Patents

Literature

37results about How to "Improve mold precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Elastic photosensitive resin for 3D printing of digital light processing (DLP) and preparation method of elastic photosensitive resin

The invention belongs to the field of a high molecular material, and particularly relates to photo-cured elastic photosensitive resin with wavelength being 405 nanometers for 3D printing of digital light processing (DLP). The elastic photosensitive resin comprises the following raw materials based on parts by weight: 10-50 parts of elastic acrylate, 30-70 parts of active diluents, 1-10 parts of photoinitiator, 0.01-0.05 part of flatting agent, 0.01-0.05 part of dispersning agent and 0.01-0.05 part of polymerization inhibitor. The elastic photosensitive resin can be directly used for 3D printing of DLP or can be mixed with other existing photosensitive resin, a product with a complicated structure and certain elasticity can be printed, meanwhile, the elastic photosensitive resin has the characteristics of small volatile odor, rapid formation speed, small product shrinkage rate, high formation accuracy and the like.

Owner:广州谱睿汀新材料科技有限公司 +1

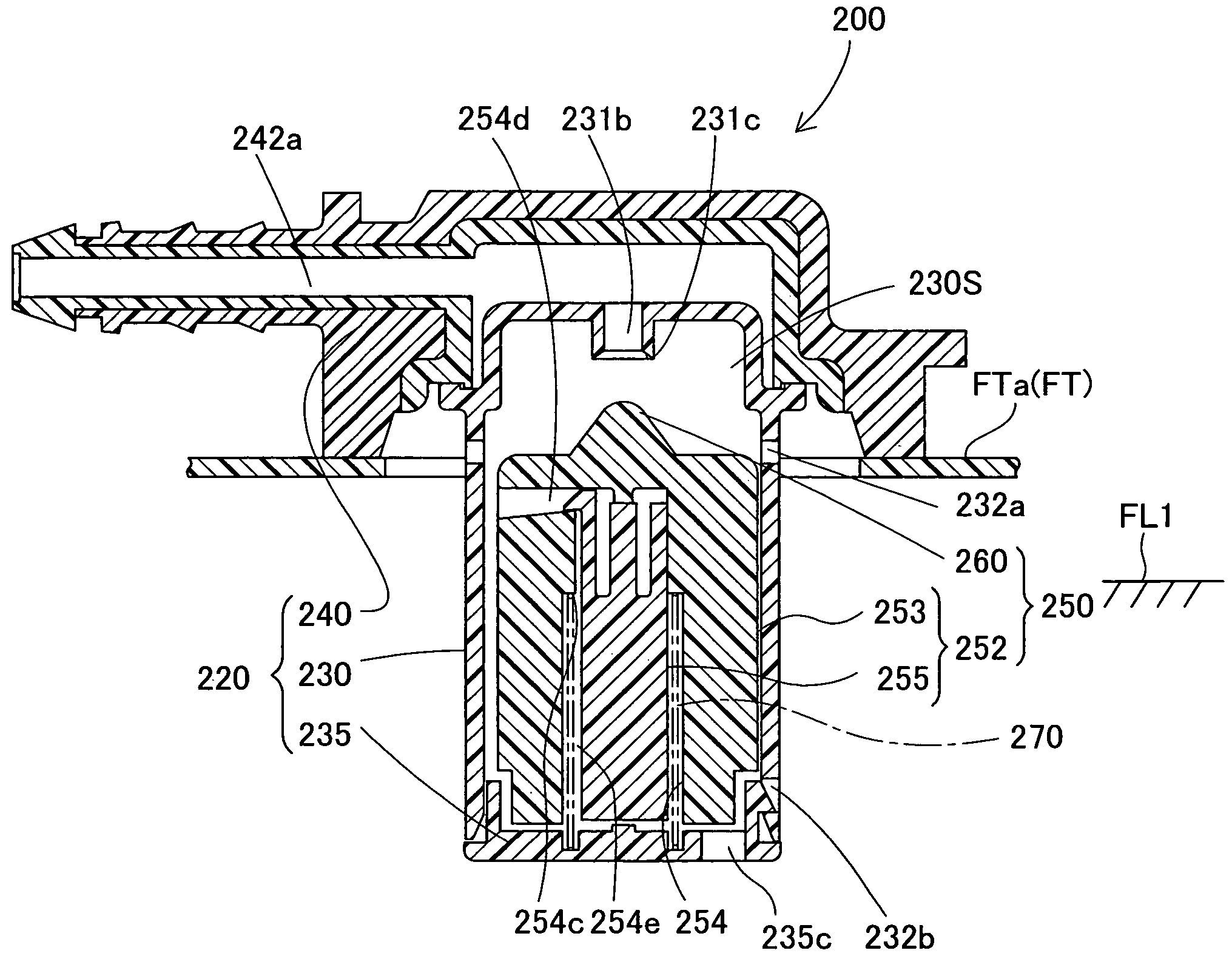

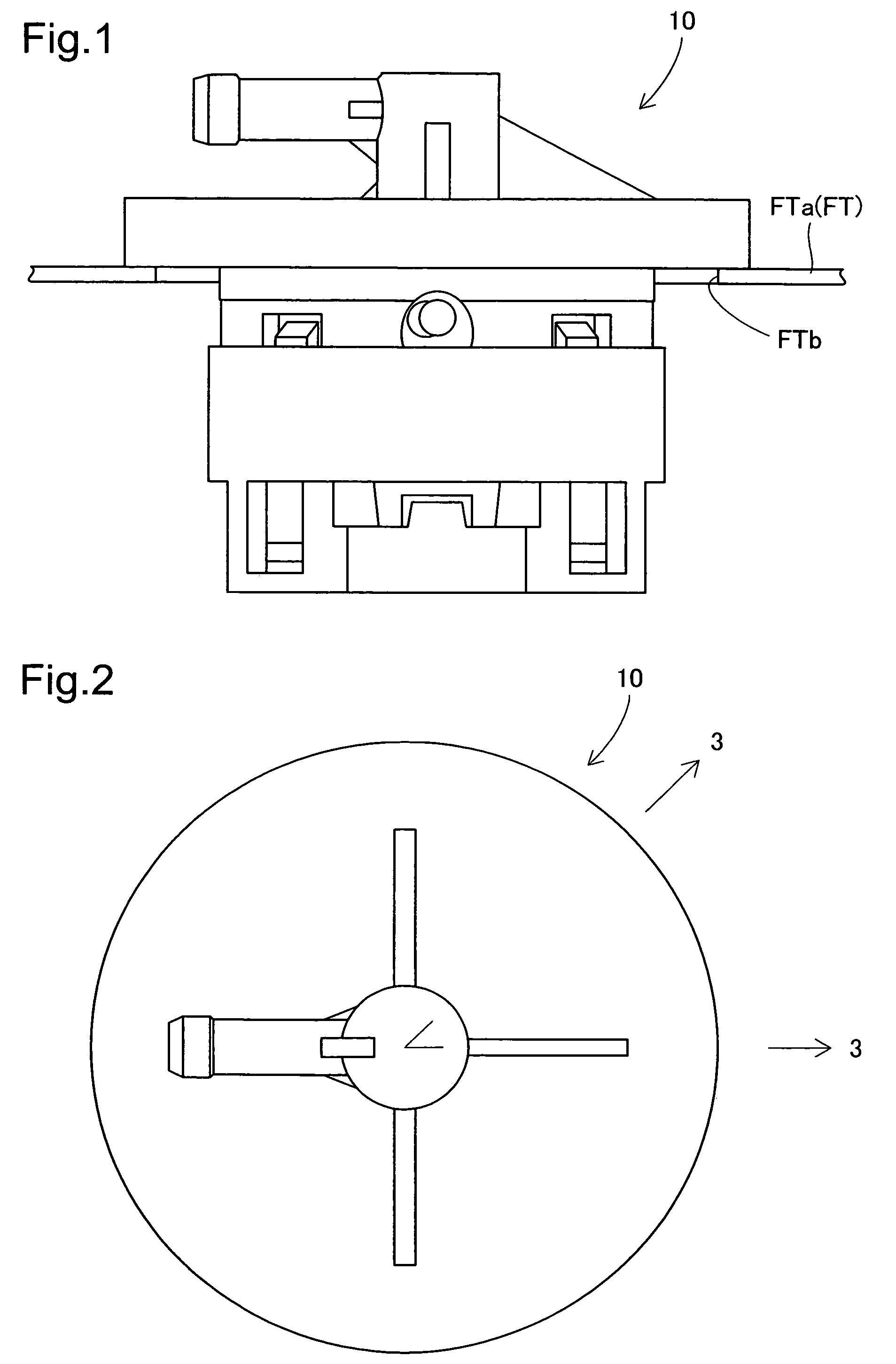

Fuel cutoff valve

ActiveUS7571740B2Low variabilityImprove mold precisionOperating means/releasing devices for valvesLarge containersGlobe valveEngineering

Owner:TOYODA GOSEI CO LTD +1

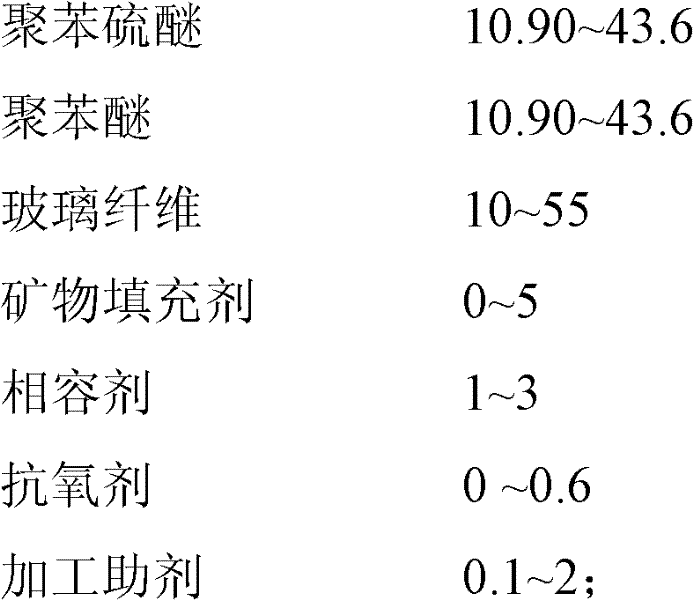

Fiberglass enhanced polyphenyl thioether/polyphenylether composite material and preparation method thereof

The invention discloses a fiberglass enhanced polyphenyl thioether / polyphenylether composite material and a preparation method thereof. The composite material is mainly prepared by the following raw materials: polyphenyl thioether, polyphenylether, fiberglass, mineral filler, a compatibility agent, an antioxidant and a processing aid. The preparation method of the fiberglass enhanced polyphenyl thioether / polyphenylether composite material comprises the following steps of: (a) firstly, respectively blasting and drying polyphenyl thioether resin and polyphenylether resin; (b) weighting the polyphenyl thioether resin and the polyphenylether resin which are dried, the mineral filler, the compatibility agent, the antioxidant and the processing aid; (c) mixing the dry materials in the step (b) to obtain a compound; and (d) adding the compound in the step (c) and the fiberglass to a double screw extruder for melt blending and pelleting. The fiberglass enhanced polyphenyl thioether / polyphenylether composite material can unconspicuously lower the temperature-resistant level and the rigidity of the polyphenyl thioether resin, further improve the molding accuracy of the polyphenyl thioether resin and decrease the cost.

Owner:SHENZHEN KEJU NEW MATERIAL

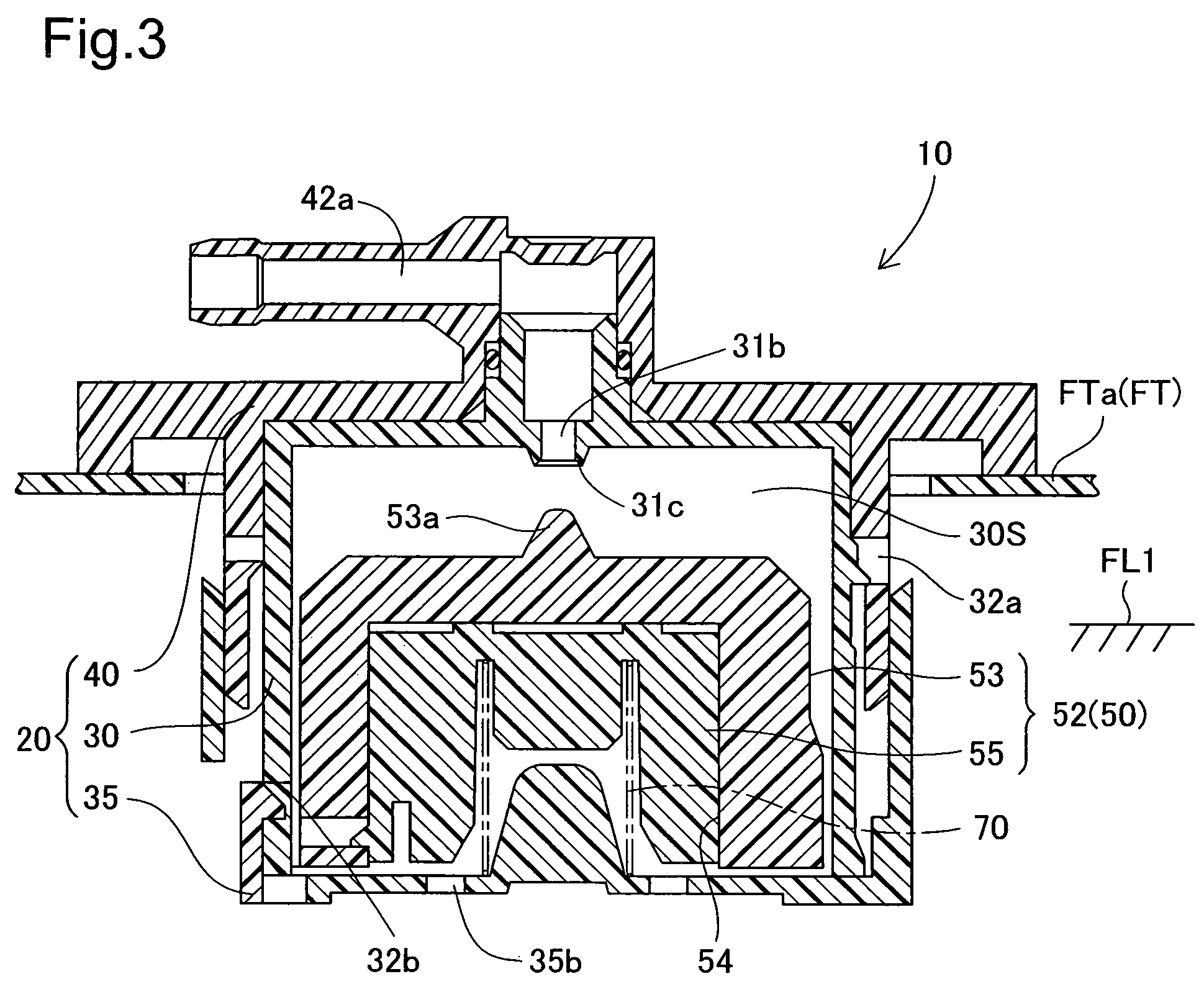

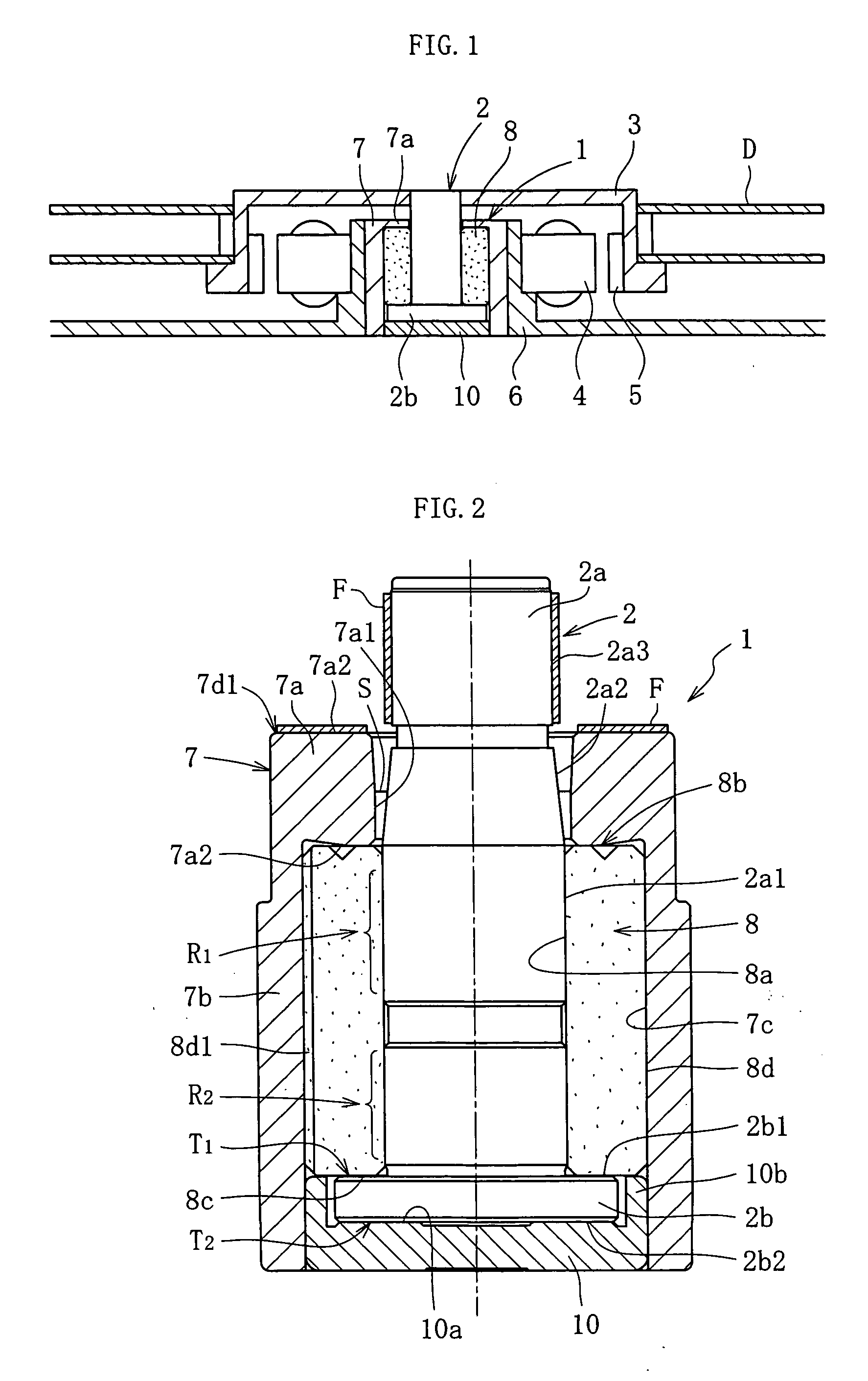

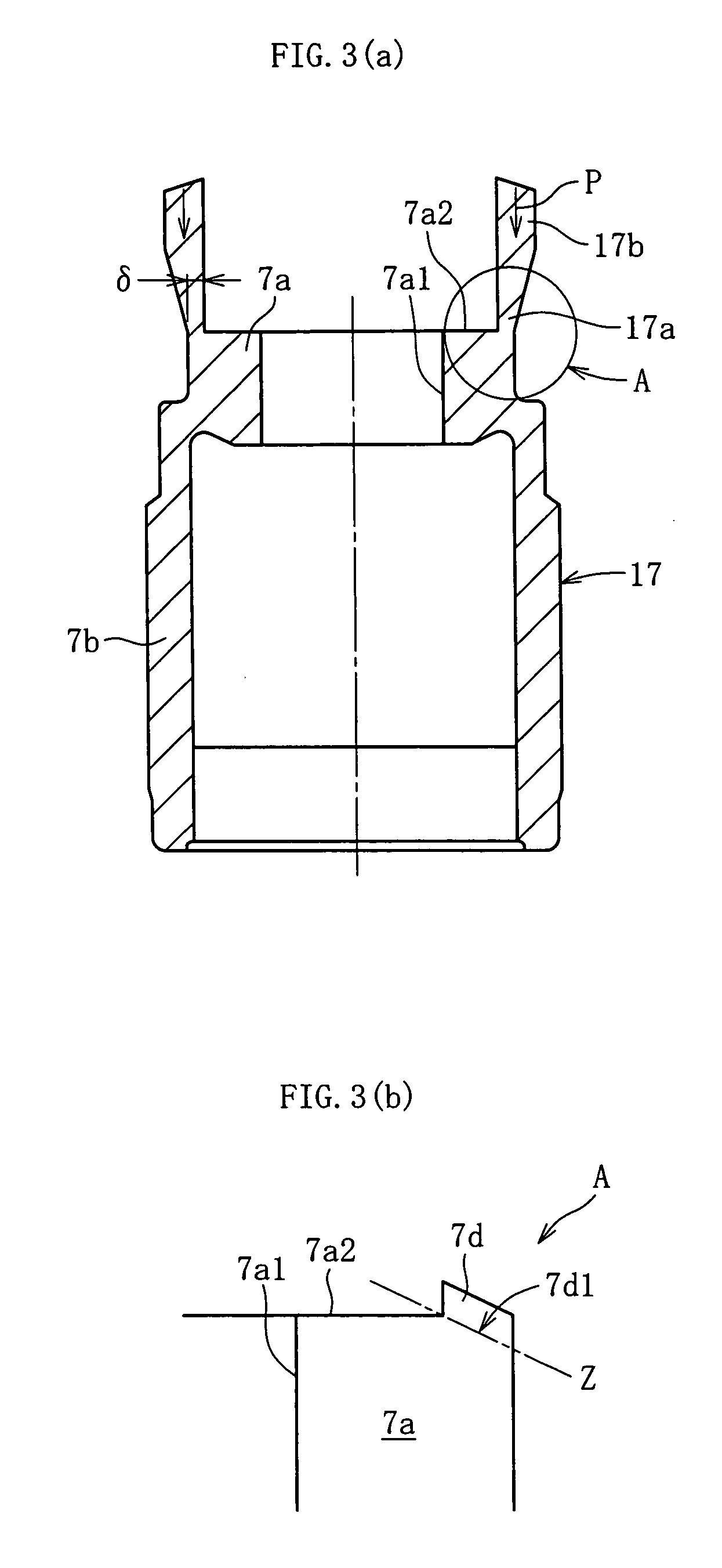

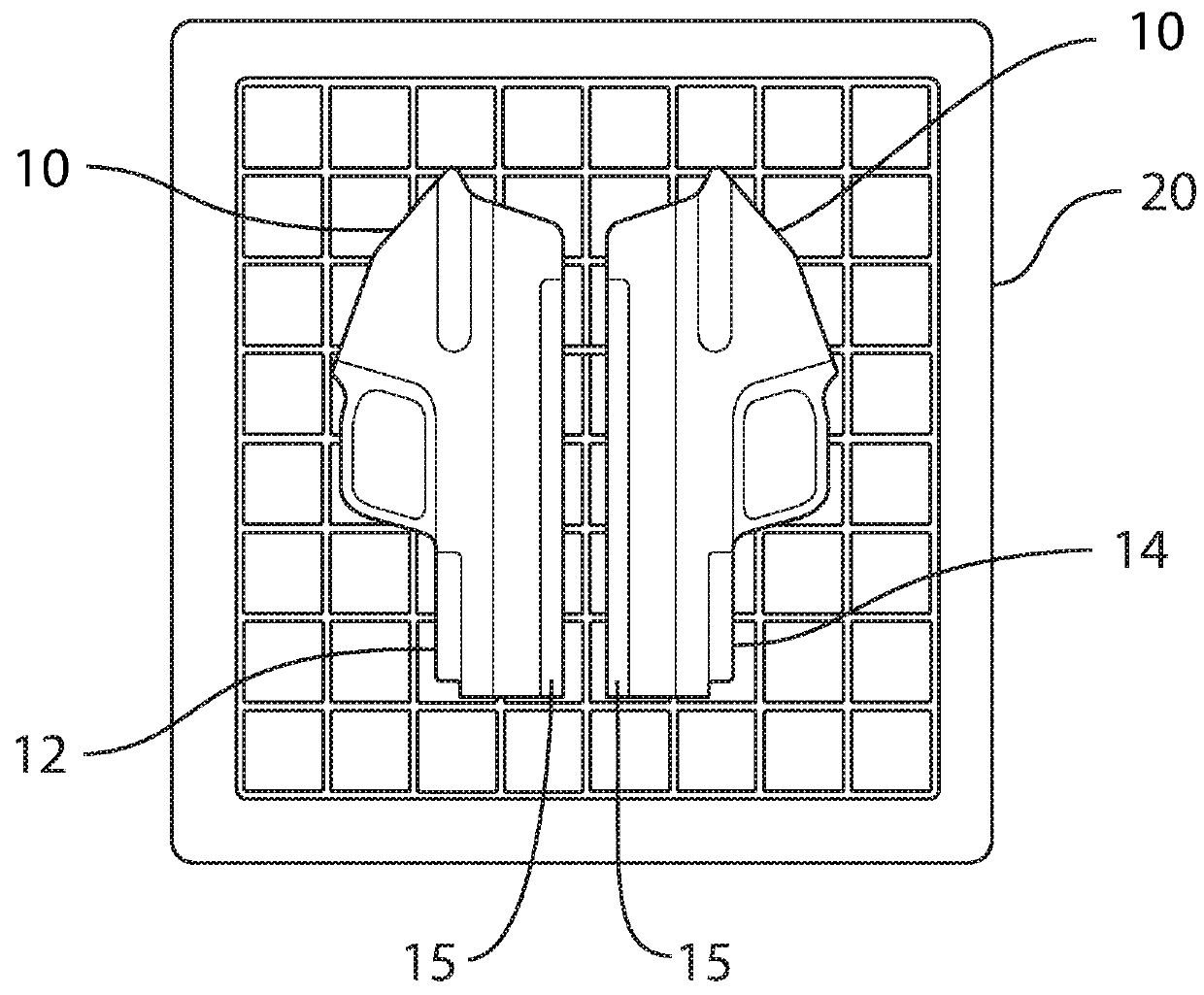

Fluid bearing device and manufacturing method thereof

InactiveUS20070177831A1Reduce manufacturing costEfficient assemblyShaftsRecord information storageFluid bearingMechanical engineering

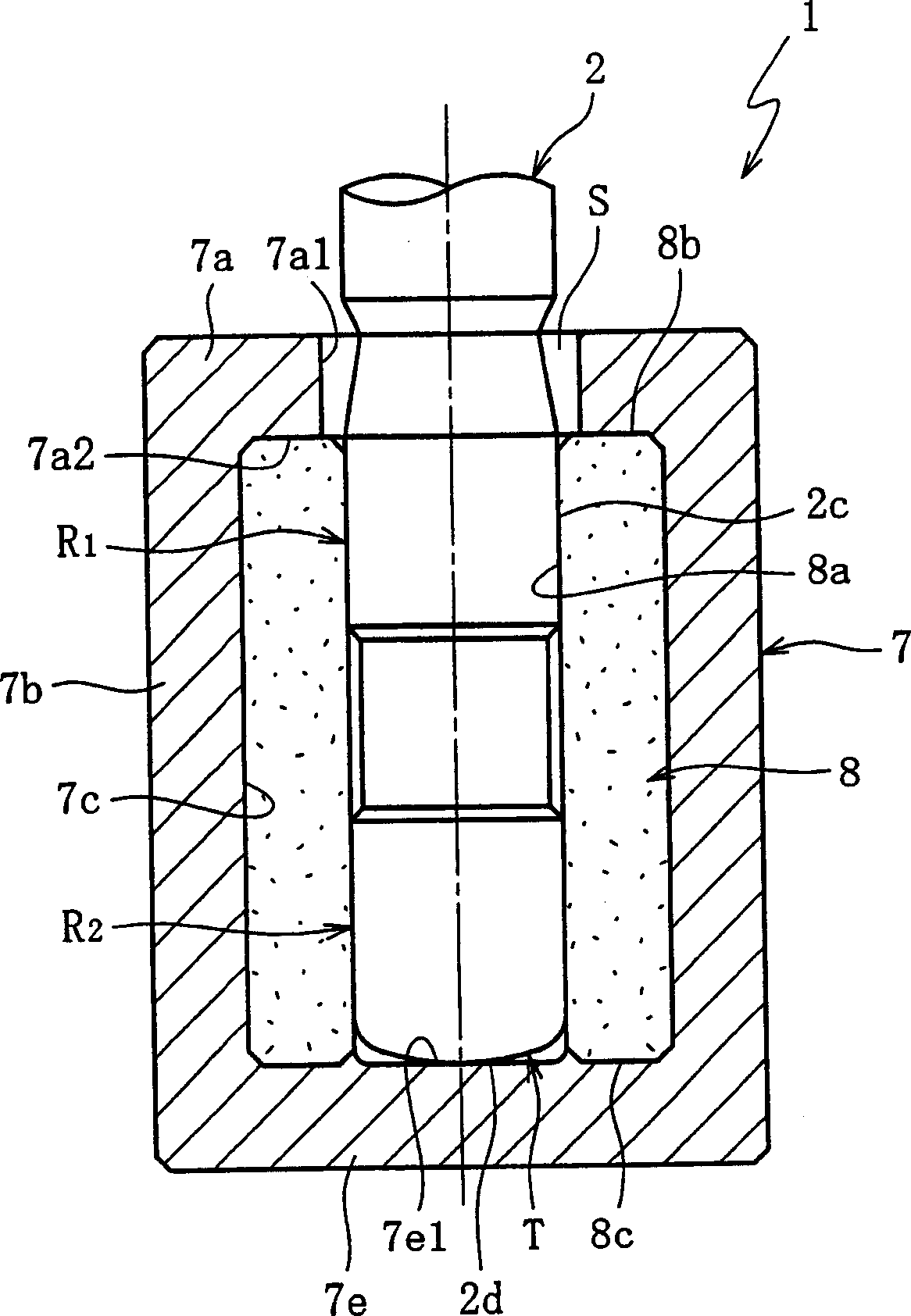

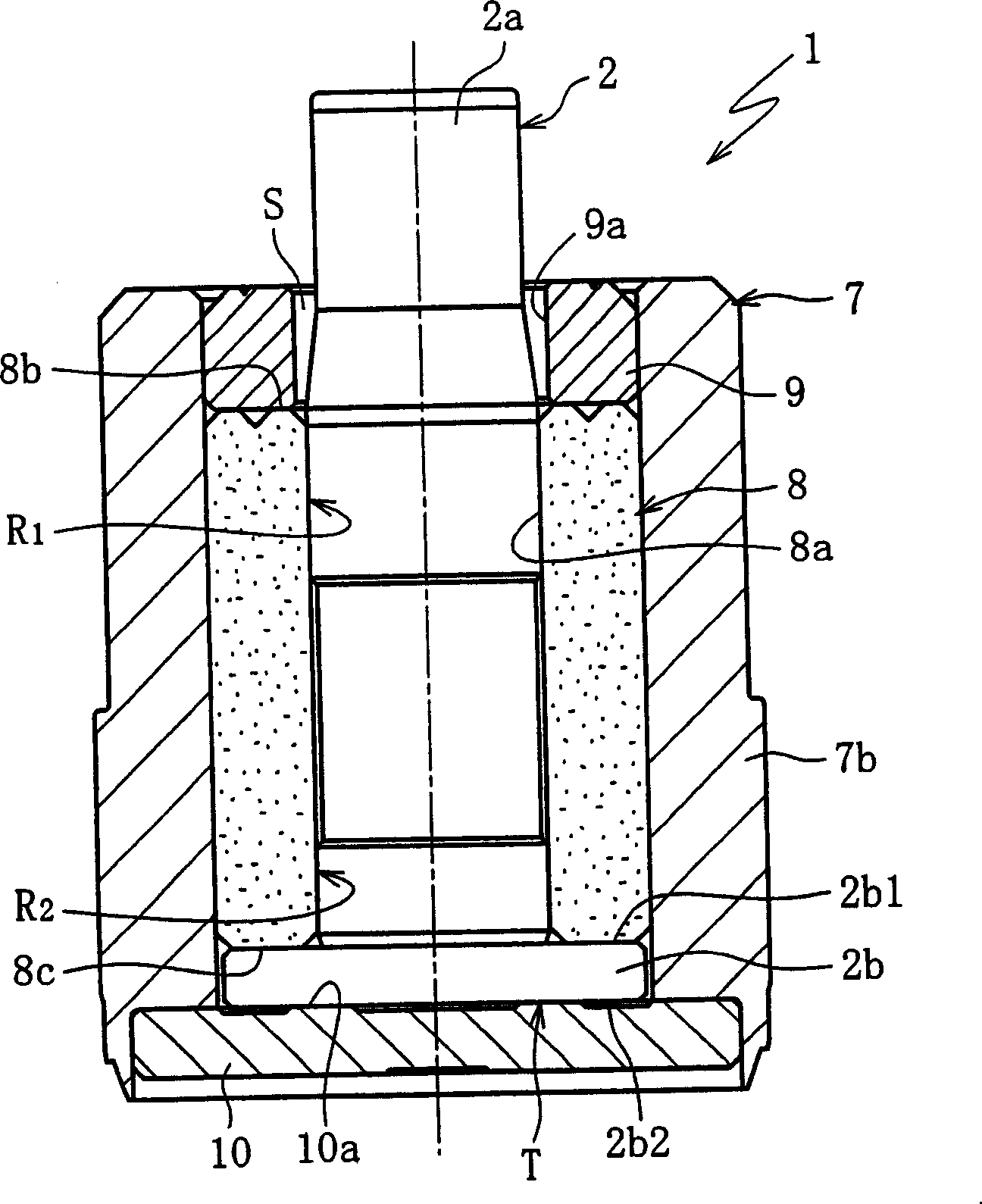

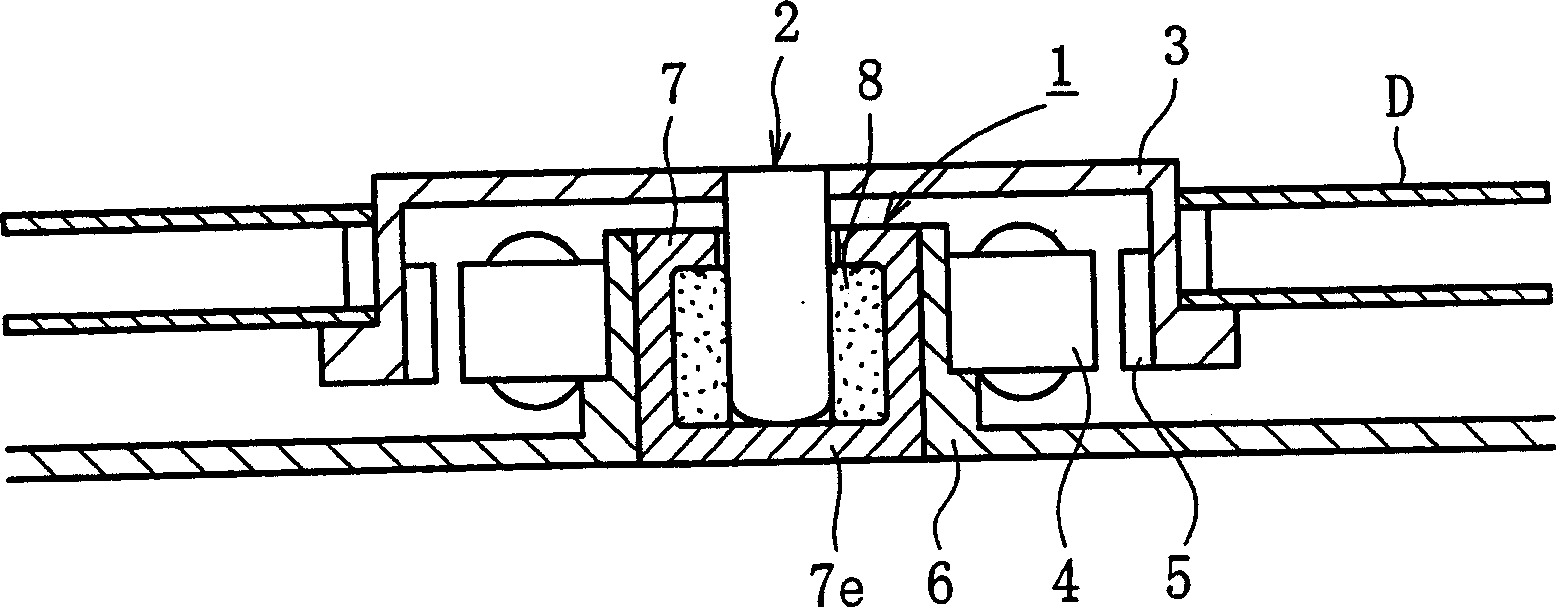

A molten resin P is filled into a cavity 17 through a film gate 17a provided a ring shape in a position corresponding with an outer peripheral edge of the outside surface 7a2 of the seal portion 7a. The molded product removed from the molding die is completed by removing the residual resin gate portion 7d. A gate removal portion 7d1 formed by removing the resin gate portion appears as a narrow ring shape at the outer peripheral edge of the outside surface 7a2 of the seal portion 7a.

Owner:NTN CORP +1

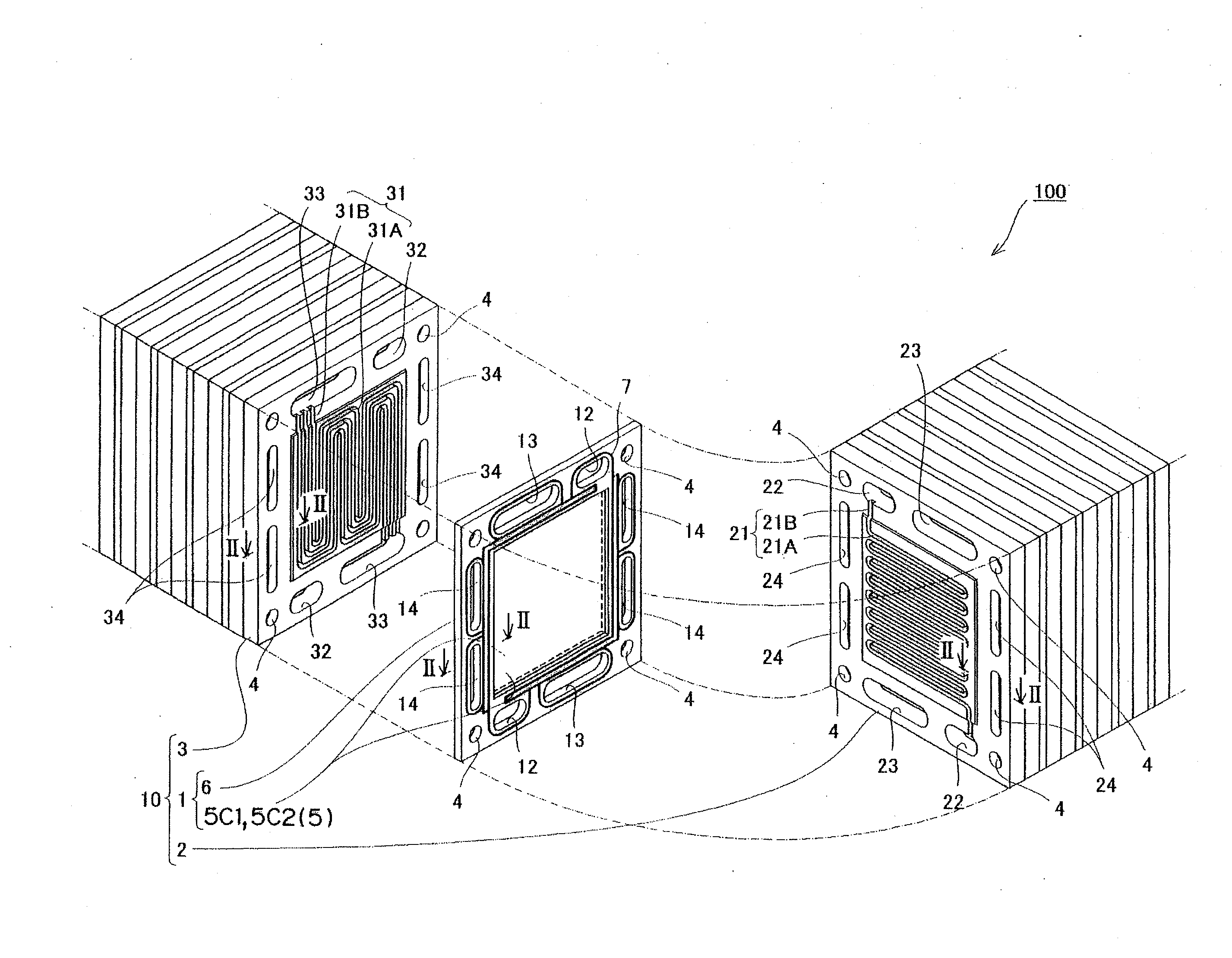

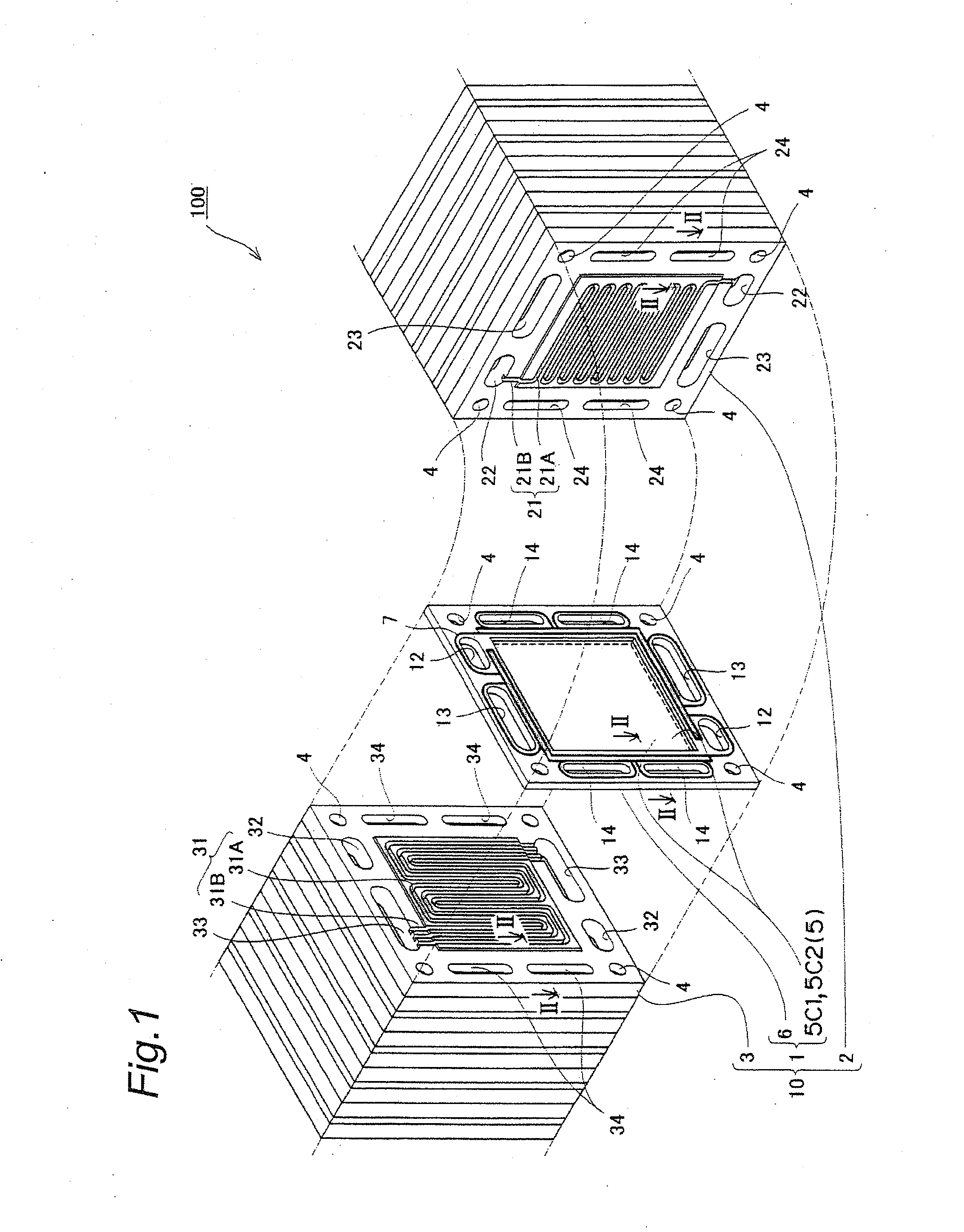

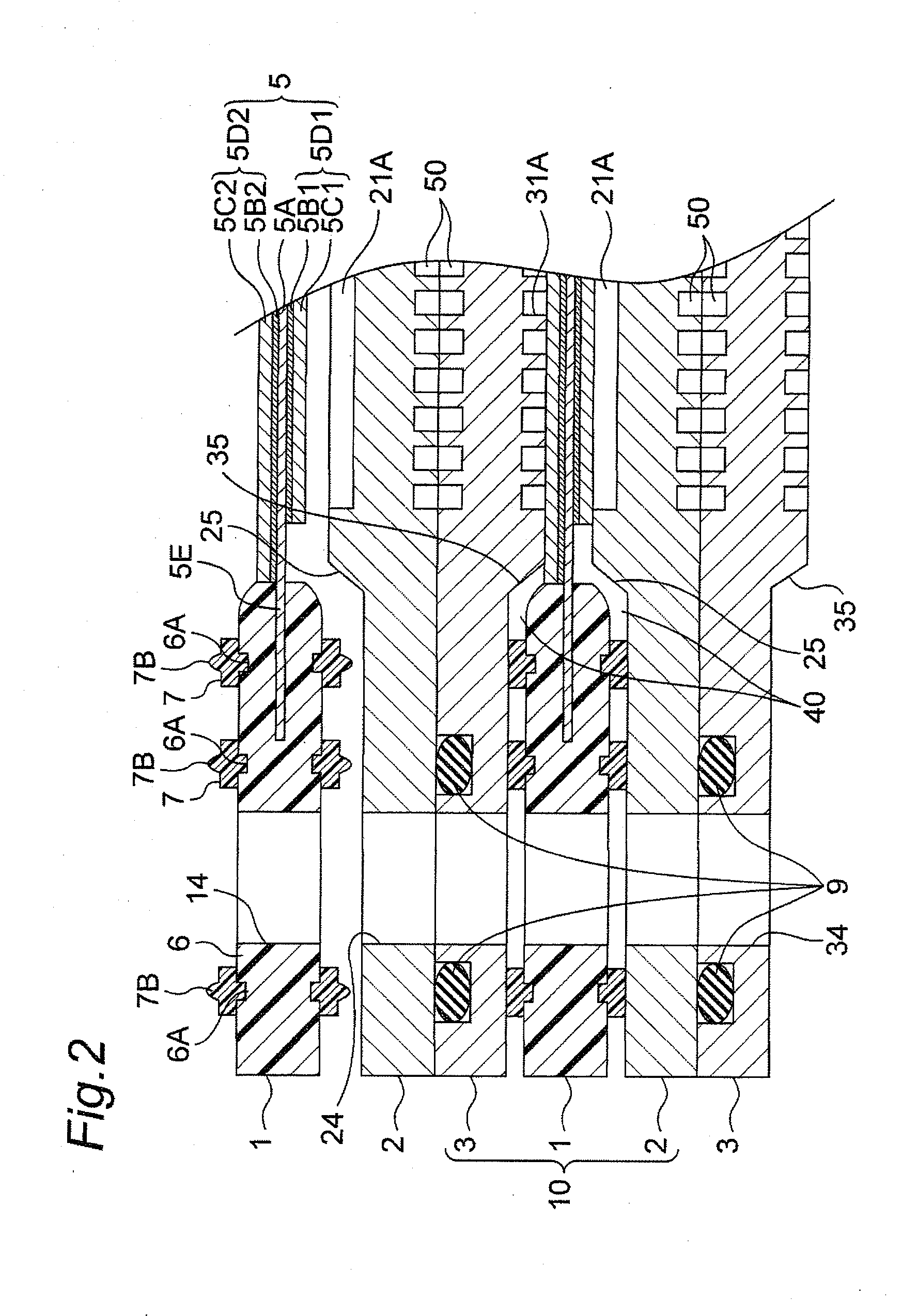

Method for producing an electrode-membrane-frame assembly

ActiveUS20100248087A1Improve mold precisionStrict controlFinal product manufactureDomestic articlesPolymer electrolytesMembrane configuration

In the method of the invention for producing an electrode-membrane-frame assembly, its principal part is formed by laying a first catalyst layer onto one of surfaces of an electrolyte membrane, arranging a first gas diffusion layer onto the surface of the first catalyst layer and inside the circumferential region of the electrolyte membrane, laying a second catalyst layer onto the other surface of the electrolyte membrane, and arranging a second gas diffusion layer onto the surface of the second catalyst layer and inside the circumferential region of the electrolyte membrane so as to make the position of the outer circumference of the second gas diffusion layer different from that of the outer circumference of the first gas diffusion layer. Then, in the state that an outer circumferential portion of either the first gas diffusion layer or the second gas diffusion layer, the portion being positioned outside a region of the first and second gas diffusion layers wherein the two layers are opposed to each other, is opposed to a portion of a flat region located inside the frame of a frame-form primary molded body, the circumferential region of the principal part is arranged on the flat region, and subsequently a secondary molded body is formed to cover the circumferential region of the electrolyte membrane with the second molded body together with the primary molded body, in order to prevent the polymer electrolyte membrane from being broken or deformed.

Owner:PANASONIC CORP

Fluid bearing device

ActiveCN1764792AReduce manufacturing costImprove mold precisionAssociation with grounding devicesShaftsEngineeringFluid bearing

The invention relates to a fluid bearing device, which can realize cost reduction and prevent itself from being charged by static electricity. A bearing sleeve is provided inside the housing, and the shaft member is inserted into the bearing sleeve. A pressure is generated in a bearing gap between the inner surface of the bearing housing and the outer peripheral surface of the shaft member by the dynamic pressure of the lubricating oil to radially support the shaft member in a non-contact state with the bearing housing. The shaft end of the shaft member is in contact with the bottom of the case, which is formed of a conductive resin compound mixed with carbon nanofibers, and whose volume resistivity is set to be 106 Ω·cm or less to conduct electricity.

Owner:NTN CORP

Zinc alloy for die

The invention provides a zinc alloy for a die. The zinc alloy for the die comprises the following components in percentage by mass: 5 percent to 22 percent of aluminium, 0.01 percent to 0.03 percent of magnesium, 1 percent to 10 percent of copper, 0.05 percent to 0.5 percent of rare earth, 0.01 percent to 0.05 percent of boron, 0.05 percent to 0.1 percent of zirconium, 0.03 percent to 0.1 percent of bismuth and the balance of zinc. According to the zinc alloy for the die, which is provided by the invention, not only can the hardness and the wear resistance be further improved, but also the phenomena of composition segregation and bottom shrinkage are obviously reduced; and on the premise of ensuring the tensile strength basically constant, the size stability and the die making accuracy of the zinc alloy are obviously improved.

Owner:ZHUZHOU SMELTER GRP

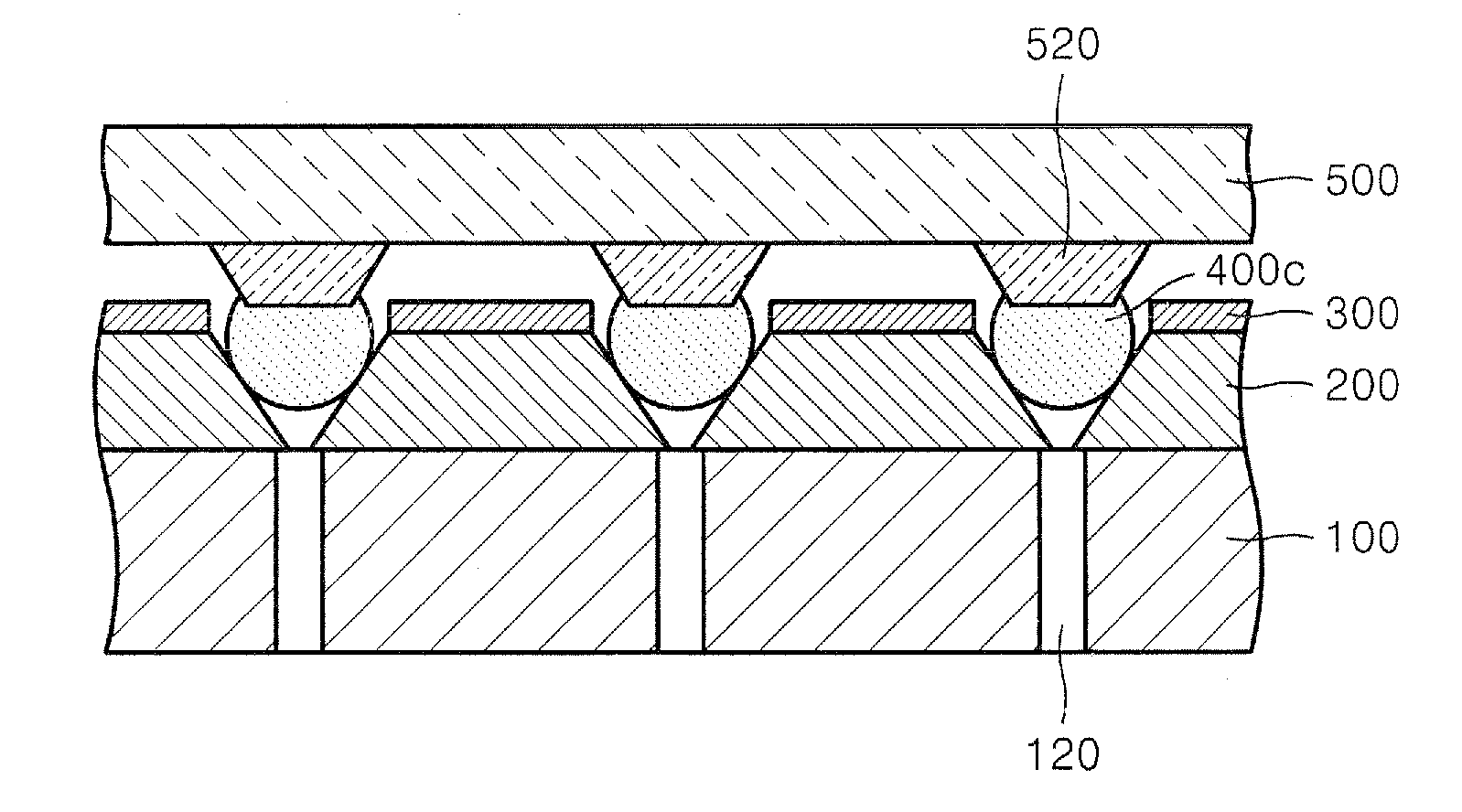

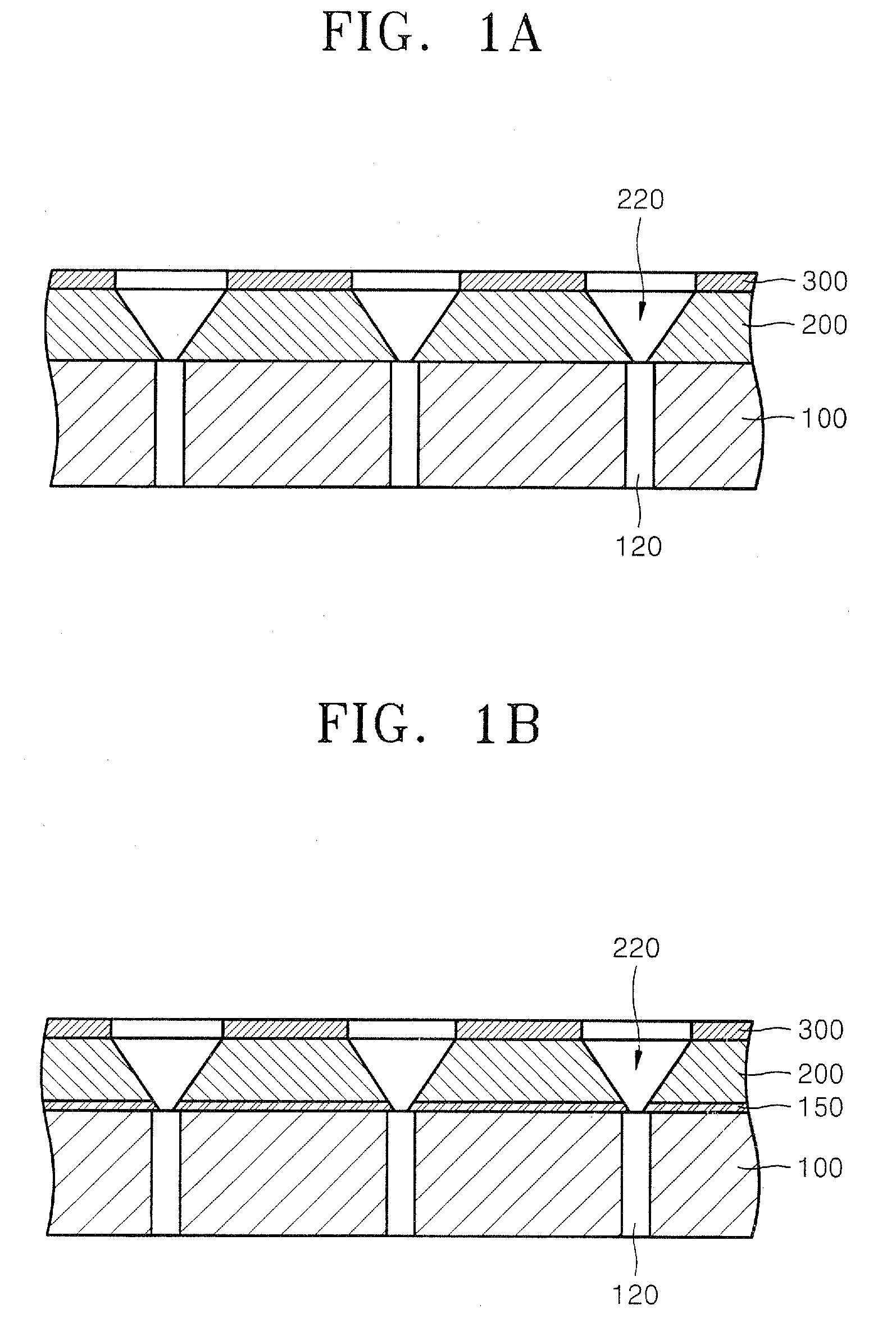

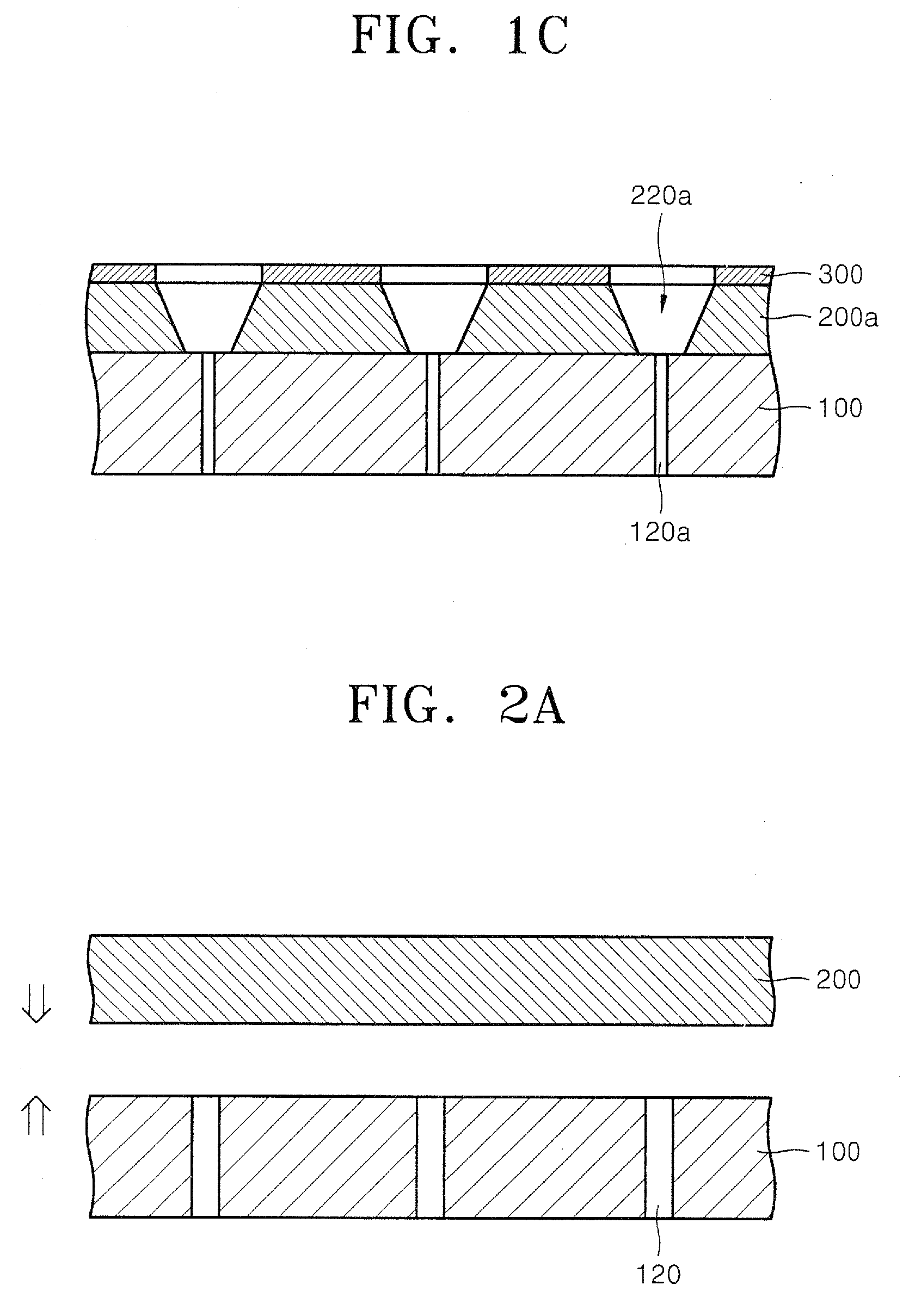

Mold for forming conductive bump, method of fabricating the mold, and method of forming bump on wafer using the mold

ActiveUS20070290367A1Improve mold precisionSemiconductor/solid-state device detailsSolid-state devicesOptoelectronicsMask layer

A mold for forming a conductive bump, a method of fabricating the mold, and a method of forming a bump on a wafer using the mold are provided. The bump can be formed by employing various materials, the mold can be repeatedly used several times because the mold is not damaged, and due to a high precision, the pitch of the bumps is not limited. The mold for forming a conductive bump comprises a first substrate having a groove to form a bump; a second substrate for vacuum adsorption formed below the first substrate, and having a through-hole in communication with the groove; and a mask layer formed on the first substrate, and used to form the groove.

Owner:SAMSUNG ELECTRONICS CO LTD

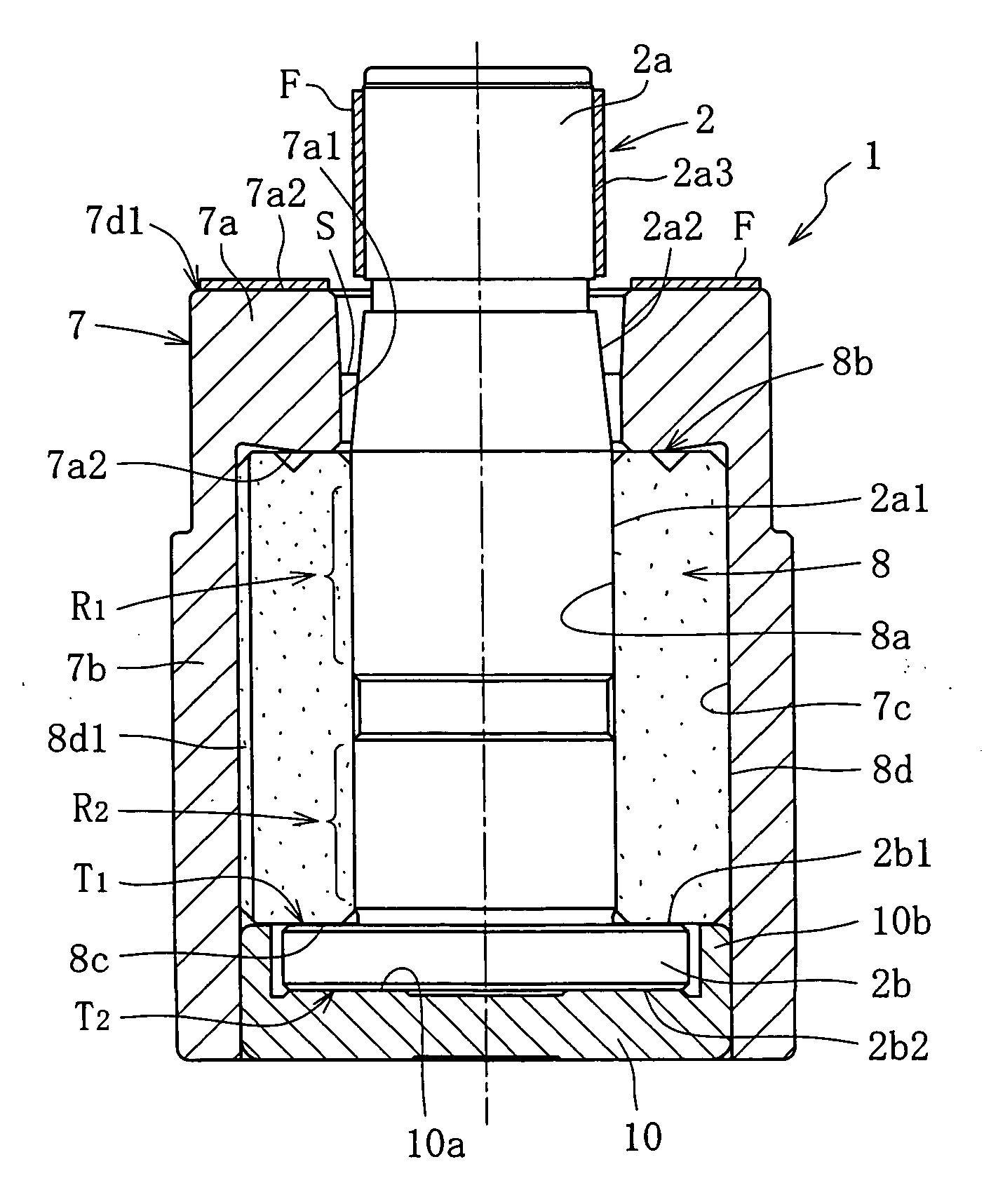

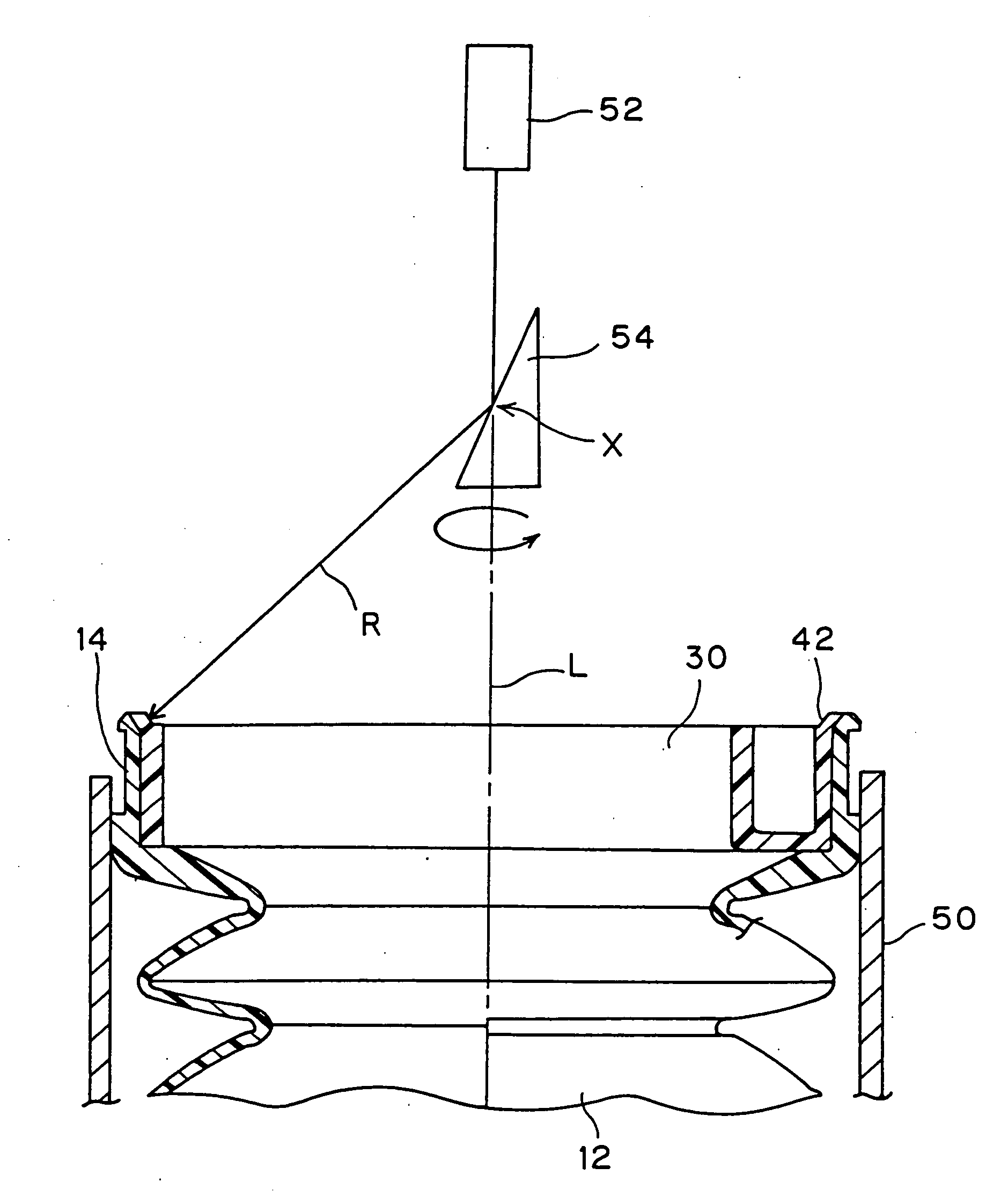

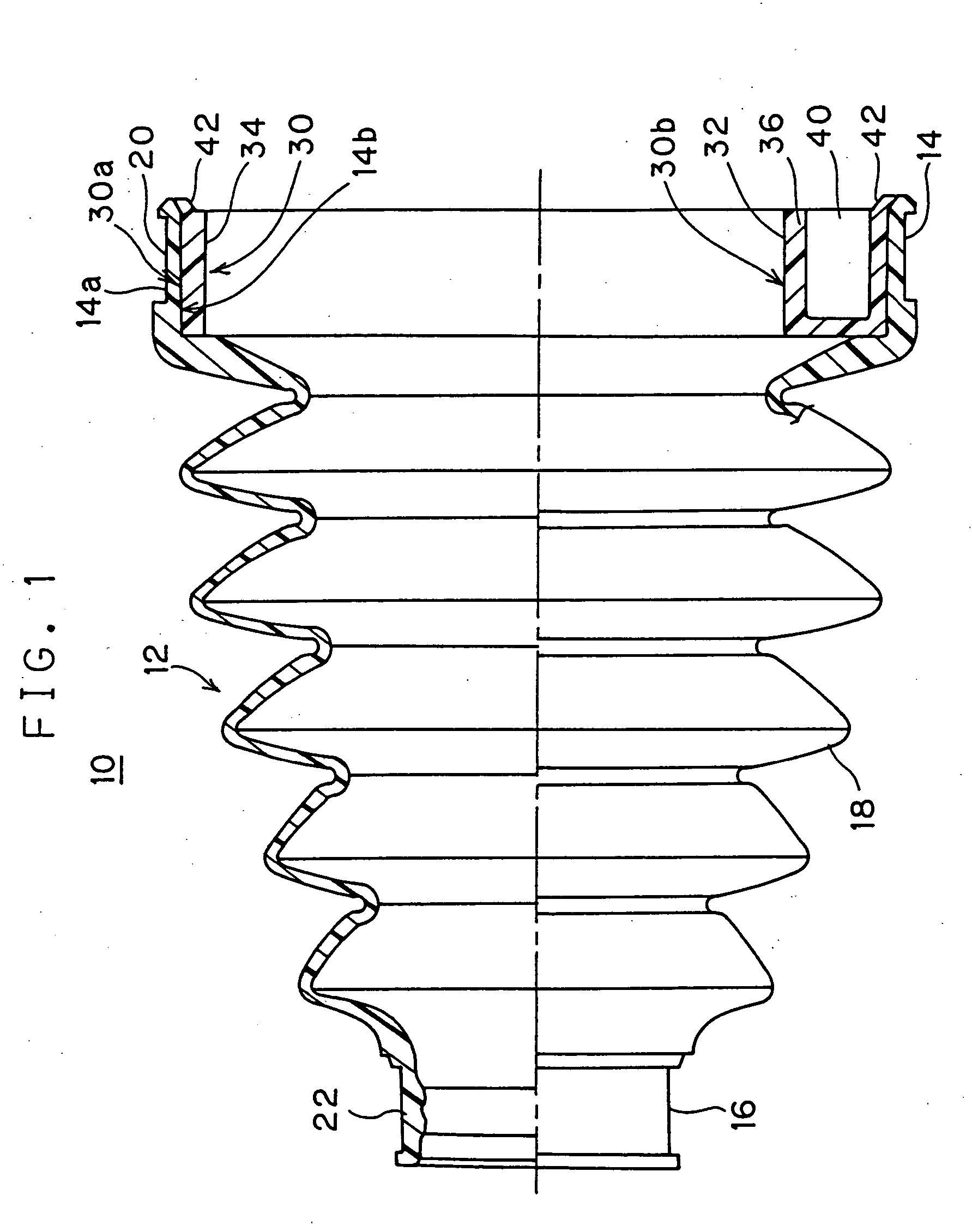

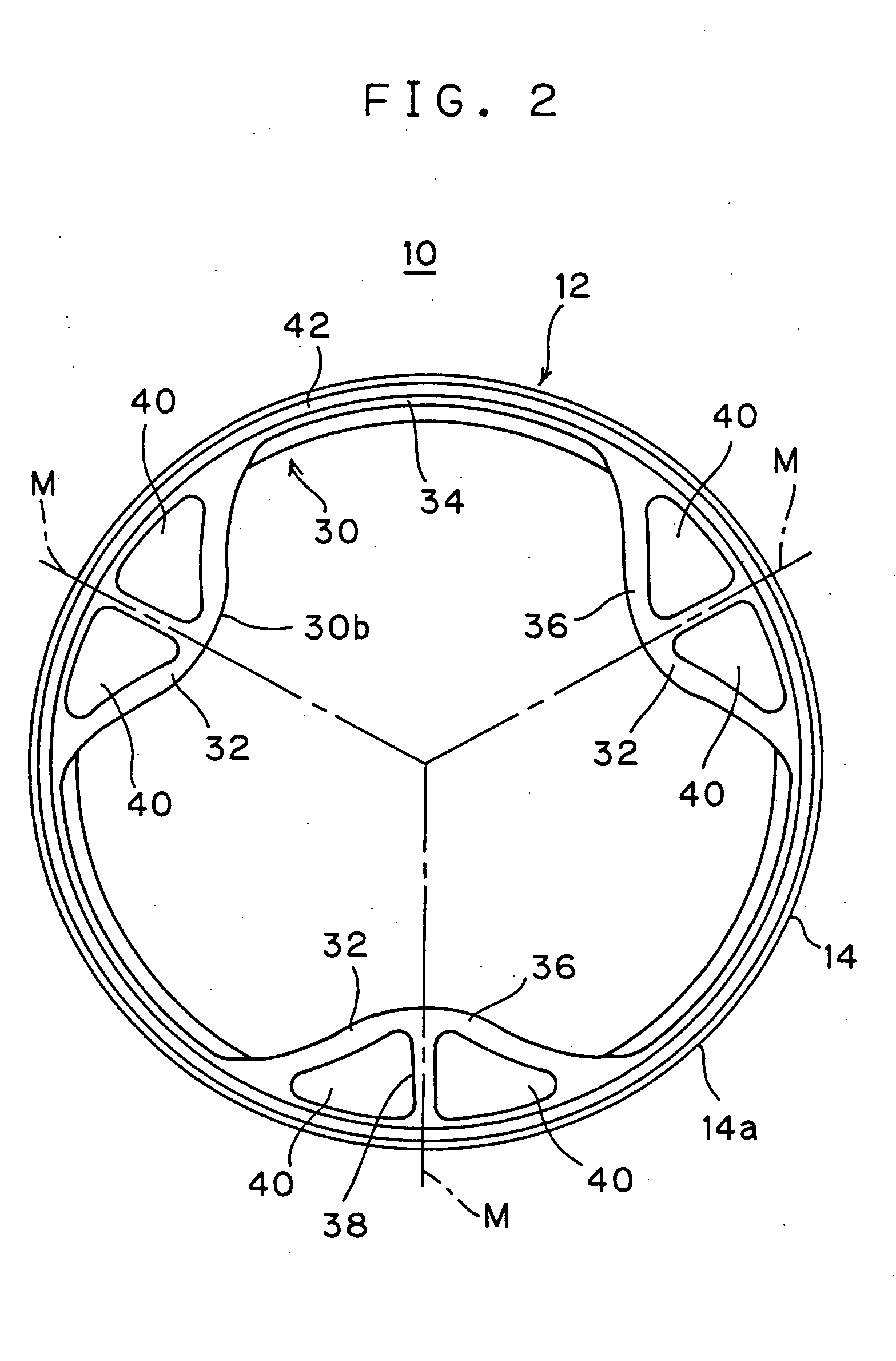

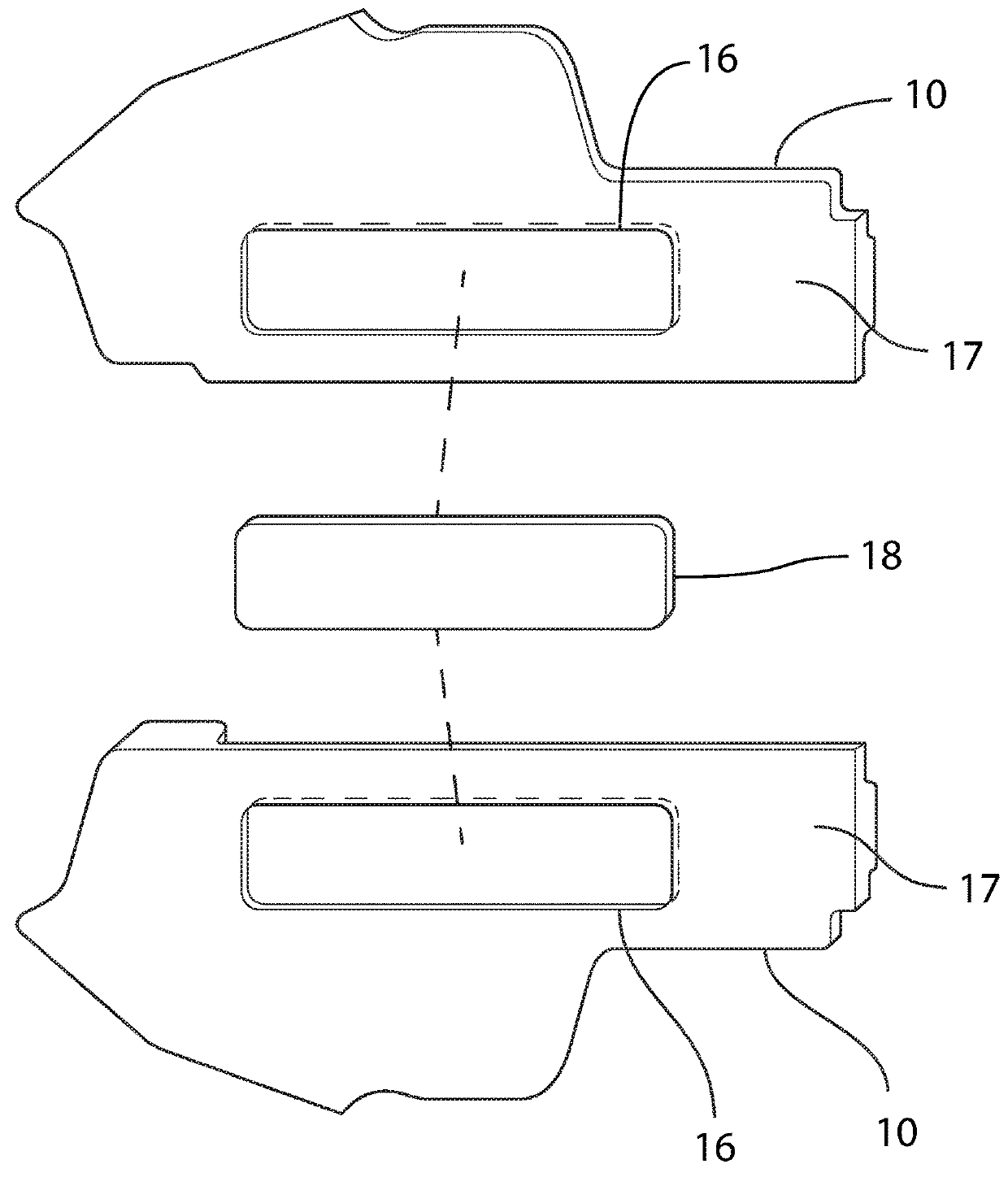

Method of producing resin joint boot

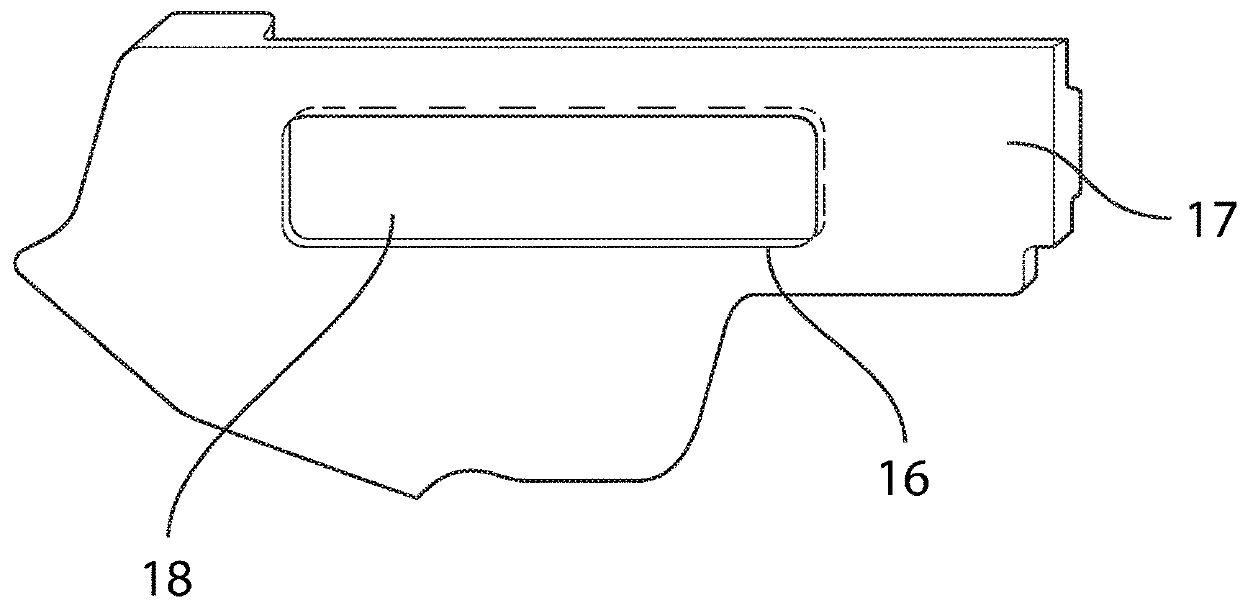

InactiveUS20060086457A1Improve mold precisionImprove sealingYielding couplingLamination ancillary operationsLaserWelding

A method of manufacturing a resin-made joint boot (10) provided with a boot body (12) including a large-diameter tubular part (14), a small-diameter tubular part (16) and a bellows section (18), and a bushing (30) fitted inside the large-diameter tubular part, wherein the boot body and the bushing are separately molded, the bushing is positioned inside the large-diameter tubular part of the boot body, and then, both are integrally fastened by laser welding. The large-diameter tubular part (14) is provided on its internal periphery with an outwardly divergent tilting surface (24) while the bushing (30) is provided with an annular projecting portion (42) to be abuttingly disposed on the tilting surface, and laser (R) is irradiated, penetrating through the annular projecting portion (42) onto the tilting surface (24).

Owner:TOYO TIRE & RUBBER CO LTD

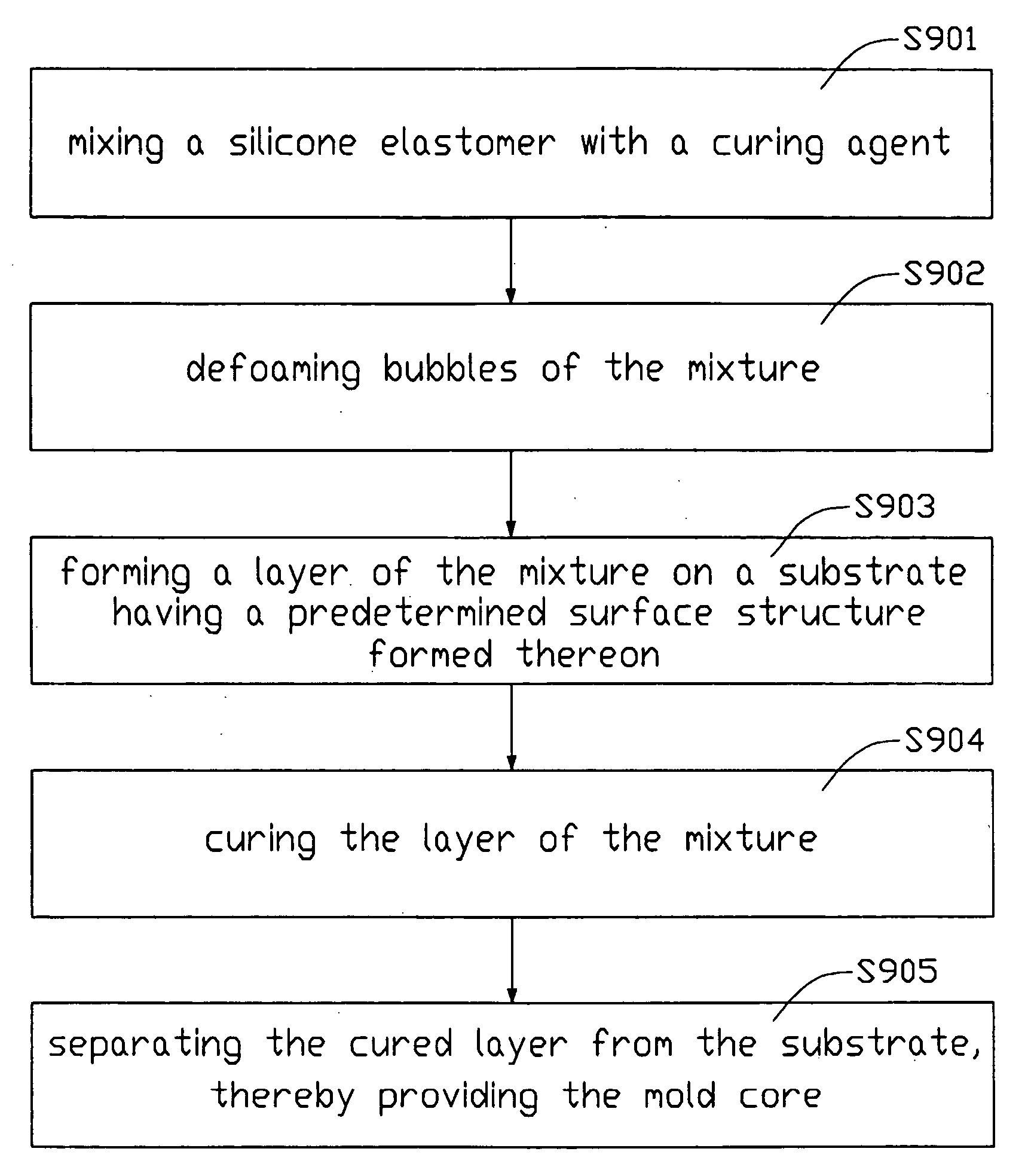

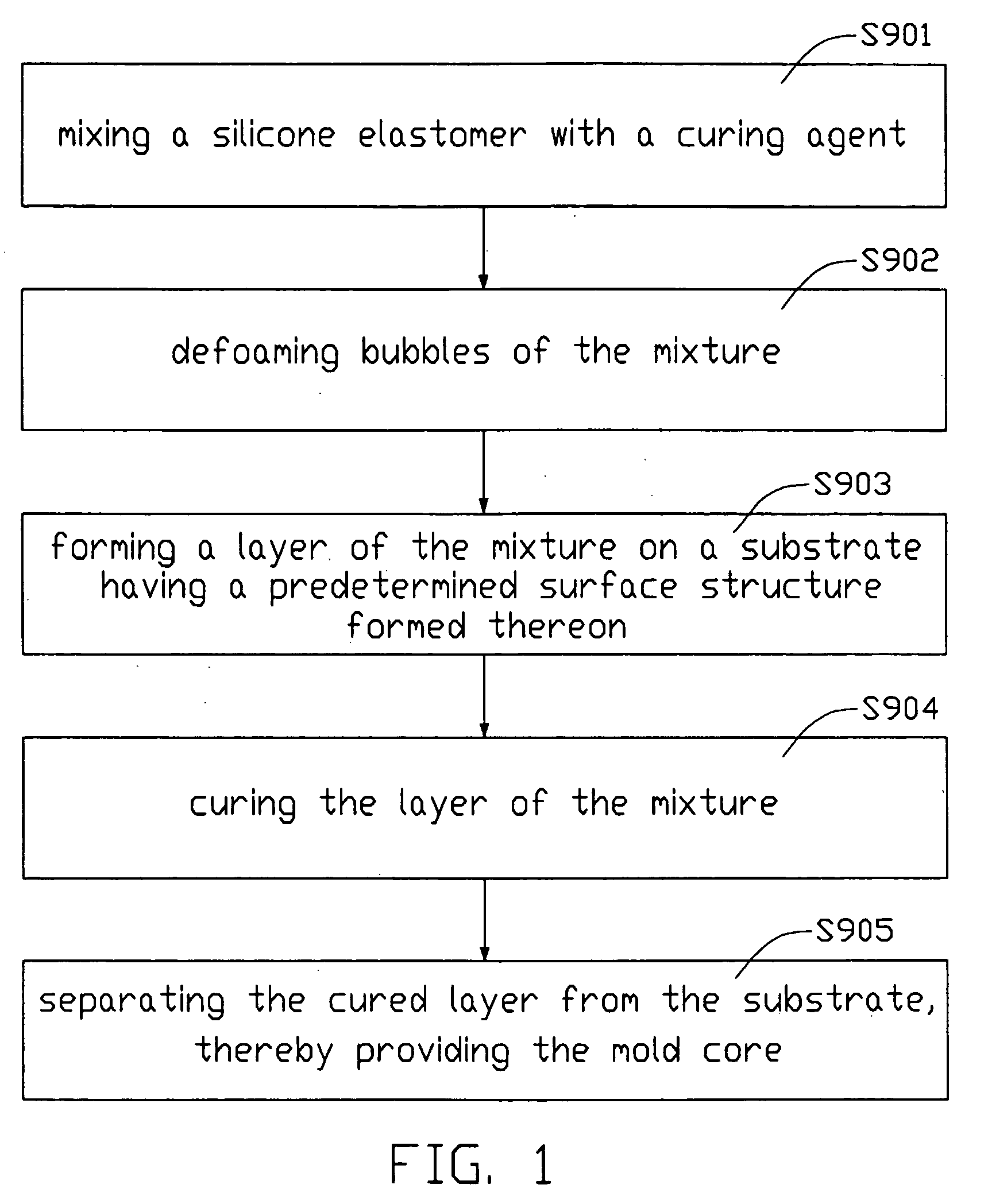

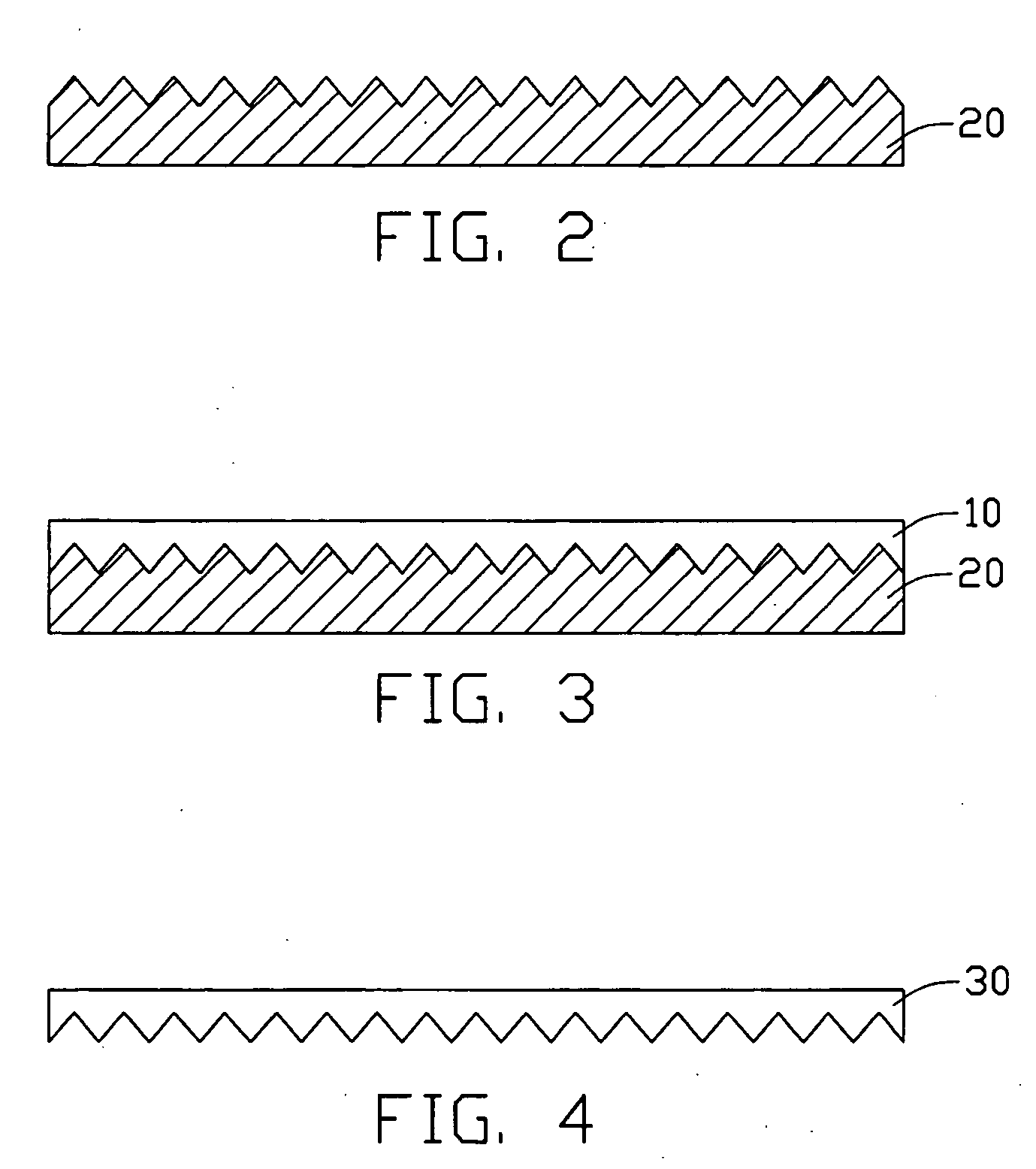

Method for fabricating mold core

A method for fabricating a mold core (30) includes the following steps: mixing a silicone elastomer with a curing agent (S901); defoaming bubbles of the mixture (S902); forming a layer (10) of the mixture on a substrate (20) having a predetermined surface structure formed thereon (S903); curing the layer of the mixture (S904); and separating the cured layer from the substrate to provide the mold core (S905). Unlike in the prior art, there is no need for steps of forming a photo-resist pattern, forming a Cu layer, and / or etching the Cu layer off. Thus, the method of the present invention has reduced complexity and costs compared with the method of the prior art. In addition, the obtained structure of the mold core corresponds more closely to the predetermined structure of the substrate. That is, the precision of the mold core is significantly increased.

Owner:HON HAI PRECISION IND CO LTD

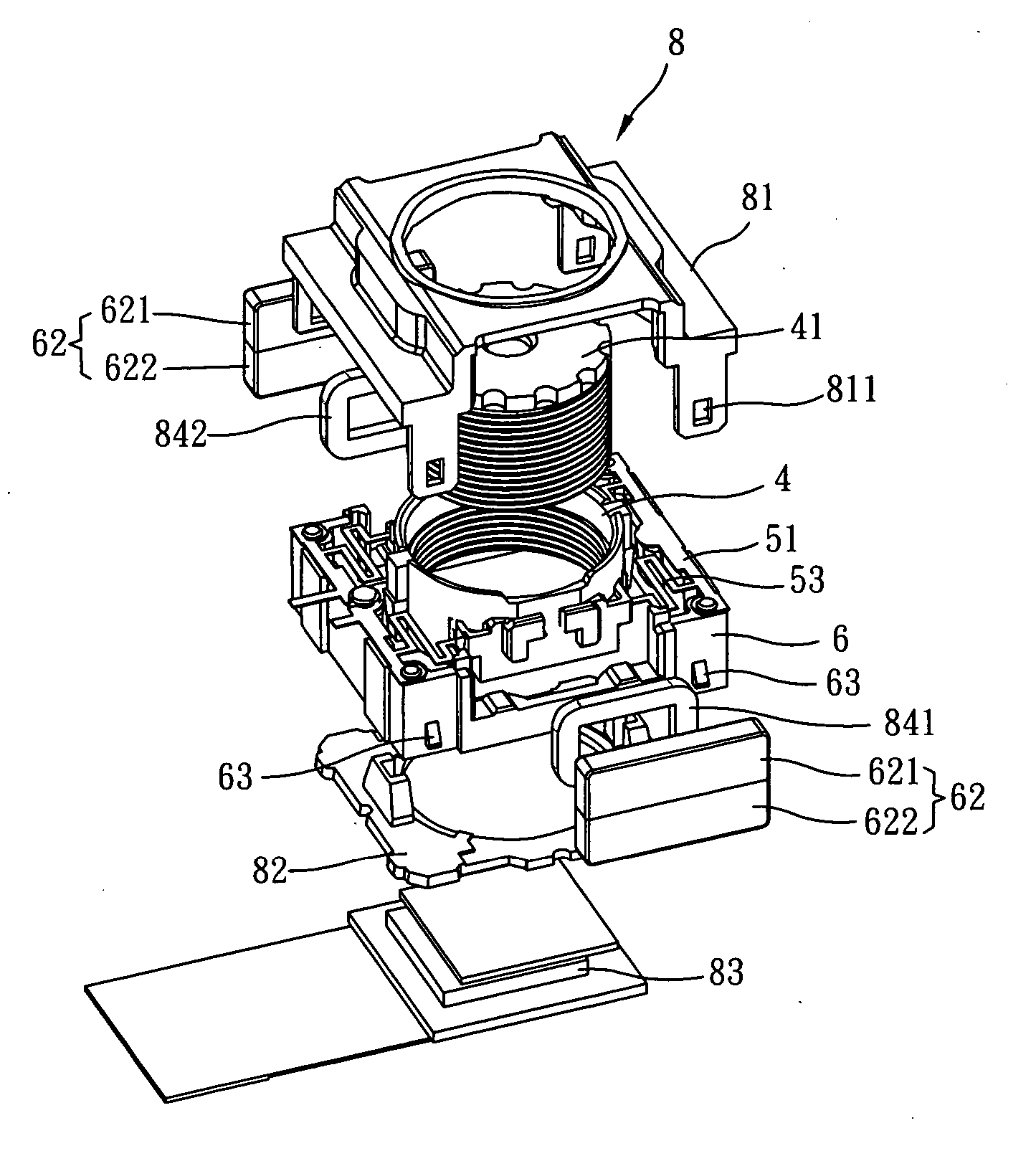

Suspension apparatus for auto-focus lens device and a method for fabricating the same

InactiveUS20060268429A1Simplify the assembly processLow costProjector focusing arrangementCamera focusing arrangementCamera lensPlastic injection molding

A suspension apparatus comprises a lens holder, a suspension spring and a supporting base. The supporting base is formed with an opening for accommodating the lens holder. The lens holder is for positioning a lens unit. The suspension spring is manufactured by stamping process to form a long strip with a plurality of suspension springs. The strip is then guided into a mold, and plastic injection molding process is performed in that mold so as to produce the lens holder and supporting base affixed respectively to either end of the suspension spring in one piece. After that, excess material of the strip is cut off. The suspension apparatus as above described is suitable for mass production. In addition, because of the high precision of mold, the inaccuracy of assembly and fabrication is minimized. The volume of the whole apparatus and the cost of production are also vastly decreased.

Owner:POWERGATE OPTICAL INC

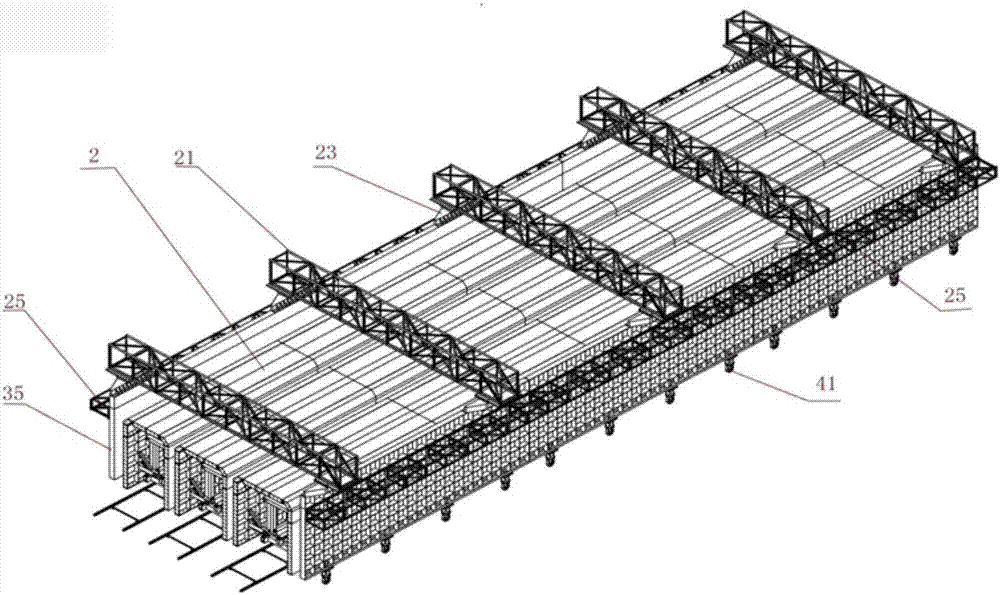

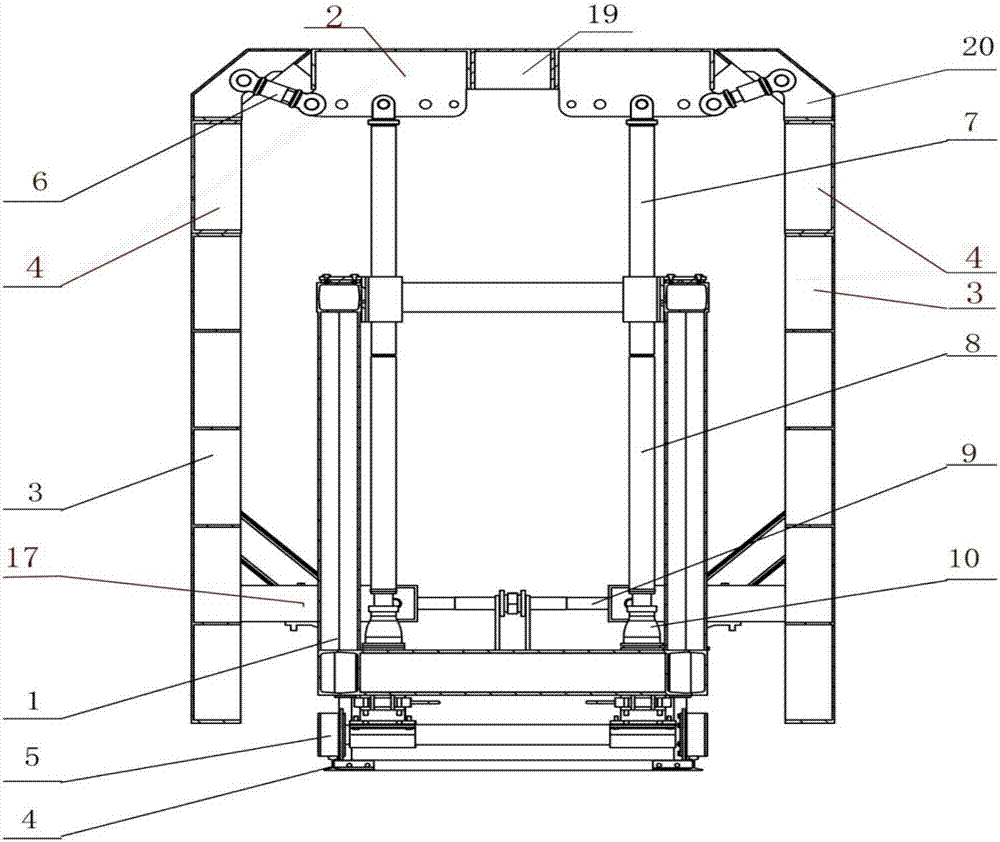

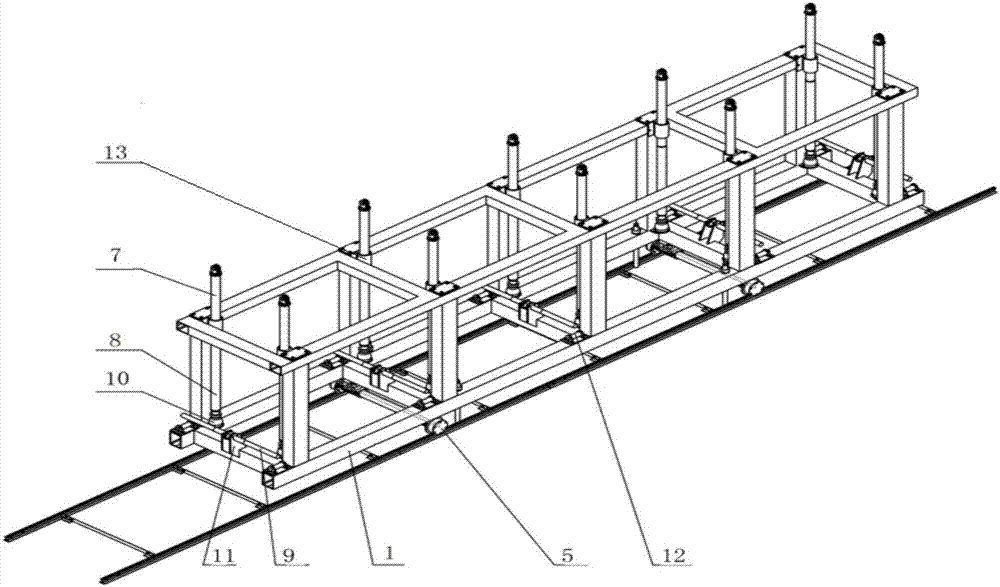

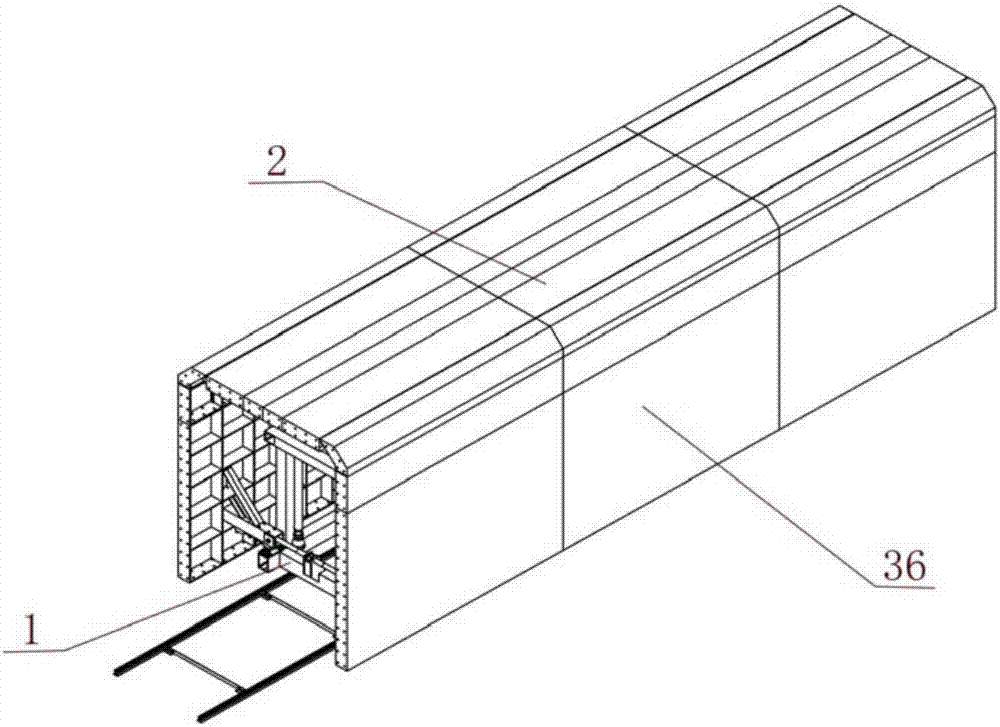

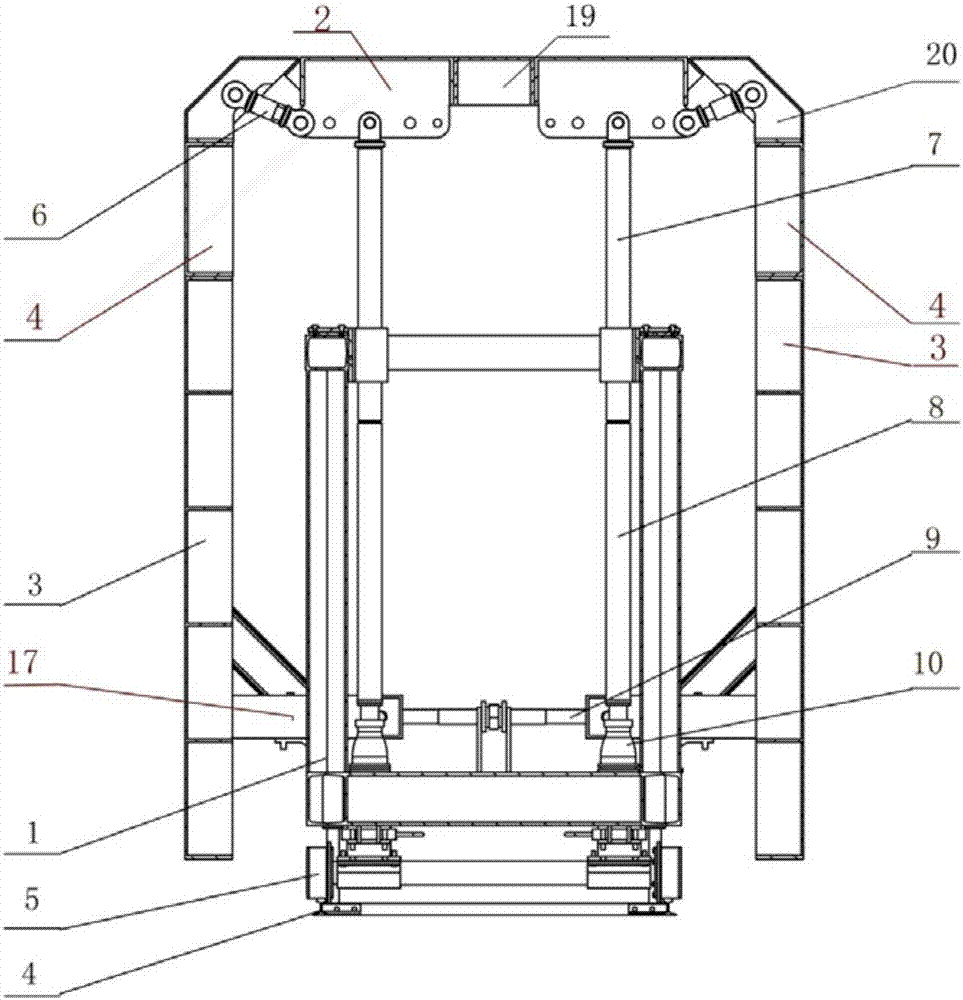

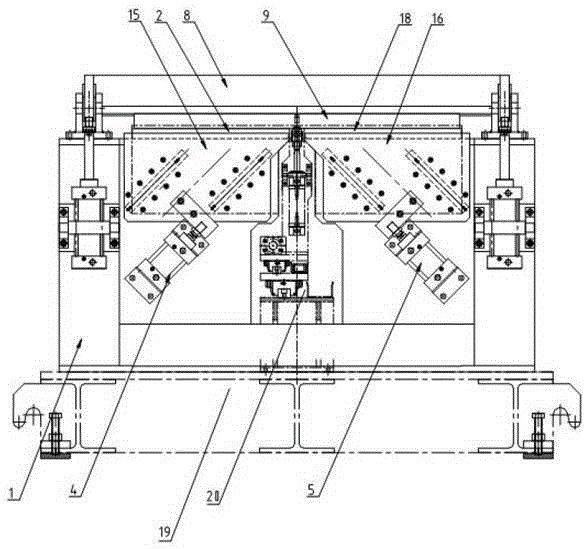

Mold used for urban comprehensive pipe gallery building construction and construction method

PendingCN107313447AImprove work efficiencyImprove mold precisionArtificial islandsUnderwater structuresVehicle frameArchitectural engineering

The invention discloses a mold used for urban comprehensive pipe gallery building construction. The mold comprises an outer side mold, a vehicle type combined inner mold and an end mold. The outer side mold is arranged outside the vehicle type combined inner mold in a covering manner. The vehicle type combined inner mold comprises side molds, a top mold, a frame and a telescopic assembly. The side molds are arranged on the two sides of the frame correspondingly. The top mold is erected above the side molds on the two sides. The two lateral sides of the top mold are movably connected with the tops of the side molds. The telescopic assembly is arranged on the frame and connects the side molds with the top mold. The end mold is connected to the end portion of the outer side mold and the end portions of the side molds and the top mold of the vehicle type combined inner mold. Pipe gallery specification determination and construction are conducted in a mold form, and the mold has the beneficial effects of being relatively simple in structure, convenient to operate, high in mold assembling precision, stable in quality, short in construction period, low in construction expense, short in construction influence period, high in production efficiency and the like.

Owner:尤兆云

Method for manufacturing base steel mould with metal arc spray coating

InactiveCN101343722AHigh work pressureImprove wear resistanceMolten spray coatingSurface patternMold filling

The invention discloses a metallic arc spraying steel-based mold manufacturing method. The metallic arc spraying steel-based mold manufacturing method comprises mold preparation, metallic arc spraying modeling, mold frame manufacturing, mold filling material casting, mold unloading and electric brush degree mold cavity surface polishing treatment, and mold component assembly and mold trial. In the metallic arc spraying modeling process, the consumption of the compressed air is controlled within 1.6 to 2m<3> / min, and the wire feeding speed of the self-consuming electrode wire is controlled within 0.1 to 4.8m / min. The invention has the advantages that the modeling precision of the metallic arc spraying steel-based mold manufacturing method is high, the replicability of the product surface pattern is good, the production efficiency is greatly enhanced, and the modeling precision of the metallic arc spraying steel-based mold manufacturing method is suitable for the new product development and small batch multiple variety production, in particular for the production of steel-based plastic molds, rubber molds and ceramic molds.

Owner:刘勇 +2

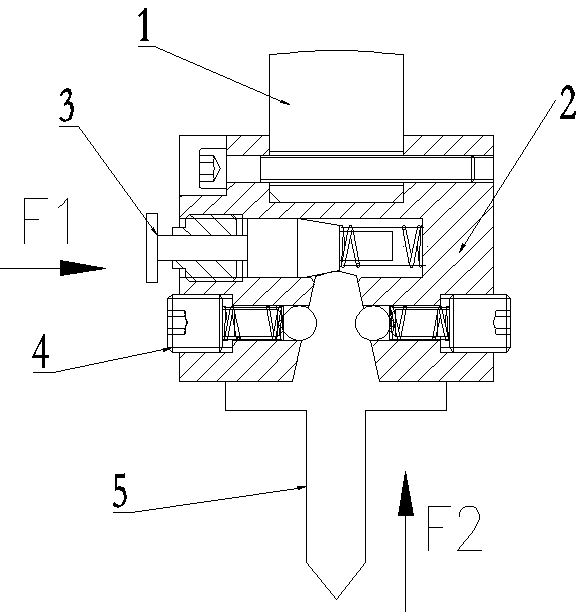

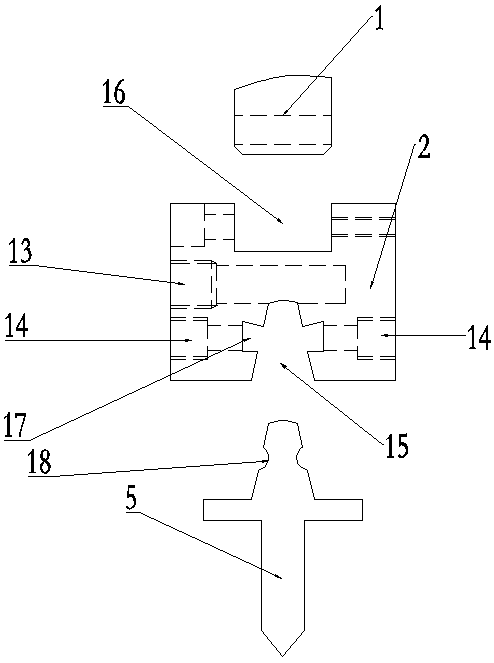

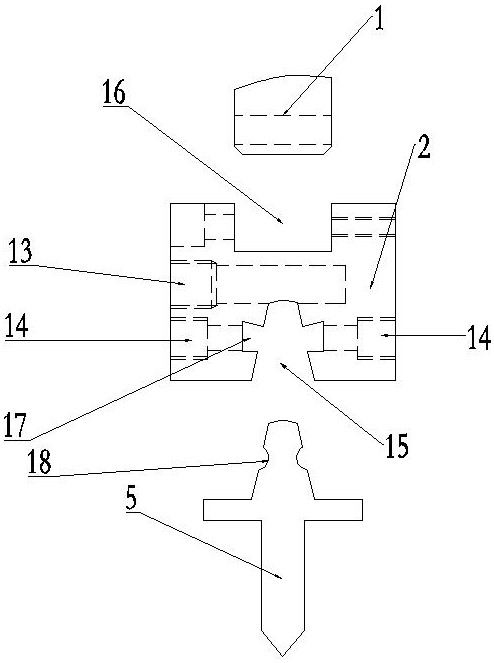

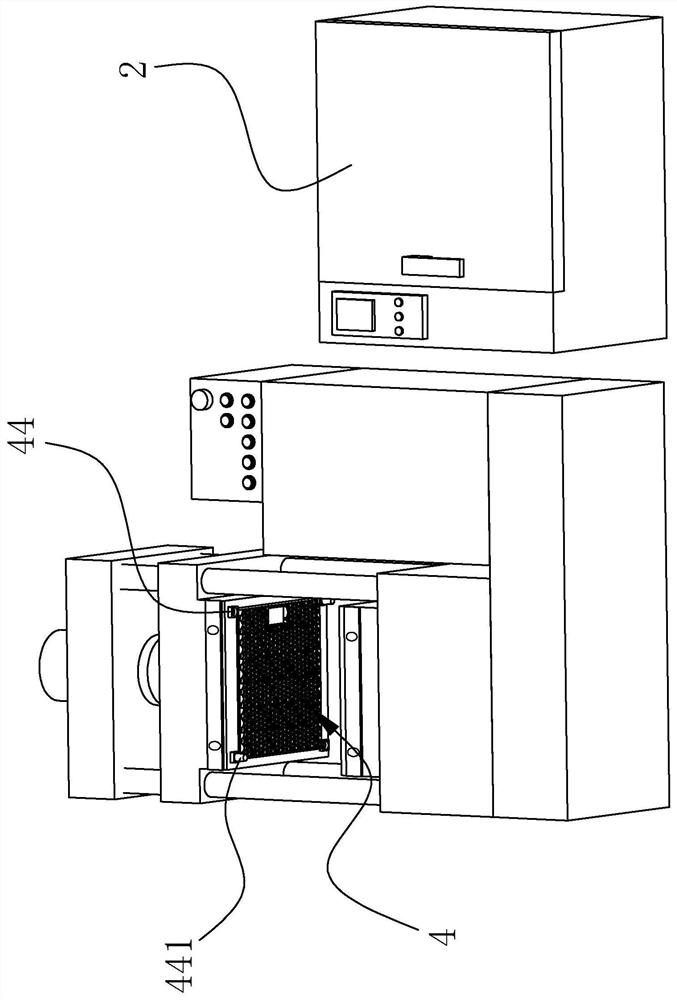

Quick replacement device for upper die of bending machine

ActiveCN110899519AFast mold changeHigh molding precisionShaping toolsStructural engineeringIndustrial engineering

The invention belongs to the technical field of bending machine dies and particularly relates to a quick replacement device for an upper die of a bending machine. The problem that screws need to be repeatedly detached when the mechanical-fixing-clamping-type upper die is mounted is solved. The quick replacement device for the upper die of the bending machine comprises the upper die and a die replacement base. The bottom of the die replacement base is provided with an upper die conical mounting groove, the upper die conical mounting groove is matched with a mounting part of the upper die, and notches are symmetrically formed in the two sides of the middle of the upper die conical mounting groove and vertically run through the die replacement base. Symmetric positioning mounting holes are formed in the portion, of the die replacement base, of the two sides of each notch and run through the notches, one side of the upper portion of one positioning mounting hole is provided with a switch mounting blind hole, and the switch mounting blind hole runs through the upper die conical mounting groove. An upper die positioning assembly is installed in each positioning mounting hole and used forfixing the upper die, and a die replacement switch assembly is installed in the switch mounting blind hole and used for detaching the upper die. The quick replacement device effectively solves the problem that the fixing screws need to be repeatedly detached when the mechanical-fixing-clamping-type upper die is mounted.

Owner:TIANSHUI METALFORMING MACHINE TOOL GROUP

Fine porous ceramic used as ceramic mold and molding technique

InactiveCN101774215AEasy to makeImprove mold precisionCeramic shaping apparatusGypsumPressure casting

The invention relates to a new ceramic mold material and a molding technique for replacing gypsum mold and technique needed by traditional ceramic mold technique. Compared with a traditional mold, the inventive mold has the advantages of high strength, long service (a single mold can be used for more than million times), high preciseness, small number of needed single variety mold (hundreds of molds are needed in the traditional technique, while 2-3 molds are needed for the new material rolling technique, 6-8 molds are needed for pressure casting to achieve continuous production), and the like. The popularization of the mold and molding technique can radically change the existing ceramic production situation, save resources and energies, reduce pollution, enhance efficiency and product quality, and provide conditions for modernization and automation of ceramic production.

Owner:胡敏渝

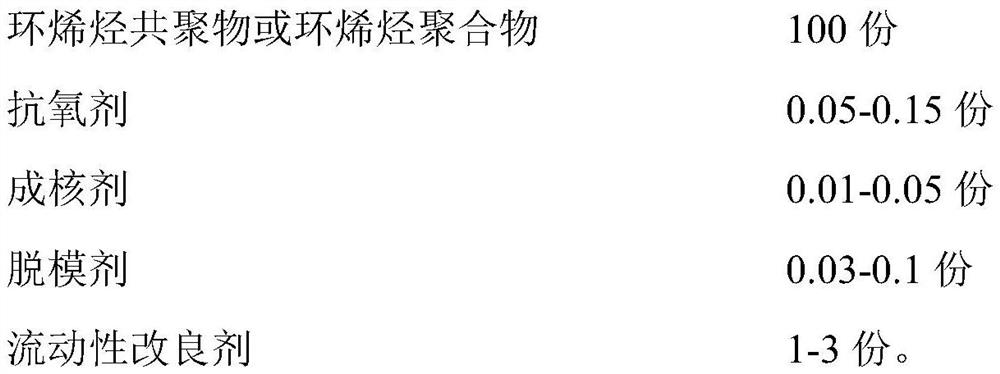

Preparation process of polymer pre-filled syringe

ActiveCN112549420ASimple designImprove mold precisionDomestic articlesProcess engineeringInjection moulding

The invention belongs to the technical field of medicine package materials, and particularly relates to a preparation process of a polymer pre-filled syringe. The preparation process comprises the following steps of (1), preparing materials: selecting a syringe needle tube material and a syringe sealing piston material; (2), mold flow design: establishing a mold flow analysis model of an injectionmolding product, and optimizing mold design and formulating optimal process parameters through mold flow analysis by testing PVT parameters of a material; (3), injection molding: respectively carrying out injection molding on the syringe needle tube material and the syringe sealing piston material according to the formulated optimal process parameters to obtain a syringe needle tube and an syringe sealing piston; (4), assembling a finished product, namely assembling the obtained syringe needle tube and syringe sealing piston with a push rod and a protective cap accessory; and (5), sterilizingand packaging, namely spraying silicon on the assembled syringe, sterilizing, analyzing, detecting, checking and accepting, packaging and warehousing. According to the method, the product with high forming precision can be obtained by optimizing the mold design and formulating the optimal technological parameters.

Owner:SHANDONG YONGJU MEDICAL TECH

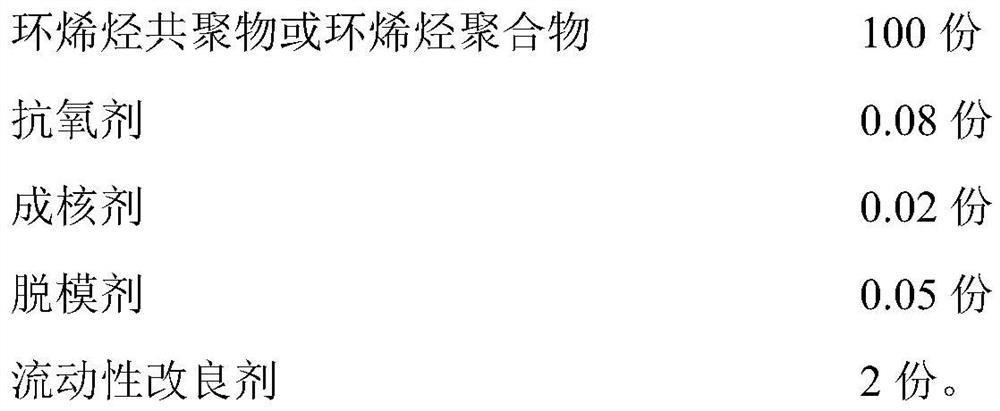

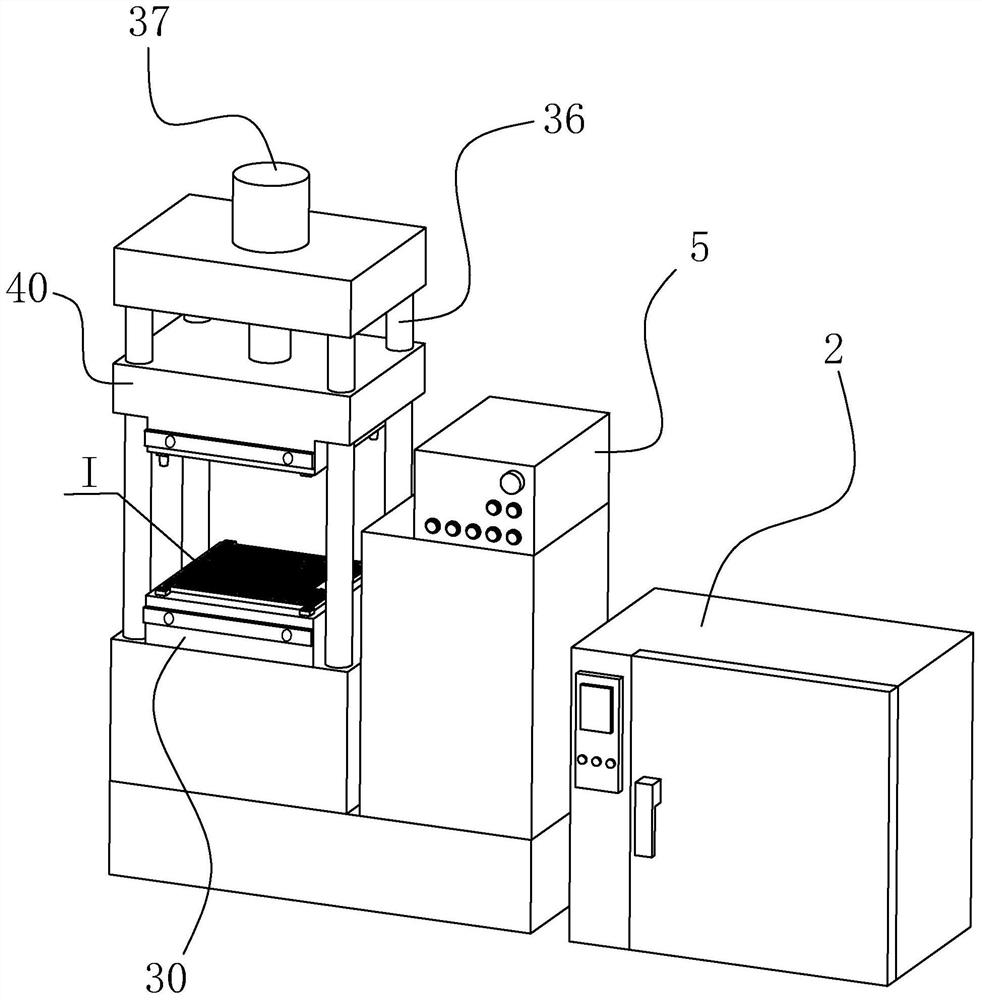

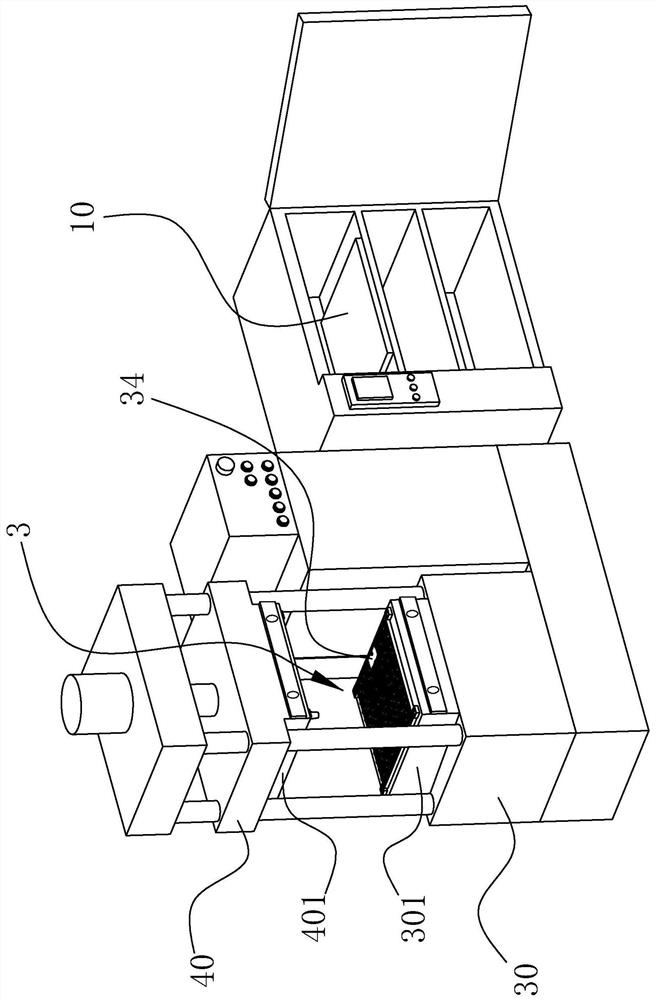

Methods and systems for manufacturing gun holster

A method for forming a molded article includes the steps of providing one of vacuum molding and press molding. A sheet of thermoformable material which is heated to a temperature at which the material is moldable is provided and the thermoformable sheet is placed over split mold die and vacuum pressure applied or placed between male and female molds on a press mold and pressure is applied. The molded sheet is removed from the dies, and the two halves of the molded sheet are joined together to form a molded article.

Owner:CATNER ANTHONY JOSEPH +1

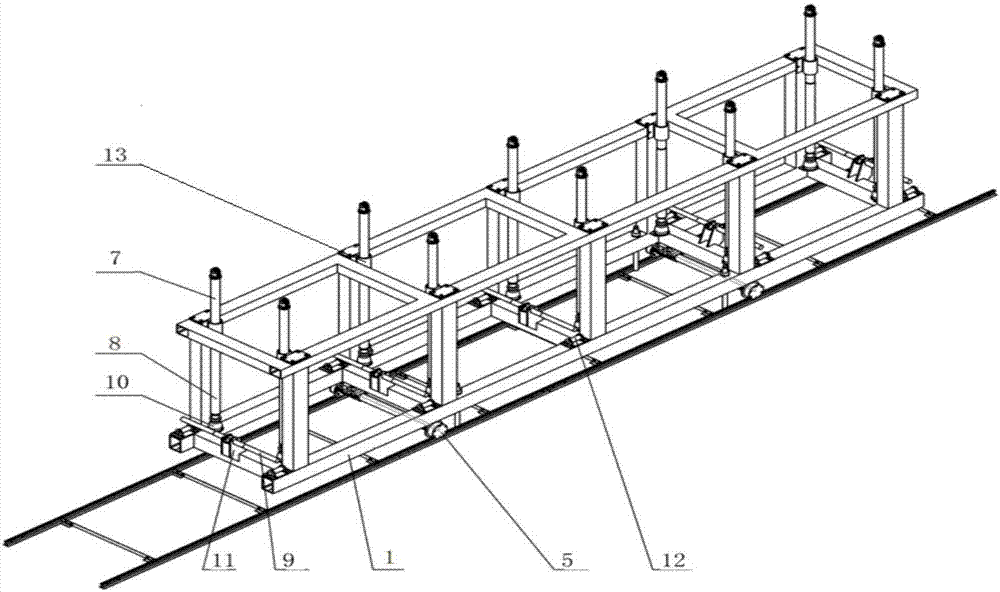

Vehicle type combined inner mold used for urban comprehensive pipe gallery building construction

PendingCN107313446ASimple structureEasy to operateArtificial islandsUnderwater structuresVehicle frameArchitectural engineering

The invention discloses a vehicle type combined inner mold used for urban comprehensive pipe gallery building construction. The vehicle type combined inner mold comprises side molds, a top mold, a frame and a telescopic assembly. The side molds are arranged on the two sides of the frame. The top mold is erected above the side molds on the two sides. The telescopic assembly is arranged on the frame and connects the side molds with the top mold. The frame is directly fixed to a construction position, then, splicing is conducted according to the scale and size of a to-be-constructed comprehensive pipe gallery so that the side molds and the top mold can be spliced, supporting is particularly achieved through the telescopic assembly, an outer mold is spliced outside the side molds and the top mold, concrete is directly poured into the space between an inner cavity mold and the outer side mold, a comprehensive pipe gallery is obtained through pouring and forming, the molds operate in a telescopic manner, and the vehicle type combined inner mold has the beneficial effects of being relatively simple in structure, convenient to operate, high in mold assembling precision, stable in quality, short in construction period, low in construction expense, short in construction influence period, high in production efficiency and the like.

Owner:尤兆云

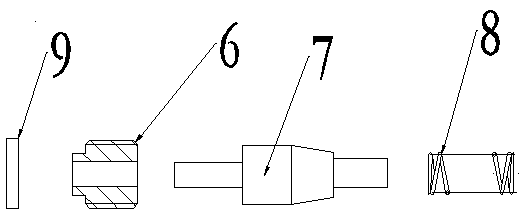

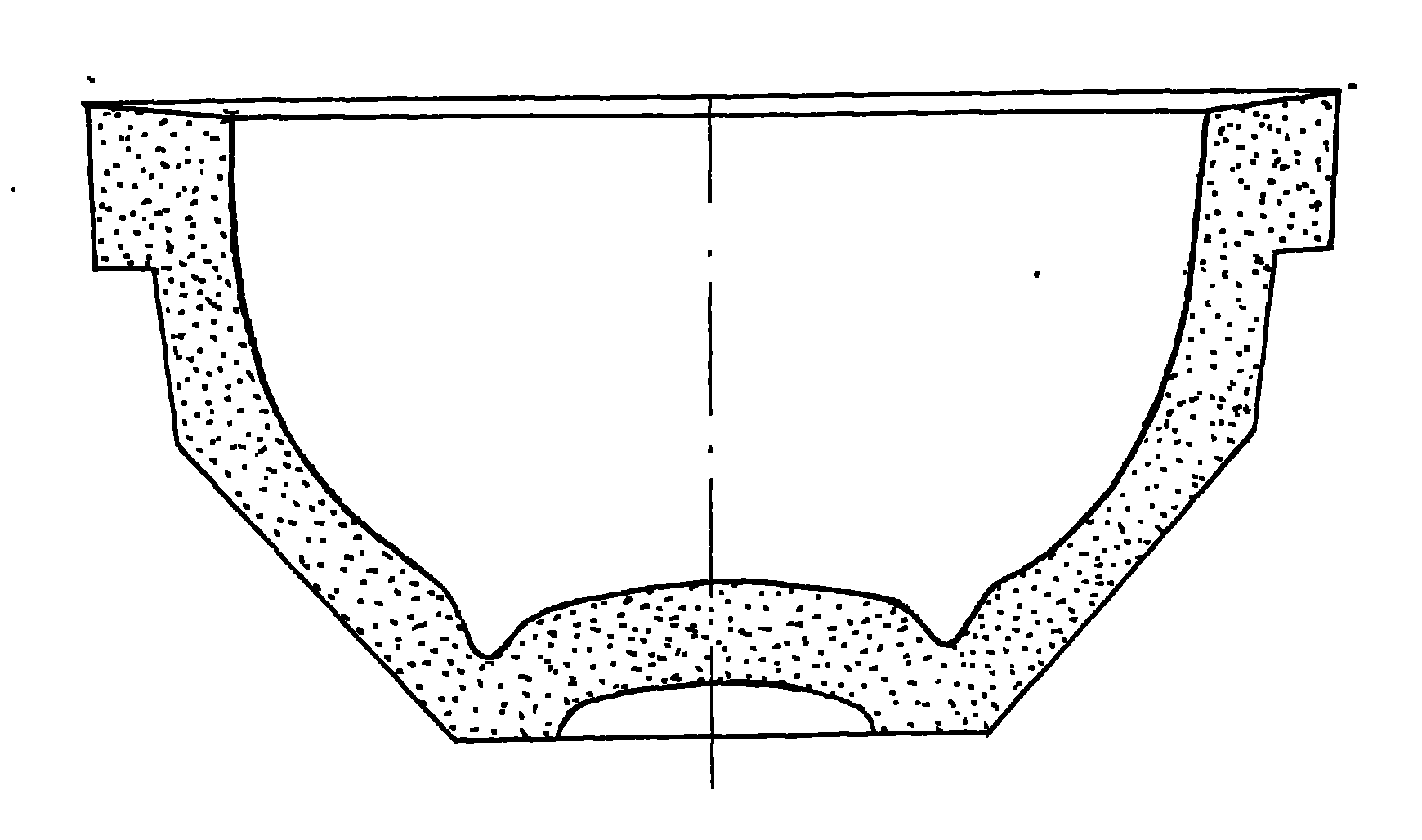

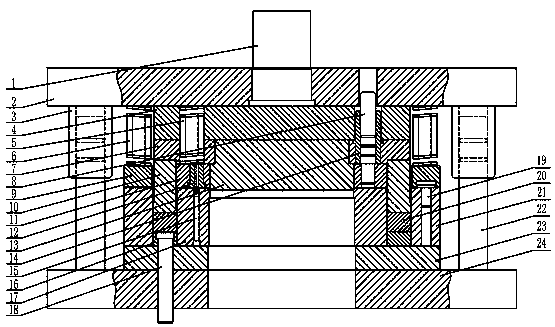

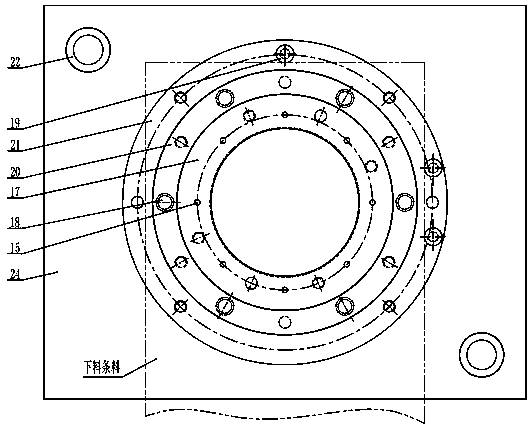

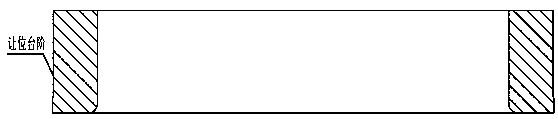

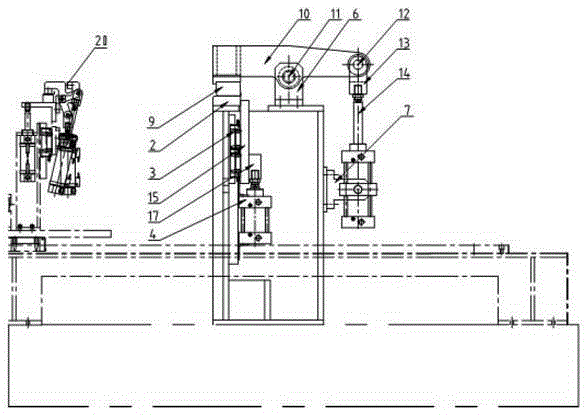

Vehicle drive rear axle brake dustproof cover composite mold and compound process

The invention relates to a vehicle drive rear axle brake dustproof cover composite mold and a compound process. The mold is divided into a mold upper half part and a mold lower half part; the mold upper half part comprises a mold handle, an upper template, a guide sleeve, an upper cushion plate, a forming unloading spring, a blanking unloading spring, an upper fixed plate, an inner guide column, ablanking unloading plate, a blanking convex mold, a forming unloading plate, a pressing convex point concave mold, a punching convex mold and an inner guide sleeve; and the mold lower half part comprises a pressing convex point convex mold, a mold corrector, a composite mold, an ejector rod, a stop pin, a blank holder, a blanking concave mold, a guide column, a lower cushion plate and a lower template. The mold precision and life and the product quality are improved by adopting such structures as a mold correcting stop port and the mold corrector for automatically correcting mold gaps. A traditional compound process with three procedures (blanking and drawing procedure, punching procedure and convex point pressing procedure) is replaced.

Owner:JIANGXI JIANGLING CHASSIS CO LTD

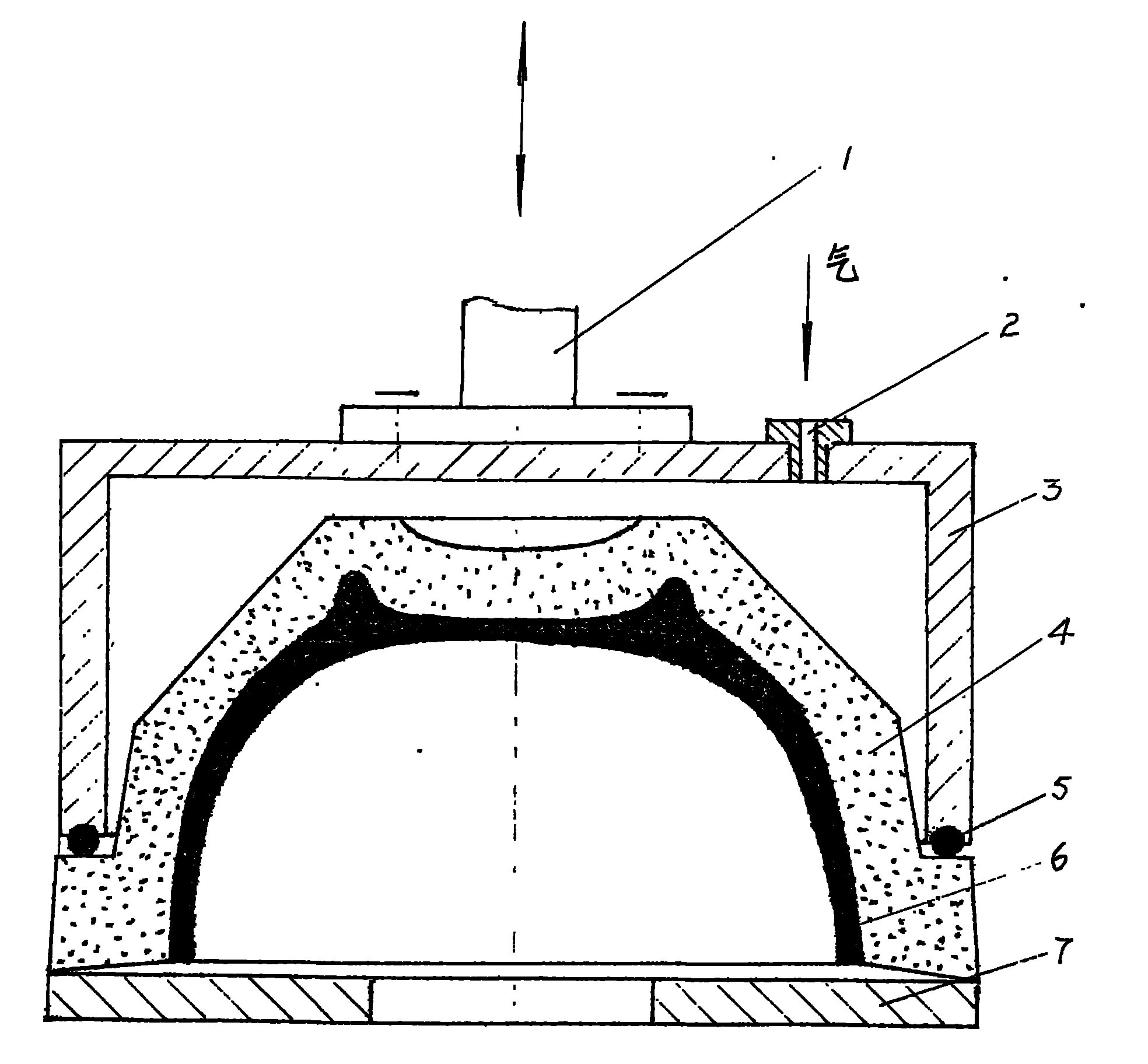

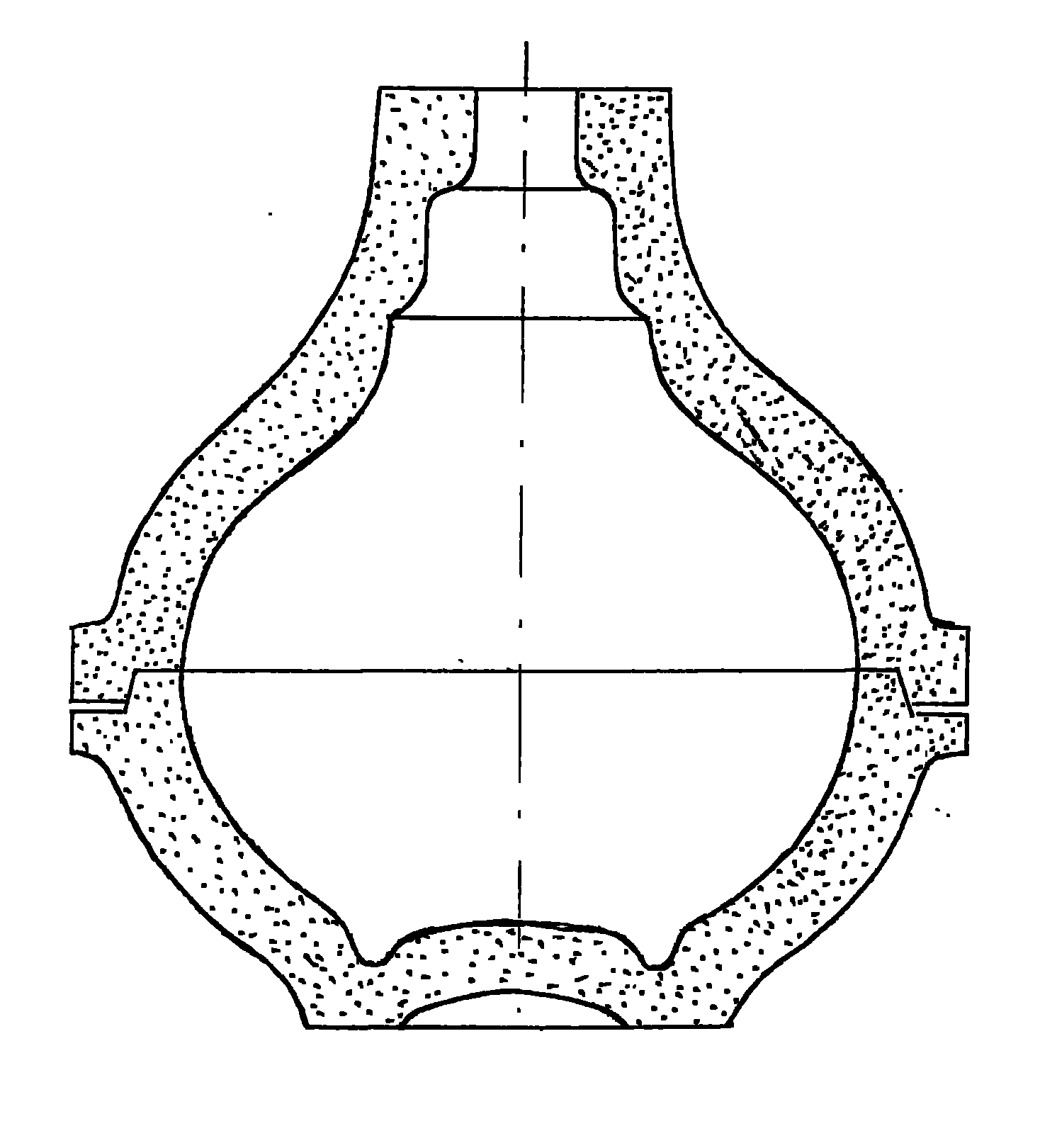

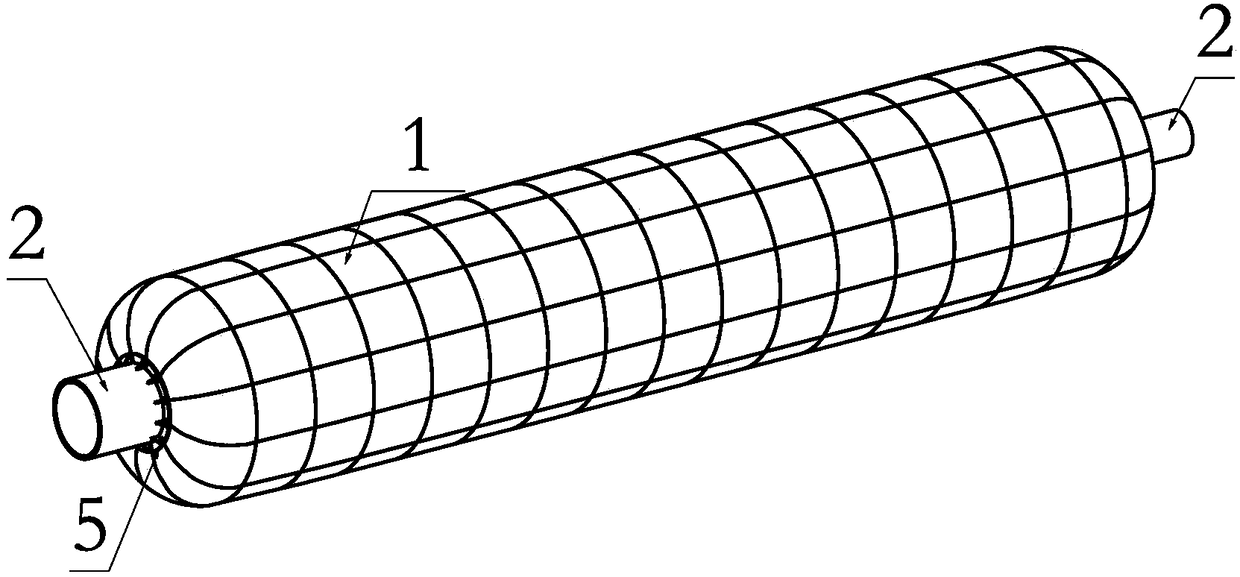

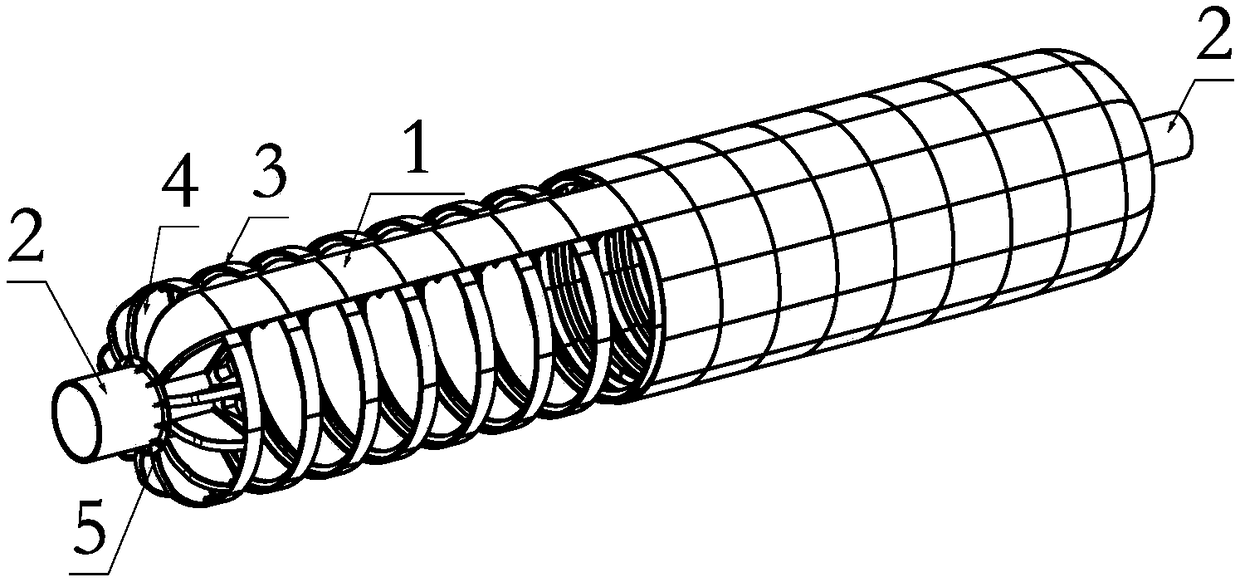

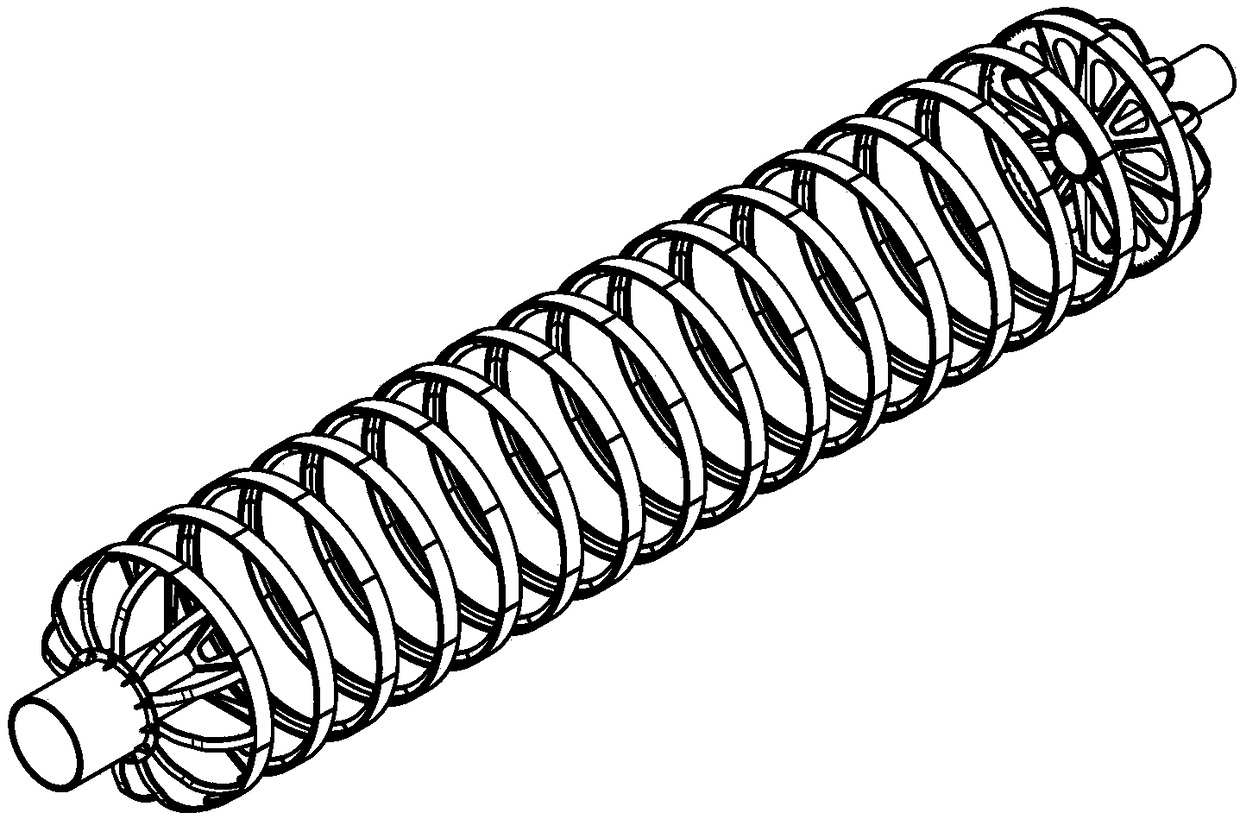

Birdcage type rocket engine shell winding and forming die and manufacturing method thereof

PendingCN108590886AImprove mold precisionSimple structureRocket engine plantsCombustion chamberEngineering

The invention relates to a birdcage type rocket engine shell winding and forming die. The die is composed of a shell, a core shaft, frames, supporting mechanisms and sealing head positioning devices,wherein the core shaft is in a sectional type, and is only arranged at the two ends of a shell sealing head, the multiple frames are arranged, all the frames are parallel to one another and are the same in structure, frame edge strips are fixed to the shell, the shell is fixed through the sealing head positioning devices, the supporting mechanisms are connected with the shell and the core shaft, and are only arranged at the two ends of the shell sealing head. The die is applied to mechanical forming, forming of an ultra-large type rocket combustion chamber shell or other barrel structures is realized, and the integral forming technology of the world ultra-large type rocket combustion chamber shell is broken through for the first time; the die is high in precision, a flexible layer betweenthe die and a product is removed, and net size forming is realized; and moreover, the die is simple in structure, convenient to assemble and disassemble, reliable in connection, large in rigidity, small in deformation, light in weight and low in cost.

Owner:绍兴宝旌复合材料有限公司 +1

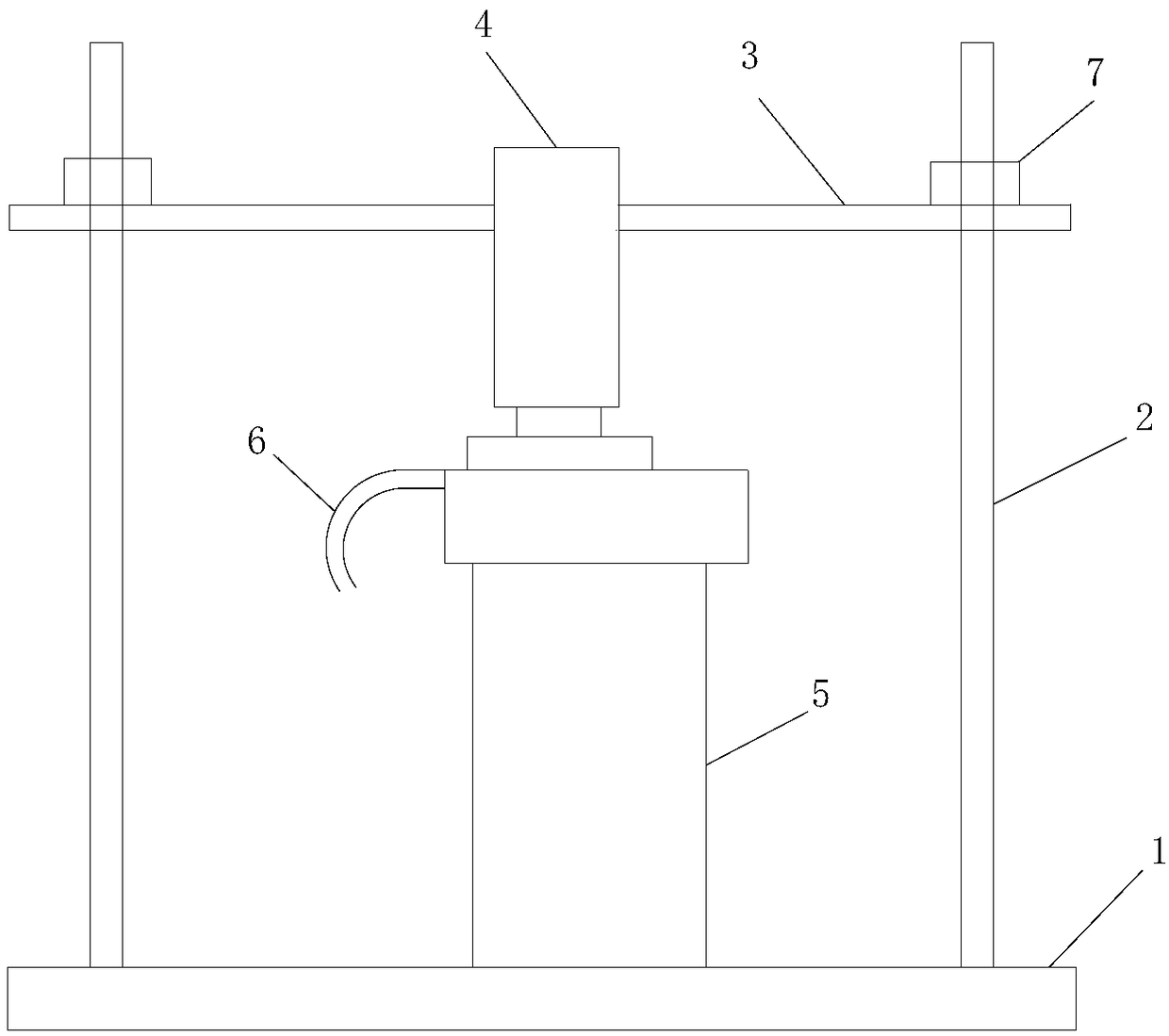

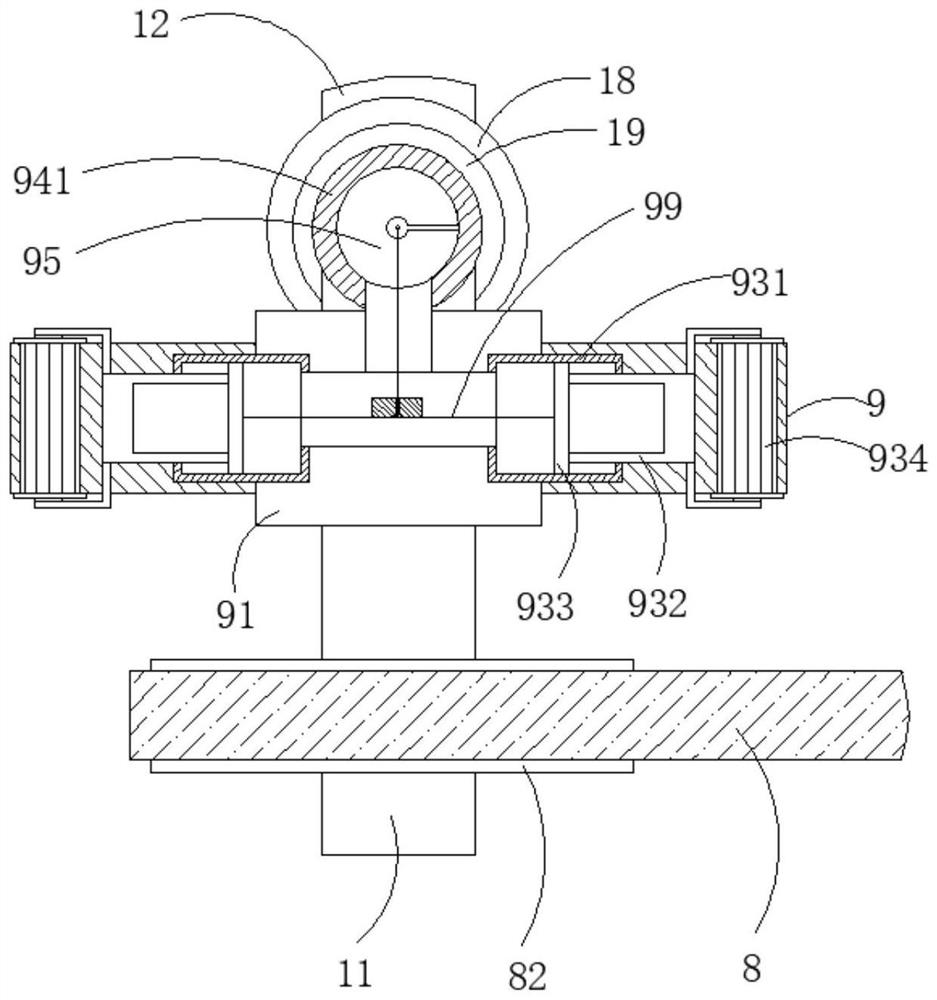

Vertical soldering clamp of hydraulic oil cylinder

InactiveCN109128655ASimple structureEasy to manufactureWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderEngineering

The invention relates to a vertical soldering clamp of a hydraulic oil cylinder. The vertical soldering clamp comprises a bottom plate, wherein two stand columns are vertically arranged on the bottomplate, a cross rod is arranged between the stand columns, a pressing head is arranged on the cross rod, and a positioning stand column is arranged on the portion, between the two stand columns, of thebottom plate; and a water cooling device is arranged on the positioning stand column, the pressing head is arranged at the top end of the water cooling device, and the cross rod on the two stand columns are tightened through nuts. In this way, the vertical soldering clamp is simple in structure, convenient to manufacture, low in cost, easy to demold and high in mold loading precision.

Owner:江苏三峘液压设备有限公司

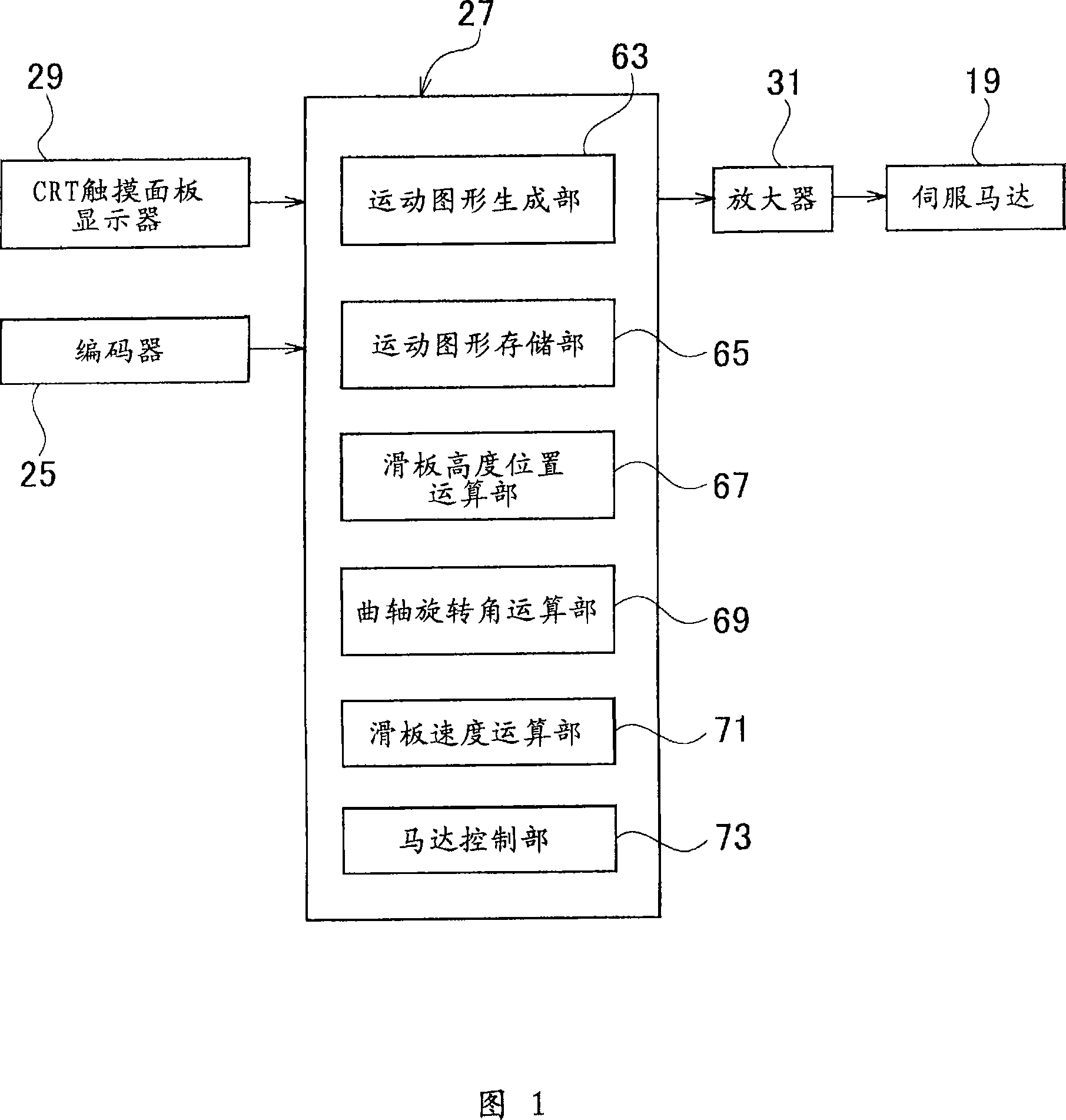

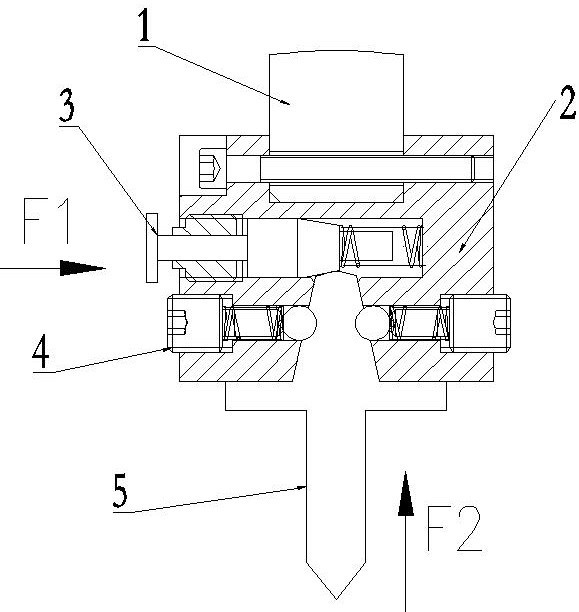

Pressing machine, crank pressing machine, and vibration processing method in these machines

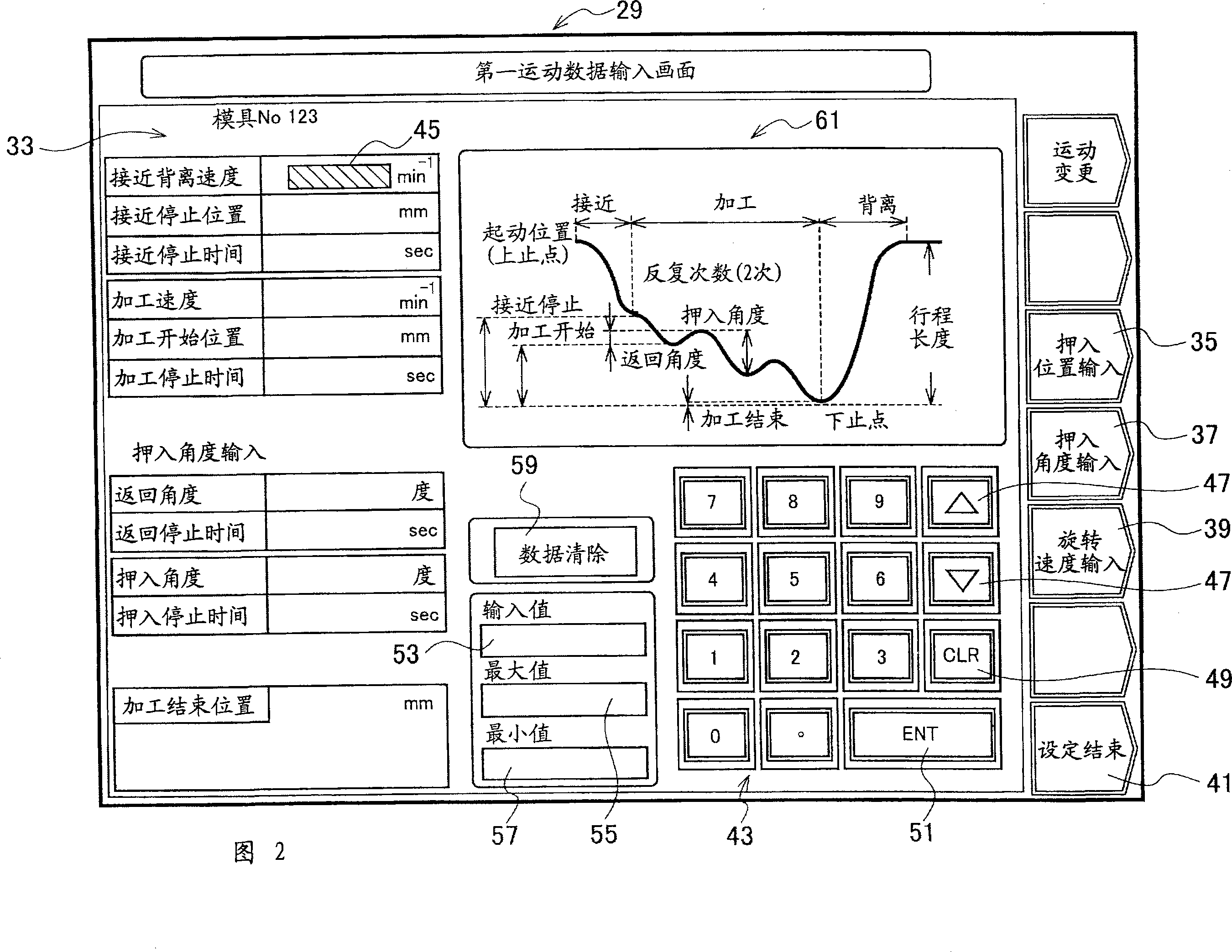

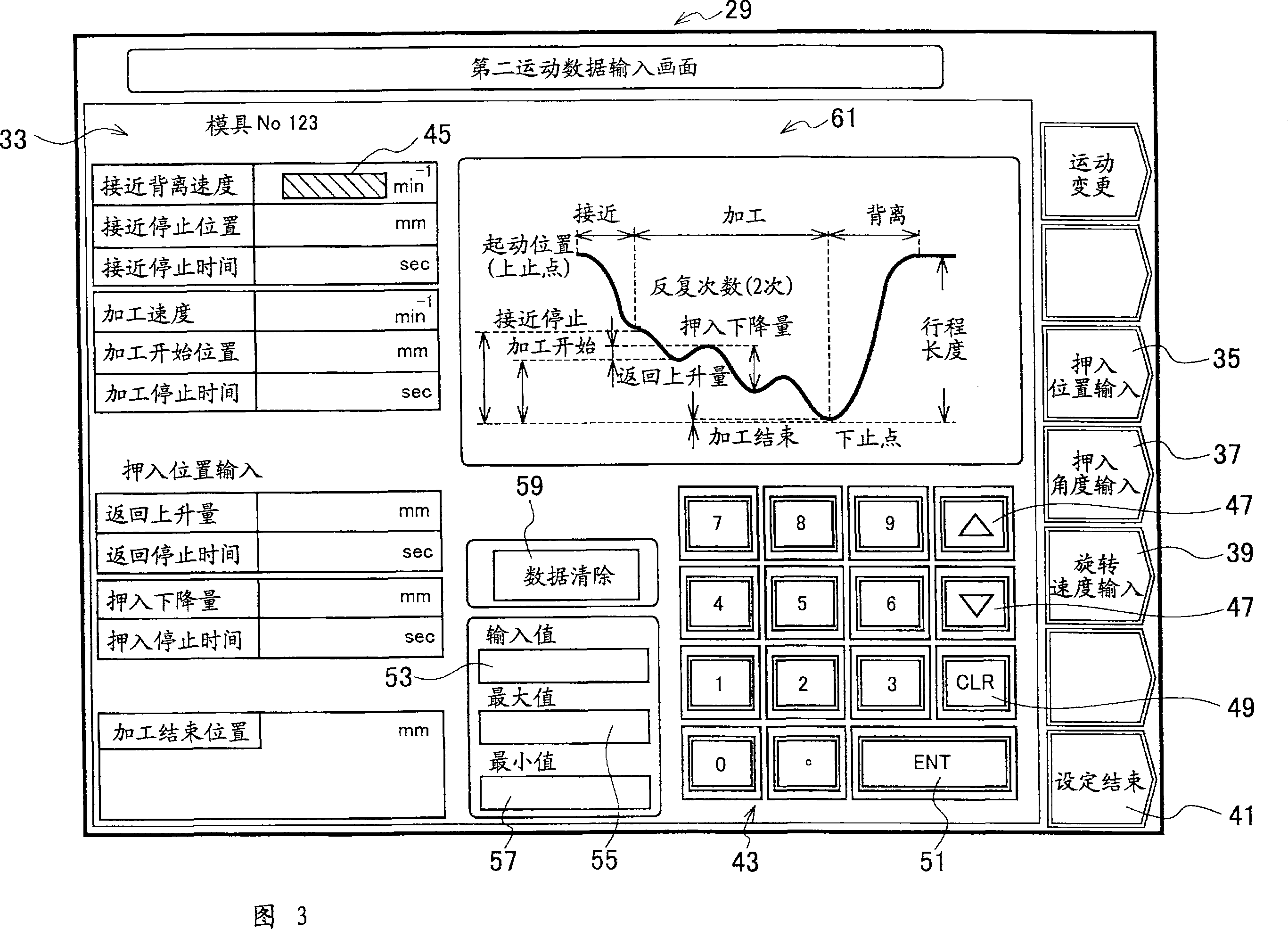

ActiveCN101208193AIncrease the number of input itemsShorten the timePress ramMotor controlEngineering

A press, comprising: an electric motor (19) that rotates a crankshaft (13) to raise and lower a slider (11); input items include the height, position, and vibration of the slider (11) at the start and end of vibration processing; The motion data of the speed of the slider (11) during processing, the rotation angle of the crankshaft (13) in one direction during the pushing operation, and the rotation angle of the crankshaft (13) in the other direction during the return operation are input and operated by the operator. The motion data input unit (29) of input; Generate the motion pattern generating unit (63) of the motion pattern of slider (11) based on the motion data input to the motion data input unit (29); (63) the motor control unit (73) to control the electric motor (19) from the generated motion pattern.

Owner:AMADA CO LTD +1

Fiberglass enhanced polyphenyl thioether/polyphenylether composite material and preparation method thereof

The invention discloses a fiberglass enhanced polyphenyl thioether / polyphenylether composite material and a preparation method thereof. The composite material is mainly prepared by the following raw materials: polyphenyl thioether, polyphenylether, fiberglass, mineral filler, a compatibility agent, an antioxidant and a processing aid. The preparation method of the fiberglass enhanced polyphenyl thioether / polyphenylether composite material comprises the following steps of: (a) firstly, respectively blasting and drying polyphenyl thioether resin and polyphenylether resin; (b) weighting the polyphenyl thioether resin and the polyphenylether resin which are dried, the mineral filler, the compatibility agent, the antioxidant and the processing aid; (c) mixing the dry materials in the step (b) to obtain a compound; and (d) adding the compound in the step (c) and the fiberglass to a double screw extruder for melt blending and pelleting. The fiberglass enhanced polyphenyl thioether / polyphenylether composite material can unconspicuously lower the temperature-resistant level and the rigidity of the polyphenyl thioether resin, further improve the molding accuracy of the polyphenyl thioether resin and decrease the cost.

Owner:SHENZHEN KEJU NEW MATERIAL

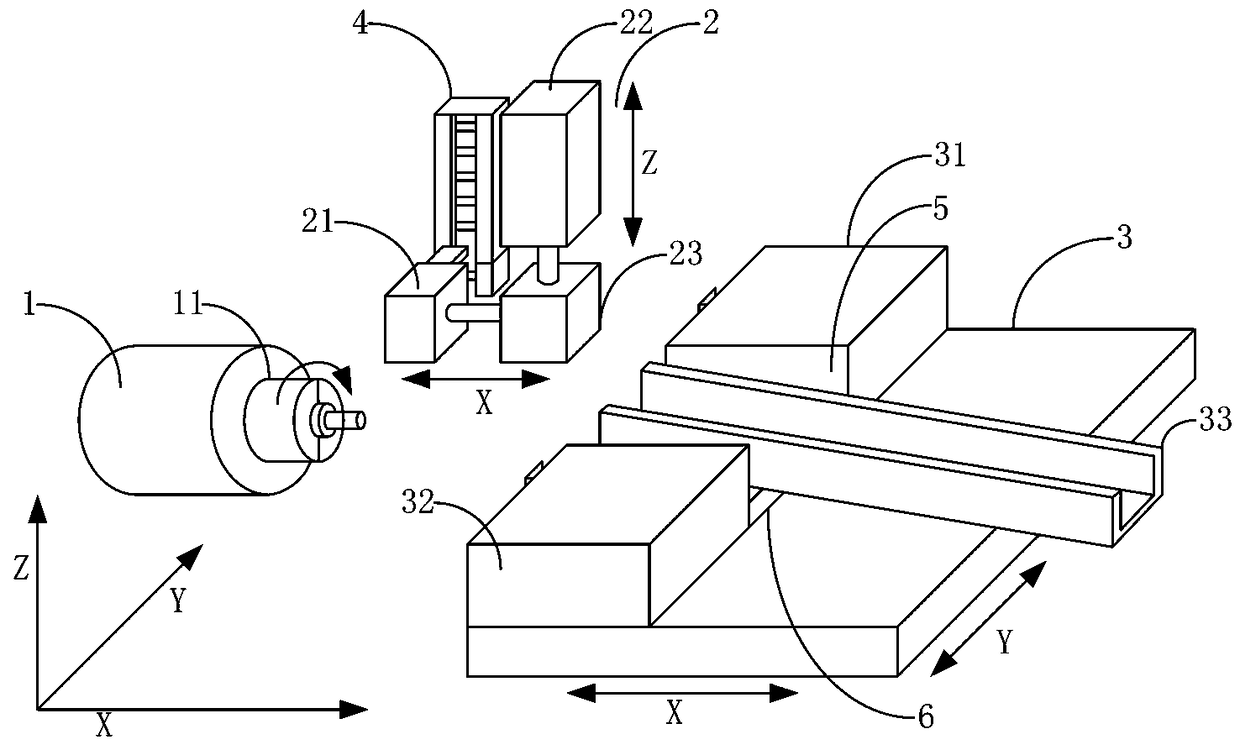

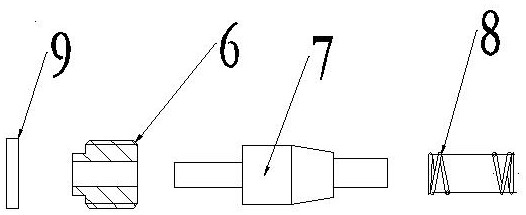

Automatic production equipment of round head pin

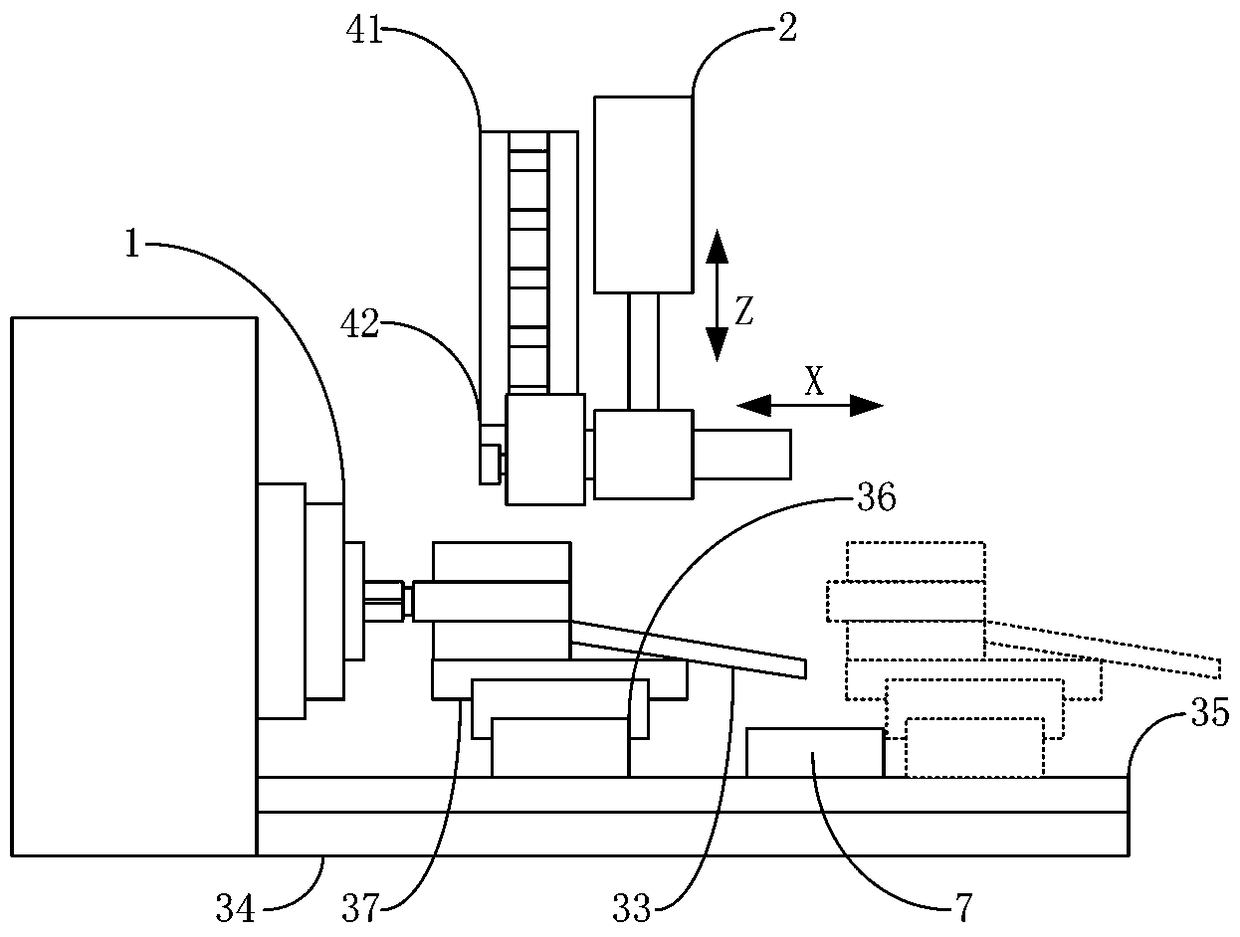

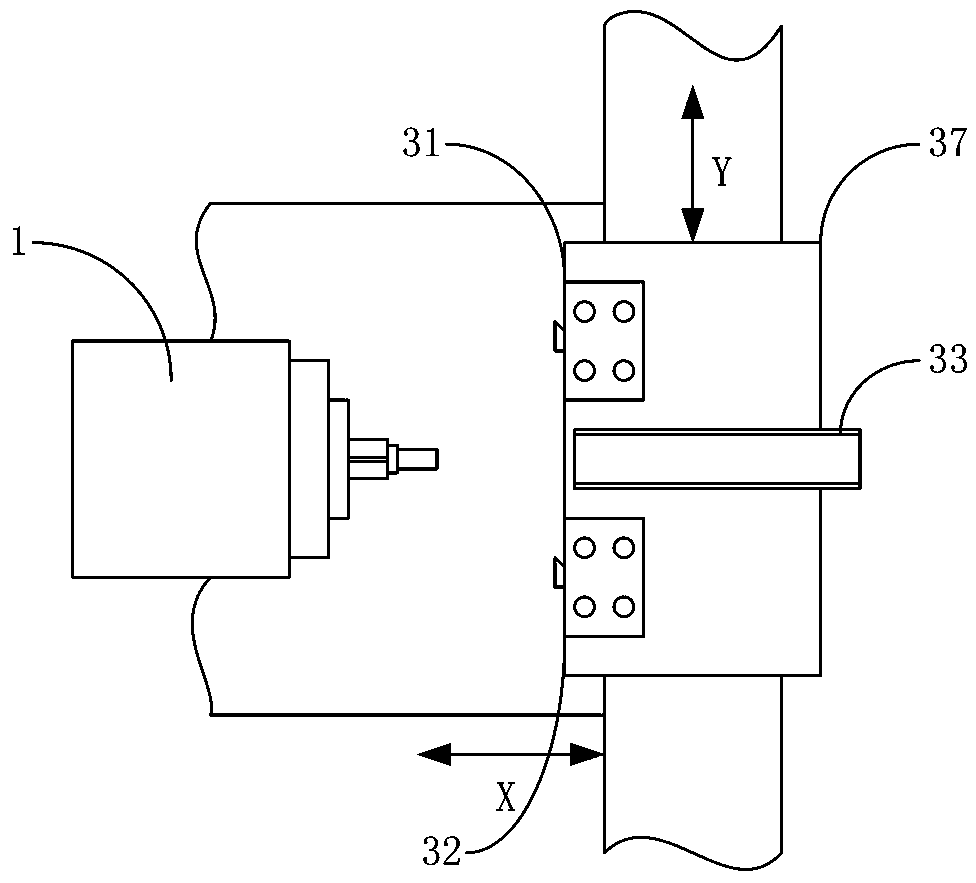

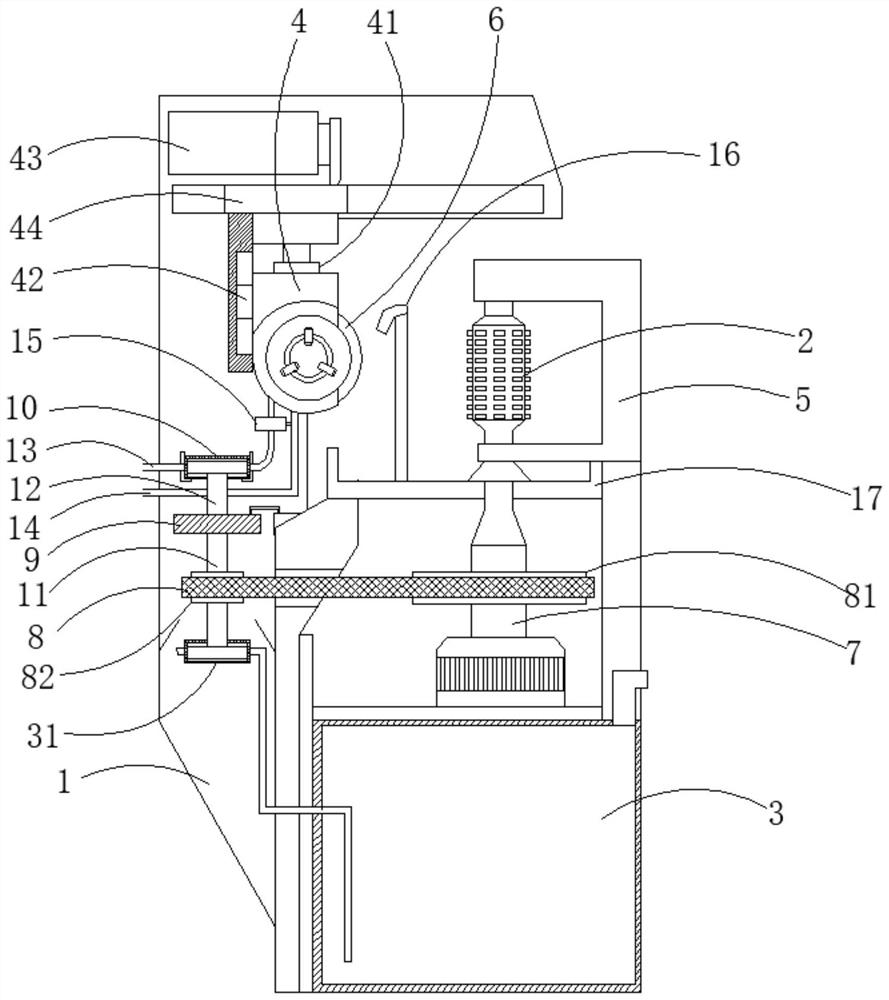

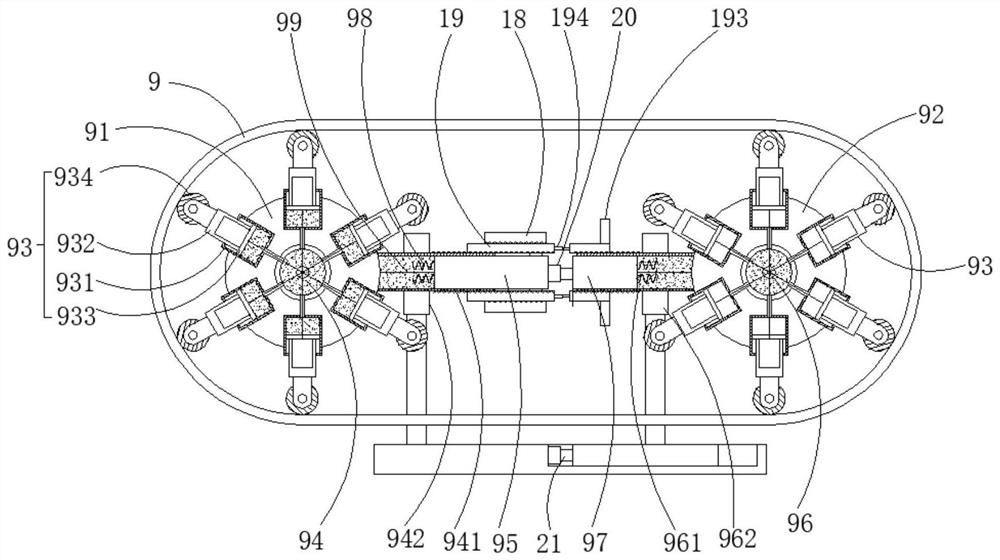

PendingCN108971523ARealize automated productionIncrease productivityAutomatic workpiece supply/removalTurning machinesEngineeringMechanical engineering

The invention discloses automatic production equipment of a round head pin. The equipment comprises a fixed rotating unit, an automatic feeding unit and a turning unit; the fixed rotating unit is usedfor reinforcing the round head pin to realize turning and rotating driving, and material claws of the automatic feeding unit at least comprise X-axis displacement and Z-axis displacement; and the turning unit comprises a first turning part, a second turning part and a discharging guide rail, wherein the first turning part is used for rough turning, the second turning part is used for finishing turning, the discharging guide rail is used for guiding out a turning finished product, and the first turning part, the second turning part and the round head pin are located on the same horizontal plane. According to the automatic production equipment of the round head pin, automatic production of the round head pins can be realized, and the production efficiency is high. Automatic feeding is realized by the cooperation of the two-shaft material claws and a feeding drawer, the discharging and turning parts are integrated, the automatic feeding and automatic discharging are reasonably allocated,the equipment design is ingenious, and the equipment cost is reduced. The turning unit is provided with two turning stations of the rough turning and the finish turning, the stroke of the two turningstations is consistent, the control is easy to realize, and the forming and machining precision is high.

Owner:斯塔比奥紧固件(昆山)有限公司

Hobbing cutter fixed type gear forming machining platform

InactiveCN114226871AGuaranteed accuracyStable Power Transmission RelationshipDriving apparatusGear-cutting machinesHydraulic motorHobbing

The hobbing cutter fixed type gear forming machining platform comprises a rack, a workpiece support, a cutter rest used for installing a hobbing cutter, a variable speed toothed belt and a gear pump, the variable speed toothed belt is in transmission through a fixed wheel disc and a movable wheel disc, the fixed wheel disc is fixedly connected to a fixed shaft in a sleeving mode, and the fixed shaft is connected with a synchronous rod through a synchronous belt; the synchronous rod is fixedly connected to the knife rest; the movable wheel disc is fixedly connected to a movable shaft in a sleeving mode, the movable shaft is fixedly connected with a gear shaft of a gear pump, and the gear pump is driven to supply oil to a hydraulic motor driving a workpiece to rotate. A stable power transmission relation can be formed between the workpiece and the hobbing cutter of the hobbing cutter fixed type gear forming machining platform, and the forming machining precision of a gear is high; the speed change gear belt increases the applicability of the whole gear forming machining platform, stable speed change and power transmission can be kept, meanwhile, it is guaranteed that hydraulic pressure is stable, and the machining quality of the whole system is stable.

Owner:WUXI YONGKAIDA GEAR

A fast mold change device for the upper mold of the bending machine

Owner:TIANSHUI METALFORMING MACHINE TOOL GROUP

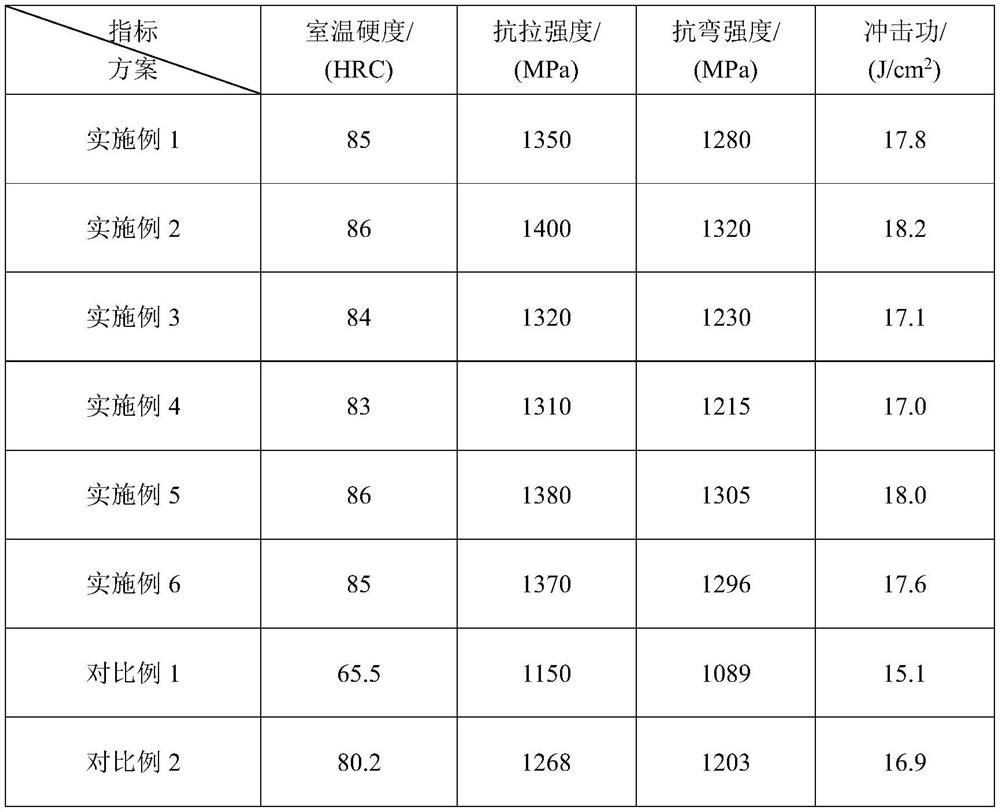

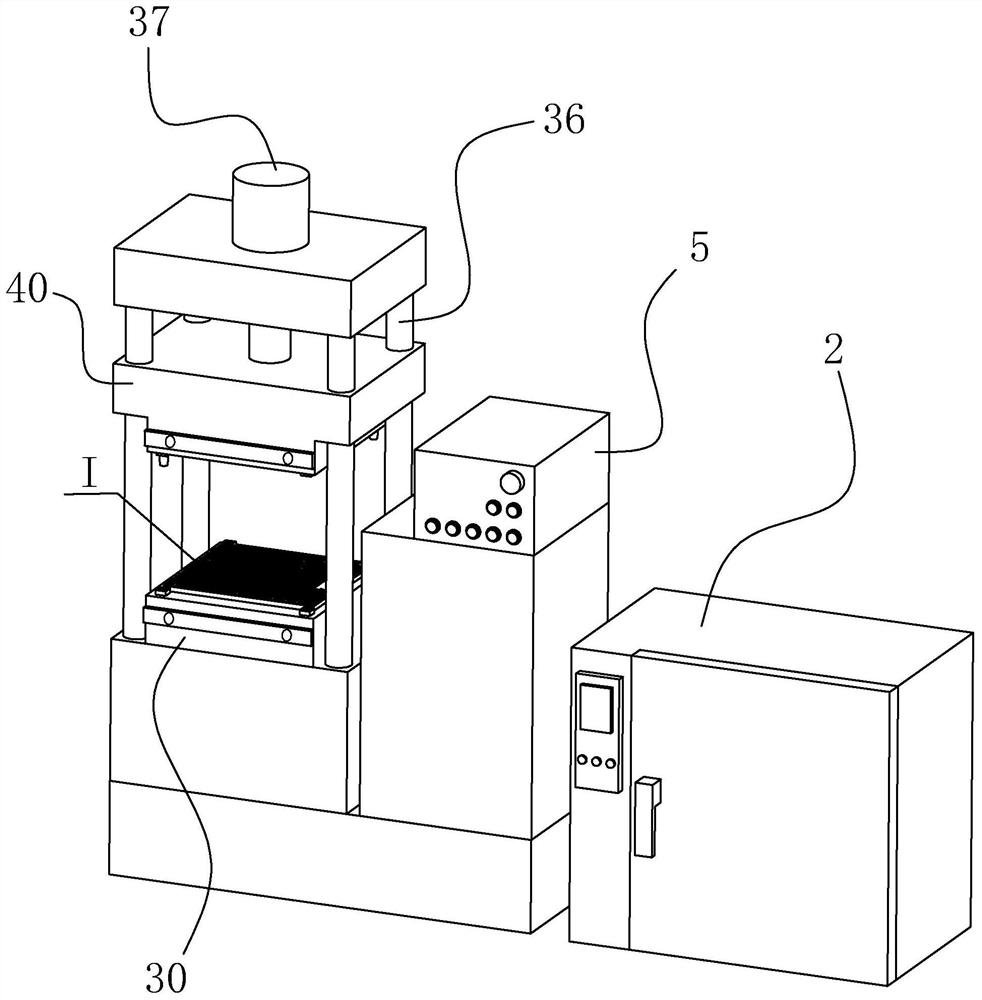

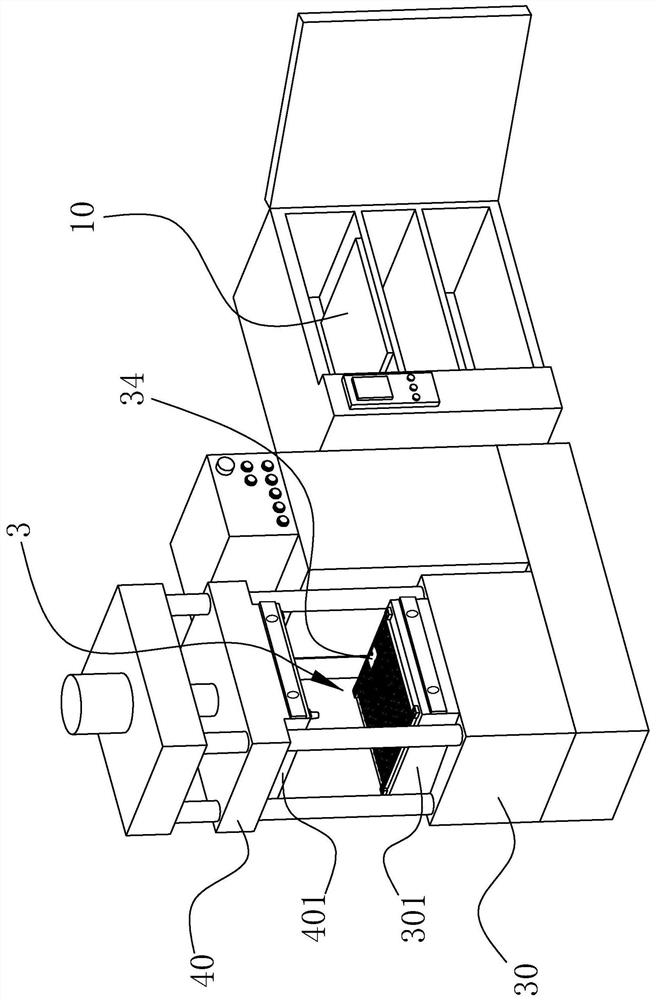

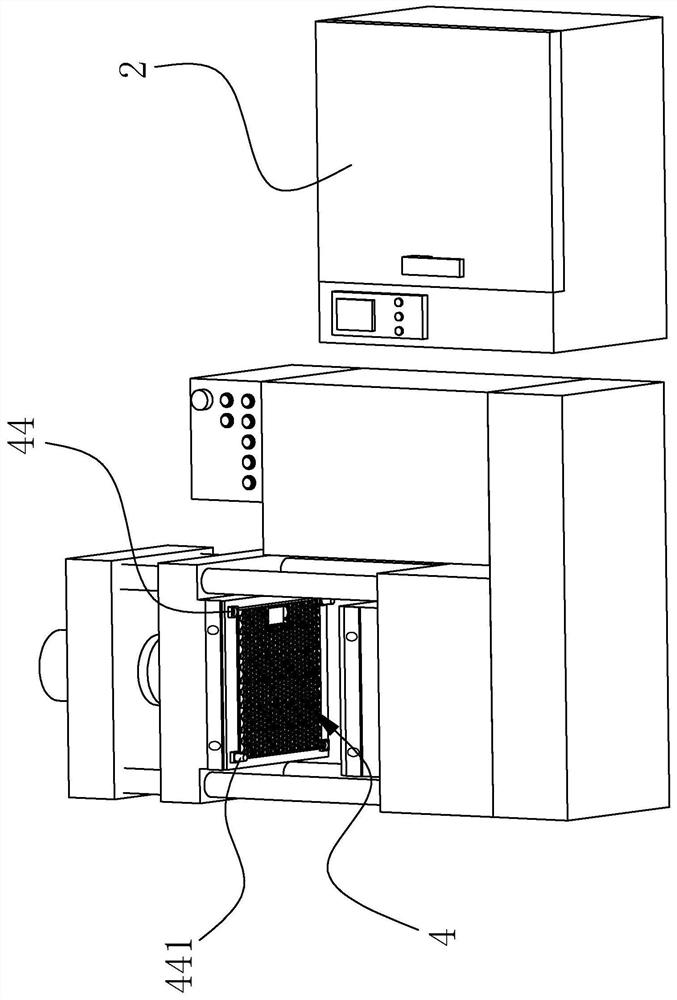

High-entropy alloy reinforced high-speed steel wear-resistant material and preparation method thereof

ActiveCN114875288AHigh hardnessImprove wear resistanceAdditive manufacturing apparatusIncreasing energy efficiencyHigh entropy alloysMetallic materials

The invention belongs to the technical field of metal materials, and relates to a high-entropy alloy reinforced high-speed steel wear-resistant material which is formed by compounding a high-entropy alloy and a high-speed steel matrix, the high-entropy alloy is FeCrCoNiHf (0.2 + x) B (0.8-x), the atomic ratio of Fe, Cr, Co, Ni, Hf and B in the high-entropy alloy is 1: 1: 1: 1: (0.2 + x): (0.8-x), x is equal to 0-0.6, the matrix is a high-speed steel material, and the high-entropy alloy is FeCrCoNiHf (0.2 + x) B (0.8-x). The mass fraction ratio of the high-entropy alloy to the high-speed steel matrix is (3-10): (97-90). The invention also discloses a preparation method of the material. The comprehensive performance of the wear-resistant material disclosed by the invention is greatly improved, particularly, key wear-resistant indexes such as high-temperature toughness and red hardness are superior to those of the existing high-speed steel wear-resistant material, the forming defects are few, and major defect accidents such as material stripping and meat falling accidents are controlled; and the high-entropy alloy is added to replace strengthening phases such as carbides separated out by depending on element supersaturation in high-alloy high-speed steel, alloying elements of the wear-resistant material are reduced, and the cost is reduced. The service life is prolonged, and the dimensional stability and the material forming finishing degree are improved.

Owner:河北中凯新创耐磨材料科技有限公司

How to make a folding seat cushion

ActiveCN112519381BNot easily deformed by heatImprove mold precisionLamination ancillary operationsLaminationCompression moldingEngineering

A method for producing a folding seat cushion, comprising the following steps: preparing a composite sheet; placing the composite sheet in an oven for baking and softening, and placing the softened composite sheet in a mold for compression molding, wherein the mold is a cold-pressed mold, and the Before being put into the composite tablet for pressing, the temperature of the lower molding surface and the upper molding surface of the mold is reduced to less than 50°C; the lower molding surface of the mold is distributed with concave and convex surfaces, and the upper molding surface of the mold is also distributed with concave surfaces. The invention has the advantages that: the production energy consumption is reduced, the production cost is saved; the molding precision is high; Formed to meet the modeling requirements of the seat cushion, the concave-convex surface is complete, the transition is smooth, and the production effect is good.

Owner:宁波甬宁户外用品有限公司

A 90-degree forming machine on an automatic forming production line

ActiveCN104001827BGuaranteed production efficiencyPrecise positioningMetal-working feeding devicesPositioning devicesProduction lineMolding machine

The invention discloses a novel 90-degree forming machine for an automatic forming production line. The novel 90-degree forming machine comprises a die set, a pressing device and a die pushing device. The die pushing device comprises a first die pushing plate and a second die pushing plate, the first die pushing plate and the second die pushing plate are fixedly connected with the inner side wall of the die set through linear guide rails, flanges and die pushing cylinders, and lower portions of the two die pushing plates are fixed onto the linear guide rails in 45-degree arrangement respectively. A gap allowing a feeding manipulator to pass through is reserved between the first die pushing plate and the second die pushing plate when the two die pushing plates returns in situ to guarantee that the feeding manipulator can pass through the forming machine, and accordingly production efficiency and machining precision in forming of embossed aluminum plates of refrigerator liners are improved.

Owner:ANHUI KECHANG MACHINERY MFG

Manufacturing method of foldable cushion

ActiveCN112519381ANot easily deformed by heatHigh molding precisionLamination ancillary operationsLaminationForming faceSoftening

The invention discloses a manufacturing method of a foldable cushion. The manufacturing method comprises the following steps: preparing a composite sheet body; and putting the composite sheet body inan oven for baking and softening, and placing the softened composite sheet body in a mold for pressing molding, wherein the mold is a cold pressing mold, and before the composite sheet body is placedin the mold to be pressed, the temperature of the lower forming face and the temperature of the upper forming face of the mold are reduced to be smaller than 50 DEG C, a concave-convex surface is distributed on the lower forming surface of the mold, and a concave surface is also distributed on the upper forming surface of the mold. The method has the advantages that the production energy consumption is reduced, the manufacturing cost is saved, and the molding precision is high; the molded cushion is convenient to take out and the mold is convenient to clean; and the steps for manufacturing thecushion are few, the process is simple, one-time forming of the upper and lower concave-convex surfaces of the concave-convex surface cushion is achieved, the modeling requirement of the cushion is met, the concave-convex surfaces are complete, transition is smooth, and the manufacturing effect is good.

Owner:宁波甬宁户外用品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com