Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Shorten the stripping time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

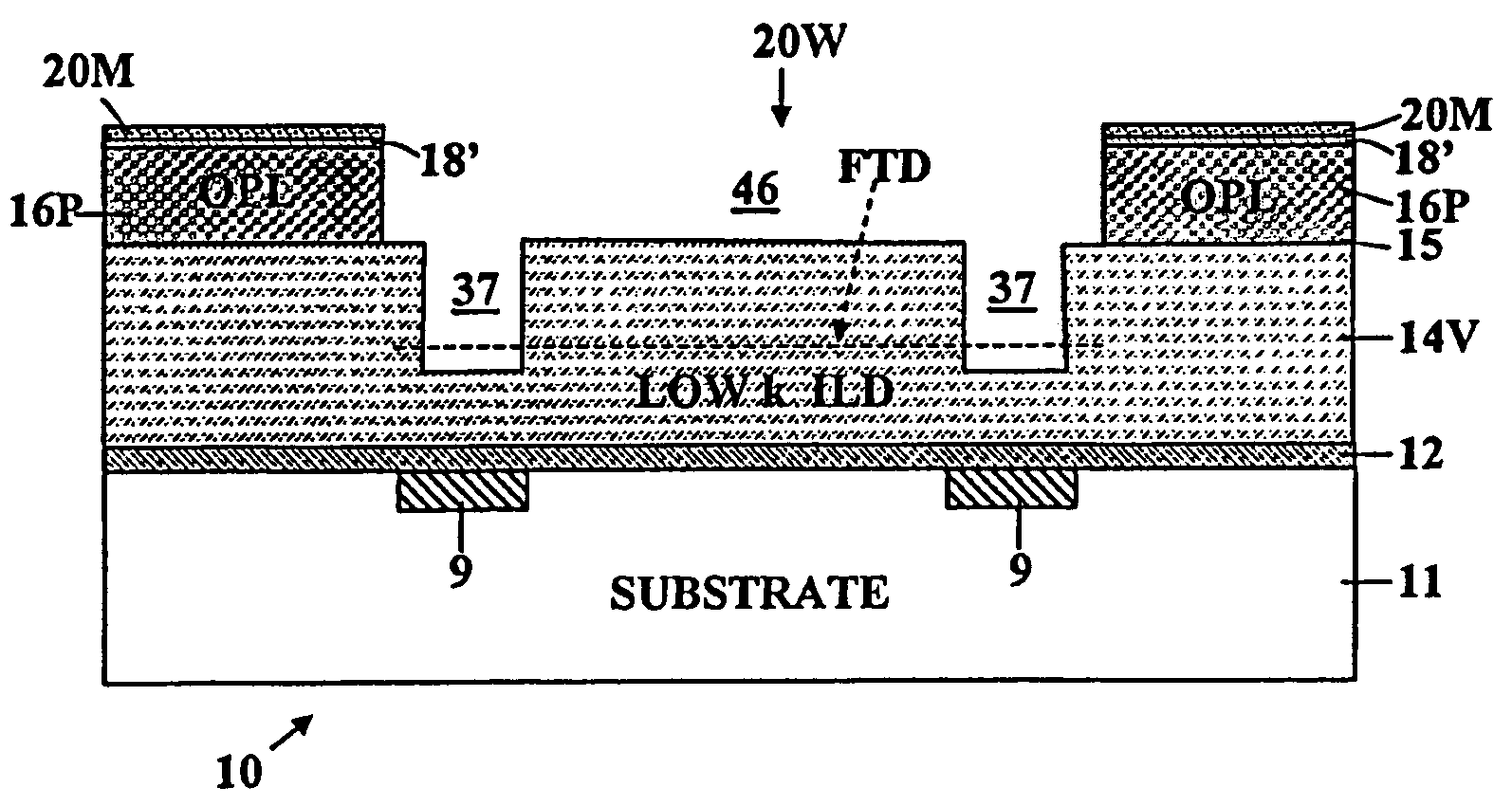

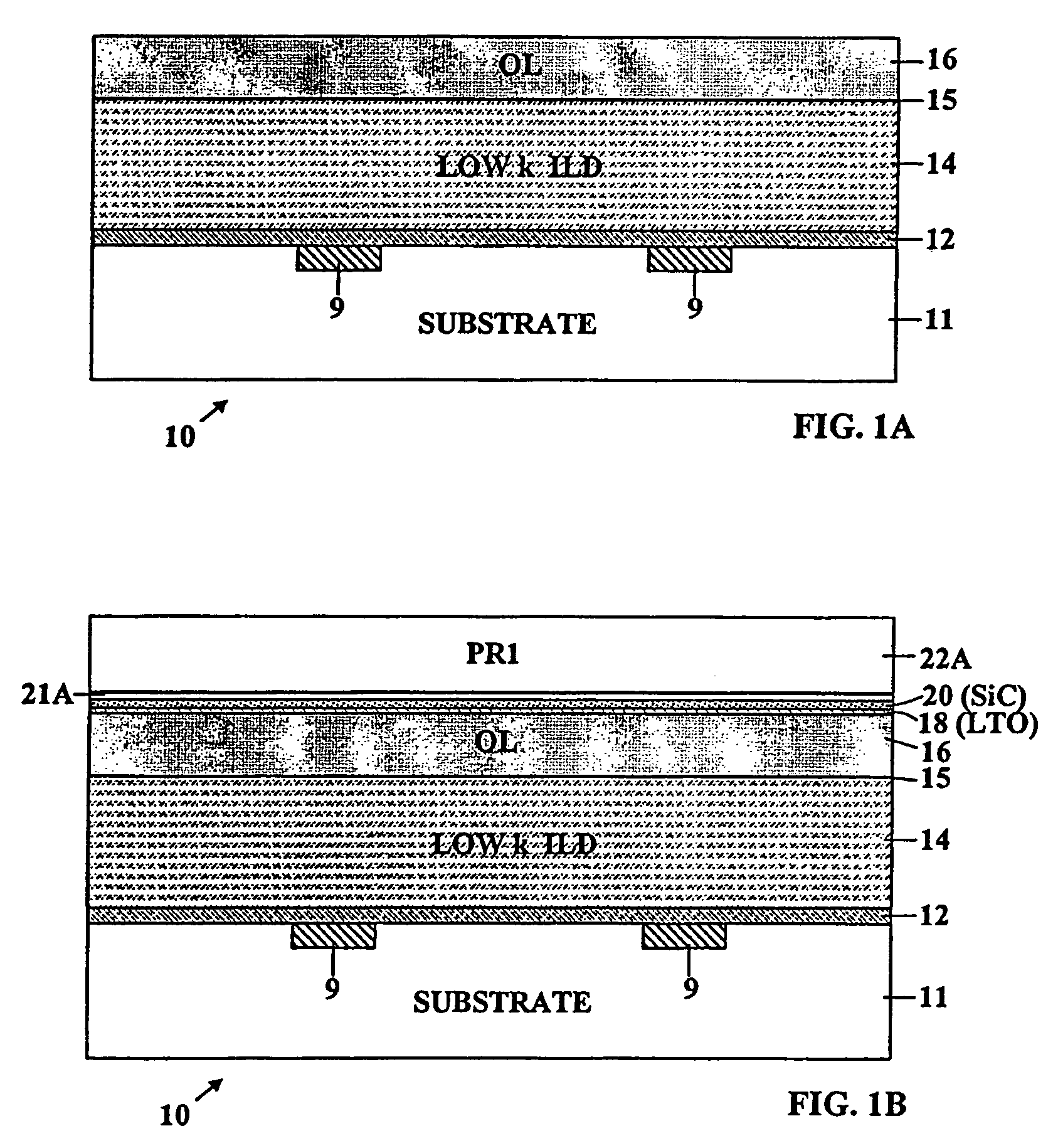

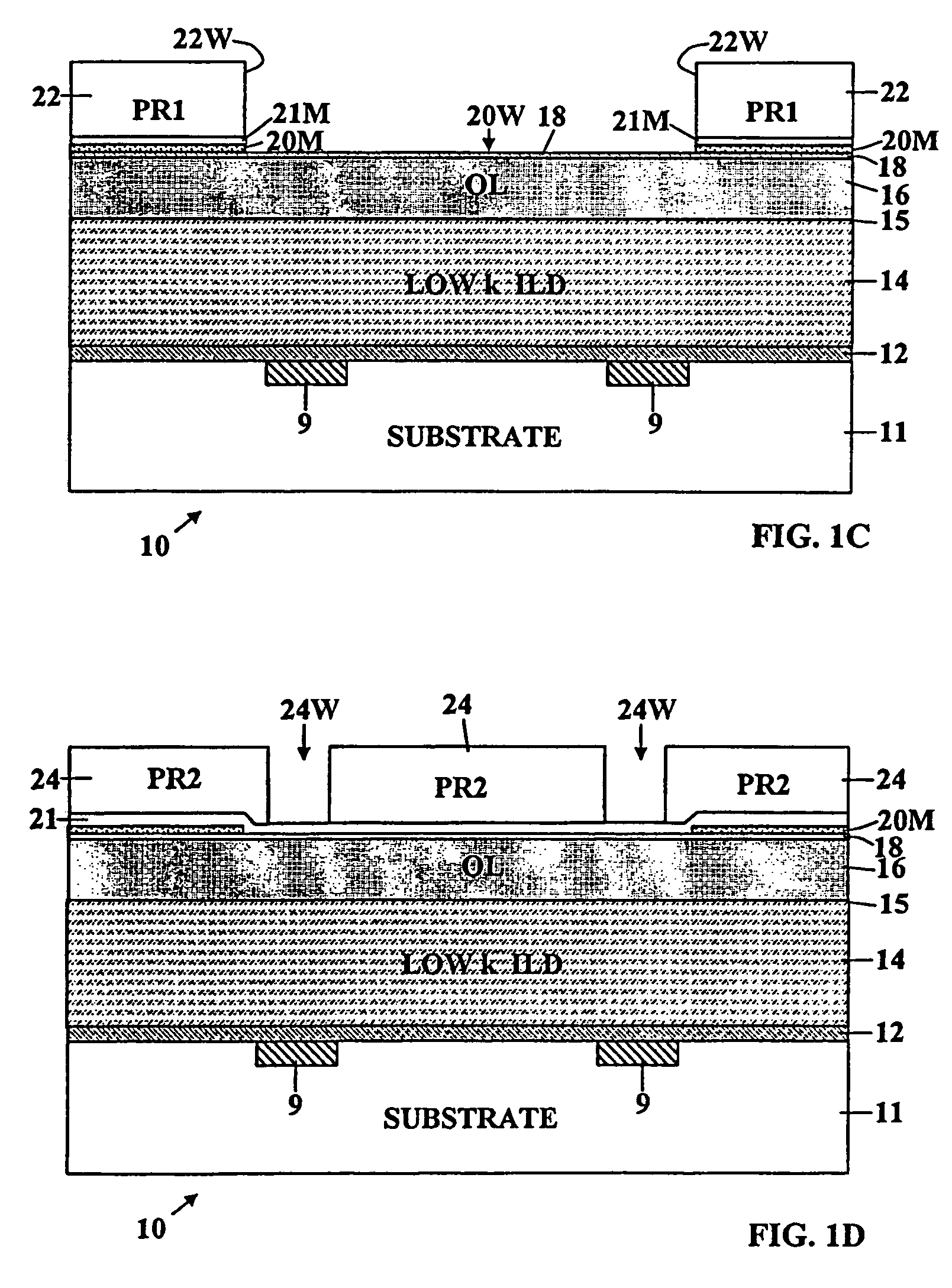

Integrated dual damascene RIE process with organic patterning layer

InactiveUS7129159B2Shorten the stripping timeSemiconductor/solid-state device manufacturingElectrical conductorOrganic layer

Owner:GLOBALFOUNDRIES INC

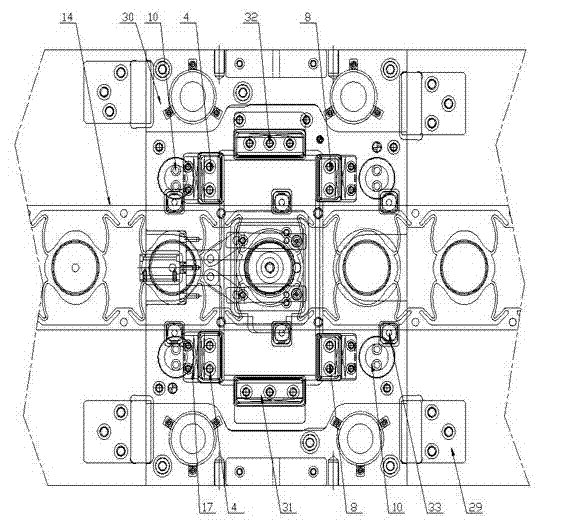

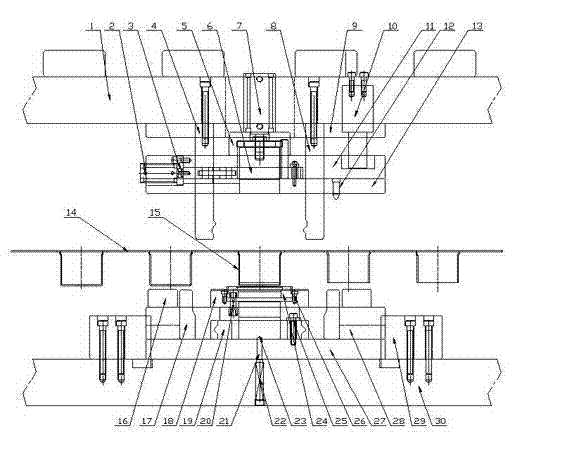

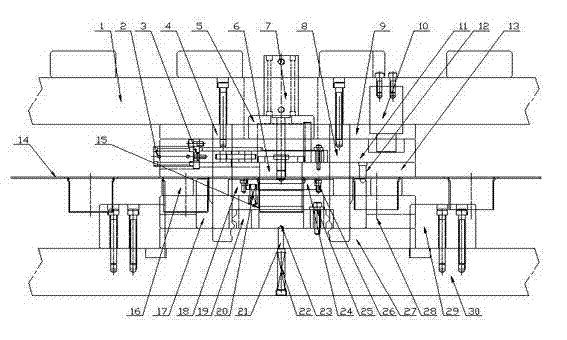

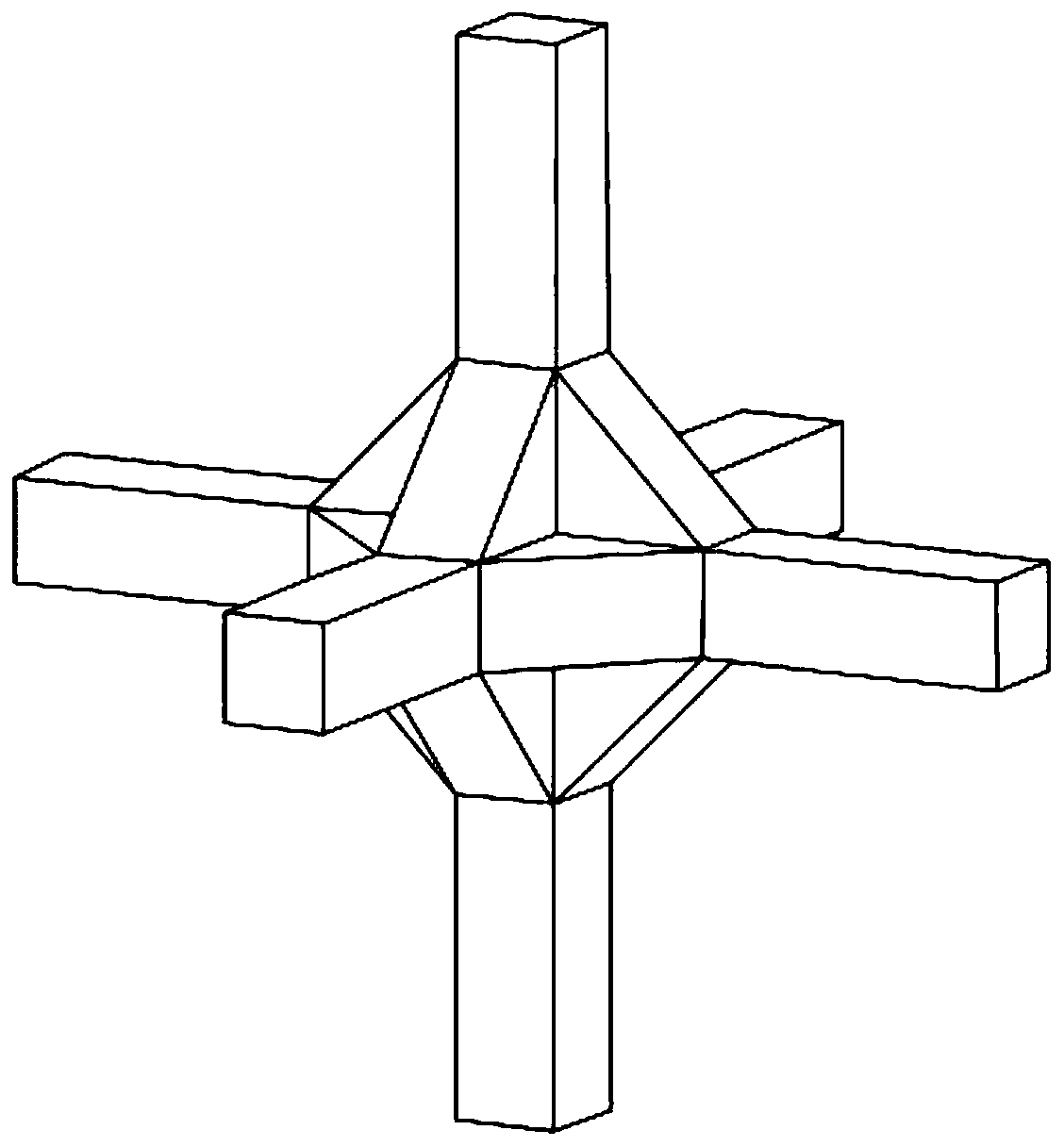

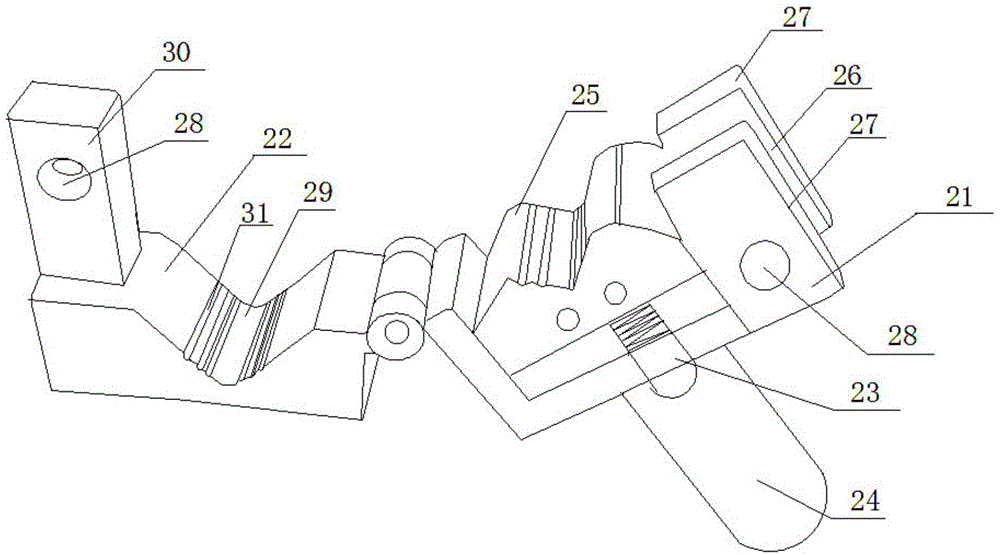

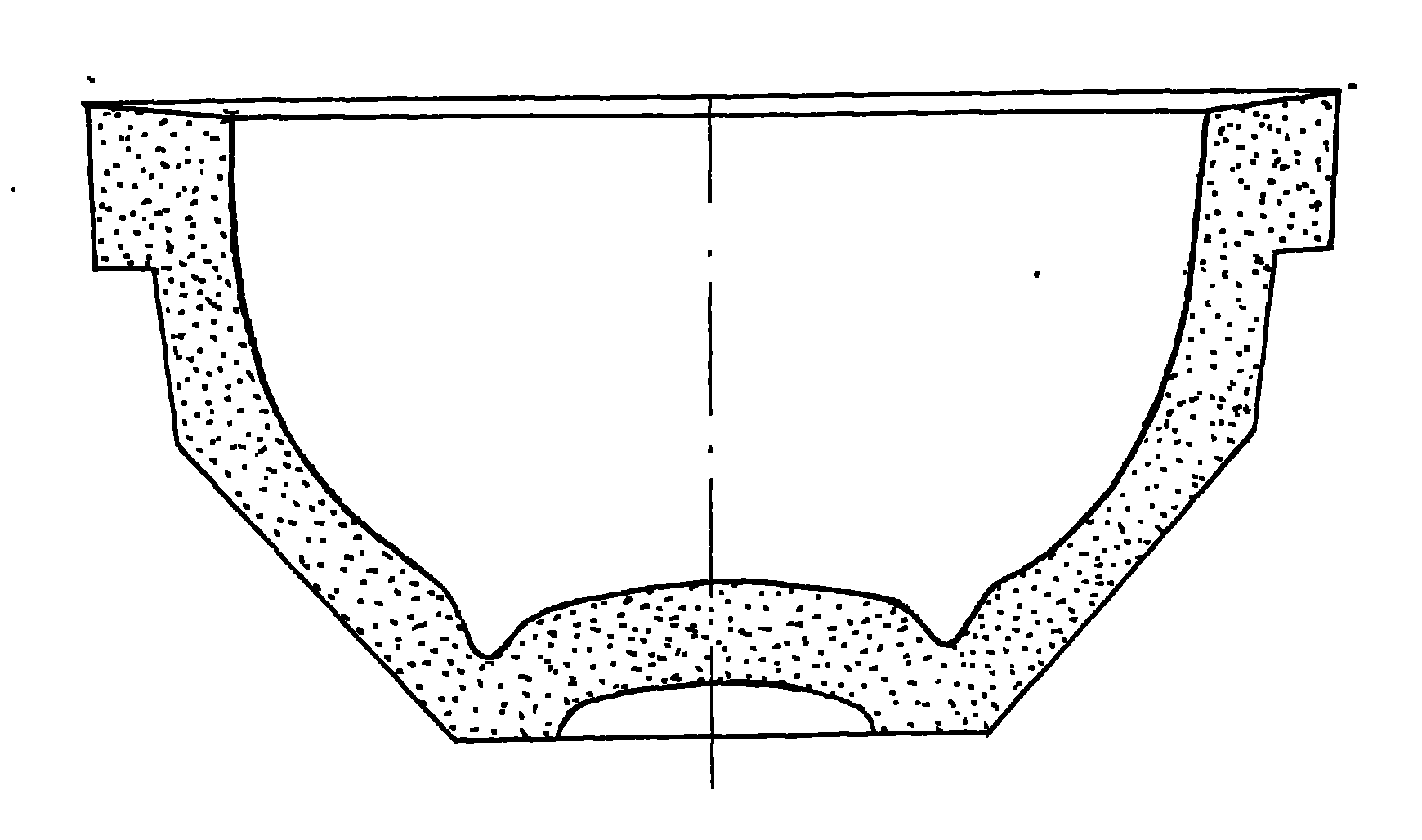

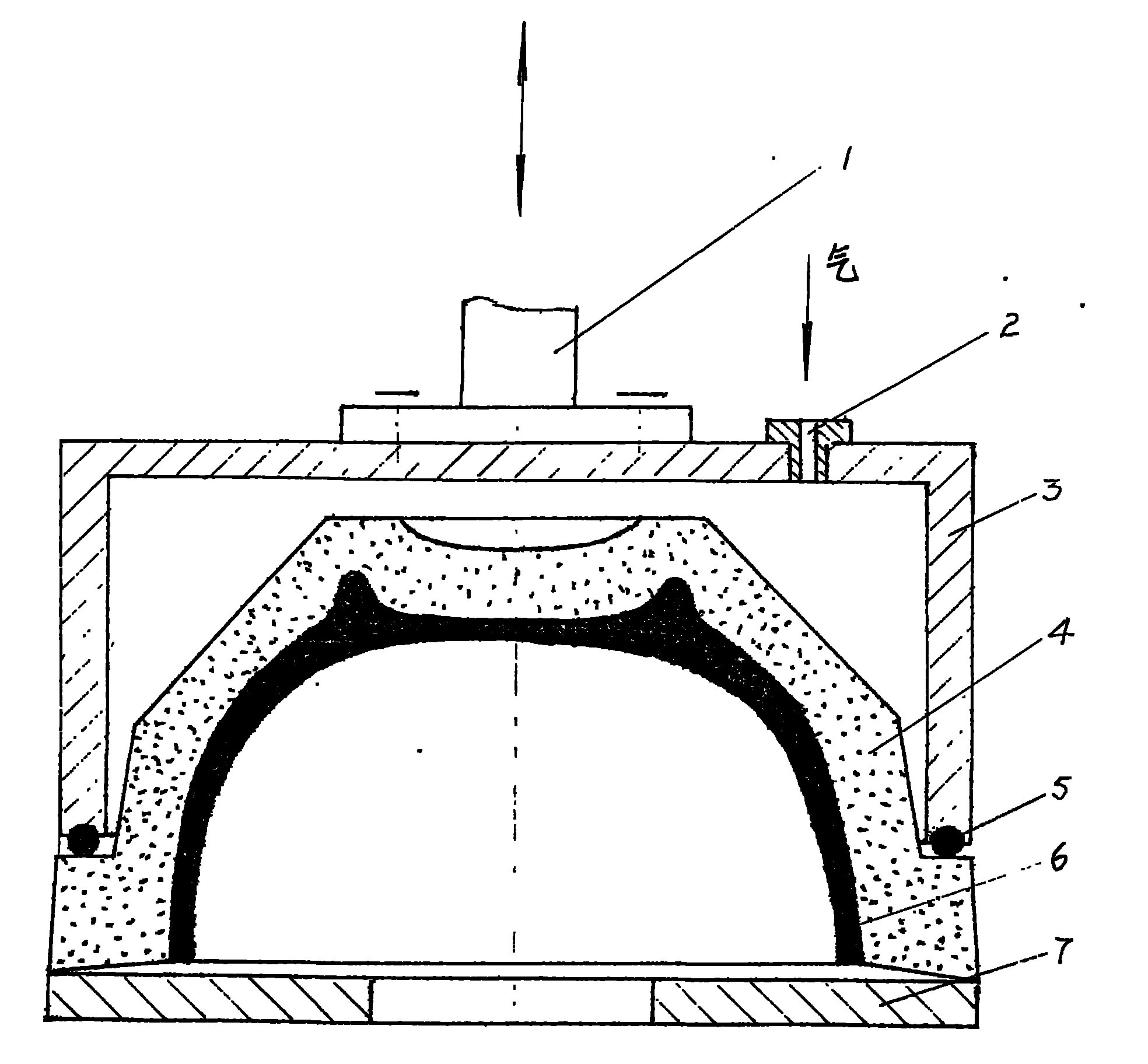

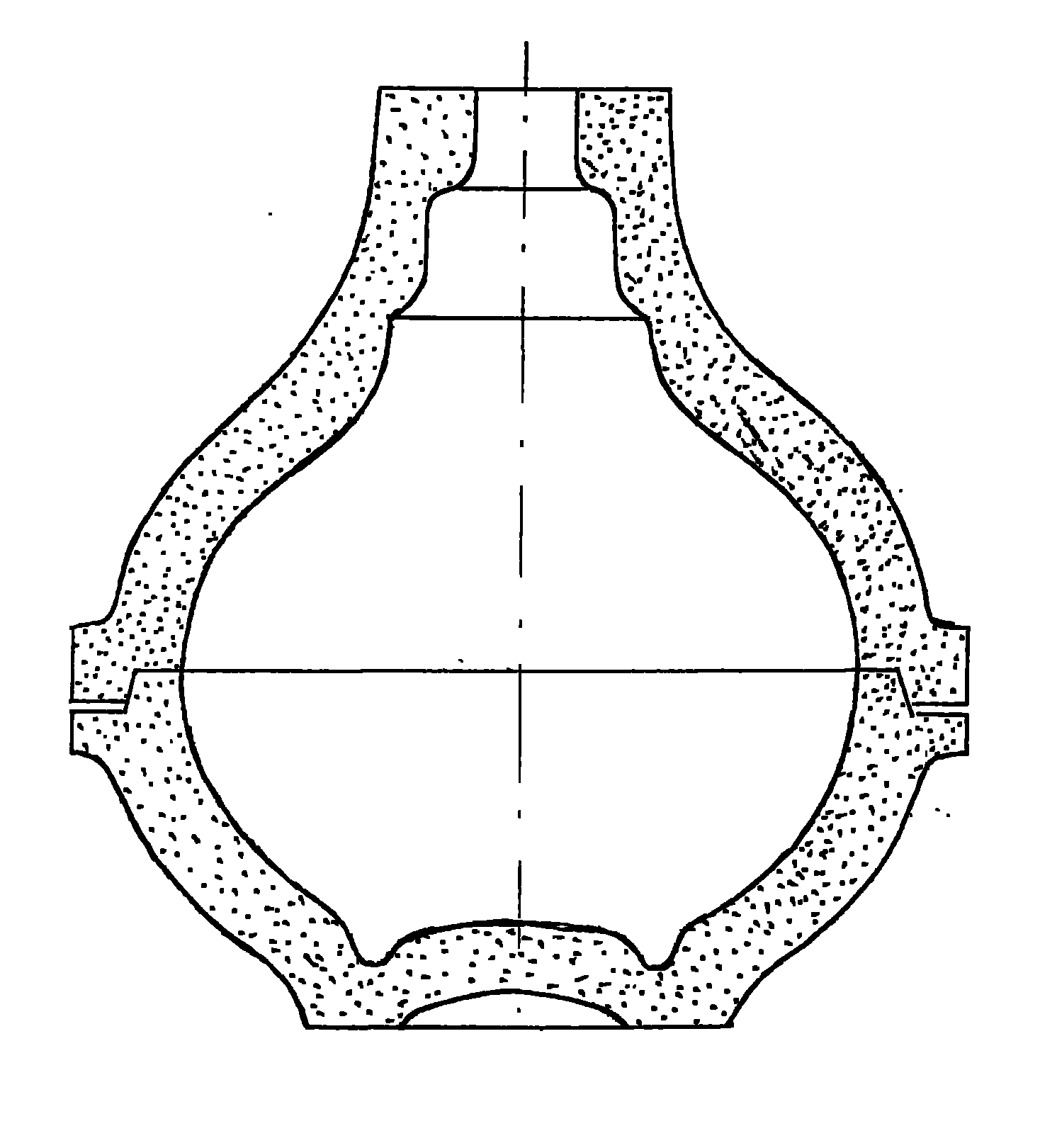

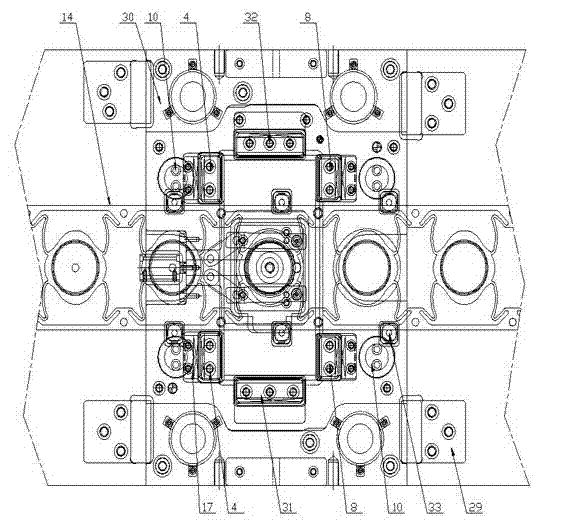

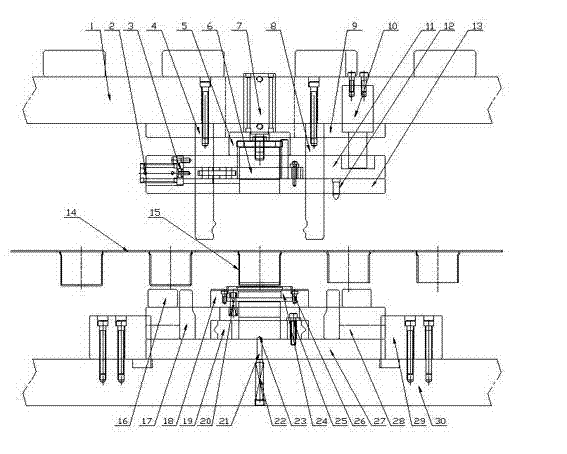

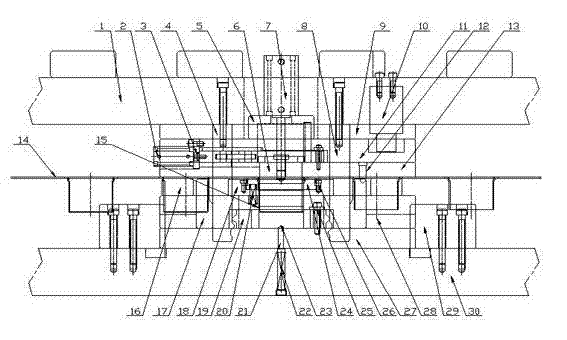

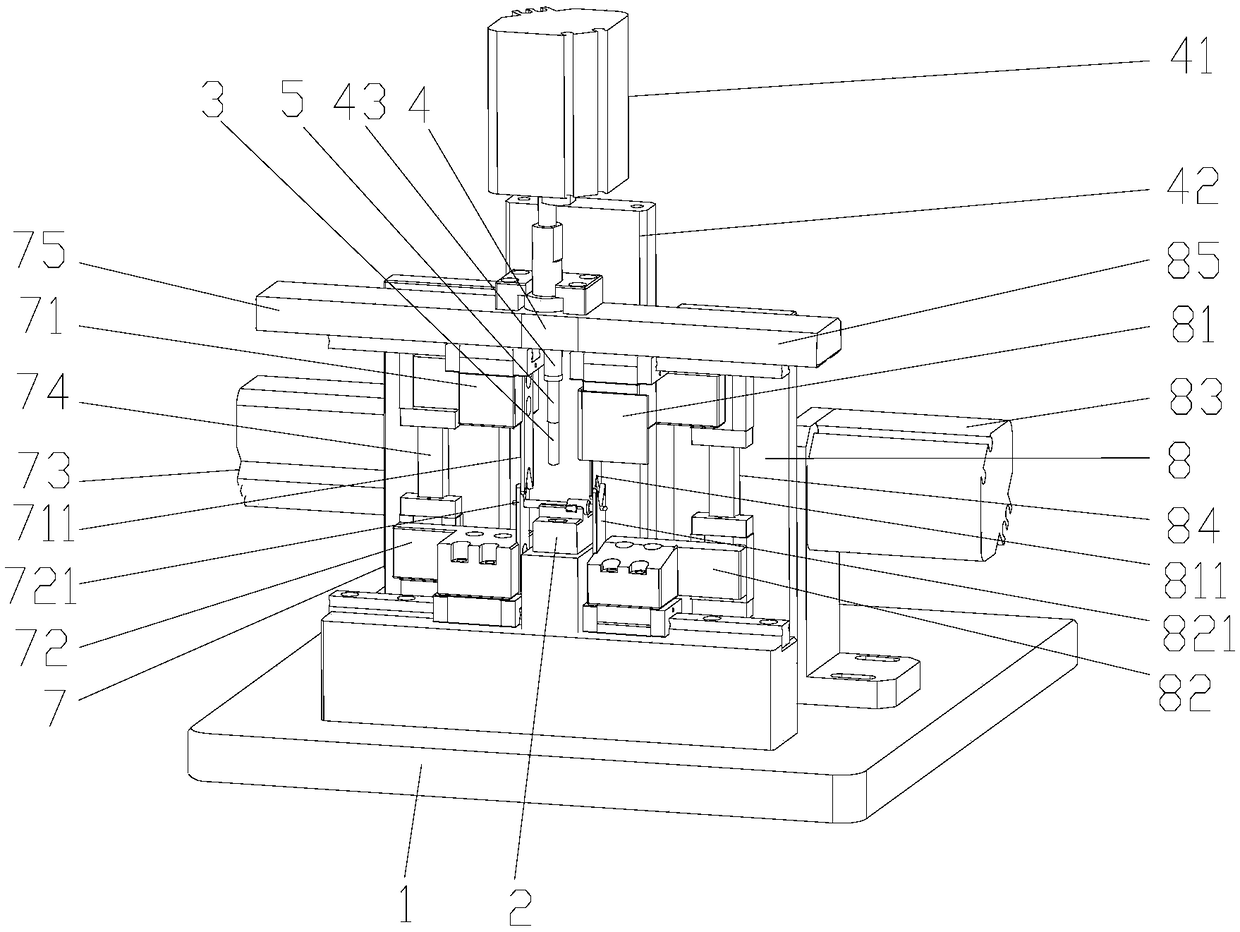

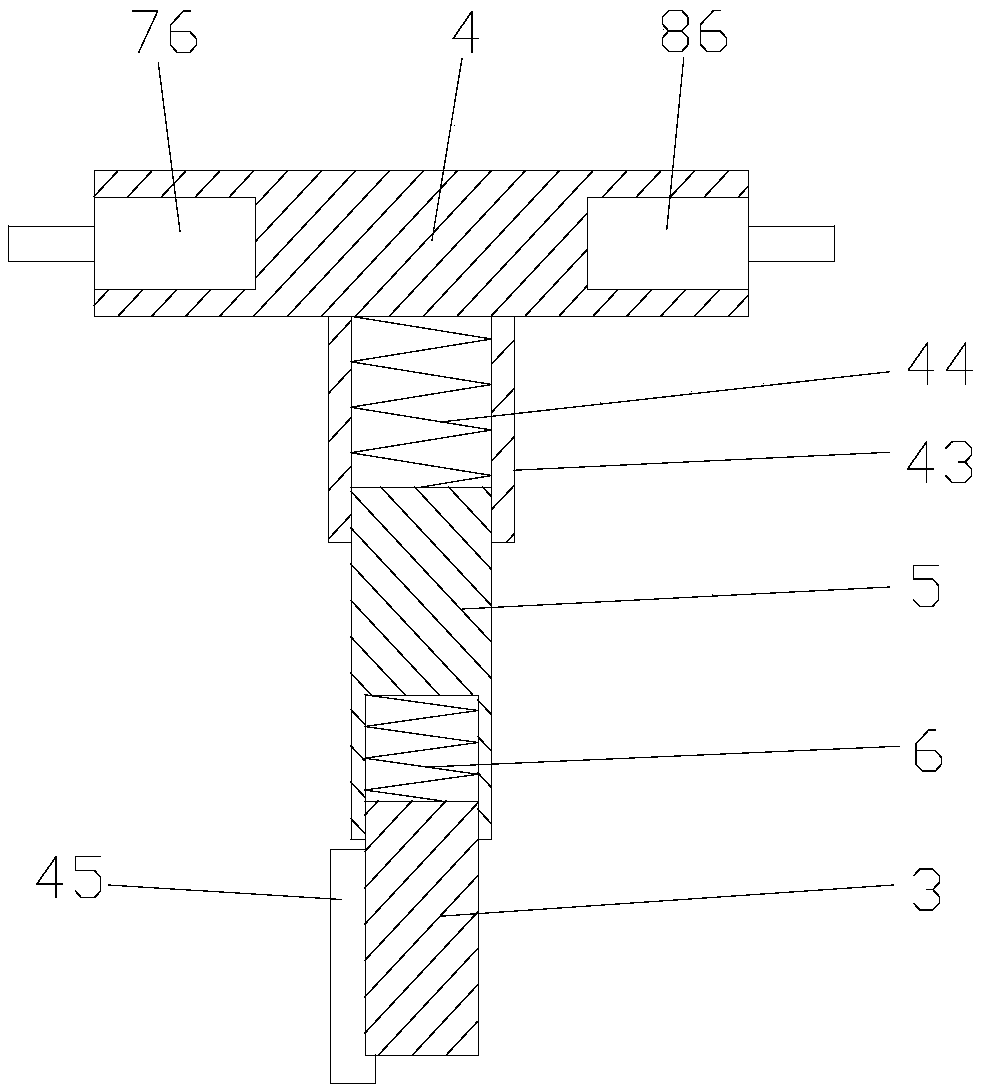

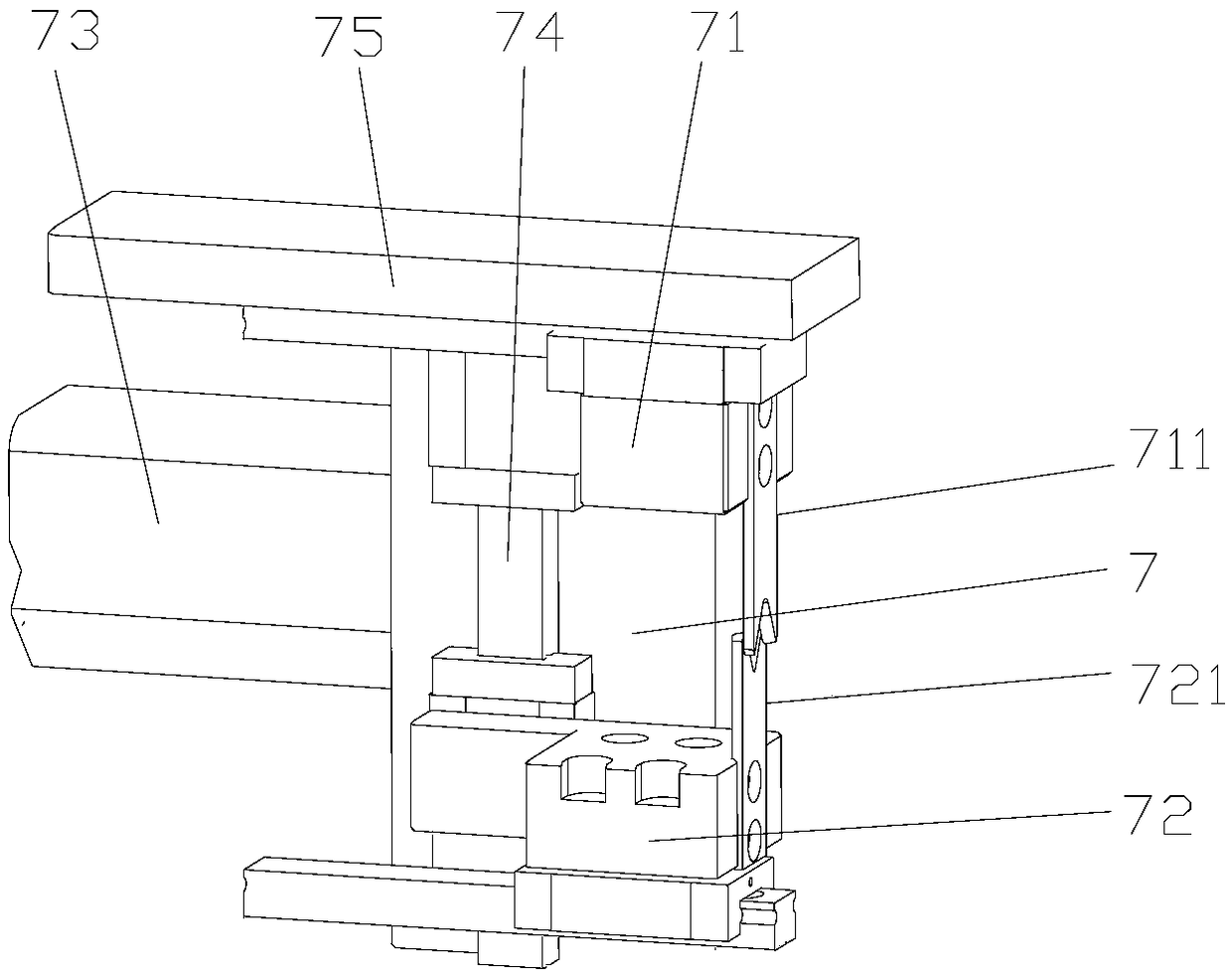

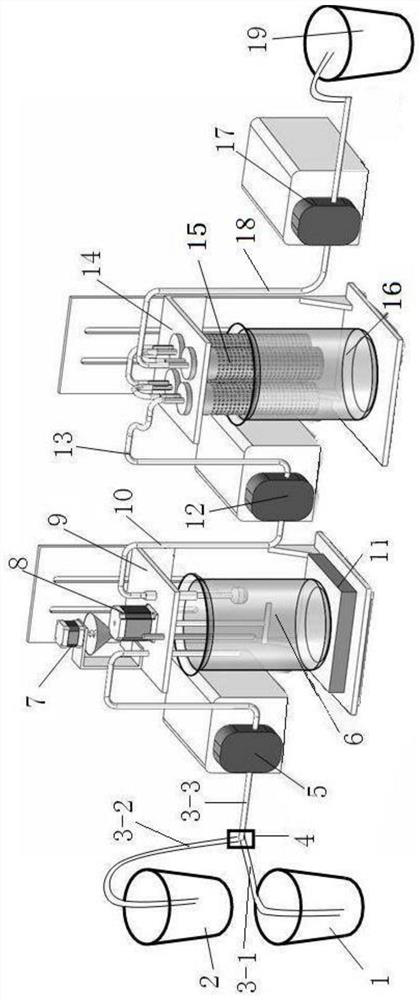

Pneumatic connection rod type rotary cutting mould

ActiveCN102172709AGuaranteed accuracyIncrease productivityShaping toolsEngineeringMechanical engineering

The invention discloses a pneumatic connection rod type rotary cutting mould which comprises an upper mould and a lower mould, wherein the upper mould comprises an upper mould seat, a convex mould fixing plate, a discharge plate and a pressure plate; a nitrogen spring is arranged in the upper mould seat; a rotary cutting concave mould and a guide pin are arranged in the pressure plate; the lower mould comprises a lower mould plate, a lower base plate and a lower mould seat; a rotary cutting convex mould is arranged in the limit grooves arranged on the upper surface of the lower base plate and the lower end surface of the lower mould plate, and corresponds to the rotary cutting concave mould; the lower part of the rotary cutting convex mould is also provided with a rotary cutting convex mould resetting mechanism; in the convex mould fixing plate, a front driving block, a rear driving block, a left driving block and a right driving block of the rotary cutting convex mould are also arranged in the front, rear, left and right directions of the mould; the four driving blocks cooperate with the outer side of the rotary cutting convex mould; and a pneumatic connection rod mechanism is arranged in a limit groove formed by the upper surface of the pressure plate and the lower end surface of the discharge plate. The pneumatic connection rod type rotary cutting mould disclosed by the invention not only can guarantee the product precision and improve the production efficiency, but also finish all processes in a set of progressive mould, thereby greatly saving the cost and improving the market competitiveness.

Owner:LEMTECH PRECISION MATERIAL (CHINA) CO LTD

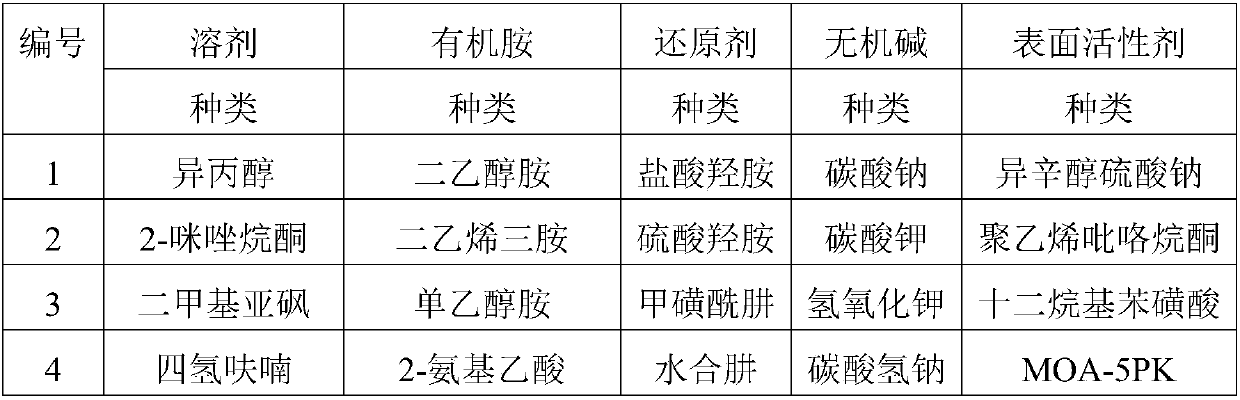

Anisotropic conductive adhesive remover and preparation method thereof

ActiveCN103122288AImprove degumming efficiencyShorten stripping timeSurface-active non-soap compounds and soap mixture detergentsAnisotropic conductive adhesiveEther

The invention provides an anisotropic conductive adhesive remover. The anisotropic conductive adhesive remover contains a solvent, a surfactant and a stable solubilizer, wherein the solvent comprises halogenated alkane, ethanol and ethyl acetate, and the stable solubilizer is a butyl ether derivative. The invention also provides a preparation method for the anisotropic conductive adhesive remover. The anisotropic conductive adhesive remover provided by the invention is high in adhesive removing efficiency and short in adhesive removing time.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

Method for removing ceramic mold core of hollow blade of aeroengine

A method for removing a ceramic mold core of a hollow blade of an aeroengine comprises the three steps of primary core-removing, secondary core-removing and acid liquid neutralizing and cleaning, wherein the concentration of KOH alkaline liquid used for core-removing is 30%-40%, the temperature of the alkaline liquid for core-removing of each time is 150 DEG C, the core-removing pressure is 0.2-0.7 MPa, and the core-removing time of each time is 20 h. According to the method, the method that the concentration of the alkaline liquid is decreased, pressurizing and depressurizing are conducted atintervals in the process is adopted, so that the alkaline liquid is boiled and makes full contact with the mold core, thus, the scouring action is achieved, and the full core-removing effect is achieved; and the temperature of the alkaline liquid is increased by increasing the pressure instead of increasing the concentration of the KOH alkaline liquid, therefore, core-removing is facilitated, corrosion to a casting can be relieved, the core-removing time is shortened to two days, and the qualification rate of one-time core-removing reaches 98% or above.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

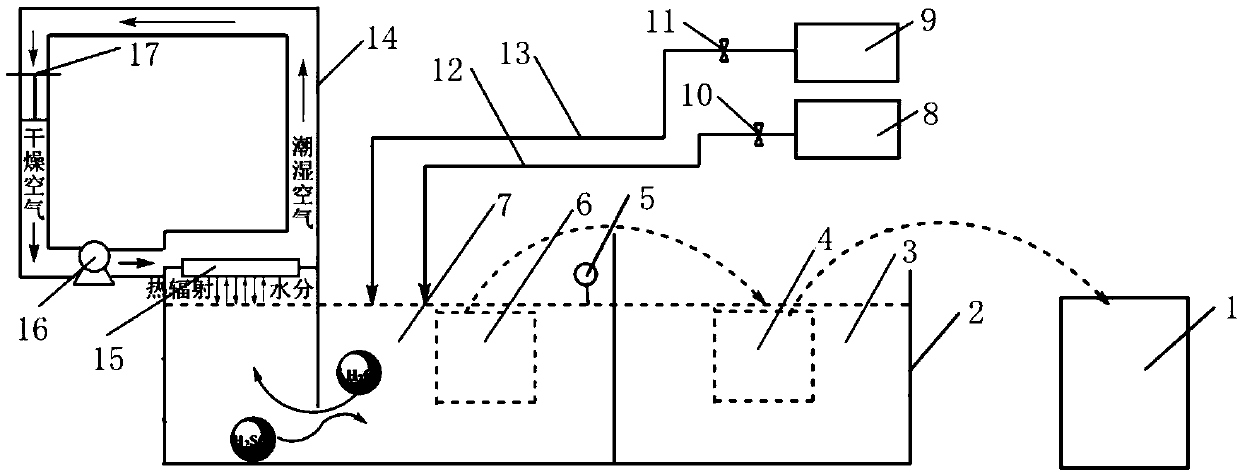

Preparation method of fermented Pu'er tea

InactiveCN109497173AFast preparationQuality improvementPre-extraction tea treatmentClimate change adaptationTea leafRaw material

The invention discloses a preparation method of fermented Pu'er tea. The preparation method comprises the following steps of S1, picking of tea leaves; S2, fixation; S3, rolling; S4, airing; S5, wetting by water; S6, piling; S7, finishing of piling; S8, deblocking; S9, drying; S10, steaming and compressing; S11, spreading and airing. The preparation method of the fermented Pu'er tea has the advantages that the whole set of production technology of finished fermented Pu'er tea from picking of tea leaves to final spreading and airing is provided, the high-quality fermented Pu'er tea can be quickly prepared, the appearance feature and inherent quality of the prepared fermented Pu'er tea are high, and the fermented Pu'er tea is suitable for long-term drinking, and is suitable for being used asthe raw material for producing tangerine Pu'er tea; by utilizing the rolling technique, compared with the prior art, the strip forming time of the fermented Pu'er tea is obviously shortened, the strip forming efficiency and strip forming appearance quality are improved, and the processing efficiency of the fermented Pu'er tea is further improved.

Owner:湖南绿盟农业科技股份有限公司

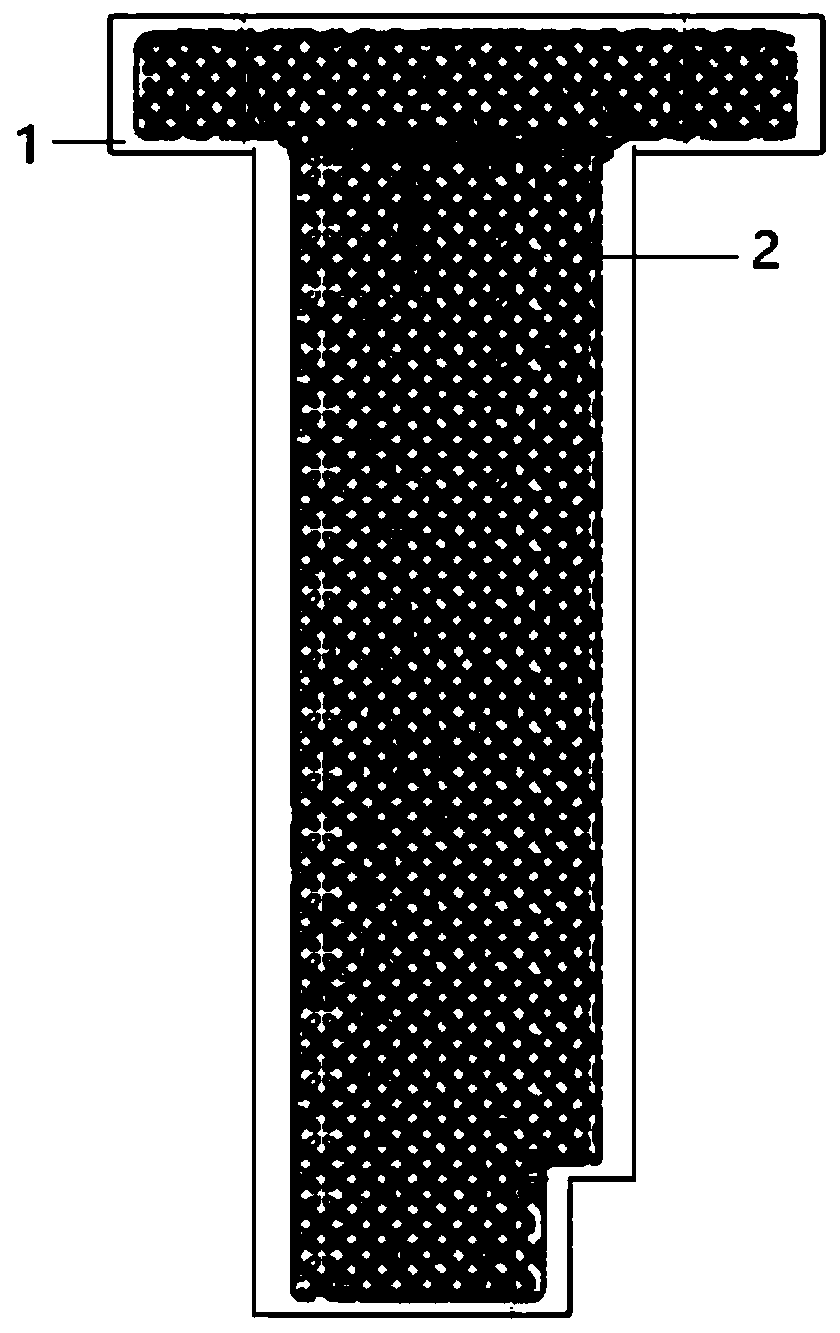

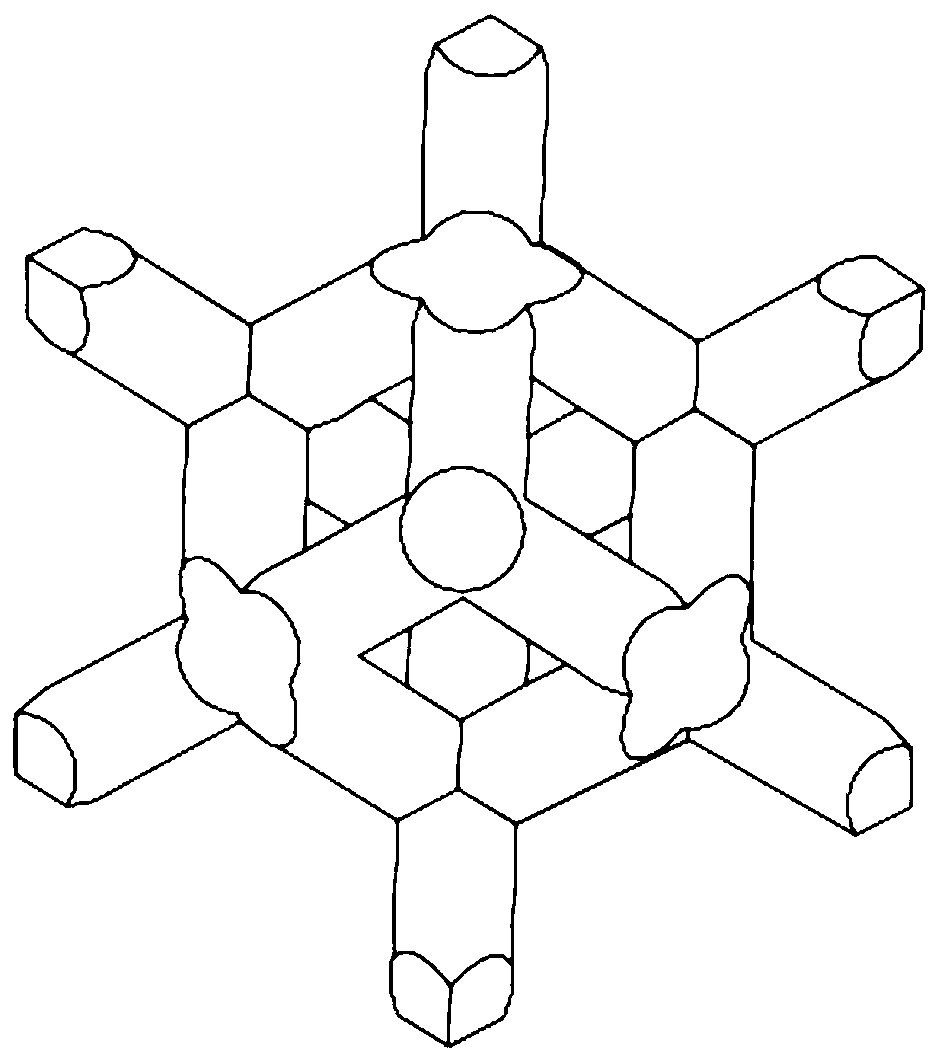

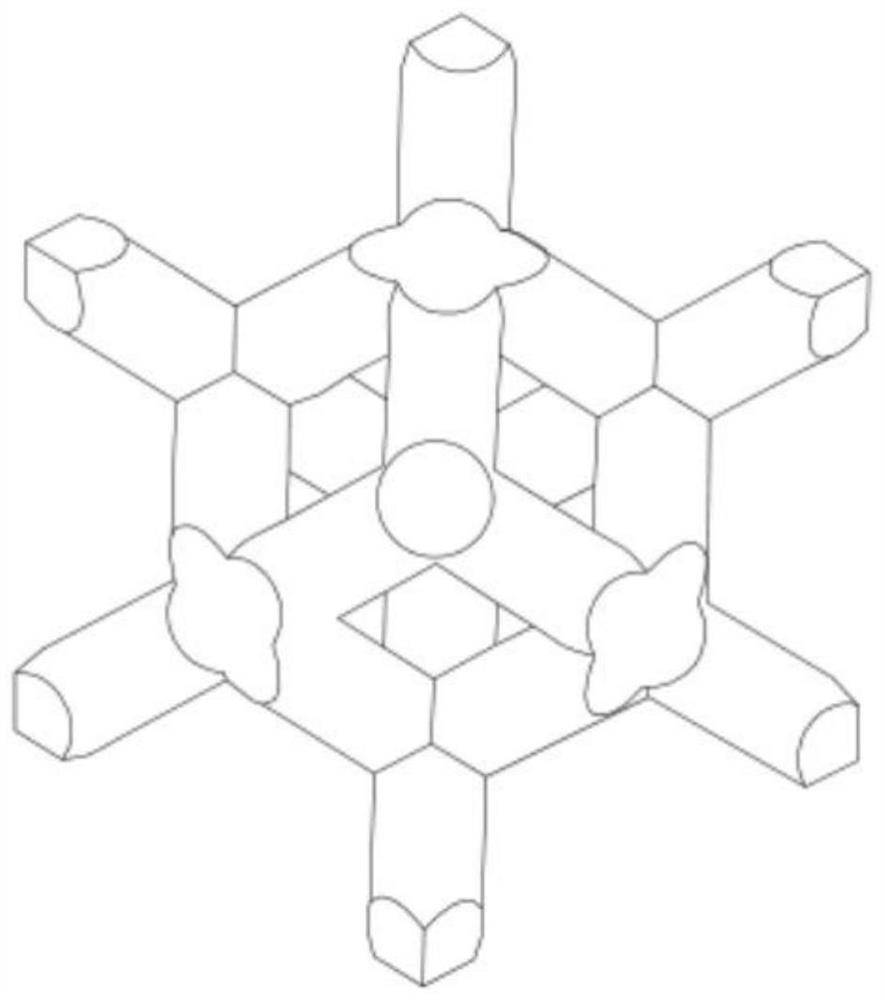

Hollow blade easy-to-remove aluminum oxide ceramic core and preparation method thereof

ActiveCN110773700AEasy to removeGuaranteed impact resistanceAdditive manufacturing apparatusFoundry mouldsOxide ceramicSlurry

The invention provides a hollow blade easy-to-remove aluminum oxide ceramic core and a preparation method thereof. According to the ceramic core, a shell and a space lattice structure in the shell arecombined, and when the relative density of the space lattice structure is 20 to 50 percent and the thickness of the shell is 0.4 to 0.5 mm, high void ratio of the ceramic core is realized and the deflection and the bending resistance of the ceramic core are guaranteed; and according to the preparation method, stable printing is facilitated by high flowability and low viscosity of ceramic slurry,the properties of the ceramic core are improved well by cooperating with the space lattice structure, the ceramic slurry is printed into a needed forming green body by 3D printing equipment, and the formed ceramic core is obtained by degreasing and sintering the formed green body. The ceramic core has high strength and short core removing time, saves ceramic materials, shortens process flow and provides an efficient solution for the problem about removal of the aluminum oxide ceramic core.

Owner:武汉因泰莱激光科技有限公司

Glass water degumming device and degumming method

PendingCN109570174AEasy to cleanGood removal effectDispersed particle separationSemiconductor/solid-state device manufacturingWater pipeMicroprocessor

The invention discloses a glass wafer degumming device. The glass wafer degumming device comprises a degumming tank, a dehydrating component, a concentrated sulfuric acid tank, a hydrogen peroxide tank and a microprocessor; the degumming tank comprises a washing tank and a rinsing tank which are arranged adjacently; the washing tank is filled with concentrated hydrochloric acid and hydrogen peroxide; the upper portion inside the washing tank is provided with a washing basket; the upper portion inside the rinsing tank is provided with a rinsing basket; the concentrated sulfuric acid tank communicates with the washing tank via concentrated sulfuric acid pipe; the hydrogen peroxide tank communicates with the washing tank via a hydrogen peroxide pipe; one side of the upper portion of the washing tank is provided with a tank cover; the other side of the upper portion of the washing tank is used for arranging the dehydrating component; and the dehydrating component comprises an electric heating plate, an absorption bin, a temperature sensor, a circulating pipe, a desiccant bag and a fan. The invention further provides a method for degumming glass wafers by using the glass wafer degummingdevice. The glass wafer degumming device can be used for effectively removing ultraviolet curing glue on the glass wafer, can realize continuous proceeding of a degumming process without frequently replacing the degumming liquid, improves the work efficiency, saves resources and protects the environment.

Owner:SUZHOU JIMCEL ELECTRONICS NEW MATERIAL

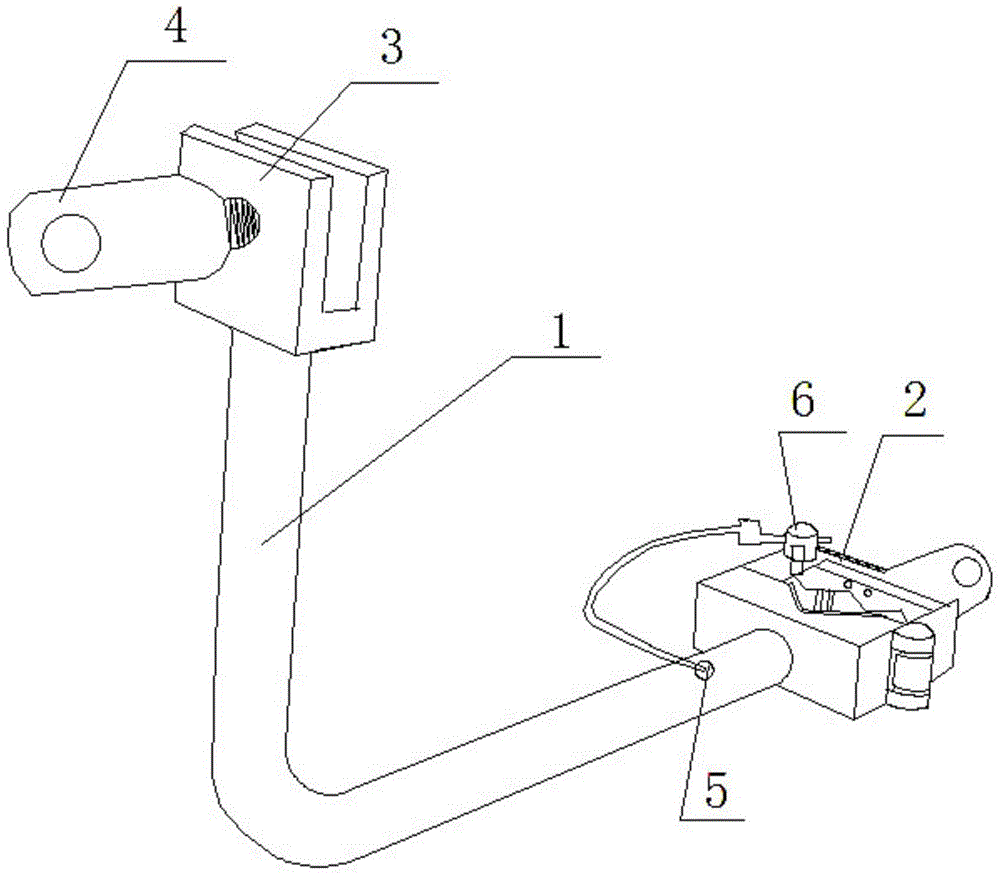

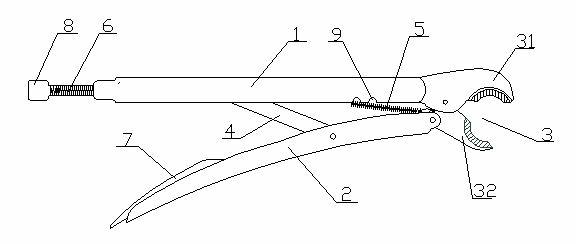

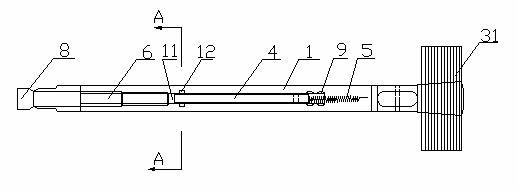

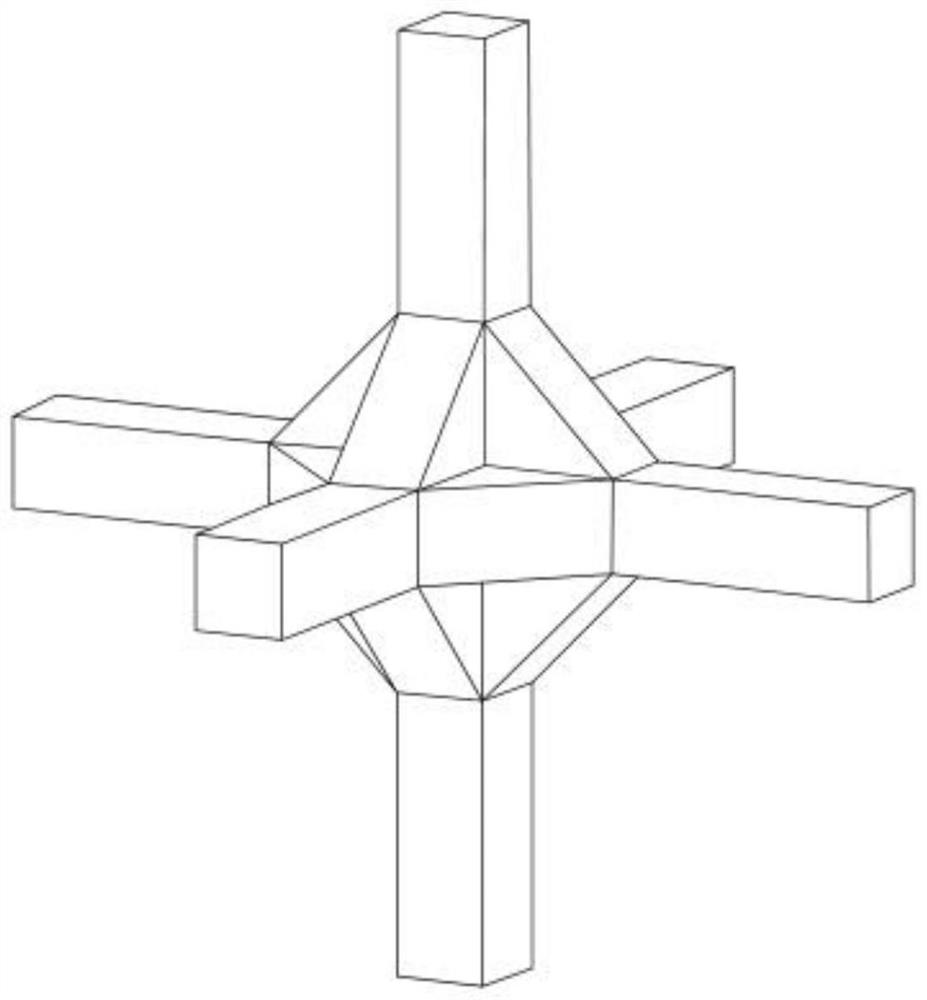

Fixing device used for stripping insulating layer of insulated conductor

InactiveCN104538818AShorten the stripping timeReduce physical exertionLine/current collector detailsApparatus for removing/armouring cablesEngineeringWire rope

The invention discloses a fixing device used for stripping an insulating layer of an insulated conductor. The fixing device comprises a right-angled connecting rod, one end of the right-angled connecting rod is provided with a bib clamp, the other end of the right-angled connecting rod is provided with a duckbilled clamp, and the duckbilled clamp is provided with a turncap further facilitating rotating and screwing. A rod body, close to one end of the bib clamp, of the right-angled connecting rod is provided with a round hole, and a steel wire rope provided with a bolt is tied on the rod body and is fixed to the rod body. The bib clamp comprises a first part and a second part which are freely connected through a hinge piece, the first part is an inverted-U-shaped block body, a round hole is formed in the middle of the first part, a spiral bolt penetrates through the round hole and is connected with a W-shaped contact face which is in fit contact with the second part, and the W-shaped contact face can move upwards and downwards along with screwing of the spiral bolt. The fixing device has the advantages that the fixing device can fix a wire, so the wire can not rotate and the wire stripping time can be greatly shortened; manual support is not needed, and physical output is greatly reduced.

Owner:STATE GRID CORP OF CHINA +1

Solder-resistor/character ink stripping technology

ActiveCN106714466AReduce concentrationReduce alkalinityNon-metallic protective coating applicationResistScreen printing

The invention provides a solder-resistor / character ink stripping technology. The technology comprises the following steps that a 10-16wt% of a stripping agent solution of a solder-resistor / character ink is configured, and a stripping agent comprises 40g / L of NaOH, 10g / L Na2S2O3 and TX-101ml / L; a heater heats a stripping cylinder to 80 to 85 DEG C; a returned printed circuit board rack is placed in the stripping cylinder and immersed for 1 hour; the immersed returned printed circuit board rack is taken out and washed by tap water or brushed by a nylon brush at the room temperature; and drying is carried out for 1 hour at the temperature of 100 DEG C, and a pretreatment process of solder-resist / character ink screen-printing is turned to. The technology is suitable for common FR-4 base materials and halogen-free base materials, ripple exposure is prevented, and copper and golden surfaces are not attacked. According to the technology, complex equipment is not needed, the technology is simple, material resources are wide, the cost is low, the preparation cost is low, the production process is free of pollution, and the technology is suitable for industrial production.

Owner:东莞市斯坦得电子材料有限公司

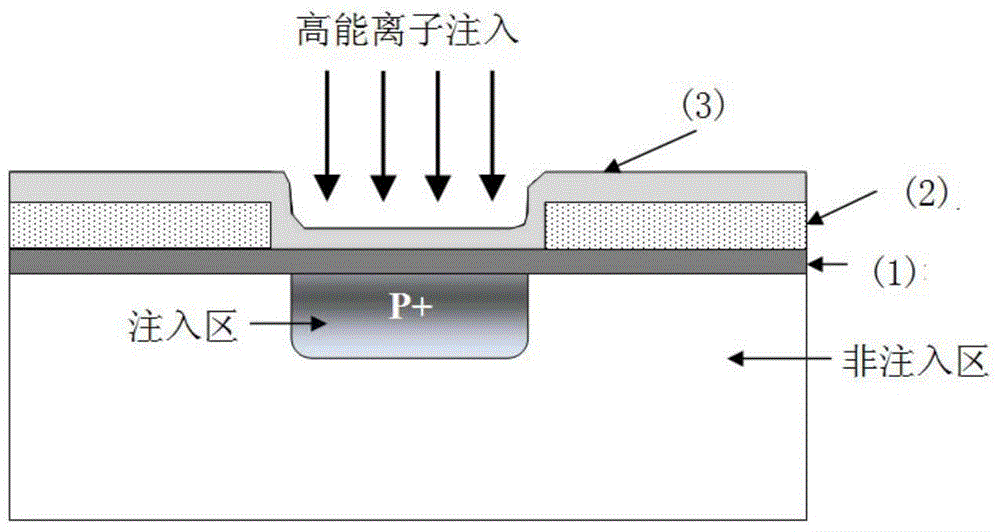

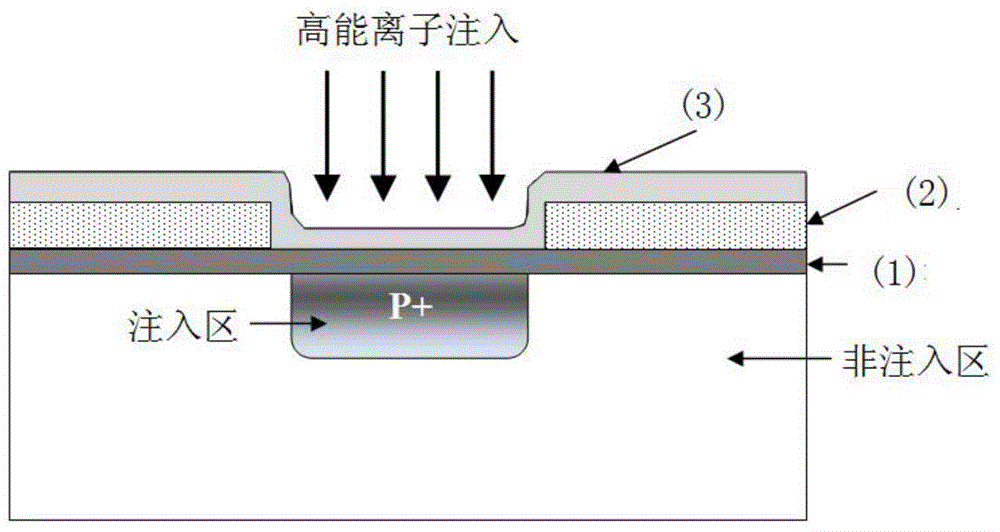

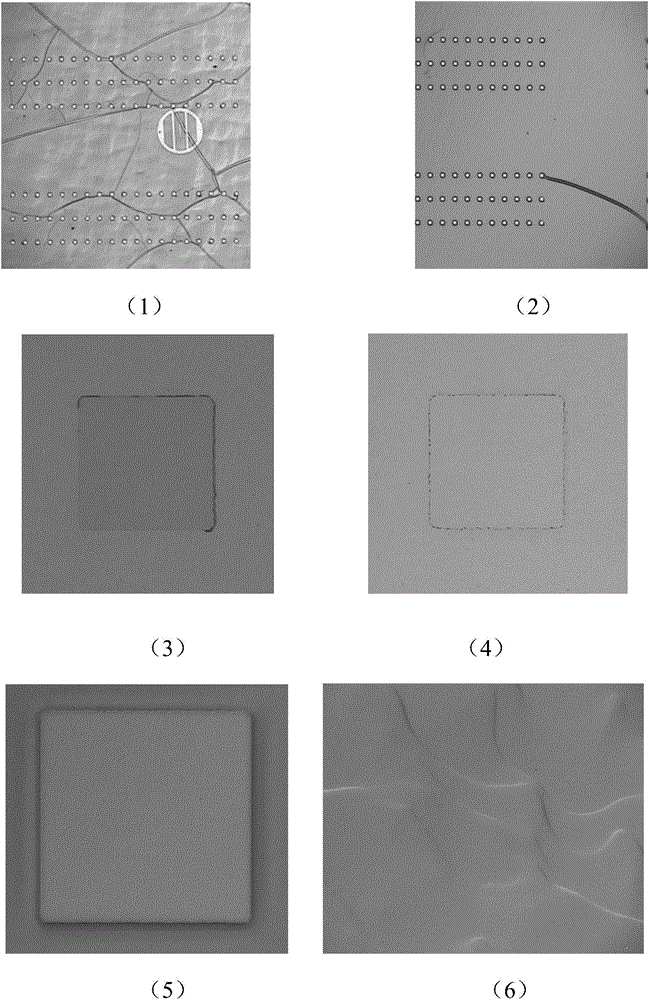

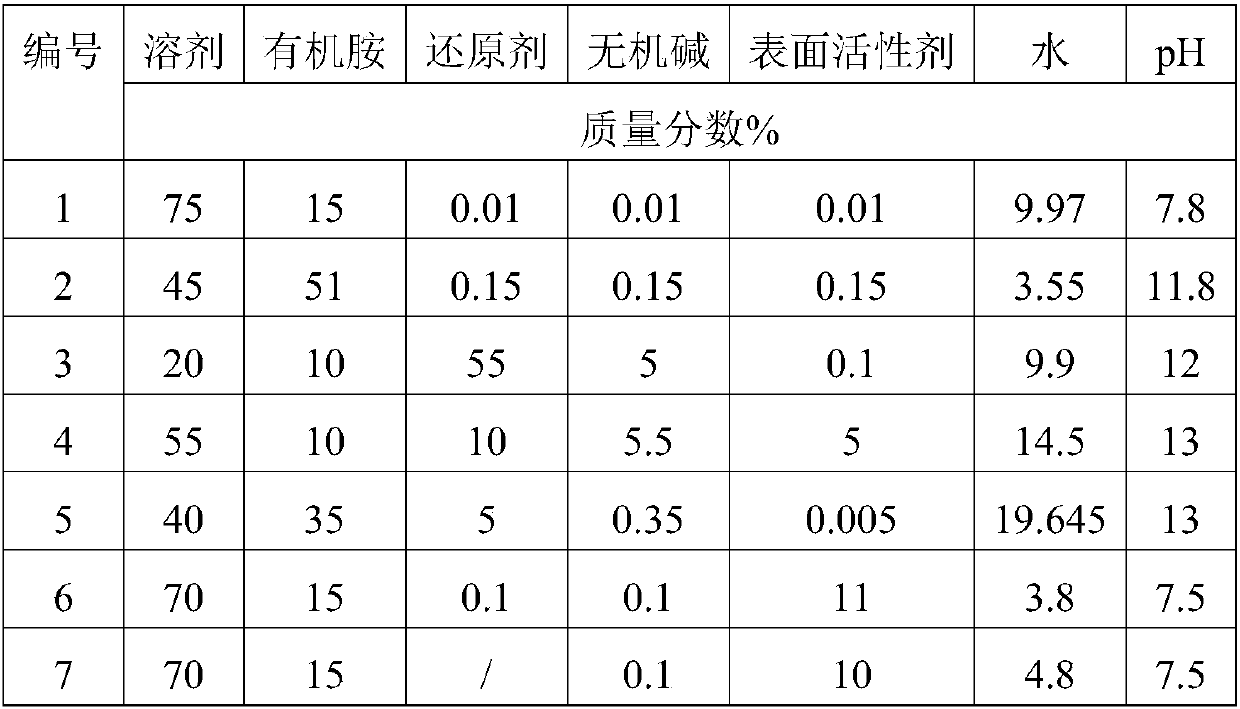

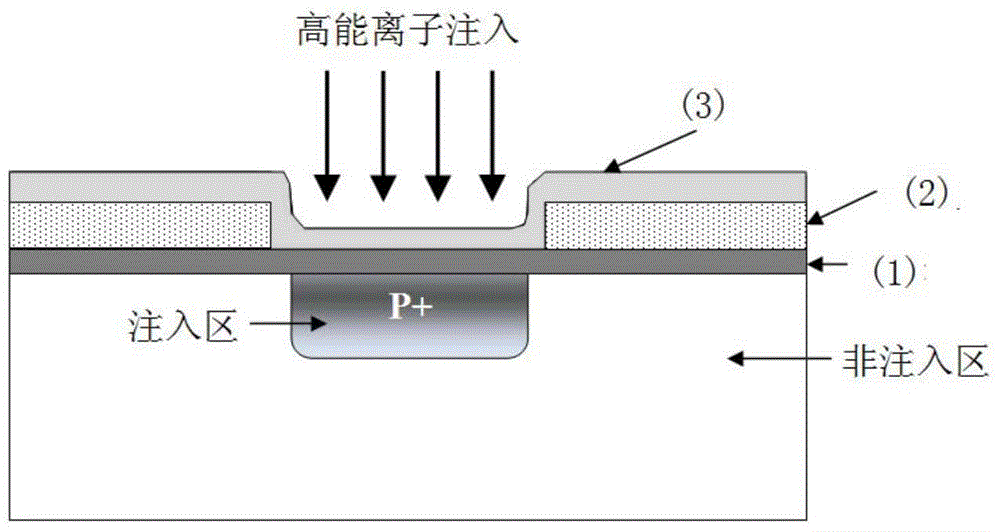

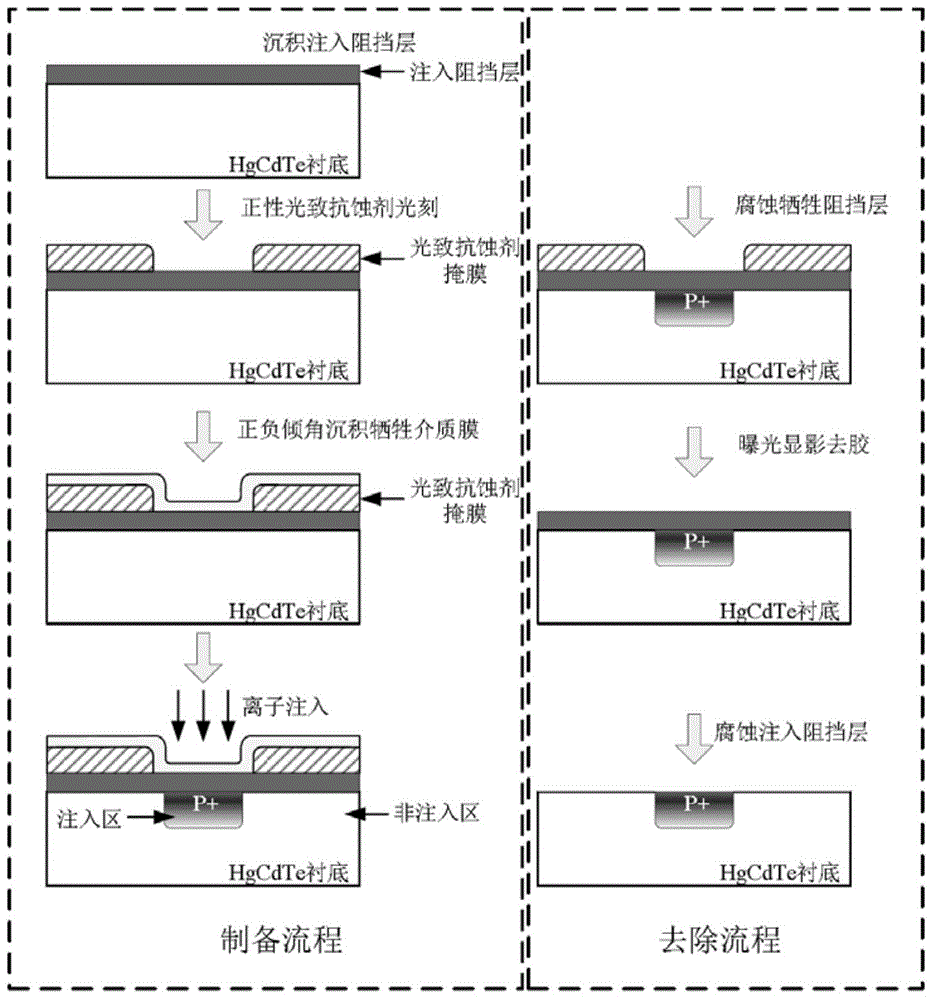

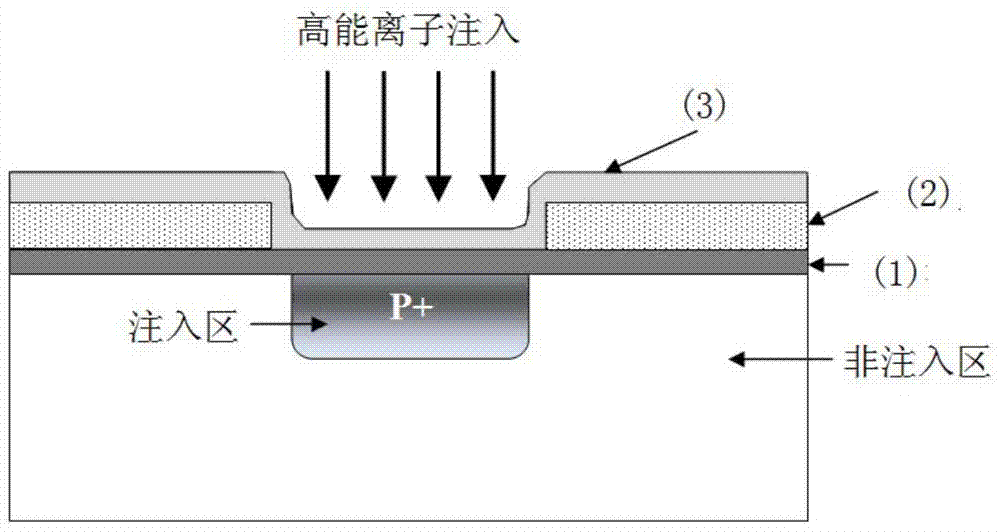

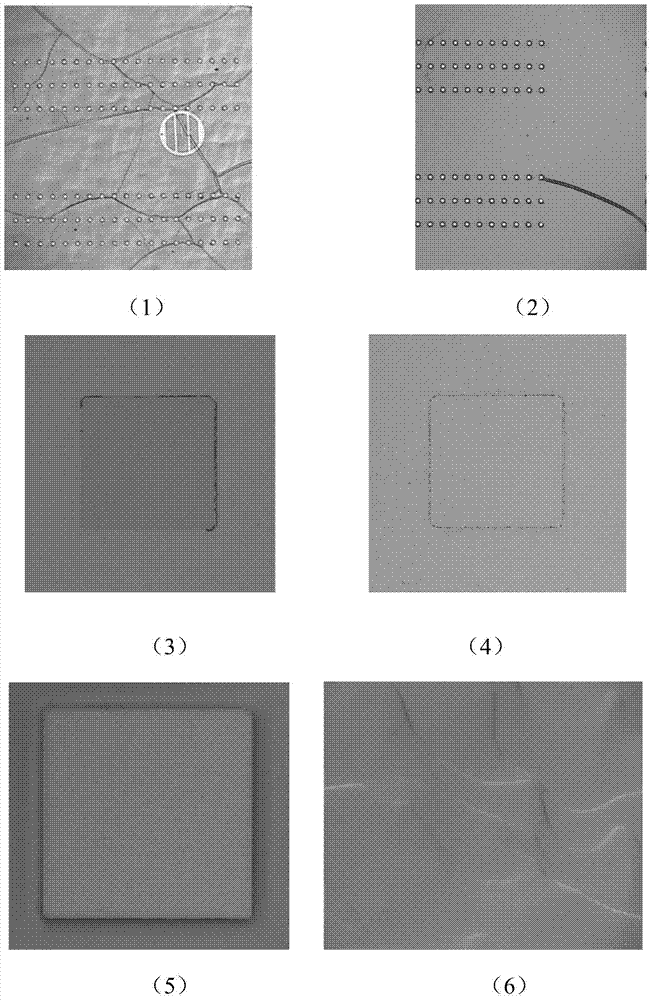

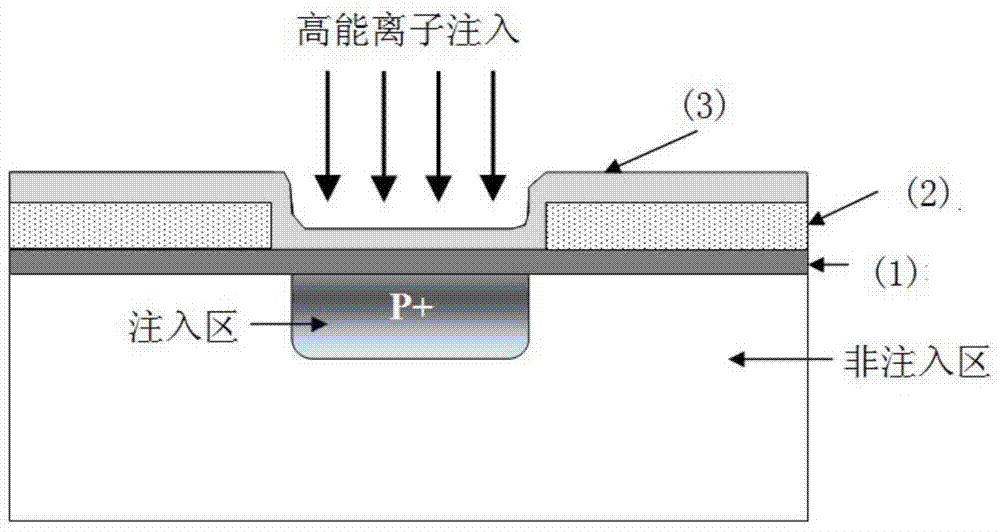

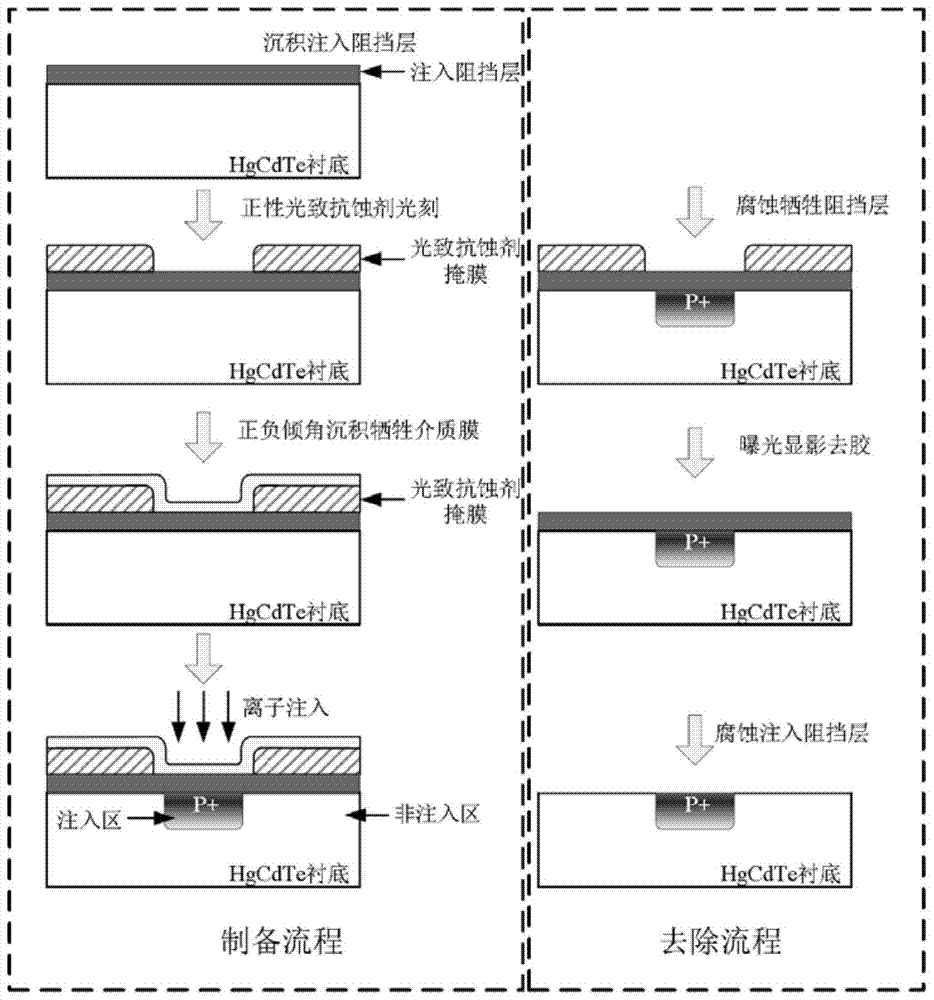

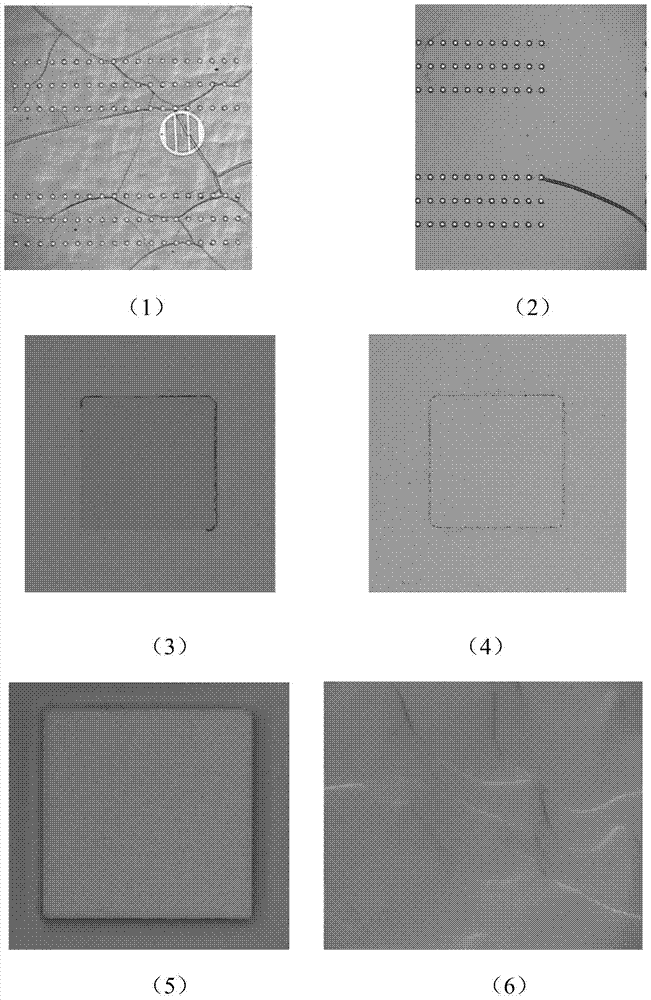

Composite mask for high-energy ion implantation

InactiveCN104576335AAvoid process problemsAvoid sex changeSemiconductor/solid-state device manufacturingDielectricResist

The invention discloses a composite mask for high-energy ion implantation. The mask is a composite photoresist mask of a three-layer structure. According to the mask, a photoresist mask pattern is manufactured between an implantation barrier layer dielectric film and a surface layer sacrifice dielectric film and used as a high-energy ion implantation mask. By the adoption of the composite mask, the problem of chapping denaturation of the photoresist mask under high-energy ion bombardment can be solved, the mask is removed without residues, the surface cleanness of a chip is guaranteed, and device performance is improved.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

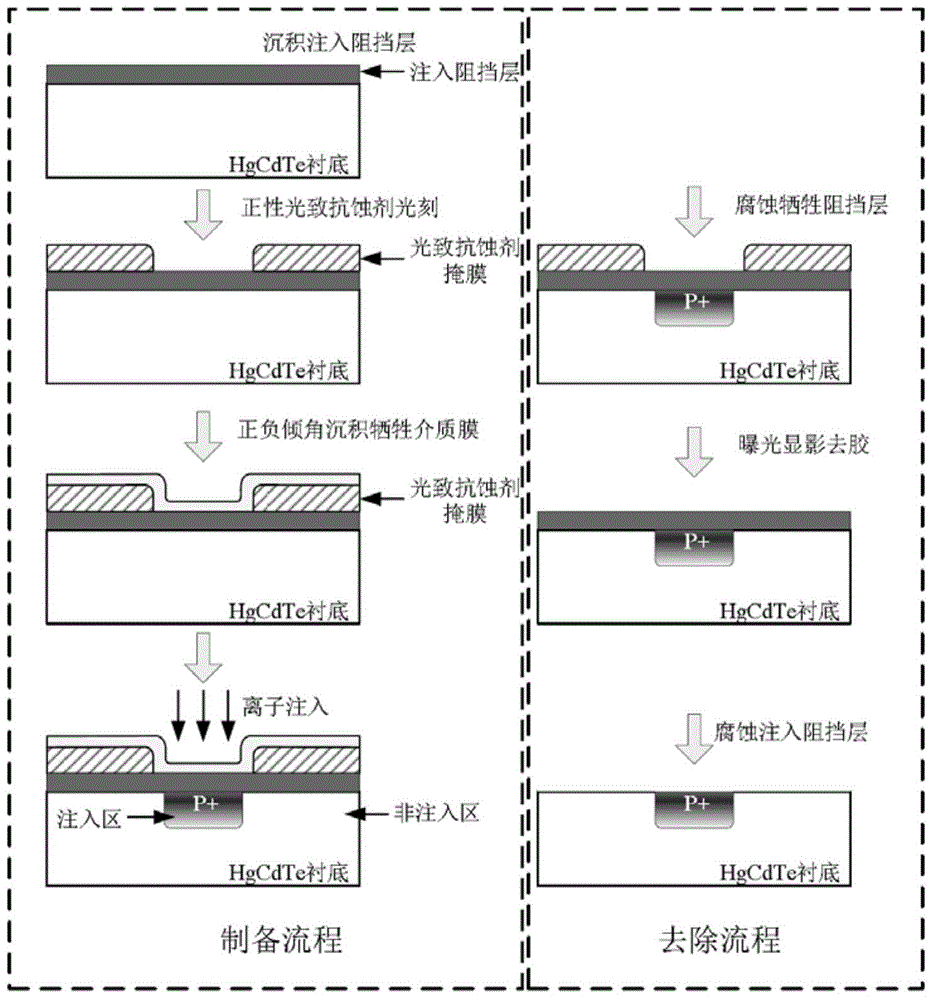

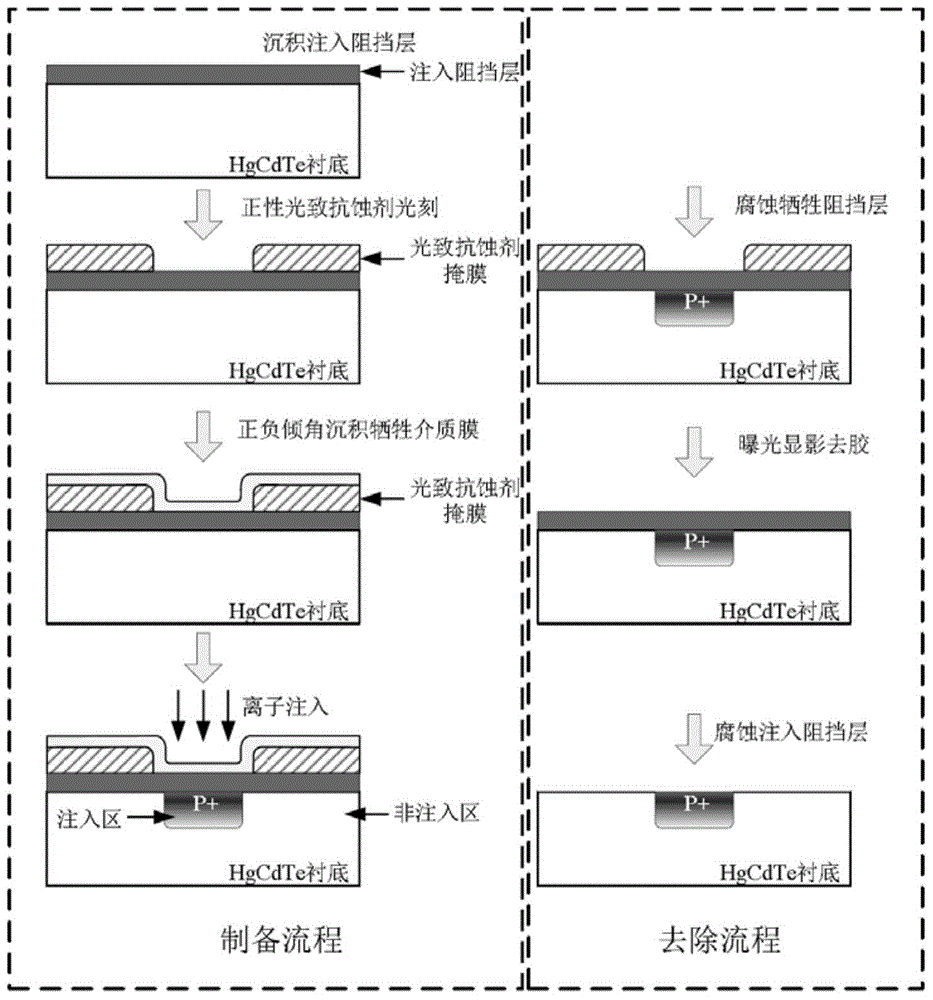

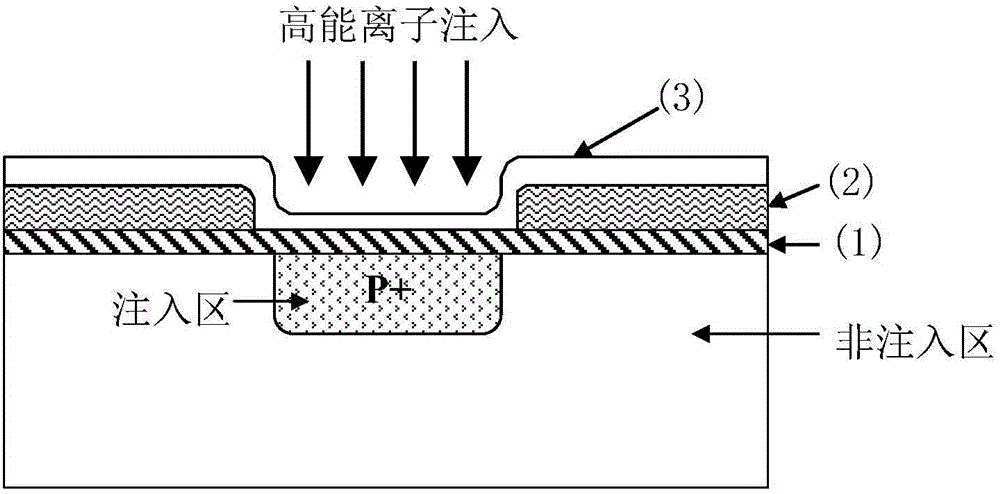

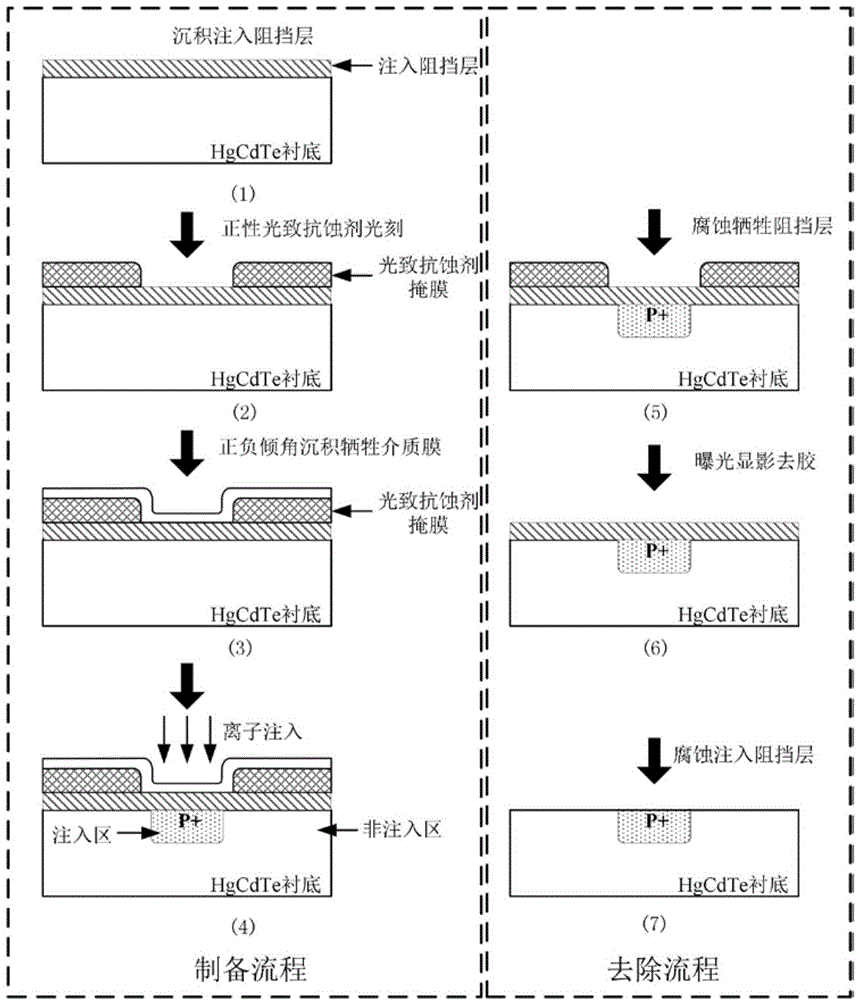

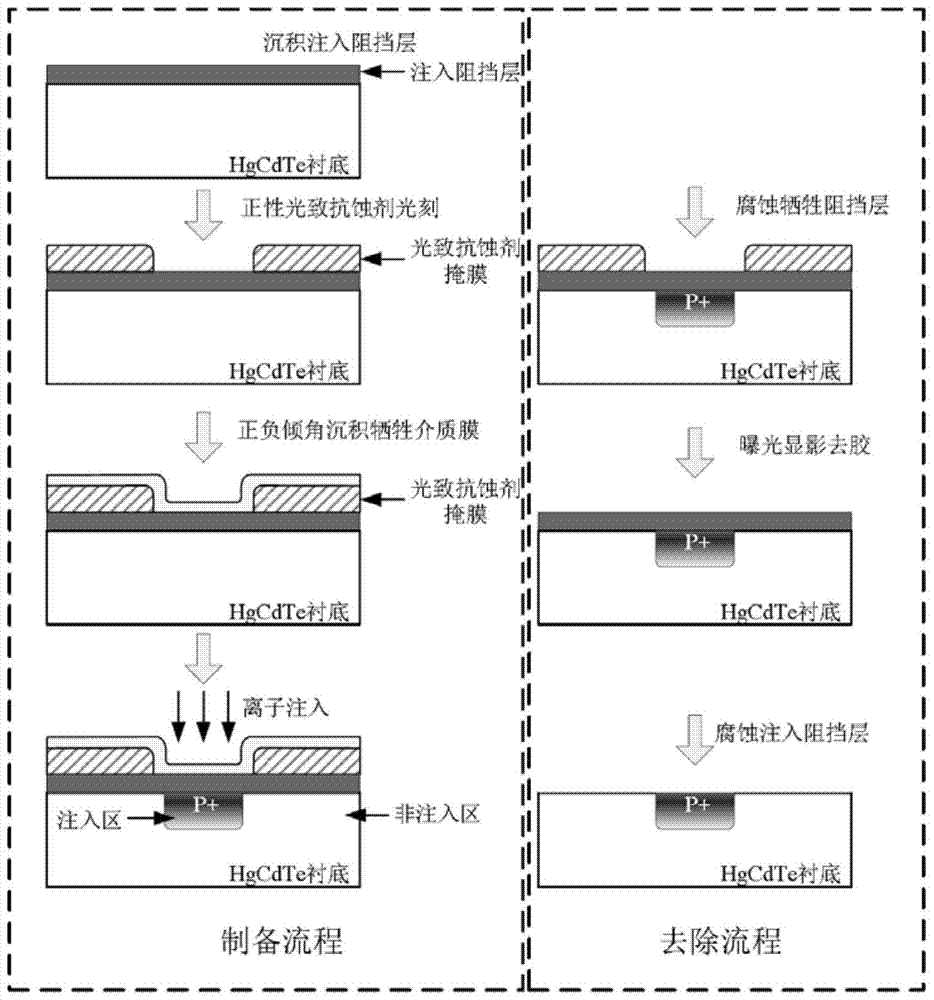

Removal method of composite mask for injecting high-energy particles

ActiveCN104616974AAvoid process problemsAvoid sex changeSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusDielectricResist

The invention discloses a removal method of a composite mark for injecting high-energy particles. The mask is a composite photoresist mask with a three-layer structure; a photoresist mask pattern is manufactured between an injecting resisting layer dielectric film and a surface sacrificing dielectric film through the mask to be used as a high-energy particles injecting mask; two dielectric film etching agents for removing the composite mask are different; when removing the mask, the sacrificing dielectric film, the photoresist mask and the resisting layer dielectric film are sequentially removed. With the adoption of the composite mask, the problem that the photoresist mask is cracked and denatured under the attack of the high-energy particles can be avoided; in addition, the mask can be removed without residue; the cleanness of the surface of a chip is ensured, and the device performances can be improved.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Fine porous ceramic used as ceramic mold and molding technique

InactiveCN101774215AEasy to makeImprove mold precisionCeramic shaping apparatusGypsumPressure casting

The invention relates to a new ceramic mold material and a molding technique for replacing gypsum mold and technique needed by traditional ceramic mold technique. Compared with a traditional mold, the inventive mold has the advantages of high strength, long service (a single mold can be used for more than million times), high preciseness, small number of needed single variety mold (hundreds of molds are needed in the traditional technique, while 2-3 molds are needed for the new material rolling technique, 6-8 molds are needed for pressure casting to achieve continuous production), and the like. The popularization of the mold and molding technique can radically change the existing ceramic production situation, save resources and energies, reduce pollution, enhance efficiency and product quality, and provide conditions for modernization and automation of ceramic production.

Owner:胡敏渝

Preparation method of ceramic core easy to release

InactiveCN108326239AShorten the stripping timeReduce the difficulty of core removalFoundry mouldsFoundry coresInvestment castingGraphite

The invention relates to a preparation method of a ceramic core easy to release. The preparation method is mainly applied to the technical field of investment casting precision casting. The method comprises the following steps of (1) preparation of a graphite core; (2) external coating preparation and coating; and (3) sintering. In the step (1), preparation of the graphite core comprises the following steps of a, sizing agent preparation; b, forming; and c, sintering of the graphite core; in the step (2), an external coating comprises a first external coating and a second external coating. Thepreparation process of the first external coating and the second external coating comprises the following steps of putting raw materials into a planetary mill for treatment for 30 minutes, and uniformly mixing for later use; and in the step (3), the graphite core in the sintering process can be oxidized and removed, and meanwhile, the external slurry is sintered to form a compact shell, so that the structure of the ceramic core has the characteristics of being loose and multi-hole inside, and compact in appearance. The method is simple and easy to realize, and wide in application prospect, and can effectively reduce the production cost of castings.

Owner:辽宁航安型芯科技股份有限公司

Tool for fixing 10kV insulated conductors

InactiveCN102324711AResolve swingReduce security risksApparatus for overhead lines/cablesInsulation layerEngineering

The invention relates to a special method or equipment for installing, maintaining, repairing or dismantling electric cables or electric wires, in particular to a tool for fixing 10kV insulated conductors. The tool for fixing the 10kV insulated conductors is characterized by comprising a main clamp arm, an auxiliary clamp arm, a clamp jaw, a transmission bar and an offsetting spring; the clamp jaw comprises a fixing part and a movable part which are hinged with each other and are respectively installed at the front end of the main clamp arm and the front end of the auxiliary clamp arm; a long-shaped groove is arranged at the internal side of the main clamp arm; a position-limiting member is installed in the long-shaped groove; one end of the transmission bar is fixedly connected onto the auxiliary clamp arm; and the other end of the transmission bar is a movable end which is positioned in the groove of the main clamp arm, can slide in the groove by taking the long groove as a guide rail and supports against the position-limiting member. By fixing the insulated conductors and using a wire-stripping tool in a coordination manner, the tool for fixing the 10kV insulated conductors has the advantages that: the problem of swinging caused by the distortion and energy storage of the conductors is solved; and the insulation layers are easy to strip off, and the discontinuous wire-stripping or the repeated wire-stripping is not needed, so that the time for stripping is reduced, the working efficiency is greatly enhanced, and the potential safety hazards of wires are prevented or reduced.

Owner:STATE GRID CORP OF CHINA +2

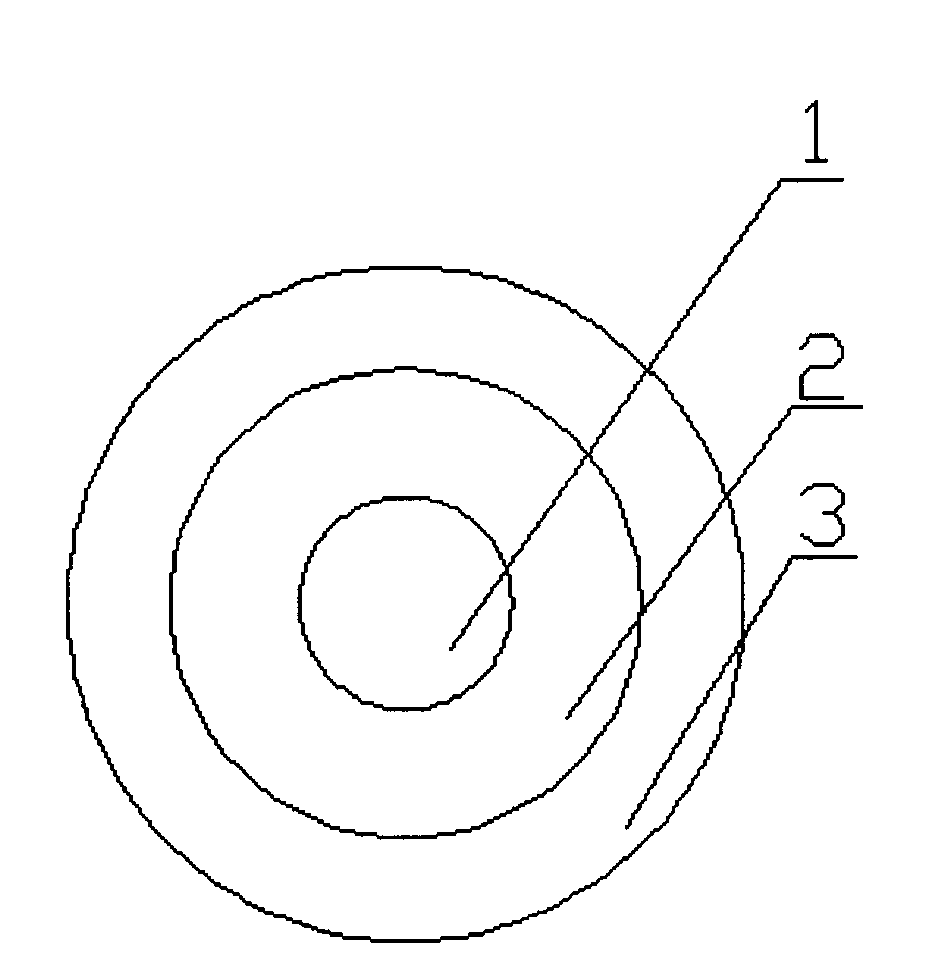

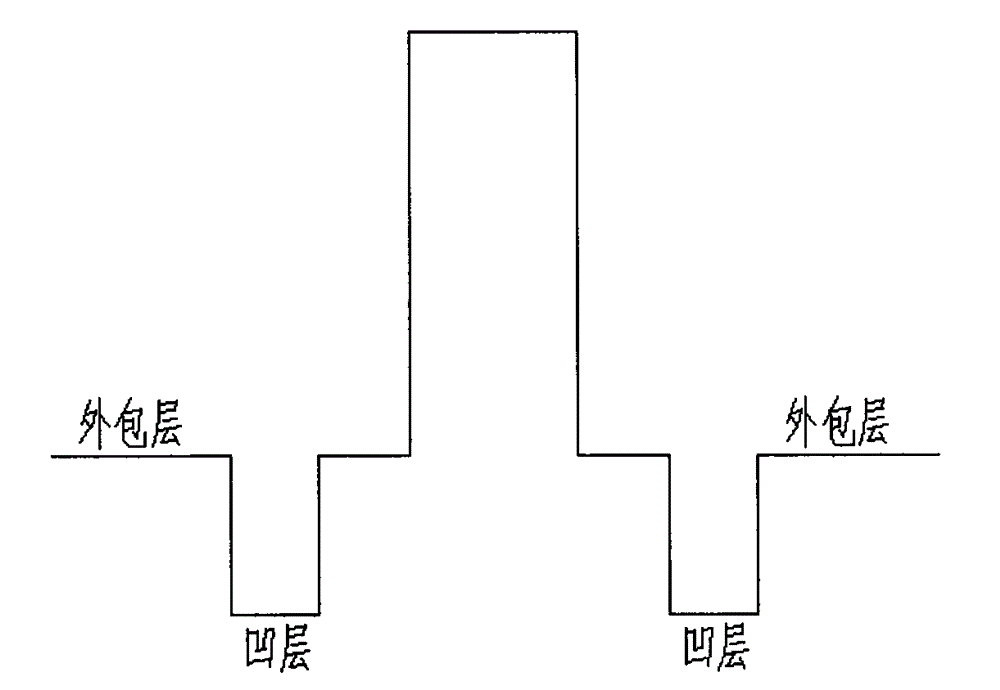

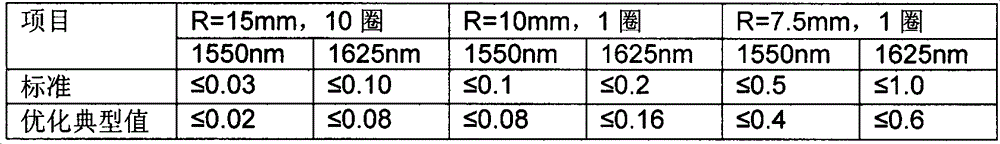

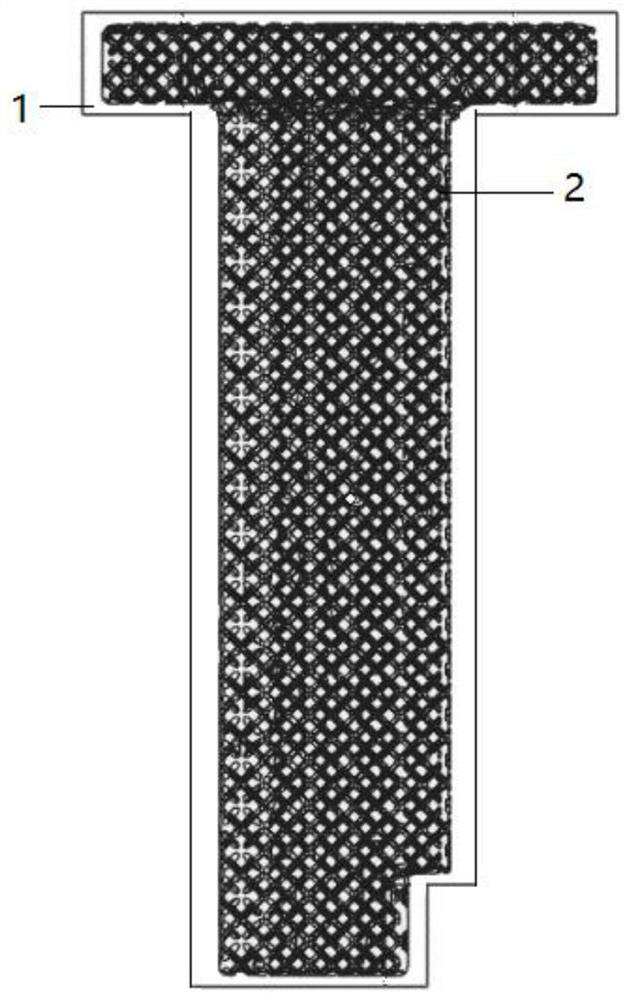

Low bending loss low water peak single mode fiber with stable diameter and production process of low water peak single mode fiber

InactiveCN102981214AExcellent peelabilityImprove bending resistanceGlass making apparatusOptical fibre with multilayer core/claddingEngineeringBend loss

The invention discloses a low bending loss low water peak single mode fiber with a stable diameter. The cladding diameter of the optical fiber is 124-125 mu m, the inner coating diameter is 190-195 mu m, and the outer coating diameter is 240-246 mu m. A production process of the low bending loss low water peak single mode fiber includes the following steps that an F element is added to a core of the optical fiber, the refractive index section of a rod is prefabricated to be a recessed cladding structure, the recessed amplitude is 0.05%-0.14%, and simultaneously, a coating material is subjected to modified optimization. The low water peak single mode fiber is simple in structure, high in practicability, excellent in bending resistance and suitable for being widely used in the industry, simultaneously, stripping performances of coatings are superior to those of similar optical fibers, and the coating stripping time of a single optical fiber is shortened by two seconds.

Owner:ZHONGTIAN TECH FIBER OPTICS

A stripping process of solder resist/character ink

ActiveCN106714466BReduce concentrationReduce attackNon-metallic protective coating applicationScreen printingResist

The invention provides a solder-resistor / character ink stripping technology. The technology comprises the following steps that a 10-16wt% of a stripping agent solution of a solder-resistor / character ink is configured, and a stripping agent comprises 40g / L of NaOH, 10g / L Na2S2O3 and TX-101ml / L; a heater heats a stripping cylinder to 80 to 85 DEG C; a returned printed circuit board rack is placed in the stripping cylinder and immersed for 1 hour; the immersed returned printed circuit board rack is taken out and washed by tap water or brushed by a nylon brush at the room temperature; and drying is carried out for 1 hour at the temperature of 100 DEG C, and a pretreatment process of solder-resist / character ink screen-printing is turned to. The technology is suitable for common FR-4 base materials and halogen-free base materials, ripple exposure is prevented, and copper and golden surfaces are not attacked. According to the technology, complex equipment is not needed, the technology is simple, material resources are wide, the cost is low, the preparation cost is low, the production process is free of pollution, and the technology is suitable for industrial production.

Owner:东莞市斯坦得电子材料有限公司

Pneumatic connection rod type rotary cutting mould

The invention discloses a pneumatic connection rod type rotary cutting mould which comprises an upper mould and a lower mould, wherein the upper mould comprises an upper mould seat, a convex mould fixing plate, a discharge plate and a pressure plate; a nitrogen spring is arranged in the upper mould seat; a rotary cutting concave mould and a guide pin are arranged in the pressure plate; the lower mould comprises a lower mould plate, a lower base plate and a lower mould seat; a rotary cutting convex mould is arranged in the limit grooves arranged on the upper surface of the lower base plate andthe lower end surface of the lower mould plate, and corresponds to the rotary cutting concave mould; the lower part of the rotary cutting convex mould is also provided with a rotary cutting convex mould resetting mechanism; in the convex mould fixing plate, a front driving block, a rear driving block, a left driving block and a right driving block of the rotary cutting convex mould are also arranged in the front, rear, left and right directions of the mould; the four driving blocks cooperate with the outer side of the rotary cutting convex mould; and a pneumatic connection rod mechanism is arranged in a limit groove formed by the upper surface of the pressure plate and the lower end surface of the discharge plate. The pneumatic connection rod type rotary cutting mould disclosed by the invention not only can guarantee the product precision and improve the production efficiency, but also finish all processes in a set of progressive mould, thereby greatly saving the cost and improving the market competitiveness.

Owner:LEMTECH PRECISION MATERIAL (CHINA) CO LTD

Detape method for integrated circuit packaging post-treatment

PendingCN110071054AExtend your lifeReduce generationSemiconductor/solid-state device manufacturingEngineeringElectroplating

The invention discloses a detape method for integrated circuit packaging post-treatment. The detape method for integrated circuit packaging post-processing method comprises the following steps that ina chemical detape process, the following operations are added: one or more of inert gas bubbling, overflow and ultrasonic processing are carried out. According to the detape method, the service lifeof an adhesive remover can be prolonged (up to 4 months or above), and a conventional adhesive remover is matched, so that tape glue or flash or bur can be independently removed, or the tape glue andthe flash and bur can be removed simultaneously, and the occurrence of burrs of a subsequent electroplating process can be reduced; no damage is caused to a plastic package body and a base material; and the detape time can be obviously shortened.

Owner:SHANGHAI SINYANG SEMICON MATERIALS

Composite mask for high energy ion implantation

InactiveCN104867837AAvoid process problemsAvoid sex changeSemiconductor/solid-state device manufacturingResistDielectric

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

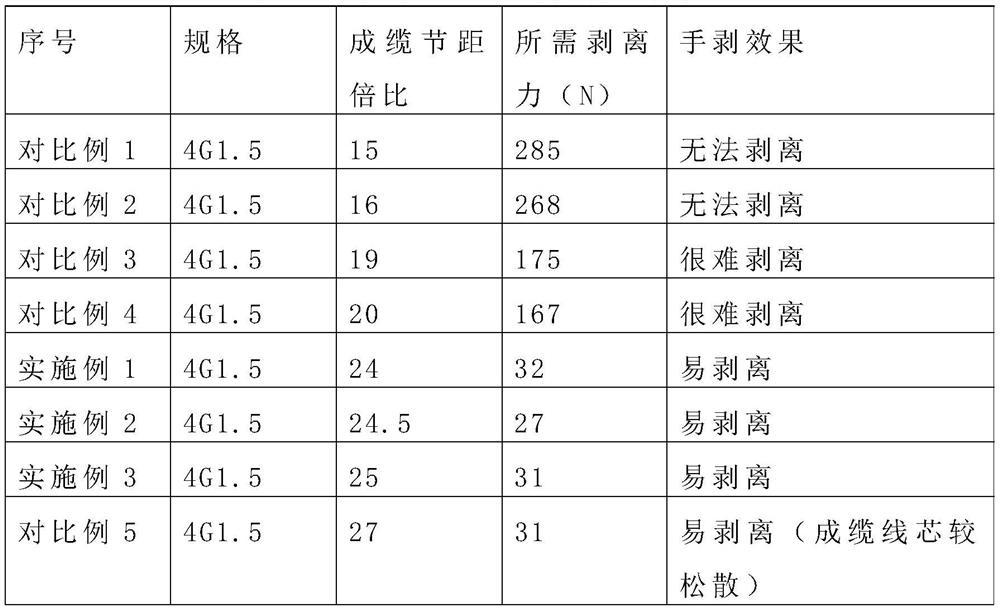

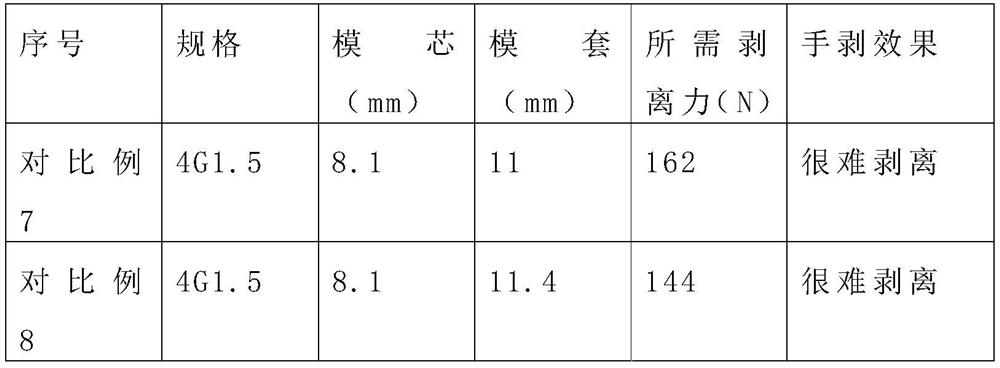

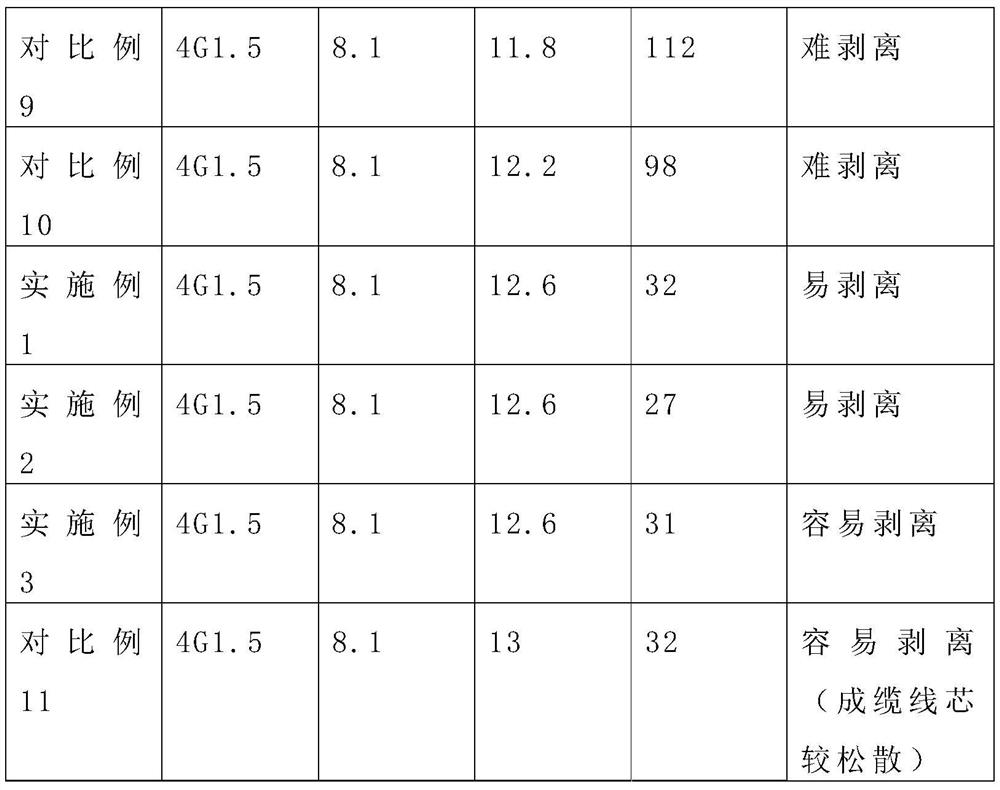

Processing technology of easy-to-peel sheathed cable

InactiveCN111863354AAvoid stickinessReduce frictionPackagingInsulating conductors/cablesStructural engineeringElectric cables

The invention discloses a processing technology of an easy-to-peel sheathed cable. The processing technology comprises the following steps: S1, extruding to prepare insulating wire cores; S2, cablingand stranding the insulated wire cores in the step S1 to prepare a cable core, the cabling pitch being L, the cabling outer diameter being D, and L = 24D-25D; S3, extruding the cable core in the stepS2, so that the cable core is wrapped with a sheath to form a cable; and S4, taking up and packaging the cable in the step S3. The technical problem that a sheath in the cable is difficult to peel offin the prior art is solved.

Owner:BAOSHENG SCI & TECH INNOVATION

Chip stripping method of LED lamp beads

ActiveCN110137125AHighly consistentShort corrosion timeSolid-state devicesSemiconductor/solid-state device manufacturingOrganic solventEngineering

The invention relates to a chip stripping method of LED lamp beads. The method comprises the steps of: a) shearing the upper end of LED lamp beads to allow a distance between the sheared region and achip to be 0.25-0.5mm; b) welding and fixing the N sheared lamp beads on a LED support strip in a linear direction, wherein the heights of the lamp beads after welding are consistent; c) putting the LED support strip into an oven for baking to heat and soften the lamp beads; and d) putting the baked LED lamp beads into a culture dish for immersion by employing an organic solvent, wherein the glueat the surfaces of the chips in the LED lamp beads are dissolved by the organic solvent, and the chips are stripped off from the lamp beads, and the stripped chips are taken out from the culture dishby employing tweezers. The time of stripping of the LED lamp bead chips is reduced, an ordinary organic solvent is only used to prevent the chips from being damaged by lamp bead corrosive liquid so asto improve the stripping efficiency of the lamp bead chips, reduce the use of the lamp bead corrosive liquid, reduce the damaging to the personnel, the environment and LED chips caused by the lamp bead corrosive liquid and improve the analysis efficiency of the poor LED lamp beads.

Owner:SHANDONG INSPUR HUAGUANG OPTOELECTRONICS

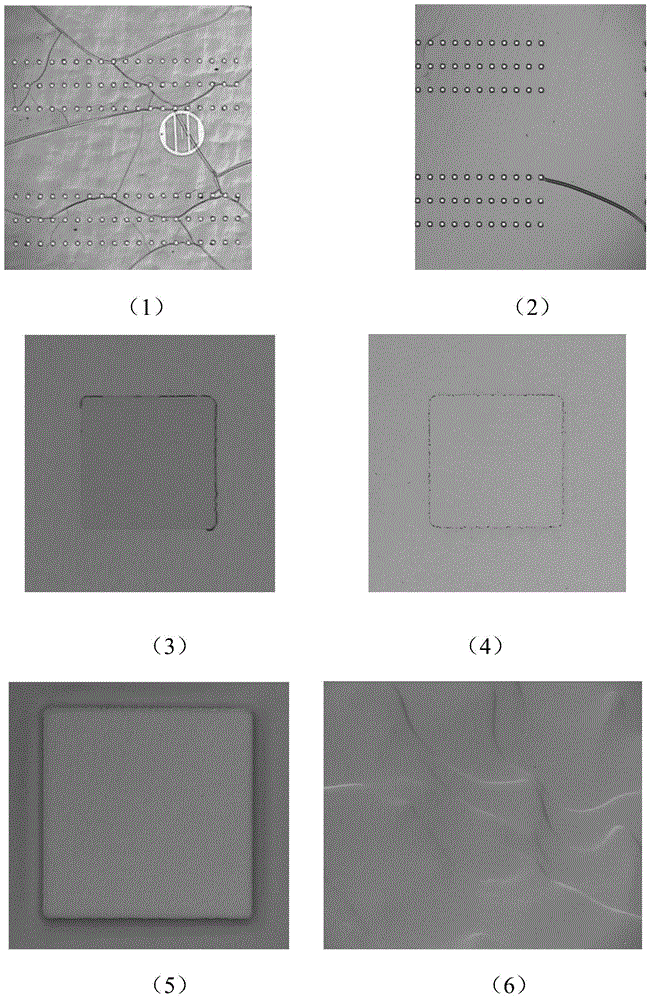

Preparation method of composite mask for high-energy ion implantation

ActiveCN104599958AAvoid process problemsAvoid sex changeSemiconductor/solid-state device manufacturingResistDielectric

The invention discloses a preparation method of a composite mask for high-energy ion implantation. The mask is a composite photoresist mask with a three-layer structure, a photoresist mask figure of the composite mask is made between an implantation barrier layer dielectric film and a surface layer sacrifice dielectric film, and is used for high-energy ion implantation of the mask. The preparation method comprises the steps that the mask figure is formed on the surface of the implantation barrier layer dielectric film through positive photoresist in a photoetching mode, and the surface layer sacrifice dielectric film grows in an injection region, and the side wall and the top end of the photoresist mask through a positive and negative inclination film evaporation technology, and is used for high-energy ion implantation. The composite mask can solve the problem that the photoresist mask chaps and denatures under the high-energy ion bombardment, no residue is left when the mask is removed, the surface cleanliness of a chip is guaranteed, and device performance is improved.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Automatic cable stripping machine

PendingCN108736388AIncrease productivityImprove strip qualityApparatus for removing/armouring cablesElectronic waste recyclingEngineeringMechanical engineering

The invention relates to the technical field of cable outer layer stripping, and particularly relates to an automatic cable stripping machine. The automatic cable stripping machine comprises a machinestand and a machine stand cable placement table; a left cable stripping mechanism and a right cable stripping mechanism which are used for carrying out cable stripping on a cable on the cable placement table are respectively arranged at both sides of the cable placement table; a cable pressure mechanism is arranged at the upper side of the cable placement table; the cable pressure mechanism comprises a pressure rod, a pressure plate and a driving mechanism; the pressure rod is connected with the pressure plate by a connection rod; the bottom end of the connection rod sleeves the upper end ofthe pressure rod; a spring is arranged between the bottom end of the connection rod and the top end of the pressure rod; the top end of the connection rod is connected with the pressure plate by a force unloading mechanism; the force unloading mechanism comprises a force unloading barrel arranged at the bottom of the pressure plate and a force unloading spring inside the force unloading barrel; the upper end of the connection rod is embedded in the force unloading barrel and is in sliding fit with the inner wall of the force unloading barrel; the bottom end of the force unloading spring is pressed against the top end of the connection rod; and a limiting mechanism for limiting a descent height of the connection rod is arranged at the position of the cable placement table. The single-side or both-side simultaneous stripping operation of the cable is implemented, and production efficiency is high.

Owner:CHANGZHOU INST OF LIGHT IND TECH

A hollow blade easily removable alumina ceramic core and preparation method thereof

ActiveCN110773700BEasy to removeGuaranteed impact resistanceAdditive manufacturing apparatusFoundry mouldsOxide ceramicSlurry

The invention provides a hollow blade easy-to-remove aluminum oxide ceramic core and a preparation method thereof. According to the ceramic core, a shell and a space lattice structure in the shell arecombined, and when the relative density of the space lattice structure is 20 to 50 percent and the thickness of the shell is 0.4 to 0.5 mm, high void ratio of the ceramic core is realized and the deflection and the bending resistance of the ceramic core are guaranteed; and according to the preparation method, stable printing is facilitated by high flowability and low viscosity of ceramic slurry,the properties of the ceramic core are improved well by cooperating with the space lattice structure, the ceramic slurry is printed into a needed forming green body by 3D printing equipment, and the formed ceramic core is obtained by degreasing and sintering the formed green body. The ceramic core has high strength and short core removing time, saves ceramic materials, shortens process flow and provides an efficient solution for the problem about removal of the aluminum oxide ceramic core.

Owner:武汉因泰莱激光科技有限公司

A method for preparing a composite mask for high-energy ion implantation

ActiveCN104599958BAvoid process problemsAvoid sex changeSemiconductor/solid-state device manufacturingResistDielectric

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

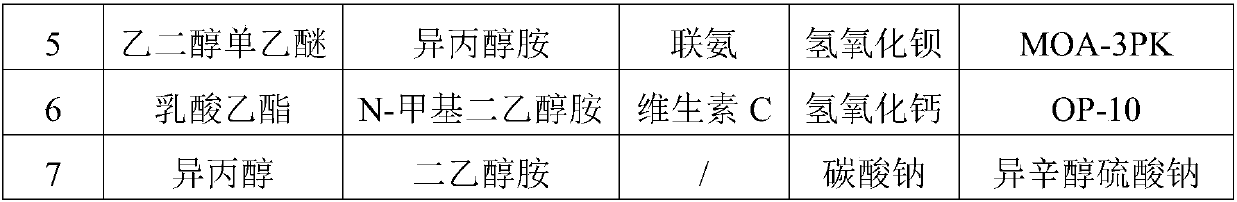

Rapid environment-friendly deplating solution

The invention provides a rapid environment-friendly deplating solution. The rapid environment-friendly deplating solution comprises a gold beneficiation agent, anti-staining salt and water, wherein the ratio of the gold beneficiation agent to the anti-staining salt is 2 to 1, the rapid environment-friendly deplating solution can be used for removing gold, silver and nickel, the deplating solutionhas no strong toxicity and does not need a specific room, the cost of an enterprise is greatly reduced, and the deplating time is greatly reduced.

Owner:FUJIAN MINHANG ELECTRONICS

A method for removing composite mask for high-energy ion implantation

ActiveCN104616974BAvoid process problemsAvoid sex changeSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusDielectricResist

The invention discloses a removal method of a composite mark for injecting high-energy particles. The mask is a composite photoresist mask with a three-layer structure; a photoresist mask pattern is manufactured between an injecting resisting layer dielectric film and a surface sacrificing dielectric film through the mask to be used as a high-energy particles injecting mask; two dielectric film etching agents for removing the composite mask are different; when removing the mask, the sacrificing dielectric film, the photoresist mask and the resisting layer dielectric film are sequentially removed. With the adoption of the composite mask, the problem that the photoresist mask is cracked and denatured under the attack of the high-energy particles can be avoided; in addition, the mask can be removed without residue; the cleanness of the surface of a chip is ensured, and the device performances can be improved.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

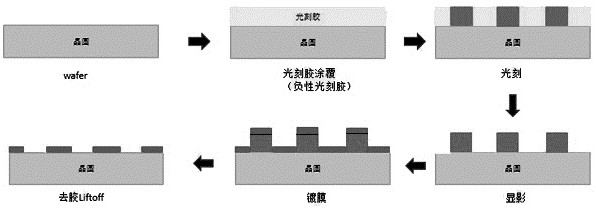

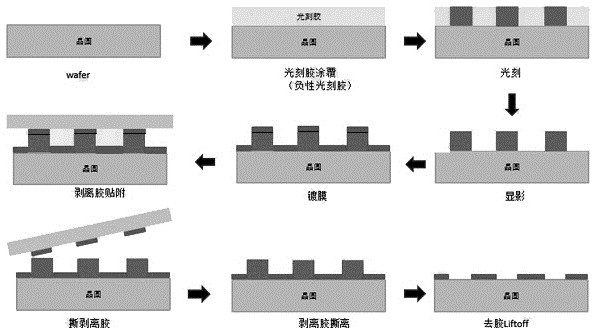

Wafer optical film graphical processing efficient photoresist removing process method

PendingCN114415483AGood removal effectImprove graphics processing efficiencyPhotomechanical coating apparatusPhotosensitive material processingAdhesive beltOptical thin film

The invention discloses an efficient photoresist removing process method for wafer optical thin film graphical processing. According to the method, the optical thin film deposited on the photoresist is removed by adopting a stripping adhesive tape pasting mode, and the exposed photoresist is directly contacted with the photoresist removing liquid in the photoresist removing process and is easier to remove, so that the photoresist removing time is greatly shortened, and the wafer optical thin film patterning processing efficiency is improved. The problems that in a traditional photoresist removing lift mode, due to blocking of an optical thin film above a photoresist layer, photoresist removing liquid cannot make direct contact with photoresist, photoresist removing is difficult, time is long, and efficiency is low are solved.

Owner:HANGZHOU MDK OPTO ELECTRONICS CO LTD

A kind of continuous preparation and purification device and method of graphene oxide

ActiveCN110342506BGood size uniformityRealize continuous preparationSingle layer graphenePeristaltic pumpStrong acids

The invention discloses a continuous preparation and purification device for graphene oxide, which includes a reactor, a concentrated sulfuric acid solution storage bottle and a water / hydrogen peroxide storage bottle connected to the reactor through a delivery pipe, and a three-way valve is arranged on the delivery pipe. Directly below and directly above are correspondingly equipped with an ultrasonic plate, a feeder, a stirring paddle, and a first lifting platform connected to the reactor through a discharge pipe, and the discharge pipe is connected to the filter column through a second conveying pipe provided with a second peristaltic pump. The filter column is connected to the graphene oxide storage bottle through the third conveying pipe provided with the third peristaltic pump; the invention also discloses a preparation method of graphene oxide: the strong acid and the oxidant are separately fed and oxidized with graphite, and then stripped and purification to obtain graphene oxide. The device of the present invention is provided with a concentrated sulfuric acid solution storage bottle, a feeder, a reactor and a filter, and realizes the continuous preparation and purification of graphene oxide; the method of the present invention improves the preparation and purification efficiency of graphene oxide, and realizes concentrated sulfuric acid Solution recovery and continuous utilization.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com