Stable anti-shaking device of double-stand leveling unit band steel and control method thereof

A stable control method and double-stand technology, applied in the direction of length measuring device, tension/pressure control, metal rolling, etc., to improve the quality of finished strip steel and solve the effect of tension control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

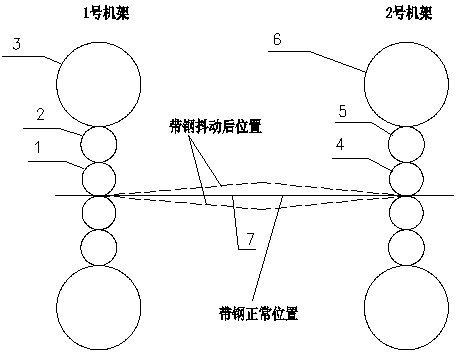

Problems solved by technology

Method used

Image

Examples

Embodiment 1

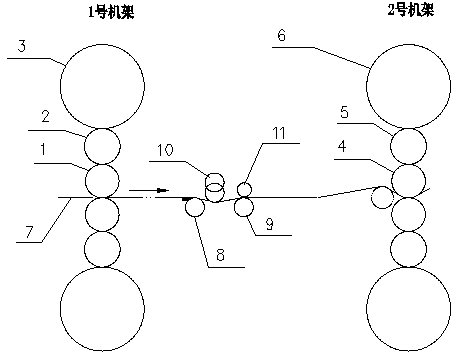

[0069] Under the double-frame mode, the implementation process of the double-frame levelling unit strip steel stability control method of the present invention is as follows:

[0070] Step 1, collect the equipment parameters of the leveling unit, mainly including the distance between the leveling unit frames , determined to be 5m;

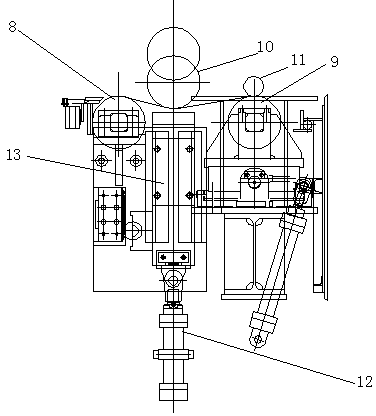

[0071] Step 2, determine the parameters of the anti-shake device, including: the diameter of the first roller 8 of the anti-shake device is φ260mm, the diameter of the second roller 9 is φ260mm, the diameter of the third roller 10 is φ260mm, and the surface of the roller is chrome-plated , the roll diameter value of the fourth roll 11 is φ200mm;

[0072] Step 3, collecting the characteristic parameters of the strip to be flattened, the yield strength of the flattened strip is 300 ;

[0073] Step 4, according to the process conditions, the intermediate tension between the racks is set to 100 ;

[0074] Step 5, given the value of ...

Embodiment 2

[0078] Under the single frame mode, the implementation process of the strip steel stability control method of the two-frame skin pass unit of the present invention is as follows:

[0079] Step 1, collect the equipment parameters of the leveling unit, mainly including the distance between the exit of No. 1 rack and the exit S roller , determined to be 6m;

[0080] Step 2, determine the parameters of the anti-shake device, including: the diameter of the first roller 8 of the anti-shake device is φ260mm, the diameter of the second roller 9 is φ260mm, the diameter of the third roller 10 is φ260mm, and the surface of the roller is chrome-plated , the roll diameter value of the fourth roll 11 is φ200mm;

[0081] Step 3, collecting the characteristic parameters of the strip to be flattened, the yield strength of the flattened strip is 200 ;

[0082] Step 4. According to the process conditions, the outlet tension between the No. 1 racks is set to 60 ;

[0083] Step 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com