How to make a folding seat cushion

A manufacturing method and cushion technology, applied in chemical instruments and methods, lamination auxiliary operations, lamination, etc., can solve the problems of high energy consumption, high production cost, low efficiency, etc., achieve high mold making precision and save production cost , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

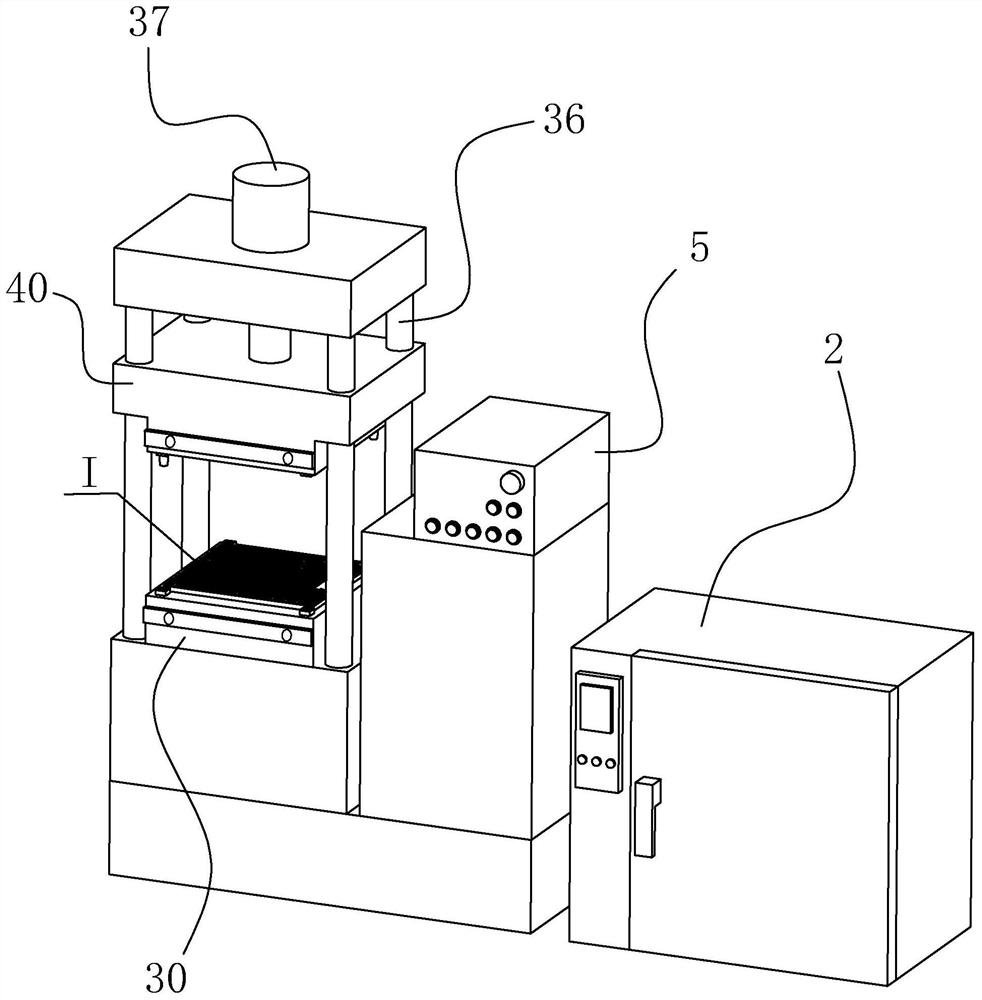

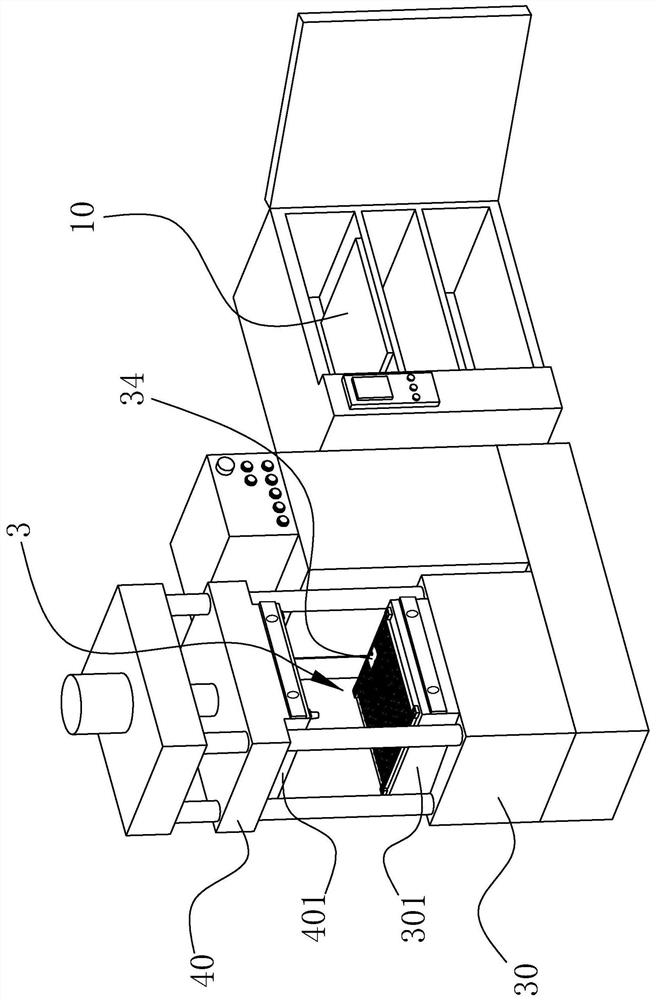

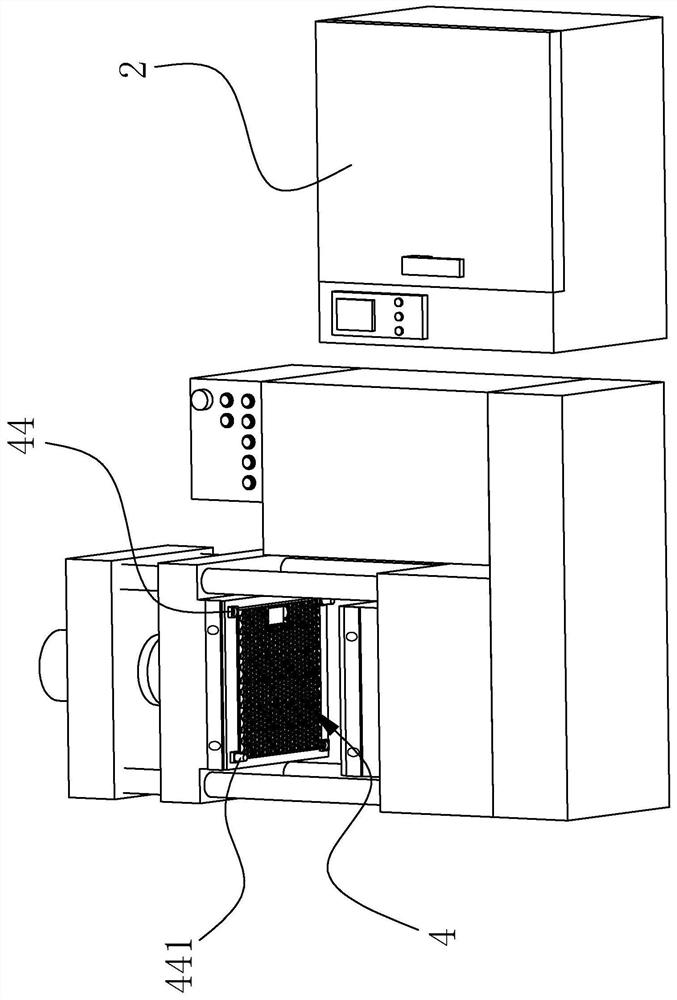

[0032] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

[0033] like Figure 1 to Figure 10 As shown, the manufacturing method of the folding seat cushion of this embodiment includes the following steps:

[0034] 1. Compound the surface layer film on the surface of the foamed substrate to obtain the composite sheet body 10 to be molded;

[0035] 2. Place the composite sheet 10 in a mold and press to form, to obtain the desired concave-convex surface cushion 1;

[0036] Before step 2, the composite sheet 10 is placed in the oven 2 to be baked and softened, and then the softened composite sheet 10 is placed in a mold for compression molding. Before pressing the body 10, the temperature of the lower molding surface 3 and the upper molding surface 4 of the mold is lowered to less than 50°C; the lower molding surface 3 of the mold is distributed with grid-like regularly arranged arc concave parts 31. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com