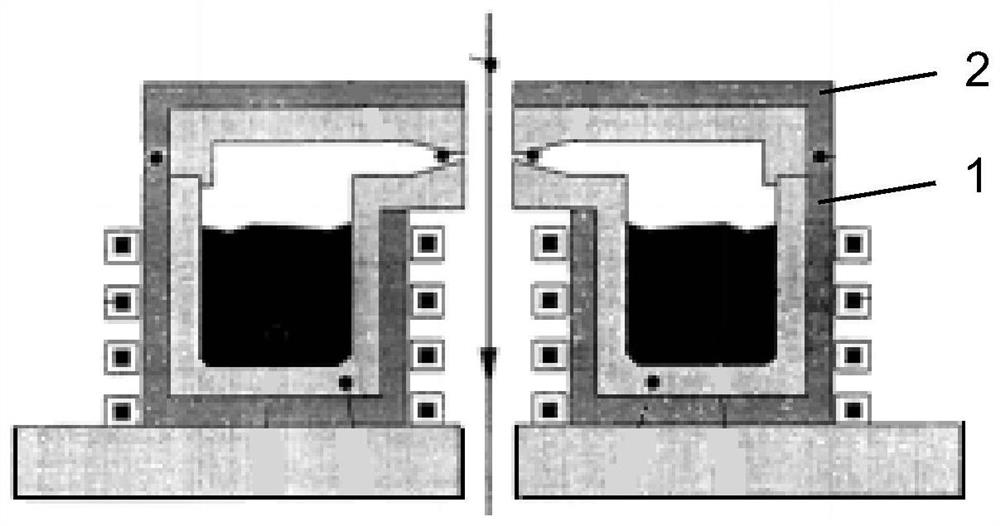

Method for controlling side guides of a metal strip

ActiveUS20120267415A1Long maintenance intervalsImprove strip qualityRoll force/gap control deviceMetal-working feeding devicesMetal stripsStrip mill

The invention relates to a method for controlling a side guide of a metal strip (1), in particular in the inlet or outlet of roll stands or driving apparatuses, wherein the side guide comprises a guide (2, 4) disposed laterally to the metal strip (1) on both sides of the metal strip (1), and the guides (2, 4) can be displaced independently of each other. One of the guides (2) is thereby driven by means of position control, and a second of the guides (4) is driven by means of force control, wherein forces of the metal strip (1) acting on the first guide (2) and the second guide (4) are measured. The target force for the second, force-controlled guide (4) is thereby prescribed as a function of the measured force on the first, position-controlled guide (2), wherein as the force on the first, position-controlled guide (2) increases, the target force for the second, force-controlled guide (4) is reduced. In particular, damage to the guides (2, 4) and to the metal strip (1) can be prevented or at least reduced by means of said type of controlling.

Owner:SMS DEMAG AG

Stripping device and feeding and discharging equipment

PendingCN112193873AAvoid wrinklesGuaranteed assembly accuracyArticle feedersArticle deliveryAdhesive beltMobile phone

The invention belongs to the technical field of mobile phone production and manufacturing, and discloses a stripping device and feeding and discharging equipment. The stripping device comprises: a stripping workbench, wherein the stripping workbench is used for bearing an adhesive tape, the side, away from the stripping workbench, of the adhesive tape is a bonding surface, the bonding surface is used for bonding a sheet material, the sheet material is provided with a plurality of second to-be-assembled parts, and an inlet and an outlet are formed in the two ends of the stripping workbench respectively; and an adhesive tape conveying mechanism, wherein the adhesive tape conveying mechanism is arranged below the stripping workbench, the adhesive tape conveying mechanism is configured to convey the adhesive tape and tension and wind the adhesive tape around the inlet and the outlet respectively, and the parts, located on the two sides of the outlet, of the adhesive tape form an included angle, so that the plurality of second to-be-assembled parts are separated from the sheet material at the outlet; According to the stripping device, through the arrangement of the stripping workbench and the adhesive tape conveying mechanism, stripping of the plurality of second to-be-assembled parts can be achieved along with movement of the adhesive tape, the stripping efficiency is high, two-hand contact is not needed, wrinkles of the plurality of second to-be-assembled parts are avoided, and the stripping quality is improved.

Owner:苏州鑫信腾科技有限公司

Wire stripping device

InactiveCN110021896ARealize mechanization, automation and intelligenceIncreased stripping length rangeApparatus for removing/armouring cablesStripping - actionEngineering

The invention discloses a wire stripping device. The wire stripping device comprises a wire stripping structure. The wire stripping structure comprises a cutter head driving assembly, a first cutter head assembly, a second cutter head assembly and a control module. The controlled end of a first driving structure of the cutter head driving assembly and the controlled end of a second driving structure are connected with the control end of the control module. The first driving structure drives a first connecting shaft to rotate so as to drive the first cutter head assembly and the second cutter head assembly to rotate; the second driving structure drives the first connecting shaft and a second connecting shaft to move along the axis; and a wire stripping knife on the cutter head assembly is controlled to be opened and closed by rotating and moving along the axial direction, so that the wire stripping action is realized. The wire stripping device can solve the problems of low wire stripping efficiency, low precision and the like in the prior art.

Owner:彩美伟业精密电子(昆山)有限公司

Low-frequency cable assembly crimping system wire cable laser stripping device

PendingCN108110588AAvoid position changesImprove stabilityConnection formation by deformationEngineeringElectric cables

The invention discloses a low-frequency cable assembly crimping system wire cable laser stripping device, which comprises a chassis, wherein the side part of the chassis is provided with a carbon dioxide laser emission device, a fan, a water tank and a tracked guiding device, the tracked guiding device comprises a pedestal plate, two sets of track conveying devices, a guide tube and a guide blockare installed on the pedestal plate, each track conveying device comprises a roller frame, a stepping motor and two rollers are mounted on each roller frame, and the stepping motors can drive the rollers to rotate. According to the low-frequency cable assembly crimping system wire cable laser stripping device, the guide tube, the guide block and the track conveying devices are combined, both endsof a wire cable pass through the guide tube and the guide block separately, and the middle part of the wire cable is driven by the track conveying devices.

Owner:无锡胜维电气有限公司

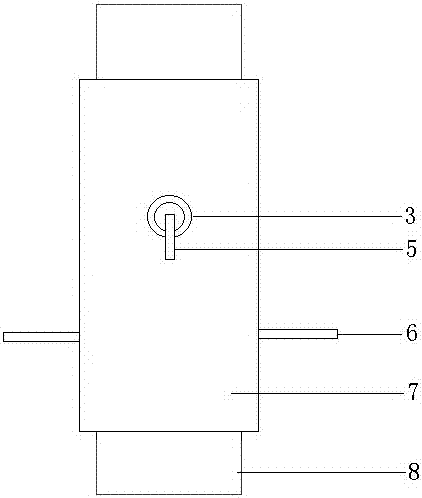

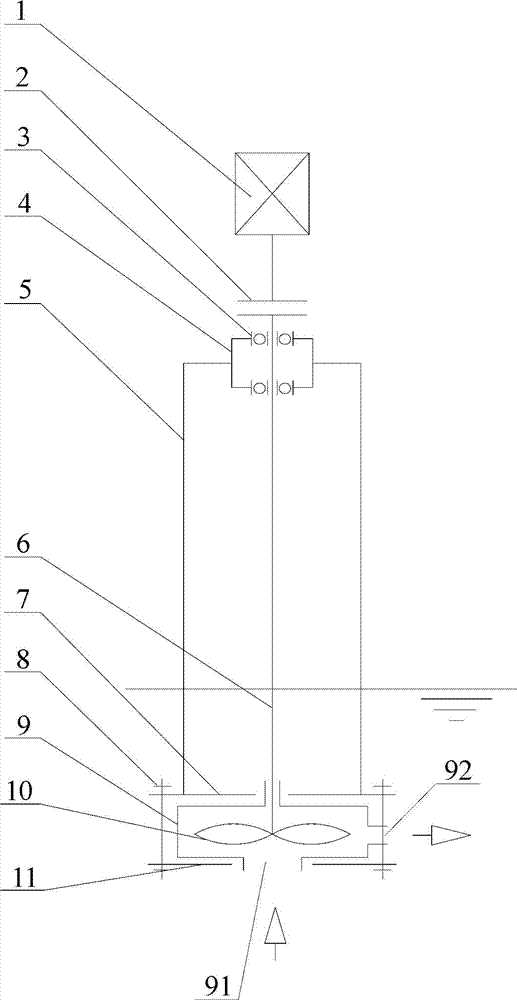

Zinc liquid pump for hot galvanizing

InactiveCN104847665ARemove completelySimple structureSpecific fluid pumpsNon-positive displacement fluid enginesImpellerCoupling

The invention relates to the field of pumping devices or systems, in particular to a zinc liquid pump for hot galvanizing. The zinc liquid pump for hot galvanizing comprises a driving motor (1) and a coupling (2), and is characterized by further comprising a bearing (3), a bearing base (4), a connecting rod (5), a pump shaft (6), a pump upper flange (7), a connecting bolt (8), a pump shell (9), an impeller (10) and a pump lower flange (11), wherein an output shaft of the coupling (2) is connected with the top end of the pump shaft (6); the impeller (10) is arranged in the pump shell (9); the bottom end of the pump shaft (6) penetrates into the pump shell (9) to be connected with the impeller (10); the top end of the pump shaft (6) coats the inner ring of the bearing (3); the bearing (3) is arranged in the bearing base (4); and the bearing base (4) and the pump upper flange (7) are fixedly connected by using the connecting rod (5). The zinc liquid pump for hot galvanizing is simple in structure, convenient to use and thorough in slag removal.

Owner:SHANGHAI DONGXIN METALLURGY TECH ENG

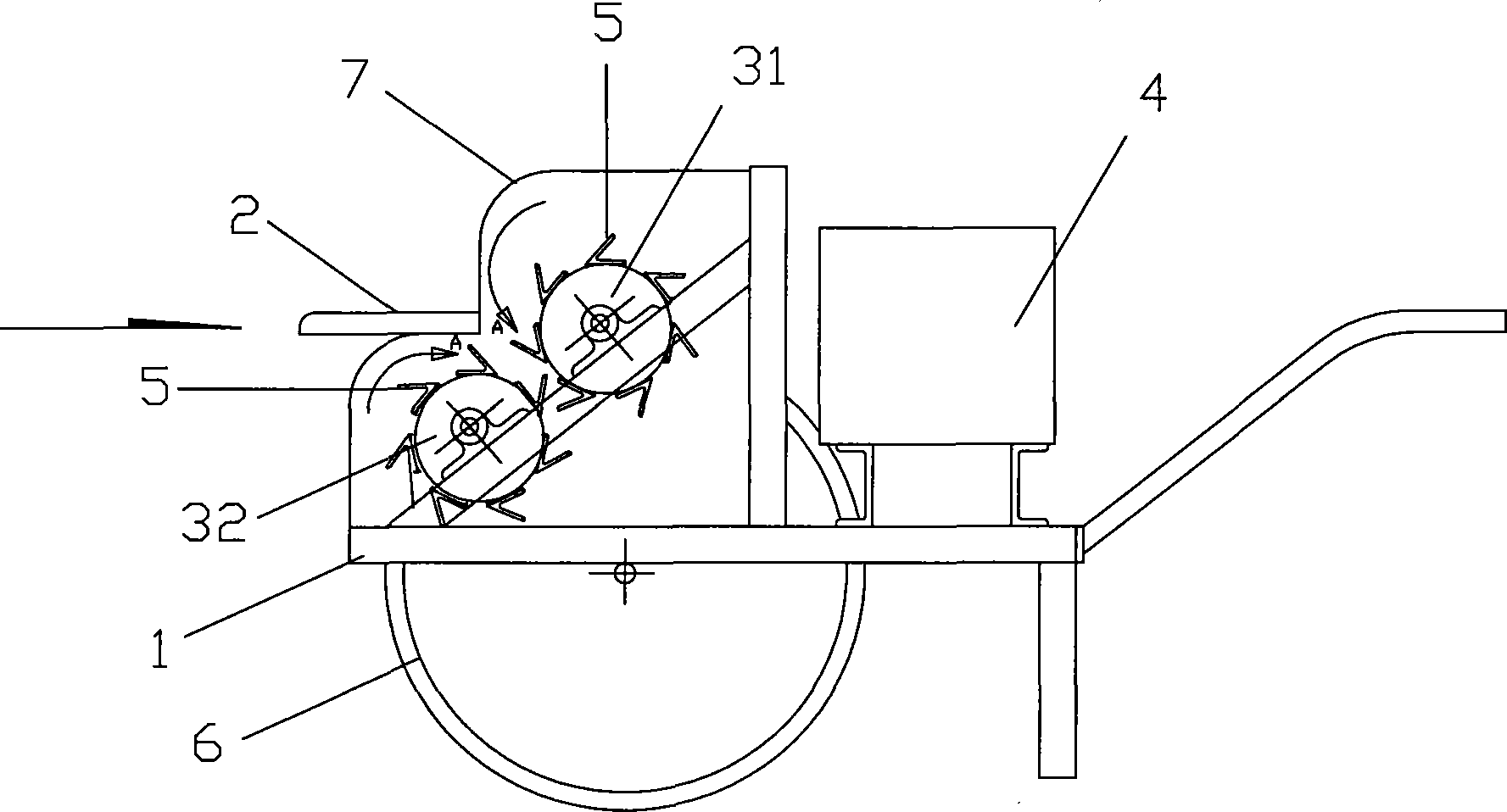

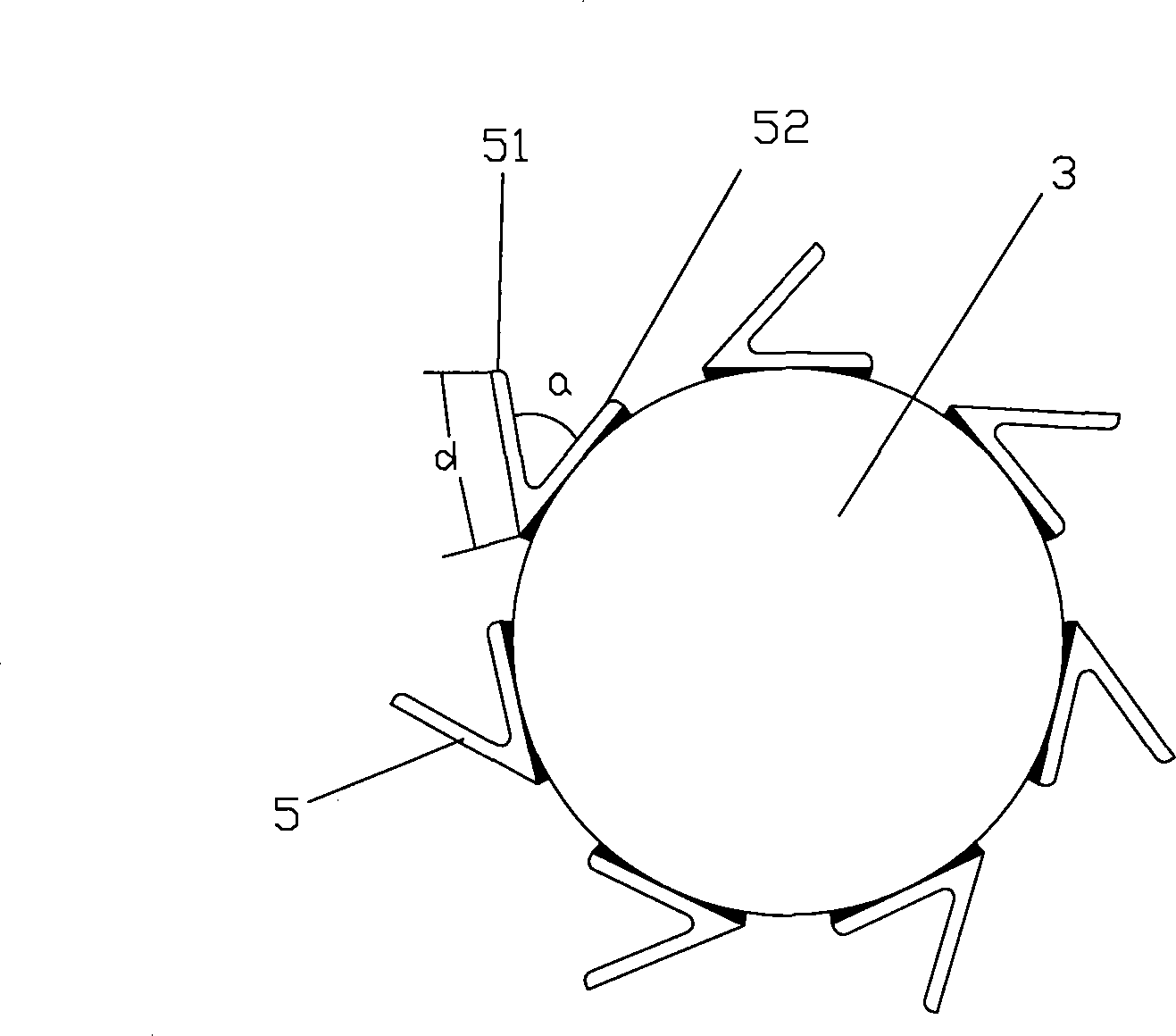

Return pull-type decorticating machine

InactiveCN101250754AEasy to processAvoid entanglementMechanical fibre separationMechanical engineeringHemp fiber

A reverse-drawing decorticating machine comprises a frame, a hemp feeding channel and a decorticating roller which are installed on the frame, a power arrangement which is used for driving the decorticating roller and a beating plate which is installed on the circumferential surface of the decorticating roller, the reverse-drawing decorticating machine is characterized in that the beating plate comprises a working part and an interconnecting piece which is connected with the decorticating roller, the angle a between the working part and the interconnecting piece is 40DEG C-50DEG C, and the orientation of the angle a between the working part and the interconnecting piece is opposite to the rotation direction A of the decorticating roller, the beating plate of the decorticating machine of the invention has big reaction area with the hemp, which can fully hummer and pressure a hemp rod, efficiently reduce the damage of hemp fiber and improve the efficiency of hemp decorticating and quality of the hemp decorticating.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

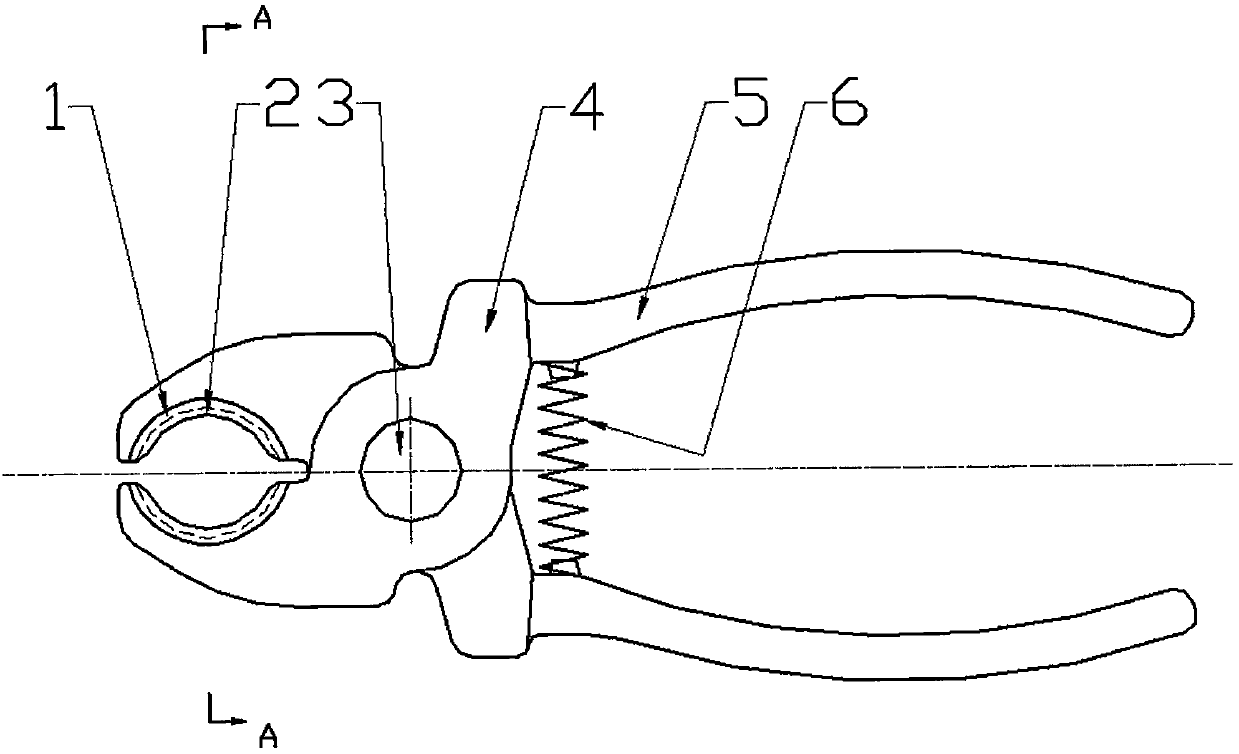

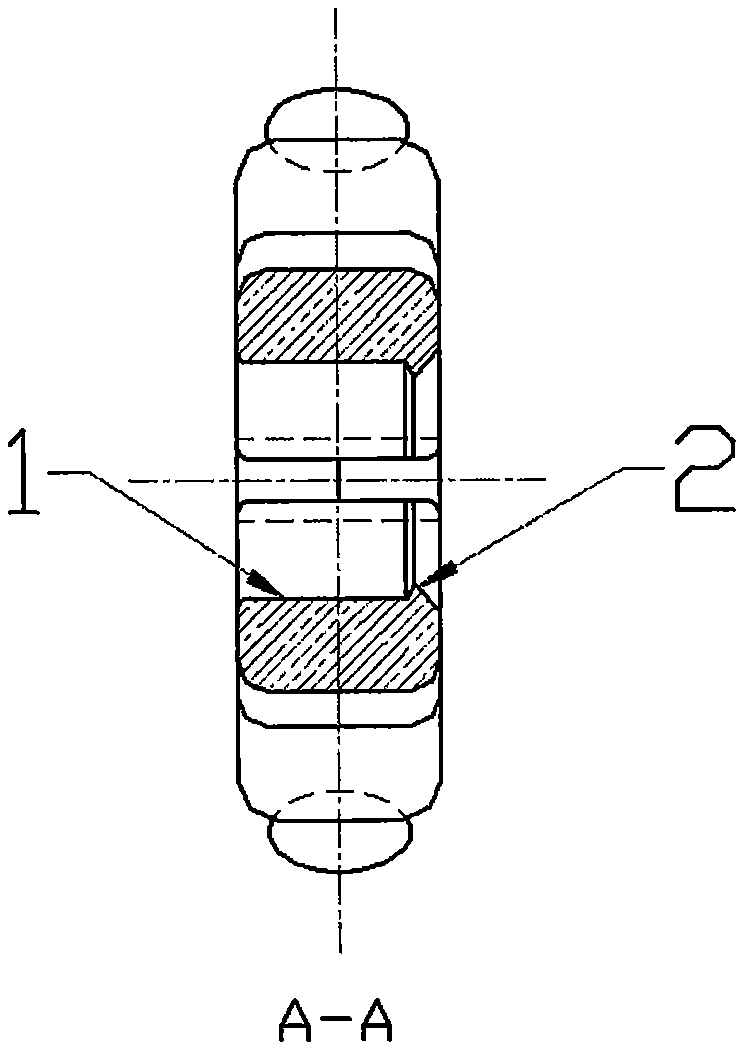

Wire stripper for sheath flexible cable

PendingCN111276910AImprove stripping efficiencyImprove strip qualityApparatus for removing/armouring cablesEngineeringElectric cables

The invention relates to a wire stripper for a sheath flexible cable, which belongs to the field of electric tools and can be used for stripping the sheath flexible cable or other similar cables and wires. The invention aims to provide the wire stripper for the sheath flexible cable, which tears a sheath or a conductor insulation through a bending method and can continuously complete tearing and stripping, so that the wire stripping is labor-saving and efficient. The wire stripper is characterized in that the jaw is in an arc shape and is composed of an upper arc and a lower arc which are symmetrical, arc-shaped pliers teeth are arranged on one side of the jaw along the jaw, the section of each pliers tooth is in a sawtooth shape, the working direction of the pliers teeth faces the other side of the jaw, the front sections of the grips extend towards the two sides respectively, and the spring enables the jaw to be opened.

Owner:SHANDONG UNIV OF SCI & TECH

Hot rolling process for producing electrical steel free of metal flow stacking defect

InactiveCN107812786AImprove strip qualityConvenient hot rolling processTemperature control deviceMetal rolling arrangementsElectrical steelSteel belt

The invention relates to a hot rolling process for producing electrical steel free of a metal flow stacking defect. Firstly, chemical components of the electrical steel are determined, and the electrical steel is cast into a plate blank, wherein the chemical components of the electrical steel specifically comprise 0.0025% or less of C, 0.38%-0.44% of Si, 0.24-0.35% of Mn, 0.06%-0.075% of P, less than 0.0072% of S, 0.003%-0.004% of Als, 0.003%-0.0042% of N and the balance Fe and unavoidable impurity elements. The hot rolling process has the characteristics that the quality of steel strips is improved, the steel strip hot rolling process is greatly facilitated, and the production percent of pass of steel strips is greatly improved by changing the hot rolling process.

Owner:NINGBO IRON & STEEL

A high-efficiency photovoltaic cable stripping machine

ActiveCN109802337BFast startupAccurate and fast stripping operationApparatus for removing/armouring cablesStructural engineeringOperational safety

The invention relates to an efficient photovoltaic cable stripping machine. The cable stripping machine comprises a case, and a fixed plate is vertically connected to the center of the top of the case. Rails are symmetrically connected to the left side of the top of the case. The tops of the rails are slidingly connected with a movable plate, and wire stripping cylinders are symmetrically connected to the right side of the top of the case. Moreover, piston rods of the cable stripping cylinders slidingly pass through the fixed plate to be fixedly connected to the side surface of the movable plate. A first cable stripping hole and a second cable stripping hole are respectively formed in the centers of the fixed plate and the movable plate in a penetrating manner. The inner side of the firstcable stripping hole is rotationally connected with a cable stripping pipe through a bearing. The left and right ends of the cable stripping pipe are respectively in cup joint with a rotating gear anda rotating clamp. The cable stripping machine is convenient to strip cables, is high in starting speed, can achieve the automatic stripping, is convenient to adjust, can adapt to stripping of cablesof different sizes, is convenient to operate, is safe and reliable, can accurately and quickly strip the cables, cannot damage the wires, improves cable stripping efficiency and quality, and is good in application prospect.

Owner:吴江市华林精密五金机械有限公司

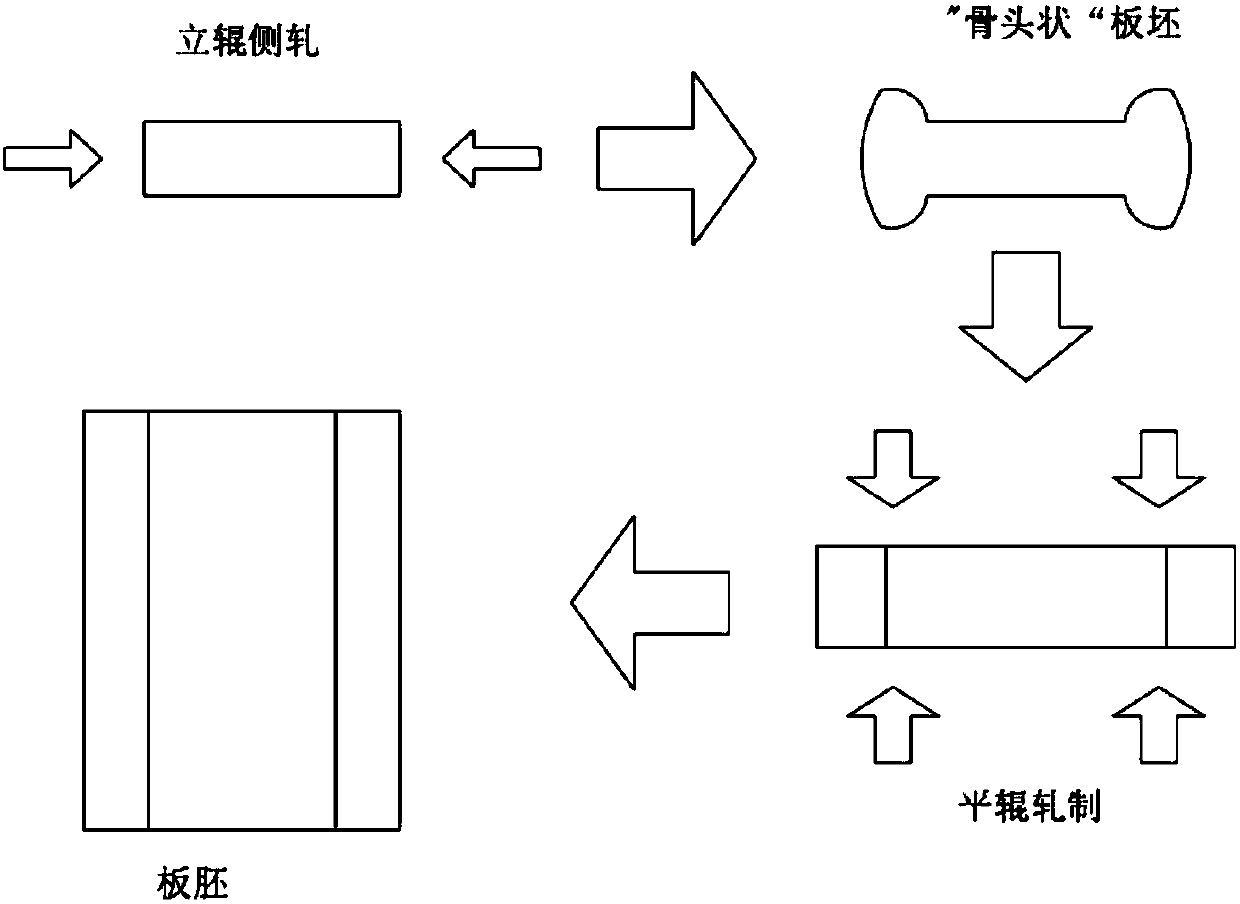

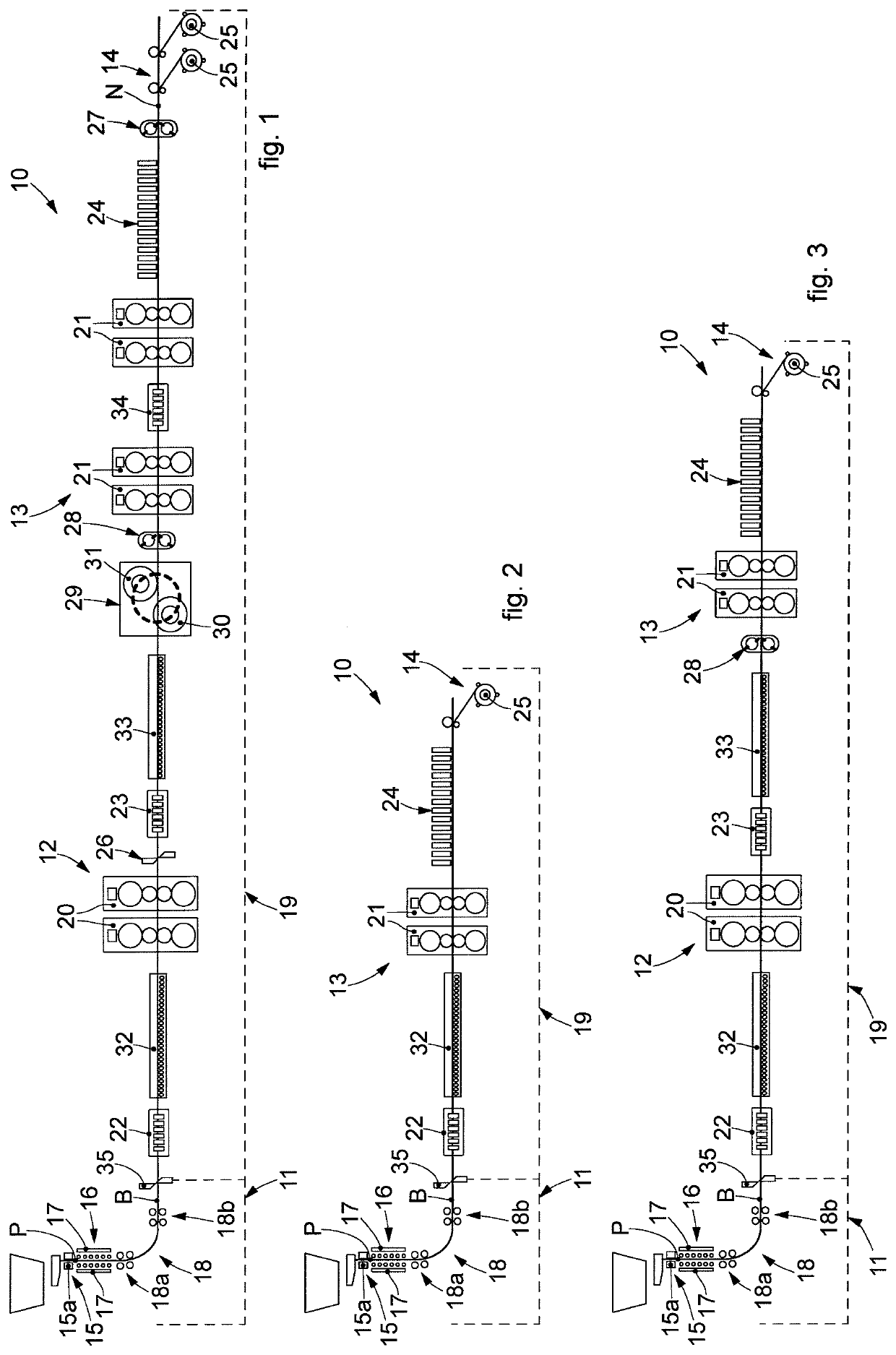

Method to produce a metal strip, and production plant implementing said method

InactiveUS20220001442A1Improve stripping efficiencyImprove strip qualityMetal rolling arrangementsMetal stripsContinuous caster

Method to produce metal strip that comprises the casting of a cast product through a casting machine provided with a crystallizer to obtain a slab, and the hot rolling of the slab in a rolling station to obtain metal strip. The casting machine, during casting, exerts an action of reducing the thickness of the cast product exiting the crystallizer.

Owner:DANIELI & C OFF MEC SPA

Vacuum coating device with flow restraining type nozzle

ActiveCN112553578AImprove strip qualityGood for initial distributionVacuum evaporation coatingSputtering coatingCrucibleInduction heater

The invention discloses a vacuum coating device with a flow restraining type nozzle. The vacuum coating device comprises a crucible, an induction heater is arranged on the outer side of the crucible,a flow distribution box body is connected to the top of the crucible through a steam pipeline, a horizontal pressure stabilizing plate is arranged in the flow distribution box body, a nozzle is formedin the top of the flow distribution box body, and a pressure regulating valve is arranged on the steam pipeline; the pressure stabilizing plate is of a porous structure, a flow restraining plate is connected to the lower surface of the pressure stabilizing plate, the flow restraining plate is further arranged in the horizontal direction, and a gap is formed between the side edge of the flow restraining plate and the inner wall of the flow distribution box body; and a jet flow relaxation area is formed between the connecting position of the flow distribution box body and the steam pipeline andthe lower surface of the pressure stabilizing plate, and a jet flow acceleration area is formed between the upper surface of the pressure stabilizing plate and the connecting position of the flow distribution box body and the nozzle. When high-temperature steam makes contact with a low-temperature steel plate, uniform coatings are formed on the surface of the steel plate.

Owner:BAOSHAN IRON & STEEL CO LTD

Stable anti-shaking device of double-stand leveling unit band steel and control method thereof

ActiveCN102688890BImprove strip qualityQuality improvementRolling equipment maintainenceMeasuring devicesHydraulic cylinderStrip steel

The invention discloses a stable anti-shaking device of double-stand leveling unit band steel and a control method thereof. The anti-shaking device comprises four rollers, wherein the first roller (8) and the second roller (9) are located below a rolling line; the third roller (10) and the fourth roller (11) are located above the rolling line; the third roller realizes lifting through a hydraulic cylinder (12) and a synchronizing mechanism (13); the fourth roller realizes leveling as well as lifting up and pressing down in the tape threading process through the hydraulic cylinder; the third roller is located between the first roller and the second roller; the fourth roller is located above the second roller; in the rolling process of the leveler, the first roller, the second roller and the third roller operate and the fourth roller lifts up; and the anti-shaking device is mounted between a stand 1 and a stand 2 of the leveling unit. The stable anti-shaking device disclosed by the invention can be used for solving the problems of shaking in the operation process of the double-stand leveling unit band steel as well as tension control among the band steel stands and stable tape threading, realizes single-stand rolling of the double-stand leveling unit and improves the quality of the finished product of band steel.

Owner:BAOSHAN IRON & STEEL CO LTD

Flexible wire stripping device for cable

PendingCN109787160AImprove stripping efficiencyWon't hurtApparatus for removing/armouring cablesElectronic waste recyclingPower cableEngineering

The invention relates to the technical field of cable tools, in particular to a flexible wire stripping device for a cable. The device comprises a rack base and a wire stripping device body, wherein the wire stripping device body is fixedly installed on the rack base and comprises a cable conveying unit for the cable to move between every two pieces of work, a cable clamping unit used for clampingcables, an axial cutting unit used for carrying out axial stripping and cutting on the cable, a radial cutting unit used for carrying out radial stripping and cutting on the cable, a protective coverused for carrying out safety protection in a wire stripping process, and a control unit used for controlling each mechanism to harmonically work to finish cable wire striping. By use of the structurearrangement, the middle wire striping and end part wire striping of power cables of different wire diameters can be finished, wire stripping efficiency and quality is improved, and the labor intensity of personnel is lightened.

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST

Automatic cable stripping machine

PendingCN108736388AIncrease productivityImprove strip qualityApparatus for removing/armouring cablesElectronic waste recyclingEngineeringMechanical engineering

The invention relates to the technical field of cable outer layer stripping, and particularly relates to an automatic cable stripping machine. The automatic cable stripping machine comprises a machinestand and a machine stand cable placement table; a left cable stripping mechanism and a right cable stripping mechanism which are used for carrying out cable stripping on a cable on the cable placement table are respectively arranged at both sides of the cable placement table; a cable pressure mechanism is arranged at the upper side of the cable placement table; the cable pressure mechanism comprises a pressure rod, a pressure plate and a driving mechanism; the pressure rod is connected with the pressure plate by a connection rod; the bottom end of the connection rod sleeves the upper end ofthe pressure rod; a spring is arranged between the bottom end of the connection rod and the top end of the pressure rod; the top end of the connection rod is connected with the pressure plate by a force unloading mechanism; the force unloading mechanism comprises a force unloading barrel arranged at the bottom of the pressure plate and a force unloading spring inside the force unloading barrel; the upper end of the connection rod is embedded in the force unloading barrel and is in sliding fit with the inner wall of the force unloading barrel; the bottom end of the force unloading spring is pressed against the top end of the connection rod; and a limiting mechanism for limiting a descent height of the connection rod is arranged at the position of the cable placement table. The single-side or both-side simultaneous stripping operation of the cable is implemented, and production efficiency is high.

Owner:CHANGZHOU INST OF LIGHT IND TECH

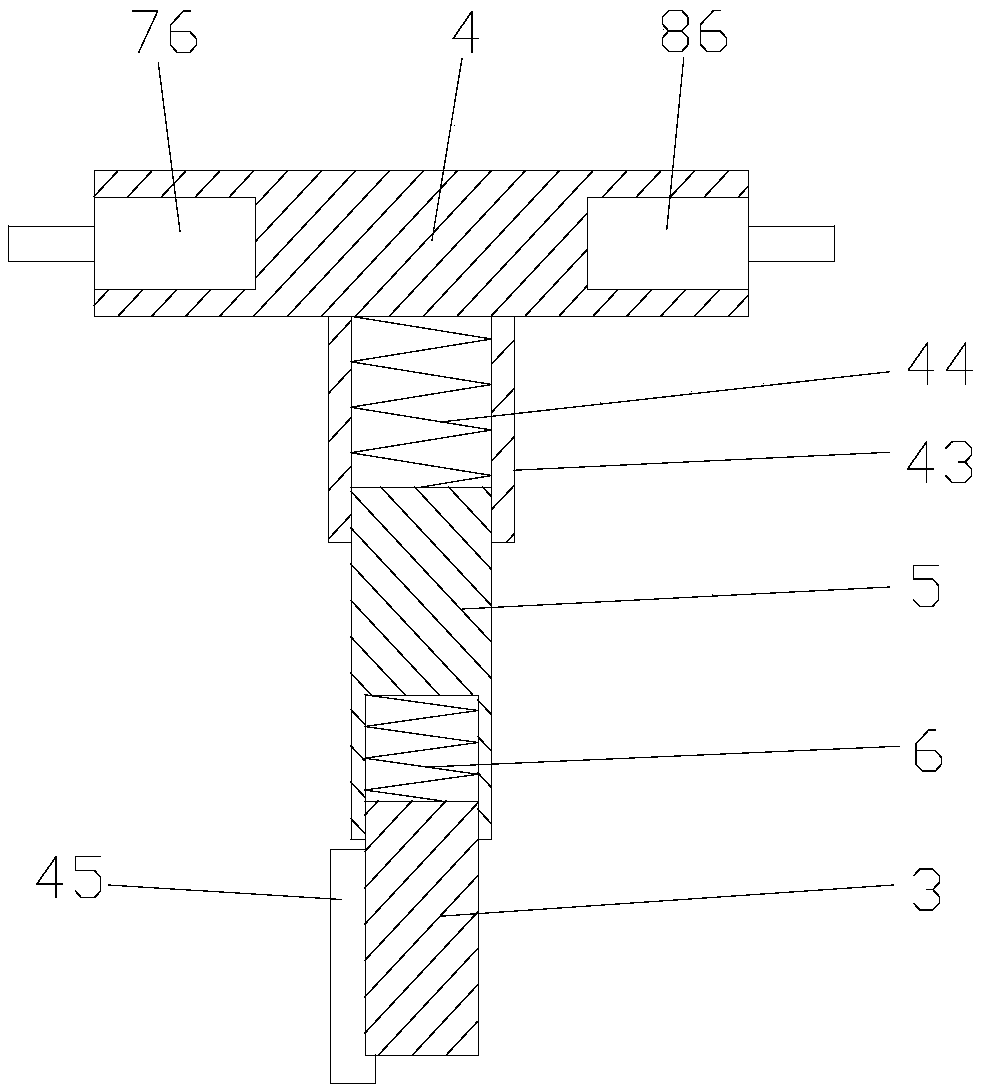

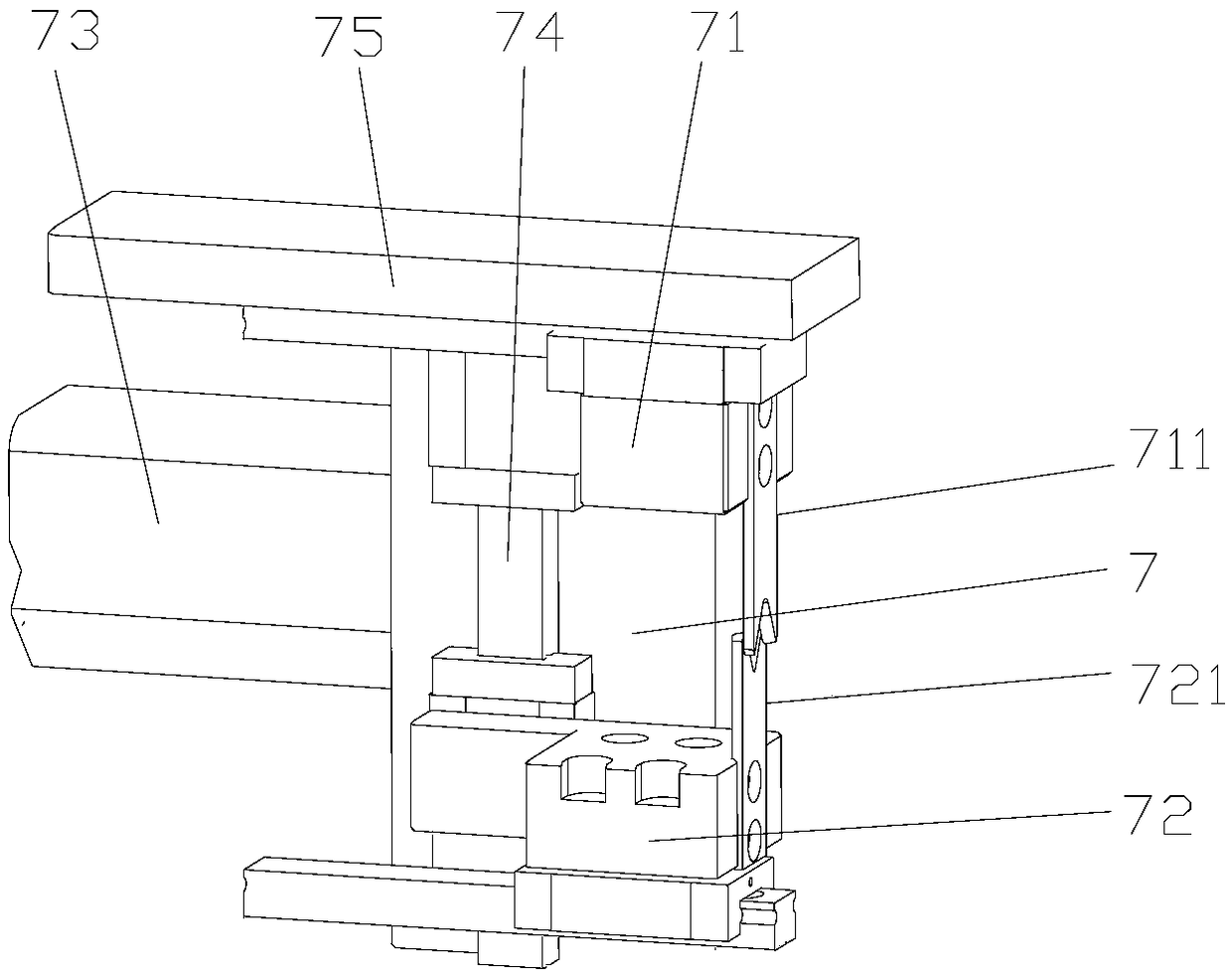

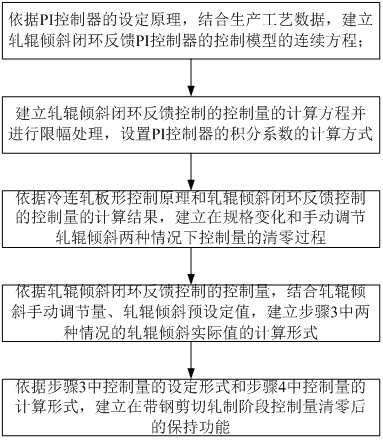

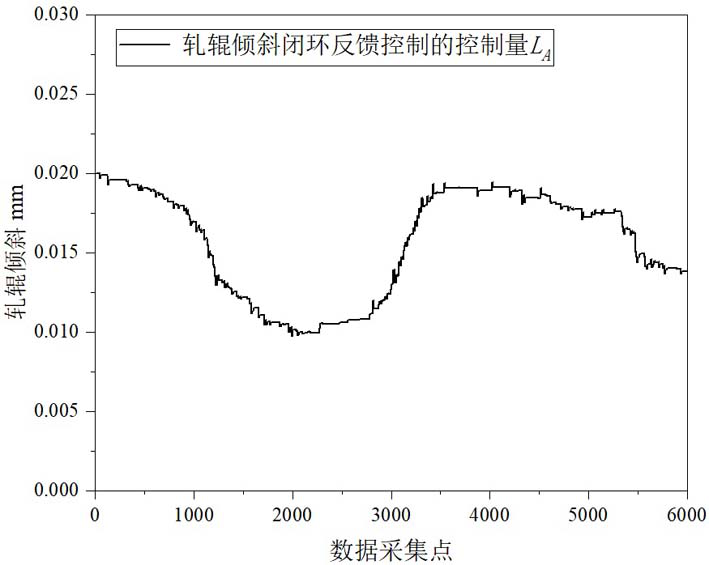

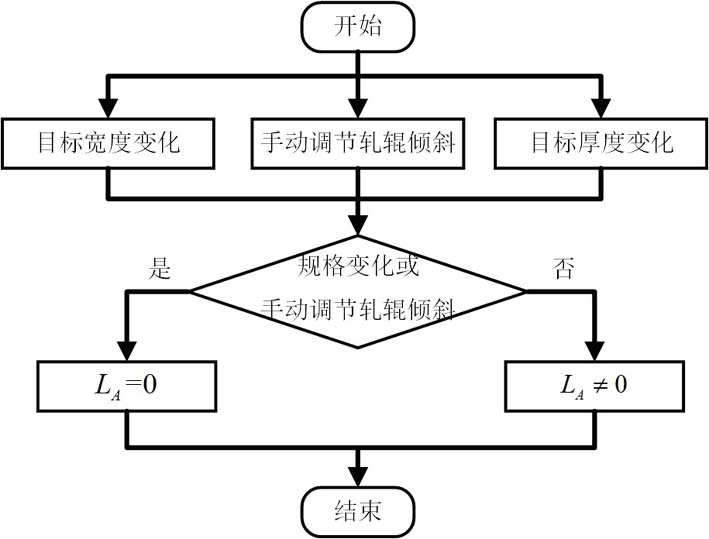

Roller inclination output control method based on plate shape closed-loop regulating variable

ActiveCN114653761AImprove strip qualityImprove stabilityTotal factory controlProfile control deviceWeld beadClosed loop feedback

The invention discloses a roll inclination output control method based on a plate shape closed-loop regulating variable, and the method comprises the steps: building a continuous equation of a control model of a roll inclination closed-loop feedback PI controller and a discrete calculation expression of the continuous equation according to a setting principle of the PI controller; by means of the process characteristics of cold-rolled strip steel production and the control characteristics of a strip shape closed-loop feedback control system, a setting mode of the controlled quantity of roller inclination closed-loop feedback control when the strip steel specification changes is established, and the controlled quantity of the roller inclination closed-loop feedback control achieves the zero clearing function when the strip steel width or thickness changes. A control quantity maintaining function of roller inclination closed-loop feedback control during shearing is established by utilizing a welding seam four-rack passing signal and a wrapper belt signal.

Owner:NORTHEASTERN UNIV +1

Vacuum coating device with filtering and homogenizing nozzle

ActiveCN112553579AImprove strip qualityImprove voltage regulationVacuum evaporation coatingSputtering coatingCrucibleInduction heater

The invention discloses a vacuum coating device with a filtering and homogenizing nozzle. The vacuum coating device is characterized by comprising a crucible, an induction heater is arranged on the outer side of the crucible, a flow distribution box body is connected to the top of the crucible through a steam pipeline, a horizontal partition plate is arranged in the flow distribution box body, a nozzle is connected to the top of the flow distribution box body, and a pressure regulating valve is arranged on the steam pipeline; the partition plate comprises a pressure dividing plate and a filterplate connected to the upper surface of the pressure dividing plate, and the pressure dividing plate and the filter plate are both of a porous structure; and the pressure dividing plate is of a sectional structure, and the position, right facing the steam pipeline, of the pressure dividing plate is provided with a D1 section, a D2 section, a D3 section, a D4 section and a D5 section, wherein theD2 section and the D3 section are correspondingly located on the two sides of the D1 section, the D4 section is located beside the D2 section, and the D5 section is located beside the D3 section. Whenhigh-temperature steam makes contact with a low-temperature steel plate, uniform coatings are formed on the surface of the steel plate.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com