Roller inclination output control method based on plate shape closed-loop regulating variable

A technology of closed-loop adjustment and output control, applied in contour control, comprehensive factory control, etc., can solve problems such as data fluctuation and data transmission strategy, and achieve the effect of improving stability and strip quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

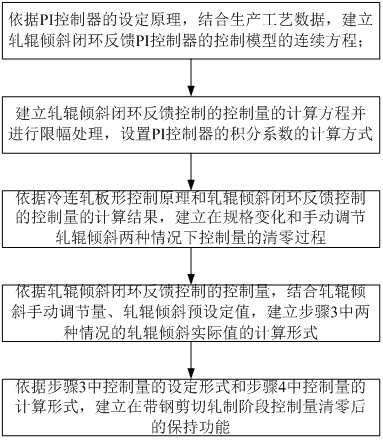

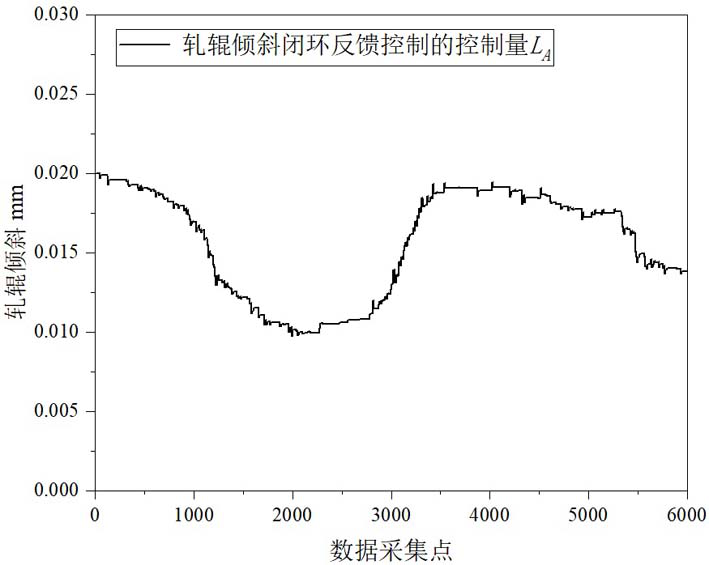

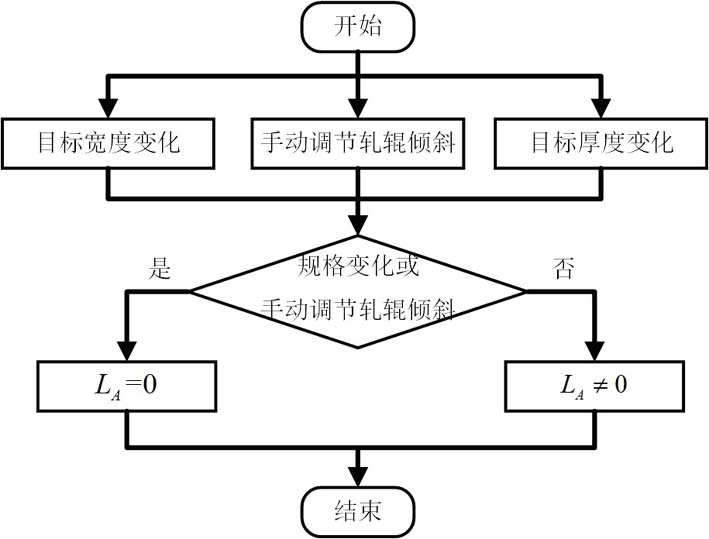

[0052] The invention develops a roll tilt output control method based on a plate shape closed-loop adjustment amount. According to the program setting logic, setting the actual value of roll inclination consists of three sub-parts: preset value of roll inclination, manual adjustment of roll inclination, and control amount of closed-loop feedback control of roll inclination. Changes in one of these sub-sections inevitably lead to large fluctuations in the actual value of the roll inclination. When the amount of variation is small, it will not cause abnormal plate features. If its variation is large, it will easily lead to product quality defects. Therefore, it is necessary to take a setting measure so that when the preset value of roll inclination, the manual adjustment amount of roll inclination, and the control amount of closed-loop feedback control of roll inclination change greatly, the actual value of roll inclination does not change significantly, but tends to change. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com