Flexible wire stripping device for cable

A wire stripping device and cable technology, applied in the direction of dismantling/armoring cable equipment, etc., can solve the problems of high labor intensity, damage to the cable core, and affect the accuracy of the cable inspection test results, etc., to achieve high stripping quality, The effect of high stripping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

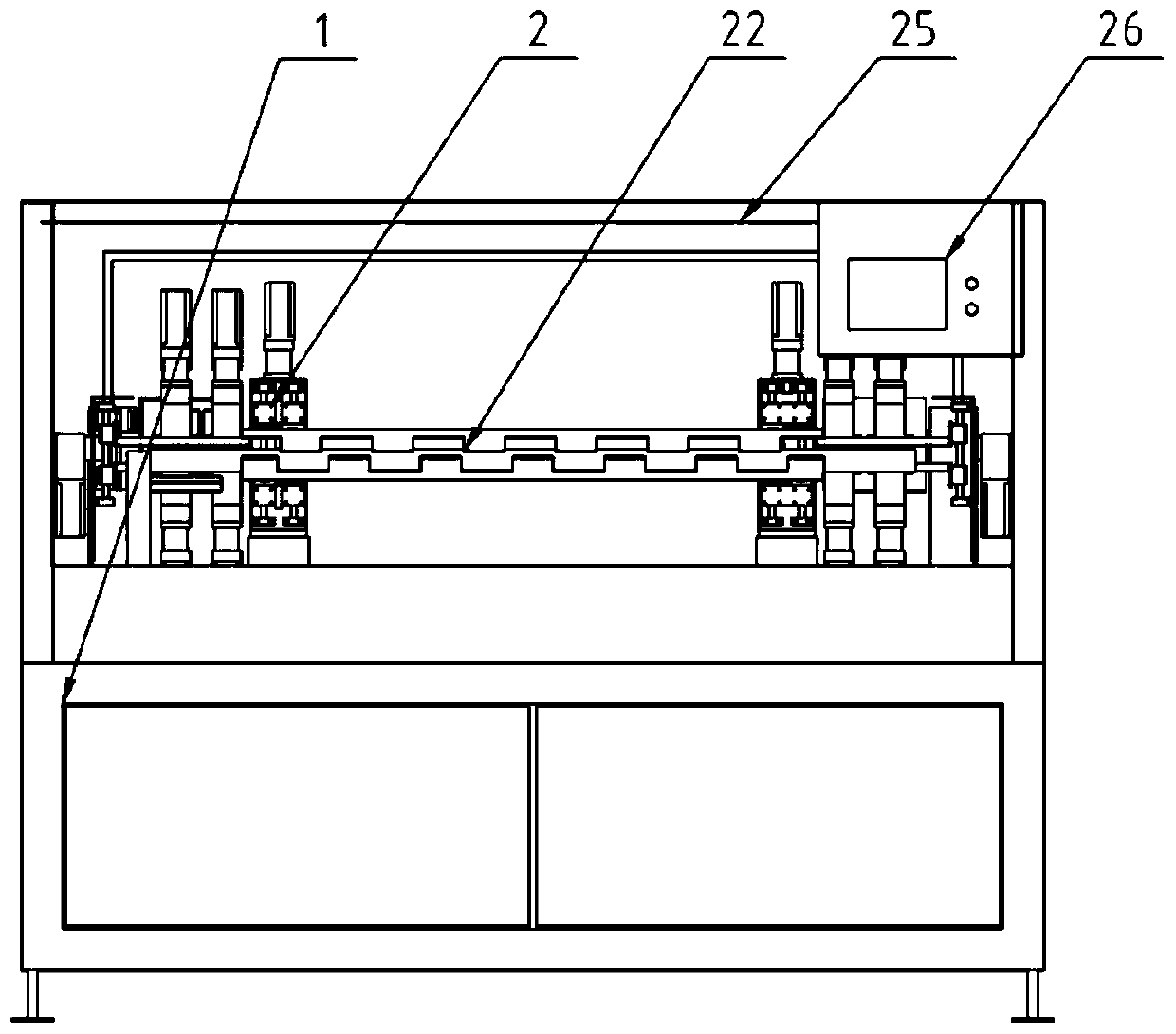

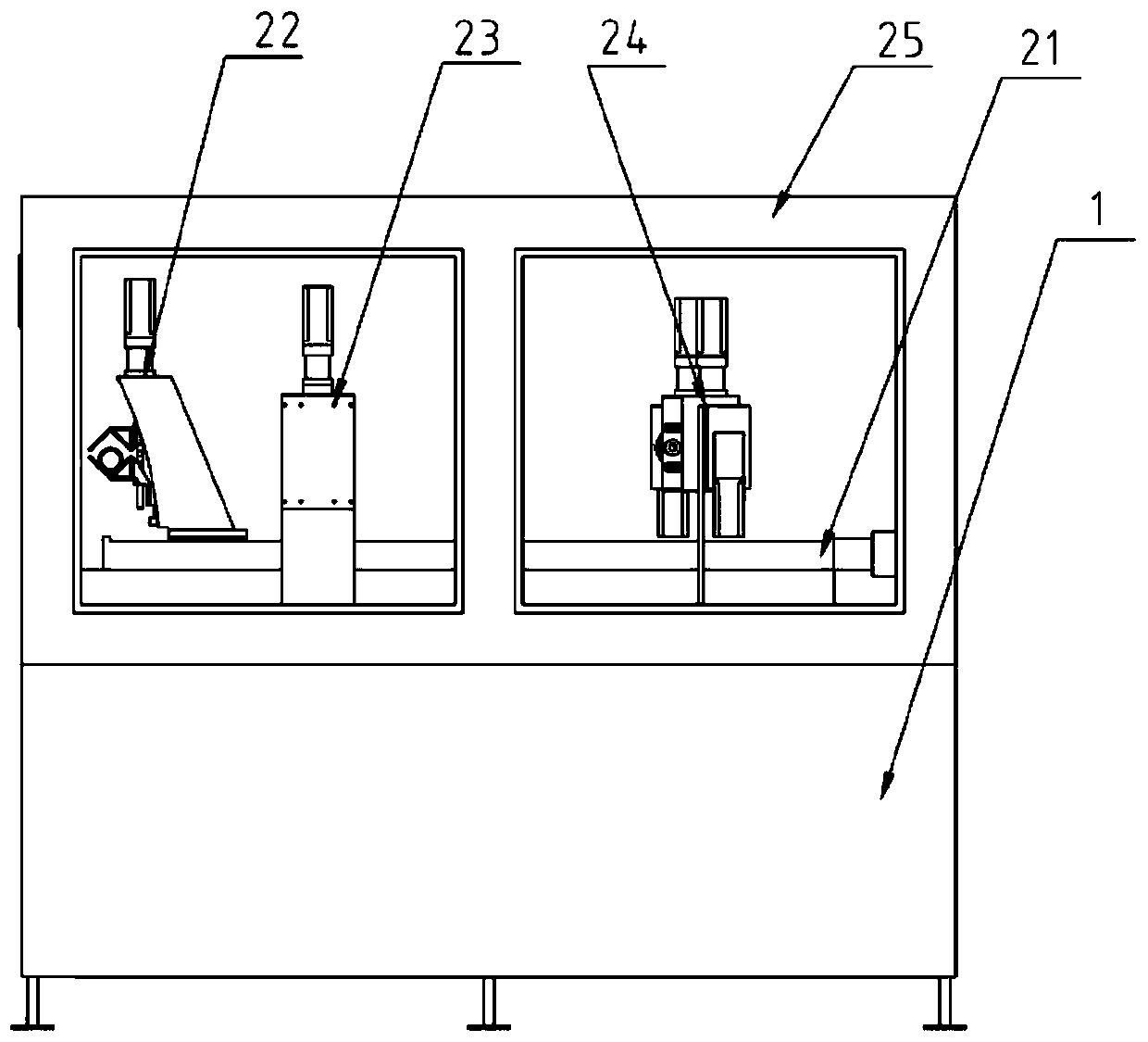

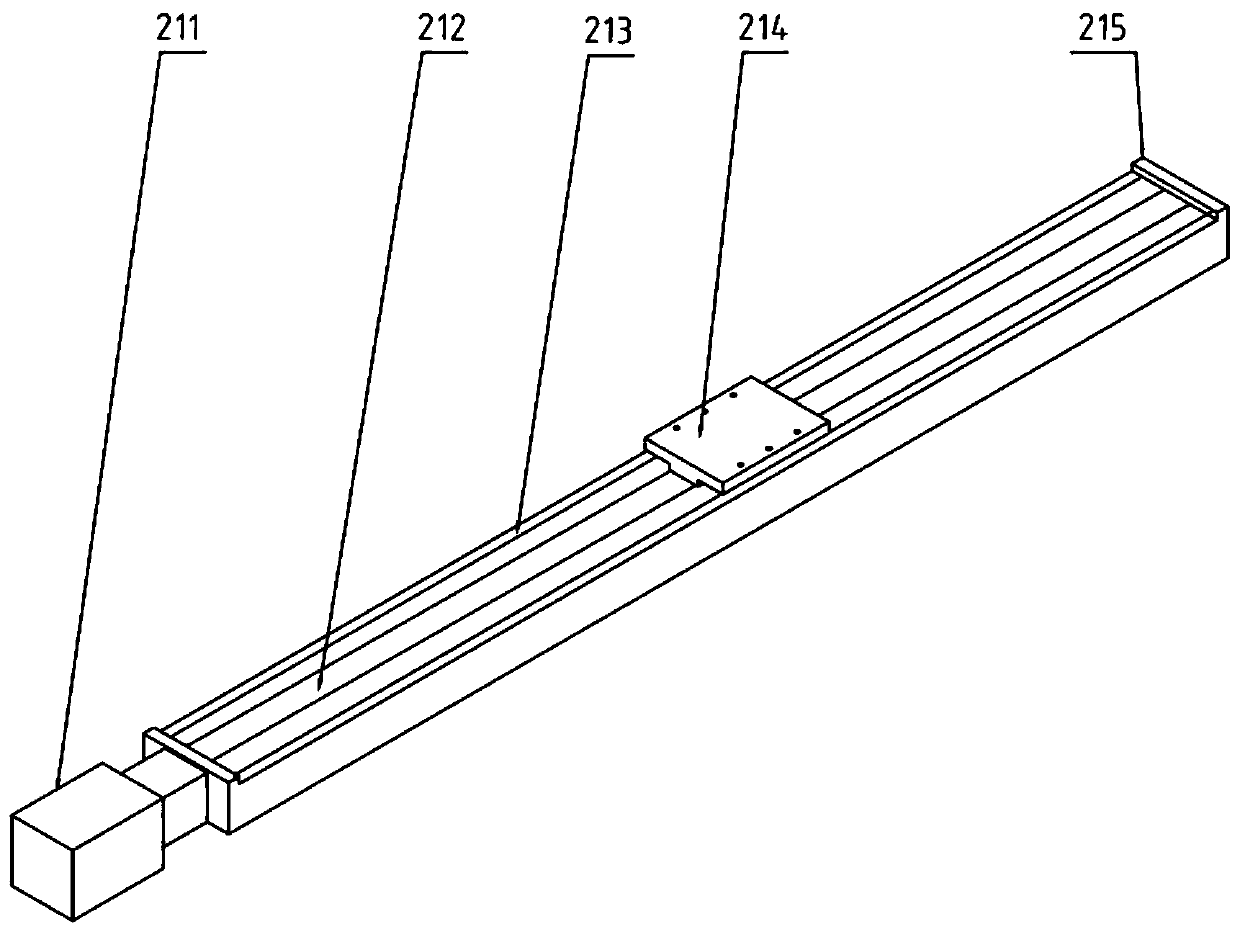

[0025] Such as Figure 1 to Figure 6 As shown, a cable flexible stripping device according to the present invention includes a frame base 1 and a stripping device body 2, the stripping device body 2 is fixedly installed on the frame base 1, and the stripping device body 2 includes a The cable conveying unit 21 circulating in each work room, the cable clamping unit 22 for clamping the cable, the axial cutting unit 23 for axially stripping and cutting the cable,

[0026] A radial cutting unit 24 for radially stripping and cutting the cable, a protective cover 25 for safety protection during the stripping process, and a control unit 26 for controlling the coordinated operation of various mechanisms to complete cable stripping.

[0027] The above constitutes the basic structure of the present invention.

[0028] The present invention ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com