Automatic cable stripping machine

A technology of automatic wire stripping and wire stripping mechanism, which is applied in the direction of dismantling/armoured cable equipment, etc., can solve the problems of removal, heavy stripping force, and high rate of defective products, so as to reduce production costs, shorten stripping time, The effect of improving the stripping quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

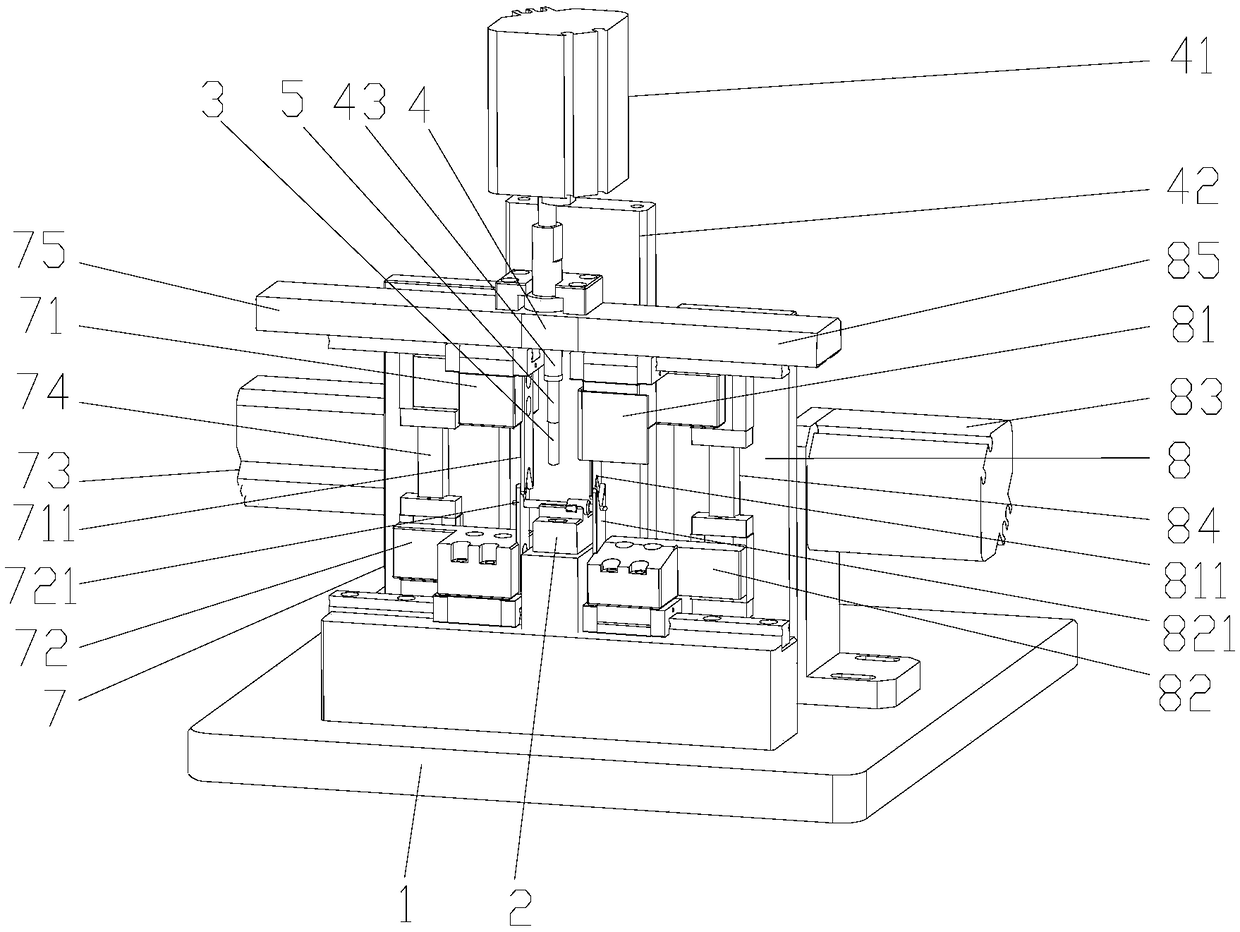

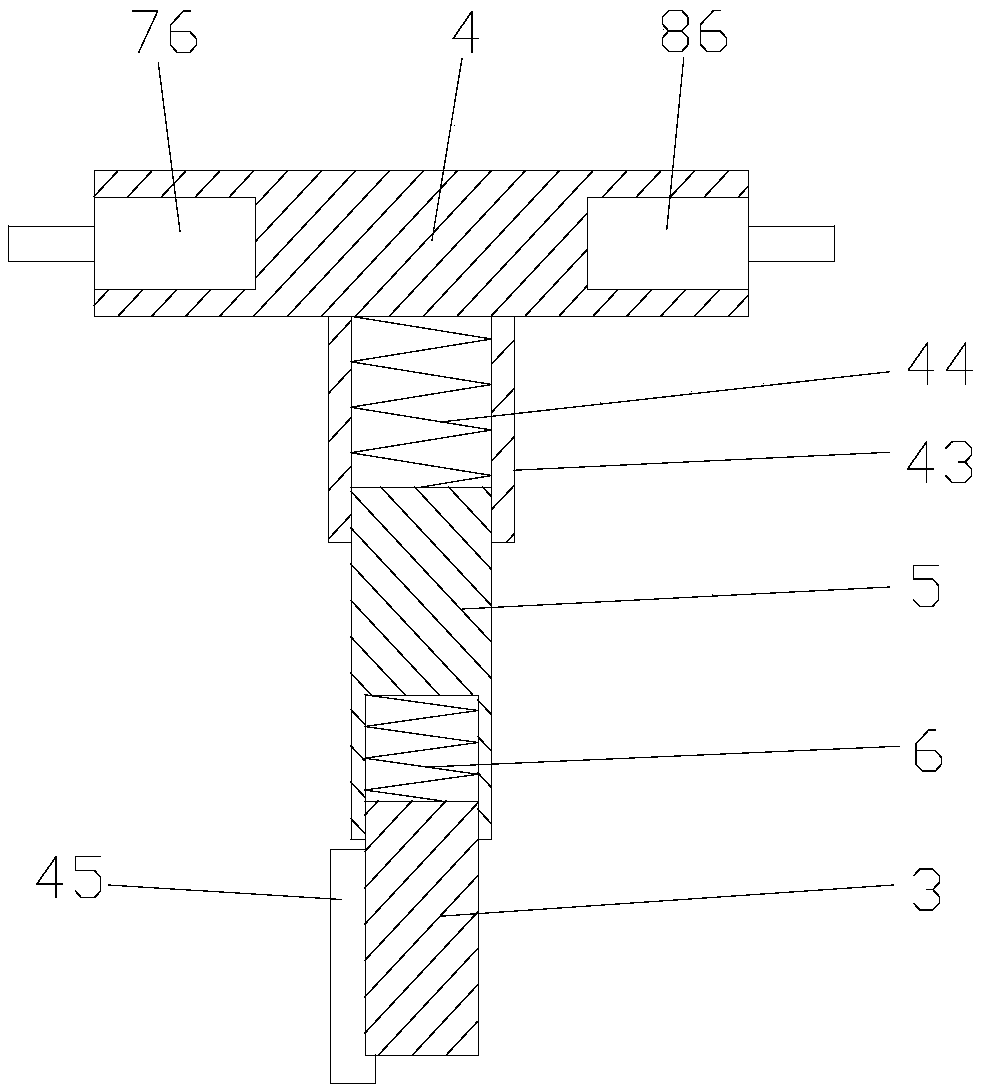

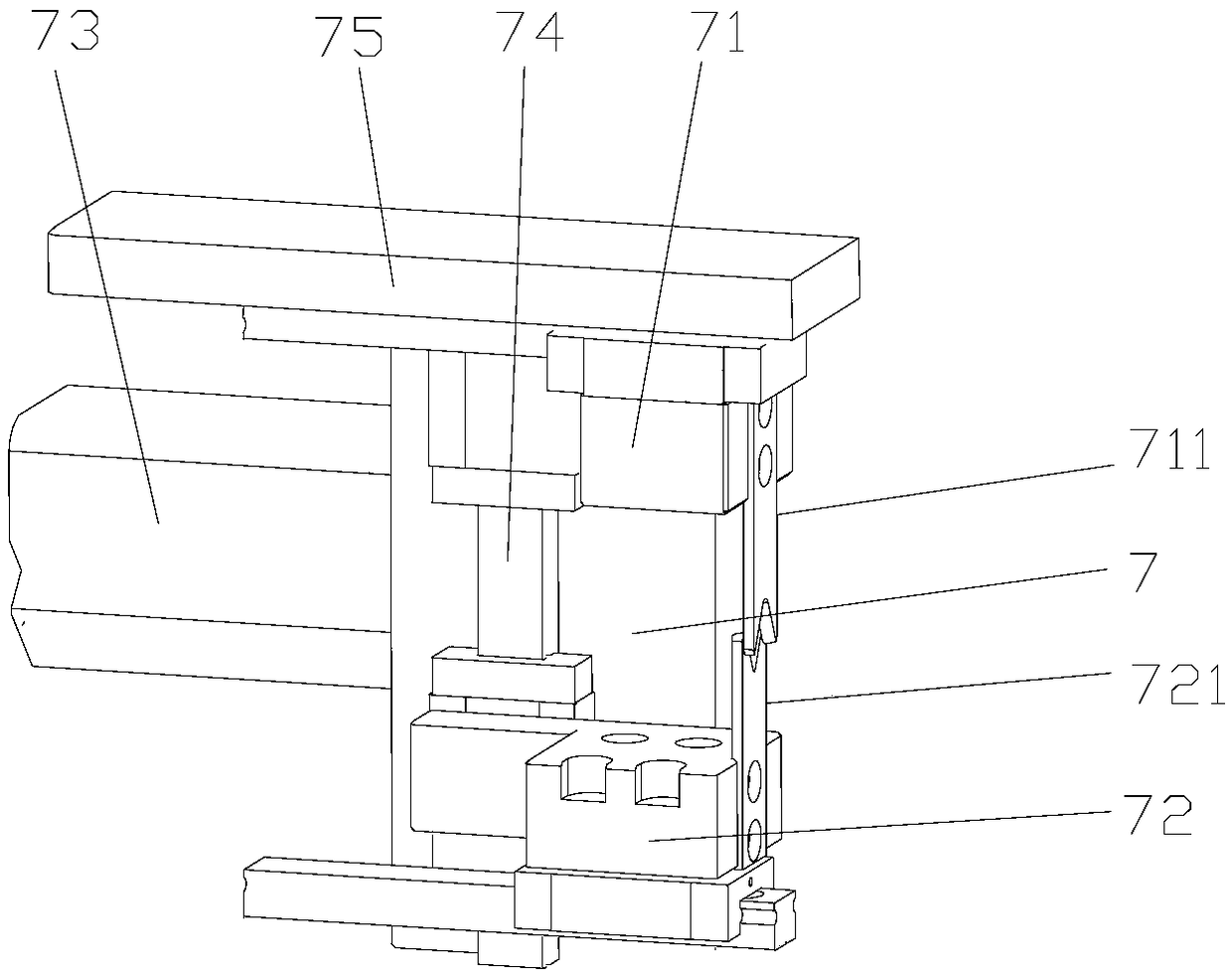

[0027] Embodiment 1: refer to figure 1 , an automatic wire stripping machine, including a machine 1 and a wire setting table 2 set on the machine 1 for placing cables. The upper surface of the wire setting table 2 is an arc structure that matches the external structure of the cable. Refer to Figure 5 , the upper surface of the wire setting table 2 is provided with a rubber layer 21, which increases friction, and at the same time provides cushioning, protects the cable, and prevents the cable from being crushed. The left stripping mechanism and the right stripping mechanism for stripping the cables on the top of the cable, and the upper side of the wire setting table 2 is provided with a crimping mechanism. Rod 3, pressing plate 4 on the upper part of pressing bar 3, vertical cylinder 41 that drives pressing plate 4 to move up and down, vertical support plate 42 is provided on the machine platform corresponding to the rear side of thread setting table 2, and vertical support p...

Embodiment 2

[0032] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the limit mechanism 45 is different. In this embodiment, the limit mechanism 45 adopts a limit cylinder with a vertical output end upward, and the output of the limit cylinder The bottom end of the connecting rod is limited. When the connecting rod reaches the limit position, the connecting rod stops falling. Through the unloading mechanism composed of the unloading cylinder, the unloading spring and the connecting rod, a vertical cylinder is driven synchronously. Complete the cable positioning and stripping operations of the cutter components on both sides. The unloading mechanism enables the left stripping mechanism, the right stripping mechanism and the crimping mechanism to cooperate with each other without interference, so that the stripping machine has a high Productivity.

Embodiment 3

[0033] Embodiment 3: refer to Figure 4 , the difference between this embodiment and Embodiment 1 is: the difference between the left connecting mechanism and the right connecting mechanism. The left side of the left connecting plate 9 is embedded with a cavity 46, and the left pressing plate 75 is provided with a left connecting cavity 751 near the pressing plate 4. The left connecting plate 9 can be turned out of the left embedded cavity 46 and then embedded in the left connecting cavity 751 to realize the left pressing plate. 75. The connection between the pressing plates 4, the right connecting mechanism is the right connecting plate 91 hinged to the right side of the pressing plate 4, the right side of the pressing plate 4 is provided with a right embedded cavity 47 for fitting the right connecting plate 91, and the right pressing plate 85 is close to the pressing plate 7 is provided with a right connecting cavity 851, and the right connecting plate 91 can be turned out f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com