Automatic production equipment of round head pin

A technology for automatic production and ball head pins, which is applied to turning equipment, turning equipment, metal processing equipment, etc., can solve the problems of low automation of round head pin turning, achieve easy control, ingenious equipment design, and reduce equipment costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The invention provides an automatic production equipment for round head pins. The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings to make it easier to understand and grasp.

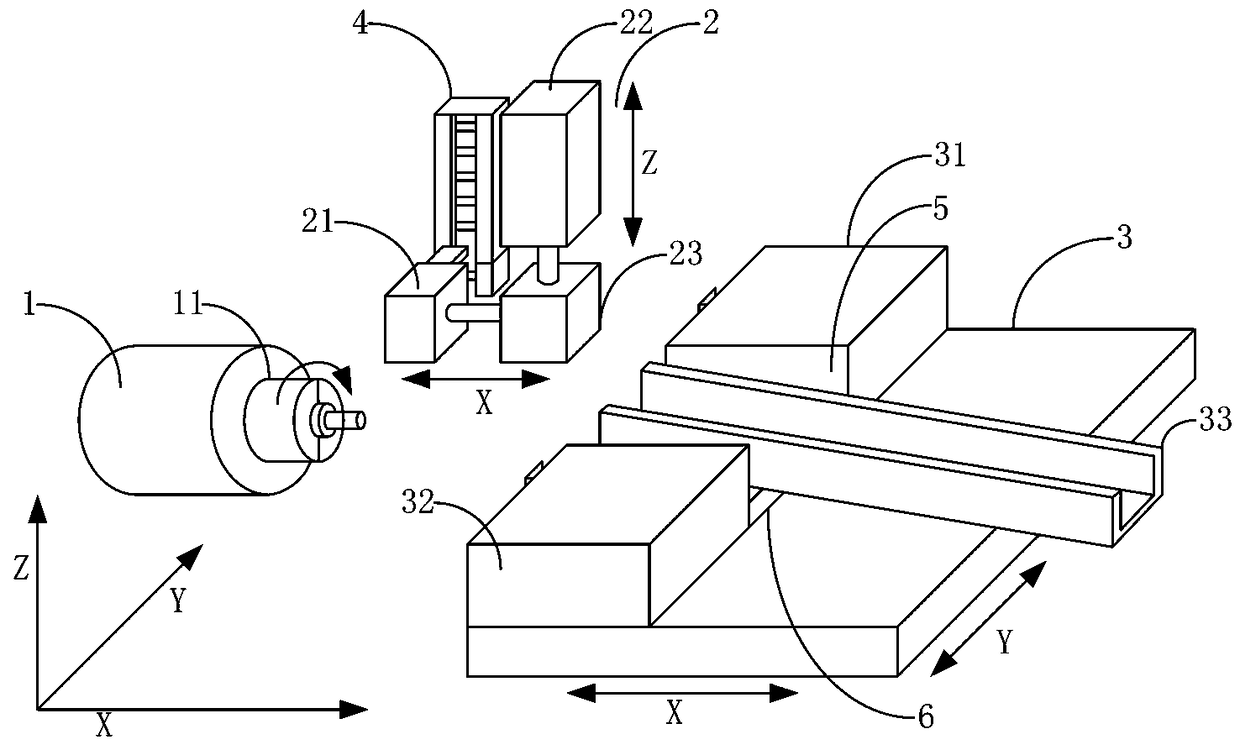

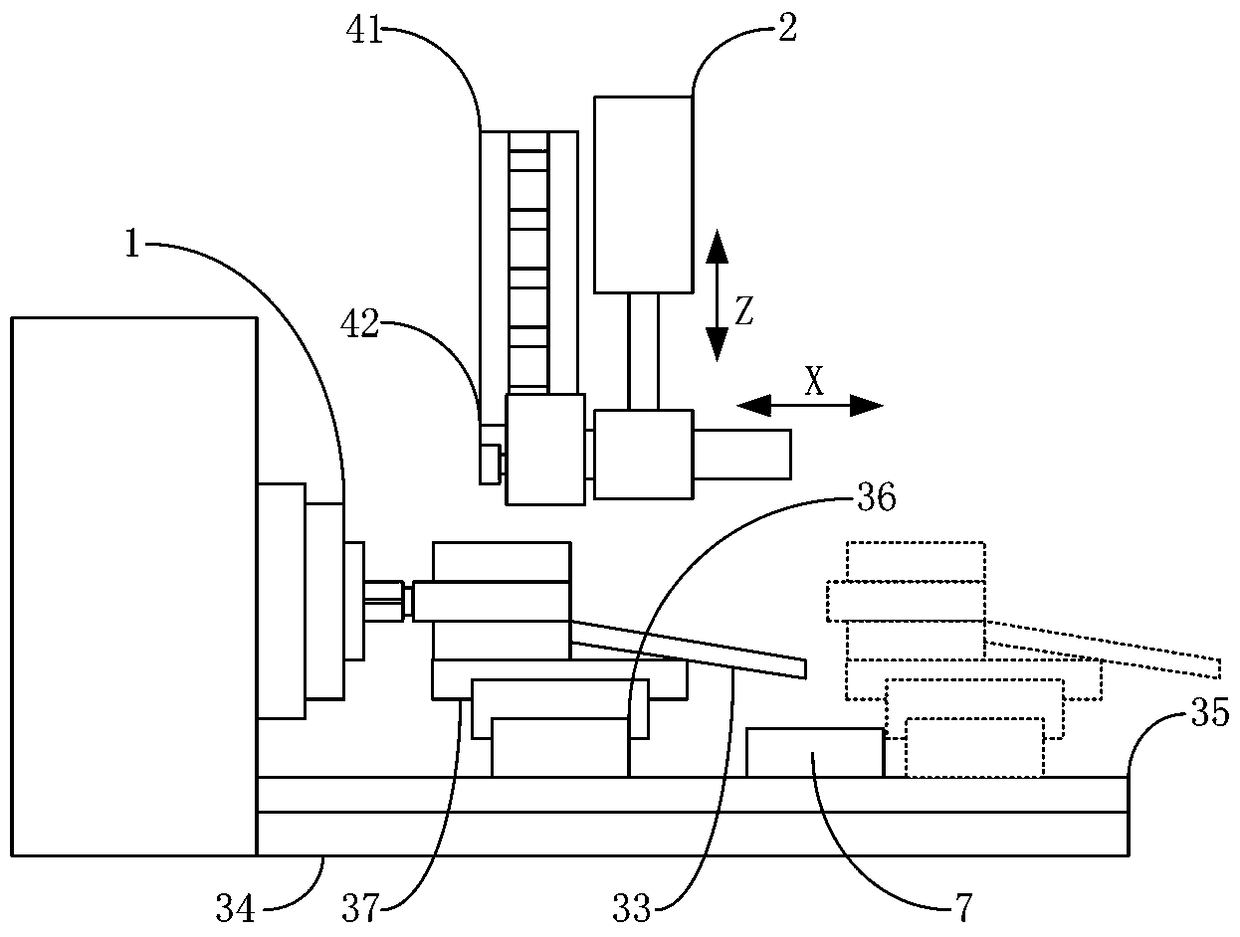

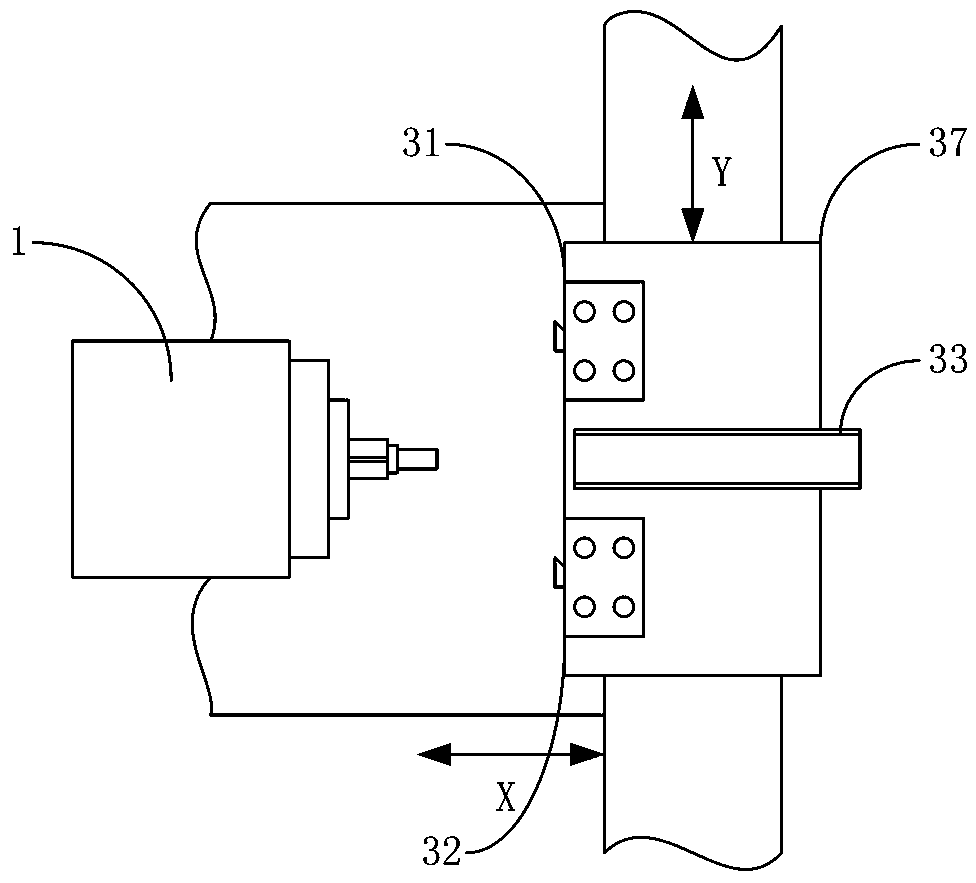

[0035] An automatic production equipment for round head pins, such as Figure 1 to Figure 5 As shown, it includes a fixed rotating unit 1, an automatic feeding unit 2 and a turning unit 3.

[0036] Among them, the fixed rotating unit 1 is used to fix the round head pin and perform rotational displacement. The round head pin is not a round pin after forming, but is the embryo body before forming. The rotating end of the fixed rotating unit 1 is provided with clamping or loosening Remove the fixed end of the fixed round head pin, and the axial direction of the fixed round head pin is the X axis.

[0037] The automatic feeding unit 2 is used to grab the fixed round pin and load it into the fixed end 11 of the fixed rotating unit 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com