Patents

Literature

36results about How to "Not easily deformed by heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

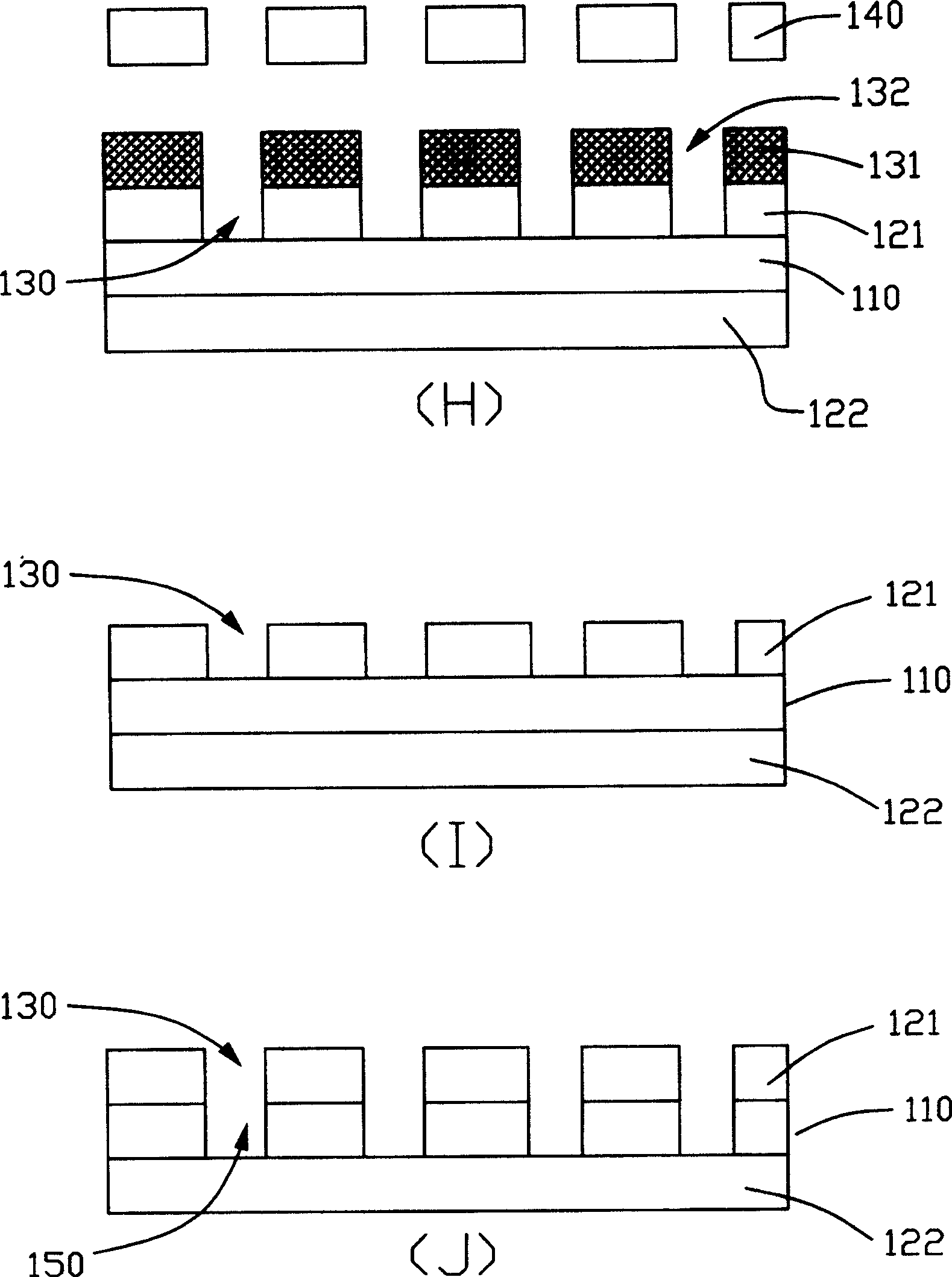

Wood plastic composite material cladding plywood formwork and manufacturing method thereof

ActiveCN103758340AReduced flatness errorGood dimensional stabilityFibre treatmentSynthetic resin layered productsPlastic filmToughness

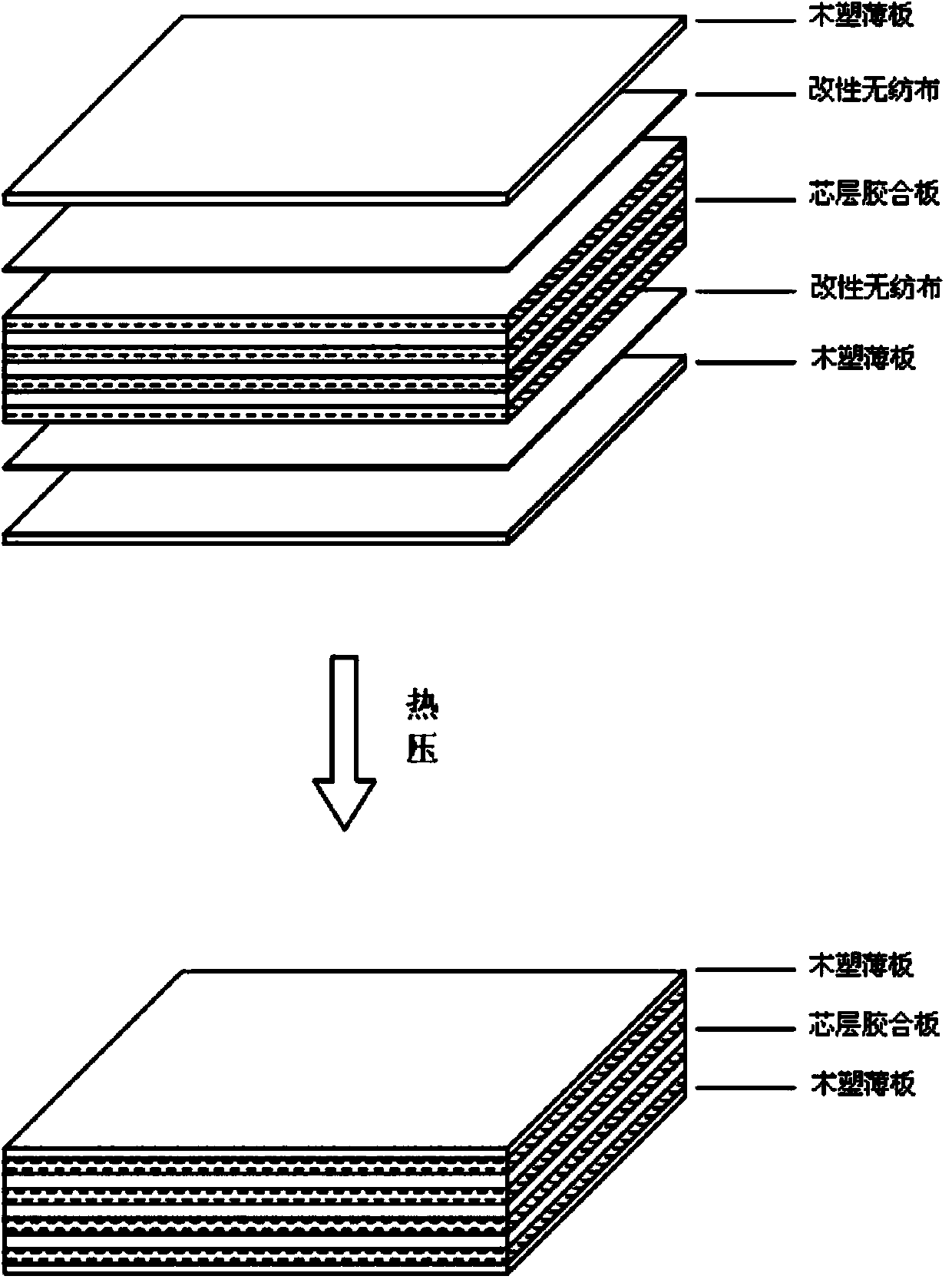

The invention relates to a plywood formwork and a manufacturing method of the plywood formwork, in particular to a wood plastic composite material cladding plywood formwork and a manufacturing method of the wood plastic composite material cladding plywood formwork. The wood plastic composite material cladding plywood formwork aims to solves the problems that a wood plywood formwork manufactured in the prior art is low in intensity and poor in durability. The wood plastic composite material cladding plywood formwork is formed by a wood plastic sheet, an improved non-woven fabric and core-layer plywood in a manufactured mode. The manufacturing method comprises the steps that the wood plastic sheet is manufactured; the non-woven fabric is improved; the core-layer plywood is manufactured; pavement is carried out; the formwork is formed. The wood plastic composite material cladding plywood formwork is low in manufacturing cost, high in intensity, good in toughness, long in service life, resistant to moisture and corrosion, stainless, bright, clean and flat in surface, light in weight, and convenient to transport and construct, a die does not swell easily, and the die is released easily. The wood plastic composite material cladding plywood formwork is used as a building formwork.

Owner:NORTHEAST FORESTRY UNIVERSITY

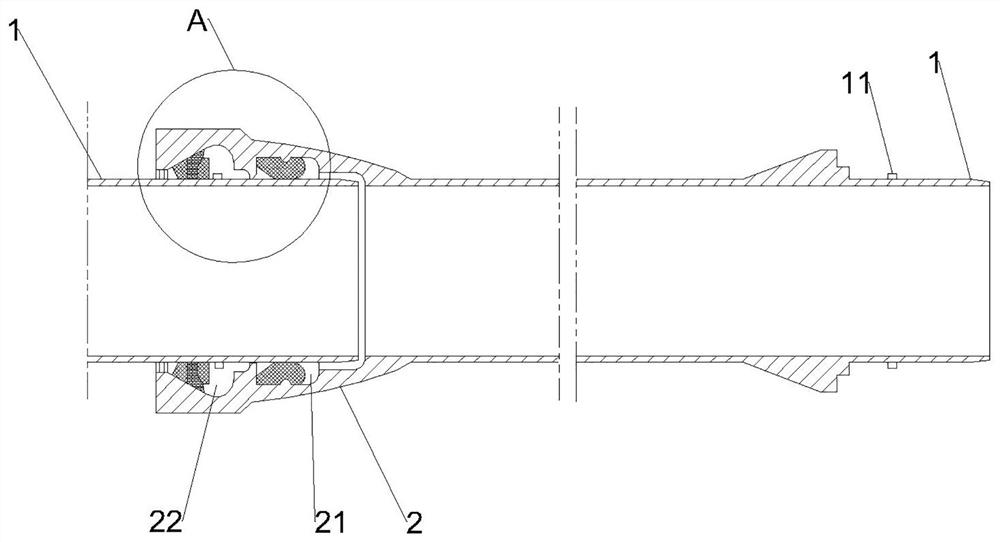

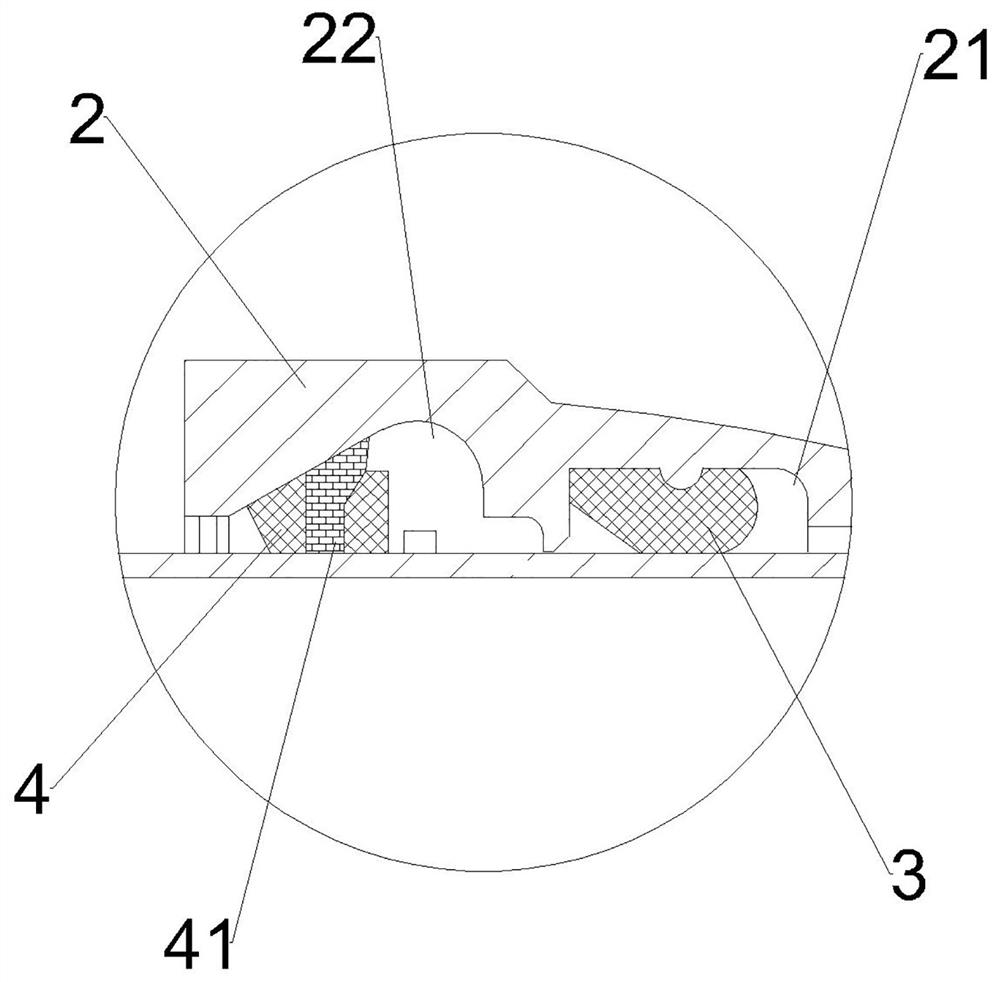

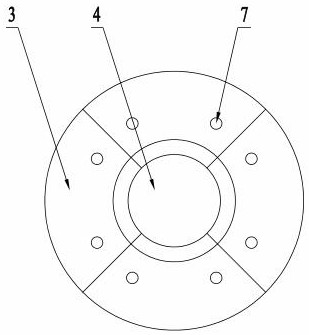

Congestion type busway jack tapping-off pile head

ActiveCN101436765AHigh dimensional accuracyMeet the connection requirementsSoldered/welded conductive connectionsBus-bar installationTransmission equipmentEmbedded system

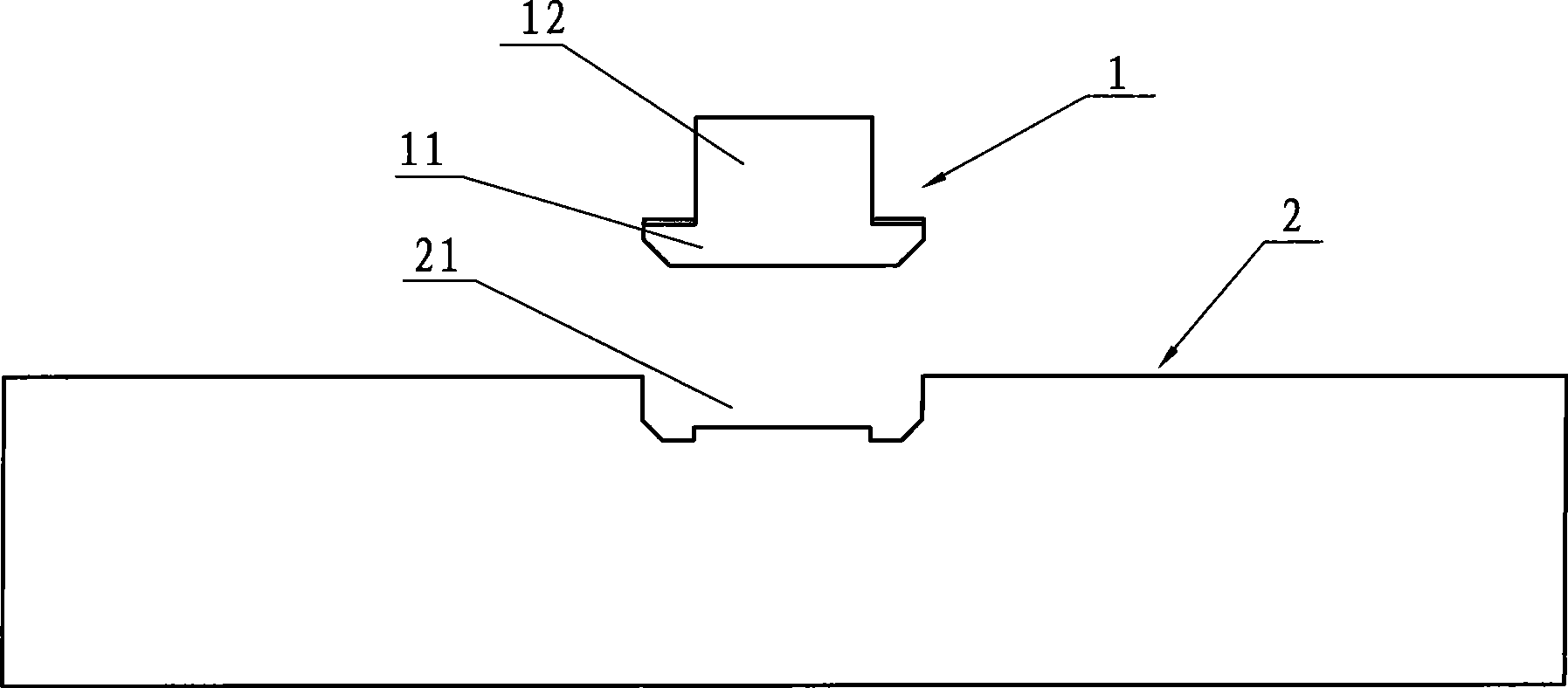

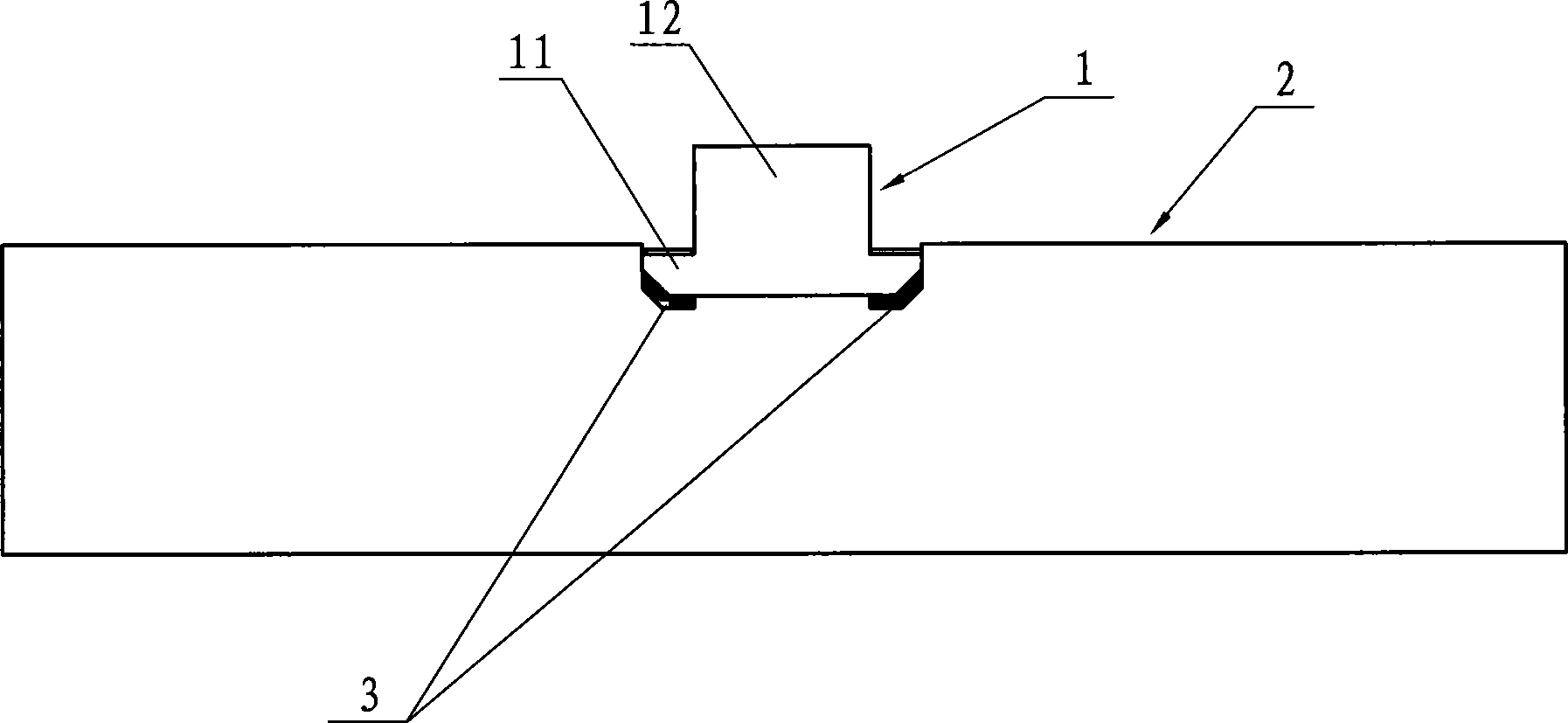

The invention relates to a transmission equipment accessory, in particular to a tapping pile head of a plug socket of an intensive bus duct for use in a tapping device of the intensive bus duct. The tapping pile head of the plug socket of the intensive bus duct comprises a pile head and a bus bar which are connected with each other. The edge of the bus bar is provided with a notch for the pile head to be embedded in. The pile head consists of a wider root part and a narrower body part and takes a reverse 'T'-shape on the whole. The root part of the pile head is embedded in the notch of the bus bar. A welded connection section is arranged between each of two sides of the root part of the pile head and the bus bar. The invention has the advantages of simple manufacturing process, good economical efficiency, insusceptibility to deformation and contribution to the improvement of the reliability of tapping contact.

Owner:WETOWN ELECTRIC GRP CO LTD

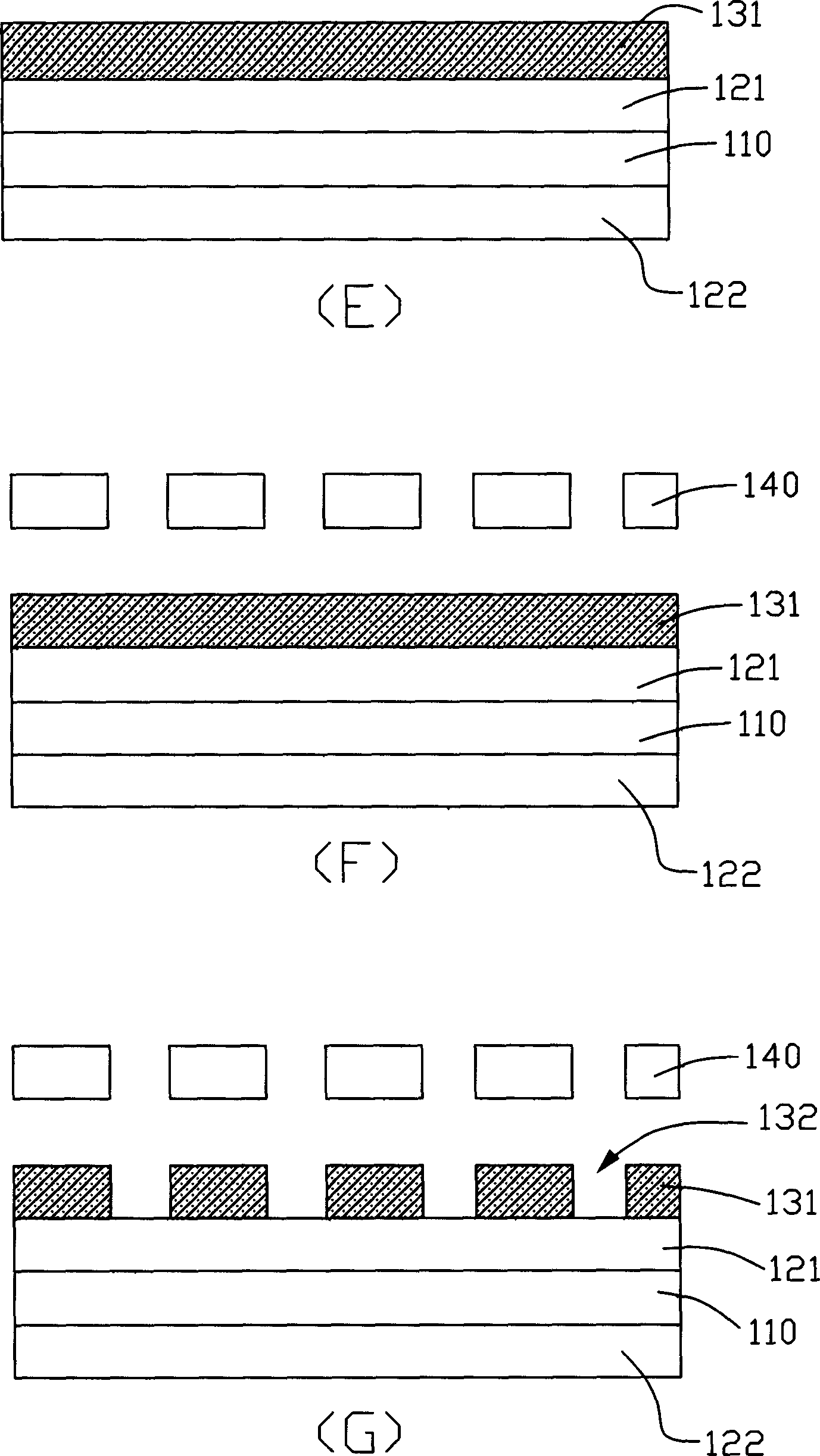

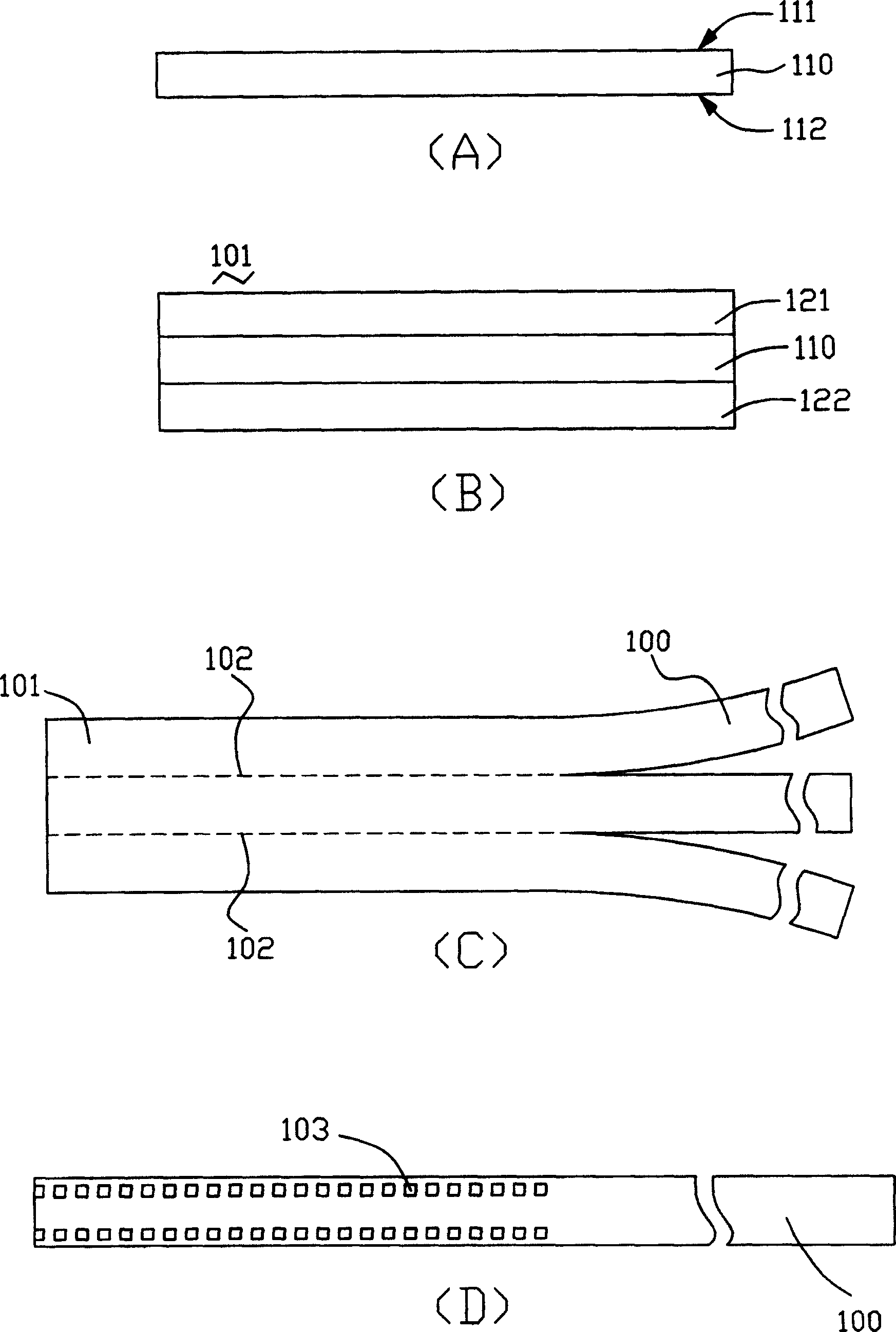

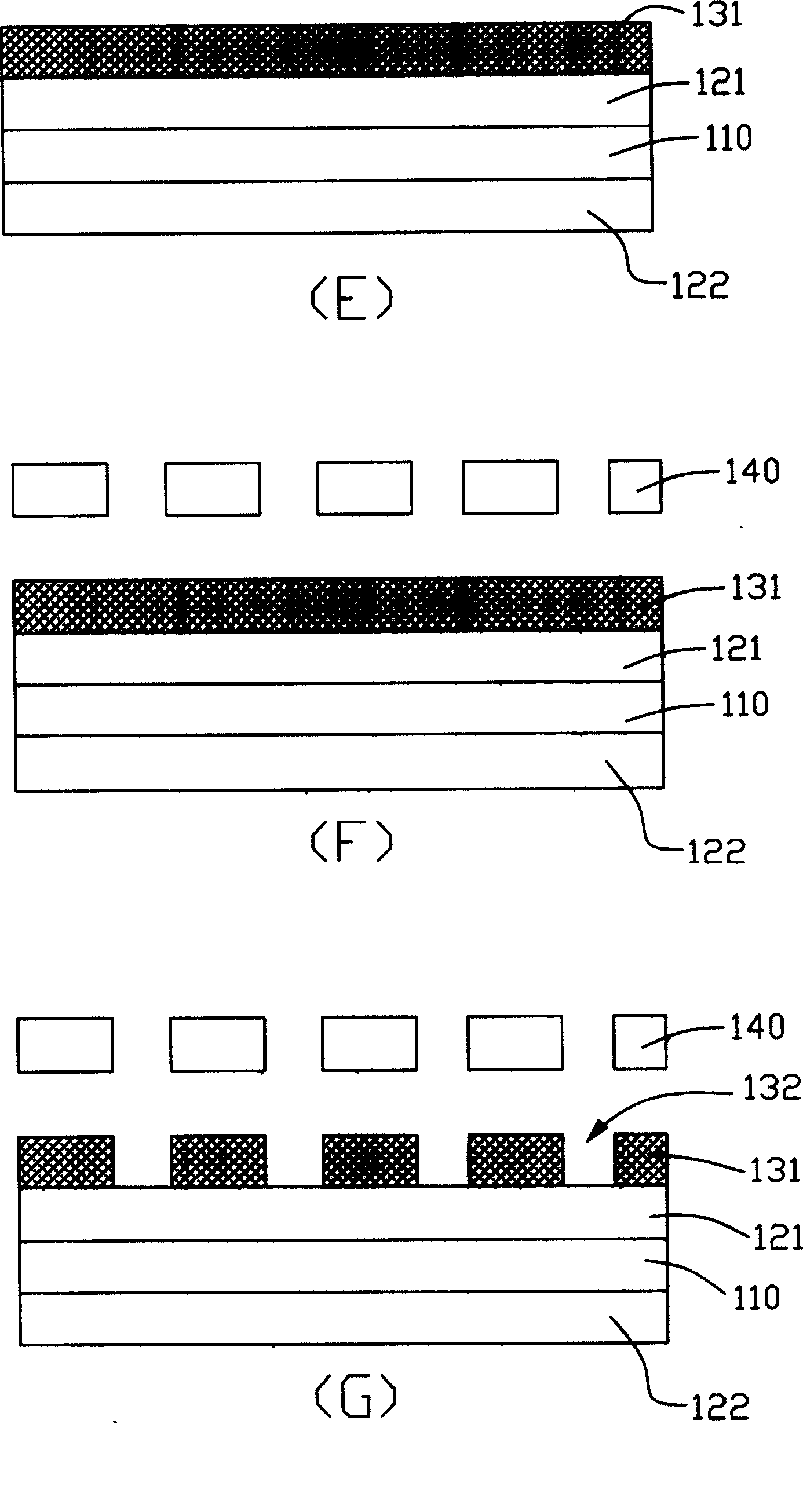

Method for manufacturing flexible circuit board

InactiveCN1937889AImprove rigidityImprove liquidityPrinted circuit aspectsInsulating layers/substrates workingFlexible circuitsCopper

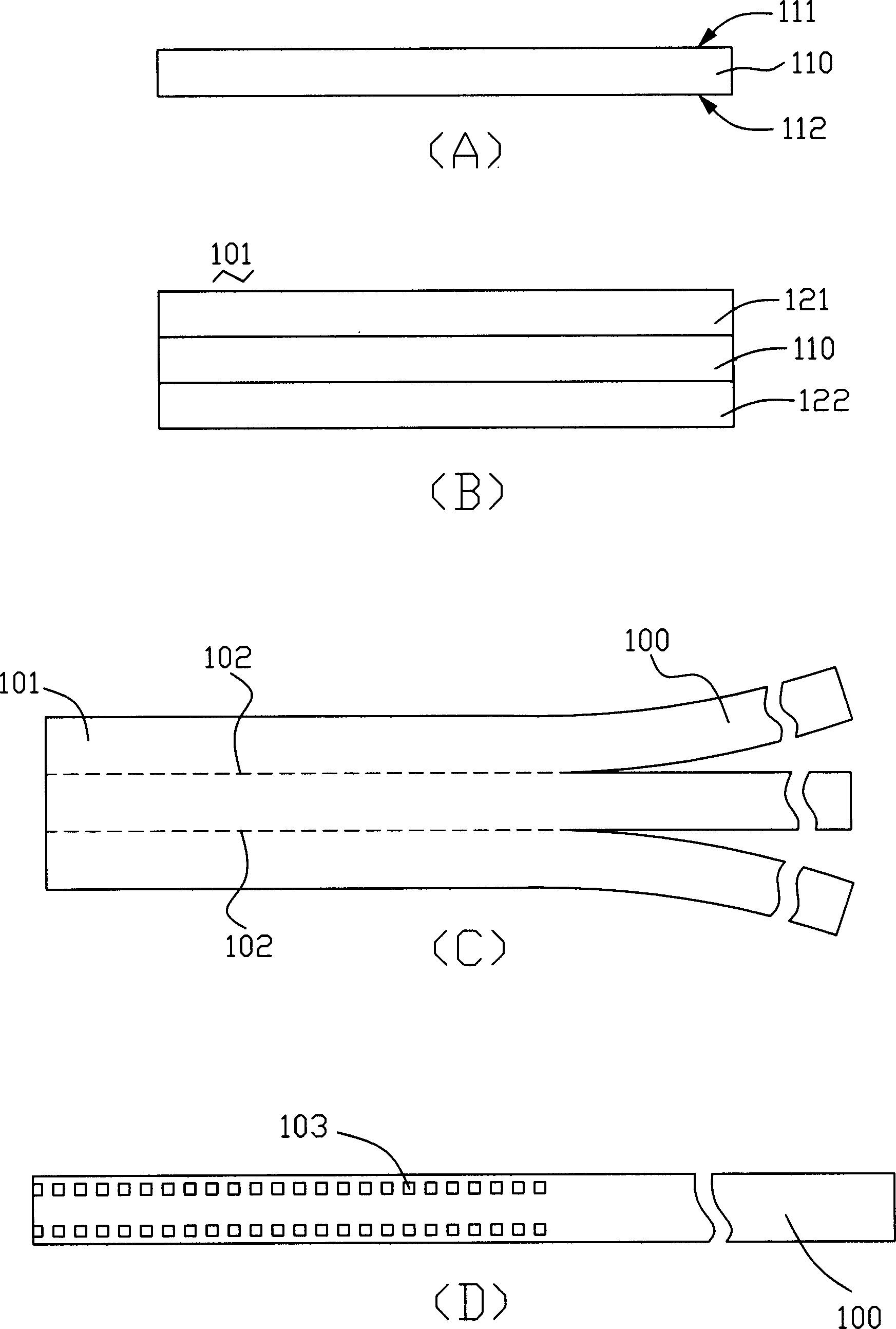

The invention supplies a kind of method of creating the flexible circuit board. The step is as follows. The treated component has the base on which there is at least one copper film. Multiple copper holes form on the copper film. The copper holes form by micro-image process that includes the step of coating photoresist layer. The photoresist material is liquid. The micro-image process also includes the steps of exposal, developing, etching and peeling film. The light cover in the step of exposal is vitric.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

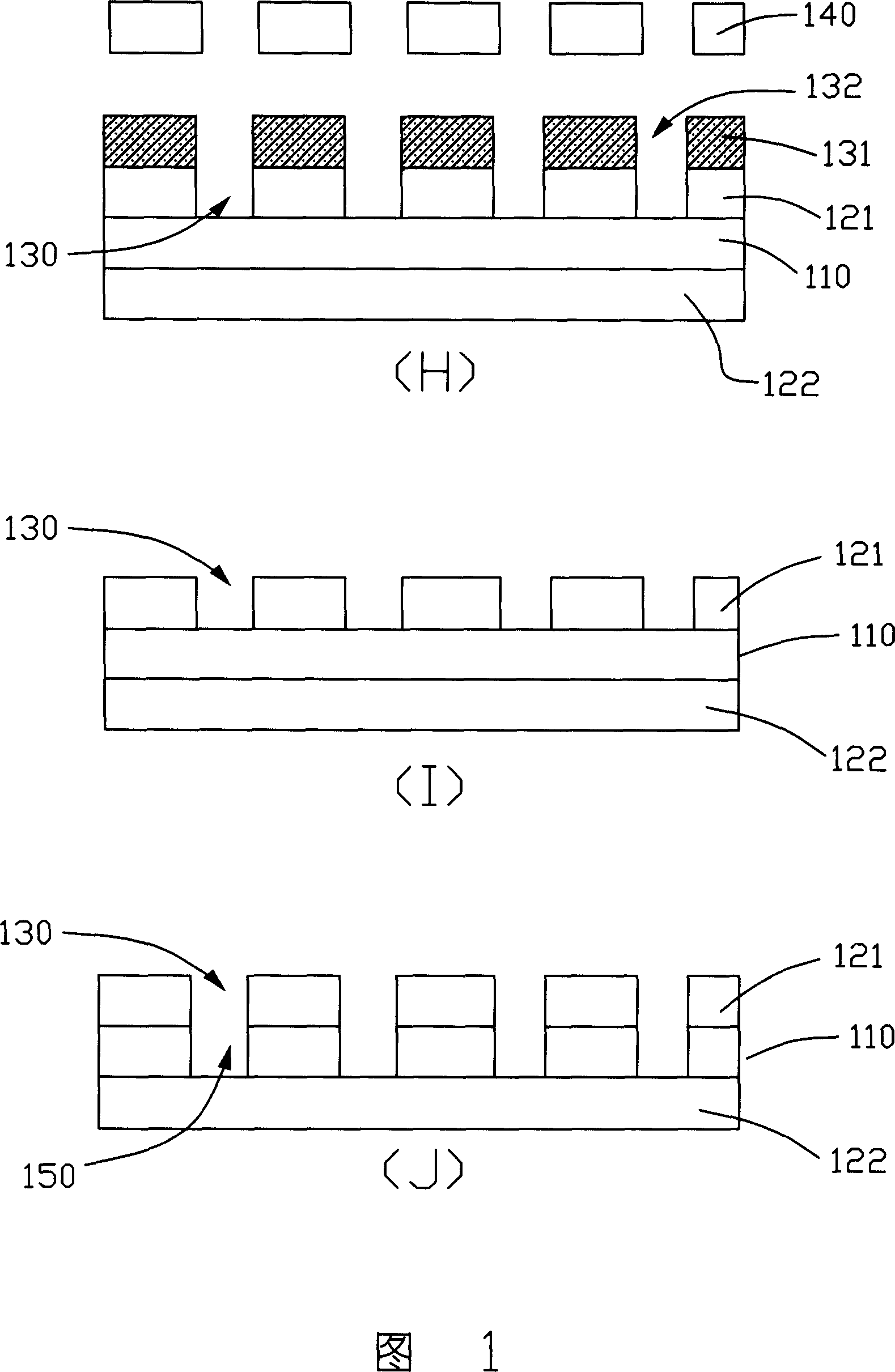

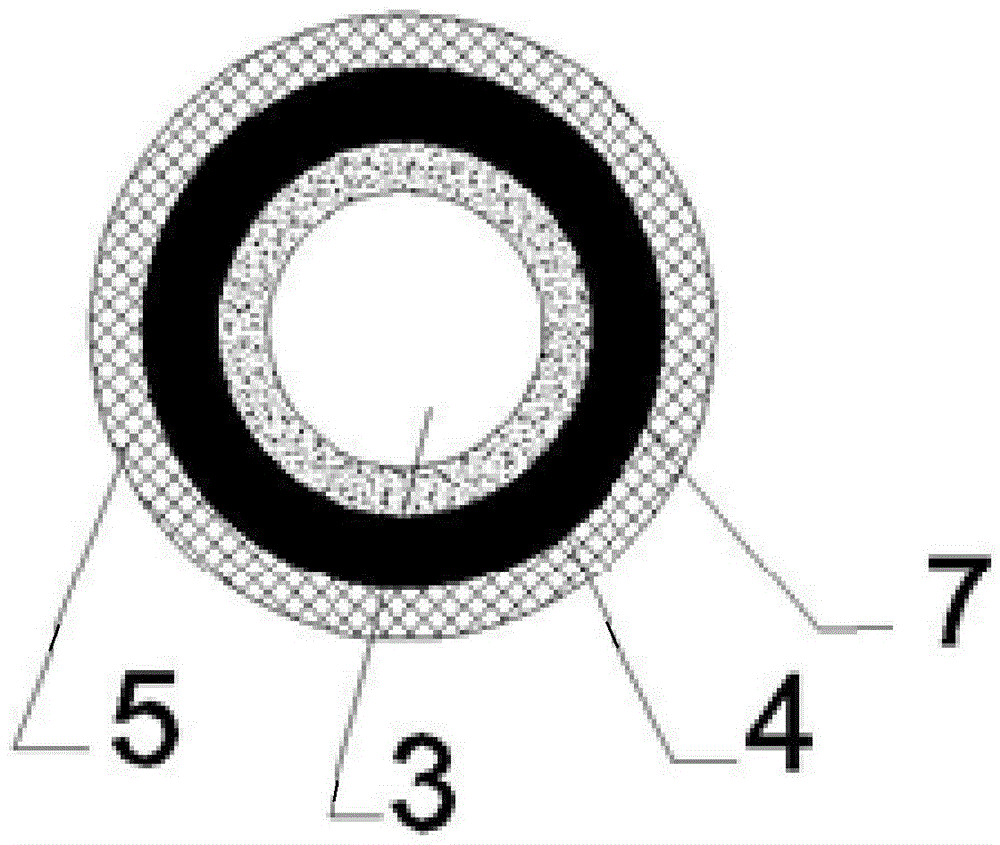

Metal hose

InactiveCN104964106AImprove wear resistanceNot easily deformed by heatFlexible pipesPipe protection against damage/wearEngineeringWear resistance

The invention discloses a metal hose. A hose body is provided with an inner pipe, a corrugated pipe and a metal net. The inner pipe is arranged inside the corrugated pipe. The metal net is arranged outside the corrugated pipe. The inner pipe is formed by sequentially lapping a plurality of manganese steel circular ring steel pipes. A heat resisting material is arranged between the corrugated pipe and the inner pipe. Connectors at the two ends of the metal pipe are in threaded connection. The connector with an inner thread and the connector with an outer thread are arranged at the two ends of the metal pipe respectively. Due to the fact that the metal net is located on the outermost layer of the hose, the abrasion resistance of the metal hose can become better during using. Meanwhile, the heat resisting material is arranged between the corrugated pipe and the inner pipe, so that the temperature distortion of the metal hose is not liable to happen due to the heat resisting material, using is facilitated, and the metal hose is safer.

Owner:江苏进源压力容器有限公司

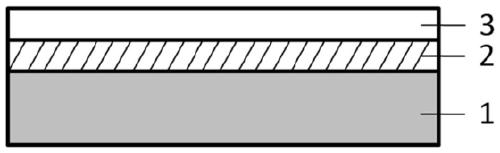

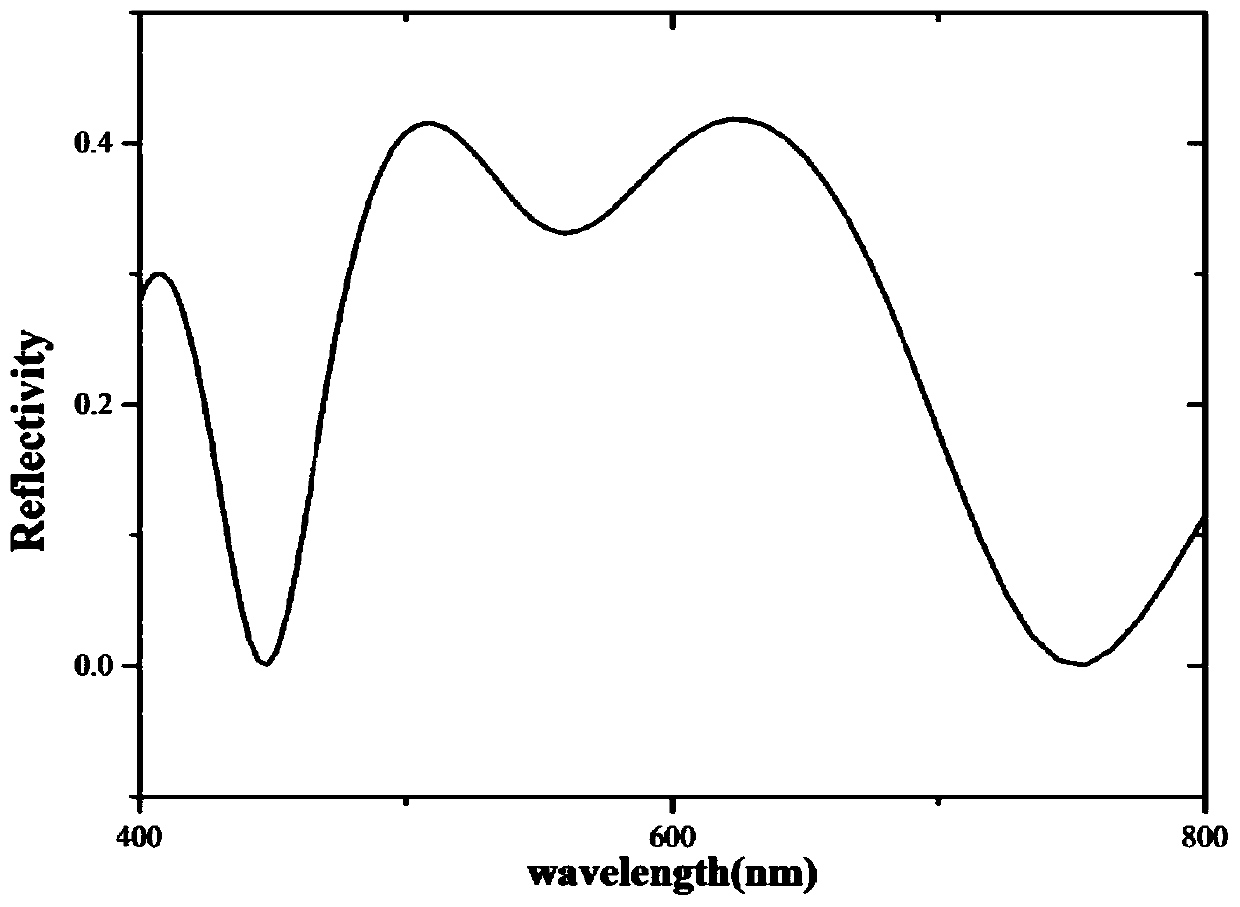

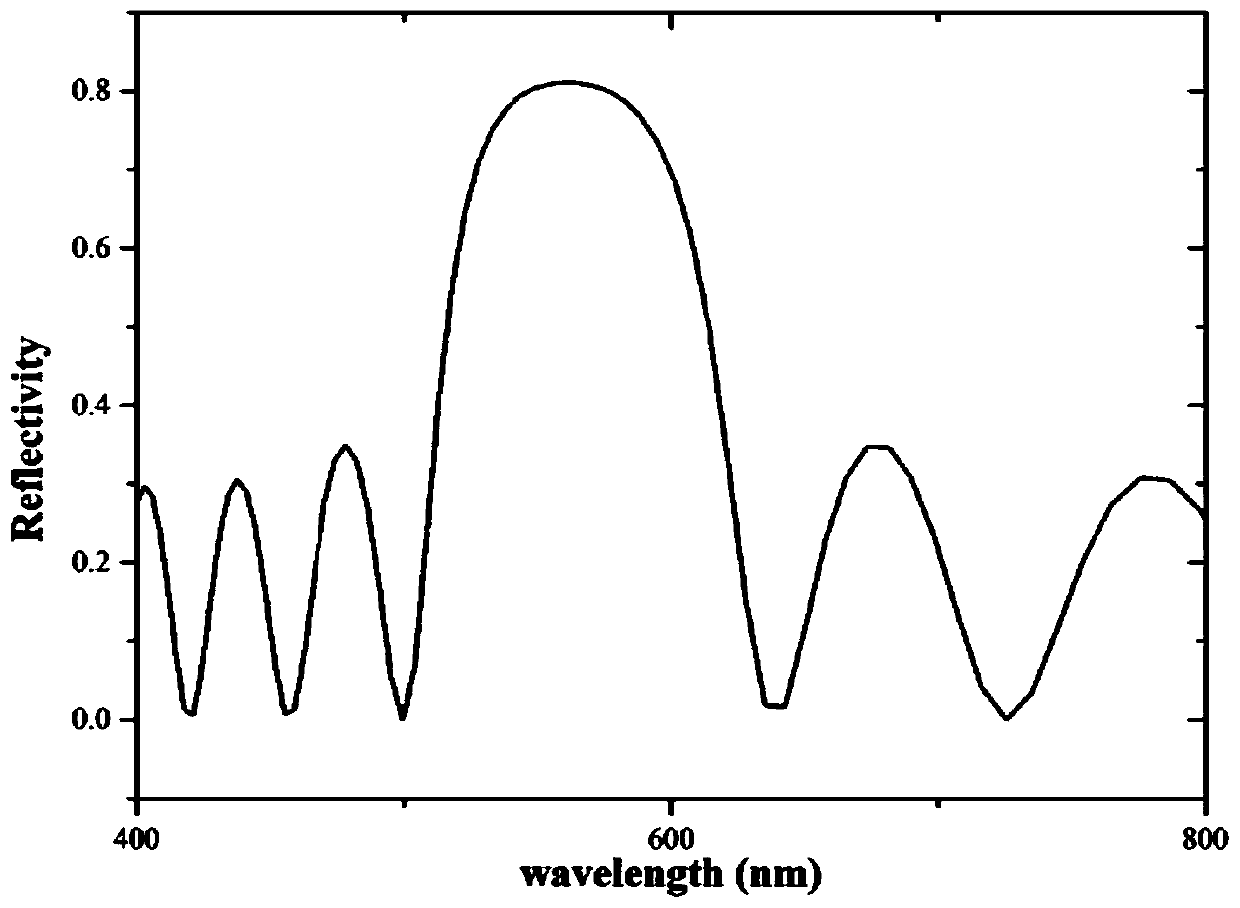

Bragg reflecting mirror based on BN(Al) film, and preparation method

ActiveCN110221369AEffective reflectionSimple processMirrorsVacuum evaporation coatingSputteringRefractive index

The invention provides a Bragg reflecting mirror based on a BN(Al) film, and a preparation method. The Bragg reflecting mirror comprises a substrate, wherein the surface of the substrate is provided with S pieces of film periodic structures, S is an integer and is greater than or equal to 1, and the film periodic structures comprise a BN low-refractive-index layer and a BAlN high-refractive-indexlayer arranged on the BN low-refractive-index layer. The preparation method for the Bragg reflecting mirror comprises the following steps that: (1) heating a clean substrate in a cavity; (2) only starting a BN target material power supply, and sputtering one layer of BN film on the surface of the substrate; (3) keeping the power of the BN target material power supply to be constant, starting an Altarget material power supply, and sputtering one layer of BAlN film; and (4) when S is greater than 1, repeating S(2) and S(3) to realize the preparation of the Bragg reflecting mirror with a plurality of thin film periodic structures. The preparation method is simple, thin film flatness is high, the Bragg reflecting mirror with the plurality of thin film periodic structures can be prepared, andlarge-area industrialized preparation can be realized.

Owner:XI AN JIAOTONG UNIV

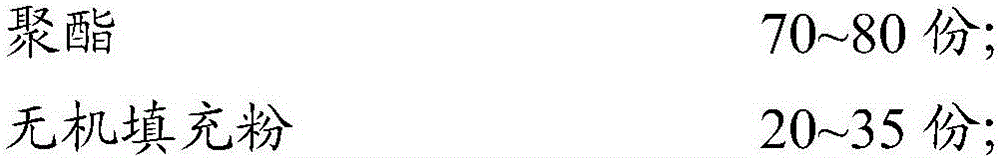

Fiber reinforced flame-retardant plastic and preparation method thereof

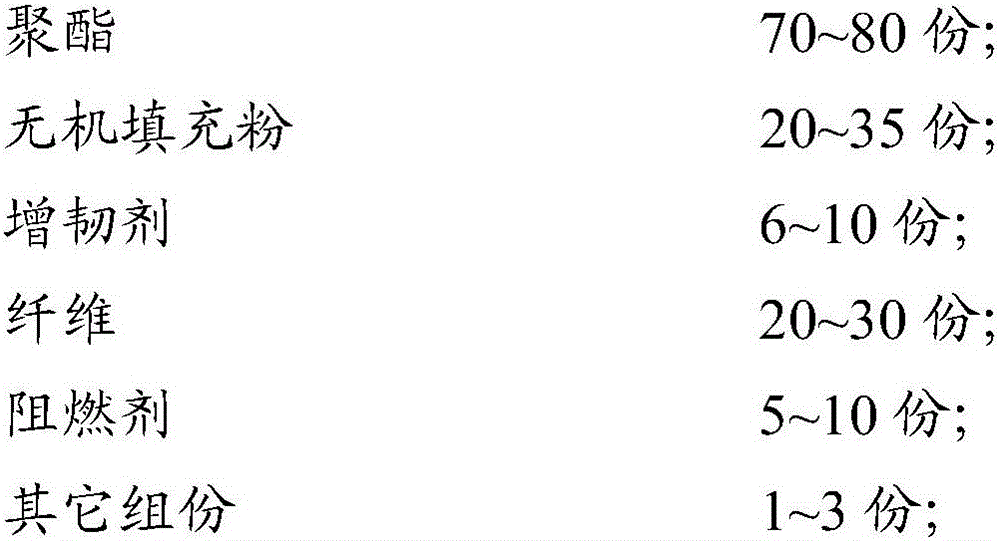

The embodiments of the invention disclose a fiber reinforced flame-retardant plastic and a preparation method thereof. The fiber reinforced flame-retardant plastic is used for solving the problems that the charging pile socket material in the prior art declines too fast on outdoor using performance, is insufficient in flame retarding, weak in impact resistance, easy to deform in long-time use, and the like. The fiber reinforced flame-retardant plastic comprises the following components in parts by weight: 70-80 parts of polyester, 20-35 parts of inorganic filling powder, 6-10 parts of flexibilizer, 20-30 parts of fibers, 5-10 parts of flame retardant and 1-5 parts of other components, wherein the other components comprise one or more of antioxidant, lubricant, coupling agent and anti-UV agent. The fiber reinforced flame-retardant plastic is safe, reliable, high-temperature resistant, stable in thermal deformation size and convenient to process, and can be used outdoors for a long term.

Owner:GUANGDONG GREAT MATERIAL CO LTD

Reinforced short fiber master batch for rubber transmission belt and preparation method

The invention relates to the technical field of a functional fiber master batch and a preparation method thereof, in particular to a reinforced short fiber master batch for a rubber transmission beltand a preparation method. The master batch is prepared from modified aramid short fibers, a polyolefin elastomer, rubber, a coupling agent, aromatic oil, a reinforced modified filling agent, a plasticizer and an antiager. The preparation method comprises the steps that the aramid short fibers are soaked in a metal hydroxide solution and then soaked in a soluble silicate solution, through repeatedwetting, the aramid short fibers with the surfaces wrapped by hard silicate shell layers are formed, dispersed in the coupling agent and subjected to standing, then other raw materials are added for refining, a rubber material is prilled through a twin-screw extruder, and the reinforced short fiber master batch for the rubber transmission belt is obtained. According to the reinforced short fiber master batch, the problems of poor interface bonding and low heat resistance of the aramid short fibers and a rubber matrix during rubber reinforcement in the prior art are solved, and the reinforced short fiber master batch has the advantages of being even in dispersion, high in bonding force, tensile strength and bonding strength and long in service life.

Owner:陇川县百信胶带有限公司

Manufacturing process of double-mouthing nodular cast iron pipe

The invention discloses a manufacturing process of a double-mouthing nodular cast iron pipe. The process includes the steps that (1) filling a dotted pouring die into a centrifugal pipe casting machine, and introducing cooling water into the outer wall of the pouring die for cooling; a manufactured sand mold core is installed on a cast steel core frame, and the cast steel core frame is installed at the mouthing end of a pouring mold; (2) spheroidizing and slagging off molten iron, and pouring the molten iron into a sector pouring ladle of the centrifugal pipe casting machine for pouring; (3) starting a pipe drawing system of the centrifugal tube casting machine, and pouring molten iron into the inner wall of the pouring mold to start pipe drawing; (4) pulling out the double-mouthing nodular cast iron pipe after drawing and molding, and annealing and removing the sand mold core; (5) a socket weld ring is welded to a socket; and (6) a sealing ring is arranged inside a sealing chamber ofa mouthing, and an anti-pulling-off ring is arranged inside an anti-pulling-off chamber. The adopted sand mold core is simple in manufacturing process, materials are not prone to deformation, the pipedrawing operation speed of the pipe drawing system of the centrifugal pipe casting machine is reasonably set, and the pipe casting quality is effectively guaranteed.

Owner:安钢集团永通球墨铸铁管有限责任公司

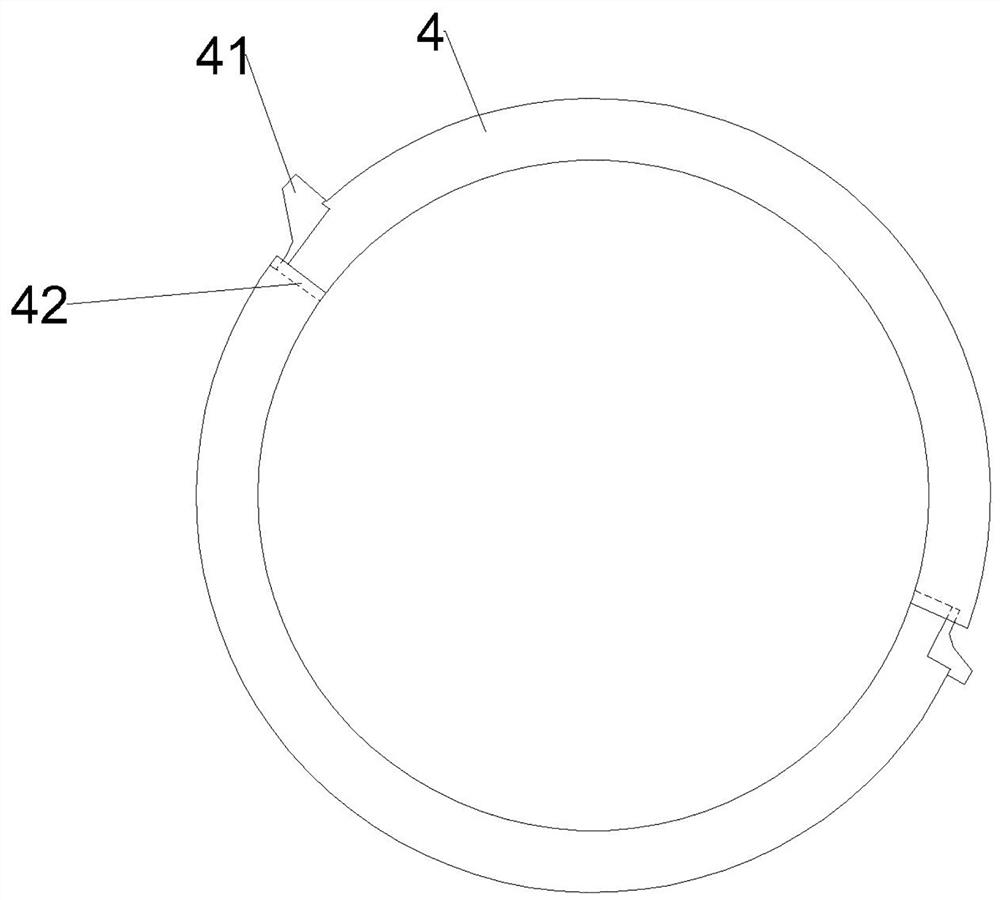

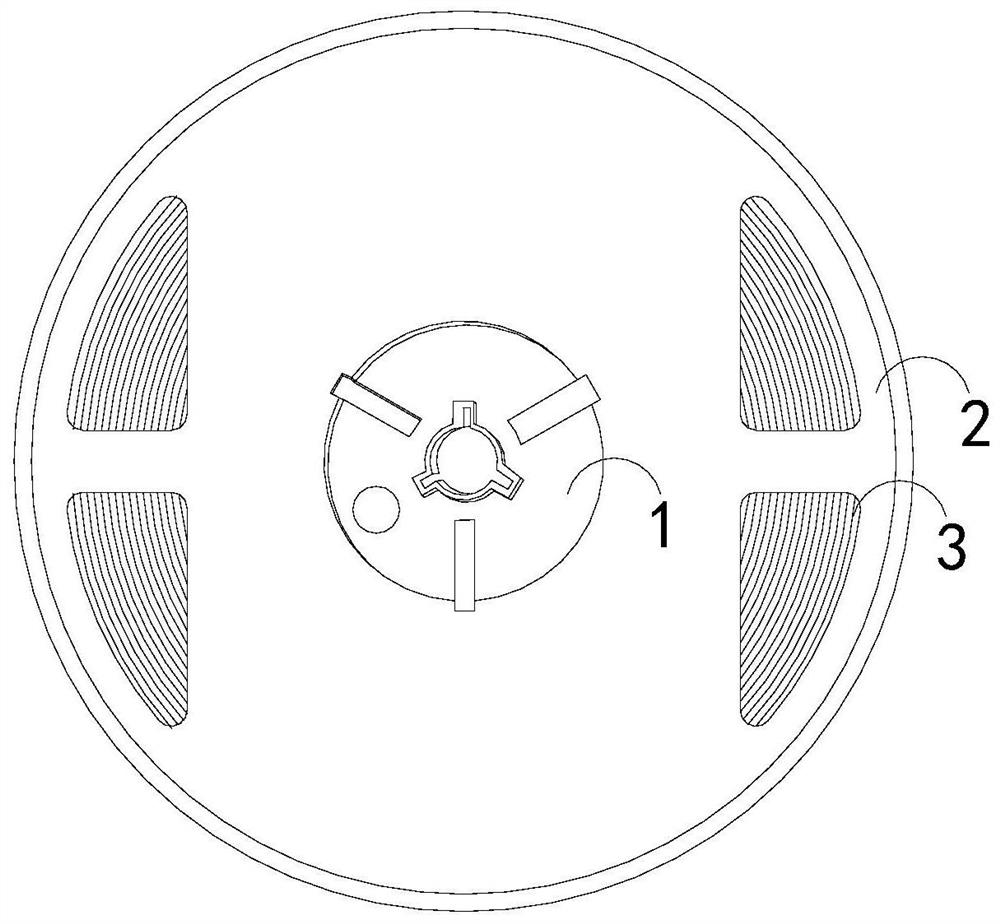

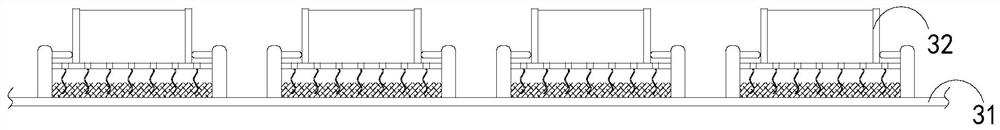

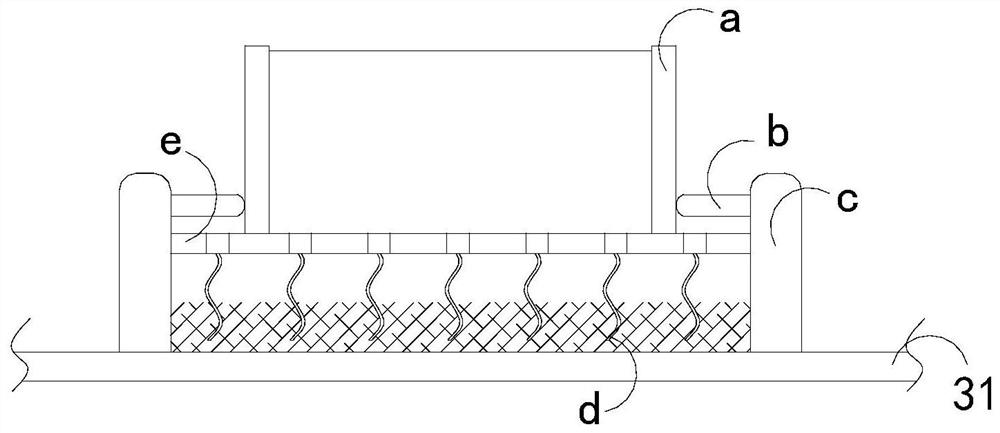

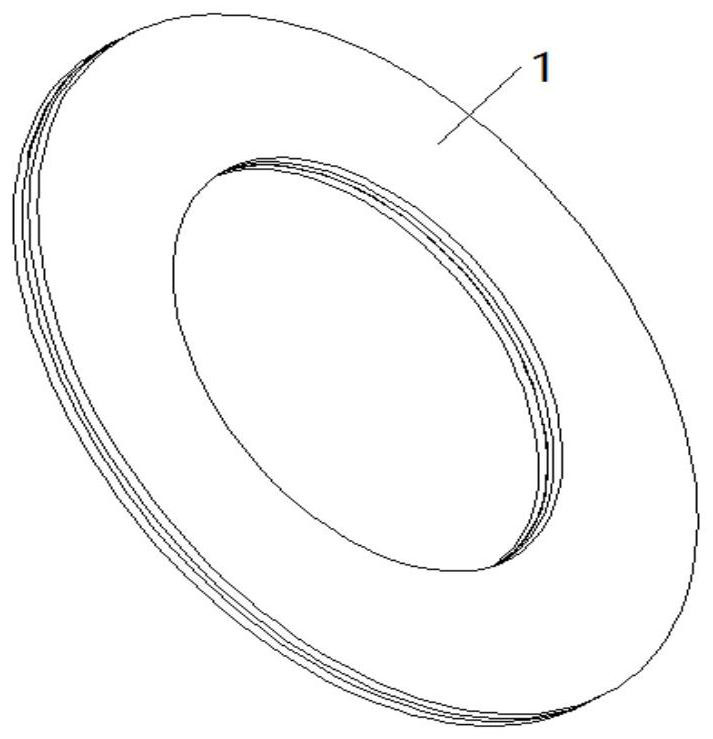

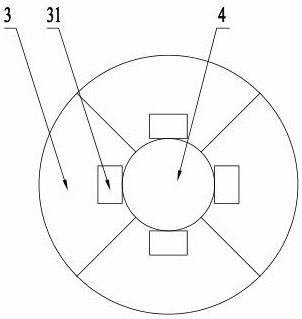

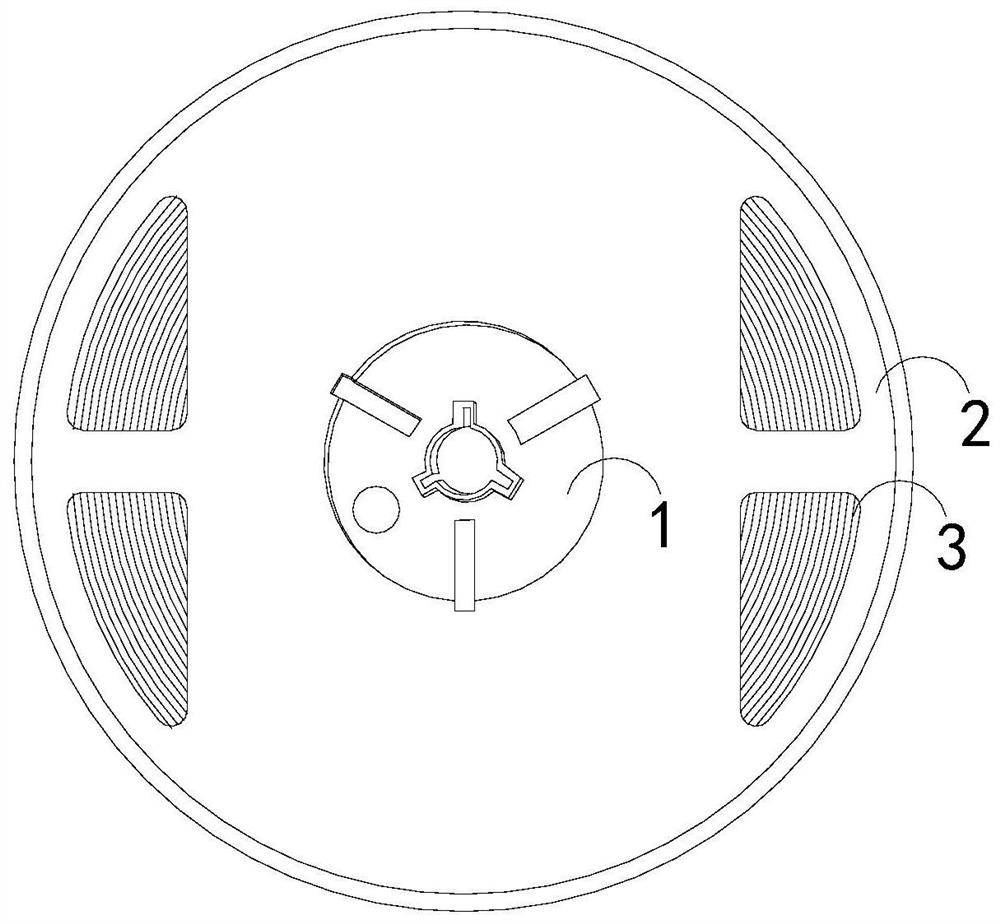

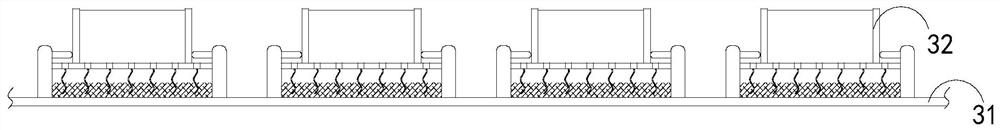

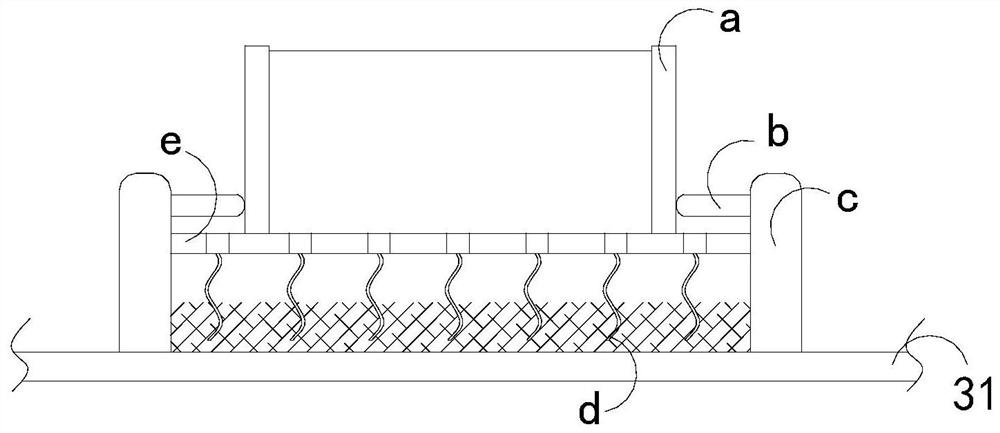

Anti-vibration capacitor and use method

InactiveCN112750620AImprove stabilityReduce resonance effectMultiple fixed capacitorsCapacitanceHeat resistance

The invention discloses an anti-vibration capacitor and a use method, the anti-vibration capacitor structurally comprises a mounting opening, a disc frame and roll strips, the mounting opening is formed in the center of the disc frame, more than two circles of roll strip are wound on the disc frame, each roll strip is composed of a PCB strip and more than two capacitor bodies, the capacitor bodies are linearly arranged on the PCB strip, the PCB strip is annularly and gradually wound on the disc frame, and the PCB strip is wound on the disc frame. Each capacitor body is provided with a capacitor, a top column, a supporting frame, an elastic strip and a placing disc, the influence of resonance on the capacitor is weakened mainly through the top columns and the elastic strips, the connection relation between the capacitor and the supporting frame is enhanced through the top columns, a base is installed to ensure that the capacitor does not horizontally shift, separation of the capacitor is completely avoided, and the problem of short circuit is solved. And the net-shaped plane structure formed by the triangular stabilizers is adopted, so that heat generated by operation can be dissipated more easily in the operation process of the capacitor, and the heat resistance is improved.

Owner:何俊建

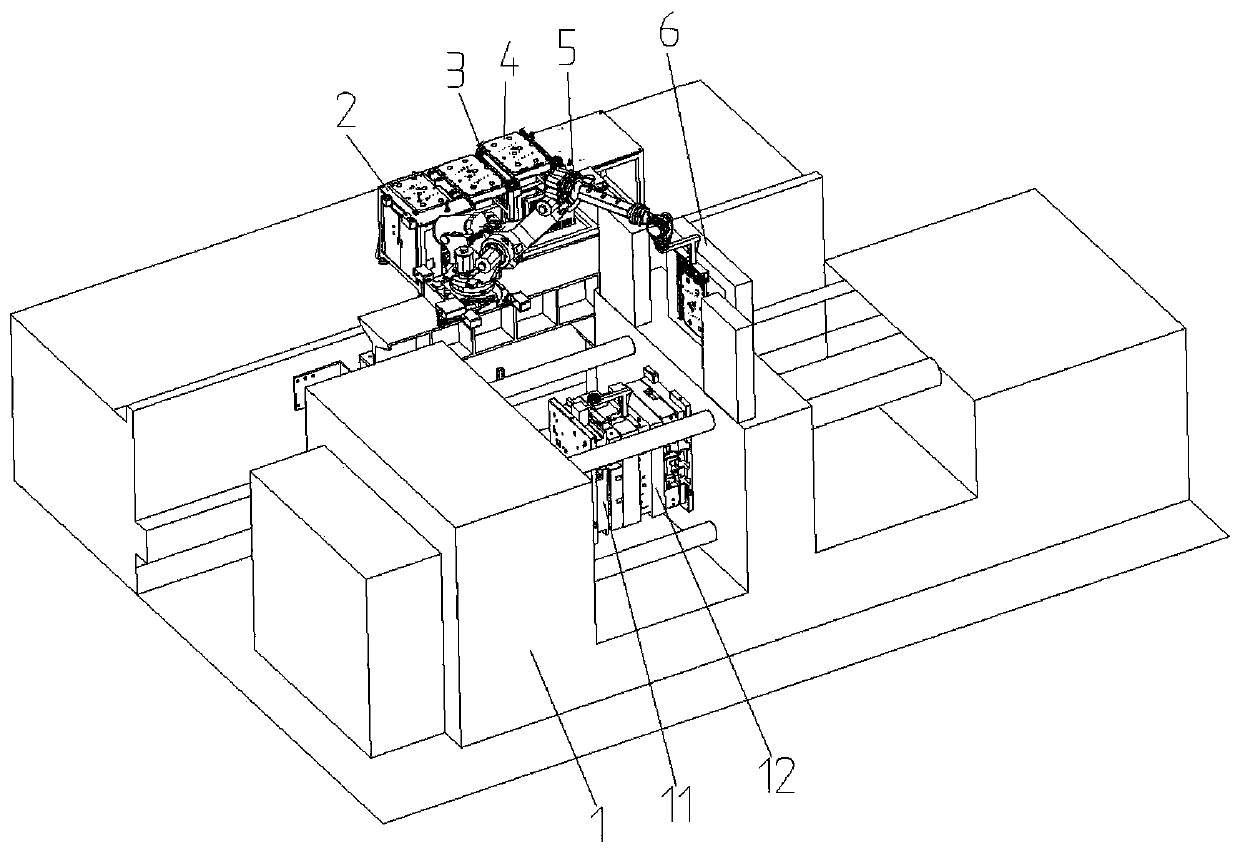

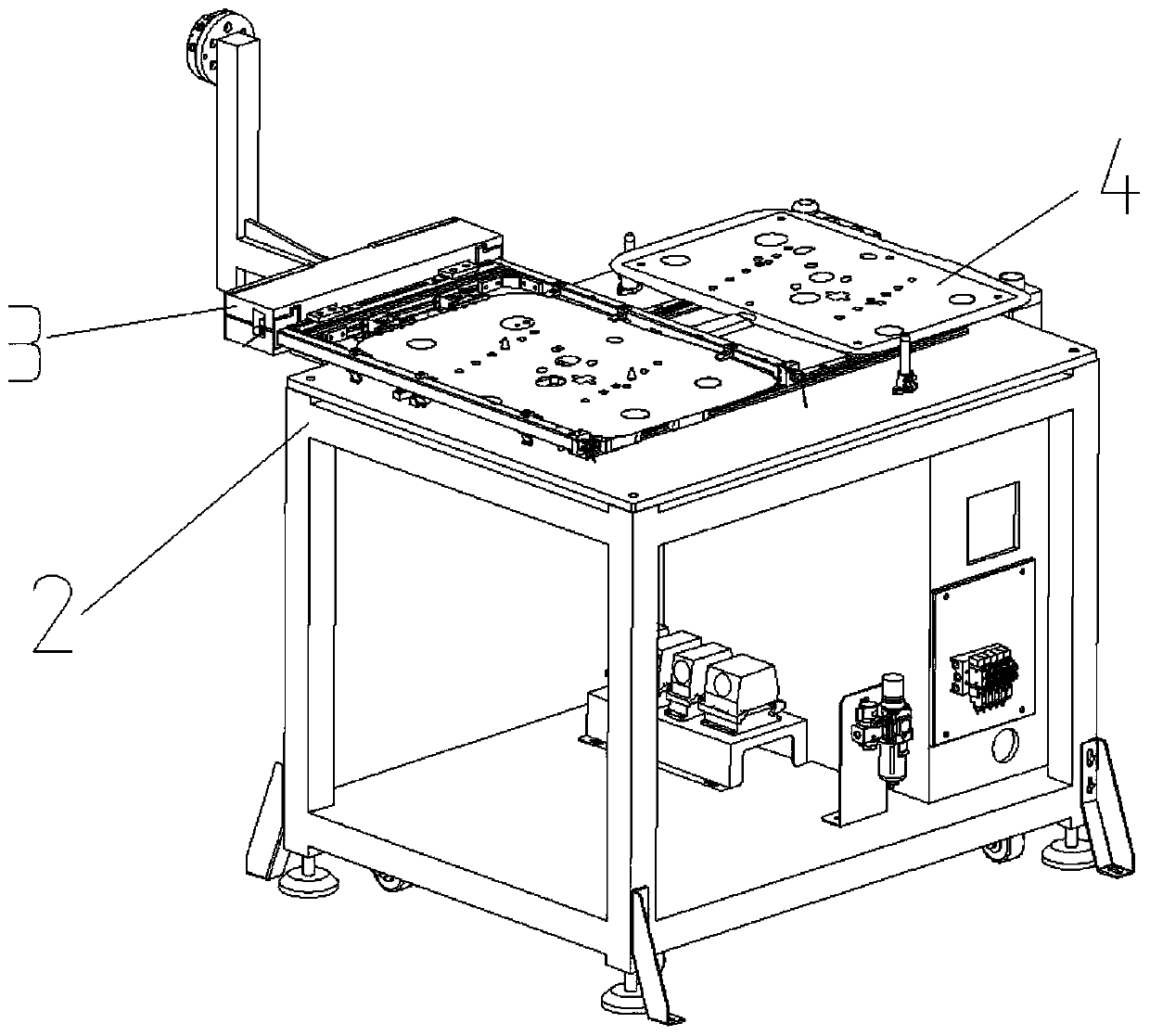

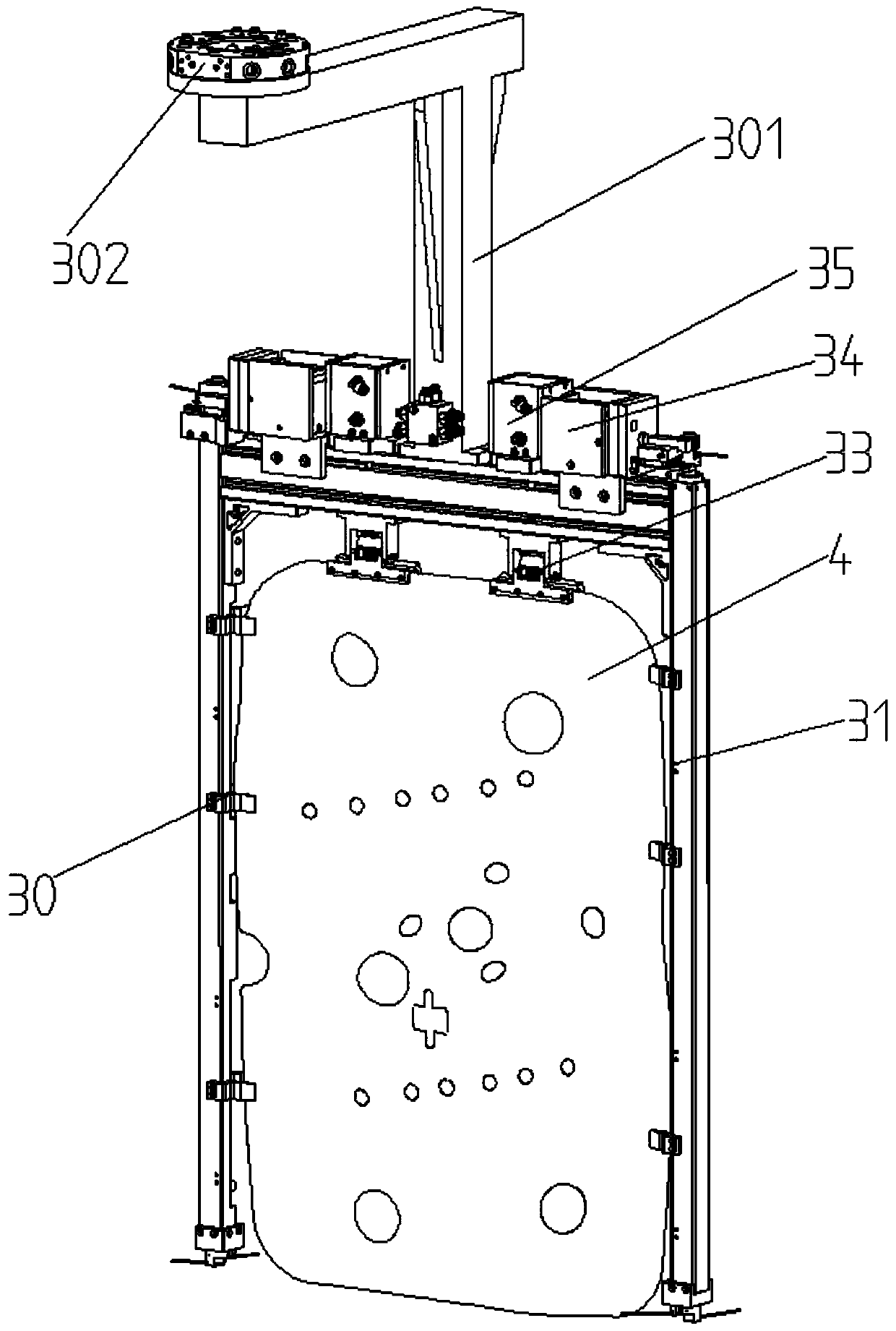

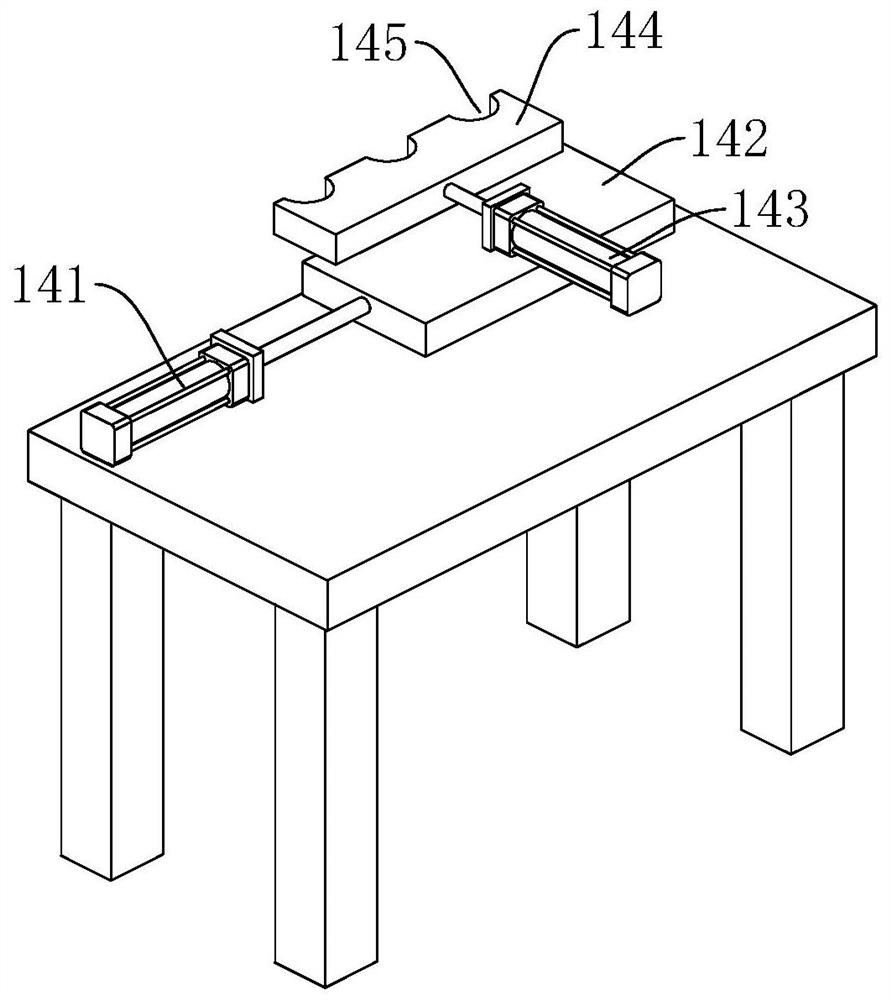

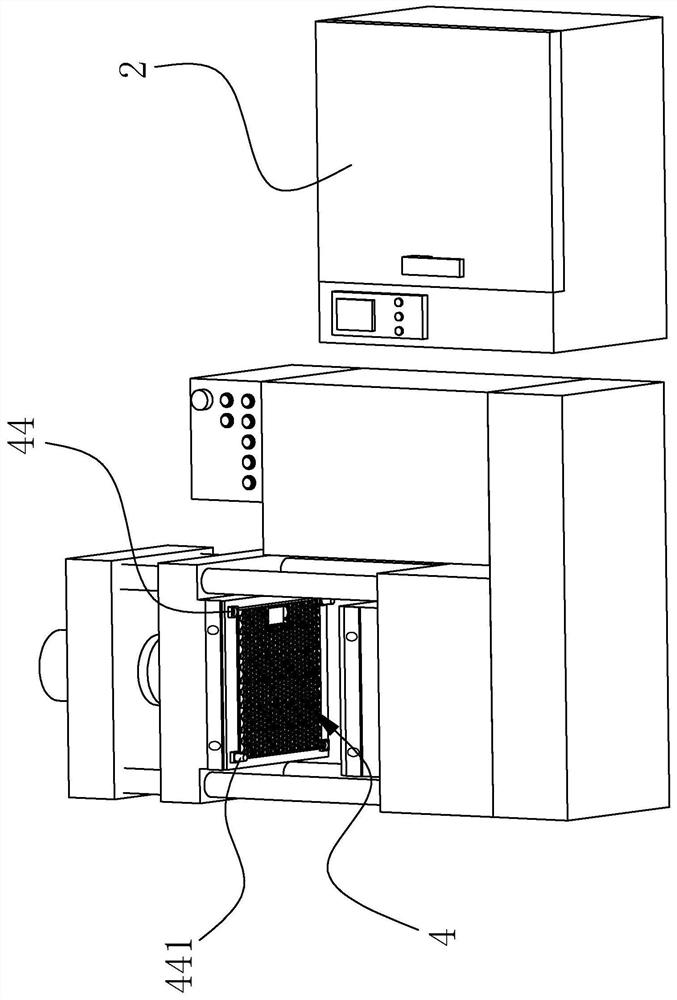

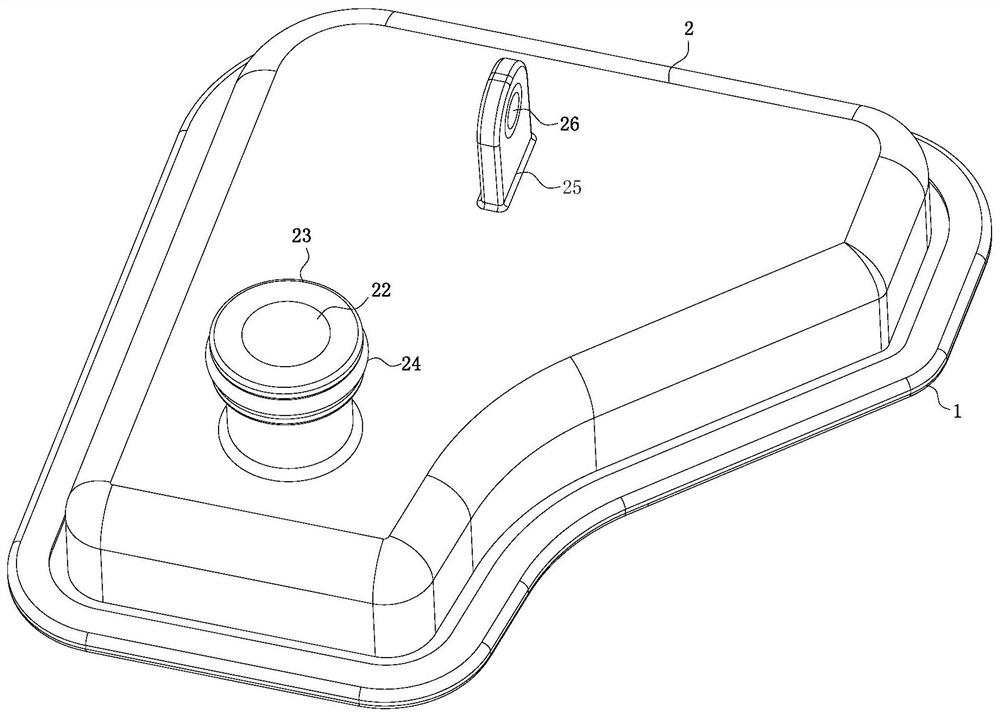

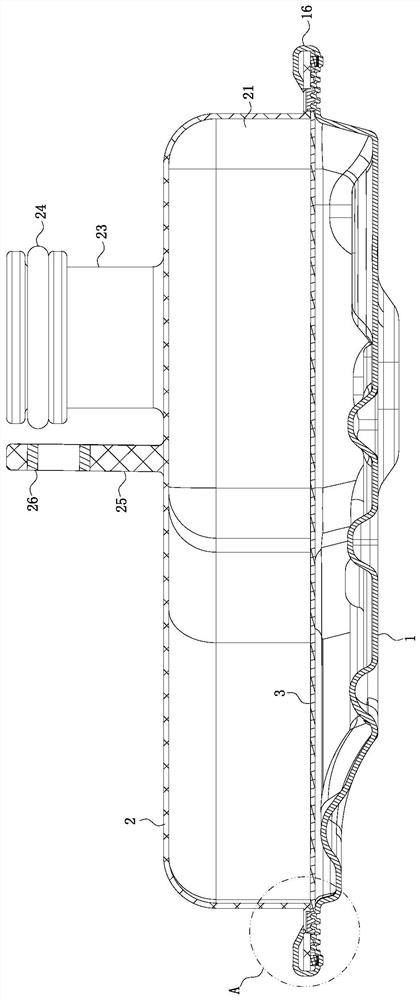

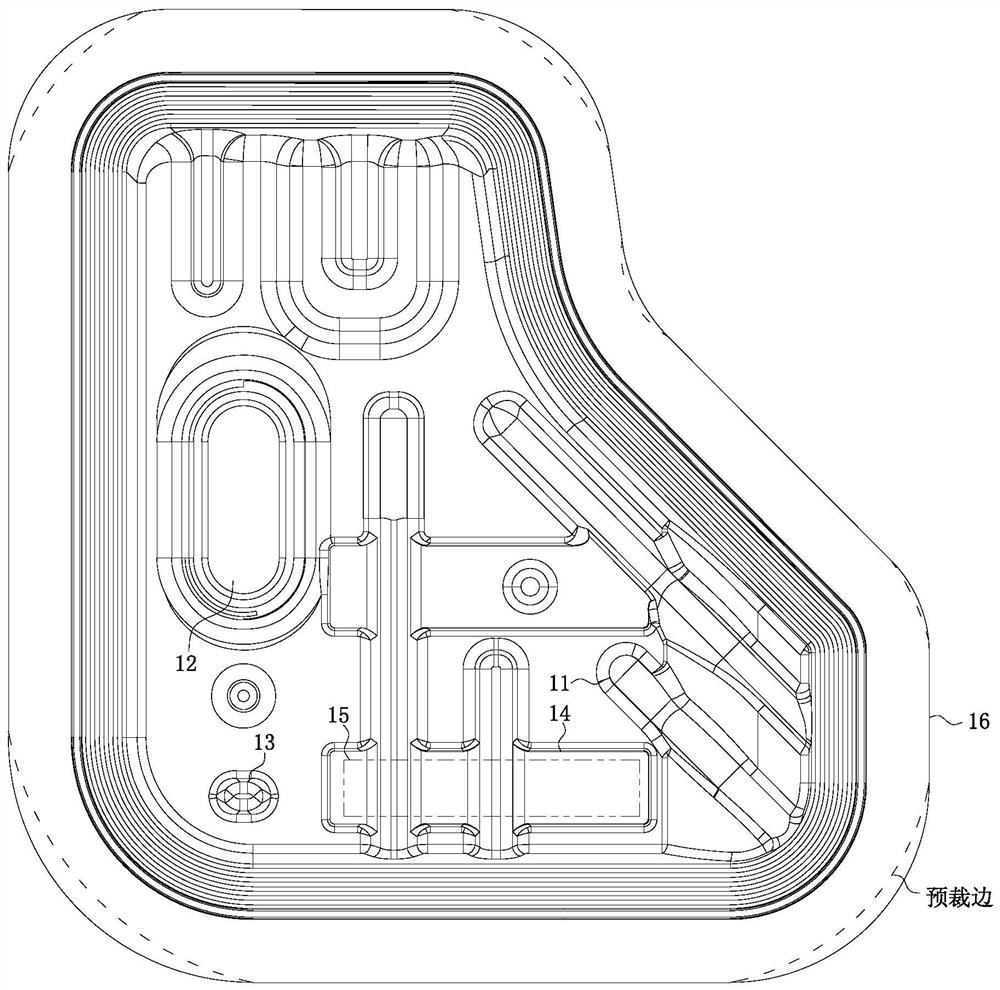

Automobile door plate injection mold

PendingCN110682562AImprove the heating effectEasy to processDomestic articlesCoatingsGlass fiberInjection molding machine

The invention discloses an automobile door plate injection mold. The automobile door plate injection mold comprises an injection machine, a jig table arranged on one side of the injection machine, a pre-buried glass fiber placed on the jig table, and a manipulator arranged on one side of the jig table, the injection machine comprises a mold moving device and a mold fixing device, and a fixing fixture is arranged on the jig table and used for being matched with the manipulator, so that the fact that moving for injection is conducted on the pre-buried glass fiber is achieved; and the specific structure of the automobile door plate injection mold comprises a first fixing assembly used for fixing in the vertical direction, a second fixing assembly used for fixing in the horizontal direction, afirst driving mechanism for driving the first driving assembly, a second driving mechanism for driving the second fixing assembly, and a connecting assembly matched with the manipulator. According tothe automobile door plate injection mold, the fact that leveling of the glass fiber is ensured in the processing process can be maintained, and the fixing fixture is not deformed in the heating process.

Owner:苏州永智自动化科技有限公司

Method for manufacturing flexible circuit board

InactiveCN100471362CImprove rigidityImprove liquidityPrinted circuit aspectsInsulating layers/substrates workingCopper platingFlexible circuits

The invention supplies a kind of method of creating the flexible circuit board. The step is as follows. The treated component has the base on which there is at least one copper film. Multiple copper holes form on the copper film. The copper holes form by micro-image process that includes the step of coating photoresist layer. The photoresist material is liquid. The micro-image process also includes the steps of exposal, developing, etching and peeling film. The light cover in the step of exposal is vitric.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

Wood plastic composite material cladding plywood formwork and manufacturing method thereof

ActiveCN103758340BReduced flatness errorGood dimensional stabilityFibre treatmentSynthetic resin layered productsPlastic filmUltimate tensile strength

Owner:NORTHEAST FORESTRY UNIVERSITY

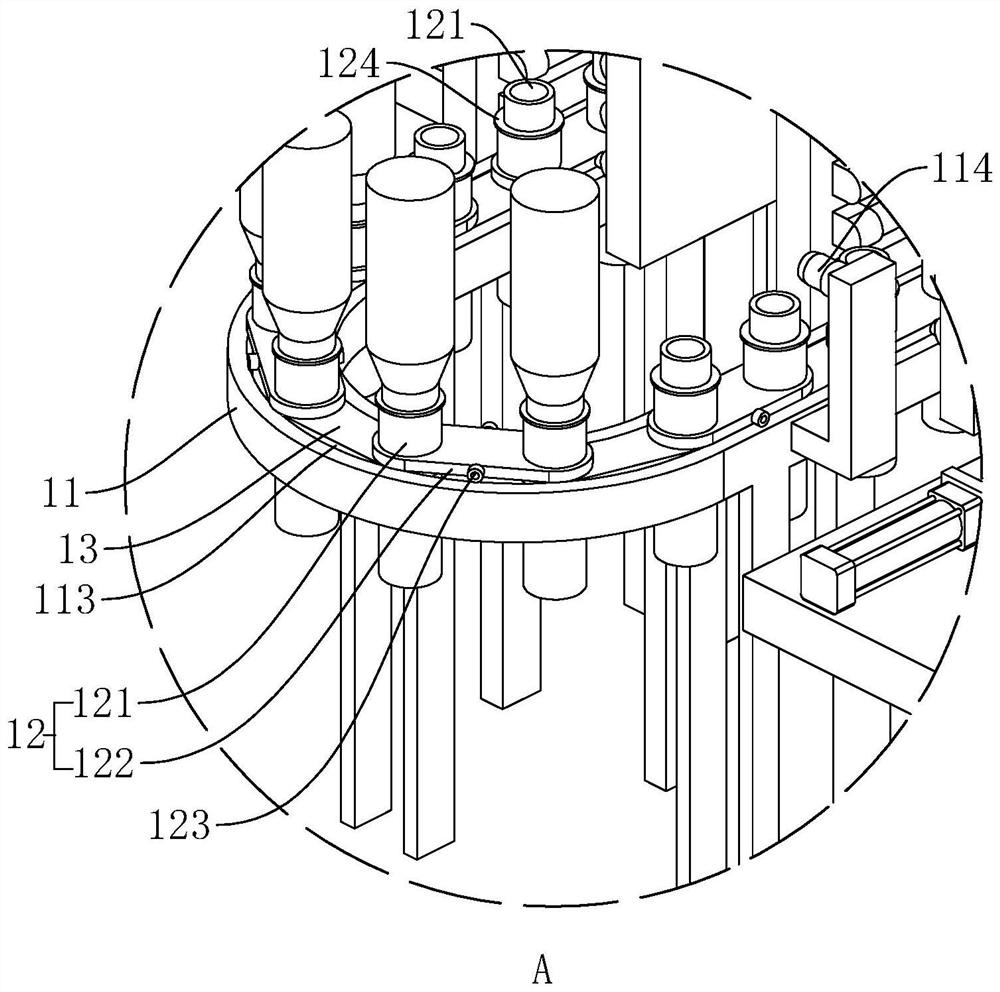

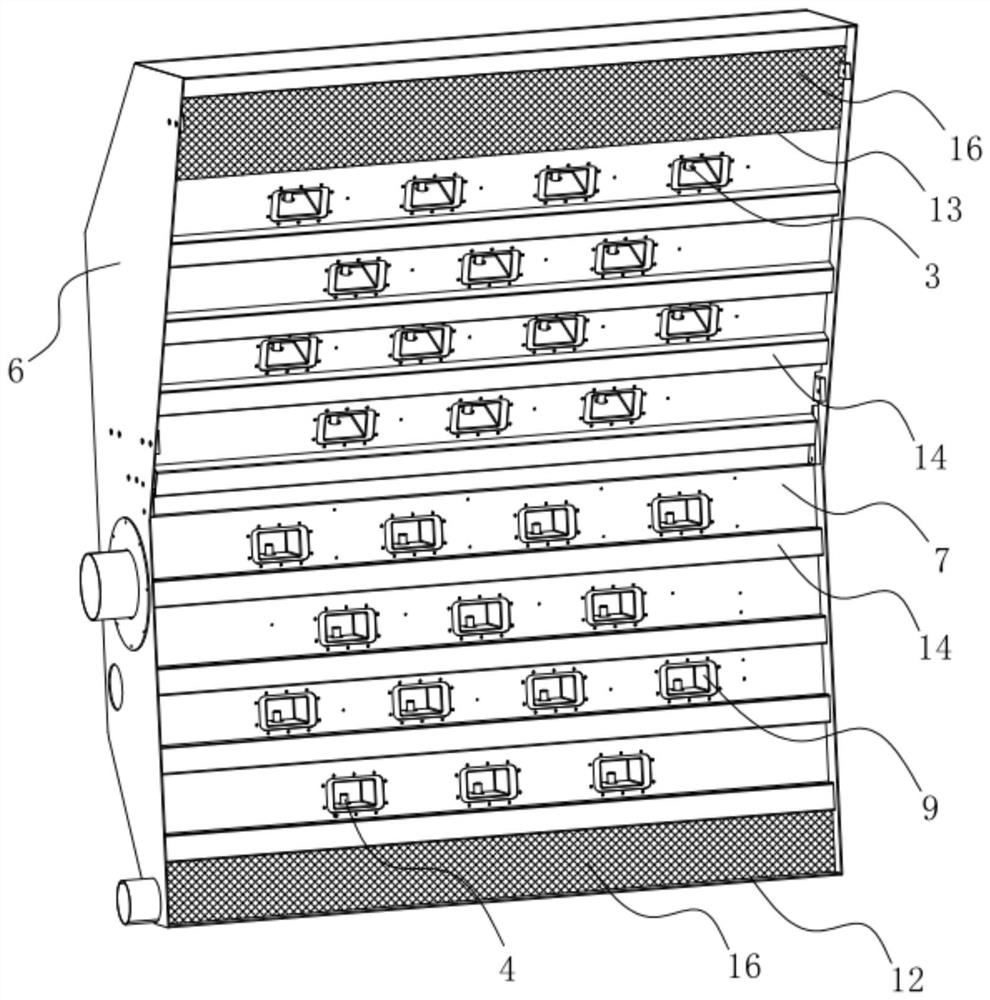

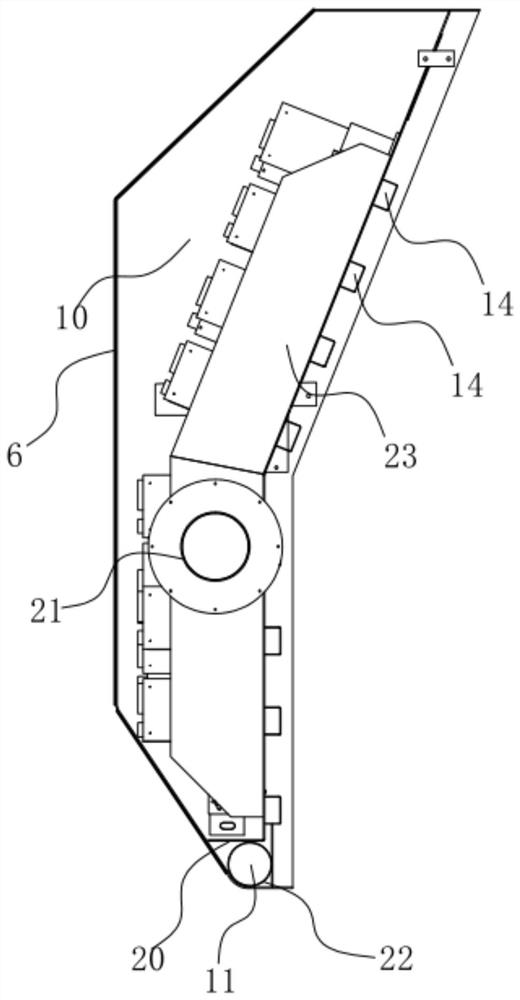

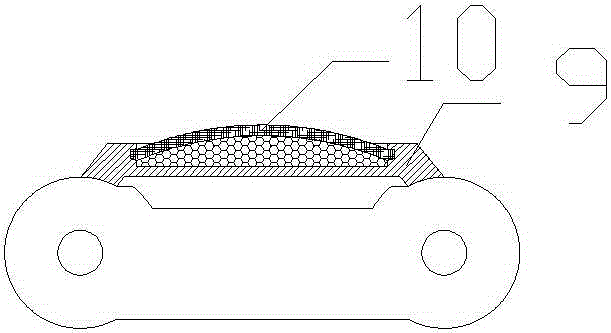

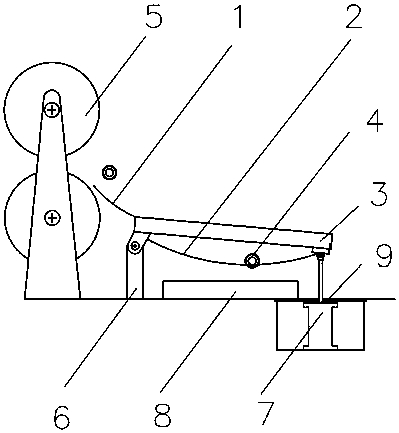

Automatic bottle blowing machine

The invention relates to an automatic bottle blowing machine. The automatic bottle blowing machine comprises a conveying mechanism used for conveying bottle blanks, a heating mechanism used for heating the bottle blanks, and a blow molding mechanism used for carrying out blow molding processing on the bottle blanks. The conveying mechanism comprises an annular conveying track and a plurality of bottle blank conveying assemblies arranged on the annular conveying track in a sliding mode. Each bottle blank conveying assembly comprises a fixing plate and two barrel-shaped bottle seats used for fixing the bottle blanks, wherein the two bottle seats are arranged at the two ends of the fixing plate in a penetrating mode, a connecting plate is connected between every two adjacent bottle blank conveying assemblies, the two ends of each connecting plate are sleeved with the bottle seats arranged at the ends, close to each other, of the corresponding two adjacent bottle blank conveying assemblies, and the two bottle seats are connected with the corresponding connecting plate in a rotating mode. According to the automatic bottle blowing machine, each fixing plate is connected with the two corresponding bottle seats, and the adjacent bottle blank conveying assemblies are connected through the connecting plates, so that the bottle blanks can be stably transmitted, the bottle blanks are accurate in position feeding and can be accurately combined with a blow molding structure to carry out blow molding operation, and the effect of improving the product quality is achieved.

Owner:杭州恒峰塑料制品有限公司

Microwave drying oven equipment of water-based ink printing machine

InactiveCN112060768ASpeed up evaporationImprove operating speedPrinting press partsProduction lineThermodynamics

The invention relates to the field of flexible package printing, in particular to microwave drying oven equipment of a water-based ink printing machine. The microwave drying oven equipment comprises aproduct conveying mechanism, an air blowing system and a microwave generator arranged beside the product conveying mechanism, wherein microwaves generated by the microwave generator are used for evaporating water in water-based ink on a product, and the air blowing system is used for blowing away water vapor on the product. The microwave drying oven equipment provided by the invention only heatswater in the water-based ink, and the water in the water-based ink can be quickly evaporated only by slight heating, so that the product is not easily deformed due to heating, and on-line drying can still be realized when the product conveying speed in a production line is relatively high.

Owner:悦美红智能数控科技(江苏)有限公司

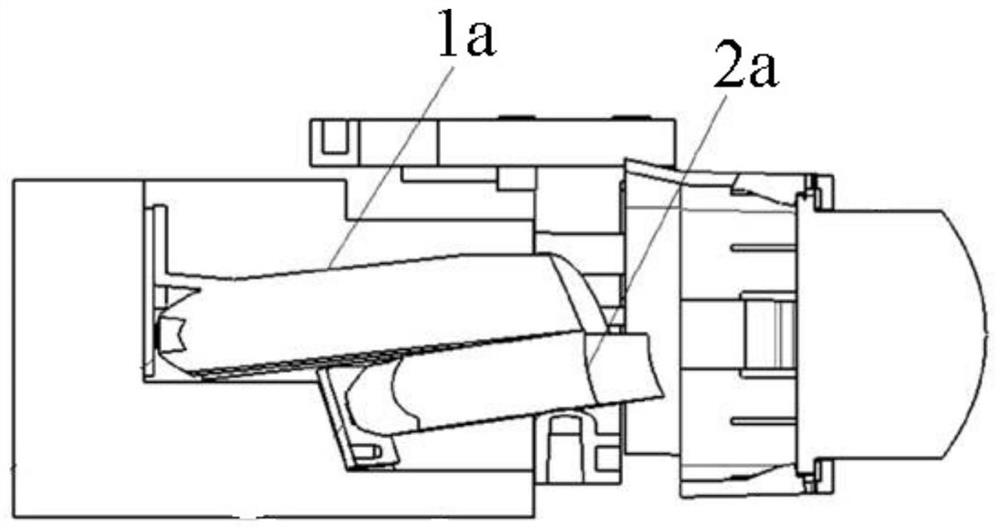

Vehicle lamp optical element, headlamp module, vehicle lamp and vehicle

PendingCN113280304ANot easy to wearNot easily deformed by heatVehicle headlampsLighting and heating apparatusHeadlampEngineering

The invention relates to a vehicle lighting device, and discloses a vehicle lamp optical element which comprises a light condensation part (11), a first light transmission part (12) and a second light transmission part (13) which are sequentially arranged, the light condensation part (11), the first light transmission part (12) and the second light transmission part (13) are integrally formed parts, the light condensation part (11) and the second light transmission part (13) are silica gel formed parts, and the first light transmission part (12) is a plastic formed part. In addition, the invention further discloses a headlamp module, a vehicle lamp and a vehicle. The vehicle lamp optical element has the advantages of low cost, high temperature resistance and wear resistance.

Owner:HASCO VISION TECHNOLOGY CO LTD

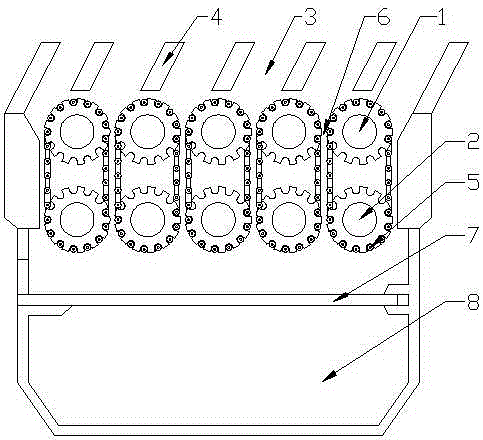

Grinding net type chain light-sensation raw material pulverizer

The invention relates to a grinding net type chain light-sensation raw material pulverizer which comprises a pulverizing cavity and a collecting cavity, wherein a plurality of chain pulverizing mechanisms are arranged in the pulverizing cavity. Each chain pulverizing mechanism comprises a driving wheel and a driven wheel, each driving wheel is in transmission connection with the corresponding driven wheel through a chain, each driving wheel is in transmission connection with a motor, and each driven wheel is rotatably connected with the inner wall of the pulverizing cavity. The longitudinal axes of all the chain pulverizing mechanisms are parallel, and a pulverizing gap used for pulverizing raw materials is formed between the chains of every two adjacent chain pulverizing mechanisms. A pressing plate is arranged between two chain link sheets of each chain link of each chain, an open groove is formed in each pressing plate, and a metal grinding net is arranged in each open groove; the periphery of each metal grinding net is fixedly connected with the corresponding pressing plate, and the space between each metal grinding net and the bottom of the corresponding open groove is filled with elastic metal wires. A screening plate is arranged between the collecting cavity and the pulverizing cavity, and one end of the screening plate is fixedly connected with the inner wall of the collecting cavity through a buckle groove.

Owner:WUXI DERBELL PHTO ELECTRONICS MATERIAL

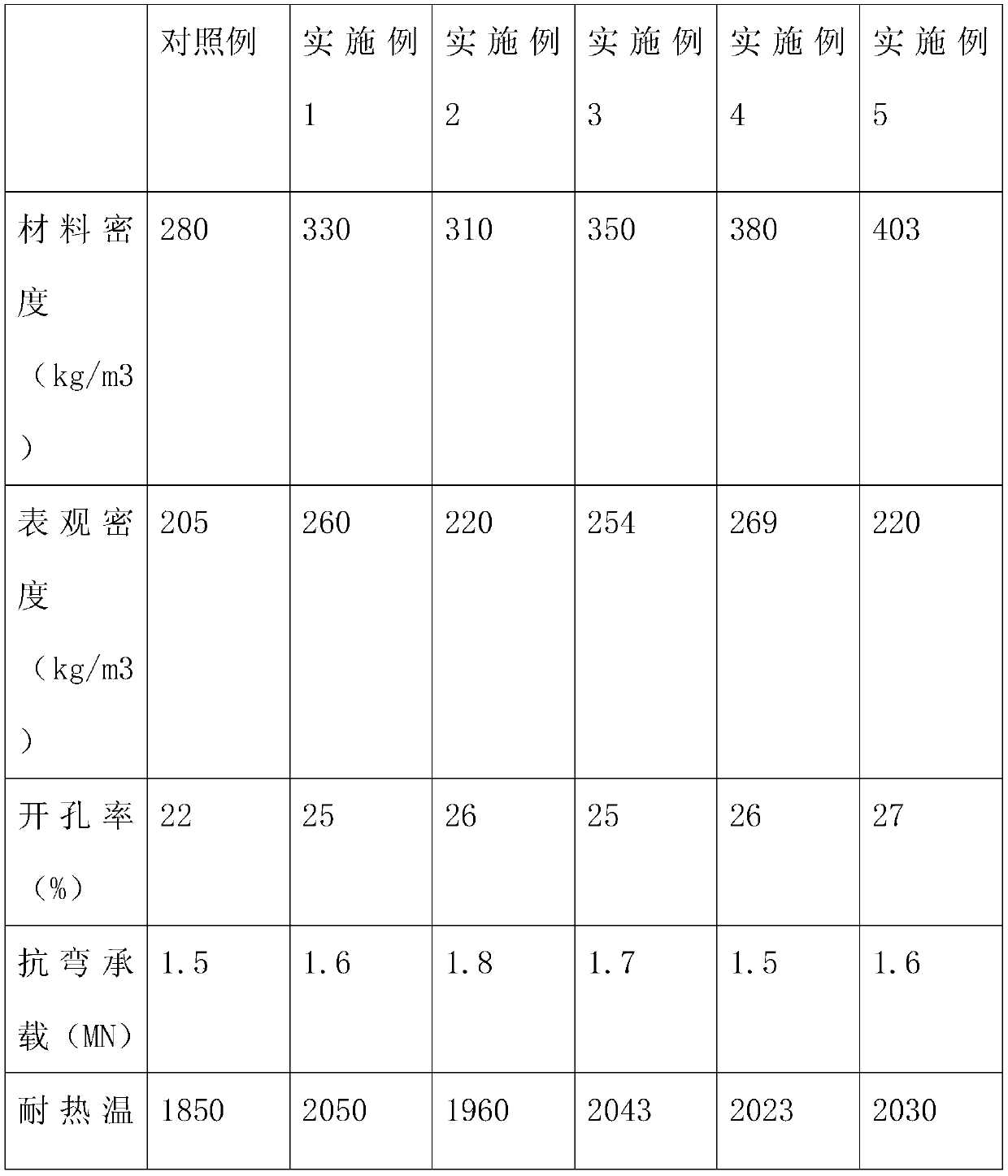

Environment-friendly aluminum alloy refractory material and preparation method thereof

The invention discloses an environment-friendly aluminum alloy refractory material and a preparation method thereof. The environment-friendly aluminum alloy refractory material comprises, by weight, 20-30 parts of aluminum alloy, 20-40 parts of aluminum oxide, 10-20 parts of silicon nitride, 10-15 parts of boron nitride, 10-15 parts of zirconium oxide, 15-20 parts of sodium silicate, 5-10 parts ofhydrochloric acid, 10-15 parts of ammonia monohydrate and 5-10 parts of an epoxy toughness modifier. The aluminum hydroxide structure with the reticular structure and the aluminum alloy jointly act,the reticular structure is stable, the added aluminum alloy can absorb heat, and the absorbed heat is not intensively transmitted, so that large tensile stress is not generated in the material, the material is effectively prevented from cracking, and the service life of the fireproof material is prolonged.

Owner:徐州鑫博金属制品有限公司

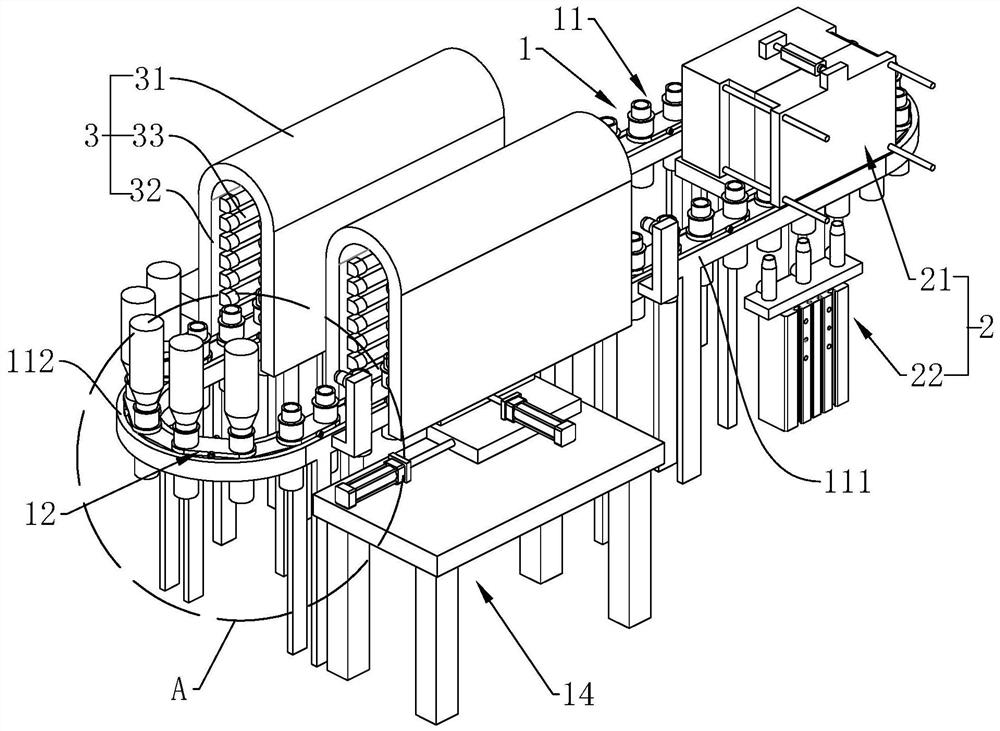

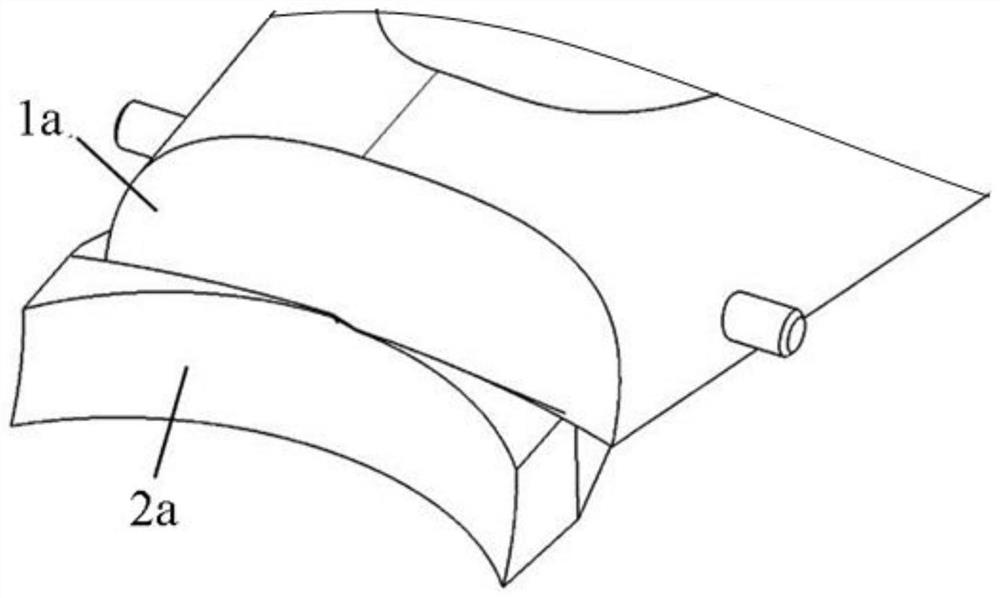

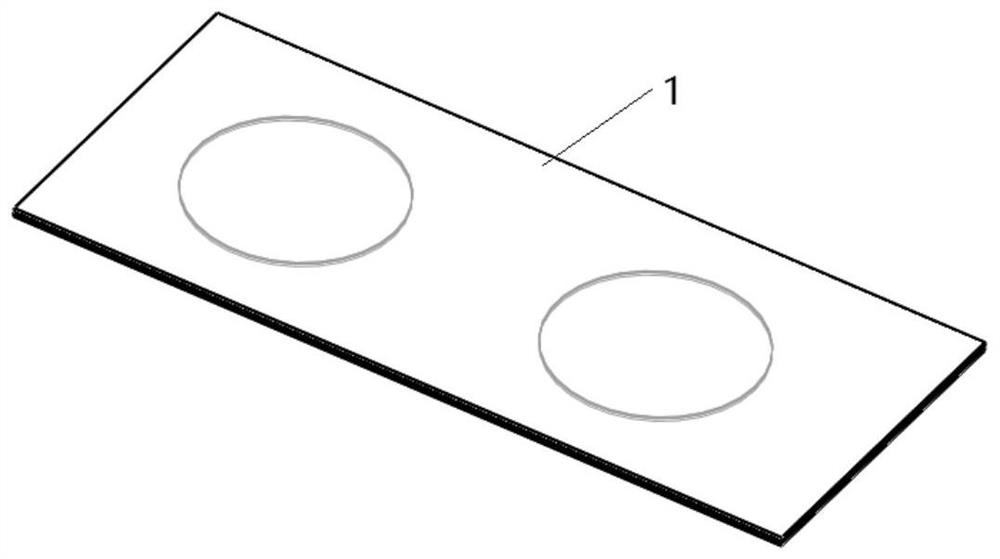

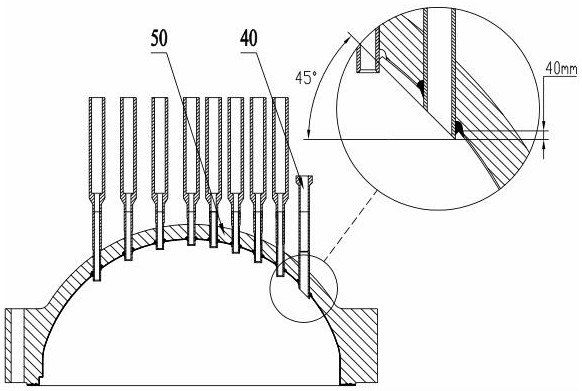

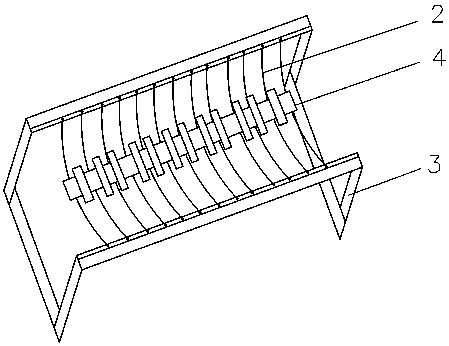

Reinforced diffusion plate and manufacturing method thereof

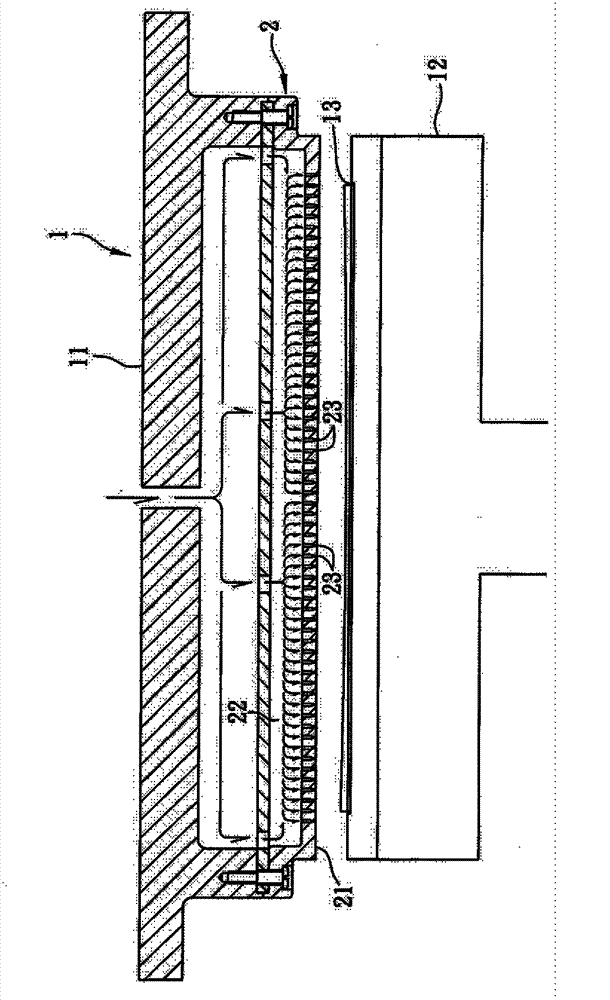

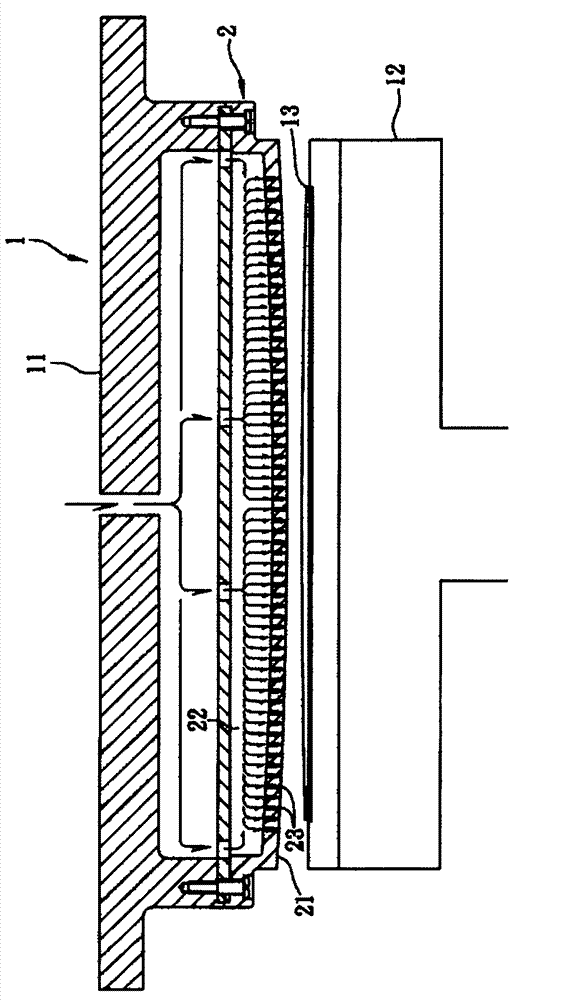

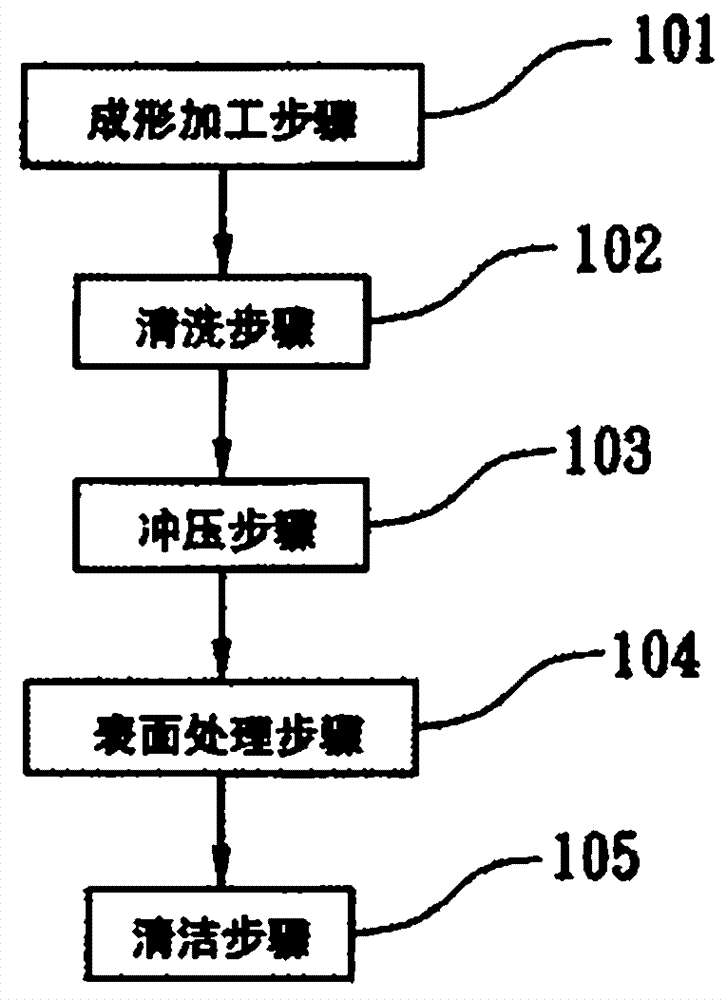

InactiveCN103194738ANot easily deformed by heatReduce downtime for maintenanceChemical vapor deposition coatingBaseboardMaterial consumption

The invention relates to a reinforced diffusion plate and a manufacturing method thereof. The manufacturing method includes a shaping processing step, a cleaning step, a stamping step, a surface treatment step and a cleaning step, the manufactured reinforced diffusion plate includes a connection portion used for the connection to an arrangement board of a film plating device, a bent portion connected with the connection portion, and a baseboard portion connected with the bent portion, and a plurality of through holes are formed on the baseboard portion. The bent portion, the connection portion and the baseboard portion cooperate with each other to define a shunting room, and the baseboard portion projects in an arc-shaped manner toward the center to the shunting room direction from the connection position with the bent portion. The above structural design of the baseboard reduces the heating bending deformation of the baseboard, and the reinforced diffusion plate can be recycled, so the material consumption cost is reduced.

Owner:KYMCO

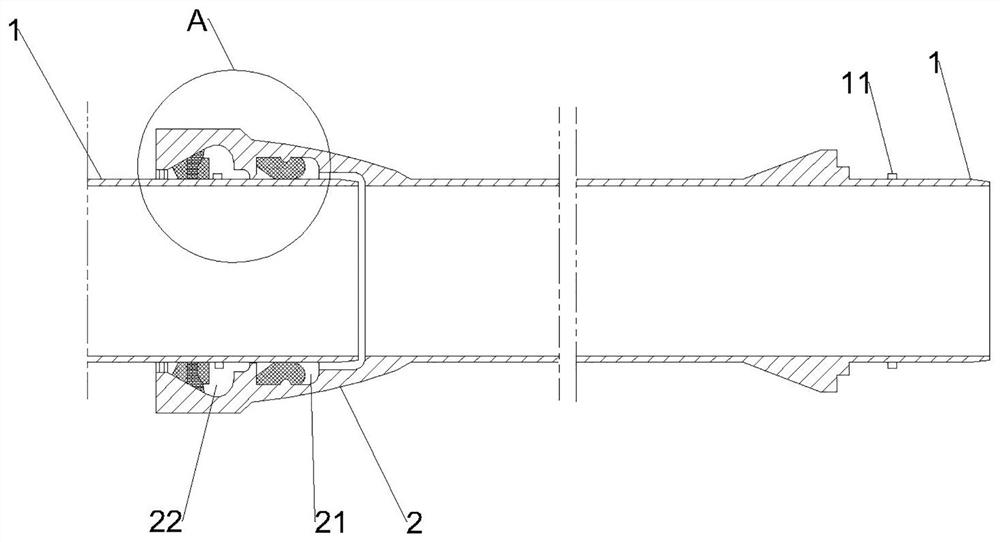

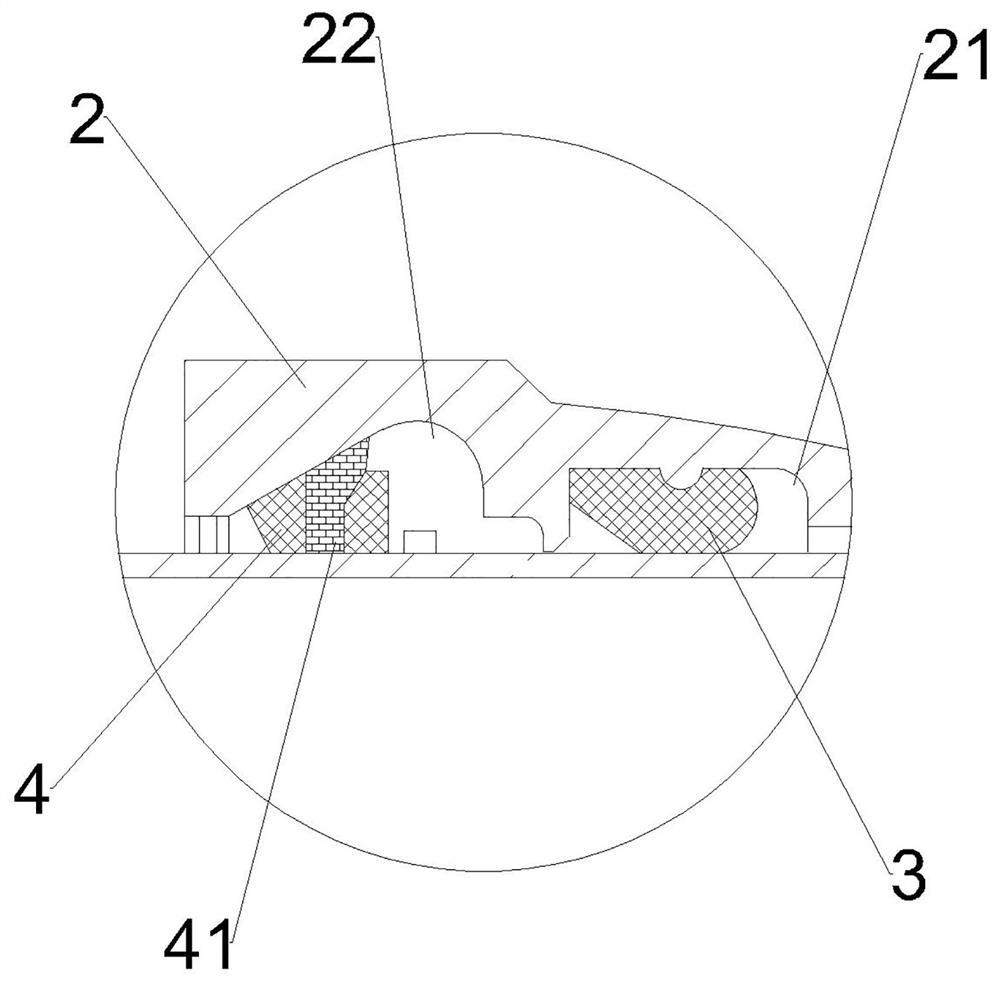

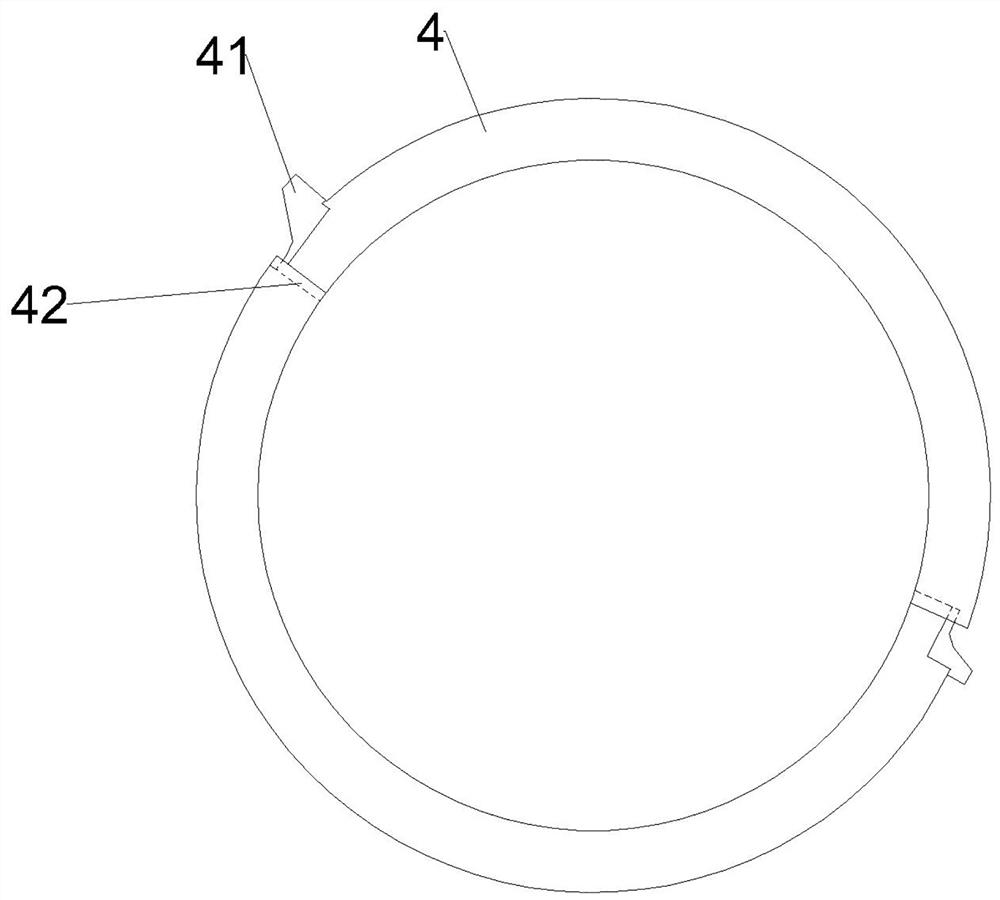

A manufacturing process of double-socket nodular cast iron pipe

The invention discloses a manufacturing process of a double-socket nodular cast iron pipe, which comprises the following steps: 1). Put the dotted pouring mold into a centrifugal pipe casting machine, pass cooling water into the outer wall of the pouring mold to cool; put the prepared sand mold The core is installed on the cast steel core frame, and the cast steel core frame is installed to the socket end of the casting mold; 2). After the molten iron is spheroidized and slag removed, it is poured into the fan-shaped bag of the centrifugal pipe casting machine and waits for pouring; 3 ). Start the pipe drawing system of the centrifugal pipe casting machine, and pour the molten iron into the inner wall of the casting mold to start drawing the pipe; 4). After drawing, pull out the double-socket ductile iron pipe, anneal and remove the sand core; 5) .Weld the socket welding ring at the socket; 6).Install the sealing ring in the sealing chamber of the socket, and install the anti-loosening ring in the anti-loosening chamber. The manufacturing process of the sand core used is simple, and the material is not easily deformed; the pipe drawing operation speed setting of the pipe drawing system of the centrifugal pipe casting machine is reasonable, which effectively guarantees the quality of the cast pipe.

Owner:安钢集团永通球墨铸铁管有限责任公司

A kind of reinforced short fiber masterbatch for rubber transmission belt and preparation method thereof

The invention relates to the technical field of functional fiber masterbatch and its preparation method, in particular to a reinforced staple fiber masterbatch for rubber transmission belts and its preparation method, which consists of the following components: modified aramid staple fiber, polyolefin elastomer, rubber, coupling Agents, aromatic oils, reinforced modified fillers, plasticizers, anti-aging agents. The preparation method includes: immersing the short aramid fiber in the metal hydroxide solution, then in the soluble silicate solution, repeating soaking to form the short aramid fiber with a hard silicate shell layer on the surface, and then mixing with the coupling agent After dispersing and standing still, the remaining raw materials are added for banburying, and the rubber material is granulated by a twin-screw extruder to obtain a reinforced short fiber masterbatch for rubber transmission belts. The invention solves the problems of poor interface bonding and insufficient heat resistance of aramid short fiber reinforced rubber in the prior art, and has the advantages of uniform dispersion, strong binding force, high tensile strength, high bonding strength and long service life. long advantage.

Owner:陇川县百信胶带有限公司

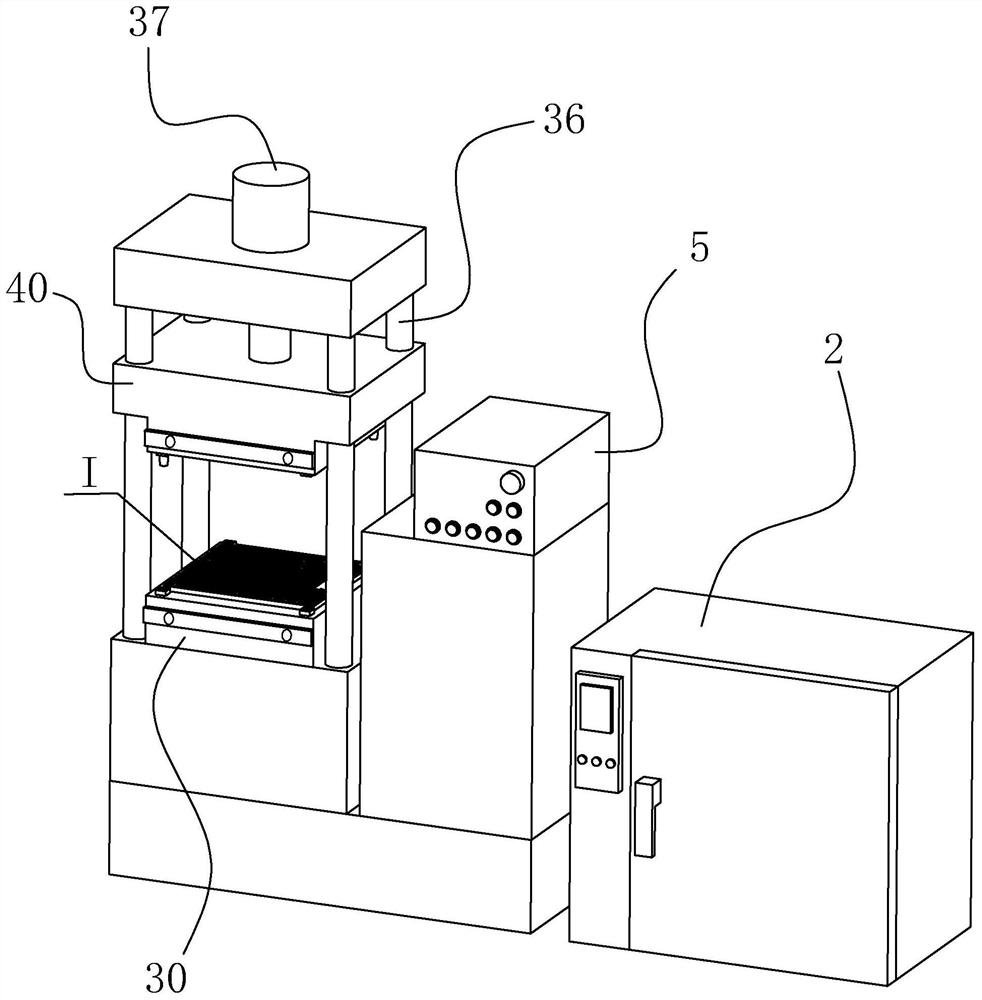

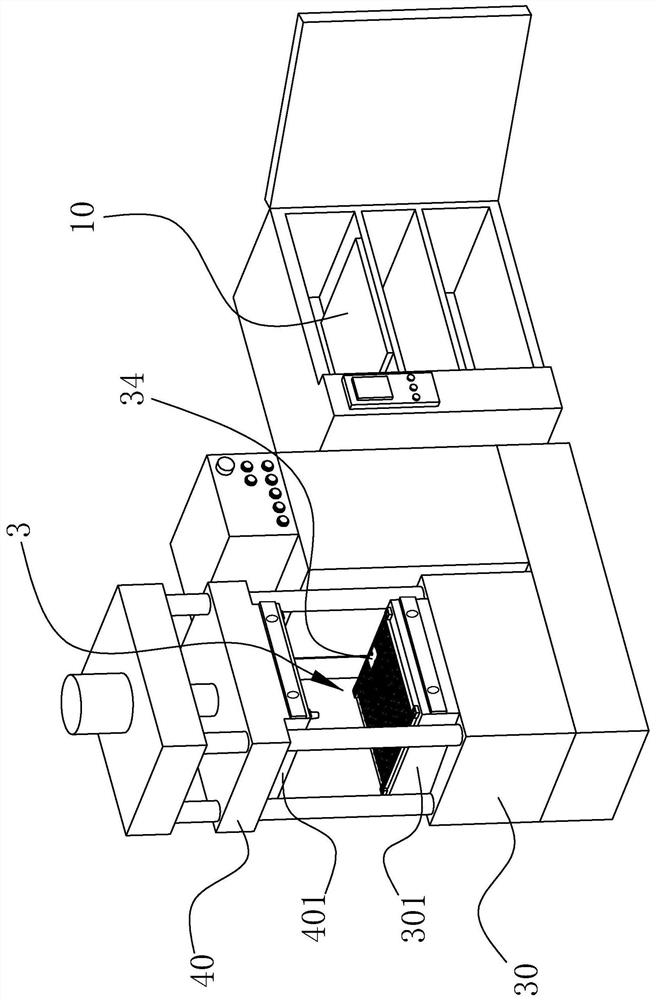

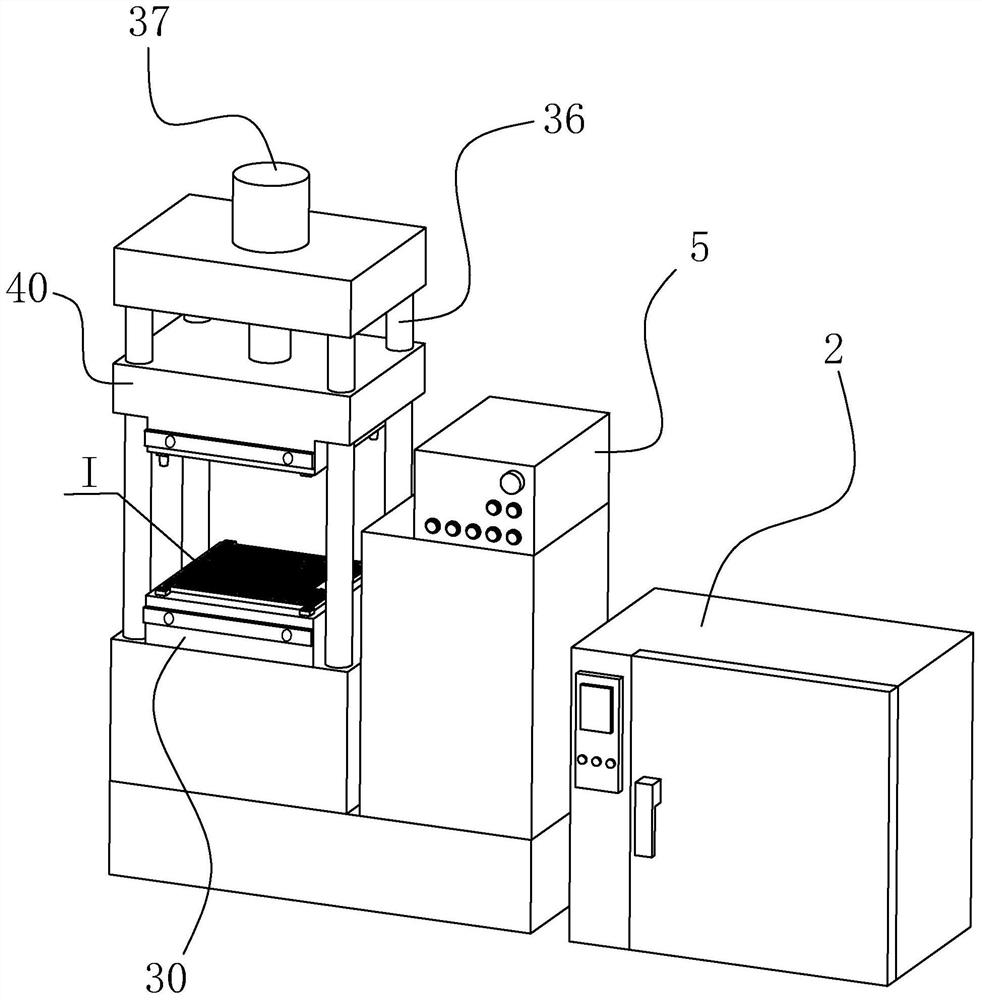

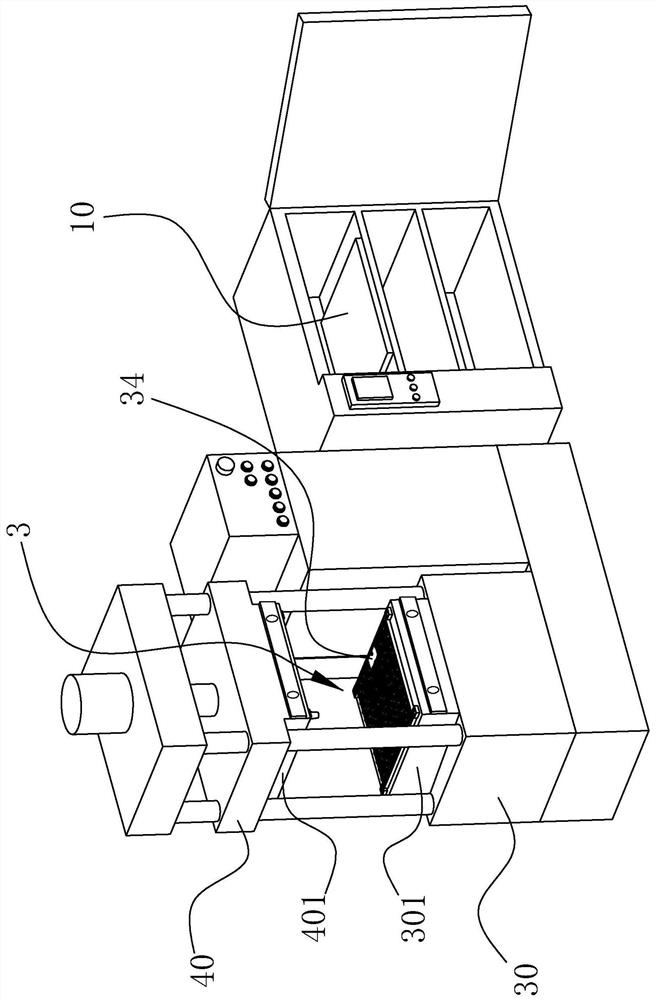

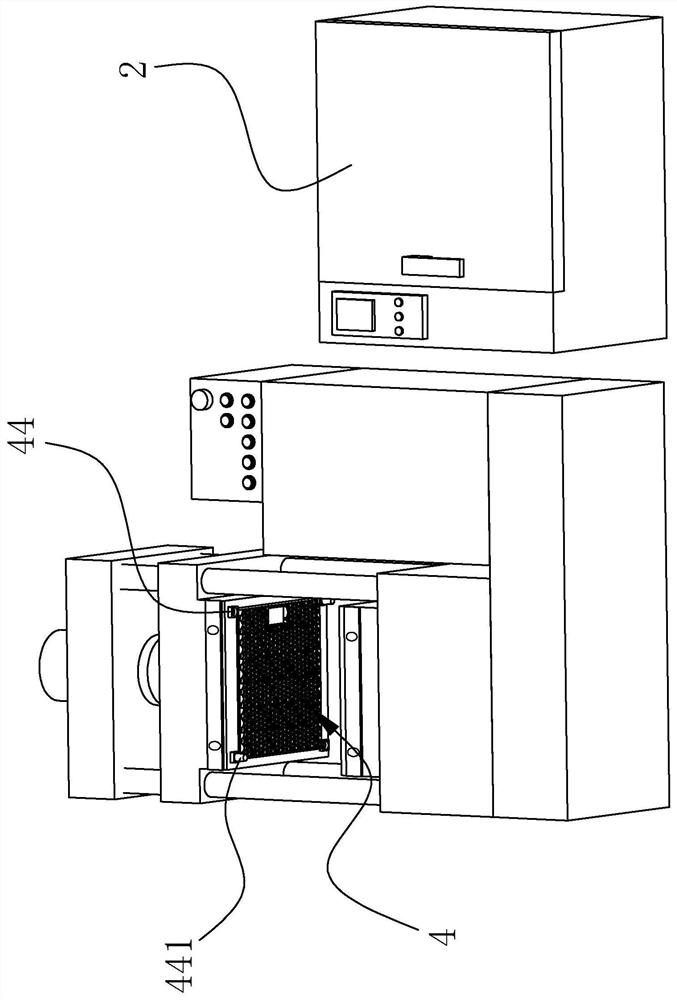

How to make a folding seat cushion

ActiveCN112519381BNot easily deformed by heatImprove mold precisionLamination ancillary operationsLaminationCompression moldingEngineering

A method for producing a folding seat cushion, comprising the following steps: preparing a composite sheet; placing the composite sheet in an oven for baking and softening, and placing the softened composite sheet in a mold for compression molding, wherein the mold is a cold-pressed mold, and the Before being put into the composite tablet for pressing, the temperature of the lower molding surface and the upper molding surface of the mold is reduced to less than 50°C; the lower molding surface of the mold is distributed with concave and convex surfaces, and the upper molding surface of the mold is also distributed with concave surfaces. The invention has the advantages that: the production energy consumption is reduced, the production cost is saved; the molding precision is high; Formed to meet the modeling requirements of the seat cushion, the concave-convex surface is complete, the transition is smooth, and the production effect is good.

Owner:宁波甬宁户外用品有限公司

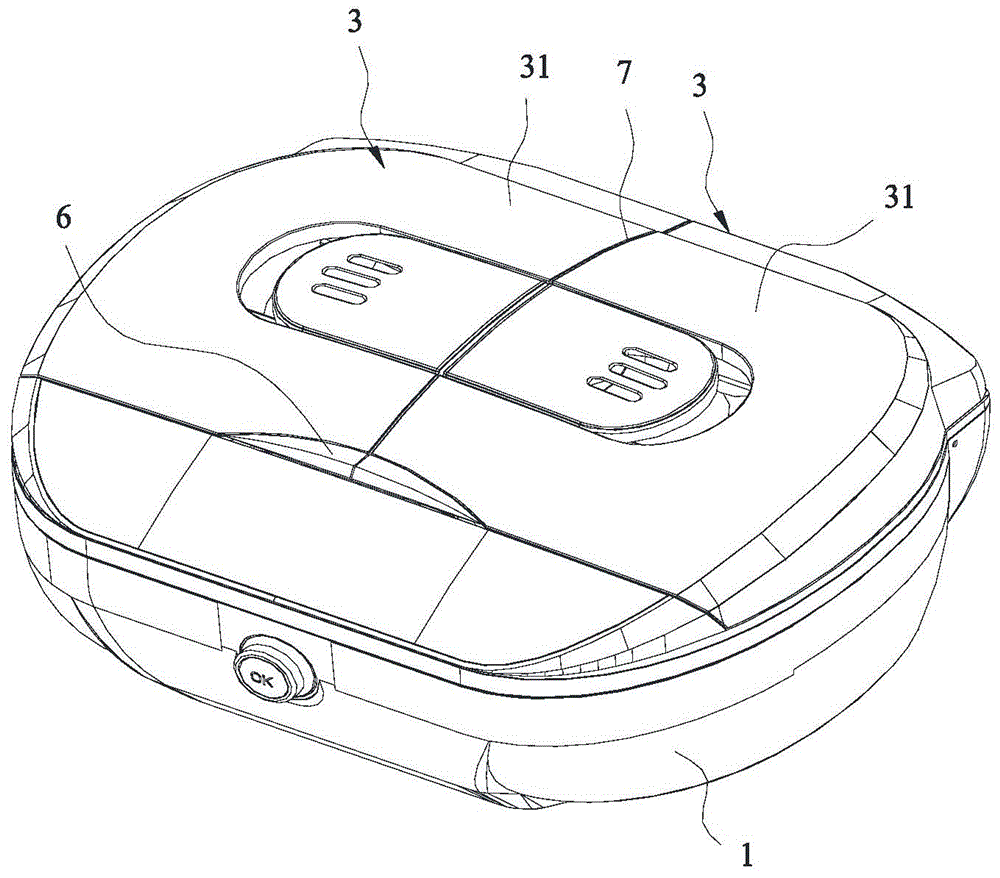

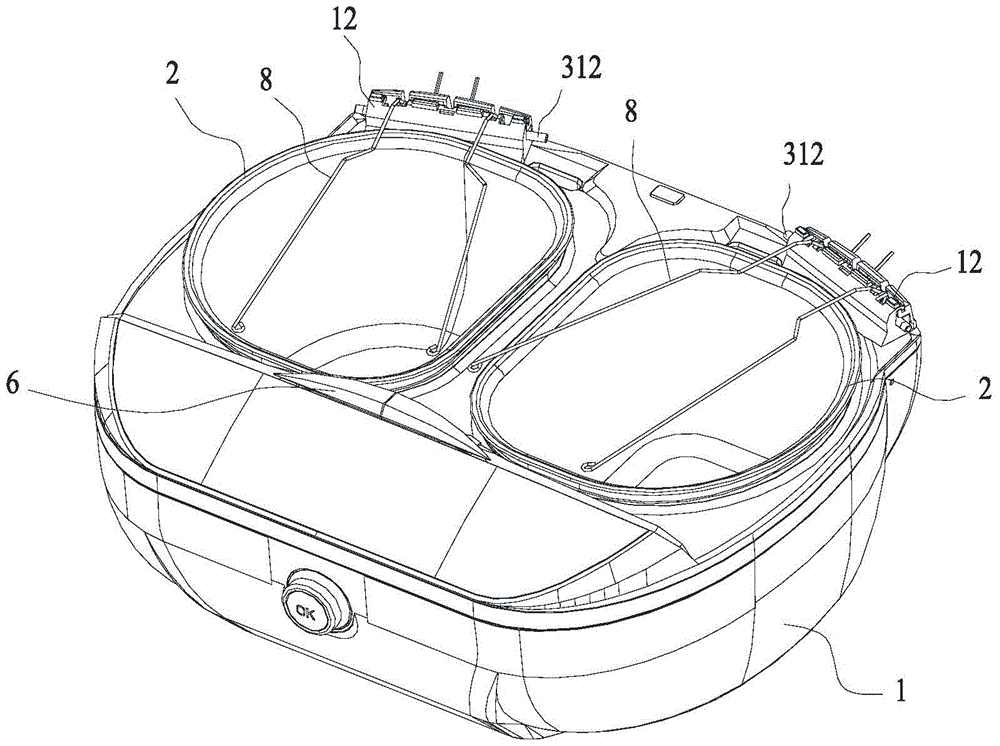

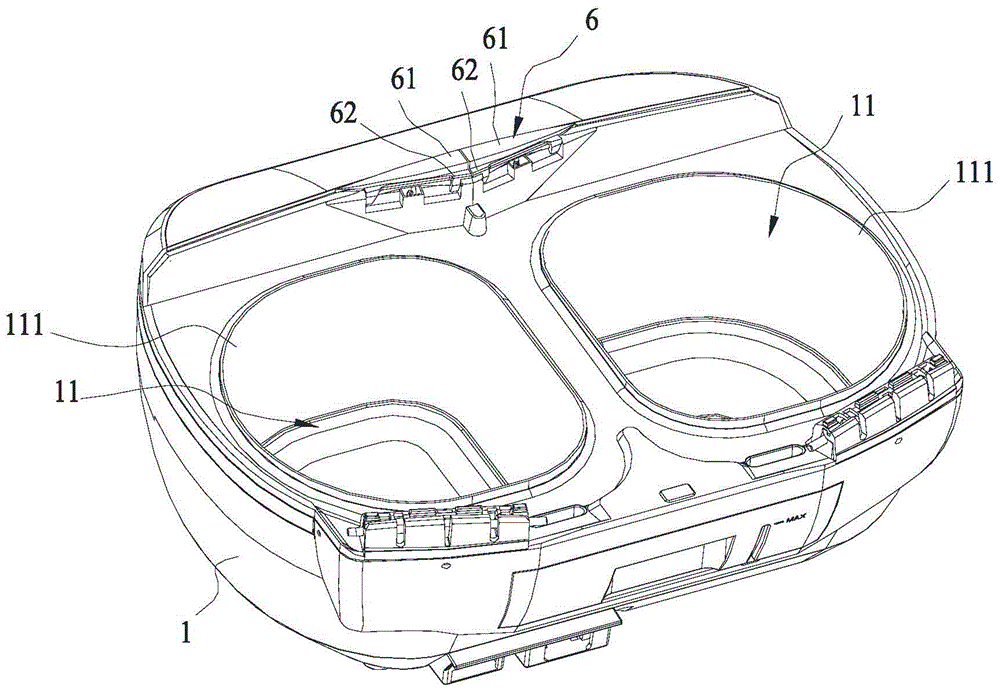

A double inner pot rice cooker

ActiveCN104814667BReduce volumeReduce occupancyCooking-vessel lids/coversMultiple-unit cooking vesselsEngineeringCooker

The invention discloses a novel double-liner electric cooker. The novel double-liner electric cooker comprises a cooker body, two liners and cooker covers. The cooker body is provided with two first inner cavities, which are separated through a first thermal insulating plate and respectively provided with a cavity opening for placing the liners in; the rear ends of the two cooker covers are hinged to the edges of the cavity openings through hinge shafts, and the axial directions of the two hinge shafts are crossed; when the hinge shafts of the two cooker covers rotate away from the cavity openings, the two cooker covers form an inverted splayed shape; the bottom of each cooker cover is provided with a second inner cavity for accommodating the top end of the corresponding liner, the wall of the second inner cavity is provided with a snapping groove, the inside of the second inner cavity is detachably and fixedly provided with a sealing member, and the circumferential edge of the sealing member is provided with a horizontal protrusion for being snapped with the snapping groove; the protrusions of the two corresponding sealing members of the two cooker covers are symmetric relative to the center of the cooker body. According to the novel double-liner electric cooker, the cooker covers are convenient to open, and on the basis that the sealing members are convenient to mount and dismount, the cooker covers can main high sealing effects.

Owner:STENTGUANGZHOU IND CO LTD

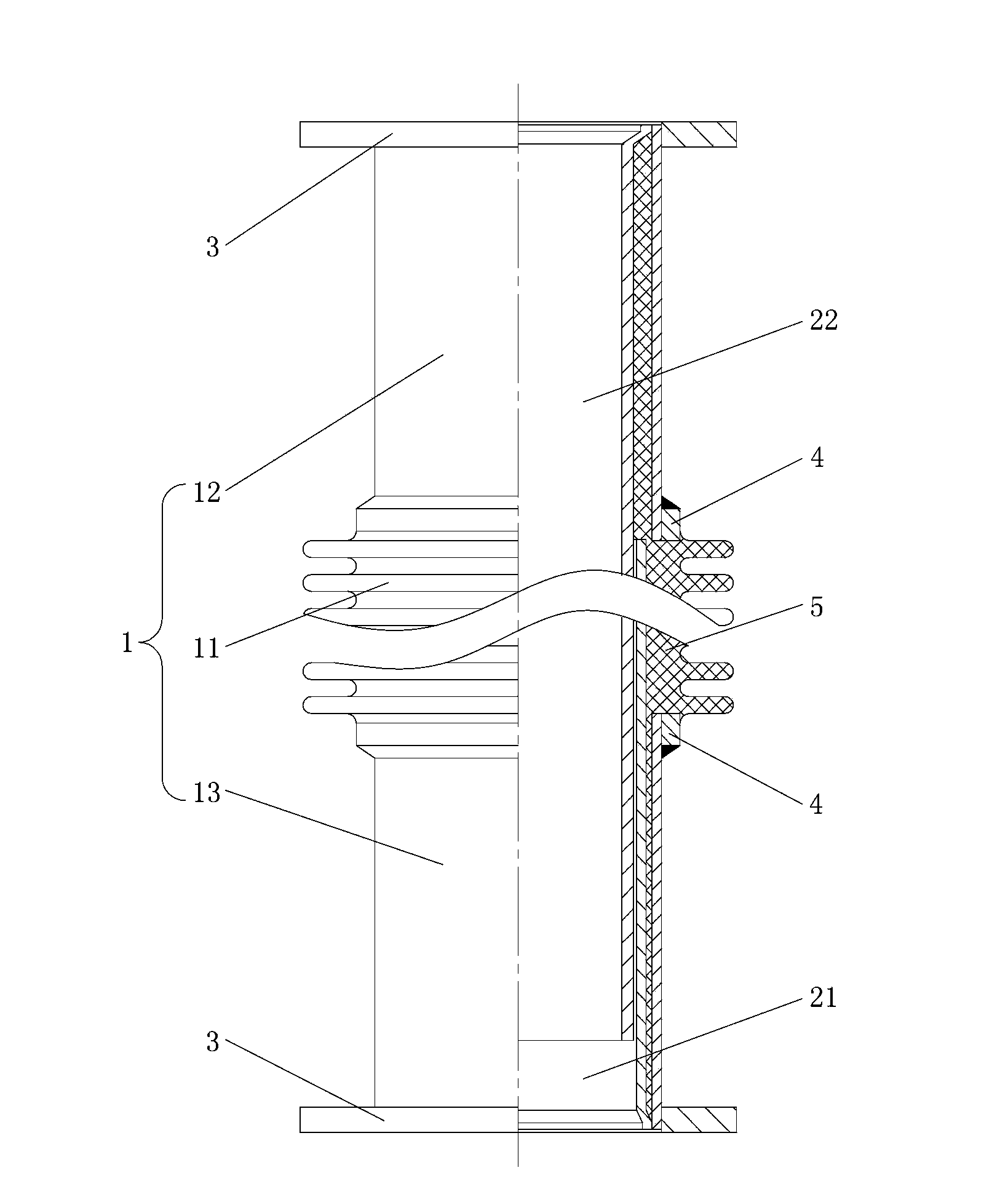

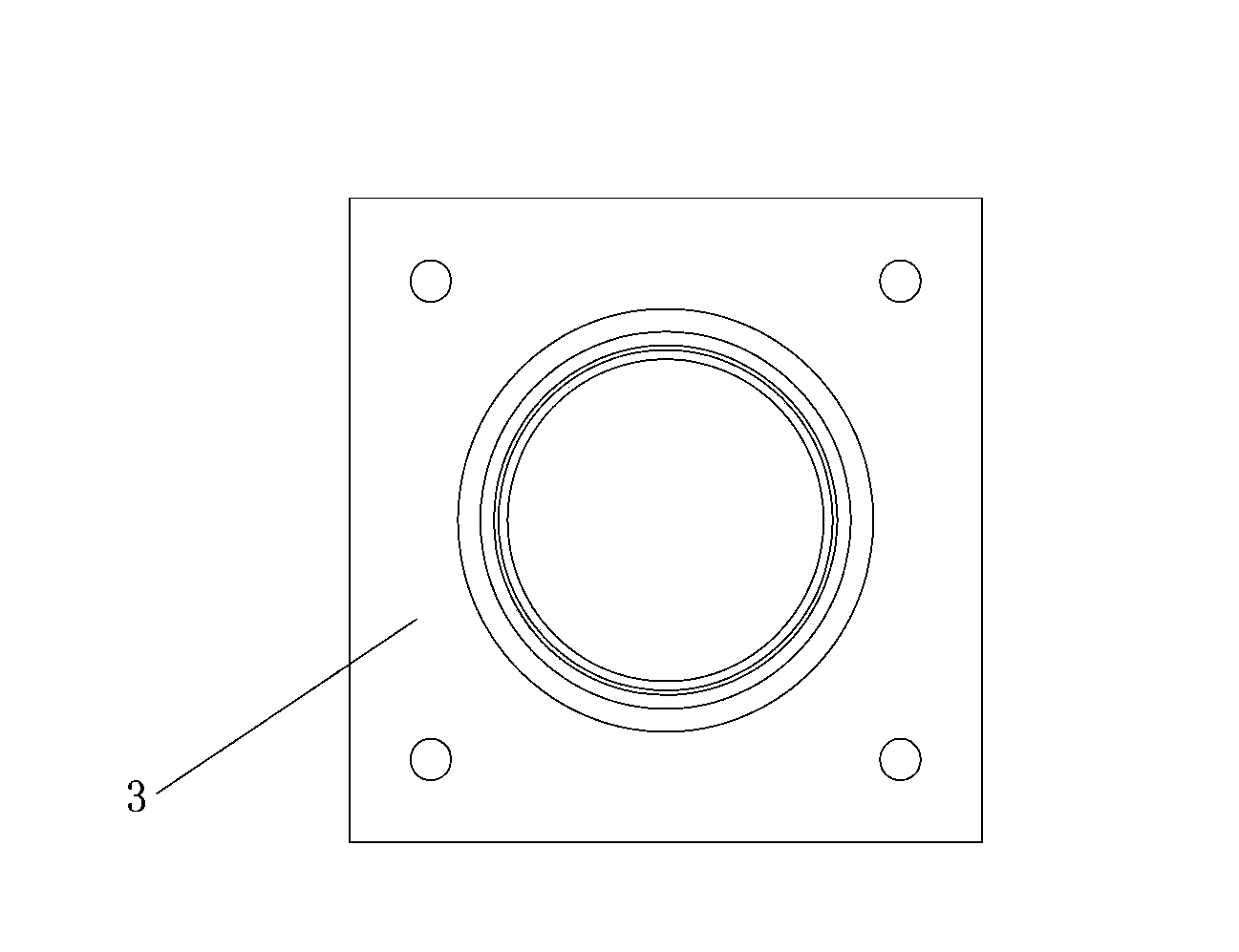

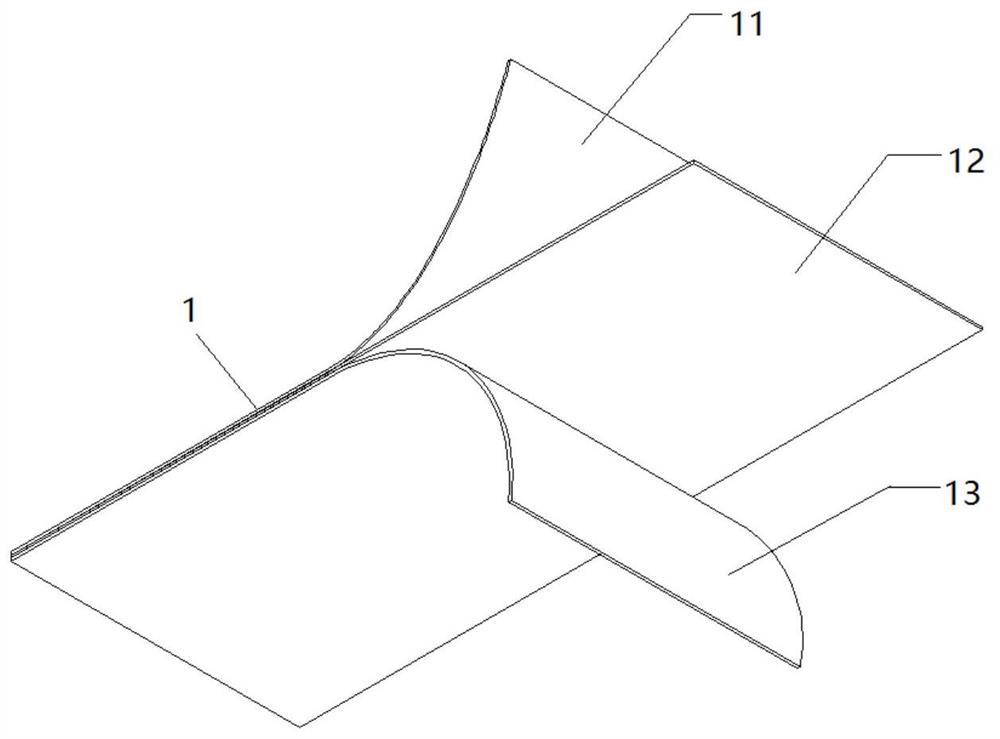

Two-way corrugated compensation pipe

InactiveCN103727345ABi-directional scalabilitySimple structureThermal insulationPipeline expansion-compensationArchitectural engineeringSmall caliber

The invention relates to a two-way corrugated compensation pipe. The two-way corrugated compensation pipe is provided with a telescopic pipe, wherein the telescopic pipe is provided with a corrugated pipe, an upper connecting pipe and a lower connecting pipe, and the upper end and the lower end of the corrugated pipe are connected with the upper connecting pipe and the lower connecting pipe in a closed mode respectively; the upper end and the lower end of the telescopic pipe are respectively and fixedly connected with a flange; a large-caliber flow guiding barrel and a small-caliber flow guiding barrel are arranged in the telescopic pipe in a sliding mode; the small-caliber flow guiding barrel is sleeved with the large-caliber flow guiding barrel in a sliding mode; the large-caliber flow guiding barrel is provided with a fixed end and a non-fixed end, the end opening of the fixed end of the large-caliber flow guiding barrel is fixedly connected with the inner wall of the lower connecting pipe on the telescopic pipe; the small-caliber flow guiding barrel is provided with a fixed end and a non-fixed end, and the end opening of the fixed end of the small-caliber flow guiding barrel is fixedly connected with the inner wall of the upper connecting pipe on the telescopic pipe. The two-way corrugated compensation pipe is simple in structure, not prone to temperature distortion and wide in application range.

Owner:常州市联谊特种不锈钢管有限公司

Sealing element, manufacturing method thereof and battery

PendingCN112670627AImprove sealingNot easily deformed by heatCell sealing materialsProcess engineeringMechanical engineering

The invention provides a sealing element, a manufacturing method thereof and a battery. The sealing element comprises a first metal layer, a sealing insulating layer and a second metal layer which are sequentially stacked. The sealing element provided by the invention is applied to the battery, and the sealing performance of the battery can be effectively improved.

Owner:ZHUHAI COSMX BATTERY CO LTD

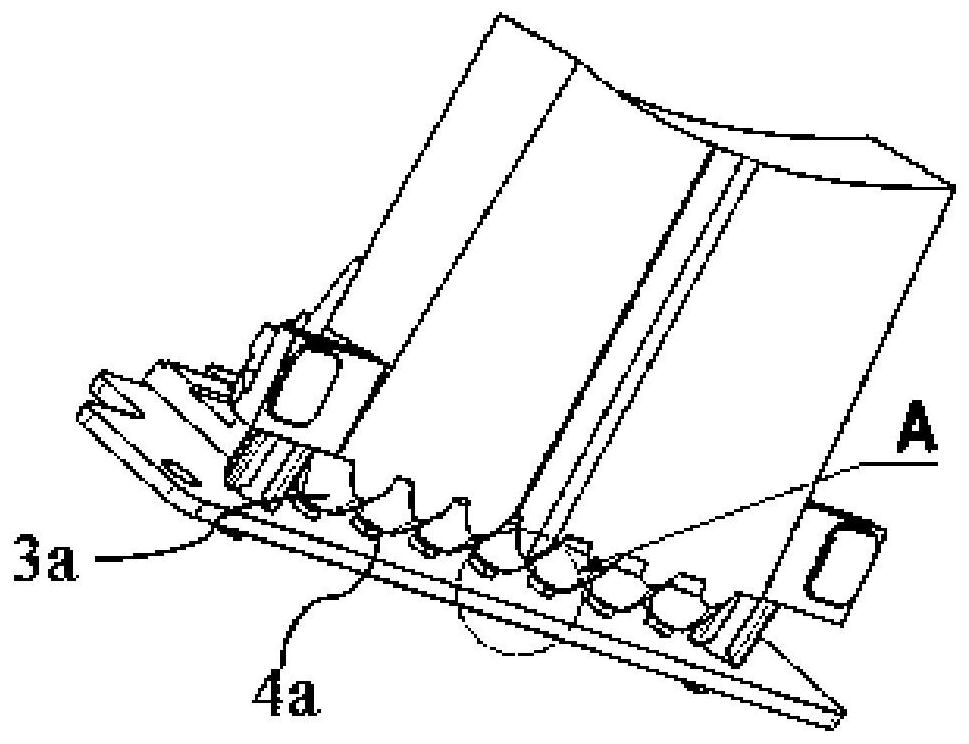

Manufacturing method of foldable cushion

ActiveCN112519381ANot easily deformed by heatHigh molding precisionLamination ancillary operationsLaminationForming faceSoftening

The invention discloses a manufacturing method of a foldable cushion. The manufacturing method comprises the following steps: preparing a composite sheet body; and putting the composite sheet body inan oven for baking and softening, and placing the softened composite sheet body in a mold for pressing molding, wherein the mold is a cold pressing mold, and before the composite sheet body is placedin the mold to be pressed, the temperature of the lower forming face and the temperature of the upper forming face of the mold are reduced to be smaller than 50 DEG C, a concave-convex surface is distributed on the lower forming surface of the mold, and a concave surface is also distributed on the upper forming surface of the mold. The method has the advantages that the production energy consumption is reduced, the manufacturing cost is saved, and the molding precision is high; the molded cushion is convenient to take out and the mold is convenient to clean; and the steps for manufacturing thecushion are few, the process is simple, one-time forming of the upper and lower concave-convex surfaces of the concave-convex surface cushion is achieved, the modeling requirement of the cushion is met, the concave-convex surfaces are complete, transition is smooth, and the manufacturing effect is good.

Owner:宁波甬宁户外用品有限公司

A metal stamping part

ActiveCN111120638BNot easily deformed by heatAvoid deformationGear lubrication/coolingLubrication elementsUltrasonic weldingStructural engineering

The invention belongs to the technical field of hardware stamping, and particularly relates to a hardware stamping part. The hardware stamping part comprises a cover plate, a shell and filter paper, wherein a turnup on the upper surface of the cover plate covers the shell; the same filter paper is jointly pressed and connected between the cover plate and the shell; an oil outlet is formed in a position, away from an oil inlet of the cover plate, of the upper surface of the shell; a joint is fixedly connected to the outer surface, at a position of the oil outlet, of the shell; an O-shaped ringis fixedly connected to a position, close to the upper end surface of the joint, of the outer arc surface of the joint; a connecting seat is fixedly connected to a position, away from the joint, at the upper surface of the shell; and a nest is pre-embedded in the connecting seat. The problems that a full-plastic engine oil filter is prone to deforming when being heated in a high-temperature gearbox and prone to gear collision when a variable gear runs at a high speed in the prior art are solved, binding manufacturing process is achieved without ultrasonic welding, equipment investment cost isgreatly saved, and the quality is stable.

Owner:茂森精艺金属(苏州)有限公司

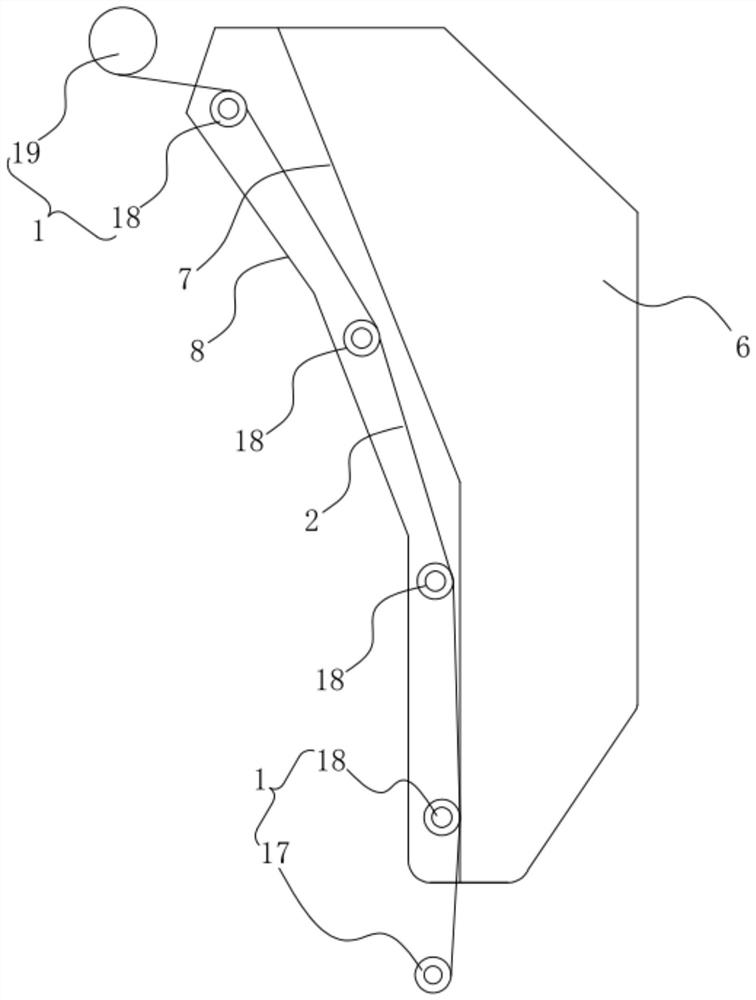

Liquid cooling supporting tool for plug-in type connecting pipe and reactor core measuring pipe anti-deformation method

The invention relates to the technical field of tube plate welding, in particular to a liquid cooling supporting tool for a plug-in type connecting tube and an anti-deformation method of a reactor core measuring tube.The liquid cooling supporting tool for the plug-in type connecting tube comprises a connecting block, a supporting rod and at least two moving rods, the connecting block is provided with an embedding groove, the end of each moving rod is provided with an embedding block, and the supporting rod is arranged in the embedding groove. The embedded block is in sliding fit with the embedded groove, all the moving rods define a conical expansion hole, the supporting rod comprises a transition section, the transition section can move in the axial direction of the expansion hole to expand the expansion hole, the moving rods are attached to the inner wall of the connecting pipe, the rigidity of the connecting pipe is improved, heat exchange transmission heat dissipation is conducted in the axial direction of the connecting pipe through a tool, and the service life of the connecting pipe is prolonged. Welding seam temperature is rapidly reduced, and welding quality is ensured; by adopting the tool to assist the welding of the reactor core measuring tube, the rigidity of the reactor core measuring tube can be improved, the temperature reduction of a welding seam between the reactor core measuring tube and the end socket can be accelerated, the welding deformation caused by overlarge circumferential temperature difference can be avoided, and the welding quality can be ensured.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

Metal wires and manufacturing and on-line cooling method thereof

PendingCN107931357AAvoid bumpingHigh heat resistance and deformation resistanceFurnace typesHeat treatment furnacesInsertion stentThermoforming

A metal wire installed on the material receiving part of the blanking device for receiving thermoformed parts in metal thermal processing, the metal wires are arranged at intervals, and the weight percentage of Fe is 10%-16% Ni-based alloy between, also includes the following composition (weight percentage): 15‑20% Cr, 0.5‑2% Al, 2.5‑3% Mo, 0‑1.2% W, 5‑10% Co , 0.3-0.8% C; adopt forging-continuous rolling-drawing process to make the metal wire; the blanking device equipped with the metal wire is integrally arranged on the blanking of the metal thermal processing equipment At the front end, after the thermoformed parts dropped on the material receiving part are clamped out of the blanking device, the lifting cylinder is operated to retract the piston rod of the lifting cylinder, thereby driving the bracket to tilt towards the ground, so that the bracket on the At least the middle hanging part of the metal wire in the material connection part is immersed in the cooling water of the cooling tank for rapid cooling.

Owner:佟林阳

A chip type anti-vibration capacitor

ActiveCN110246687BImprove stabilityReduce resonance effectMultiple fixed capacitorsCapacitanceHeat resistance

The invention discloses a patch type anti-vibration capacitor, the structure of which comprises a mounting opening, a coil frame, and a winding strip. There is an installation opening in the middle of the coil frame, and more than two winding coils are coiled on the coiling frame. The coiling strip consists of Composed of PCB slats and capacitor main body, there are more than two capacitor main bodies, which are arranged in a straight line on the PCB slats, and the PCB slats are gradually wound around the frame in a ring shape. The capacitor body is equipped with capacitors, top columns, and support frames. , elastic strips, and placement trays. The present invention mainly weakens the influence of resonance on the capacitor through the top pillar and the elastic strip, and also uses the top pillar to enhance the connection relationship between the capacitor and the support frame, and install the base. The capacitor ensures that it will not shift horizontally, completely Avoiding the detachment of the capacitor will not cause the problem of circuit short circuit, and the mesh planar structure formed by the triangular stabilizer is easier to dissipate the heat generated by the operation during the operation of the capacitor, thereby improving the heat resistance.

Owner:深圳市仁天芯科技有限公司

Straw production process

InactiveCN113134958AImprove toughnessNo damageDwelling equipmentChemicalsThermal deformationAntibacterial agent

The invention relates to the technical field of straw production, and discloses a straw production process. The process comprises the following steps of A, taking out bagged plastic raw materials, pouring the bagged plastic raw materials into a container, pouring the plastic raw materials in the container into an ultrasonic vibrating screen, and screening the plastic raw materials by using the ultrasonic vibrating screen; and B, collecting the plastic raw materials which are qualified in screening, and weighing 100-150 parts by weight of the plastic raw materials, 2-9 parts by weight of an antibacterial agent, 3-7 parts by weight of a biodegradation agent and 1.5-2.5 parts by weight of a lubricant for later use. A straw prepared through the technology can be rapidly degraded through microorganisms after being discarded, cannot pollute the surrounding environment, and is ecological and environmentally friendly, meanwhile, the straw is better in toughness, cannot be damaged after being repeatedly folded and is not prone to thermal deformation, meanwhile, unqualified products can be recycled and reused after being subjected to quality inspection in the production process, the reject ratio of the products is reduced, the utilization rate of the raw materials can be improved, the production cost is reduced, and sustainable development of resources is achieved.

Owner:山东小麦歌环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com