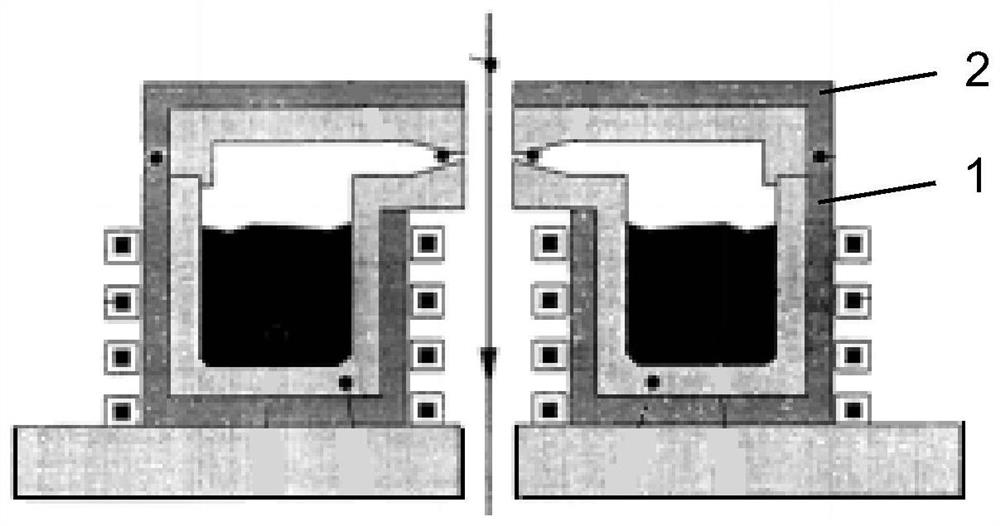

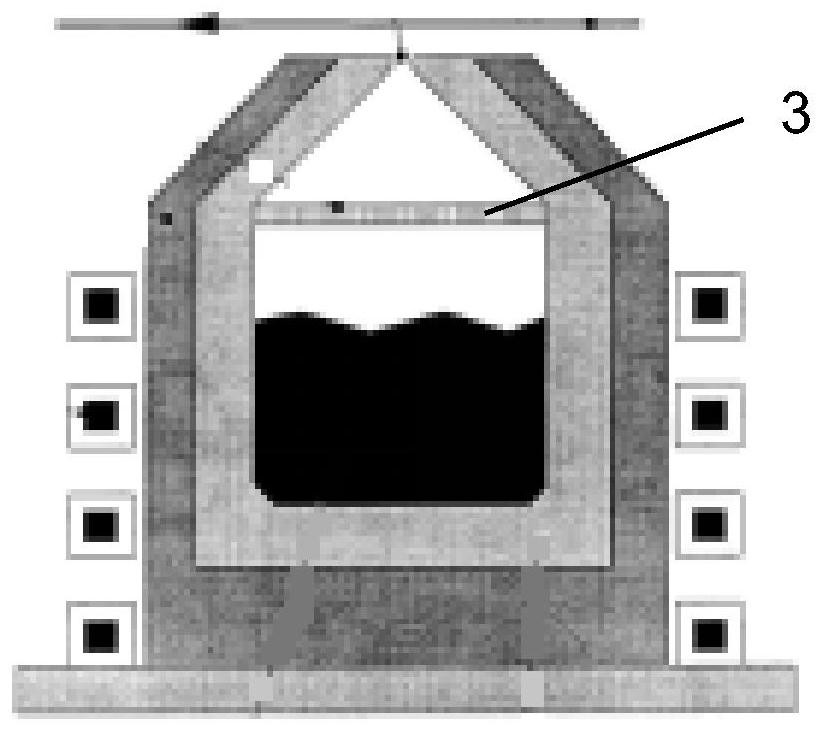

Vacuum coating device with flow restraining type nozzle

A vacuum coating and nozzle technology, which is applied in vacuum evaporation coating, sputtering coating, gaseous chemical coating, etc., can solve the problems of uneven coating of steel plate and inability to show coating, and achieve less investment, simple operation, and improved Effect of strip quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

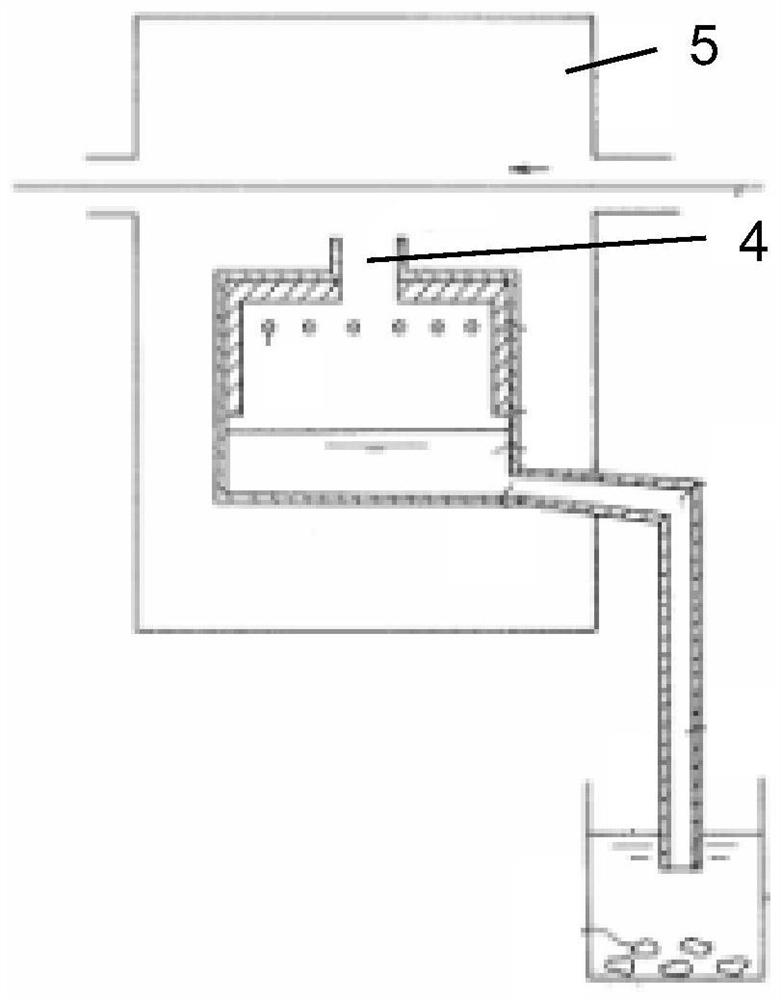

[0059] Zinc is evaporated on the surface of the steel plate 100, the width of the steel plate 100 is 1000mm, after cleaning and drying, the steel plate 100 is heated to 120°C. Use the induction heater 15 to evaporate the zinc, and control the power to make the zinc in the crucible 13 reach a pressure of 20000Pa. At this time, the pressure regulating valve 18 is in a closed state. When the gas pressure in the crucible 13 reaches 20000Pa, open the pressure regulating valve 18, and the metal The steam 22 enters the flow distribution box 17 through the steam pipe 16, the damper plate 20 adopts a rectangle, wherein V1 / V2=2, D=1mm, the voltage stabilizing plate 19 is a porous structure, S 孔隙总面积 / S 出口 =3, the internal pressure of the nozzle 21 is 5000Pa, the material of the nozzle 21 is graphite, and the outlet of the nozzle 21 adopts a slit shape, which is rectangular, S 出口 / S 入口 = 0.95.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com